Digital printing method for wool-polyester roughly spun fabric

A technology for digital printing and woolen fabrics, applied in the field of textile printing and dyeing, can solve the problems of digital printing of wool and polyester coarse textiles, etc., and achieve the effects of easy quality control, reliable process, and expanded scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

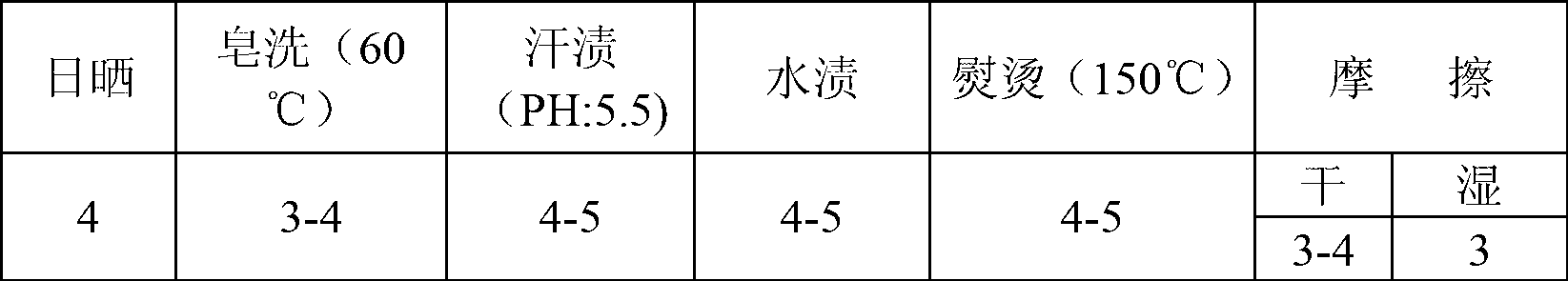

Embodiment 1

[0045] Take acid dye red, yellow, blue and black inkjet inks and disperse dye red, yellow, blue and black inkjet inks sold by Hangzhou Honghua Digital Co. In the printing machine, acid ink is poured into the ink cartridge controlling the left nozzle, and disperse ink is poured into the ink cartridge of the right nozzle.

[0046] Take the PET film coated with the ink-absorbing layer, put it into the digital printing machine, select the pattern, adjust the color according to the customer's requirements, and then use the digital printing machine to spray-paint the pattern on the PET transfer film, dry, roll, stand-by.

[0047] Take the wetting solution with 15% (weight percent) urea and 3% (weight percent) citric acid; then take a number of woolen meltons with 45% wool content and 55% polyester content that have been pretreated. The screen printing machine evenly coats the wetting liquid on the surface of the melton, and then attaches the pattern surface of the transfer film obt...

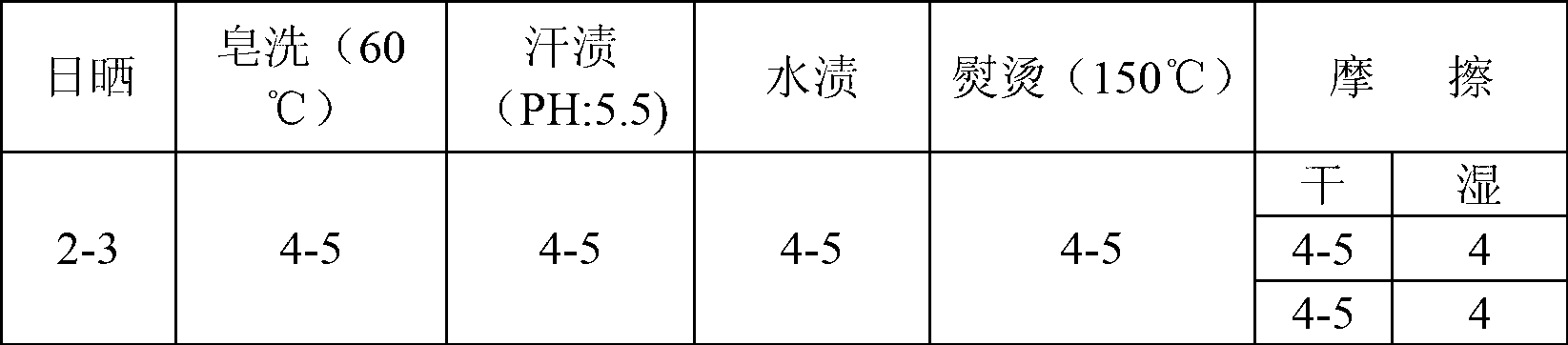

Embodiment 2

[0053] Reactive dye red, yellow, blue and black inkjet inks and disperse dye red, yellow, blue and black inkjet inks sold by Hangzhou Honghua Digital Co. In the printing machine, active ink is poured into the ink cartridge controlling the left nozzle, and disperse ink is poured into the ink cartridge of the right nozzle.

[0054] Take the 100 g / m2 full wood pulp double-adhesive paper coated with the ink-absorbing layer, put it into the digital printing machine, select the pattern, adjust the color according to the customer's requirements, and then use the digital printing machine to spray-paint the pattern on the double-sided On gummed paper, dry, roll up and set aside.

[0055] Get and add 8% (percentage by weight) urea, 7% (percentage by weight) glycerin, 4% ammonium sulfate, 2% (percentage by weight) the wetting liquid of terylene low-temperature expanding agent OP and inject the trough of padding car; The wool content of the pre-treatment is 65%, and the wool content of 3...

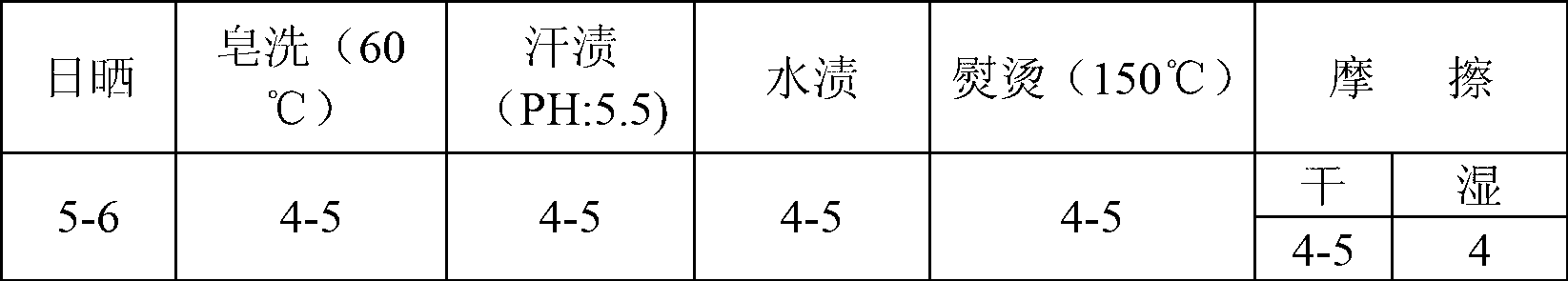

Embodiment 3

[0061] Respectively take reactive dye red, yellow, blue, light red, light gray and black inkjet inks and disperse dye red, yellow, blue, light red, light gray and black inkjet inks sold by Hangzhou Honghua Digital Co., Ltd., and pour them into In the Italian MS JPK double-group Japanese Kyocera industrial nozzle digital printing machine, the digital printing machine has a total of 12 Kyocera industrial nozzles, and 6 nozzles form a group. The ink cartridges of one group of nozzles are filled with active ink, and the ink cartridges of the other group of nozzles Pour disperse ink into it.

[0062] Take the aluminum foil coated with the ink-absorbing layer, put it into the digital printing machine, select the pattern, adjust the color according to the customer's requirements, and then use the digital printing machine to print the pattern on the aluminum foil, dry it, roll it up, and set it aside.

[0063] Take a wetting solution with 10% urea (weight percentage) and 2.5% baking s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com