Unit frame used for moving in/out sheet and man-made nail printing system device utilizing the same

A technology for artificial nails and a printing system, which is applied in the directions of printing devices, printing, printing machines, etc., can solve the problems of increasing the construction period and increasing the defective rate of artificial nails, and achieve the effects of reducing costs, improving the yield rate, and reducing printing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in more detail by citing preferred embodiments of the present invention. However, those skilled in the art of the present invention should understand that these embodiments are only used to describe the present invention more specifically, and the scope of the present invention is not limited thereto.

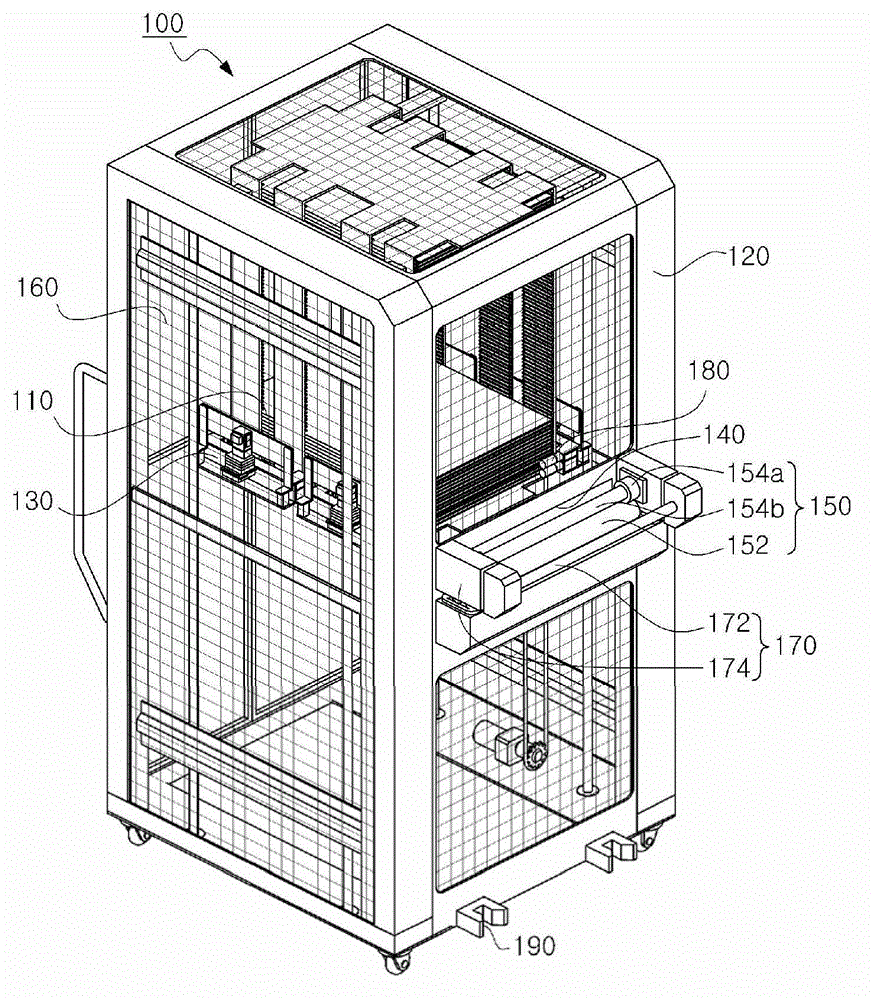

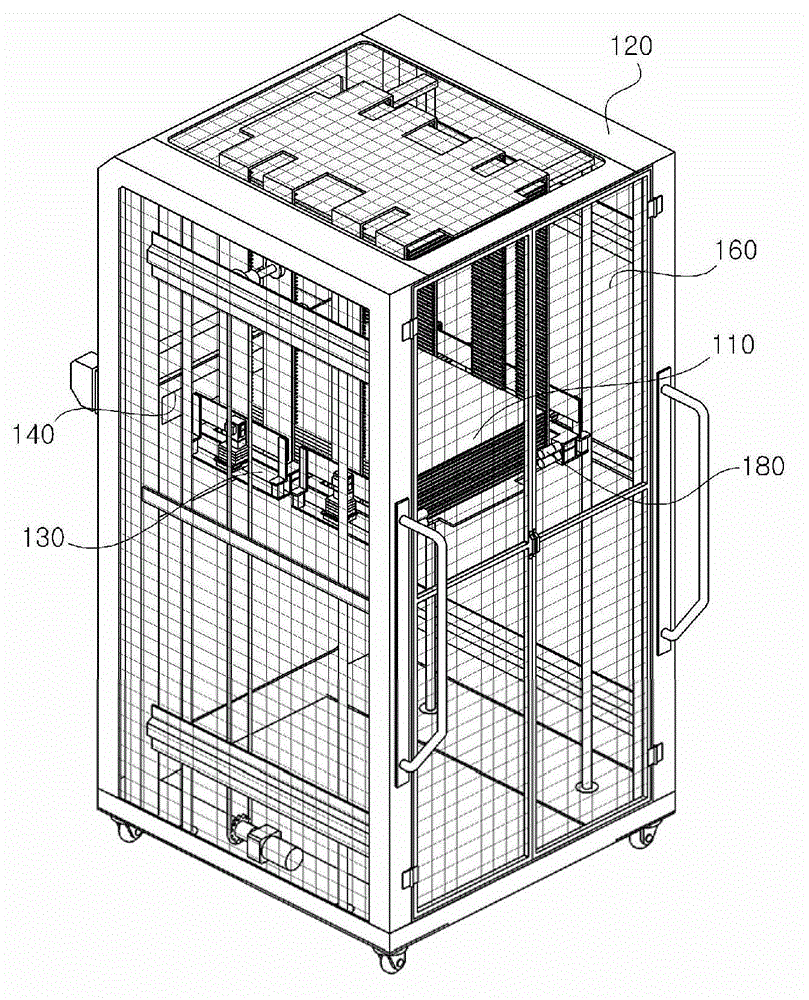

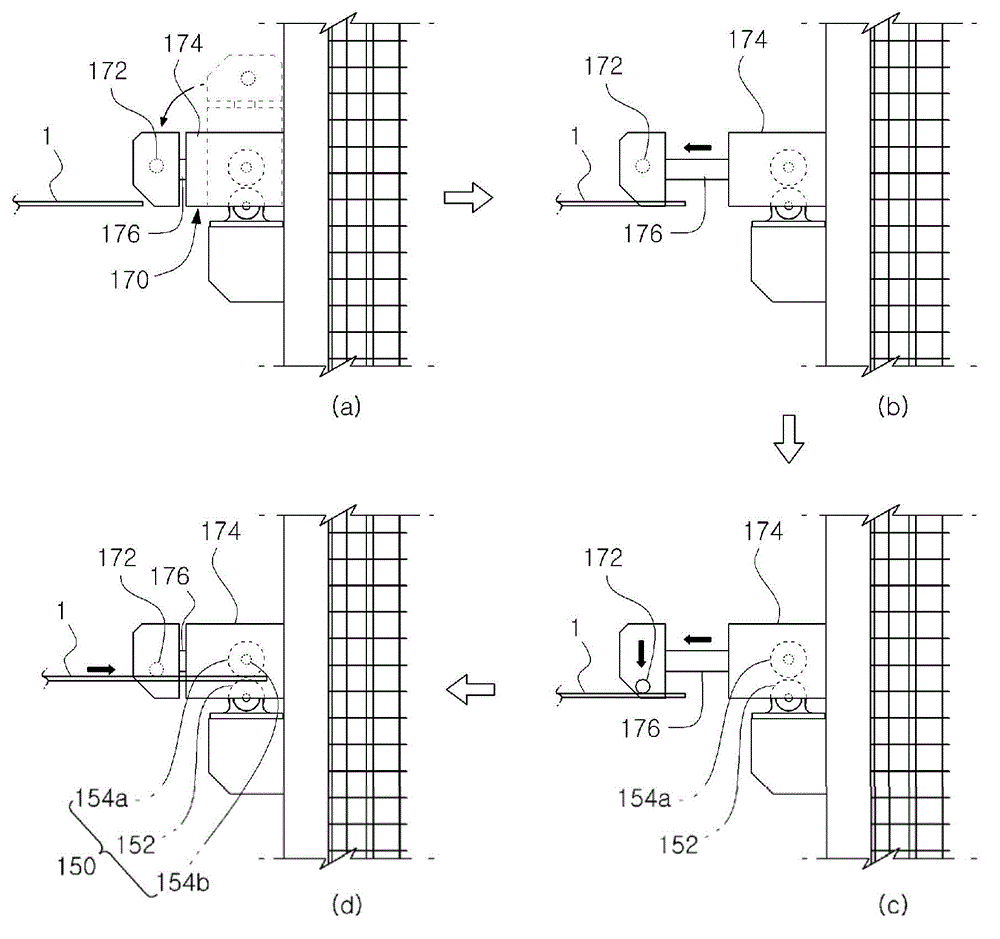

[0024] The unit frame 100 for sheet loading and unloading according to the present invention can not only automatically supply the sheet to the printing machine, but also can dry the ink printed on the sheet 1 while storing the printed sheet 1, so that it is possible to prevent the Defective products are generated in the process. In addition, it not only plays a role of supplying to the printing machine with the same structure, but also has a structure that can be stored, so the unit frame 100 for sheet loading and unloading can be reduced in manufacturing unit cost itself, and can be easily applied to existing printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com