Patents

Literature

49results about How to "Reduce printing errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

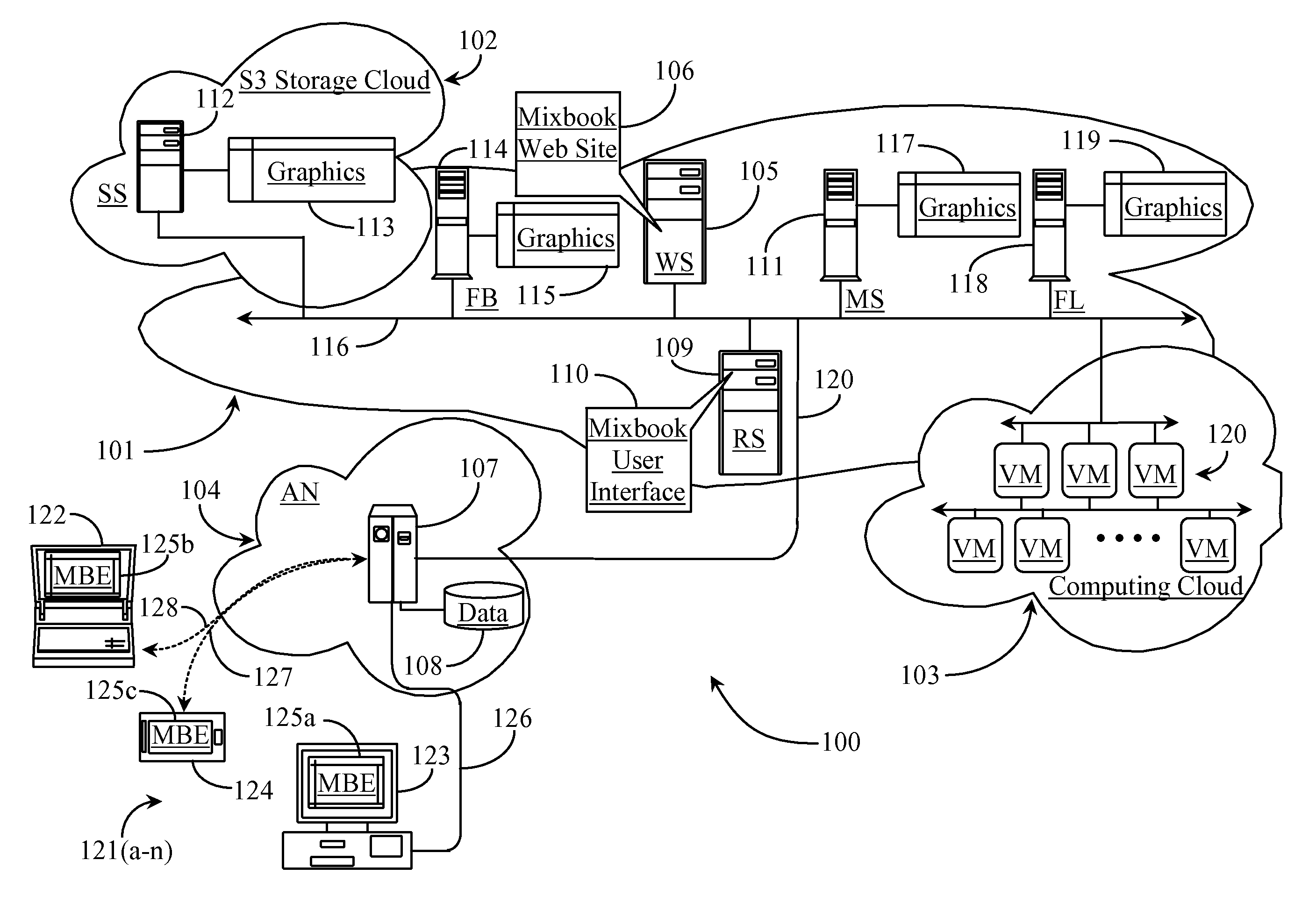

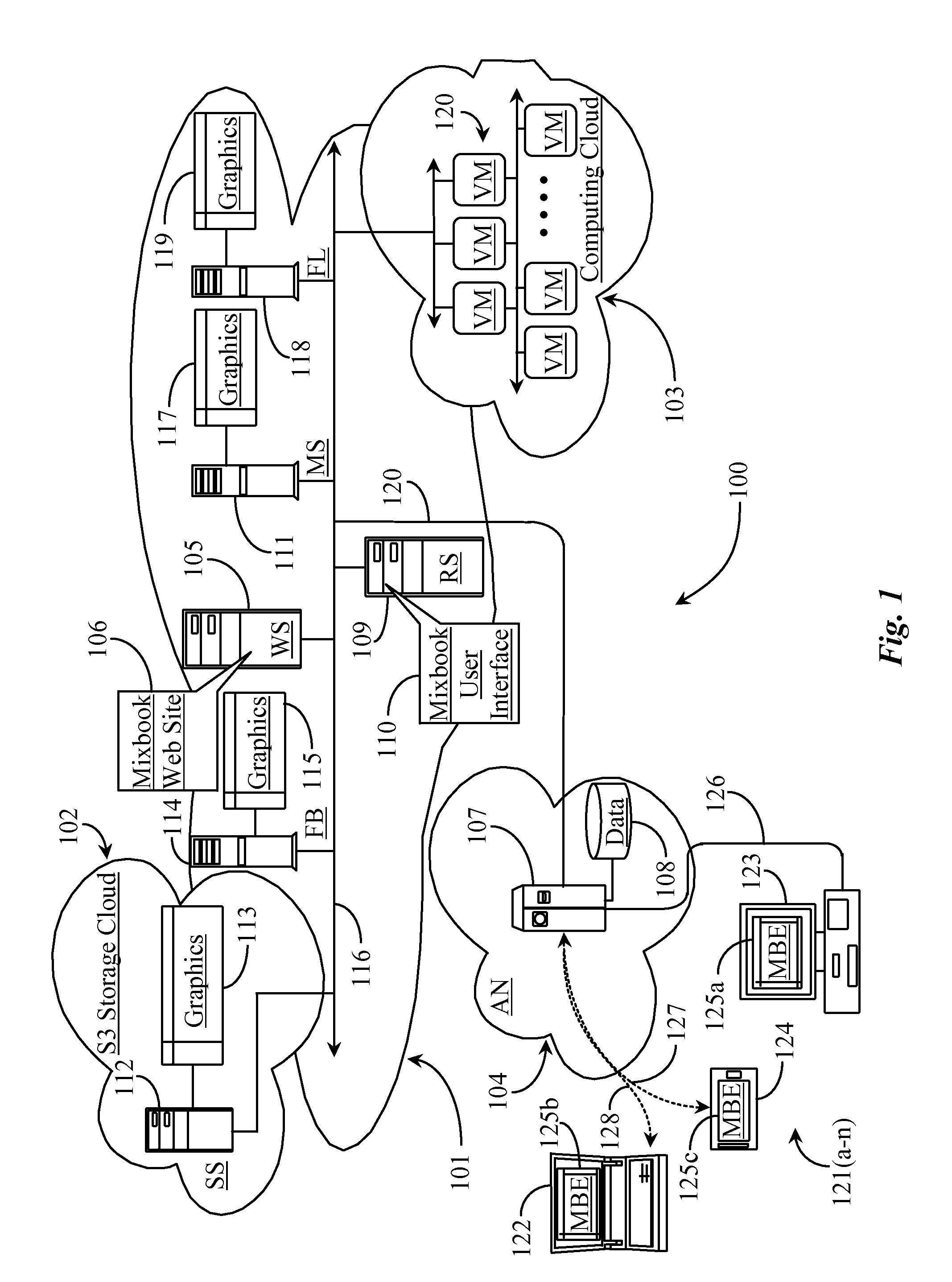

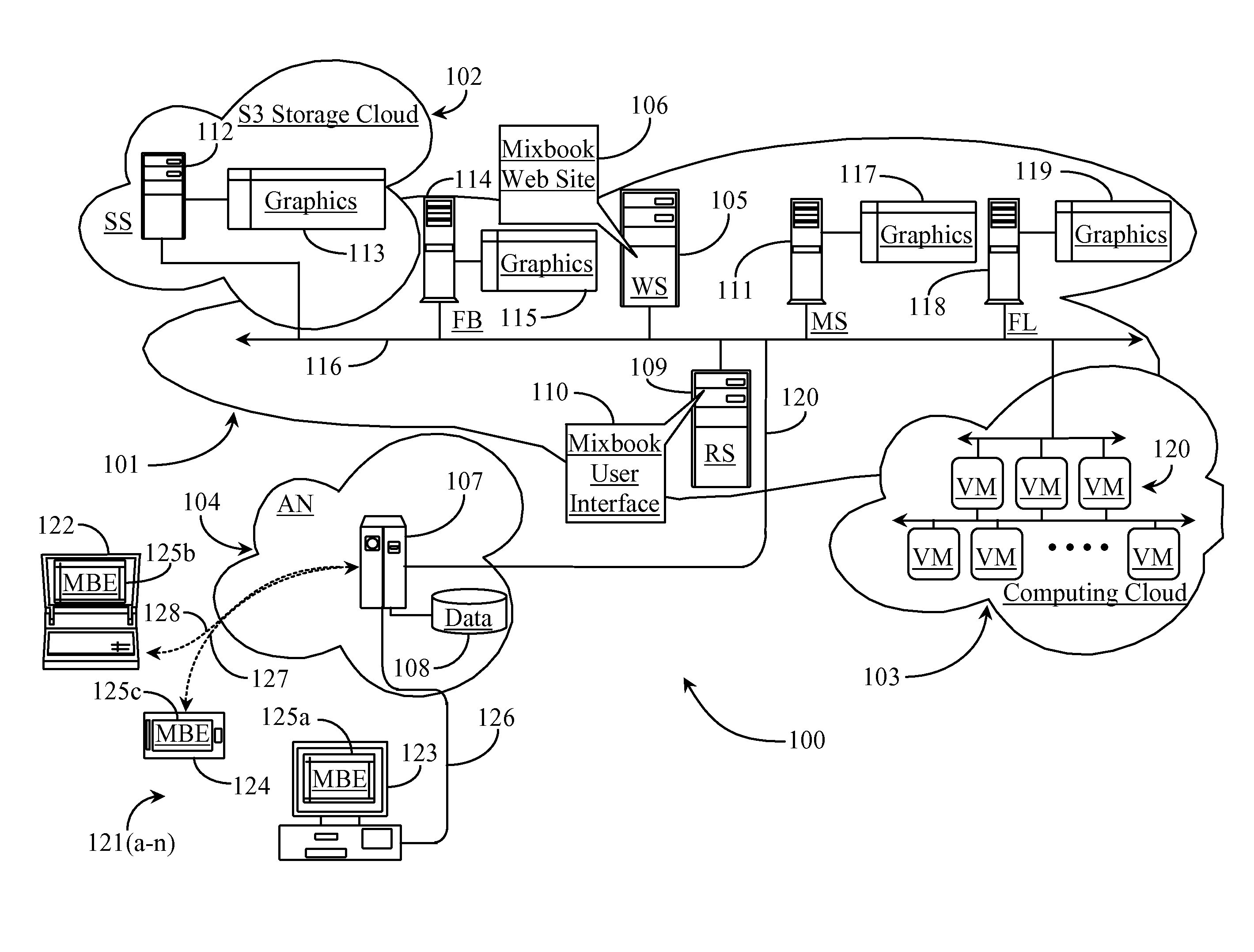

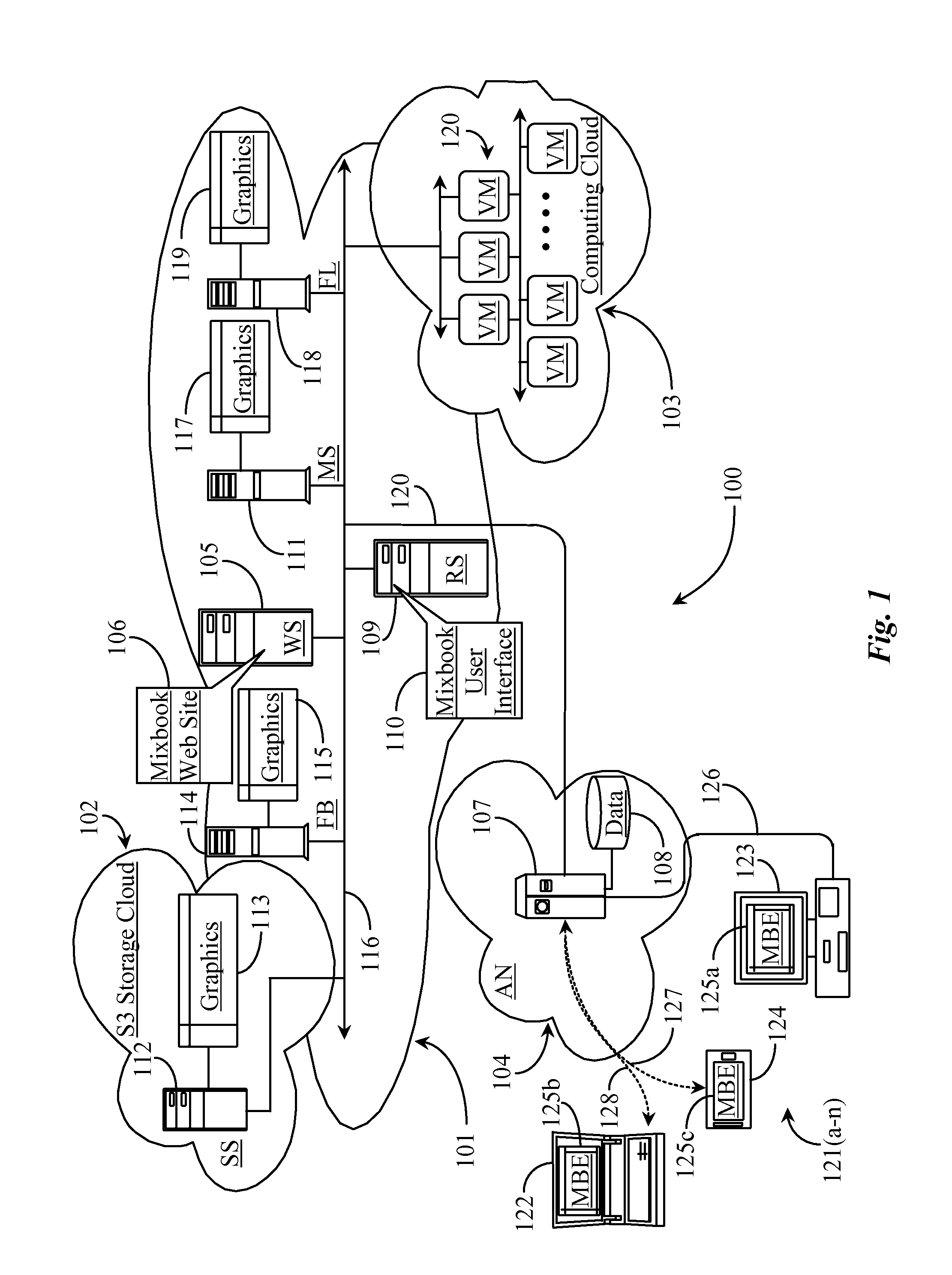

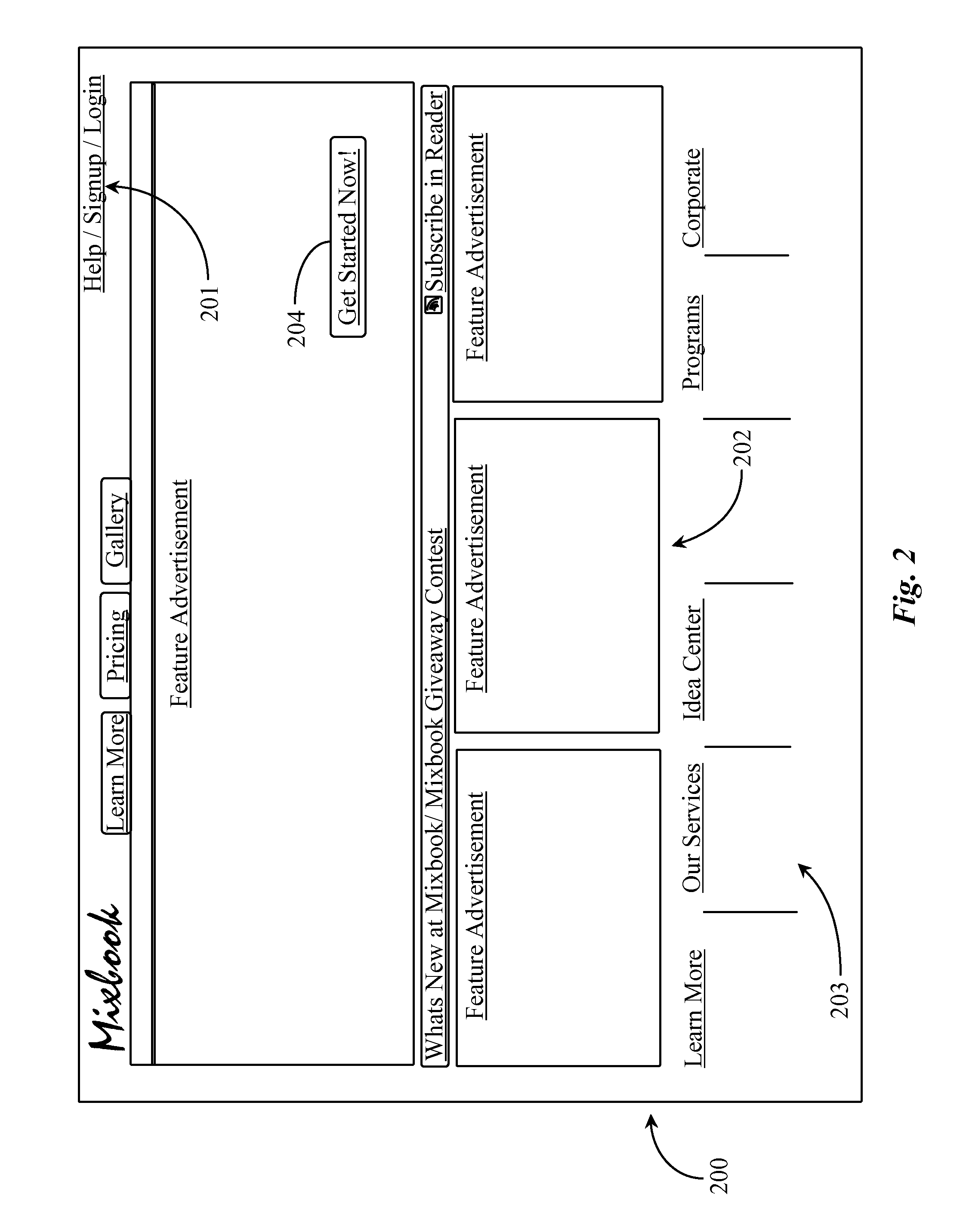

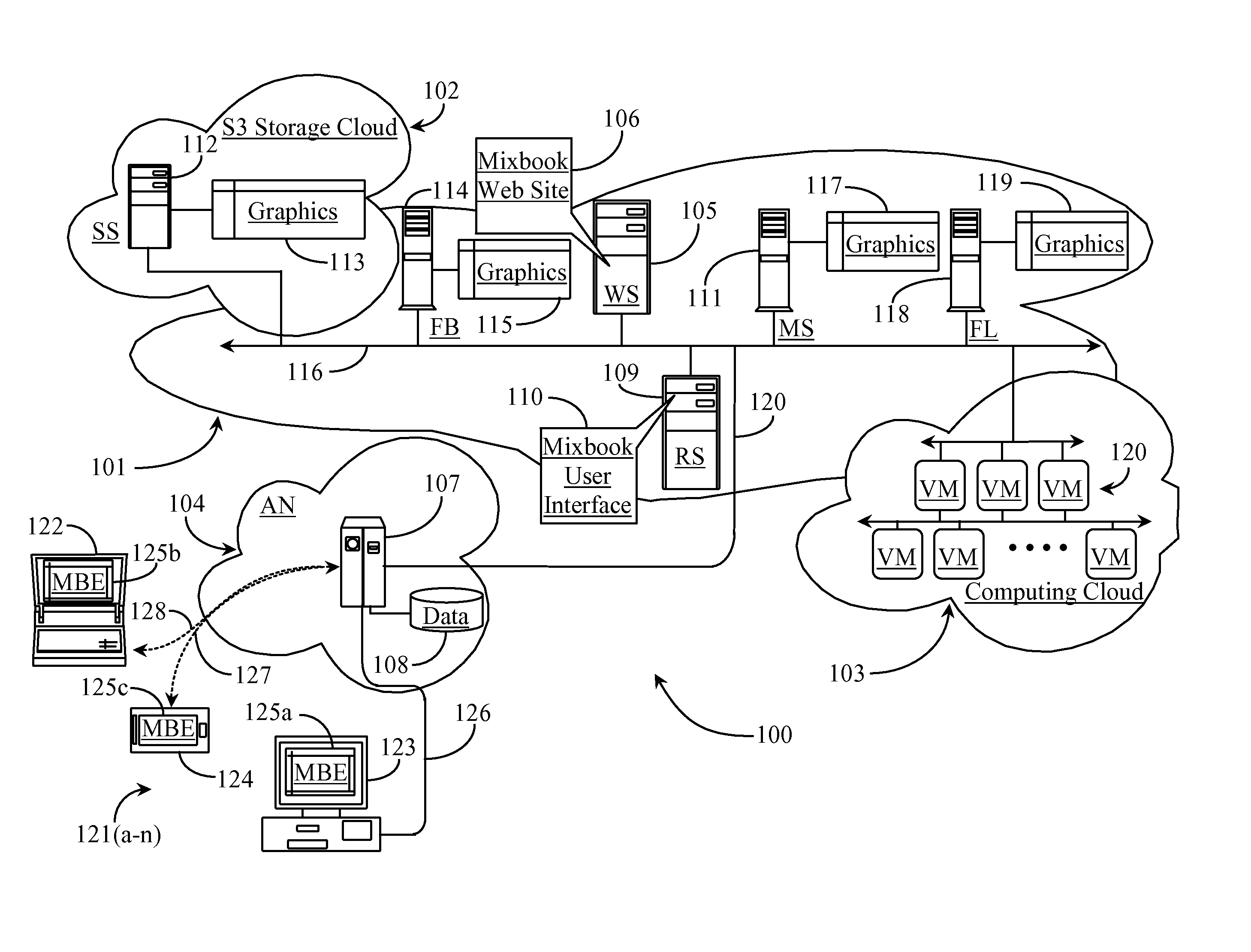

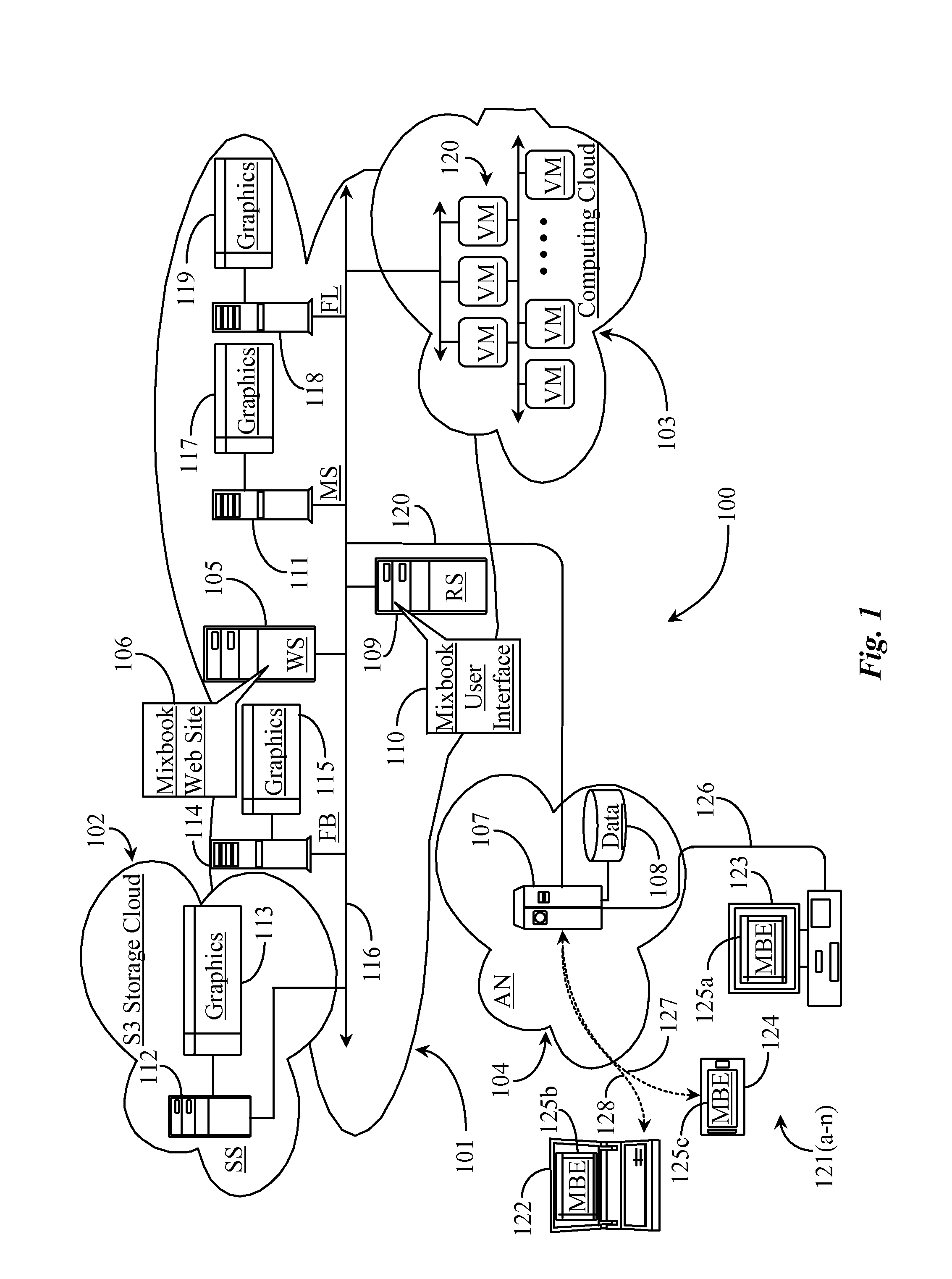

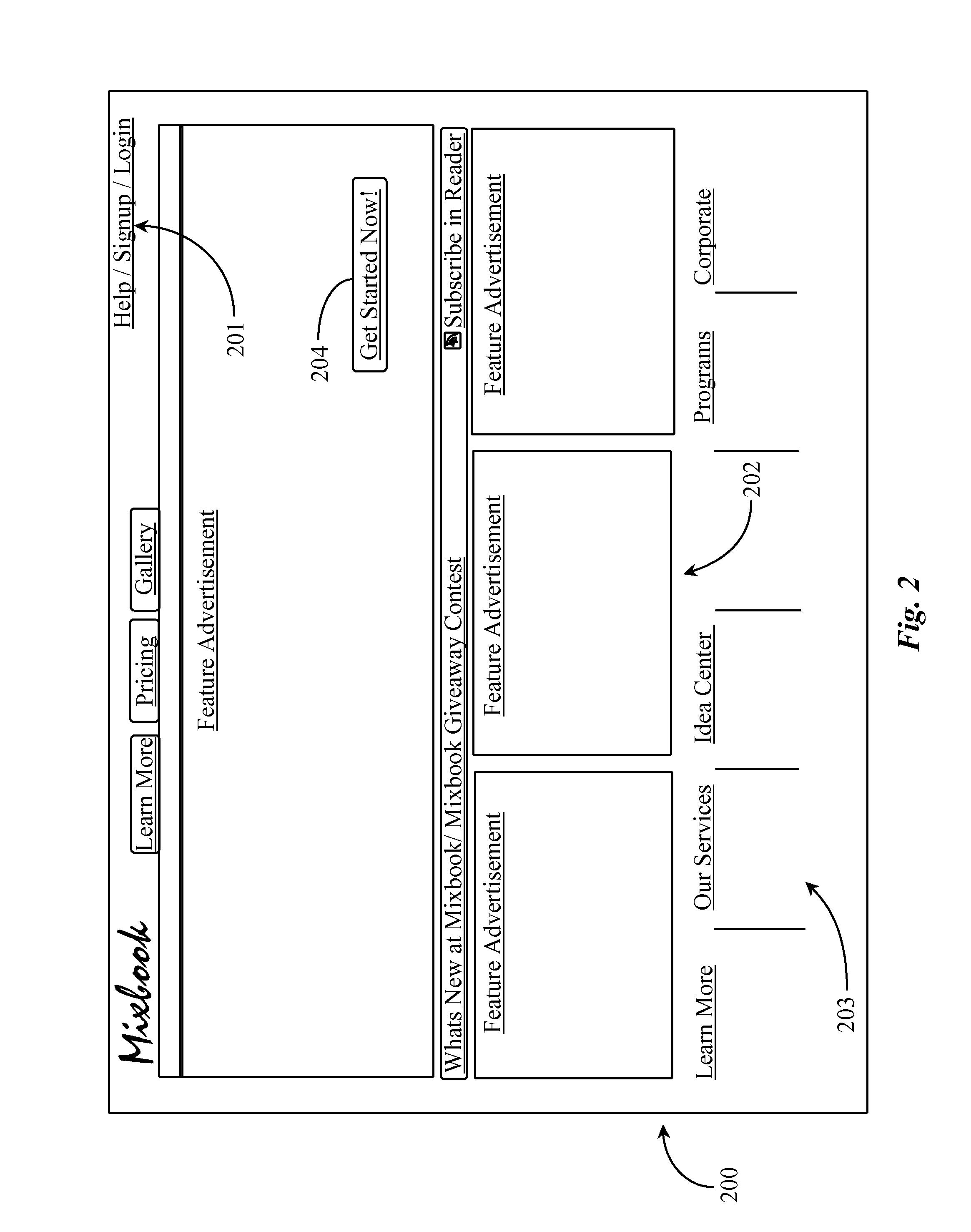

System for Establishing Online Collaborators for Collaborating on a Network-Hosted Project

InactiveUS20110016409A1Reduce printing errorsImprovement in user experience resultInput/output for user-computer interactionCharacter and pattern recognitionWeb siteGraphics

A system for hosting multiple collaborators in real time, the collaborators contributing content and or edits to content in an image and or text-based project hosted on a data network through a Website accessible to the collaborators by computer browser includes a server connected to the data network, the server having access to a digital medium containing an executable graphics user interface (GUI) for contributing content and for editing content, and a collaborator configuration interface available through the Website enabling a user to designate one or more other users as approved for collaboration on a given project. Users who are approved to collaborate have real time access to the image and or text-based project through their own versions of the network-based GUI.

Owner:INTERACTIVE MEMORIES

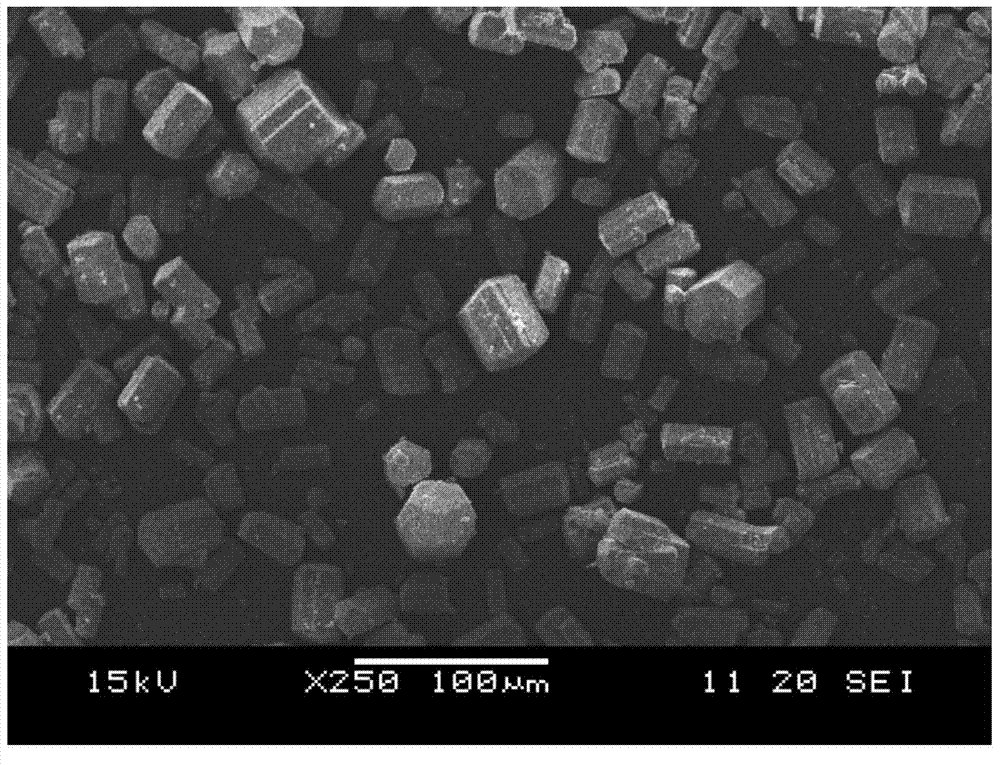

Gypsum material for 3D printing and preparation method thereof

ActiveCN104744000AHigh mechanical strengthGood dispersionAdditive manufacturing apparatusFilling materials3d printer

The invention discloses a gypsum material for 3D printing. The gypsum material is that a gypsum product is printed and formed through 1 part by mass of powder and 0.25 to 1 part by mass of liquid-phase material by a 3D printer, wherein the powder is prepared from the following raw materials in parts by mass: 90 to 98 parts of hemihydrate gypsum, 1 to 10 parts of filling material, and 0 to 2 parts of fibers; the liquid-phase material is prepared from the following raw materials in parts by mass: 80 to 90 parts of water, 5 to 15 parts of flexible adhering material, and 1 to 5 parts of coagulating material. The invention further discloses a preparation method of the gypsum material for 3D printing; the gypsum material is prepared by mixing and uniformly agitating all raw materials. The gypsum material for 3D printing and the preparation method have the advantage that the problems of small strength, poor fluidity, large fineness and poor flexibility in the prior art can be solved.

Owner:NANJING UNIV OF TECH

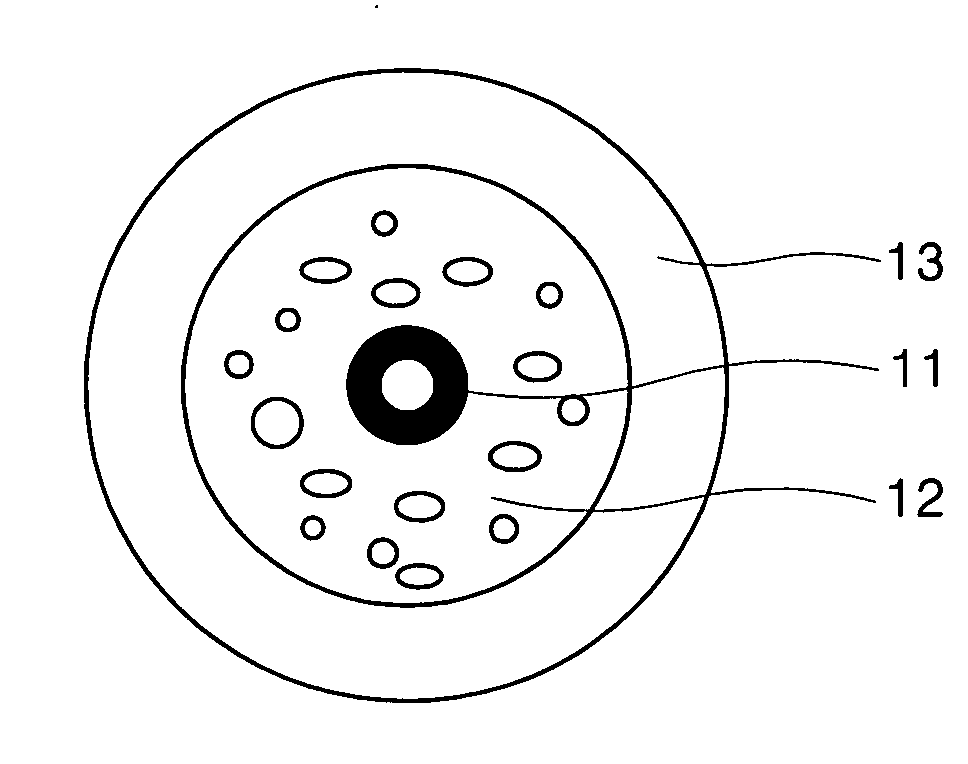

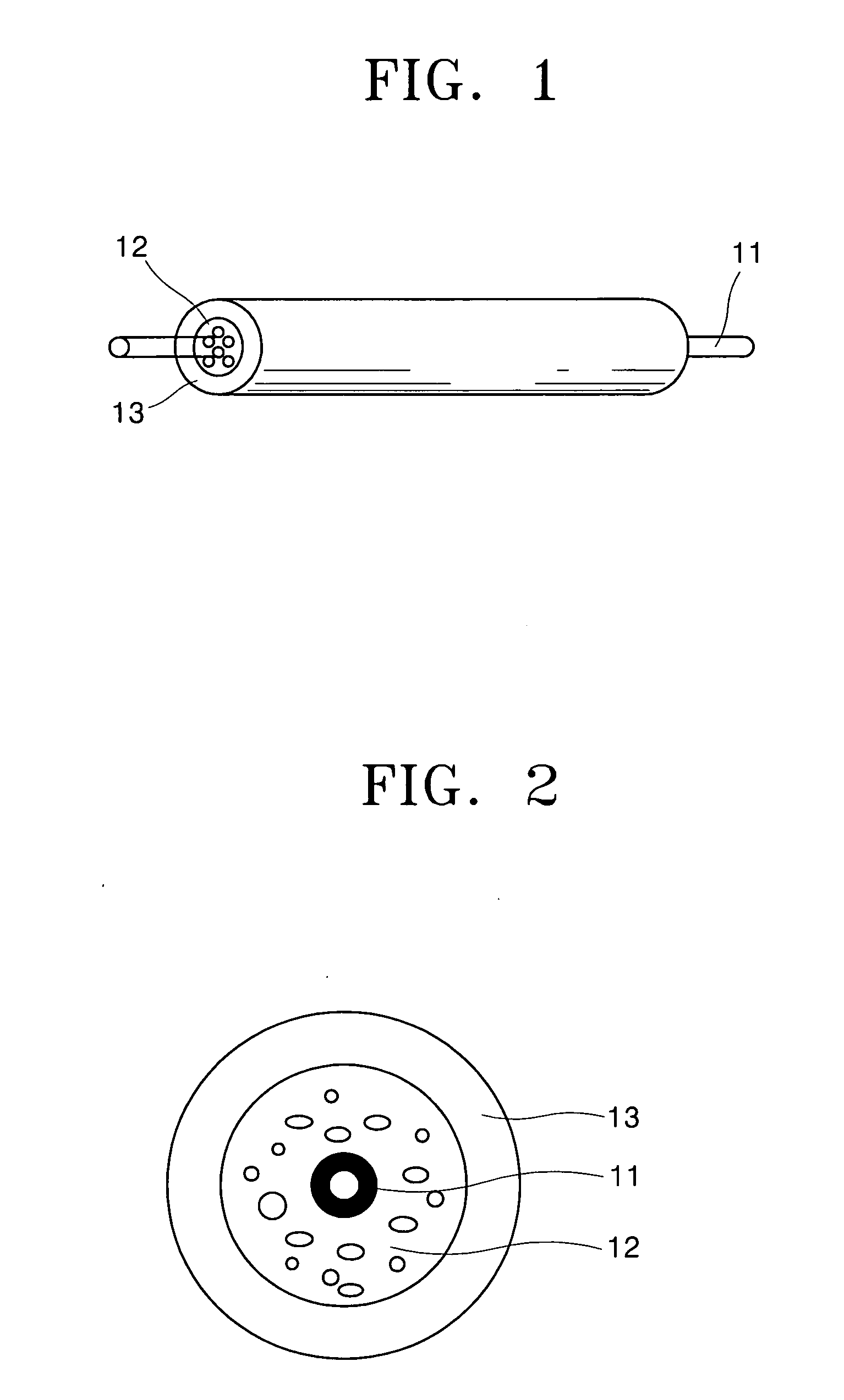

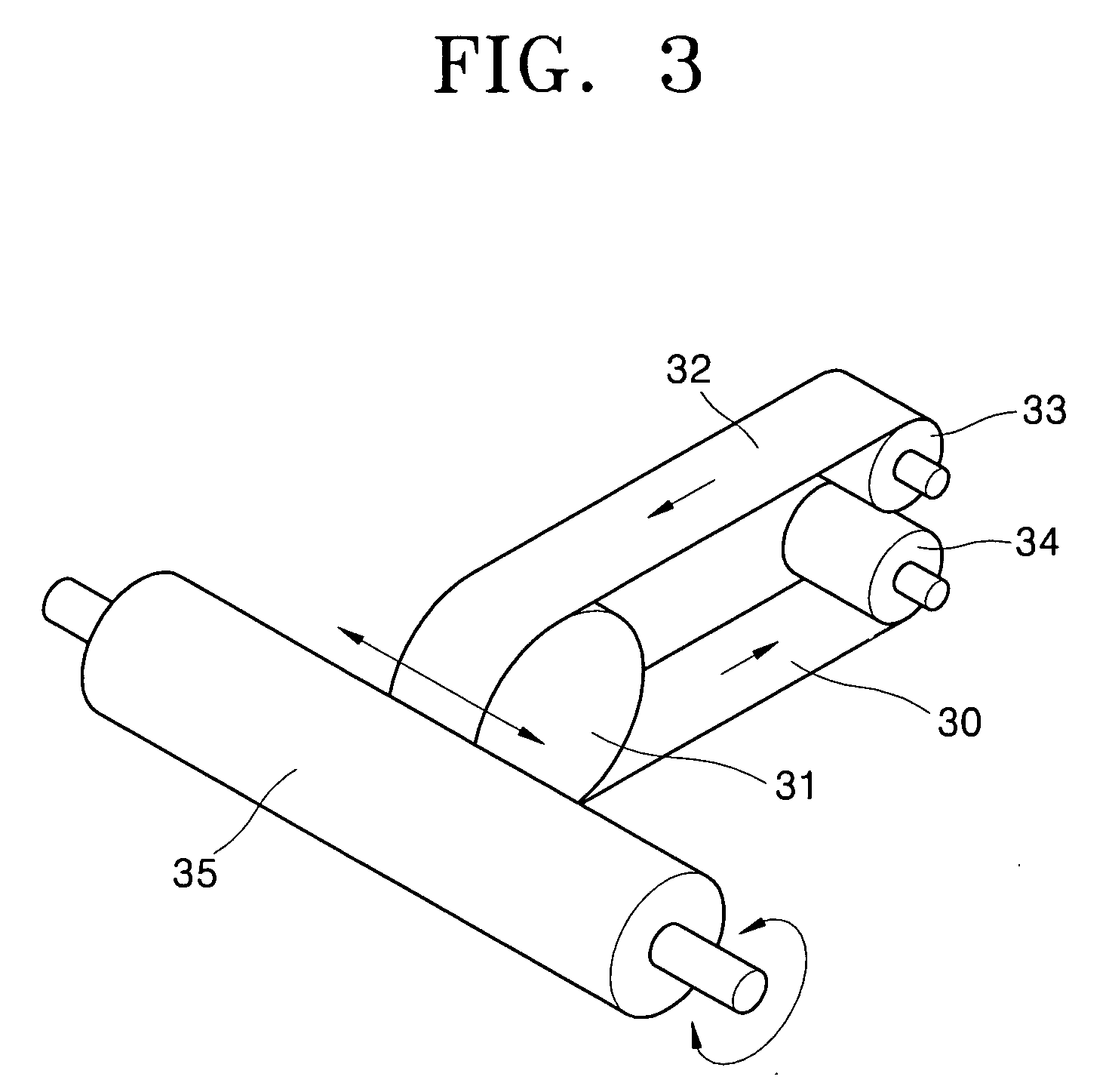

Tubular roller, method of manufacturing the same, and electro-photographic image forming apparatus having the same

InactiveUS20060183615A1Promote migrationReduce printing errorsShaft and bearingsMetal-working apparatusElectrical resistance and conductanceEngineering

An elastic tubular roller includes an inner foam layer and an outer tubular layer, the inner foam layer has a higher electrical resistance than the outer tubular layer, and the electrical resistance of the entire tubular roller is equal to or less than 108Ω. A method of manufacturing the same and an electro-photographic image forming apparatus using the same. The tubular roller is used as various kinds of electro-photographic image forming apparatuses, such as a contact non-magnetic one-component type and a magnetic two-component type, and as well as an electrical charging roller and a developing roller.

Owner:S PRINTING SOLUTION CO LTD

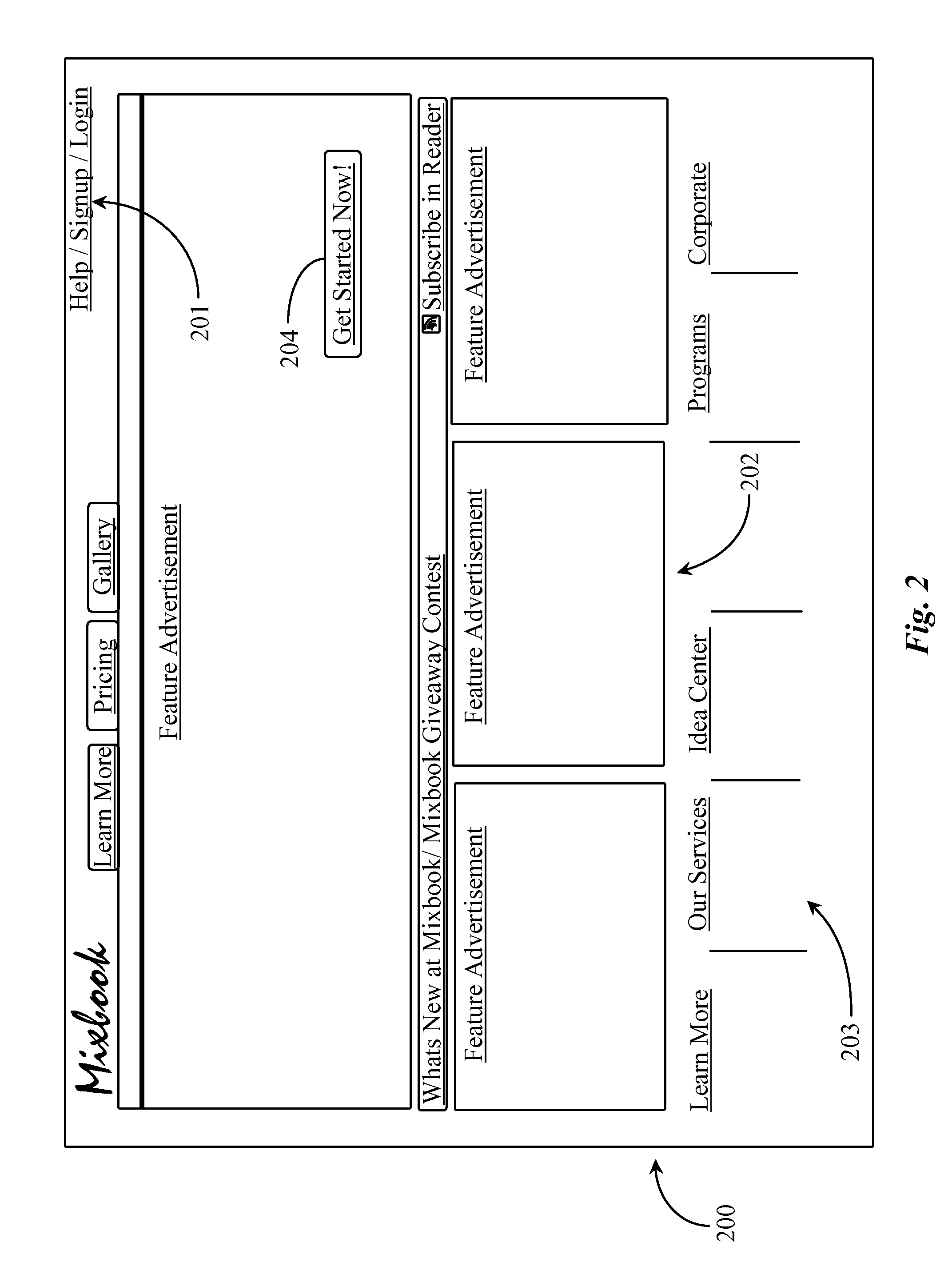

Method for Determining Effective Core Aspect Ratio for Display of Content Created in an Online Collage-Based Editor

ActiveUS20110013203A1Improve efficiencyReduce printing errorsDigitally marking record carriersVisual presentation using printersAspect ratioComputer science

In an online collage-based editor, a method for determining an effective aspect ratio for a selected project orientation that includes a group of two or more available page sizes having different aspect ratios and displaying a project page at a derived aspect ratio in the GUI during editing includes the steps (a) determining for each page size in the group, the viewable area of each page, (b) recording the aspect ratios of the viewable areas of step (a), (c) using a mathematical function, describing a total amount of error present amongst the available aspect ratios of step (b) for a given aspect ratio, (d) using a mathematical program, process, or automated calculation tool, finding the effective aspect ratio that minimizes the function and hence the error value of step (c), and (e) displaying the project page at the selected effective aspect ratio.

Owner:INTERACTIVE MEMORIES

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

Print Configuration Engine for Enabling Online Printing of Projects Created in an Online Collage-Based Editor

ActiveUS20110013226A1Improve efficiencyReduce printing errorsStill image data indexingCharacter and pattern recognitionGraphicsGraphical user interface

A print configuration engine implemented in software residing on and executable from a digital medium, the print engine integrated with a graphics user interface (GUI) for creating and editing photo-based projects over a data network, the print engine including a communications link to a compatible print server and printer connected to the data network, a print queue for queuing printing tasks, and an image tiling module. The print engine automatically senses if the pixel size of an image is greater than a pre-defined image size threshold for high resolution printing and if so tiles the image and saves the individual image tiles to memory for later reconstitution.

Owner:INTERACTIVE MEMORIES

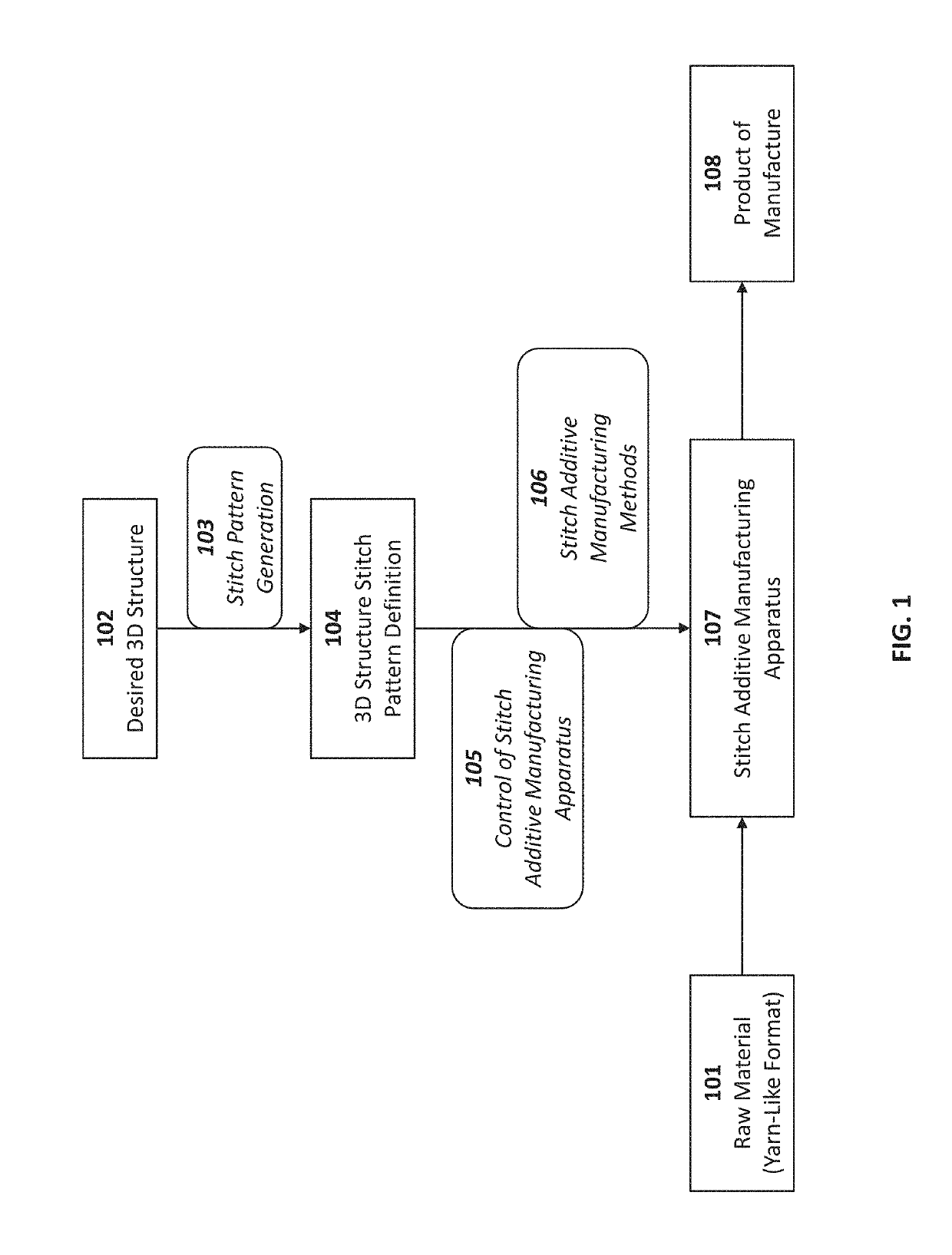

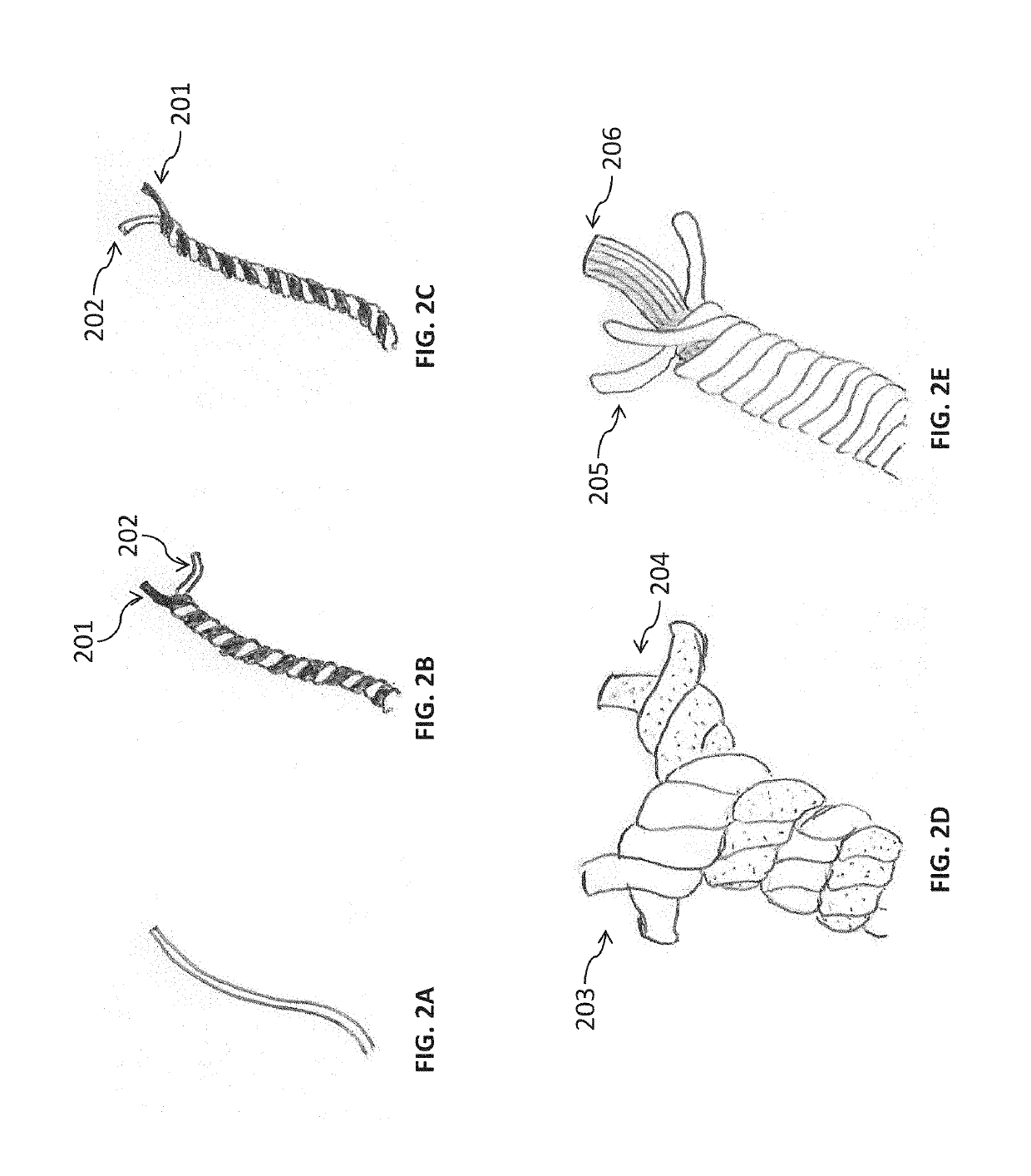

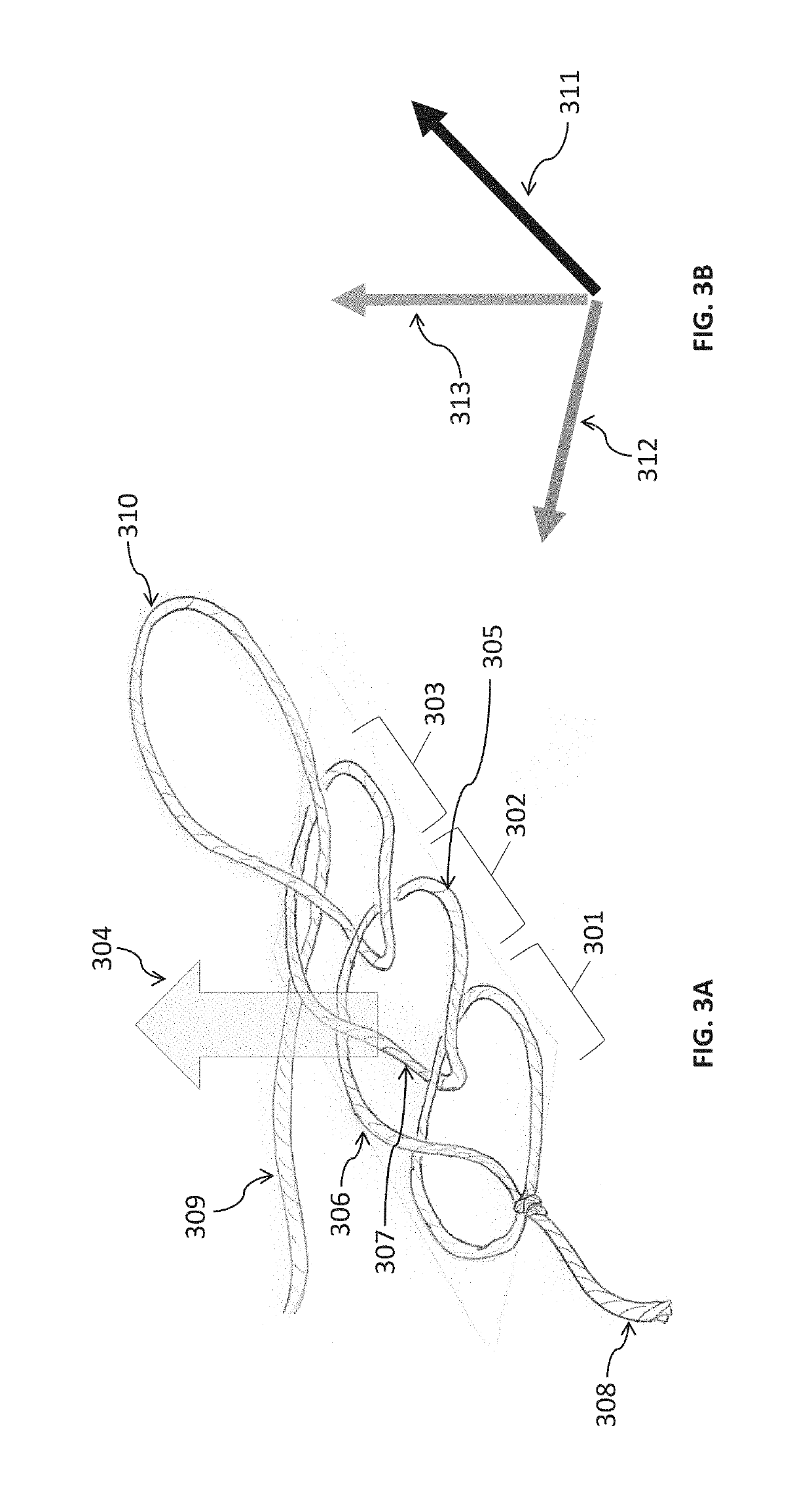

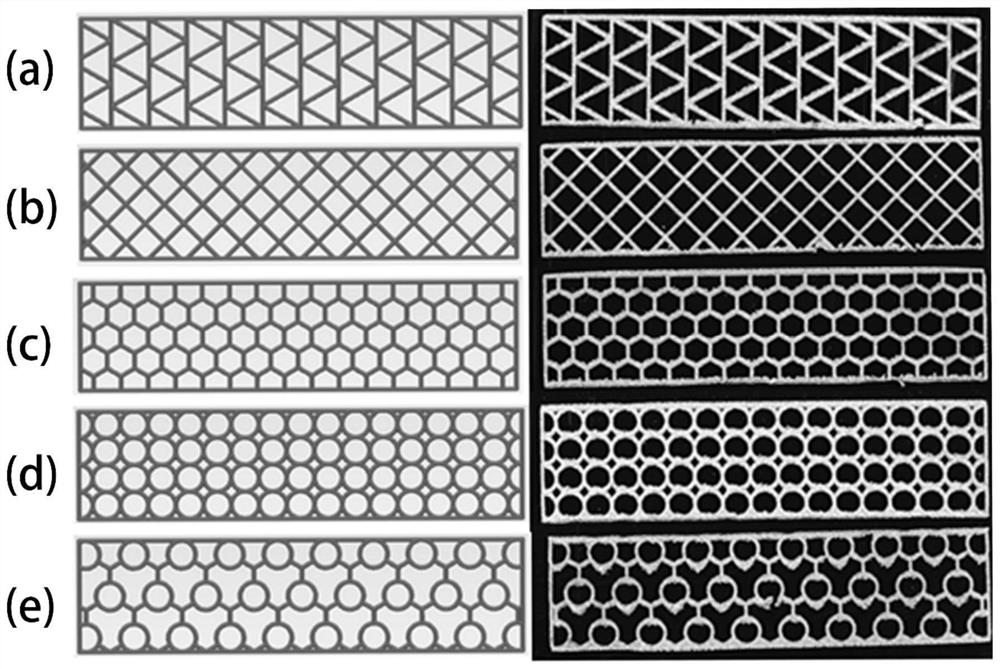

Additive manufacturing system using interlinked repeating subunits

ActiveUS20190299519A1Reduce printing errorsIncrease volumeAdditive manufacturing apparatusCeramic shaping apparatusLaser additive manufacturingManufacturing systems

An additive manufacturing system and an input material that overcomes that need to heat and extrude solidifying materials to create a three-dimensional structure. The system arranges subunits of the input material into repeating, interlinked subunits that can be arranged to manufacture a three-dimensional structure that is flexible but also has sufficient structural integrity to retain a desired shape during the additive manufacturing process or post-manufacturing usage. During the additive manufacturing process, the flexible input material can be manipulated and reformed to match the shape and structure of a target three-dimensional structure, upon which the manufactured three-dimensional structure is based. As elongated units of the input material are received by the additive manufacturing machine, the machine assembles the input material into the interlinked, repeating subunits, thereby removing the need to heat and extrude an input material to create a structure.

Owner:YEOH IVAN LI CHUEN

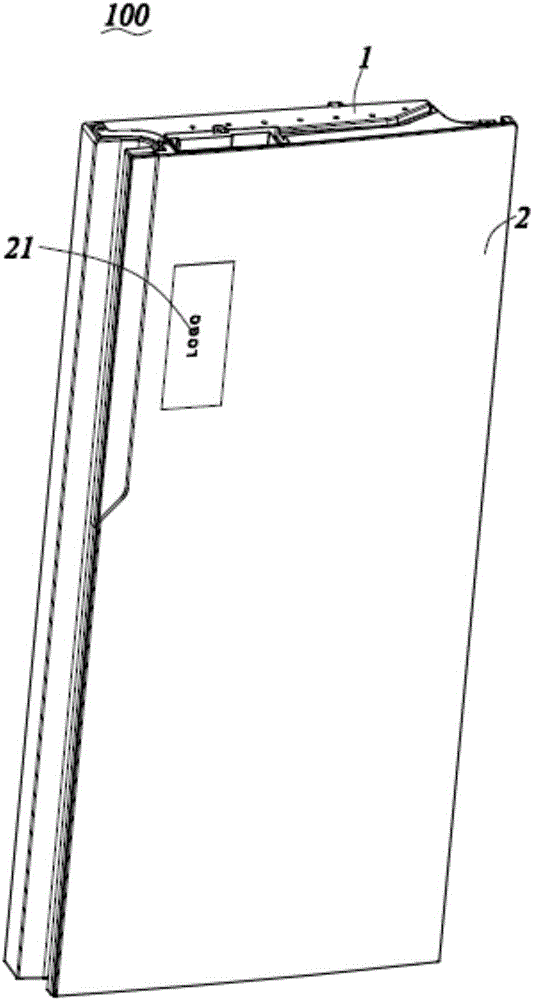

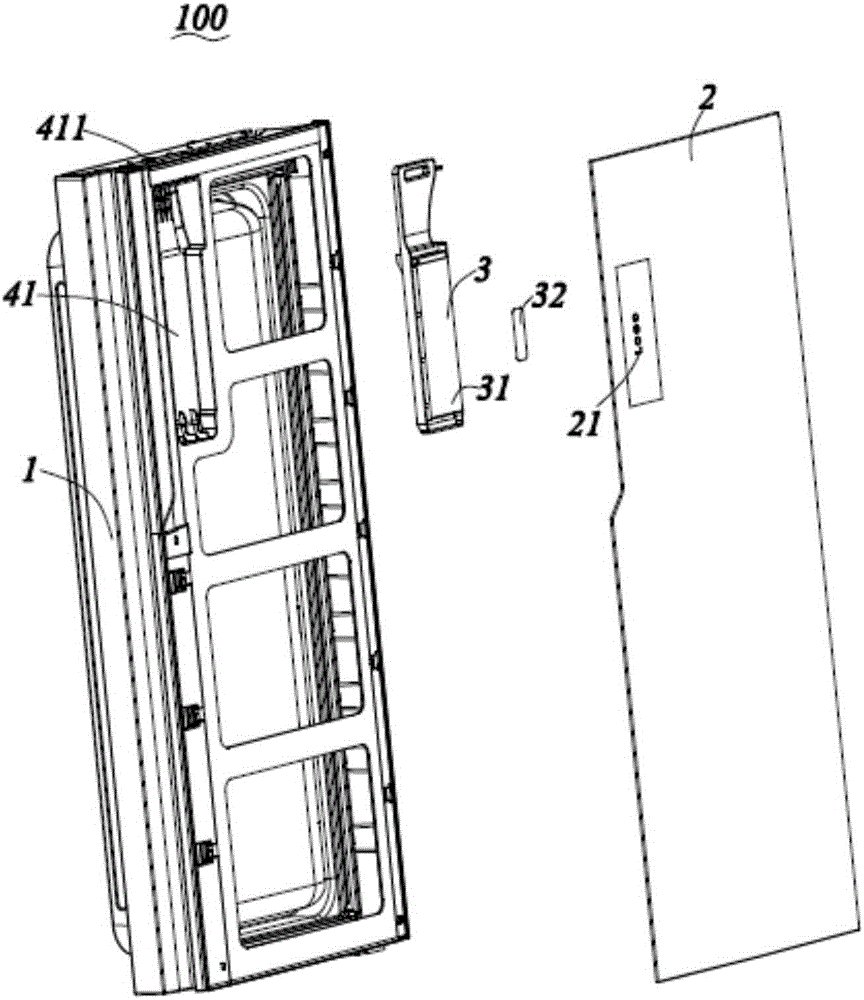

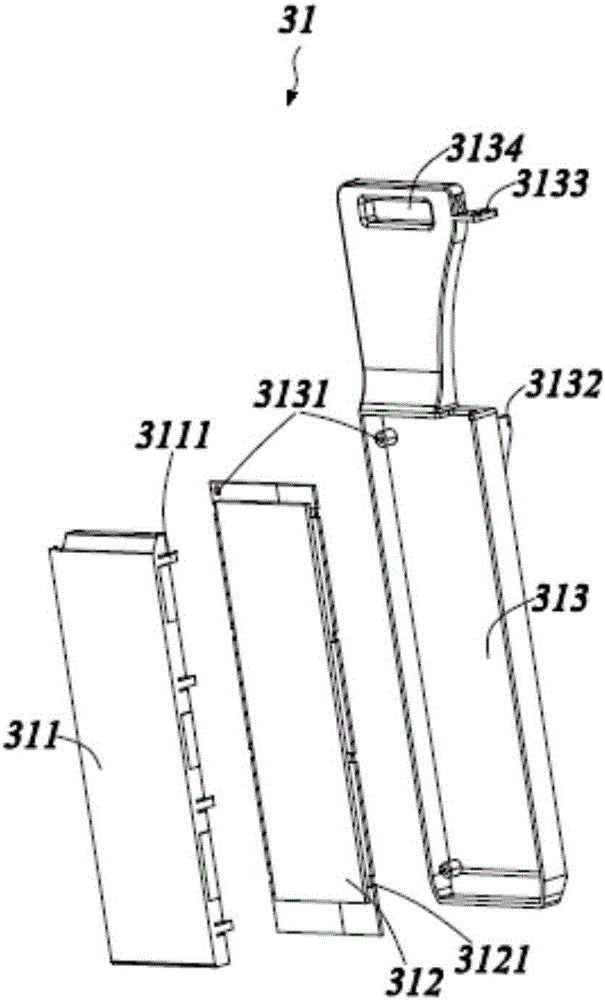

Refrigerator door body and production method of refrigerator door body

ActiveCN106123462ASolve the problem of blurred bordersImprove printing accuracyMechanical apparatusDomestic lightingDisplay deviceRefrigerated temperature

The invention provides a refrigerator door body and a production method of the refrigerator door body. The refrigerator door body comprises a frame body, a glass panel arranged on the outer side of the frame body, and an LOGO display device arranged between the frame body and the glass panel. A transparent LOGO display area is printed on the glass panel. The LOGO display device comprises a light-emitting assembly and a single transparent film. The light-emitting assembly is arranged on the side, close to the frame body, of the LOGO display area. The single transparent film is arranged between the LOGO display area and the light-emitting assembly. By the adoption of the production method of the refrigerator door body, the printing error is controlled within 0.5 mm. According to the refrigerator door body, a LOGO can emit light to be displayed, displaying is clear, and the appearance is high in quality.

Owner:HAIER SMART HOME CO LTD

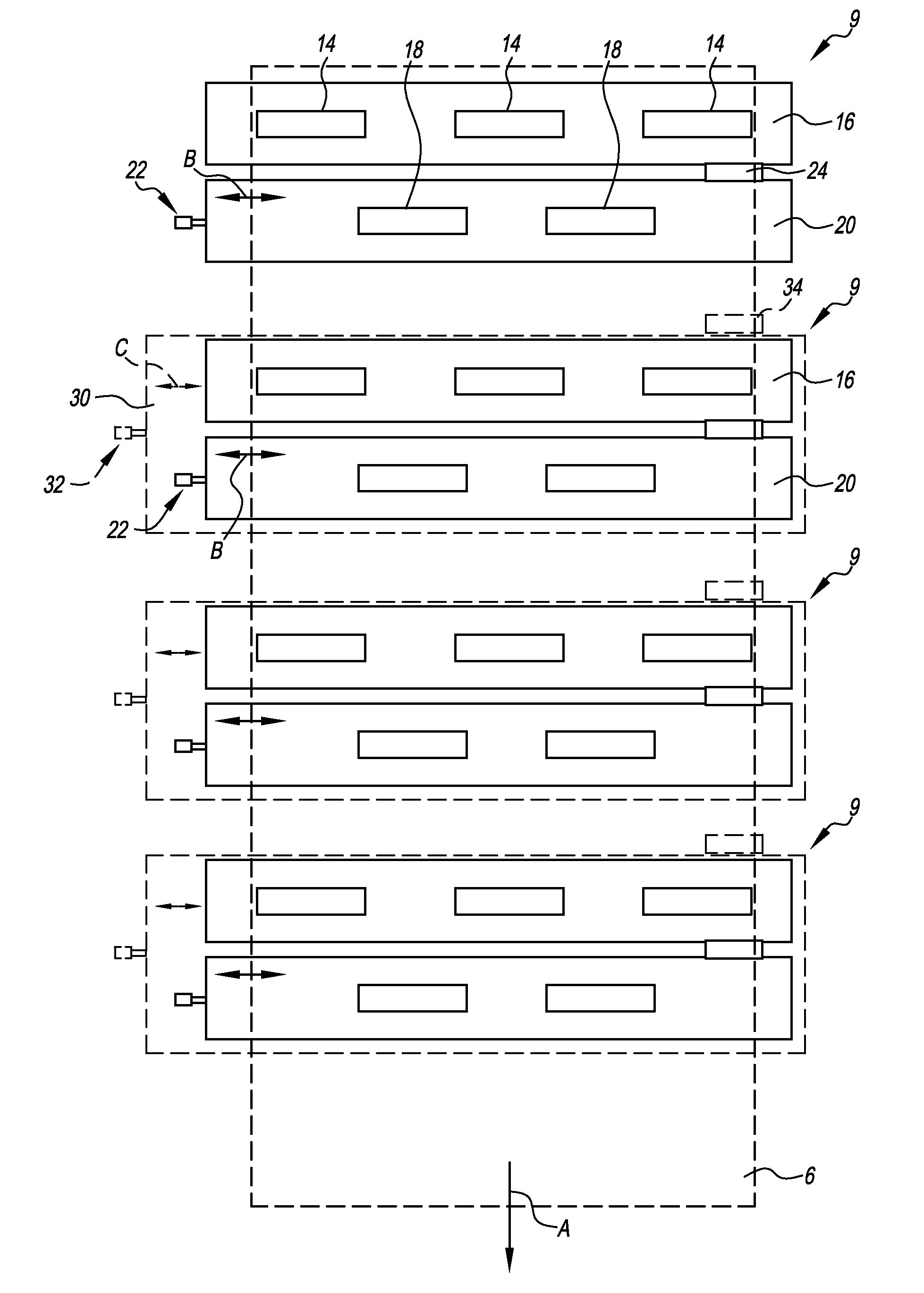

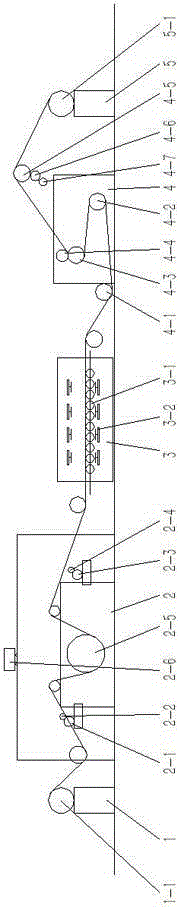

Printing device and method for printing a printing substrate

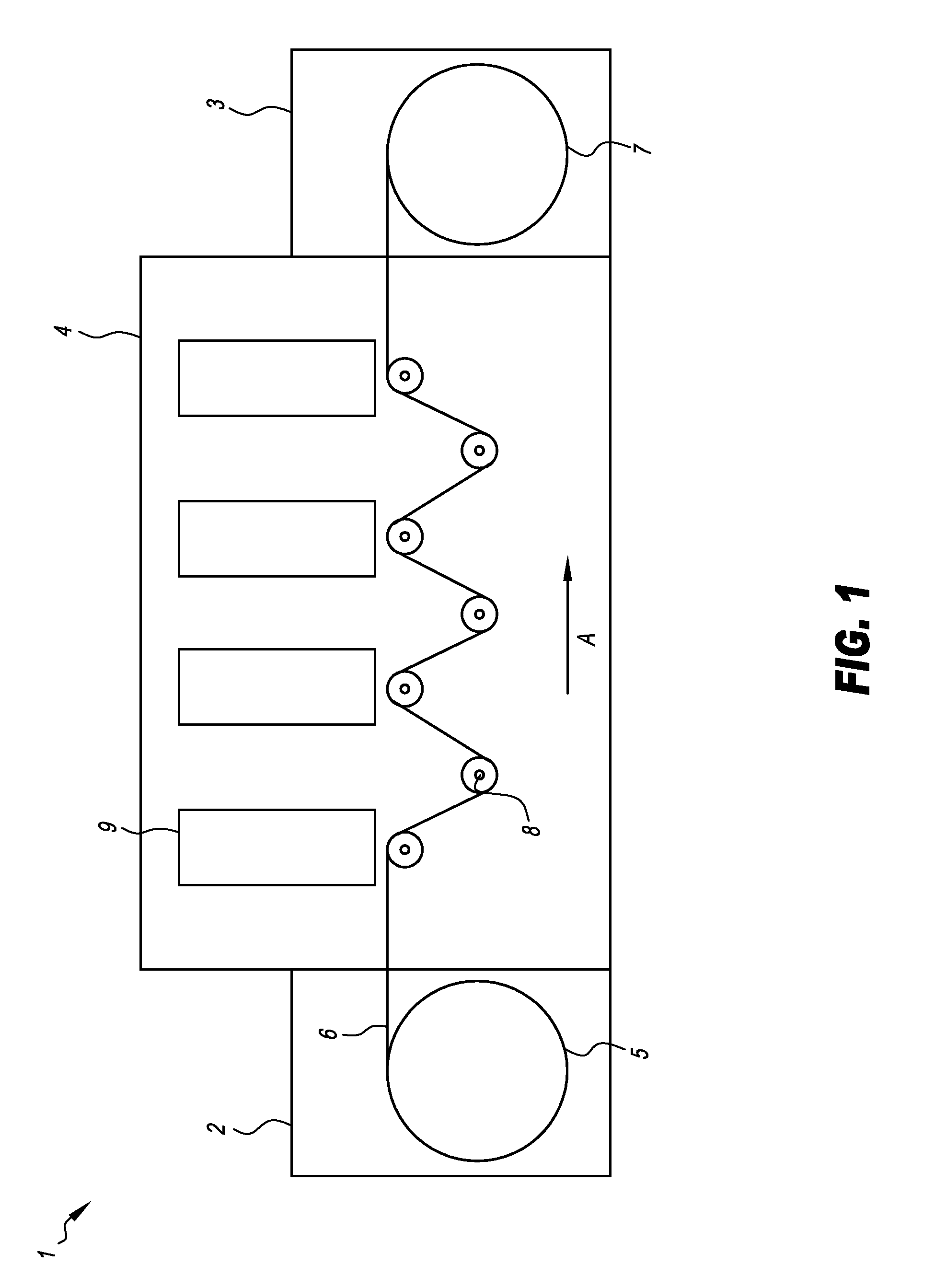

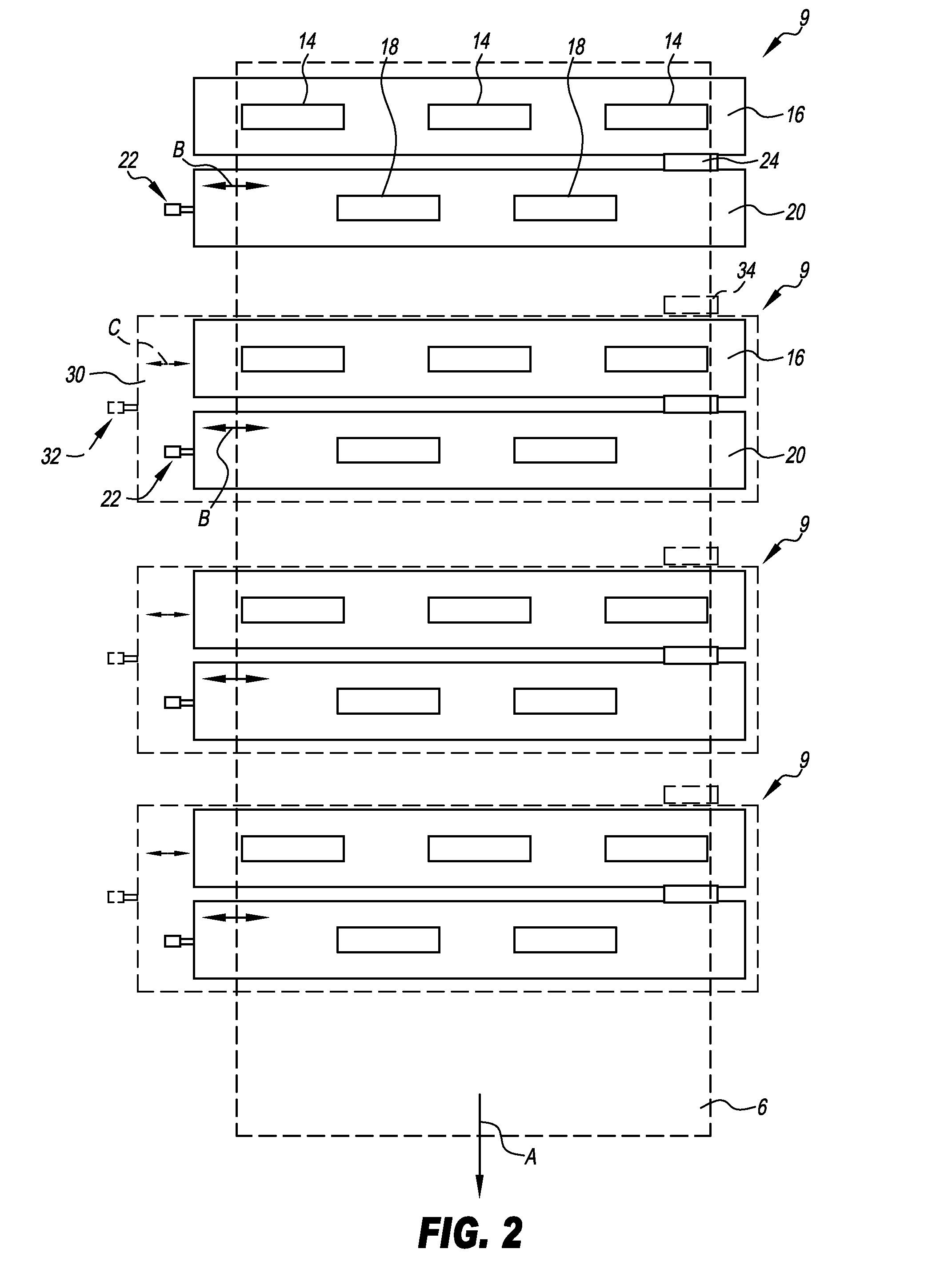

InactiveUS20120229550A1Reduce printing errorsReduce errorsOther printing apparatusReference imageFixed position

Disclosed herein is a method for printing a printing substrate (6), in which the printing substrate (6) is printed with at least one first printing unit (9) and at least one second printing unit (9), said at least one second printing unit, viewed in a transport direction (A) of the printing substrate, being located downstream of the at least one first printing unit. In this method, a reference image is applied by the at least one first printing unit (9) and a location of the reference image is determined in a direction transverse to the transport direction of the printing substrate (6) in a position that is located, viewed in transport direction of the printing substrate, between the at least one first printing unit (9) and the at least one second printing unit (9). Subsequently, a position of the at least one second printing unit (9) transverse to the transport direction (A) of the printing substrate (6) is adjusted based on the determined location of the reference image in order to align the at least one second printing unit (9) relative to the at least one first printing unit (9) while the printing substrate (6) is being printed. In addition, a printing device (1) for printing a printing substrate (6) is described, said printing device (1) comprising at least one first printing unit (9) and at least one second printing unit (9), the at least one first printing unit (9), viewed in a transport direction (A) of the printing substrate (6), being located upstream of the at least one second printing unit (9). Furthermore, at least one sensor is provided, said sensor being aligned in a prespecified fixed positional relationship with respect to the first printing unit (9) and being directed at a position of a printing substrate path that is located, viewed in transport direction of the printing substrate, between the at least one first printing unit and the at least one second printing unit, and at least one adjustment unit is provided for the adjustment of the at least one second printing unit transverse to the transport direction (A) of the printing substrate (6) based on a signal of the at least one sensor.

Owner:EASTMAN KODAK CO

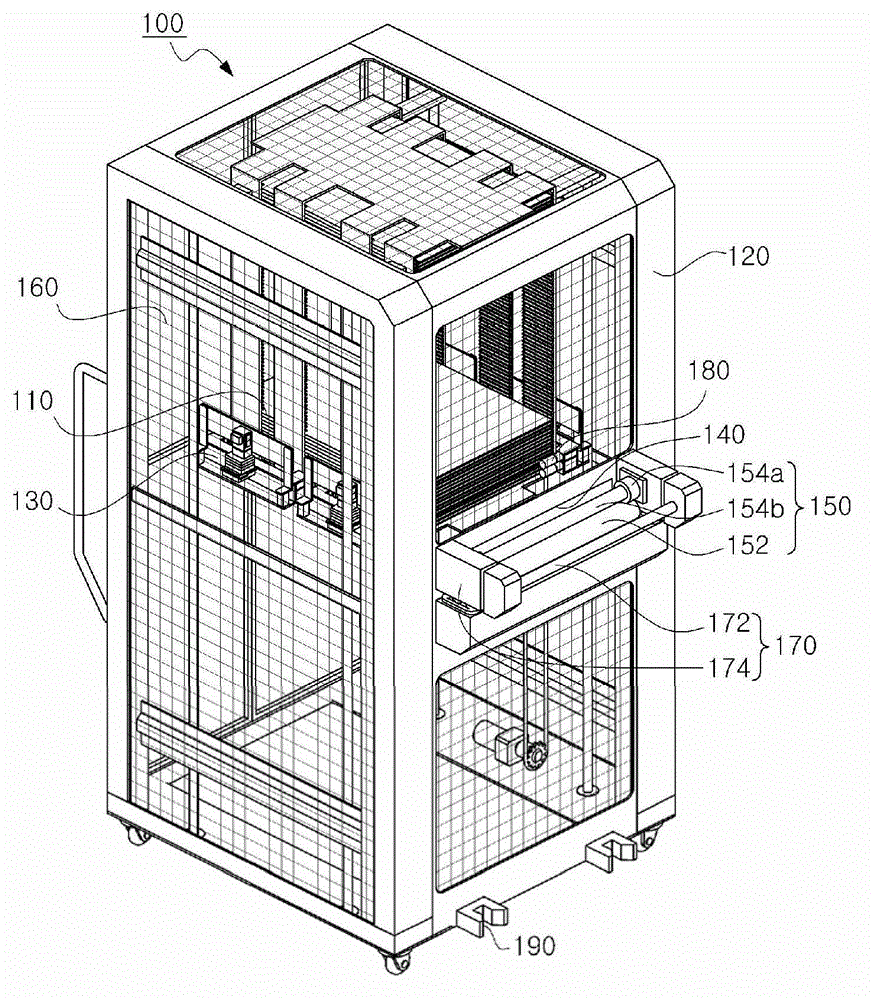

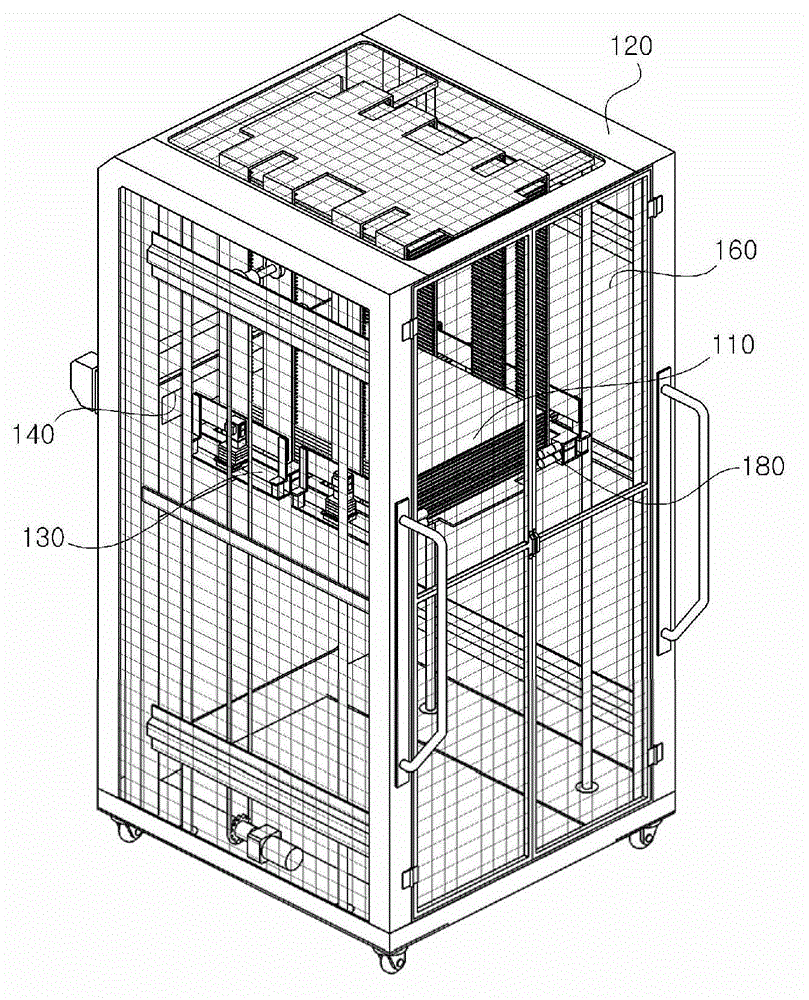

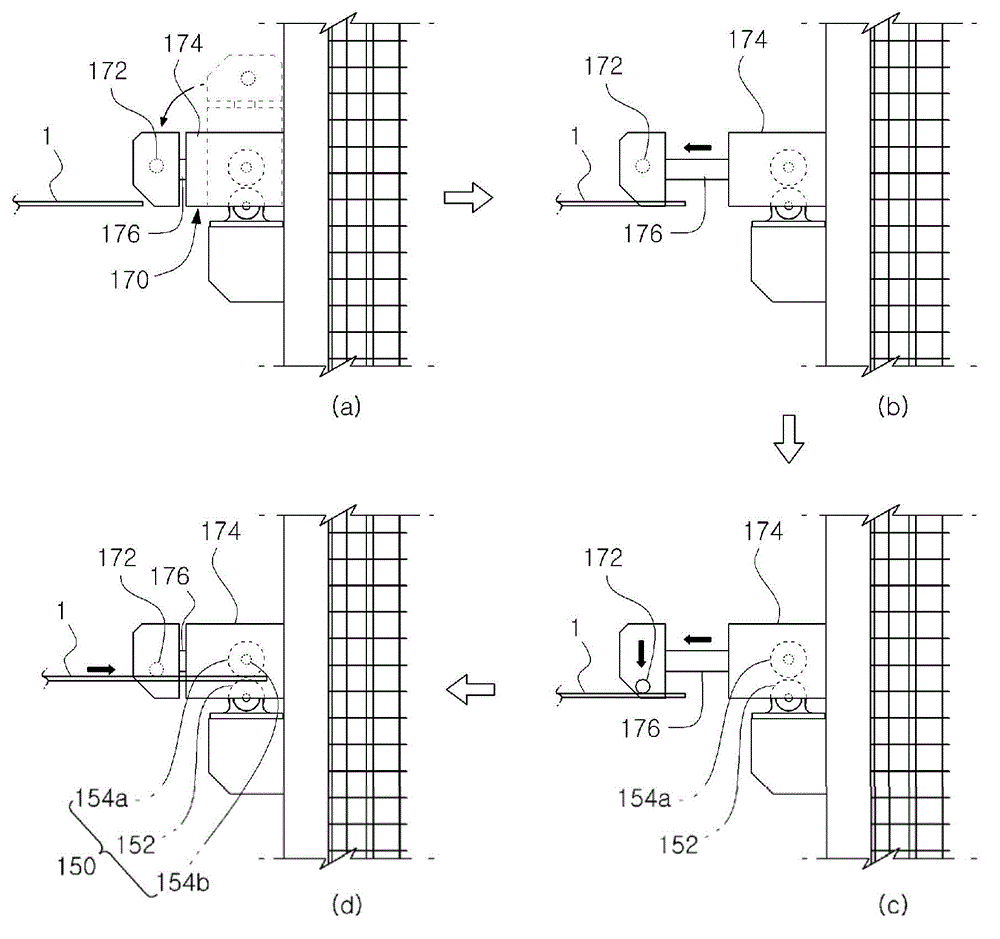

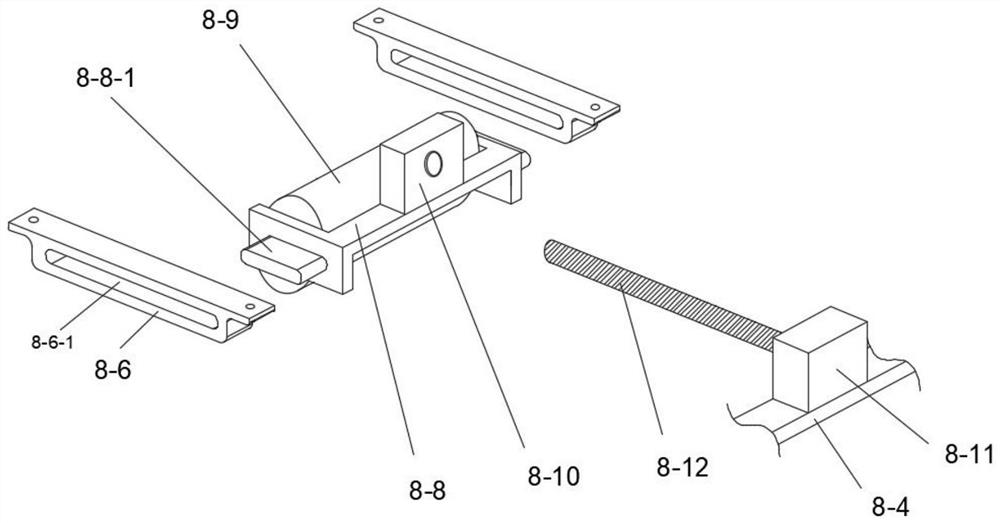

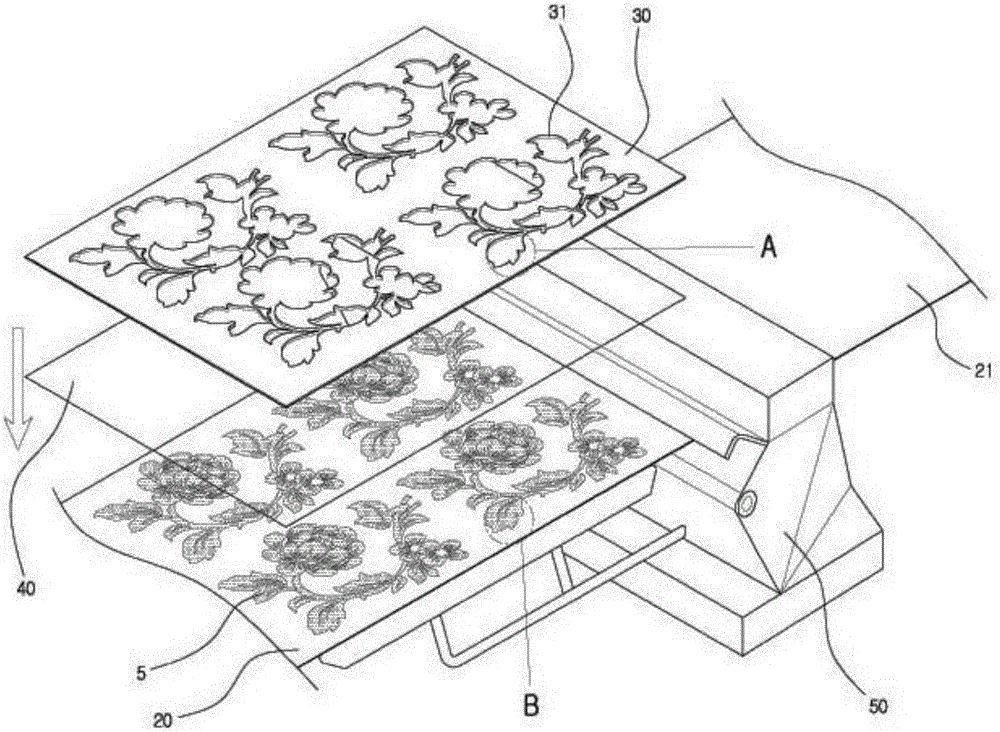

Unit frame used for moving in/out sheet and man-made nail printing system device utilizing the same

The present invention relates to a unit frame used for moving in / out a sheet and a man-made nail printing system device utilizing the same. The unit frame comprises: a sheet pallet for placing a printing-used sheet of which an upper surface is formed with a man-made nail pattern; a pallet housing for laminating a plurality of sheet pallets; a pallet lifting device arranged at the pallet housing and lifting the pallet housing up and down; an opening part for moving in and moving out the printing-used sheet; and a sheet moving mechanism comprising a lower supporting roller, a pair of impression rollers for respectively pressing edges of two sides of the upper surface of the printing-used sheet, and a pair of interval keeping rods arranged between the pair of impression rollers, and arranged at the opening part. By using the unit frame used for moving in / out the sheet of the present invention, printing error of the man-made nail can be reduced, thus yield of final products can be raised, unnecessary manpower waste also can be prevented, thereby reducing a lot of costs for producing the man-made nail.

Owner:张成龙

3D printed food package ink and preparation method thereof

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

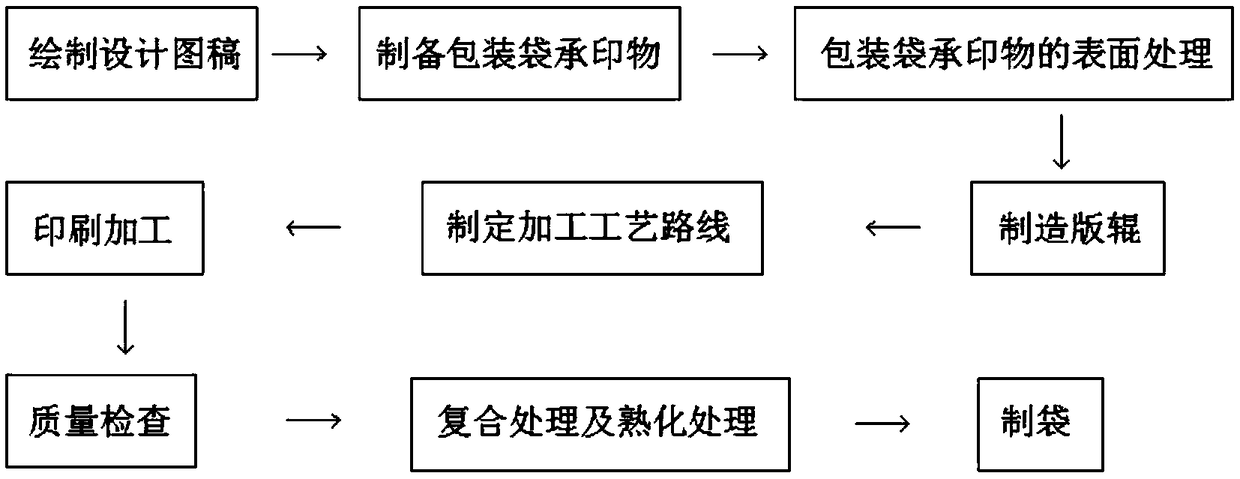

Preparation technology for environment-friendly high polymer material packaging bag

ActiveCN109159482APromote degradationShort degradation cycleBag making operationsPaper-makingFiberUltimate tensile strength

The invention provides a preparation technology for an environment-friendly high polymer material packaging bag. The preparation technology comprises the following steps that a design drawing is drawn, a packaging bag printed object is prepared, surface treatment of the packaging bag printed object is performed, a plate roller is manufactured, a processing technology route is formulated, printingprocessing is performed, quality inspection is performed, compound treatment is performed, curing treatment is performed and bag making is performed. According to the preparation technology, through polyhydroxyalkanoate and fiber materials in the composition of the packaging bag printed object, the degradability of a packaging bag can be improved, meanwhile, the degradation period of the packagingbag is short, the packaging bag can react with water to be degraded when being covered or buried in the soil, so that the degradation efficiency of the packaging bag is improved, it is guaranteed that the degradation of the packaging bag is not affected by environmental factors, the pollution to the environment after the packaging bag is abandoned is reduced, the strength and the tension of the packaging bag can be improved through the compound treatment and the curing treatment, the quality problems of film curling, wrinkling, difficulty in bag making, peeling strength declination and bag making deformation of the packaging bag occurring in the subsequent bag making process are solved, and the quality of the packaging bag is improved.

Owner:广东新天丽控股有限公司

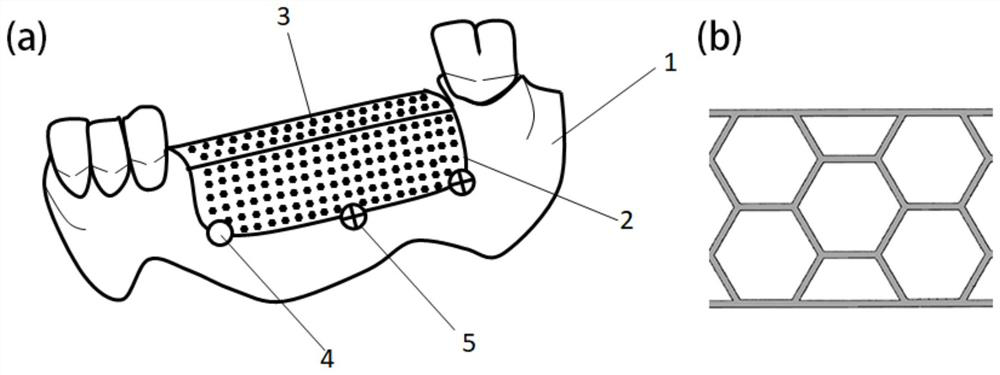

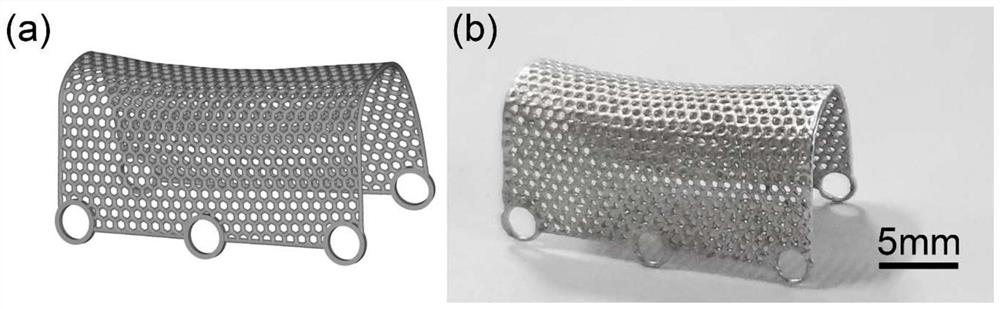

Degradable magnesium mesh for 3D printing personalized alveolar bone defect reconstruction

PendingCN114099079APrecise positioningProtection formAdditive manufacturing apparatusJoint implantsEngineeringDentistry

The invention discloses a degradable magnesium mesh for 3D printing personalized alveolar bone defect reconstruction. According to the magnesium mesh, a personalized model structure is designed according to CT data, high-precision preparation of the magnesium mesh is achieved through the 3D printing technology, and the magnesium mesh is made to be tightly attached to the anatomical appearance of the alveolar bone; the defects that a traditional titanium mesh needs to be bent in an operation and the postoperative exposure rate is high are overcome, the operation difficulty and time are reduced, and the operation success rate is increased. The surface of the magnesium mesh is of a completely-perforated regular hexagon structure, and the mesh structure has the advantages of self-supporting, easiness in forming, high printing precision, good mechanical property and the like. Meanwhile, by combining the degradability of a magnesium material and the advantage of promoting osteogenesis through bone induction of magnesium ions, the problems that a titanium mesh shields stress and cannot be degraded, and secondary operation is needed for taking out the titanium mesh during tooth implantation are solved. The preparation process is simple, the preparation period is short, raw material loss is small, repeatability is high, pollution is avoided, and the prepared magnesium mesh has the advantages of being controllable in appearance and high in precision and can serve as a new generation of oral cavity alveolar bone large-area bone defect repairing support.

Owner:SHANGHAI JIAO TONG UNIV +1

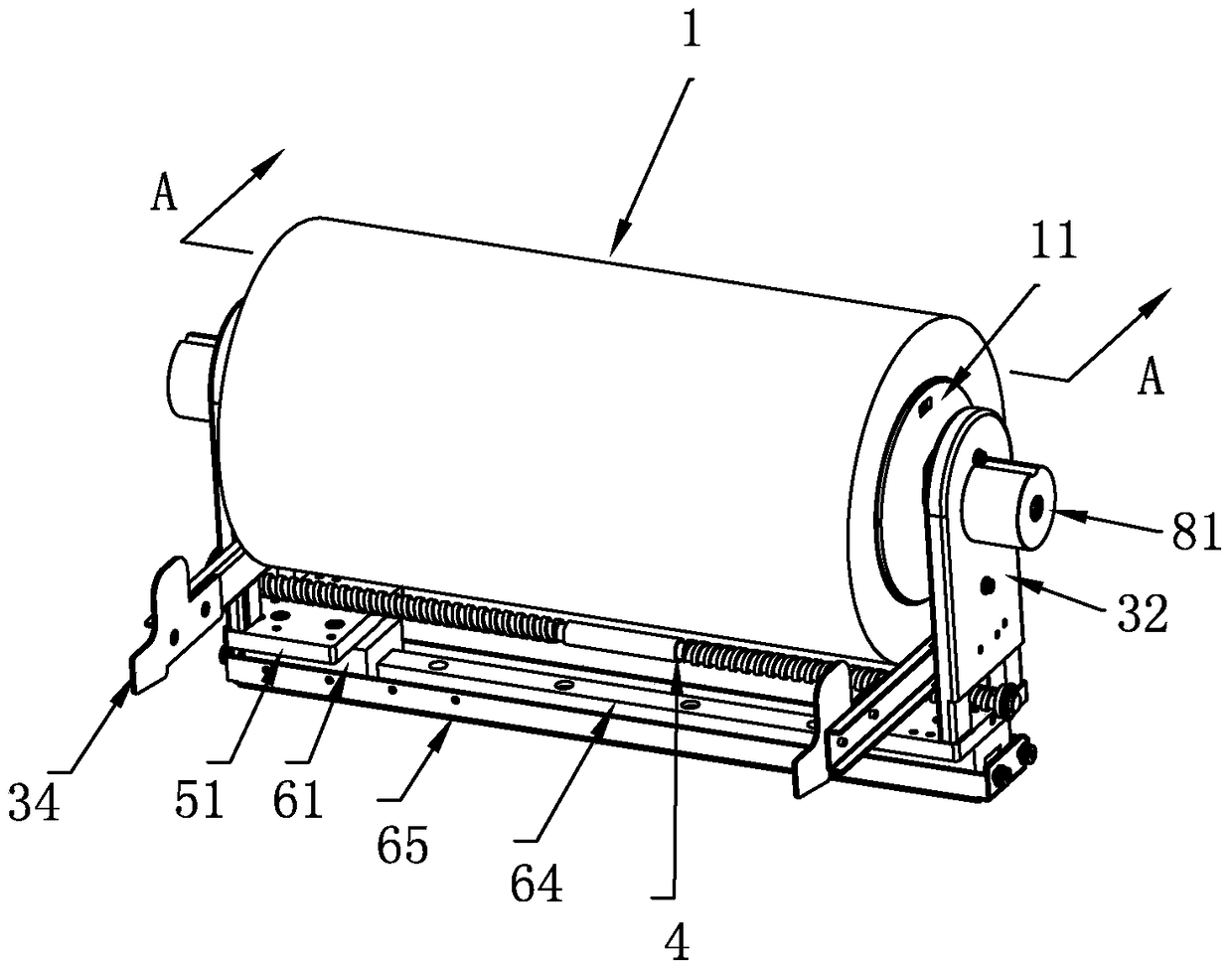

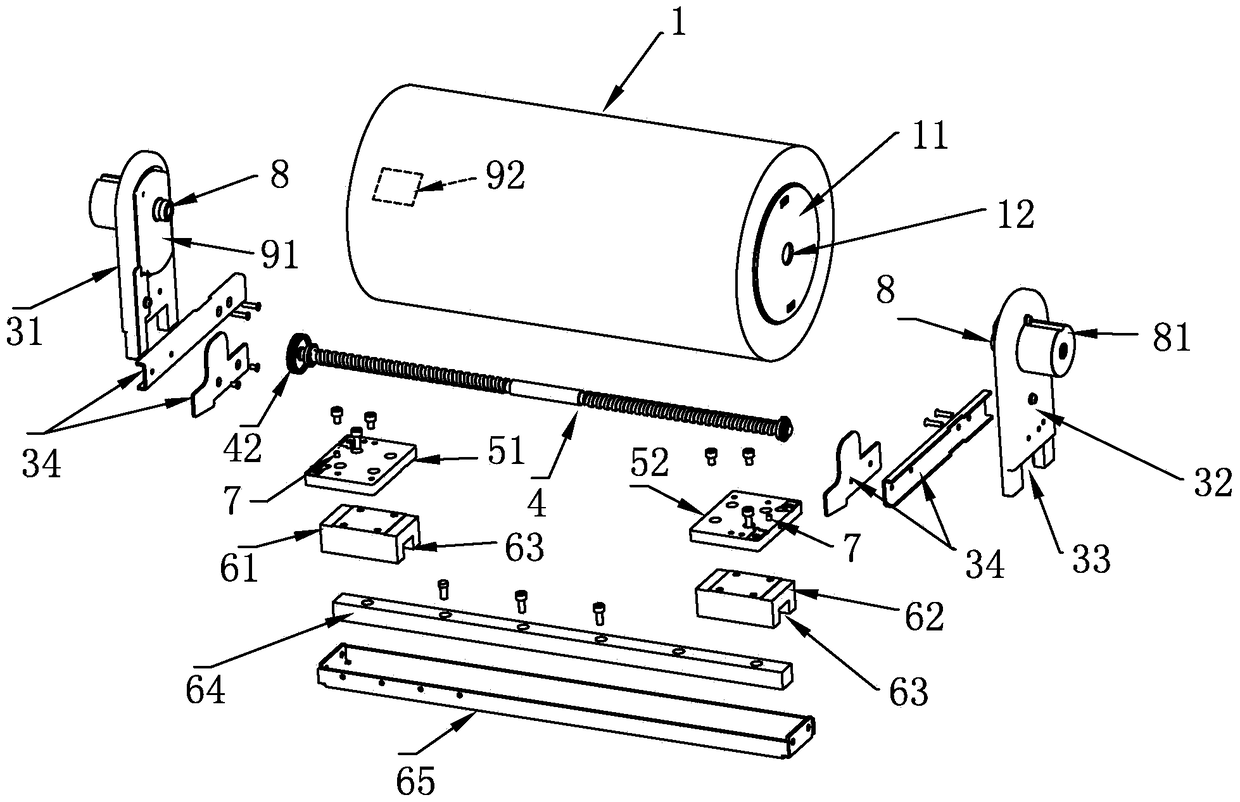

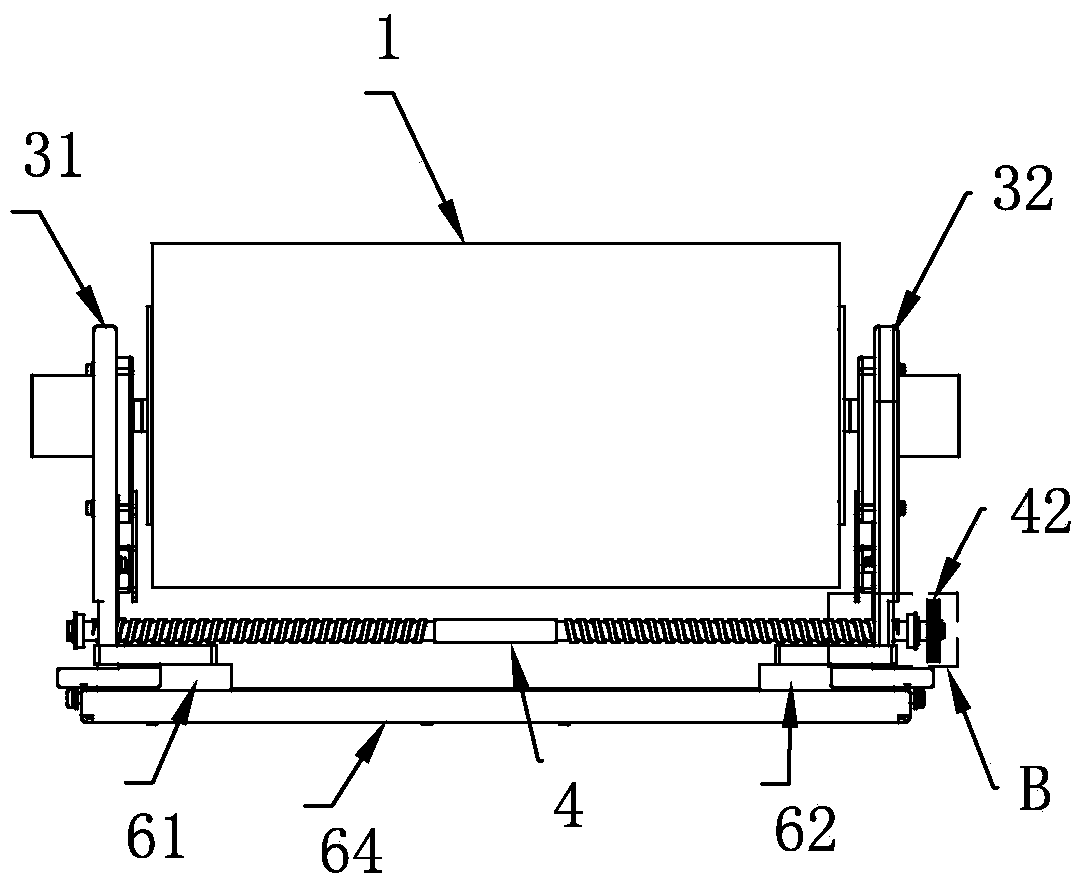

Printing supplies loading mechanism for printers

ActiveCN105599465BImprove efficiencyReduce stepsOther printing apparatusComputer printingData information

A printing consumable loading mechanism for a printer that can identify the type, specification and material data information of the printing consumables and automatically adjust the printing parameters of the printer according to the data information. It is provided between the inner side of the left baffle or right baffle in the limit device and the carrier carrying the printing consumables, which can obtain the consumable specification information including the material, thickness, width and / or shape type of the printing consumables. An automatic detection device, the automatic detection device sends the acquired specification information of the consumables to the processor in the control circuit and outputs an instruction to automatically adjust the printing settings of the printer to match the current printing consumables. Print parameters for temperature, print pressure, print speed and / or color ratio. It can improve the use efficiency of the printer, reduce the printing error rate, and promote printing automation. It is a revolutionary improvement to the full automation of label printers, and it is especially suitable for industries with large printing quantities and high quality requirements.

Owner:SHENZHEN KINGPEK CO LTD

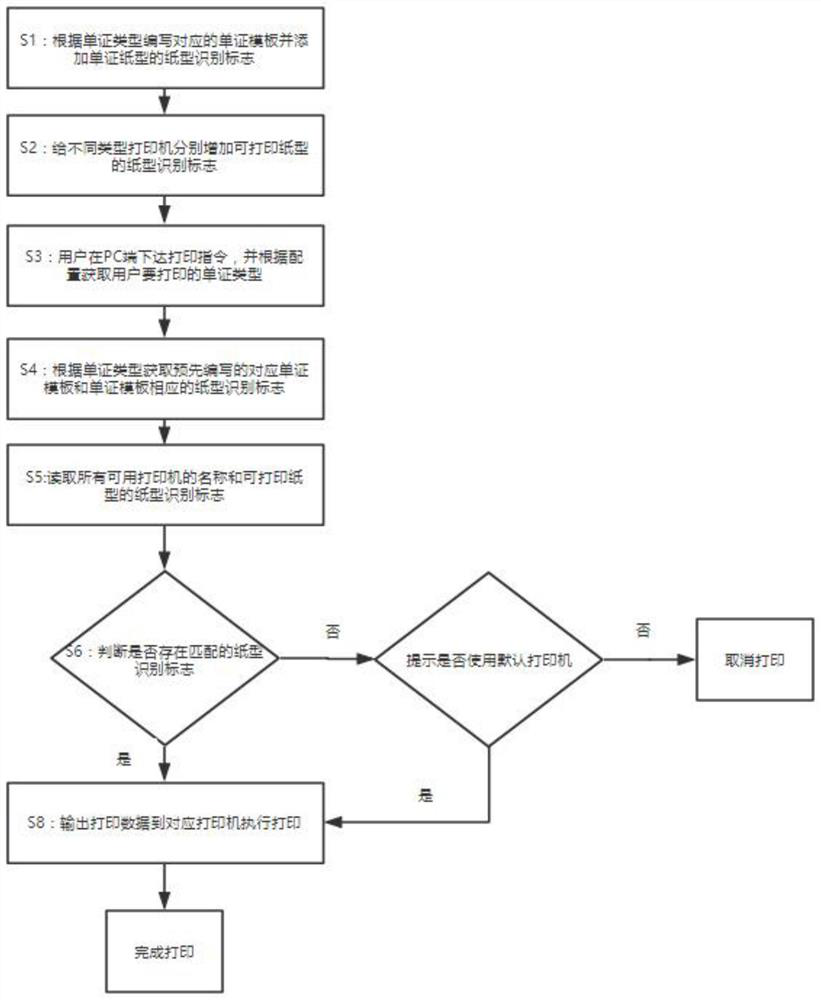

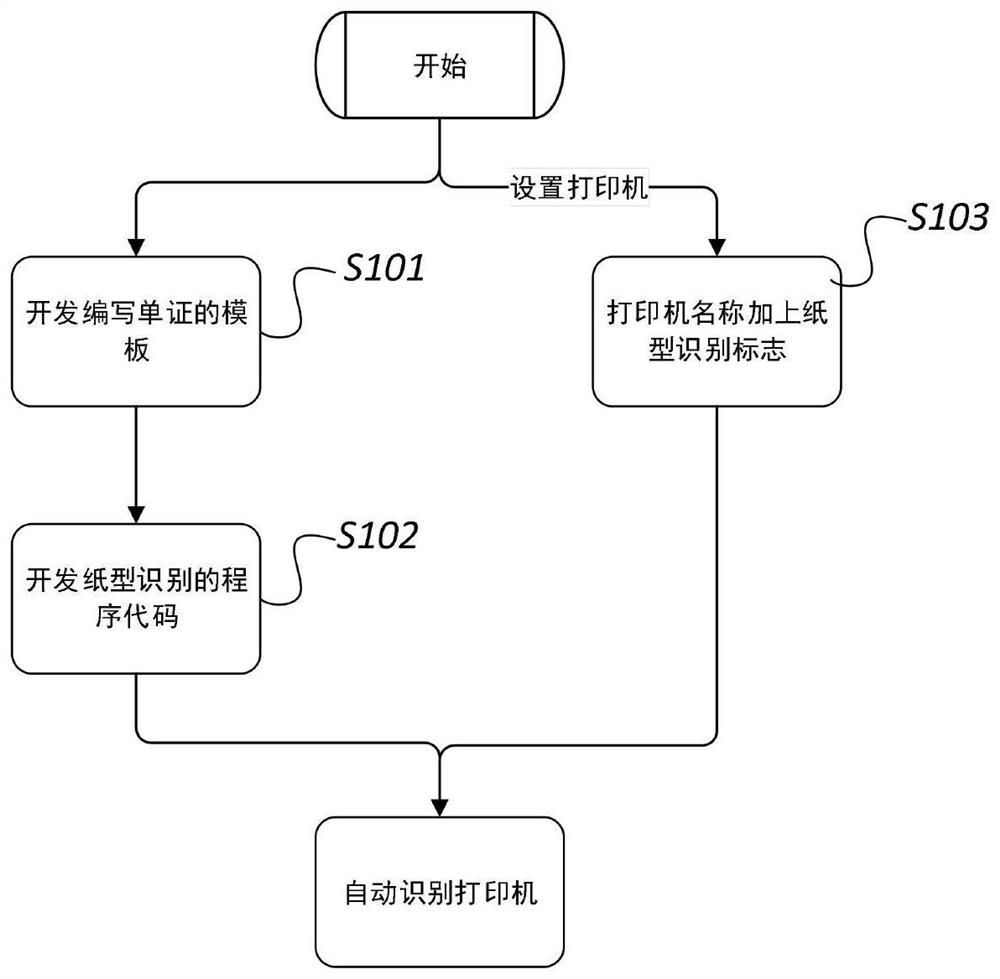

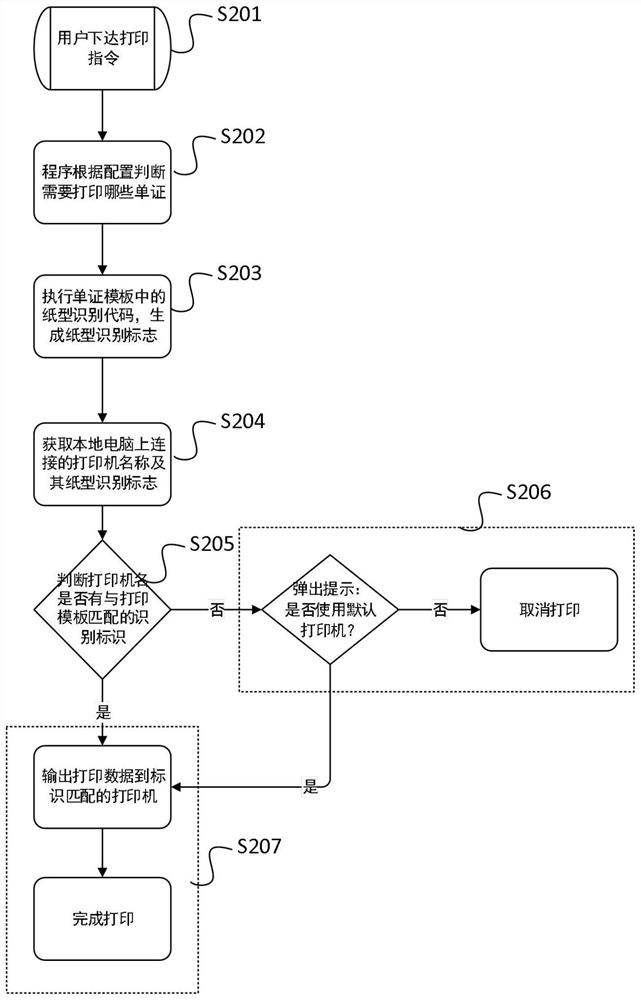

Printer automatic identification method and system based on logistics operation scene

PendingCN111736782AImprove printing efficiencyReduce printing errorsDigital output to print unitsLogistics managementComputer printing

The invention discloses a printer automatic identification method and system based on a logistics operation scene. The method comprises the following steps: compiling a document template; adding a paper type identification mark; adding a paper type identification mark to the printer; issuing a printing instruction; obtaining the type of a document to be printed; obtaining a pre-written document template; obtaining a paper type identification mark of the document template; reading the name and the paper type identification mark of the printer; matching the document paper type required by the document template with the paper type identification marks of the printable paper types of all printers; if matching fails, selecting to use a default printer or cancel printing; if matching succeeds ora default printer is used, outputting the printing data to the corresponding printer to execute printing. By the adoption of the method and system, one PC can output data to the multiple printers atthe same time, the printers can be automatically and accurately recognized, synchronous printing of the multiple printers is achieved, printing errors can be reduced, and the printing efficiency of synchronous printing of various document receipts is improved.

Owner:上海无忧供应链管理有限公司

Metal plate printing process

InactiveCN105196725AHigh color fastnessReduce printing errorsDuplicating/marking methodsOther printing apparatusPaper sheetPrinting ink

The invention discloses a metal plate printing process. The metal plate printing process comprises the following steps that 1, calico paper is printed, wherein patterns to be printed are made into a plurality of printing rollers through electric carving plate making, and the printing rollers are mounted on a calico paper transferring machine, and are smeared with printing ink to print the calico paper with the patterns to be printed; 2, a printing metal plate is printed, wherein the calico paper is placed in metal plate thermal transfer printing equipment, and enters a heating roller along with an empty metal plate for thermal transfer printing, the patterns on the calico paper are printed on the empty metal plate, the printed metal plate is obtained through rolling, and the printing ink comprises raw materials composed of resin, pigment powder and organic solvents with the mass ratio of 1:2-5:10-20. The metal plate printing process is continuous in printing process, patterns on the metal plate and the patterns the calico paper correspond, printing errors are reduced, printing efficiency is greatly improved, and cost is reduced. Colors are rich, color fastness is high, high temperature is resisted, and the metal plate can withstand long-time corrosion of air or rain water and is not likely to fade.

Owner:HANGZHOU LINAN FEIJIE PLASTIC PRINTING CO LTD

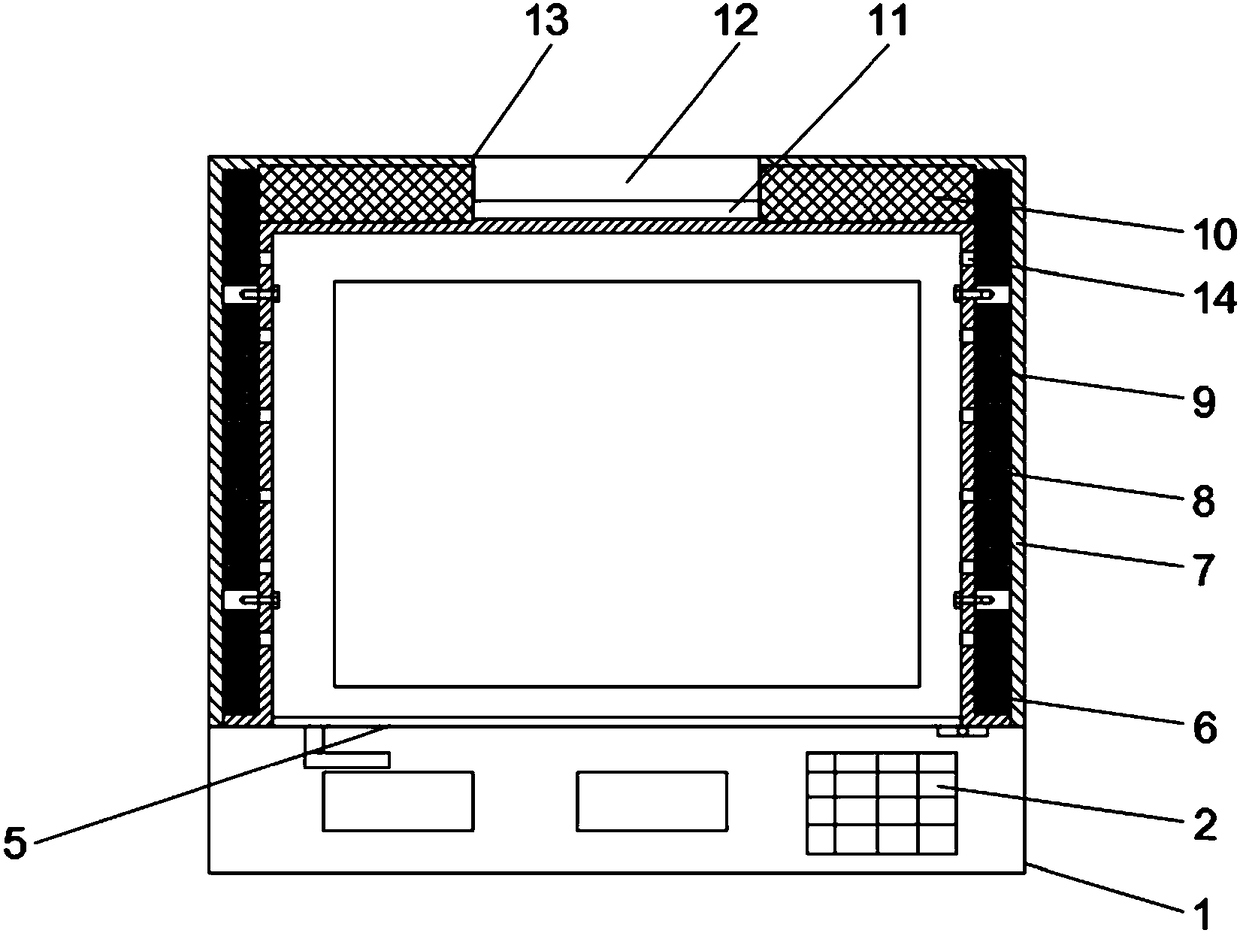

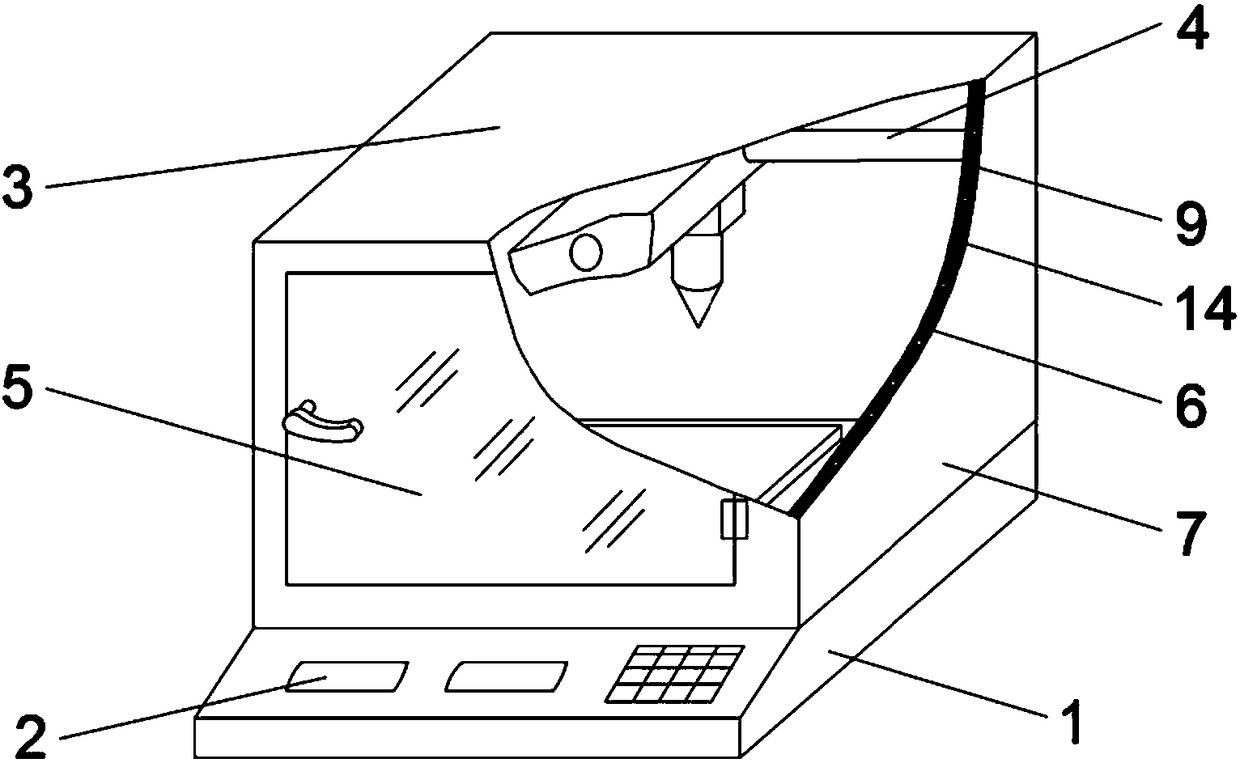

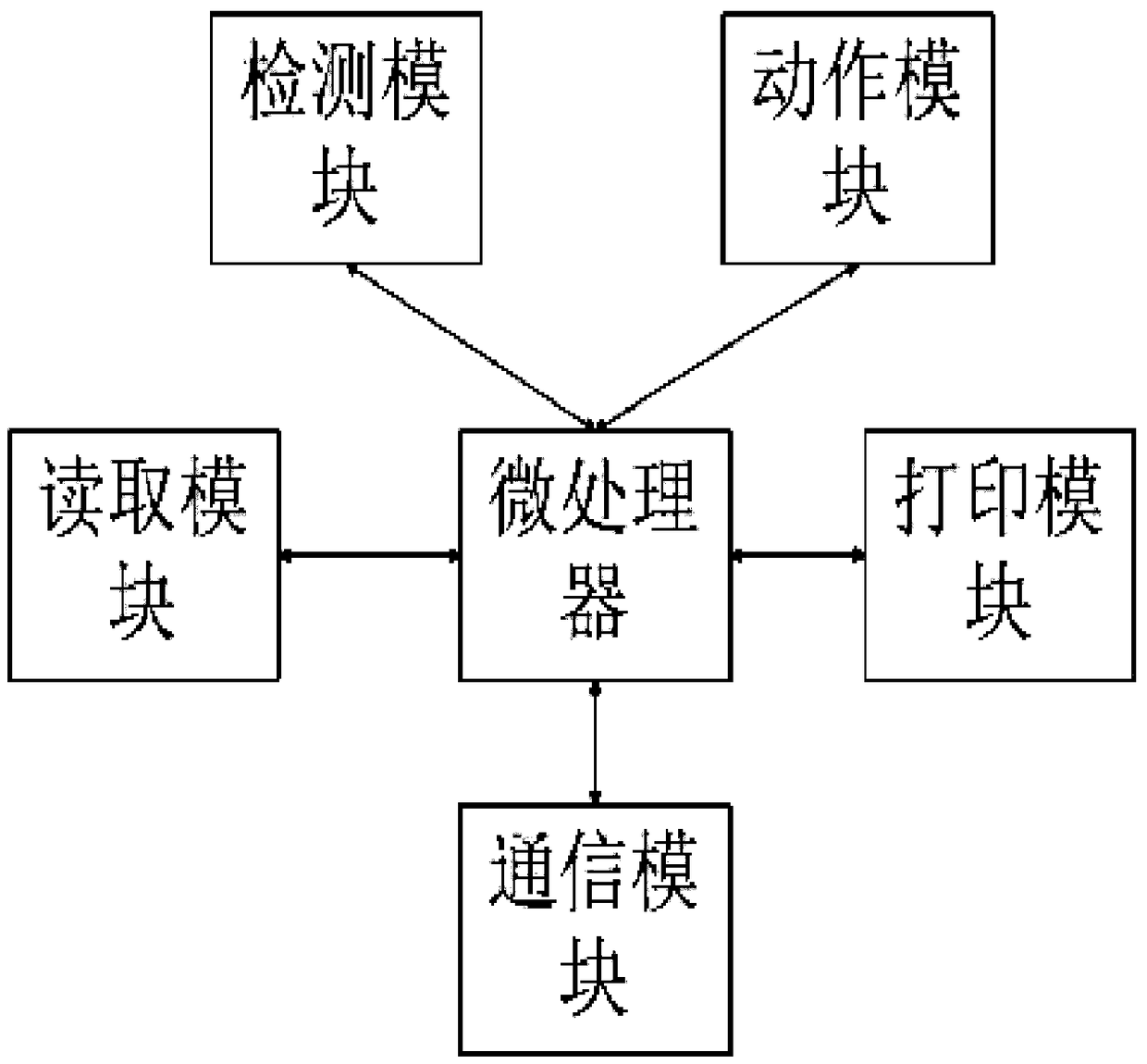

Bankbook reading and printing device for VTM

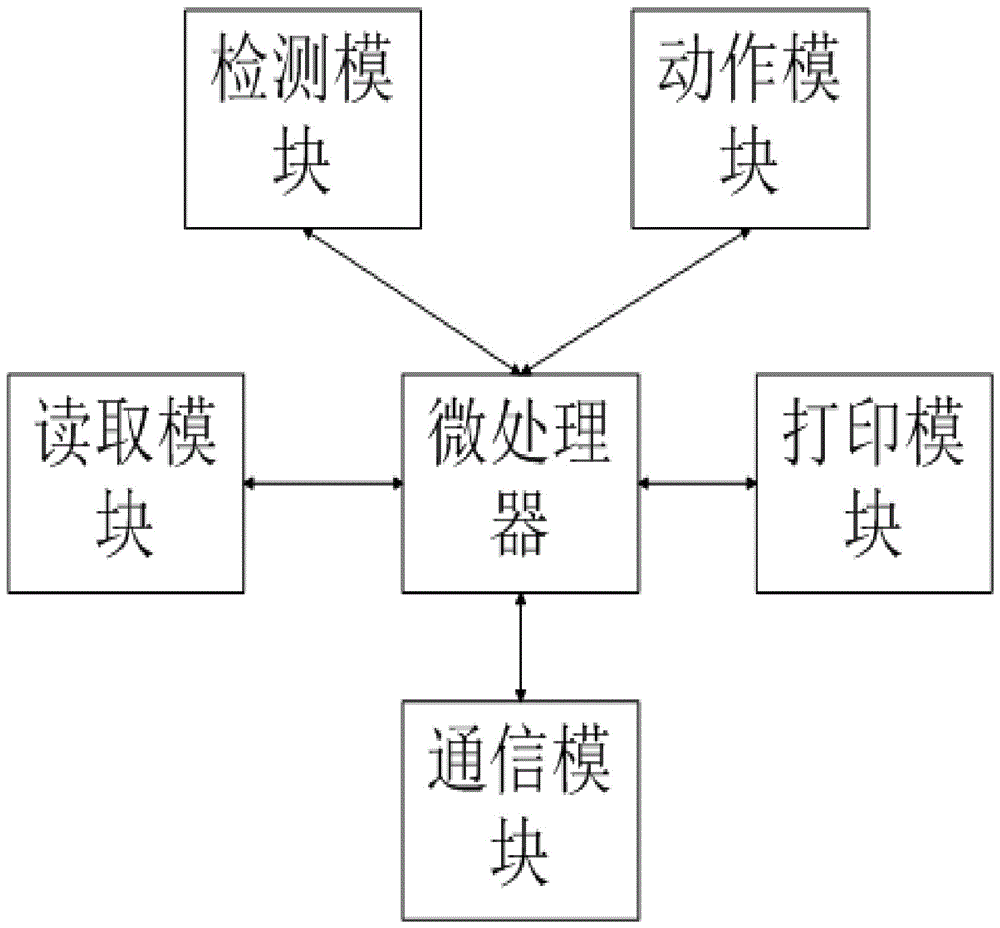

ActiveCN106335292AImprove securityReduce printing errorsComplete banking machinesTypewritersPassbookComputer module

The invention discloses a bankbook reading and printing device for a VTM. The bankbook reading and printing device comprises a detection module, a reading module, a printing module, an action module, a microprocessor and a communication module. The microprocessor can control the reading module to read magnetic track information of a bankbook and verifies the magnetic track information to ensure account accuracy thereby improving account safety to a certain extent; the microprocessor controls the detection module to detect whether the printing position is correct to ensure printing position of new transaction information closely follows the last line of the previous print, thereby preventing wasting a lot of empty printing space; and the microprocessor can also control the action module to carry out automatic page turning according to information fed back by the detection module, and when the printing content is not finished, the bankbook is not withdrawn, thereby reducing human intervention, improving automation degree of the device, preventing print content repetition or miss likely to occur when the bankbook is withdrawn, preventing possible repeated page turning due to manual page turning, and reducing printing errors.

Owner:GUANGZHOU KINGTELLER ATM TECH

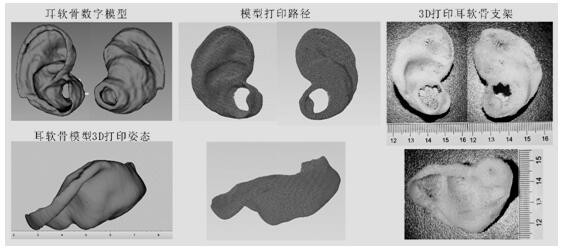

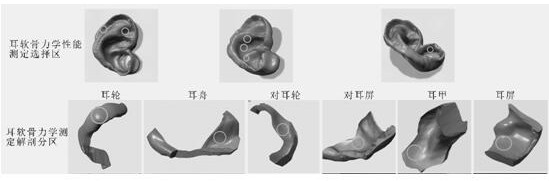

3D printed mechanical bionic auricle cartilage tissue engineering scaffold and manufacturing method thereof

ActiveCN112354017AMechanical bionics haveGood biocompatibilityAdditive manufacturing apparatusTissue regeneration3d printPoly dl lactide

The invention relates to a 3D printed mechanical bionic auricle cartilage tissue engineering scaffold and a manufacturing method thereof. A personalized auricle cartilage scaffold is printed accordingto an individual auricle cartilage structure model of a patient through a 3D printing technology, and the tissue engineering scaffold is formed by printing a biodegradable composite material (PLCL-PCL) of Poly-L-lactide-caprolactone (PLCL) and polycaprolactone (PCL) capable of being subjected to 3D printing disclosed in CN201910139657.9. The frameless, porous and pore-through auricle cartilage tissue engineering scaffold is good in biocompatibility, degradability and thermal stability, has a fine and complex three-dimensional structure of auricle cartilage, has the mechanical property characteristic similar to that of a corresponding anatomical region of natural human auricle cartilage tissue, is adaptive to the mechanical property of the natural auricle cartilage, and can be applied to construction of personalized tissue engineering auricle cartilage.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

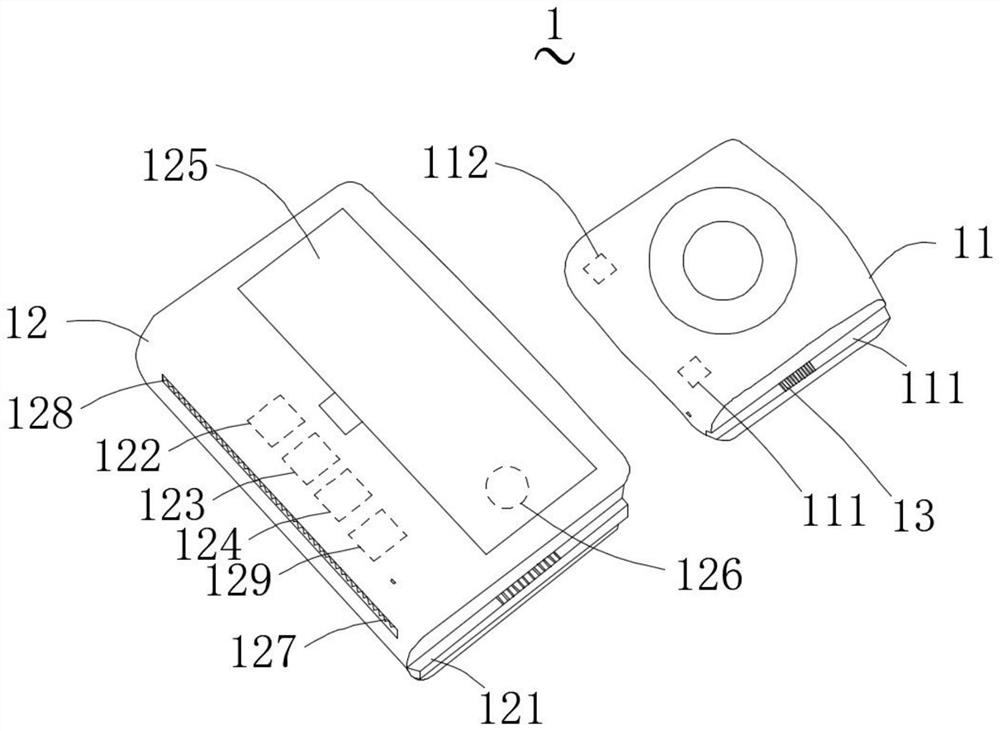

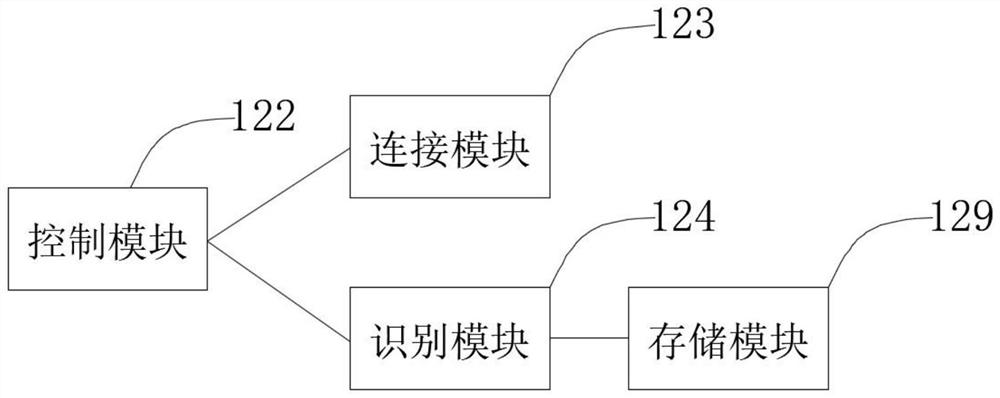

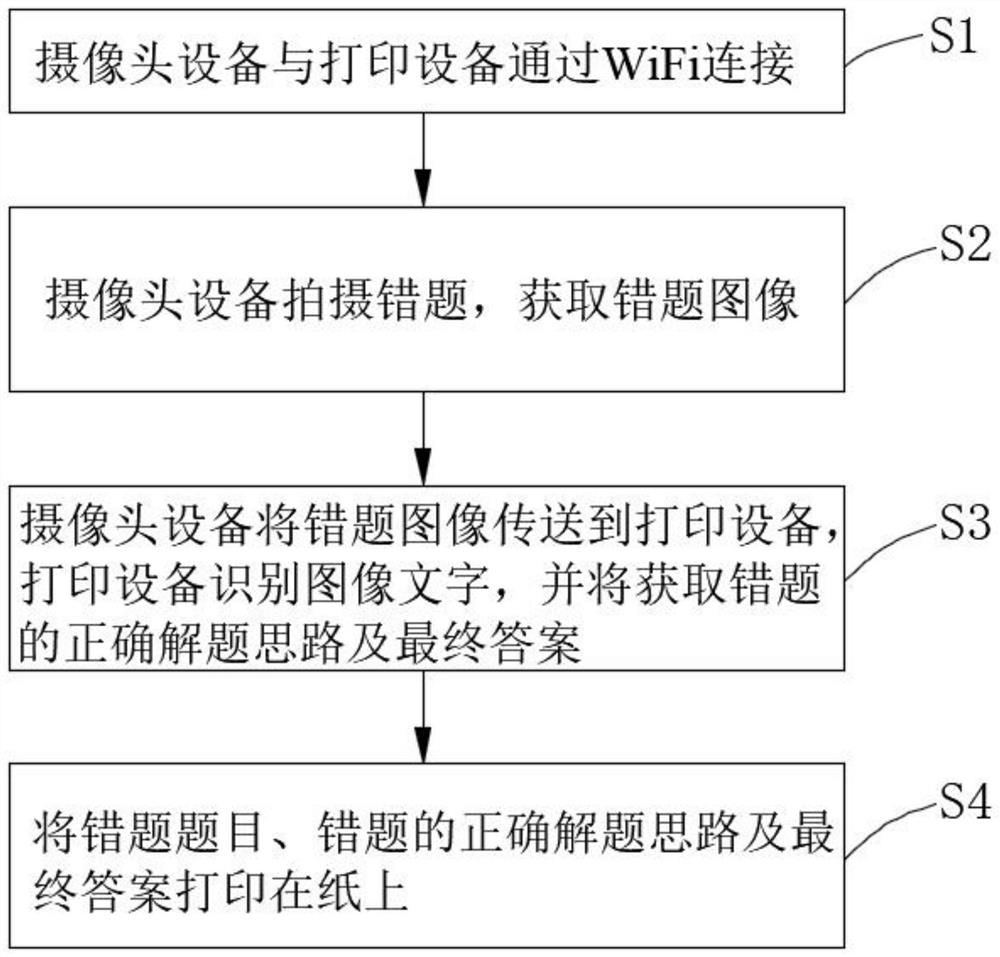

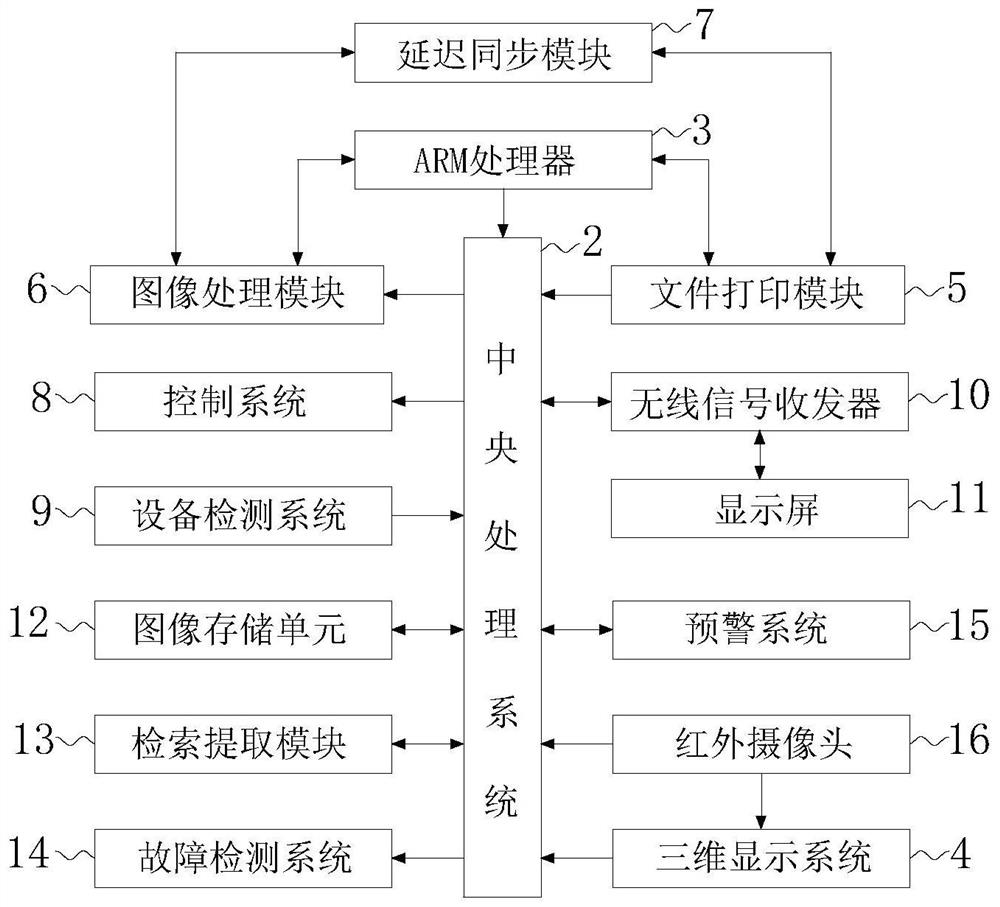

Error question printer system based on WiFi control and control method

InactiveCN113370676AImprove user experienceIncrease functional diversityTransmission systemsTypewritersComputer printingControl engineering

The invention provides an error problem printer system based on a WiFi control. The error question printer system based on the WiFi control comprises camera equipment and printing equipment, and the camera equipment is detachably connected with the printing equipment; the printing equipment comprises a control module, a connection module and an identification module, and the control module is electrically connected with the connection module and the identification module. A camera is used for shooting images of wrong questions, the printing equipment is used for printing shot wrong questions, the answering process of the wrong questions is analyzed and characters of the wrong questions are recognized through the identification module, the functional diversity of the system can be increased, the camera equipment and the printing equipment are detachably and separately used, a user can hold the camera equipment to shoot.The printing equipment is used for printing, the user can carry out long-distance shooting operation, the printing equipment can be placed at any position indoors, the user can use the printing equipment remotely, and the use experience of the user is improved.

Owner:深圳市羽恒科技有限公司

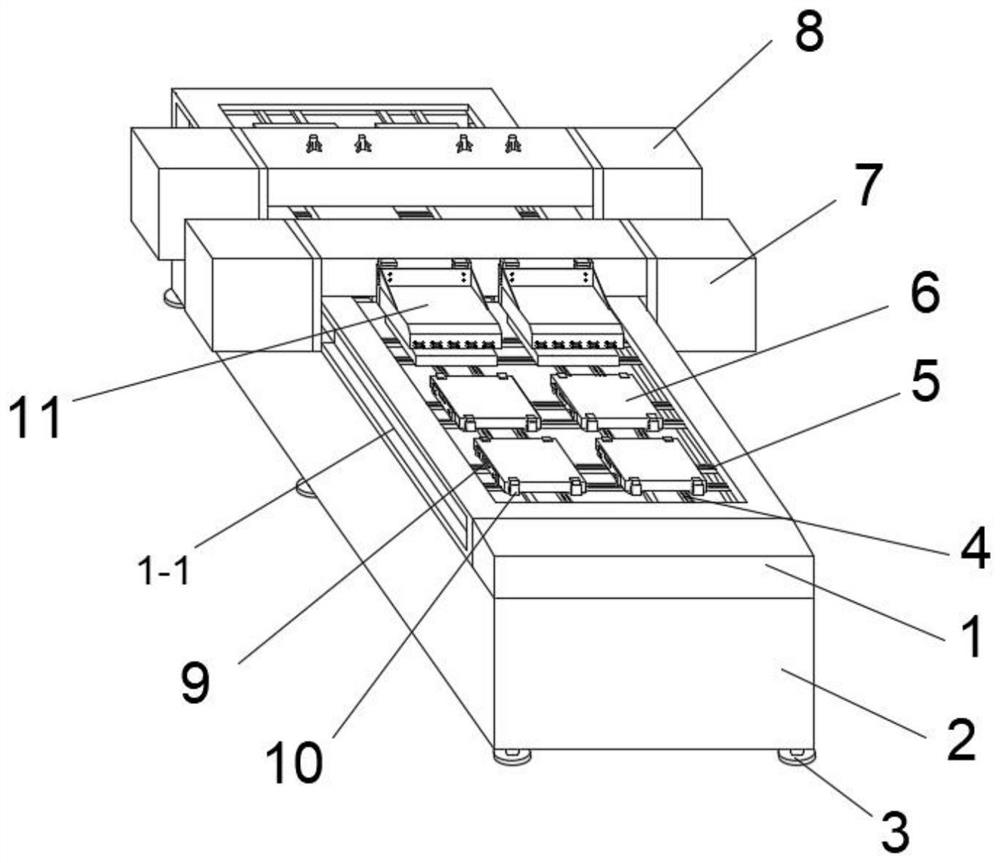

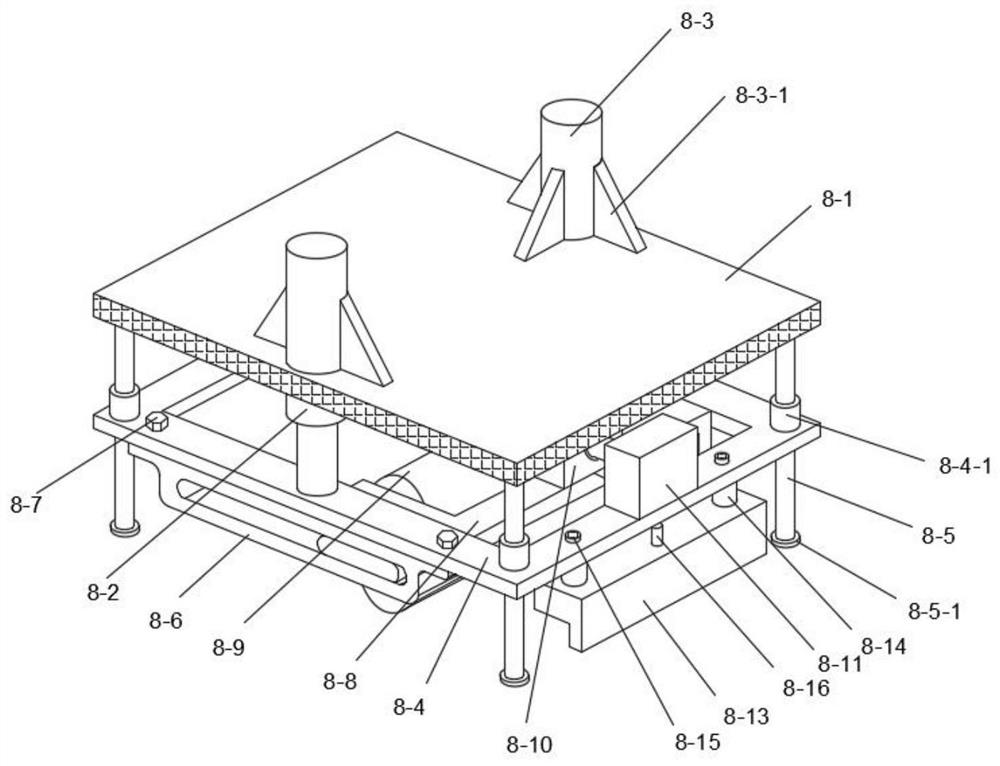

Complete equipment applied to digital 3D printing

ActiveCN112406324AWrinkle resistantGuaranteed SprayingTypewritersOther printing apparatusEngineering3D printing

The invention provides complete equipment applied to digital 3D printing. The complete equipment comprises a rack, a machine base, a foot pad, a longitudinal guide rail, a transverse guide rail, a flat plate, a spray head driving mechanism, a wrinkle removing mechanism, flat plate positioning mechanisms, flat plate pressing mechanisms and a drying mechanism, and the rack is arranged on the top surface of the machine base. The foot pad is arranged on the bottom surface of the machine base. The longitudinal guide rail and the transverse guide rail are arranged on the inner side of the rack. Theflat plates are slidably arranged on the transverse guide rail. The spray head driving mechanism is arranged on the top surface of the rack in a crossing manner. The wrinkle removing mechanism and therack can be arranged in a sliding manner through the driving mechanism. The flat plate positioning mechanisms are arranged on the side wall of one end of each flat plate. The flat plate pressing mechanisms are arranged on the two sides of each flat plate. The drying mechanism is arranged on the side wall surface of the spray head driving mechanism. The wrinkle removing process is high in efficiency, printed matters can be firmly fixed to the surfaces of the flat plates, stable operation of the printing process is guaranteed, the equipment has high drying efficiency, and the printing process is high in efficiency.

Owner:镇江市海络数码科技有限公司

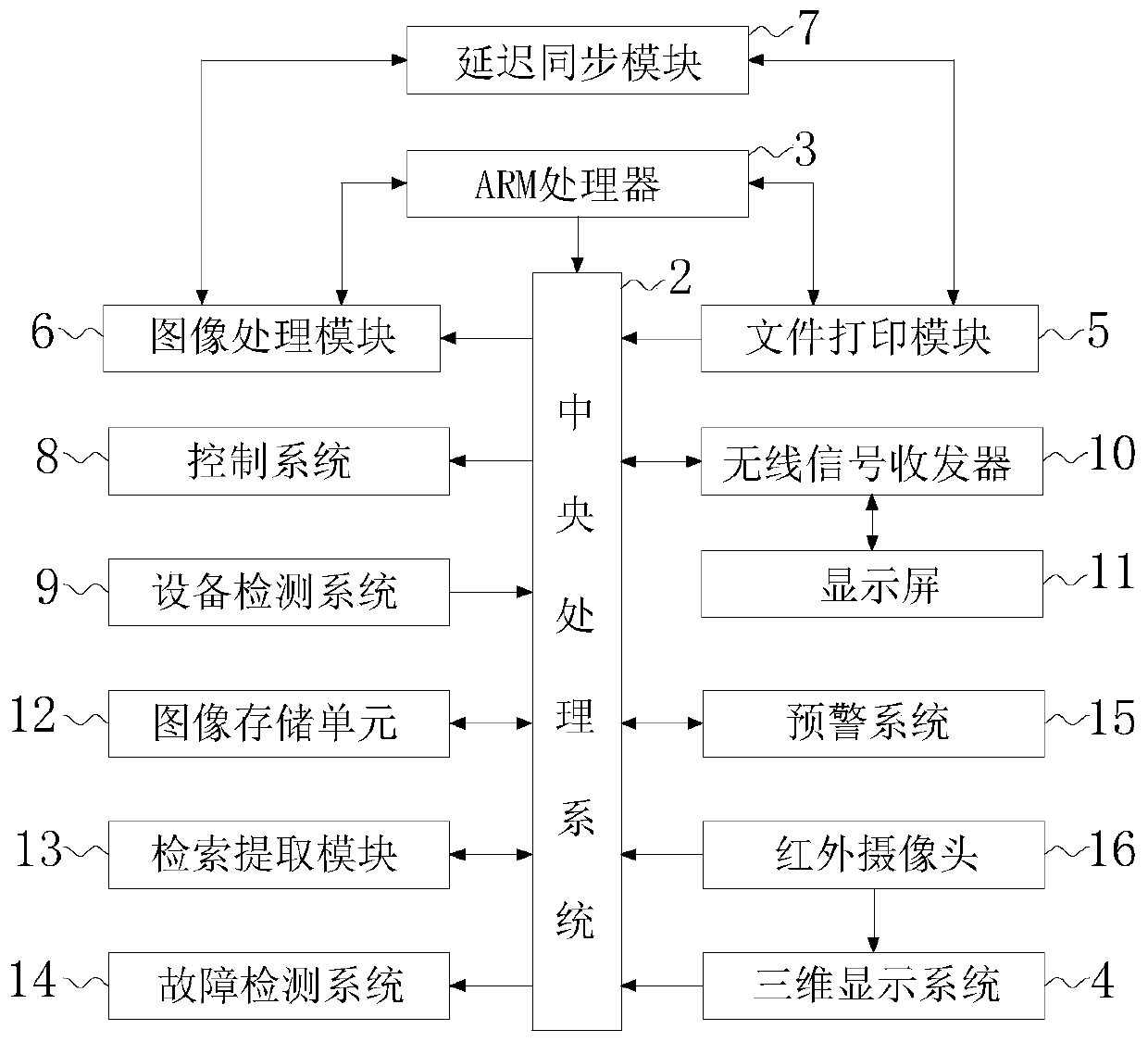

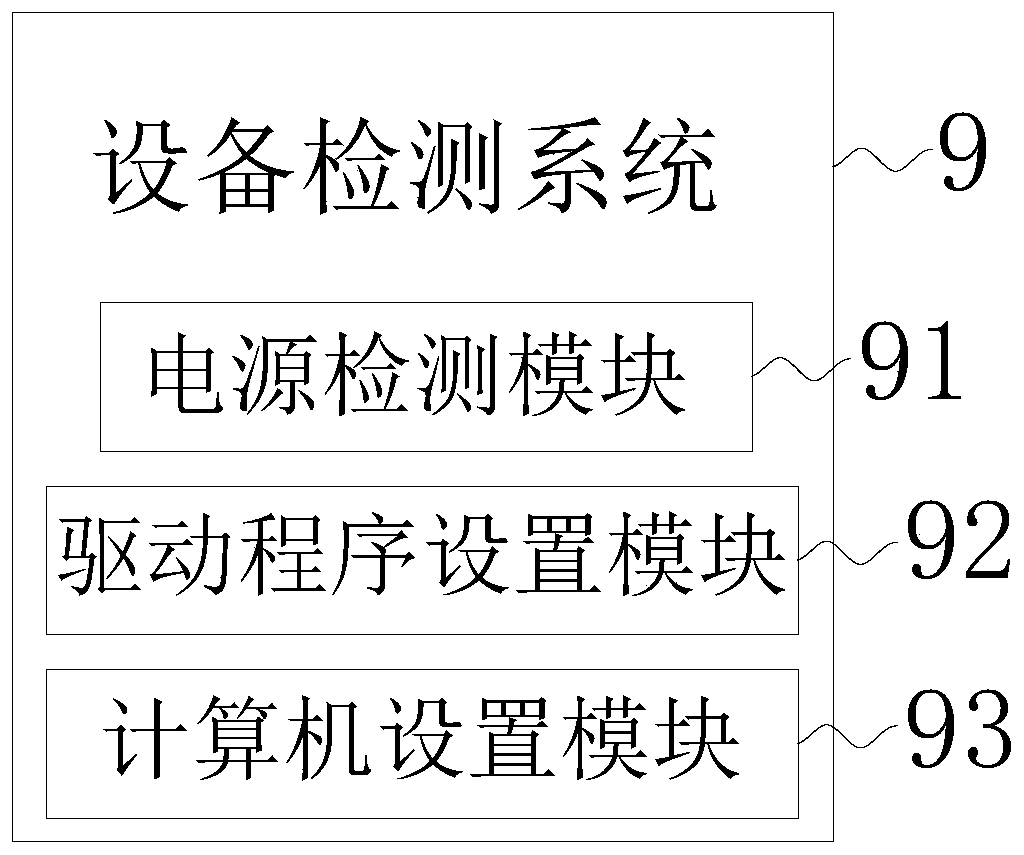

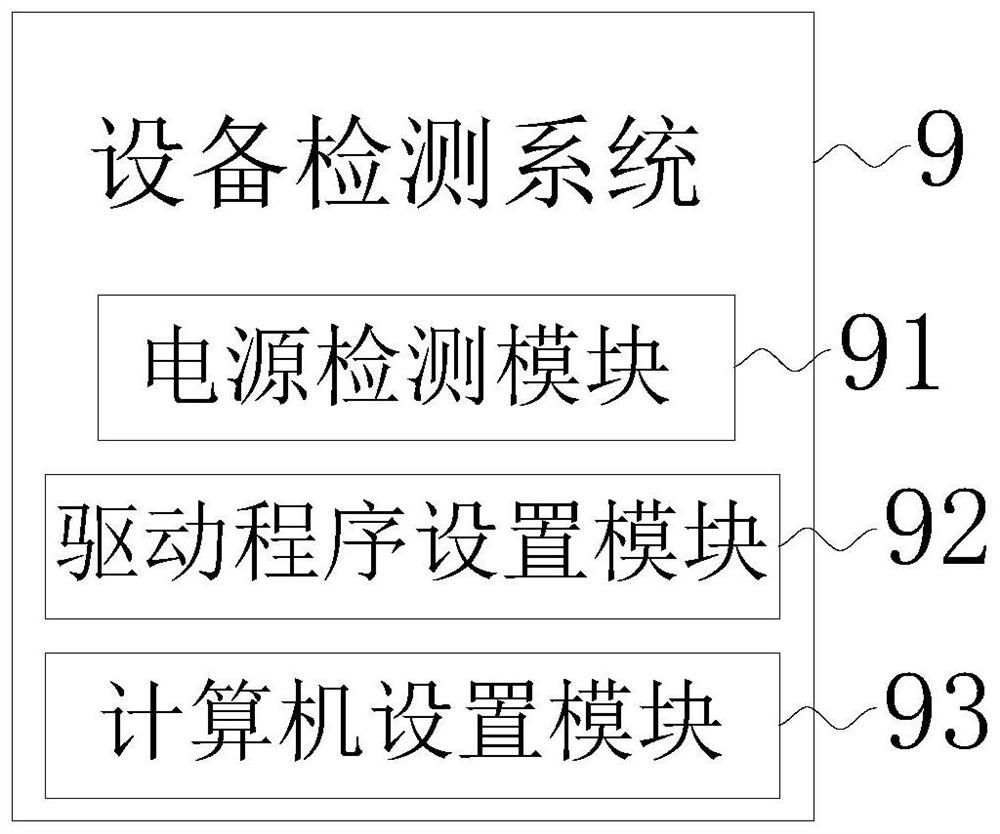

Method for reducing printing position error and imaging device using same

ActiveCN110181956AImprove accuracyA print job was aborted unexpectedlyDuplicating/marking methodsOther printing apparatusVia devicePosition error

The invention discloses a method for reducing a printing position error, and relates to the technical field of printing. The method comprises the following steps of 1, detecting weather all power cords of a using printer are successfully connected through a power supply detection module in a device detection system, after power-on is confirmed successful, preparing a driver program related to theprinter through a driver program setting module, setting parameters required during printing through a computer setting module, then sending the data to the inside of a central processing system, andcontrolling the printer to start printing through the central processing system; and 2, arranging an infrared camera on the printer. According to the method for reducing the printing position error and an imaging device using the same, various detections of the printer before use and analytical comparison with an infrared acquired image after printing can be achieved, so that the printing error can be reduced, the problem in file printing is avoided, and the practicability of the device is greatly improved.

Owner:杭州巨牛科技有限公司

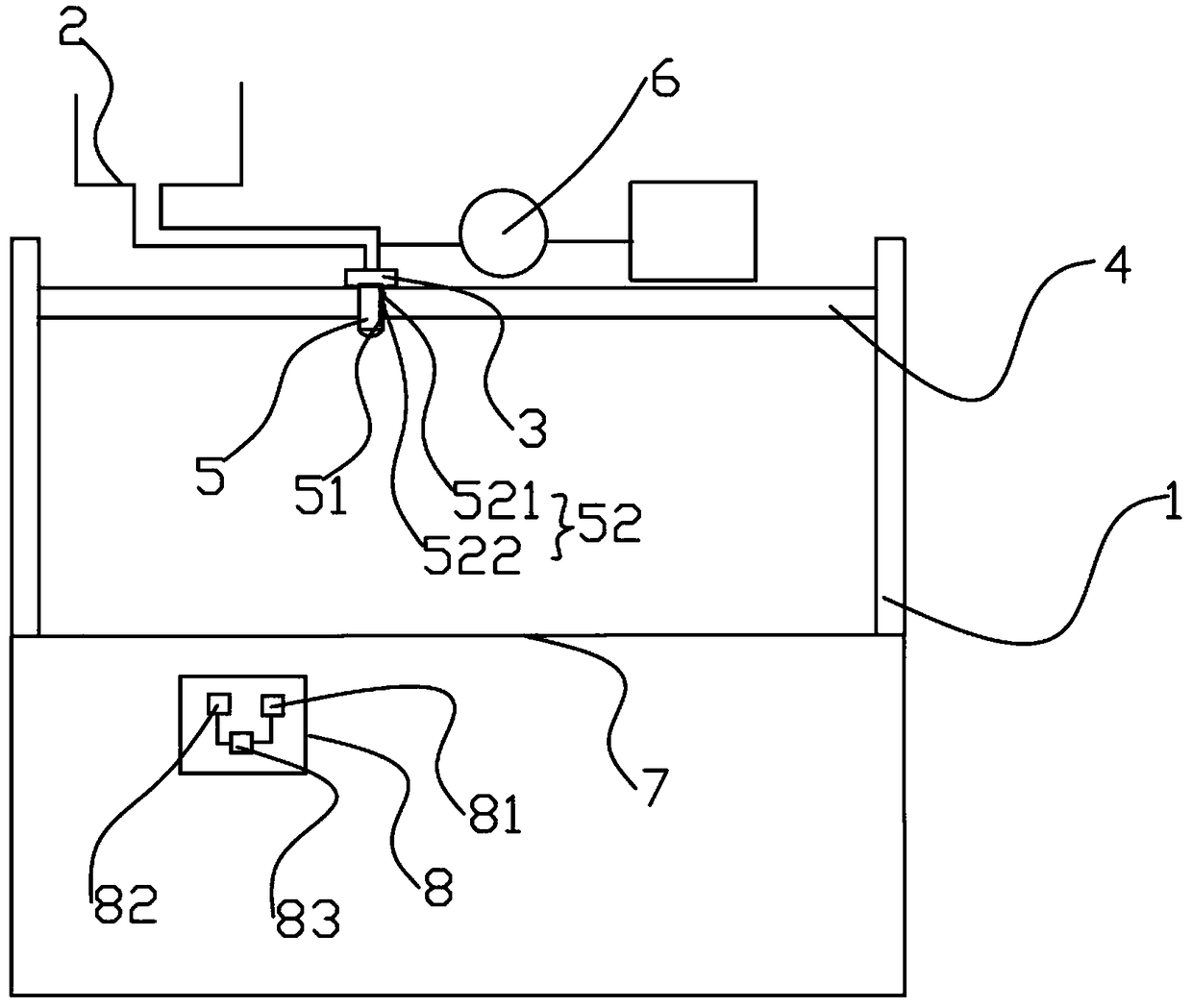

Intelligent environment-friendly 3D printer

InactiveCN108274758AReduce printing errorsEmission reductionGas treatmentAdditive manufacturing apparatusIntelligent environmentEngineering

The invention discloses an intelligent environment-friendly 3D printer. The intelligent environment-friendly 3D printer comprises a control base, a protection shell and a 3D printing assembly, whereinthe control base comprises a fixed base, and a control panel is arranged at the front end of the fixed base; a protective shell is arranged at the upper end of the fixed base, an upper shell is arranged at the upper end of the protective shell, a 3D printing component is arranged in the protective shell, and a protective door is arranged at the front end of the protective shell; and the protective shell comprises an inner shell, an outer shell is arranged outside the inner shell. According to the intelligent environment-friendly 3D printer, a filtering cavity is formed by the inner shell andthe outer shell, vibration of the 3D printing assembly is reduced through passing a noise reduction layer in the filtering cavity, the printing error during the vibration is reduced, the filtering layer at the tail end of the noise reduction layer is used for sucking and filtering the air inside the protective shell under the action of the exhaust fan, and therefore the emission of harmful gas ordust is reduced.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

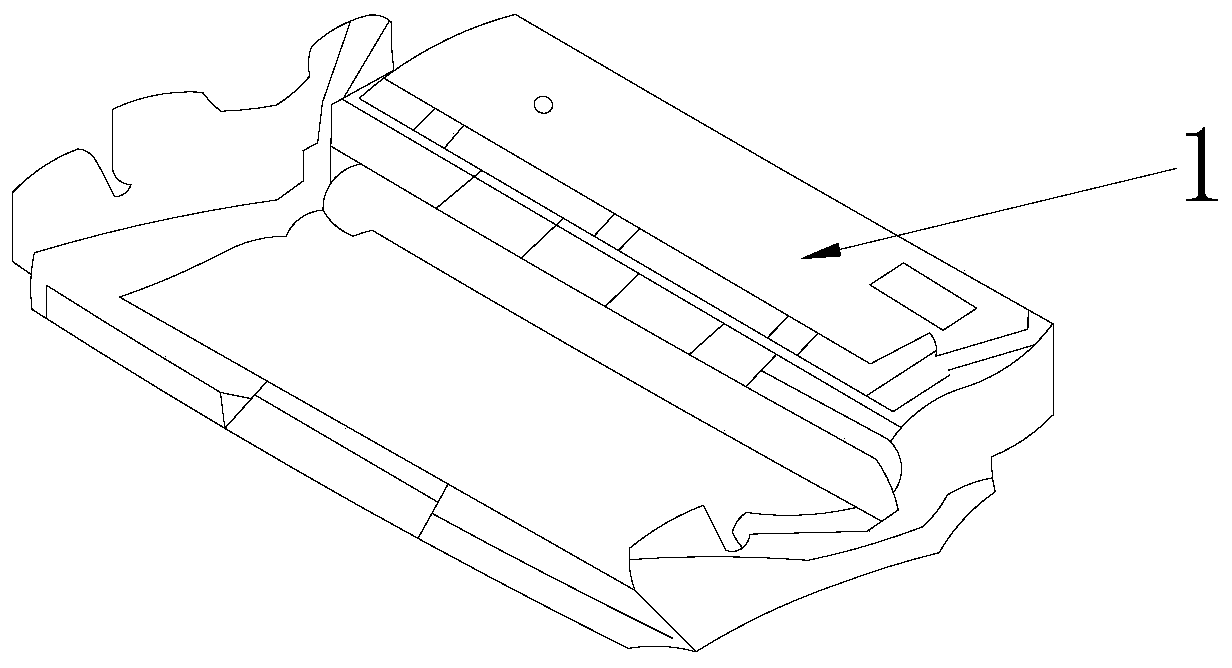

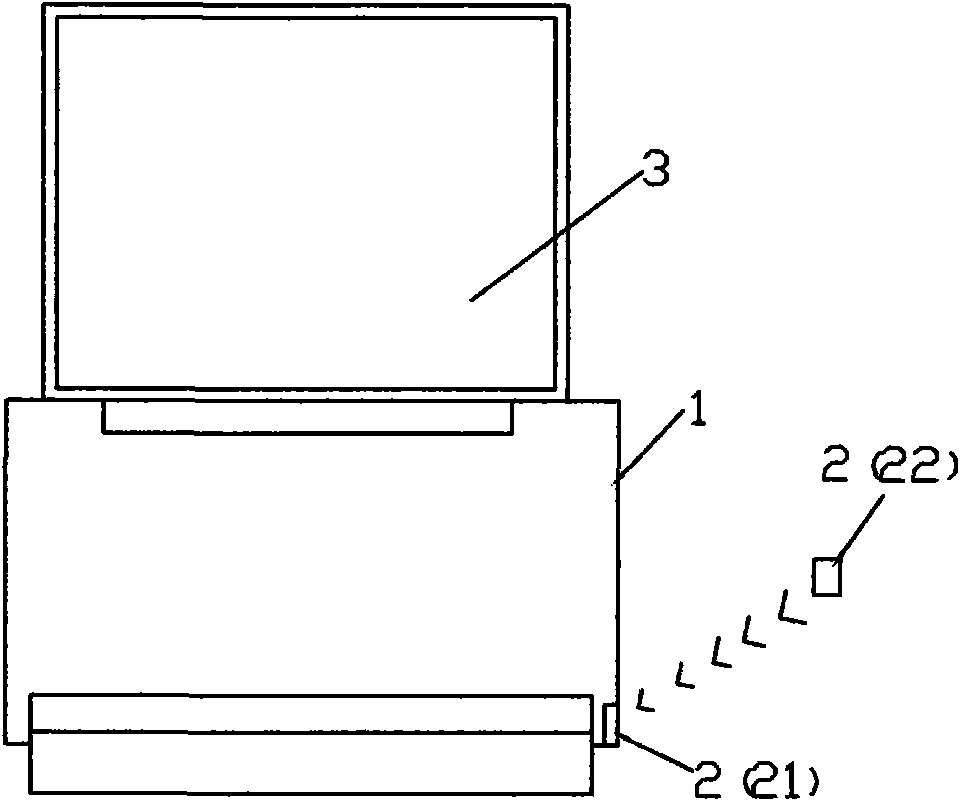

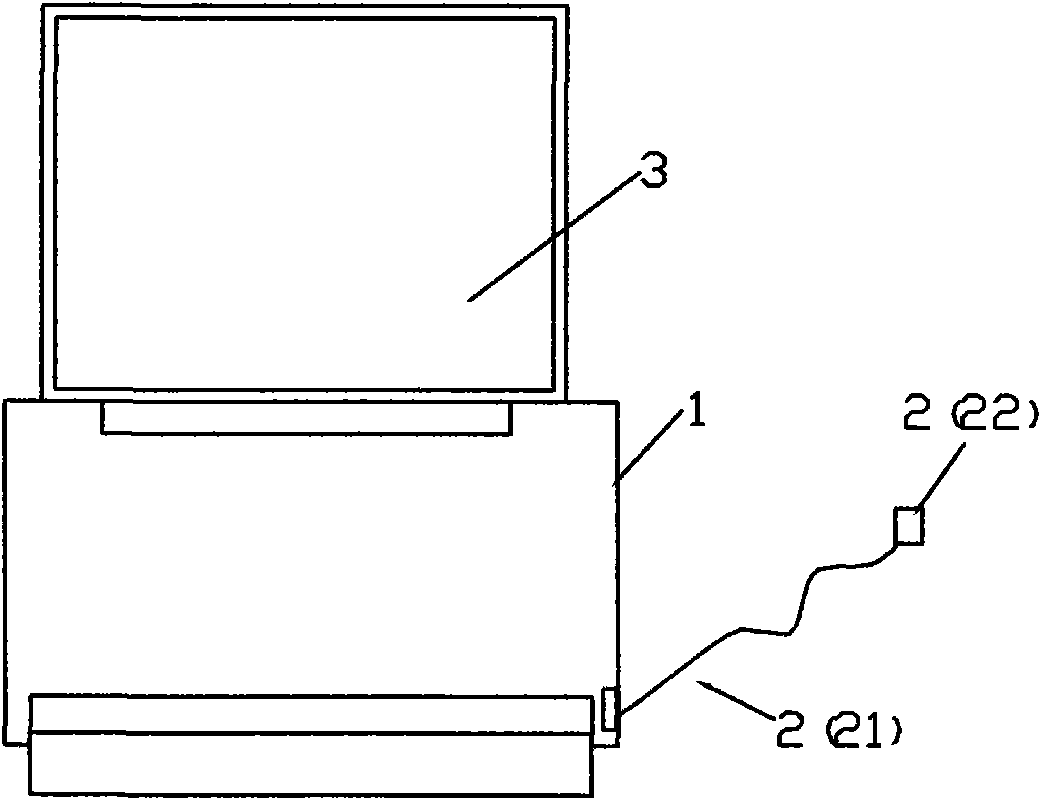

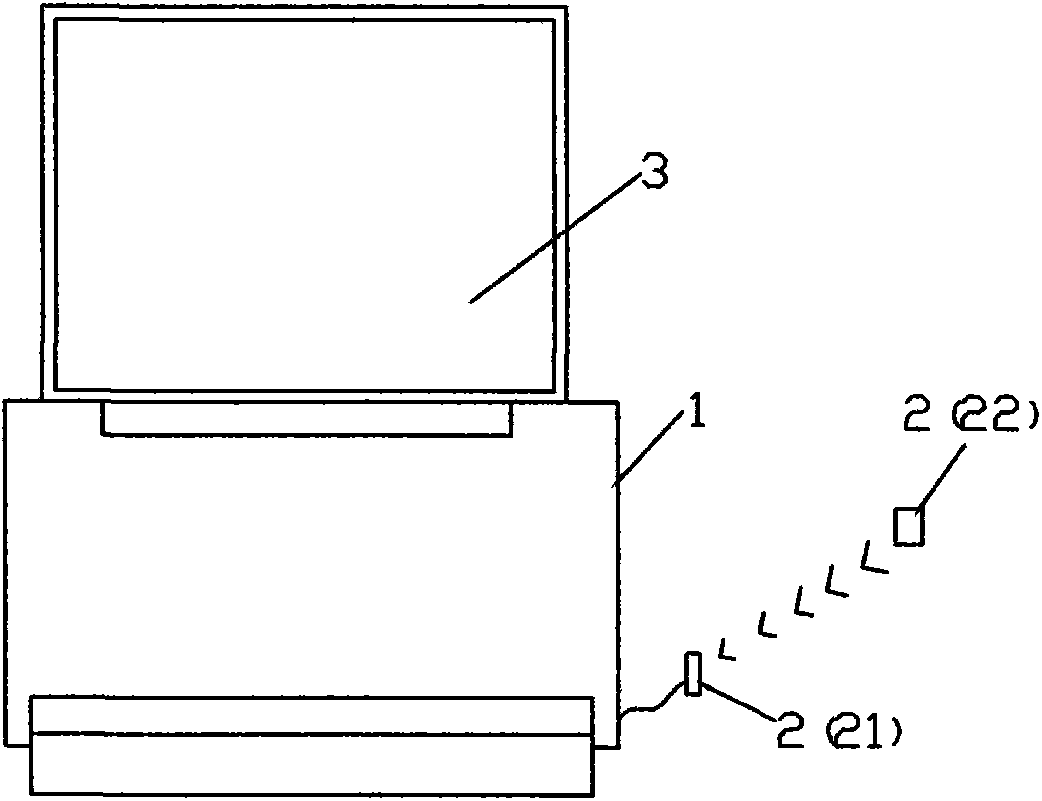

Control system and method of smart induction automatic and rapid invoice printer

InactiveCN103854394AAvoid typingImprove work efficiencyReceipt giving machinesHuman–machine interfaceControl system

The invention discloses a control system and method of a smart induction automatic and rapid invoice printer, belongs to the field of office equipment, and relates to a control system and method for an invoice printing method. The control system comprises a printer device (1) and an induction module (2), wherein the printer device (1) comprises an operating system and a man-machine interface module (3) capable of controlling generation of invoices. The control system is characterized in that the induction module (2) comprises an induction module I (21) for establishing communication with the printer device (1) and an induction module II (22) which establishes communication with the induction module (21) with the outer periphery and automatically inputs printing information to the man-machine interface operation system, wherein the induction module I (21) establishes data communication transmission with the induction module II (22) by a data line or wireless communication. The invention also discloses a control method of the control system. The control method is used for inputting customer information automatically, is simple and feasible in operation, and reduces the using cost.

Owner:季攀

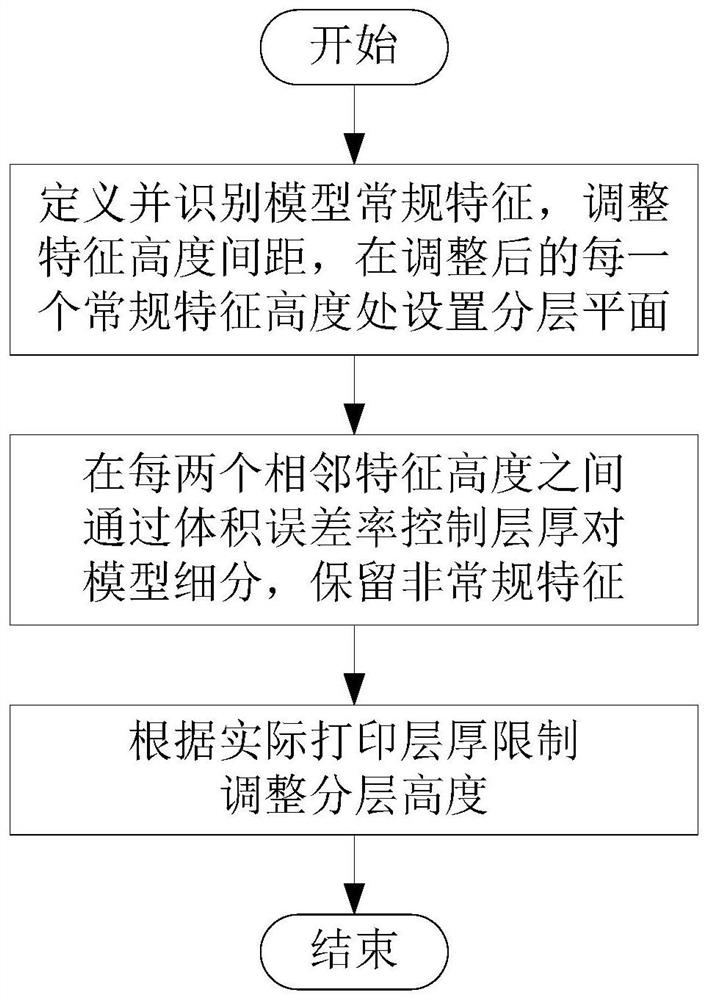

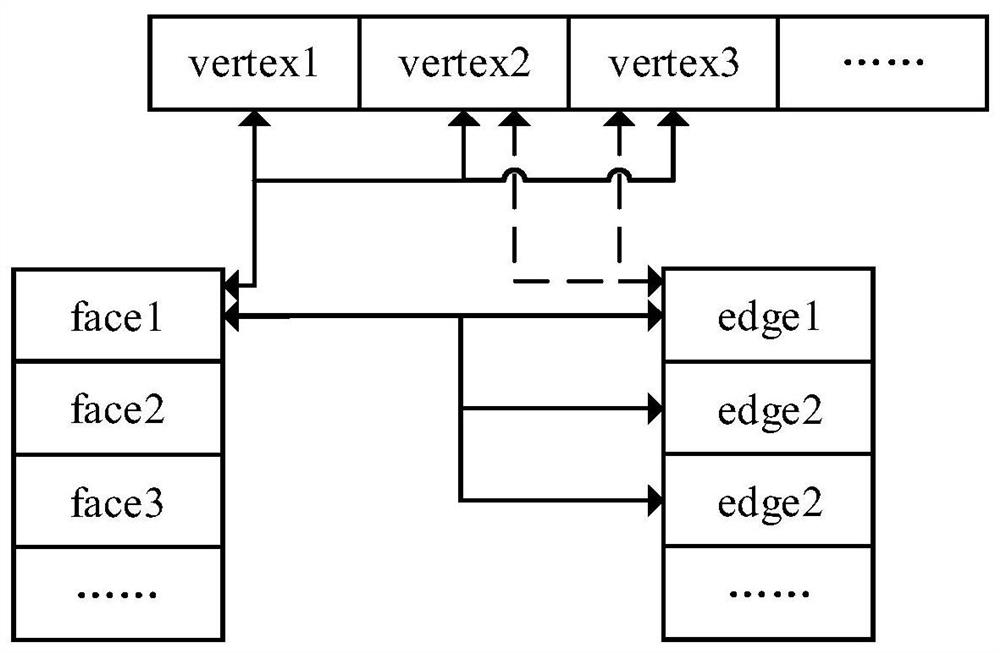

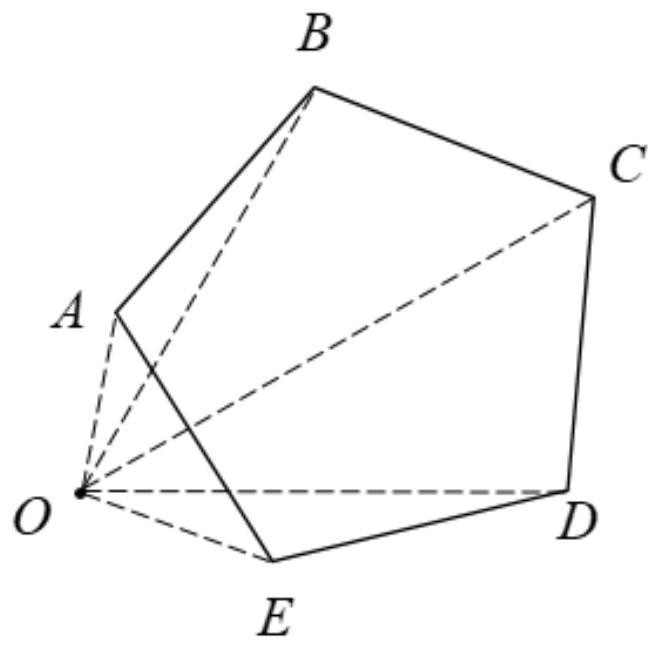

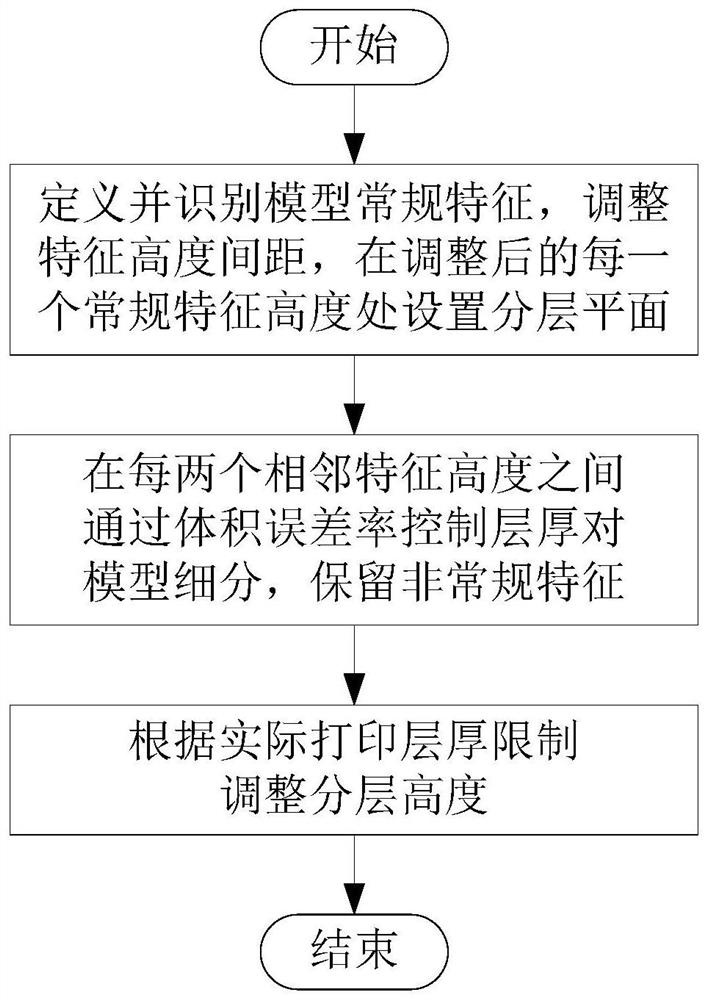

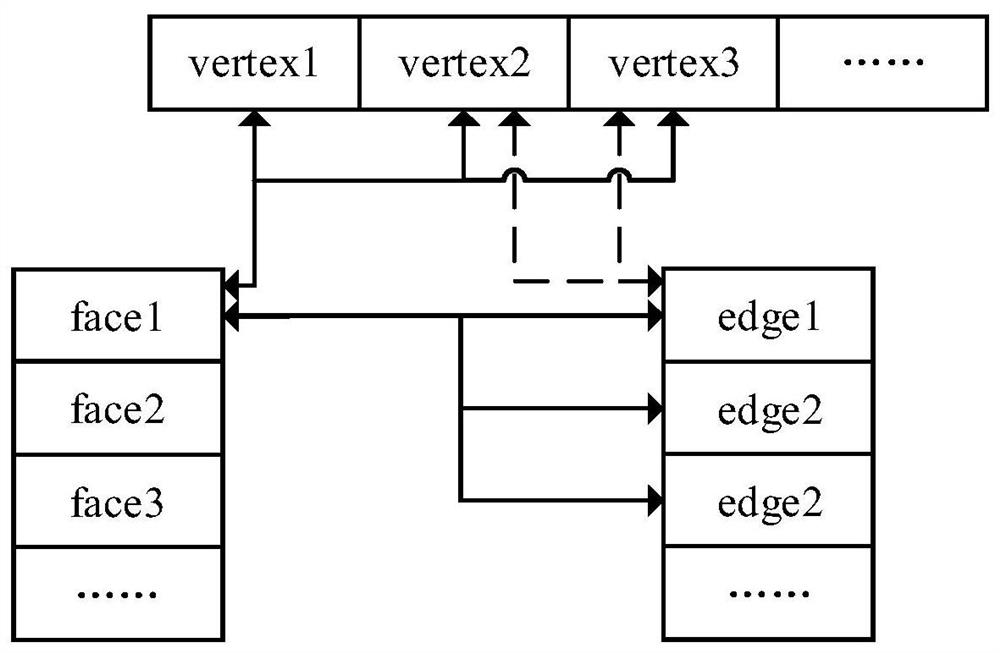

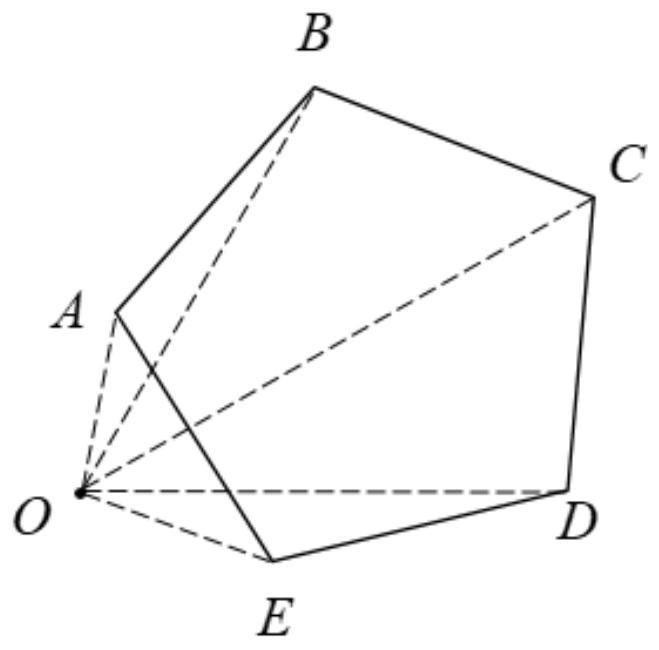

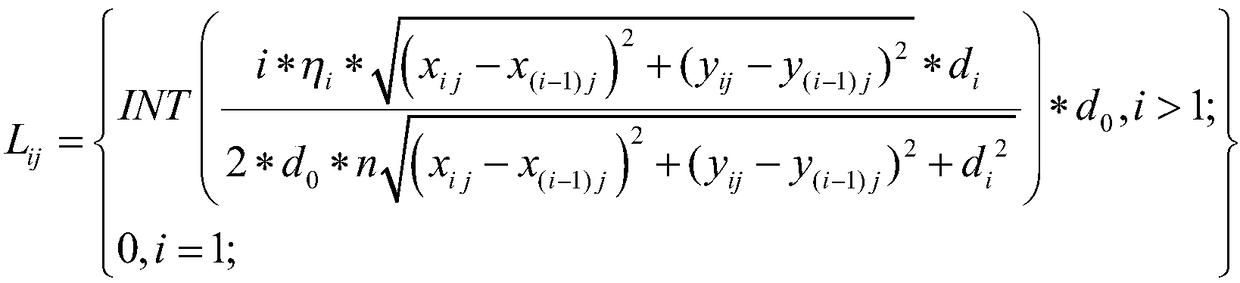

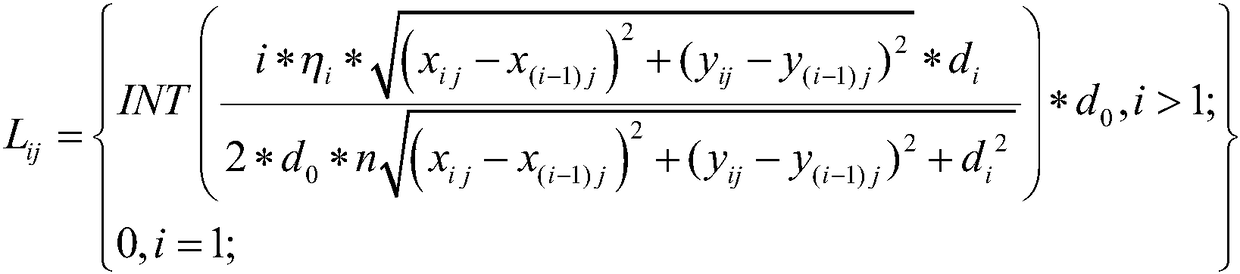

3D printing self-adaptive layering method capable of reserving unconventional features of model

ActiveCN113183470APreserve unconventional featuresHigh precisionAdditive manufacturing apparatusManufacturing data aquisition/processingComputational science3d print

The invention discloses a 3D printing self-adaptive layering method capable of reserving unconventional features of a model. The 3D printing self-adaptive layering method comprises the following steps of S1, defining and identifying conventional features of the model, adjusting the height spacing of the features, and setting a layering plane at the height of each adjusted conventional feature; S2, subdividing the model by controlling the layer thickness through the volume error rate between heights of every two adjacent conventional features, and retaining the unconventional features; and S3, adjusting the layering height according to the actual printing layer thickness limitation. According to the 3D printing self-adaptive layering method capable of reserving the unconventional features of the model, common conventional feature points, feature lines and feature surfaces of most models are defined and recognized, and it is guaranteed that the features are not lost or deviated in the printing process; and the model is subdivided at the detail features which do not meet the conventional definition by adopting a volume error rate calculation method, so that the unconventional features of the model are effectively reserved, the printing error is further reduced, and the model forming precision is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for reducing printing position error and imaging device using the method

ActiveCN110181956BReduce mistakesImprove accuracyDuplicating/marking methodsOther printing apparatusComputer hardwareComputer printing

Owner:杭州巨牛科技有限公司

A passbook reading and printing device for vtm machine

ActiveCN106335292BImprove securityReduce printing errorsComplete banking machinesTypewritersPassbookComputer module

The invention discloses a bankbook reading and printing device for a VTM. The bankbook reading and printing device comprises a detection module, a reading module, a printing module, an action module, a microprocessor and a communication module. The microprocessor can control the reading module to read magnetic track information of a bankbook and verifies the magnetic track information to ensure account accuracy thereby improving account safety to a certain extent; the microprocessor controls the detection module to detect whether the printing position is correct to ensure printing position of new transaction information closely follows the last line of the previous print, thereby preventing wasting a lot of empty printing space; and the microprocessor can also control the action module to carry out automatic page turning according to information fed back by the detection module, and when the printing content is not finished, the bankbook is not withdrawn, thereby reducing human intervention, improving automation degree of the device, preventing print content repetition or miss likely to occur when the bankbook is withdrawn, preventing possible repeated page turning due to manual page turning, and reducing printing errors.

Owner:GUANGZHOU KINGTELLER ATM TECH

An adaptive layering method for 3D printing that preserves unconventional features of models

ActiveCN113183470BPreserve unconventional featuresHigh precisionAdditive manufacturing apparatusManufacturing data aquisition/processing3d printControl layer

The invention discloses an adaptive layering method for 3D printing that retains unconventional features of a model, comprising the following steps: S1. Define and identify regular features of the model, adjust the feature height spacing, and set a split at the adjusted height of each regular feature. Layer plane; S2. Subdivide the model by controlling the layer thickness between every two adjacent conventional feature heights, and retain unconventional features; S3. Adjust the layer height according to the actual printing layer thickness limit. The present invention not only defines and recognizes the common feature points, feature lines and feature surfaces of most models, but also ensures that these features will not be lost and offset during the printing process; and the method of calculating the volume error rate is adopted when the conventional definition is not satisfied. The detailed features of the model are subdivided, which effectively retains the unconventional features of the model, further reduces the printing error, and improves the modeling accuracy of the model.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

3D printer

InactiveCN109080148AAccurate printingReduce printing errorsAdditive manufacturing apparatusManufacturing data aquisition/processing3d print3d printer

The invention relates to a 3D printer. The 3D printer comprises a bracket, a storage assembly, a high precision injection pump, a guide rail, a printing nozzle, a driving assembly, a worktable and a controller. The driving assembly drives the printing nozzle to move above the worktable; one end of the high precision injection pump is connected to the storage assembly while the other end of the high precision injection pump is connected to the printing nozzle; the controller is provided with a memory, a switching module and a processing module; and the processing module controls the 3D printerto be switched between a normal printing model and an edge printing model through the switching module. By switching the 3D printer between the normal printing model and the edge printing model, the printed model is more accurate and the printing error is reduced.

Owner:NANJING CHINA UNIV INTPROP CO LTD

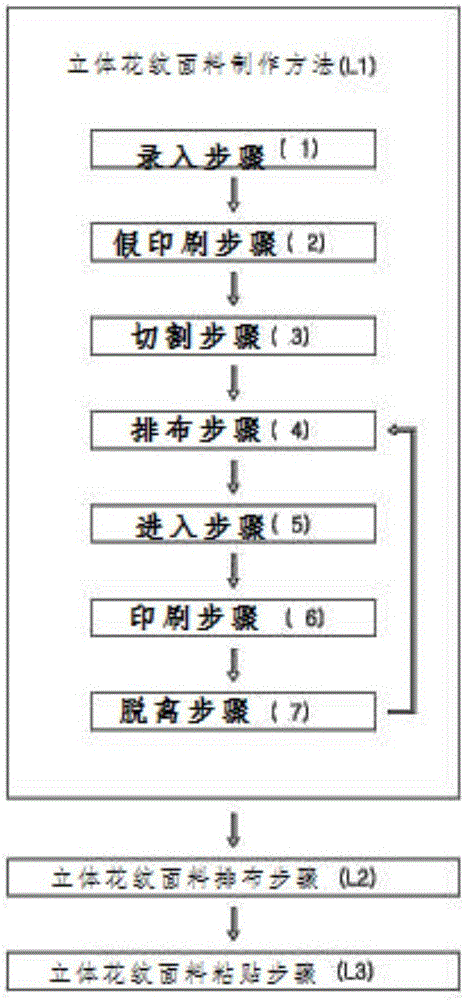

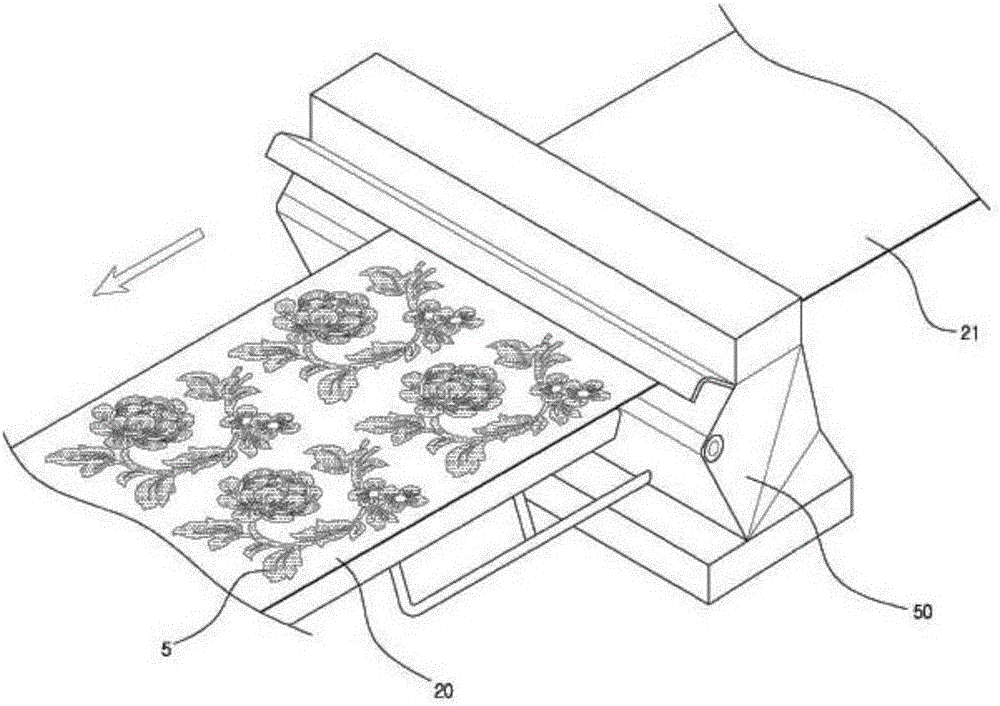

Three-dimensional pattern fabric manufacturing method

InactiveCN106183506AReduce lossesReduce the probability of defective productsOther printing apparatusPulp and paper industryPrinting press

The invention relates to a three-dimensional pattern fabric manufacturing method. The three-dimensional pattern fabric manufacturing method comprises the following steps that 1, inputting is conducted, specifically, pattern body paper is obtained through outputting of a printing machine; 2, false printing is conducted, specifically, according to a pattern design, a board is imprinted and cut to form an imprinted board, and fabric is cut to form three-dimensional fabric; 3, cutting is conducted, specifically, the pattern body paper, the imprinted board and a pattern of the three-dimensional fabric are arranged in accordance; 4, arranging is conducted, specifically, the three-dimensional fabric is output from the printing machine into which the pattern body paper is put to form the three-dimensional pattern fabric; 6, printing is conducted, specifically, separation is conducted to obtain the three-dimensional pattern fabric; 7, separation is conducted, specifically, the pattern printed on the pattern body paper is printed into the pattern on the three-dimensional fabric. According to the technical scheme, the three-dimensional pattern fabric manufacturing method is free of printing or cutting error, arranging and bonding of the fabric are completed and the three-dimensional pattern fabric is manufactured according to the method, the efficiency can be improved, and the cost is reduced.

Owner:李武荣

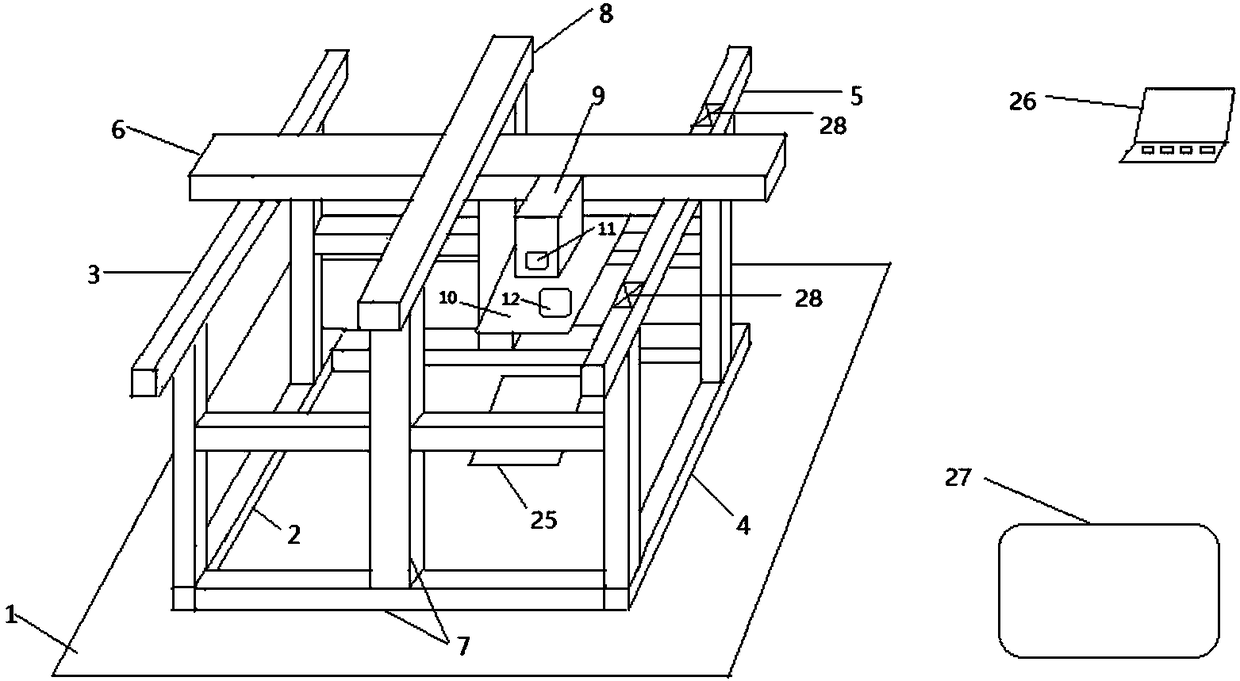

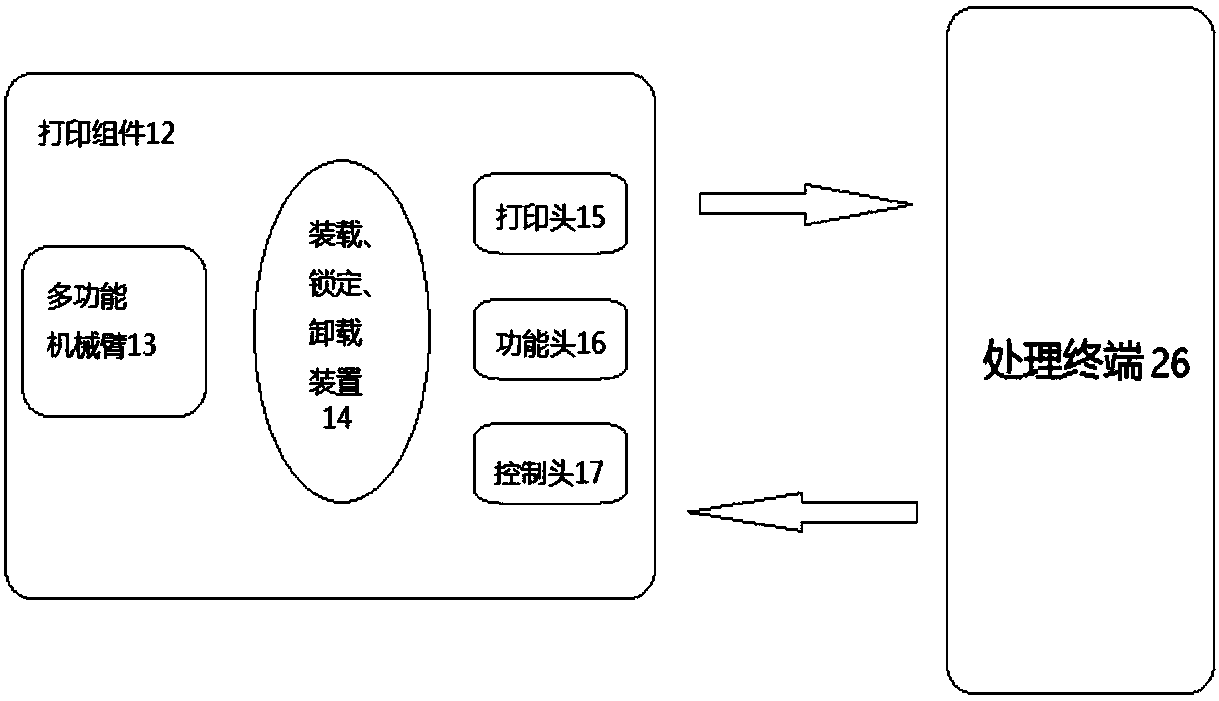

High-precision human model printing system and printing method

InactiveCN108437458AFast printEfficient printingAdditive manufacturing apparatus3D object support structuresEngineeringDimensional modeling

The invention relates to a high-precision human model printing system and a printing method. The high-precision human model printing system comprises a linear sliding platform module of an XYZ structure. Meanwhile, a sliding platform is provided with a control head, a printing head, a functional head and an IP camera, wherein the control head is provided with a plurality of kinds of controllable assemblies. Three-dimensional modeling is carried out through human image data acquired by the IP camera, and then, the sliding platform and the multiple kinds of controllable assemblies are controlledso that the printing head can carry out high-precision three-dimensional human model printing. The high-precision human model printing system and the printing method have the beneficial effects thatthe cost of present three-dimensional human model printing on the market is very high, and by means of the high-precision human model printing system structure and the printing method, a color human model can be rapidly and efficiency printed with a low cost; and a reasonable load supporting structure is arranged, the load of an X-directional motor is independently supported by a supporting leg inthe middle in the X direction, and the weight of a Y-directional motor and the weight of a Z-directional printing module are evenly distributed to a left supporting frame and a right supporting framein the X direction; and the system is more stable during working, and the printing errors are reduced.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com