Extrusion molding-photocuring integrated three-dimensional printer and printing method thereof

A 3D printer and extrusion molding technology, which is applied in the processing of accessories of the main material, additive manufacturing, processing drive devices, etc., which can solve the problem that extrusion molding equipment is difficult to form fine structures, light-curing equipment has single printing materials, and is unfavorable for model personalization. Customization and other issues to achieve the effect of facilitating the analysis of the disease, simplifying the mechanical structure, and avoiding the sudden release of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

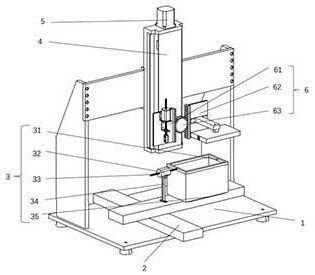

[0063] like figure 1 As shown, the embodiment of the present invention provides an extrusion molding-light curing integrated three-dimensional printer, which includes a frame 1;

[0064] X, Y-axis motion mechanism 2, fixedly arranged on the frame 1;

[0065] The light-curing molding trough module 3 is fixedly arranged on the X-axis and Y-axis motion mechanism 2, and includes a drilling hole 31, an X-axis system driving motor 32, an X-axis system motor screw 33, a motor base 34, and an optical processing device 35 ;

[0066] The two boreholes 31 are distributed symmetrically;

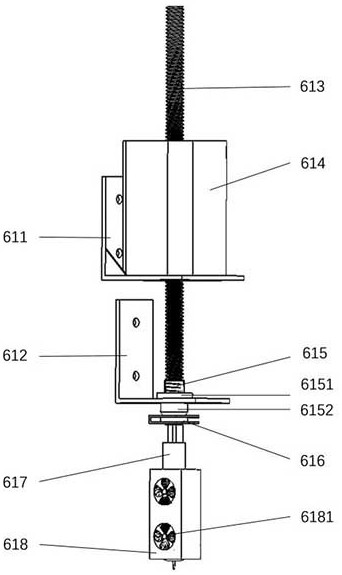

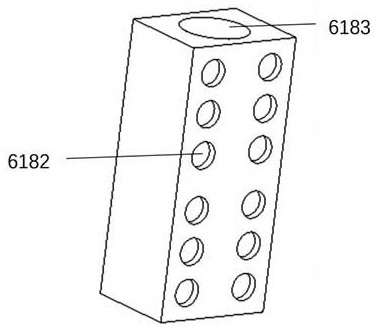

[0067] The Z-axis motion mechanism 4 is fixedly arranged on the frame 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com