Printing supplies loading mechanism for printers

A printing consumables and loading mechanism technology, applied in printing devices, printing, etc., can solve problems such as poor printing quality, wrong operation, label scrapping, etc., and achieve the effects of low investment cost, improved use efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The printing consumables 1 loading mechanism for printers of the present invention is suitable for label printers, thermal printers, thermal transfer printers, inkjet and laser printers.

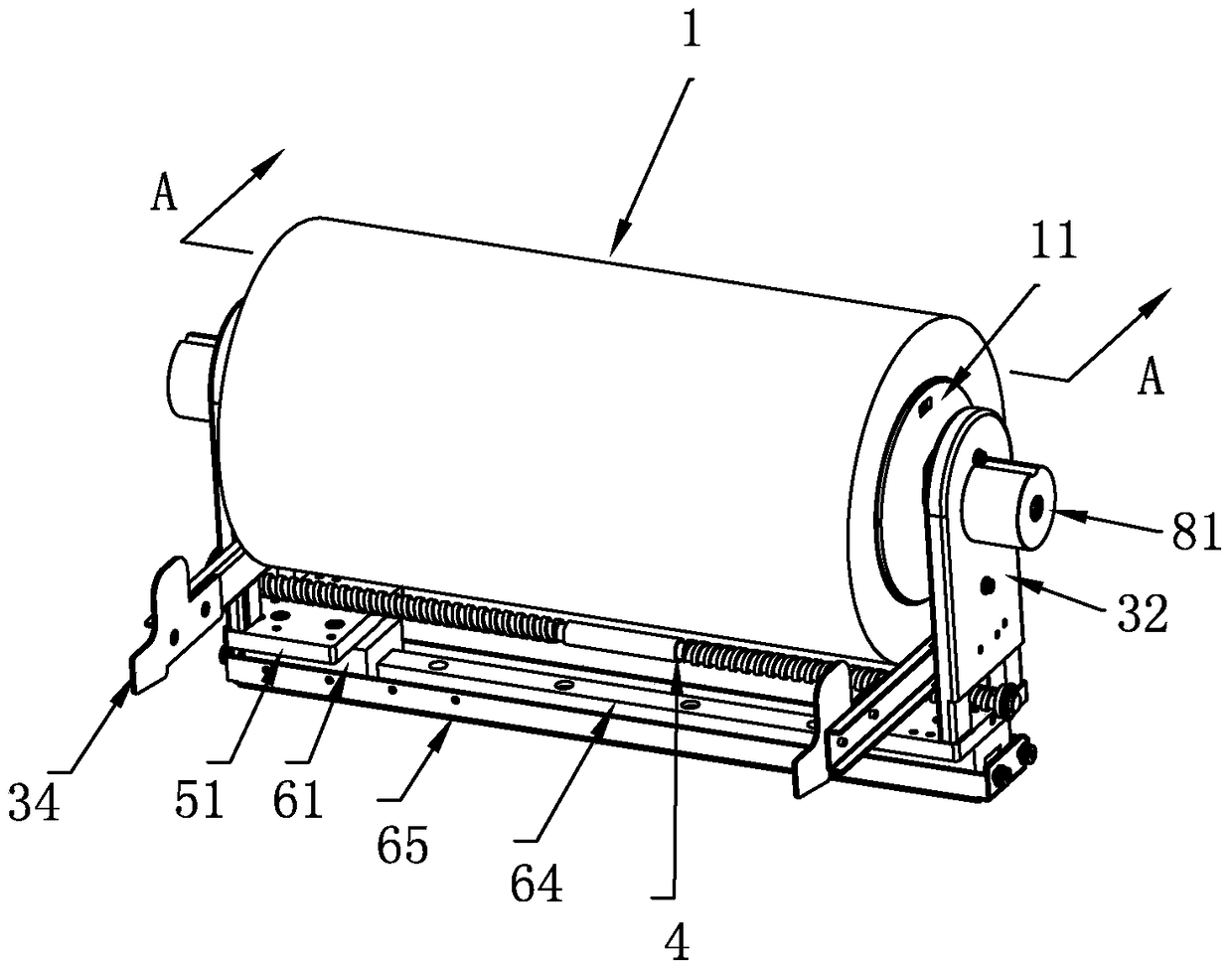

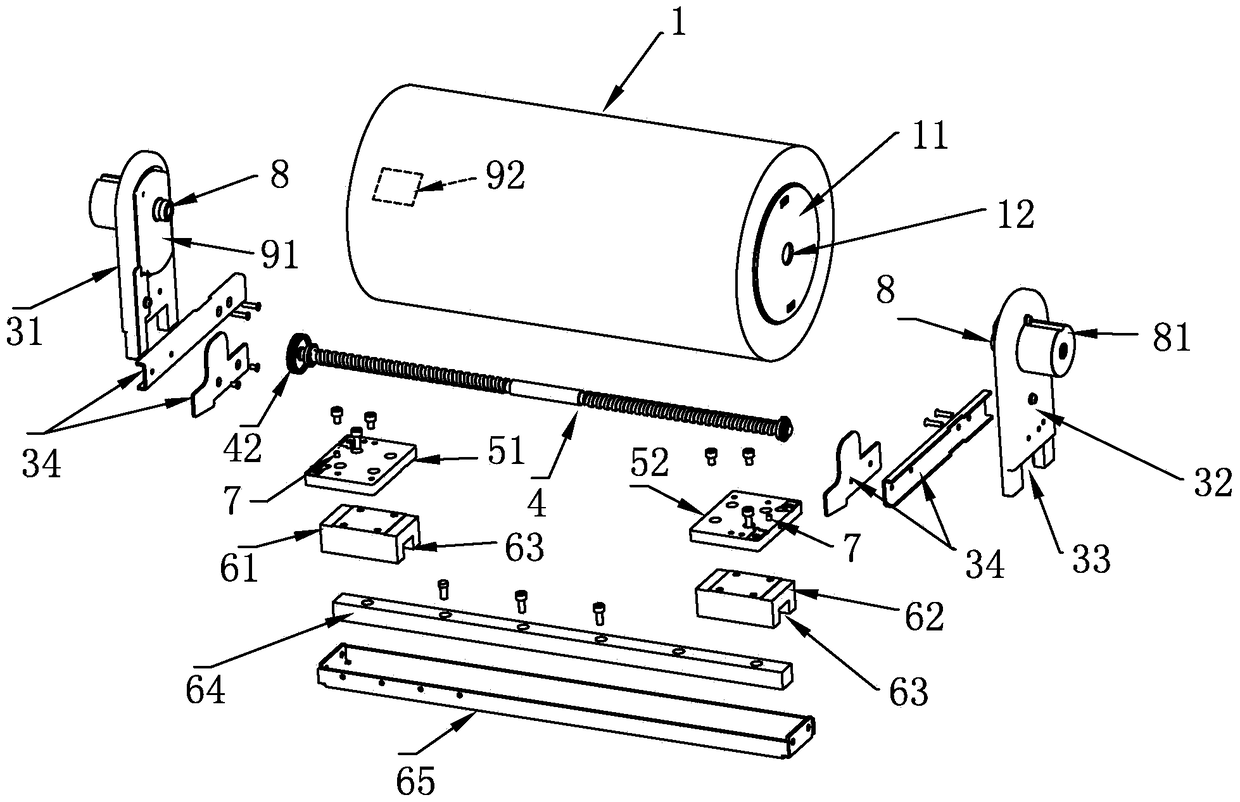

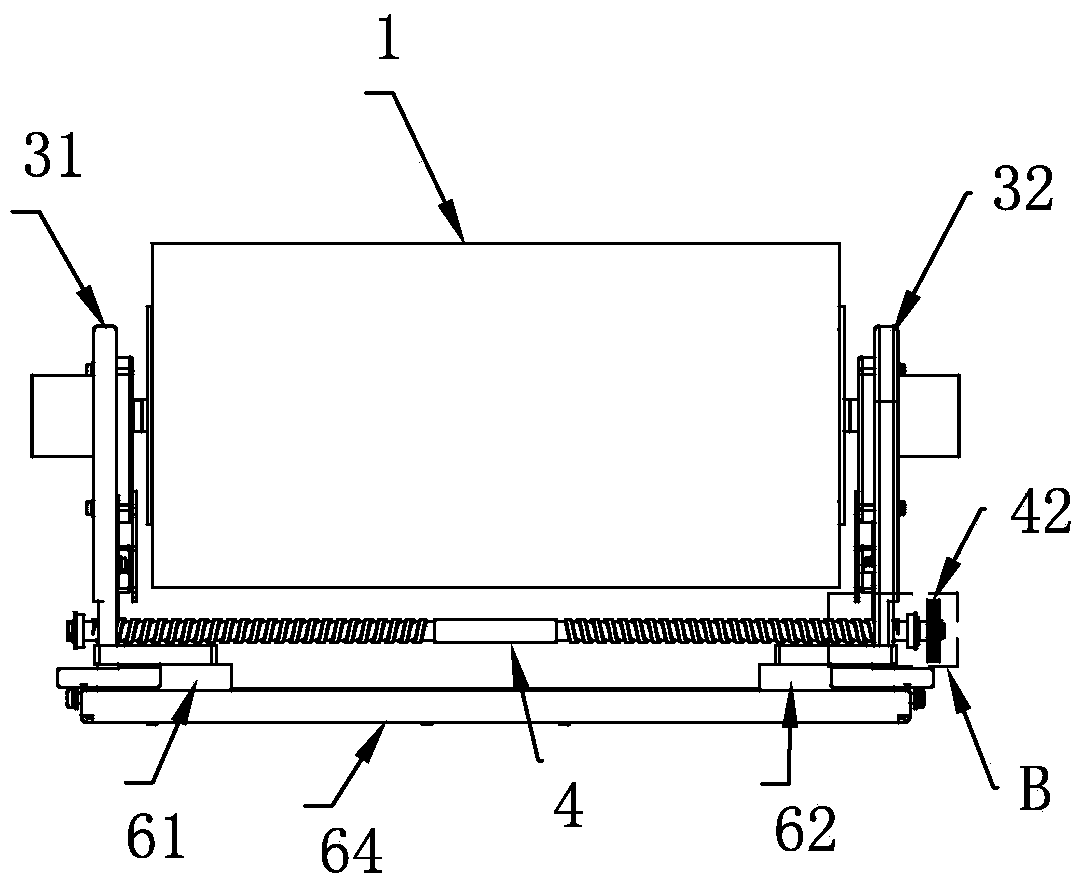

[0034] Such as figure 1 , 2 , 3, and 5, it includes a paper feeding channel 2 for storing printing consumables 1 arranged in the above-mentioned printer casing, a limit device on both sides of the paper feeding channel 2 that has a deviation-correcting effect on printing consumables 1, and a control circuit of the printer. When in use, the front end of the printing consumable 1 is output through the print head under the roller of the printing spindle. The printing consumables 1 are roll-type consumables or sheet-type consumables. Generally, roll-type consumables are composed of a reel 11 made of paper, plastic, plastic or metal and consumables wound on the reel 11, which can be Label paper roll; sheet-type consumables are composed of a pallet and flat consumables placed on the palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com