An adaptive layering method for 3D printing that preserves unconventional features of models

A 3D printing, unconventional technology, applied in the field of 3D printing adaptive layering that retains the unconventional features of the model, it can solve the problems of loss of features, loss of dense features on the outer surface of the model, etc., to reduce printing errors and improve molding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention are further described below with reference to the accompanying drawings.

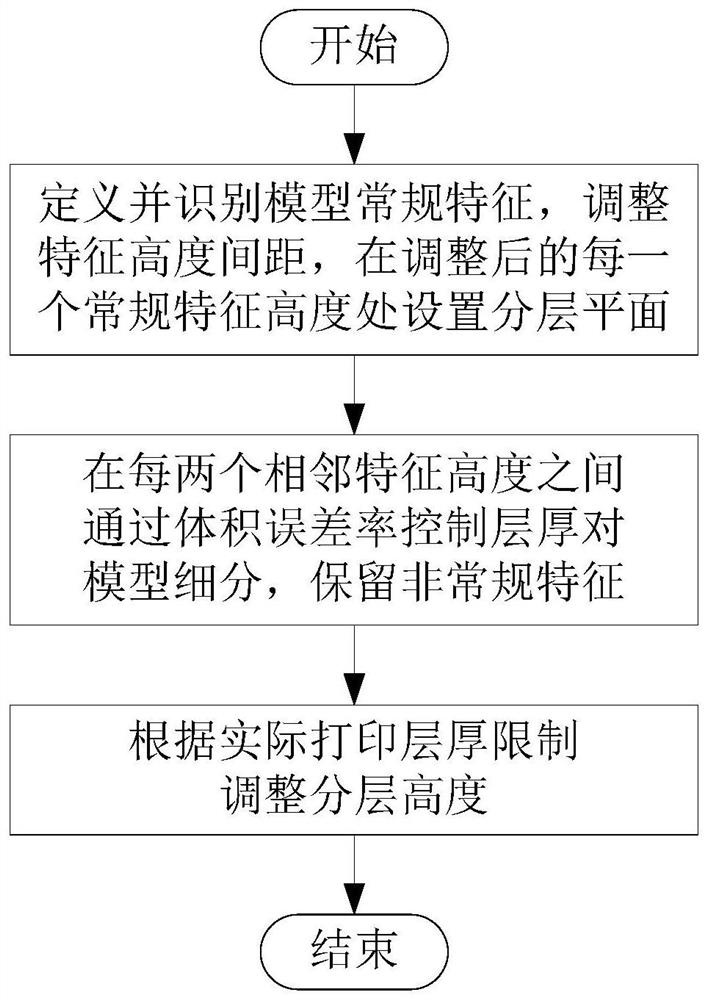

[0054] like figure 1 As shown, an adaptive layering method for 3D printing based on the volume error rate retaining the unconventional features of the model, comprising the following steps:

[0055] S1. Define and identify the regular features of the model, adjust the feature height spacing, and set a layered plane at the adjusted height of each regular feature;

[0056] Specifically, it includes the following sub-steps:

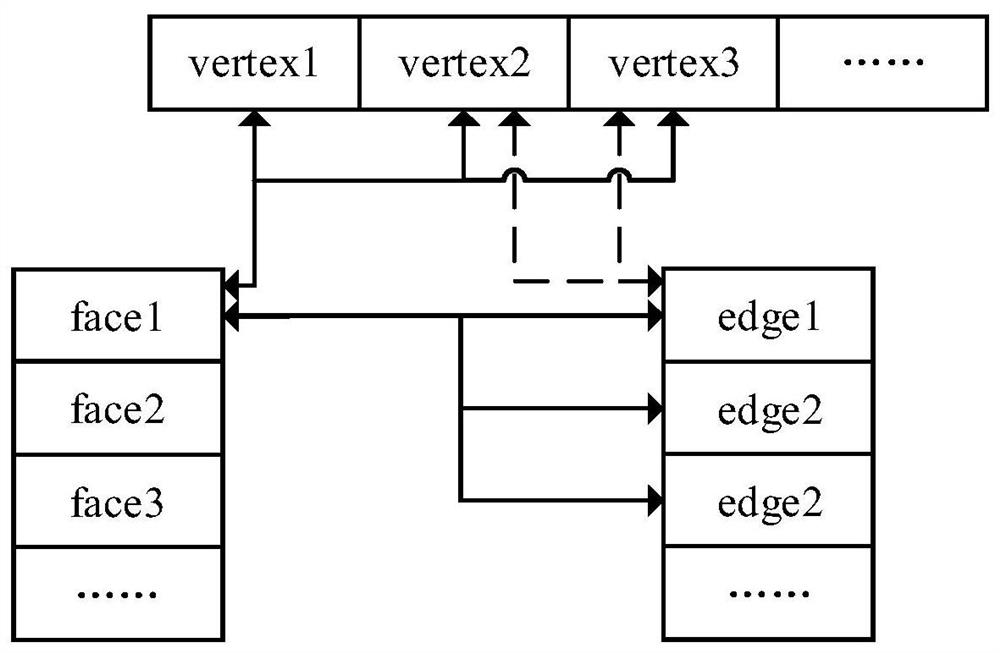

[0057] S11. Summarize the conventional features into three categories: feature points, feature lines, and feature surfaces, and then identify the feature points, feature lines, and feature surfaces respectively according to the topological structure data;

[0058] The feature points, feature lines and feature surfaces are defined as follows:

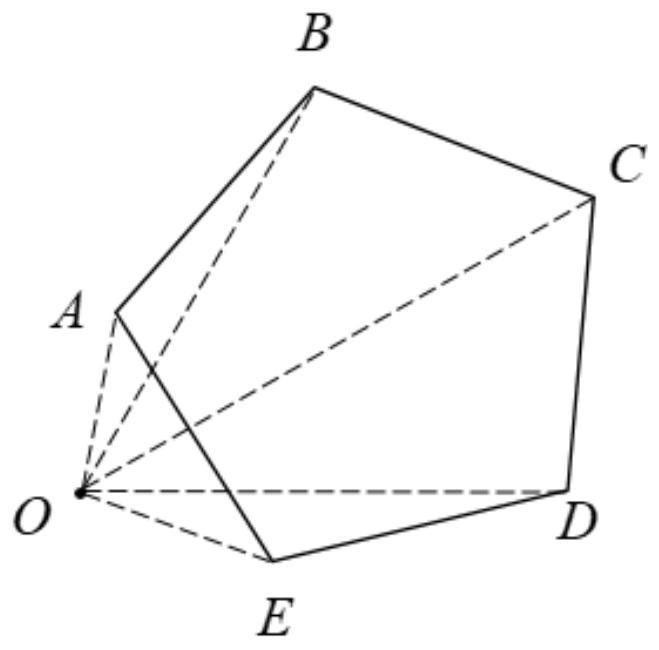

[0059] Feature point: the local highest or lowest point in the printing direction; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com