3D printer

A technology of 3D printers and printing nozzles, applied in the field of 3D printing, can solve the problem of low model accuracy, achieve the effect of accurate models and reduce printing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

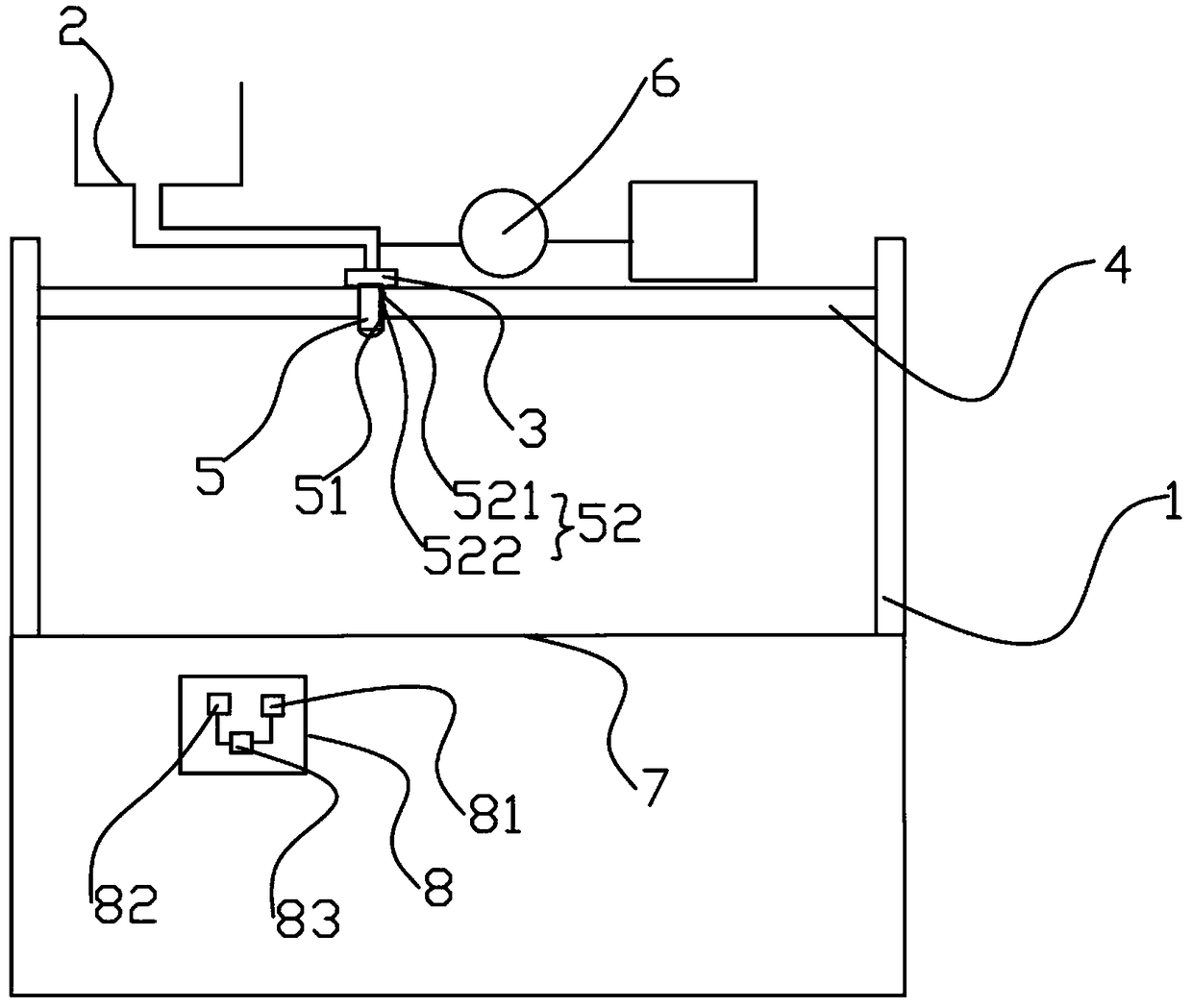

[0019] Such as figure 1 As shown, the present embodiment provides a 3D printer, including a support 1, a material storage assembly 2, a high-precision jet pump 3, a guide rail 4, a printing nozzle 5, a drive assembly 6, a workbench 7 and a controller 8, and the drive The component 6 drives the print head 5 to move above the workbench 7. One end of the high-precision jet pump 3 is connected to the storage assembly 2, and the other end is connected to the print head 5. The controller 8 is provided with a memory 81, a switching module 82 and a processing Module 83, the memory 81 is used to store data, and the processing module 83 generates the printing path of the 3D printer according to the printing model, and controls the high-precision jet pump 3 to squeeze the printing material in the material storage assembly 2 into the printing nozzle 5, and through the printing nozzle 5. Eject the printing material to the workbench 7, and the printing is completed.

[0020] During the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com