Metal plate printing process

A metal plate and process technology, applied in the field of metal plate printing process, can solve problems such as printing difficulties, achieve the effects of improving printing efficiency, not easy to fade, and high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A metal plate printing process, comprising the steps of:

[0028] 1) Printing of decal paper: the pattern to be printed is made into 8 plate-making rolls by electric engraving; the plate roll is installed on the transfer printing paper machine, and the decal paper with the pattern to be printed is printed with ink;

[0029] 2) Printing of the printed metal plate: Put the decal paper on the metal plate thermal transfer printing equipment, enter the heating roller together with the blank metal plate with the resin layer for thermal transfer printing, and print the decal paper on the blank metal plate On, wind up to get printed metal sheet.

[0030] The ink includes raw materials composed of polyvinyl butyral, pigment powder and ethanol with a mass ratio of 1:3:15.

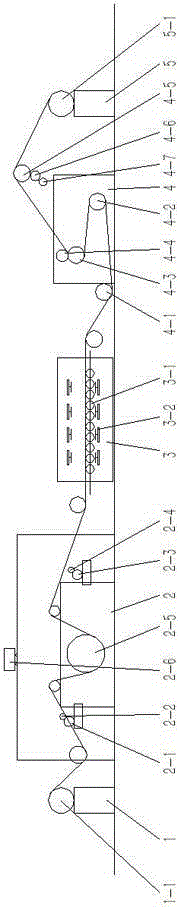

[0031] Such as figure 1 , metal plate heat transfer printing equipment, including unwinder 1, heat transfer printing machine 2, air cooler 3, threading laminator 4 and winder 5, and unwinder 1 is equipped wi...

Embodiment 2

[0035] A metal plate printing process, comprising the steps of:

[0036] 1) Printing of decal paper: the pattern to be printed is made into 6 plate rolls through electric engraving; the plate roll is installed on the transfer printing paper machine, stained with ink to print the decal paper with the pattern to be printed;

[0037] 2) Printing of the printed metal plate: Put the decal paper on the metal plate thermal transfer printing equipment, enter the heating roller together with the blank metal plate with the resin layer for thermal transfer printing, and print the decal paper on the blank metal plate On, wind up to get printed metal sheet.

[0038] The ink includes raw materials composed of polyvinyl butyral, pigment powder and ethanol with a mass ratio of 1:5:20.

[0039] Such as figure 1 , metal plate heat transfer printing equipment, including unwinder 1, heat transfer printing machine 2, air cooler 3, threading laminator 4 and winder 5, and unwinder 1 is equipped wi...

Embodiment 3

[0043] A metal plate printing process, comprising the steps of:

[0044] 1) Printing of decal paper: the pattern to be printed is made into 5 plate rolls by electric engraving; the plate roll is installed on the transfer printing paper machine, and the decal paper with the pattern to be printed is printed with ink;

[0045] 2) Printing of the printed metal plate: Put the decal paper on the metal plate thermal transfer printing equipment, enter the heating roller together with the blank metal plate with the resin layer for thermal transfer printing, and print the decal paper on the blank metal plate On, wind up to get printed metal sheet.

[0046] The ink includes raw materials composed of polyvinyl butyral, pigment powder and ethanol with a mass ratio of 1:2:10.

[0047] Such as figure 1 , metal plate heat transfer printing equipment, including unwinder 1, heat transfer printing machine 2, air cooler 3, threading laminator 4 and winder 5, and unwinder 1 is equipped with meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com