Three-dimensional pattern fabric manufacturing method

A technology of three-dimensional pattern and production method, which is applied in the direction of printing and printing devices, can solve the problems of inconsistency between patterns and cut patterns, three-dimensional fabrics that do not meet the requirements, and inconsistent pattern cutting, so as to achieve convenient heating and pasting, reduce the rate of defective products, The effect of reducing printing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

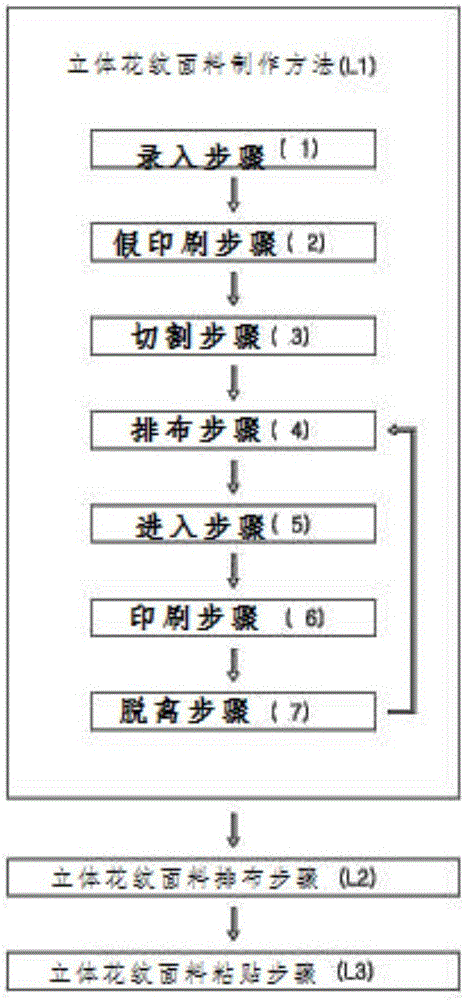

[0038] A method for manufacturing a three-dimensional pattern fabric, specifically comprising the following steps:

[0039] 1) Input step: put the pattern pattern into the printing machine, and output the pattern base paper through the printing machine;

[0040] 2) False printing step: engrave and cut the thin plate according to the placed pattern to form a stamped plate, and cut the fabric according to the placed pattern to form a three-dimensional fabric;

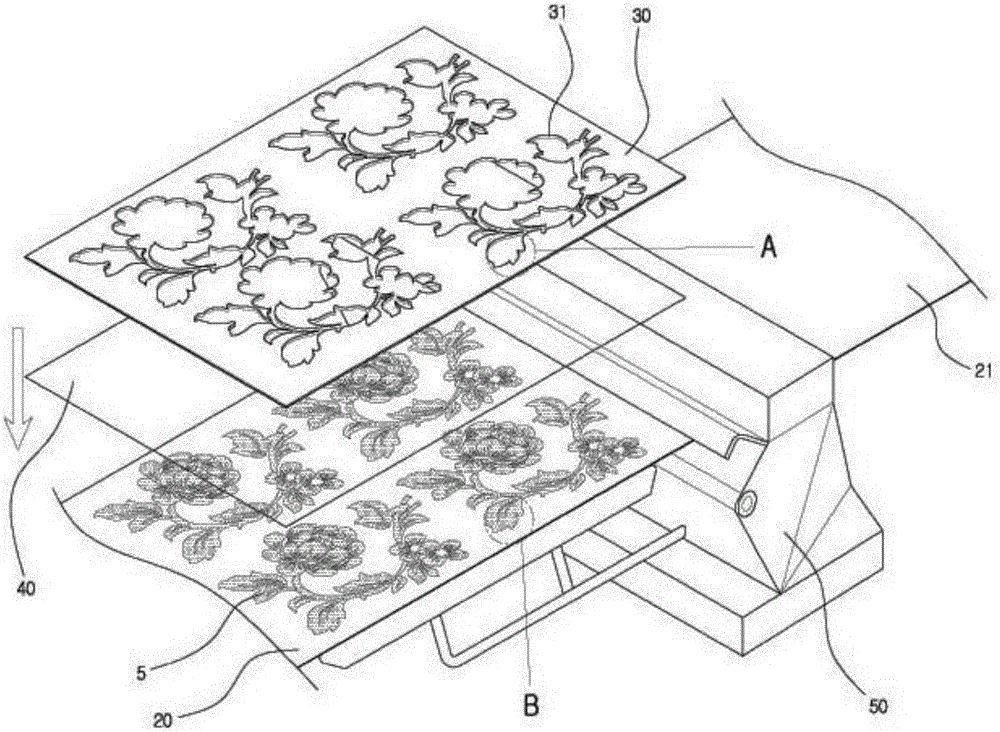

[0041] 3) Cutting step: make the pattern arrangement of pattern base paper, printing plate and three-dimensional fabric consistent;

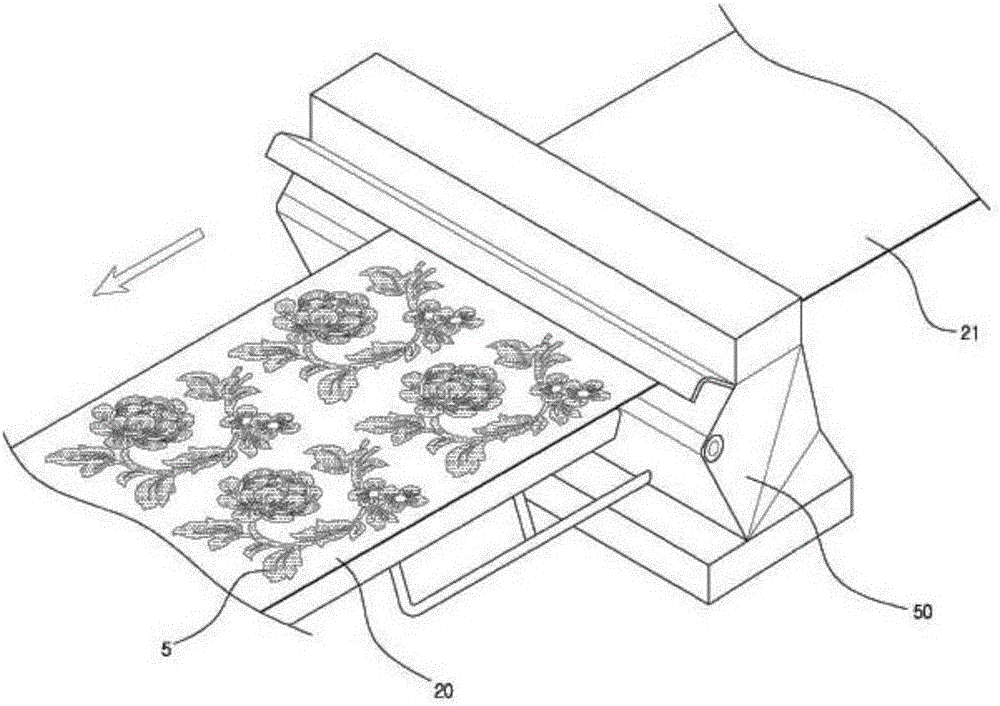

[0042] 4) Arrangement step: make the printed engraving plate and the three-dimensional fabric arranged into the printing machine together with the patterned base paper on the printing machine;

[0043] 5) Entering steps: the three-dimensional fabric is output from the printing machine that puts in the pattern base paper to form a three-dimensional pattern fabric;

[0044] 6) Printing step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com