Patents

Literature

117results about How to "Increase condensation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

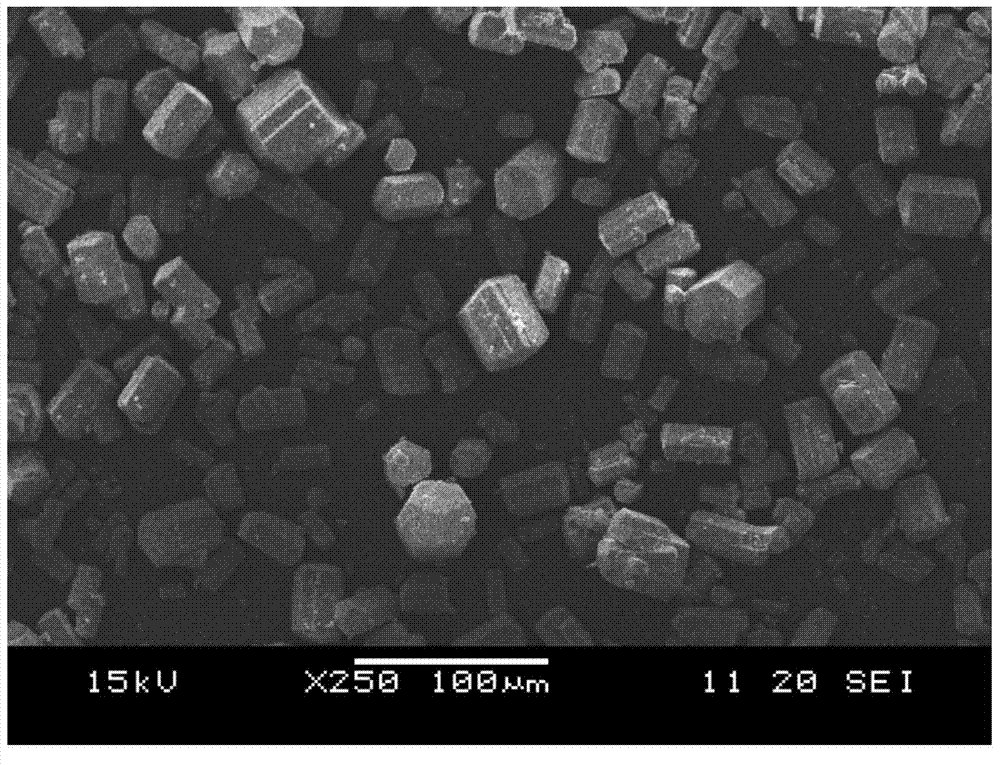

Gypsum material for 3D printing and preparation method thereof

ActiveCN104744000AHigh mechanical strengthGood dispersionAdditive manufacturing apparatusFilling materials3d printer

The invention discloses a gypsum material for 3D printing. The gypsum material is that a gypsum product is printed and formed through 1 part by mass of powder and 0.25 to 1 part by mass of liquid-phase material by a 3D printer, wherein the powder is prepared from the following raw materials in parts by mass: 90 to 98 parts of hemihydrate gypsum, 1 to 10 parts of filling material, and 0 to 2 parts of fibers; the liquid-phase material is prepared from the following raw materials in parts by mass: 80 to 90 parts of water, 5 to 15 parts of flexible adhering material, and 1 to 5 parts of coagulating material. The invention further discloses a preparation method of the gypsum material for 3D printing; the gypsum material is prepared by mixing and uniformly agitating all raw materials. The gypsum material for 3D printing and the preparation method have the advantage that the problems of small strength, poor fluidity, large fineness and poor flexibility in the prior art can be solved.

Owner:NANJING UNIV OF TECH

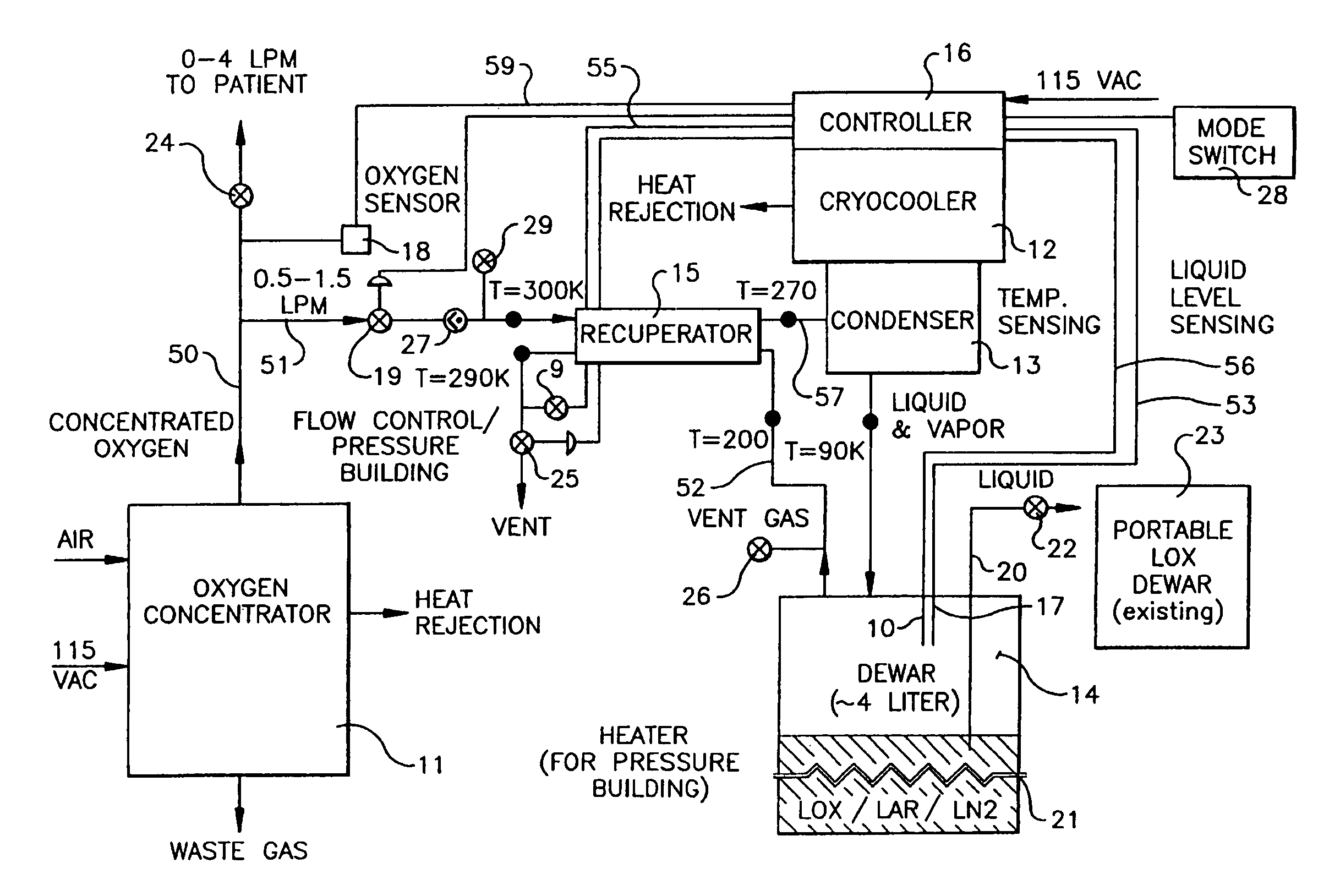

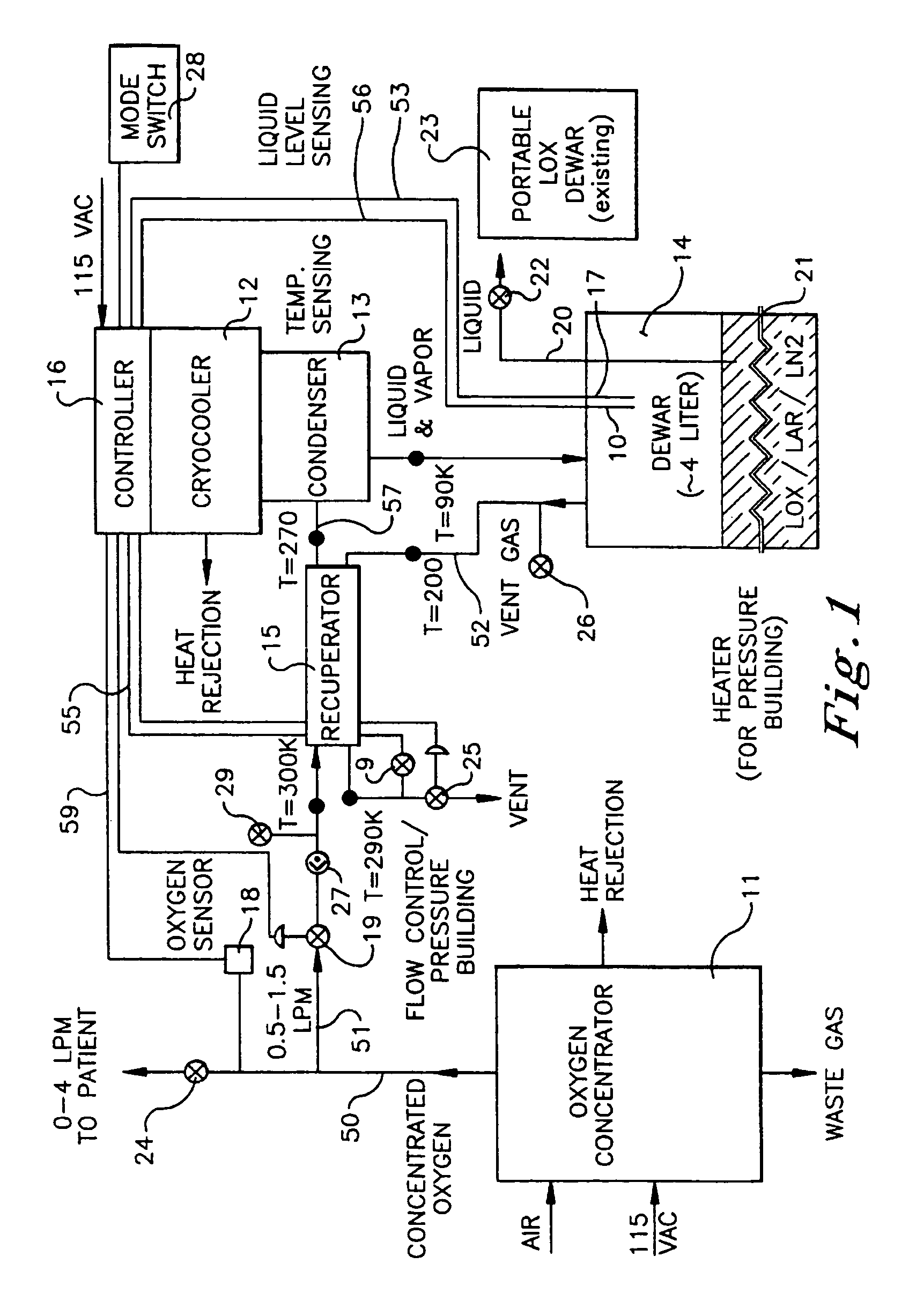

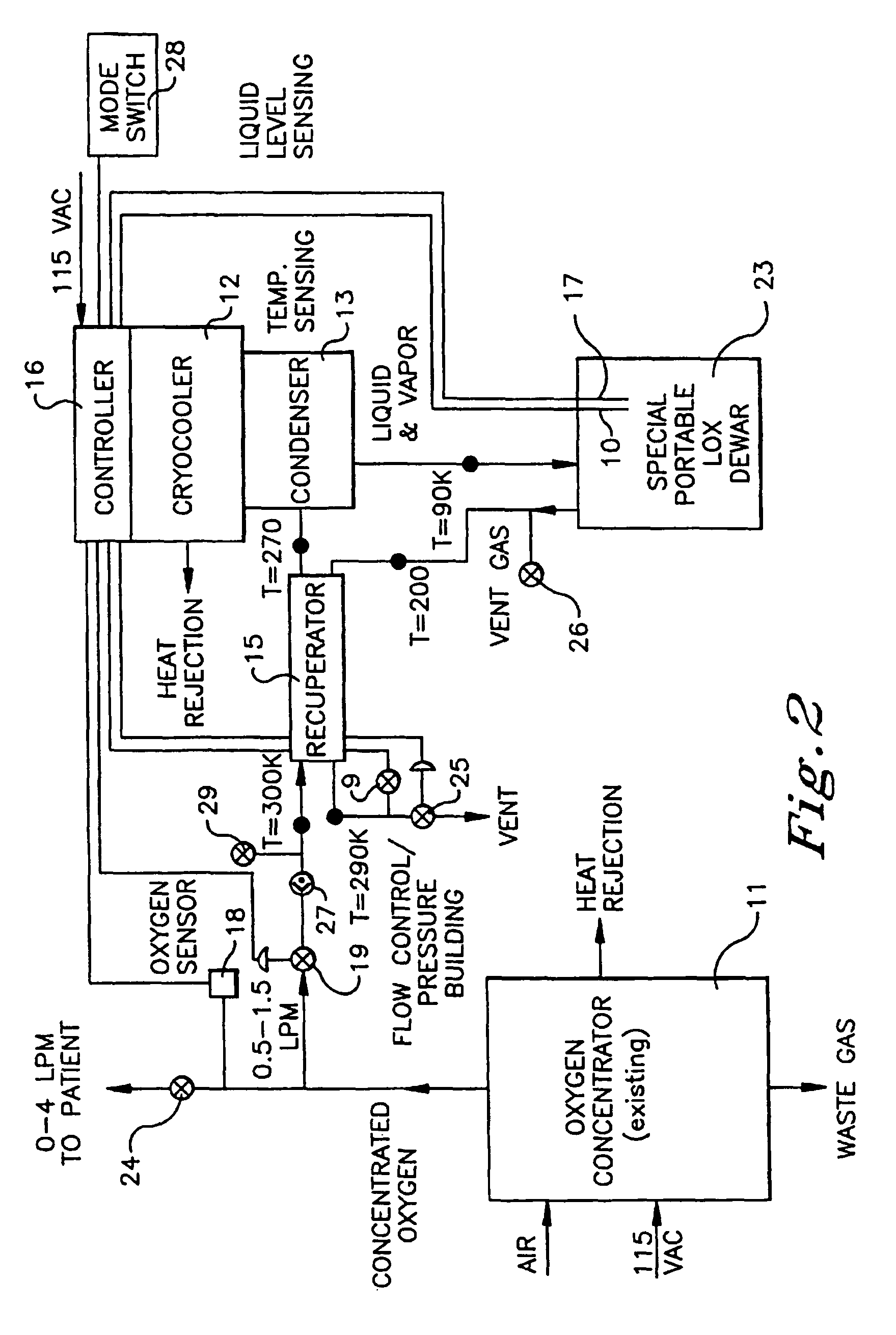

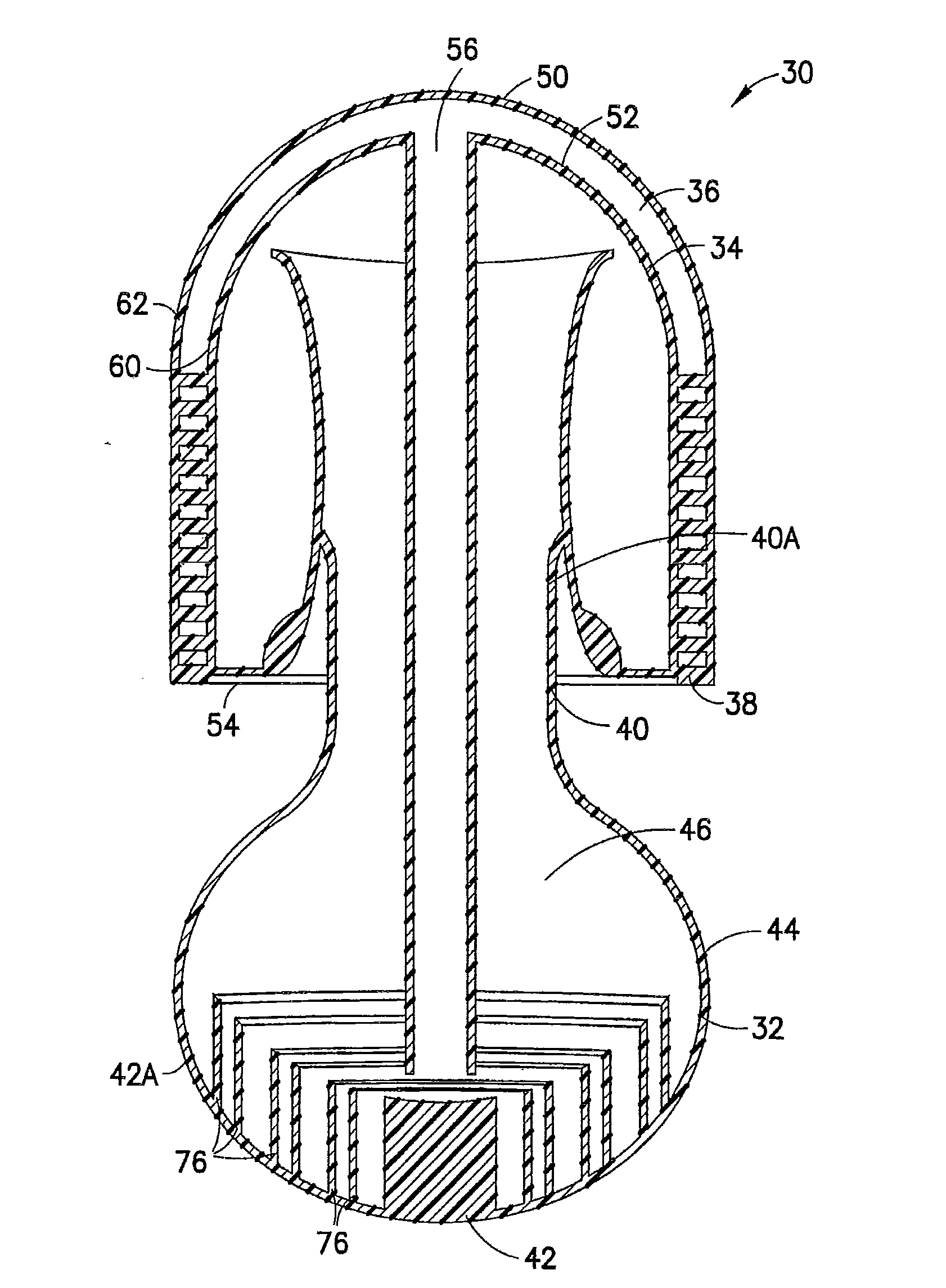

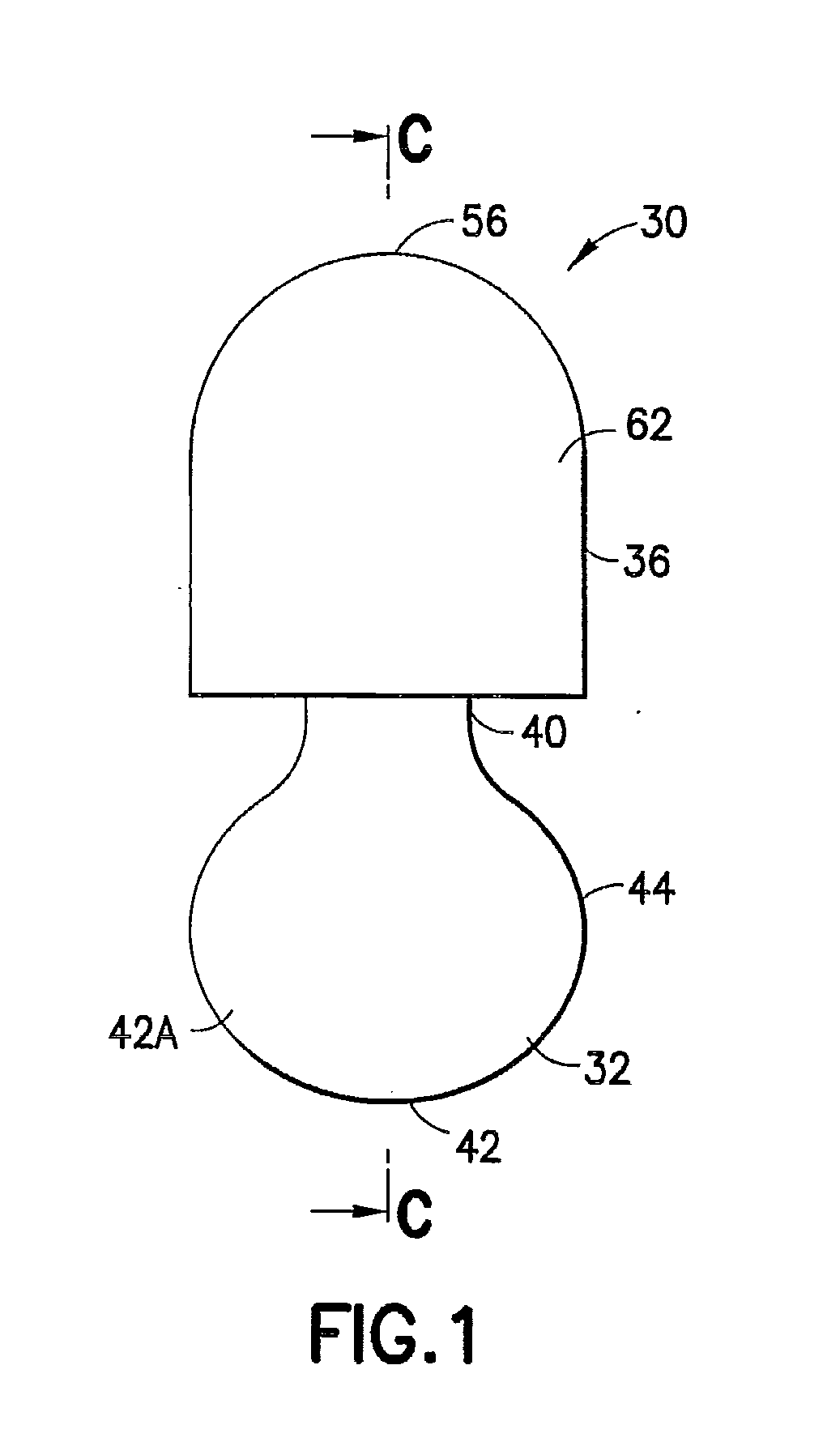

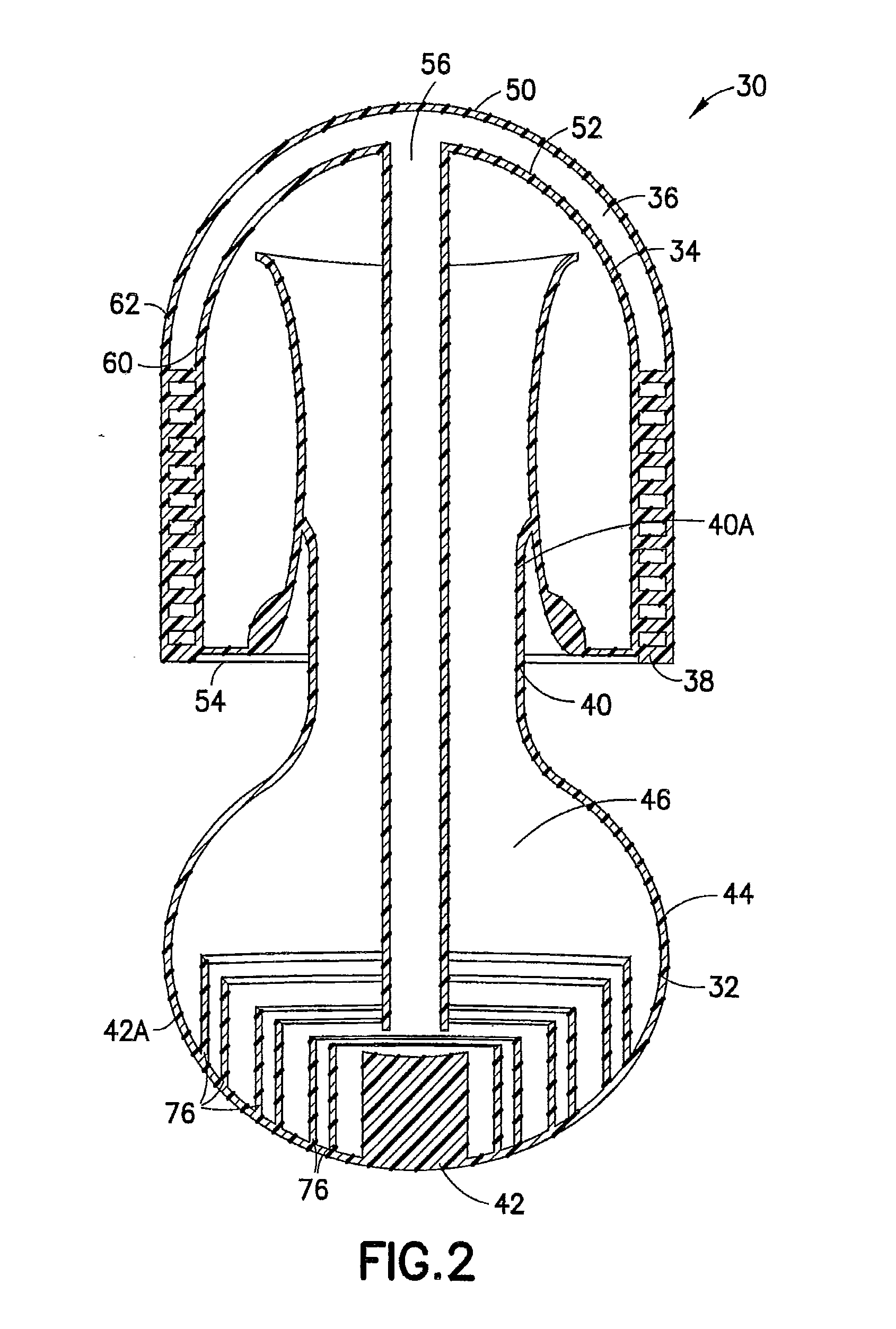

Methods and apparatus to generate liquid ambulatory oxygen from an oxygen concentrator

InactiveUSRE43398E1Increase condensation rateIncrease the areaLiquefactionOther heat production devicesAmbulatory systemCryocooler

Owner:RESPIRONICS

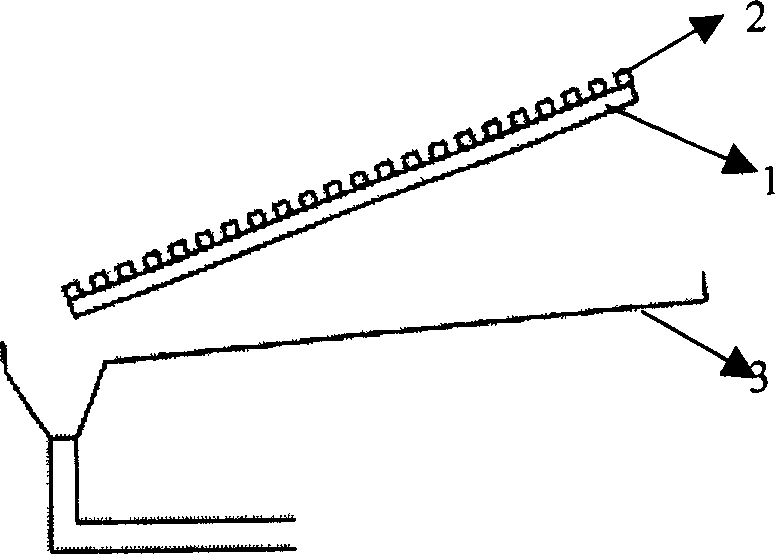

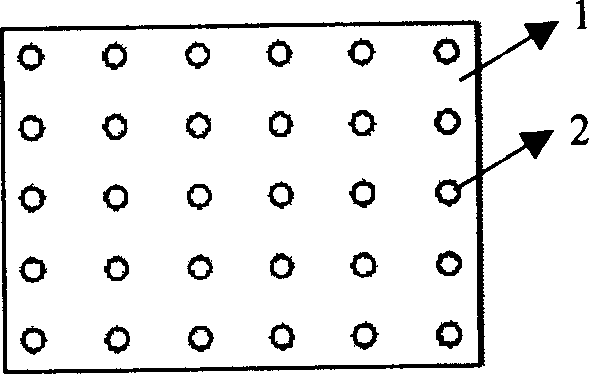

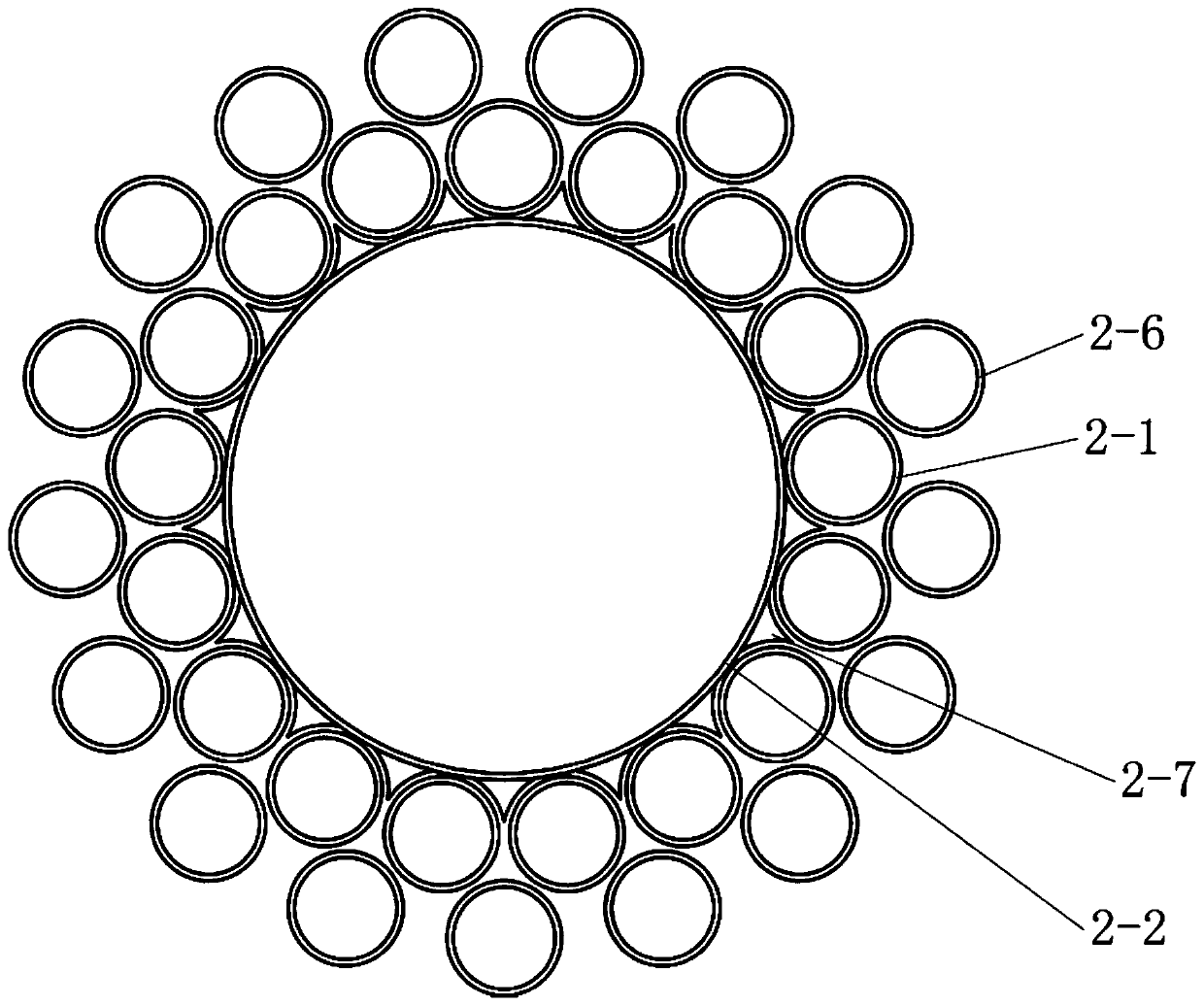

Water collecting apparatus having high water condensation rate surface

This invention relates to a water collector with high water coagulating rate surface that used in air. Its feature is that the collector surface is consisted by discharging basement, hydrophilic little prominence arranged on discharging basement and condensed water collector. the little prominence is two kinds of cylindrical form and quadrangular form, diameter of the cylindrical form is 0.2-1.0mm, height is 0.1-1mm, side length of quadrangular form is 0.2-1mm, height is 0.2-1mm, the advantages of this invention is simple and practical, the hydrophilic prominence can quickly agglutinate moisture in air, the moisture can be quickly flowed into water collector by discharging basement, so the water coagulating rate is improved.

Owner:UNIV OF SCI & TECH BEIJING

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

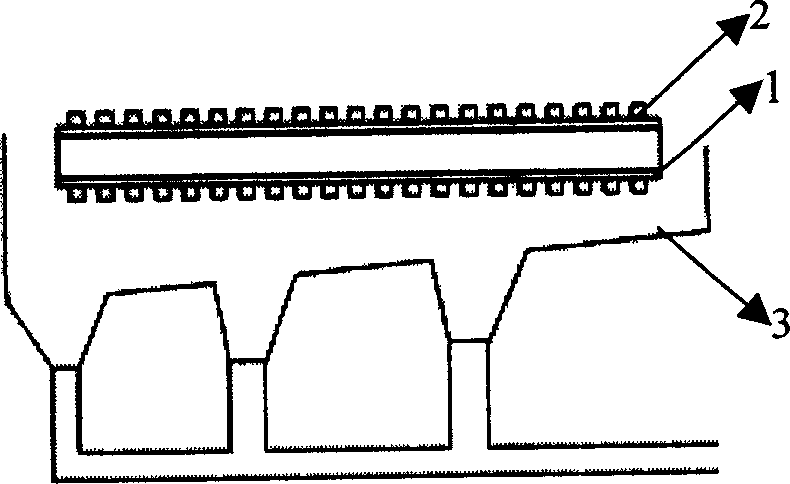

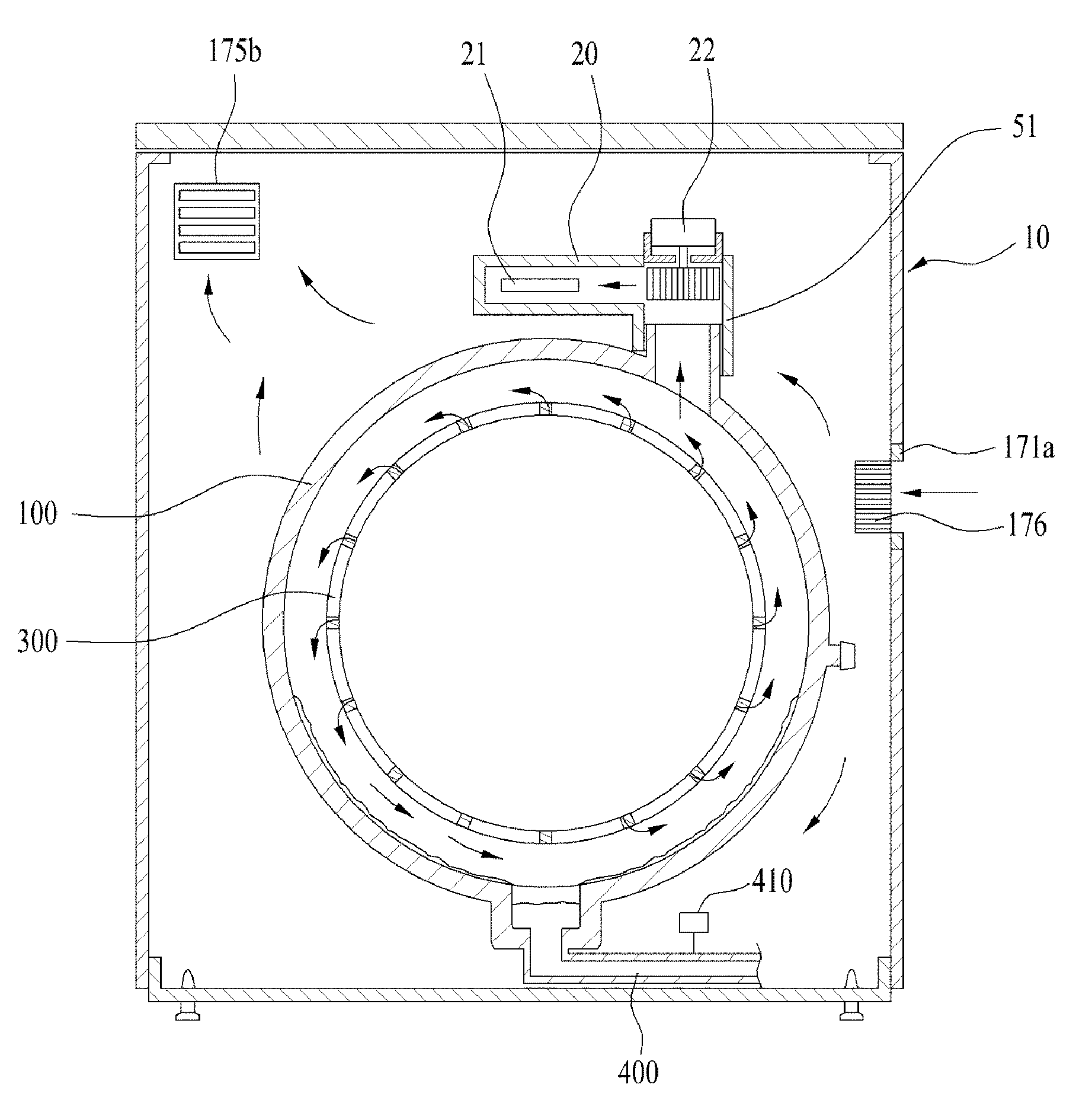

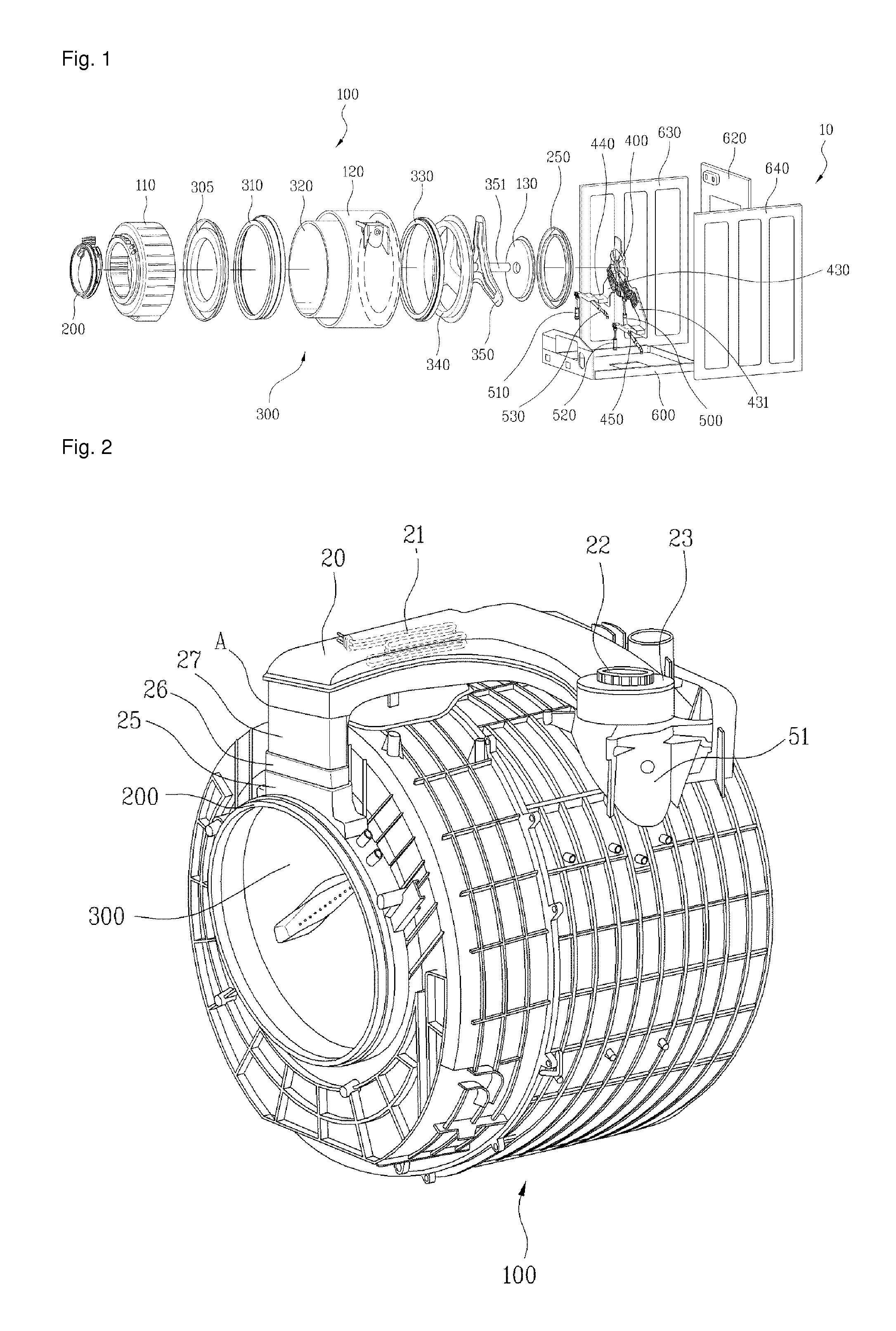

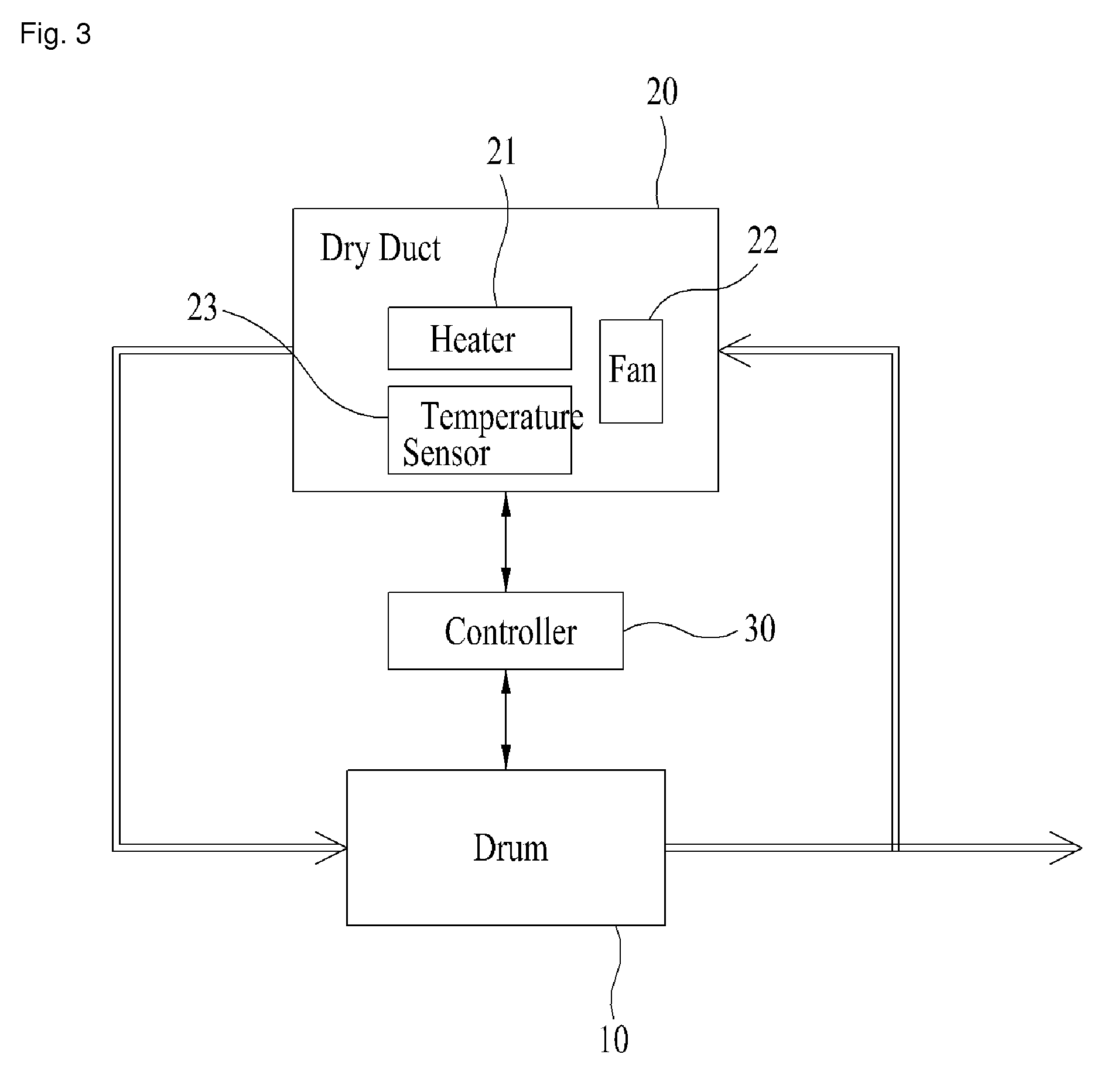

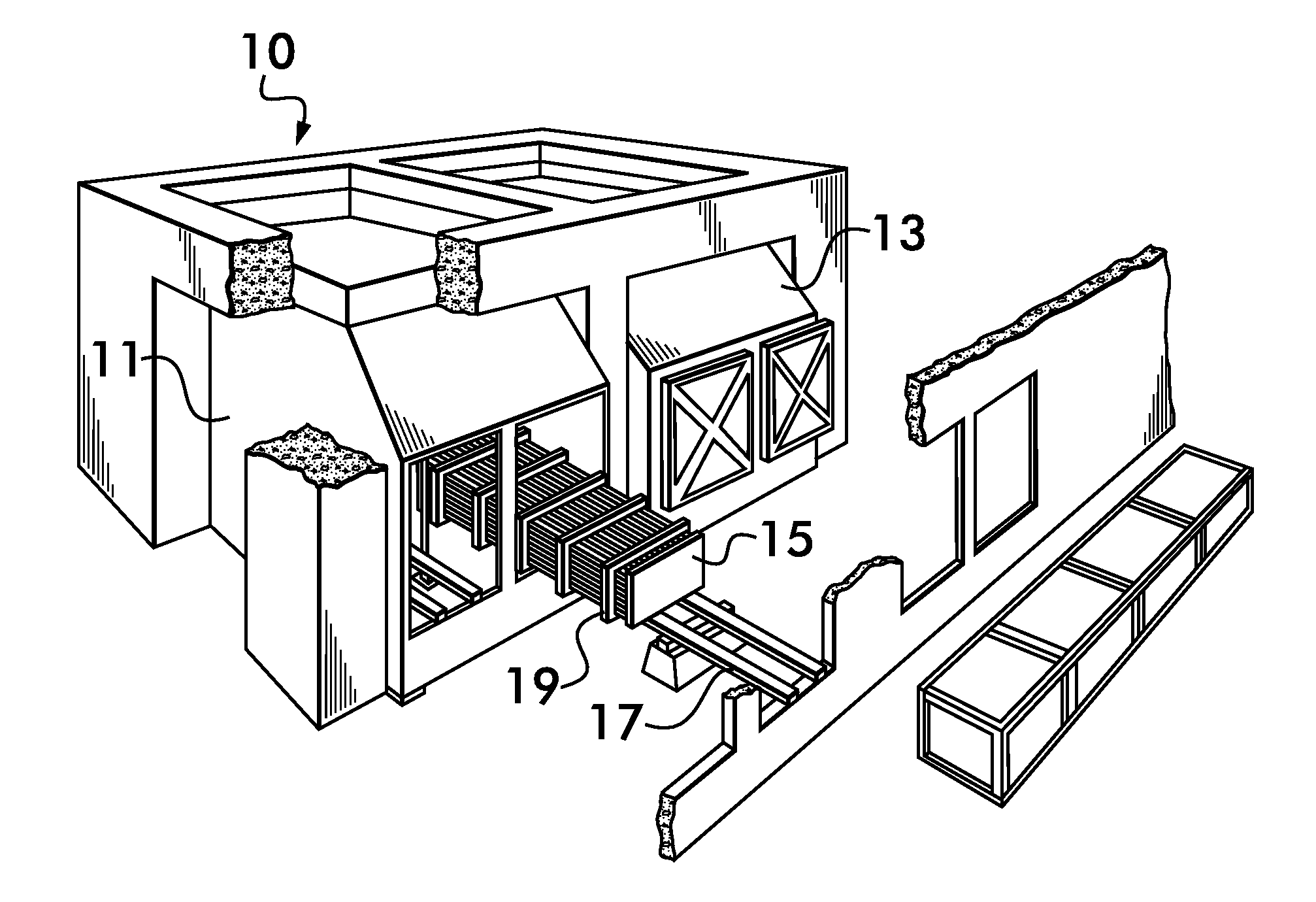

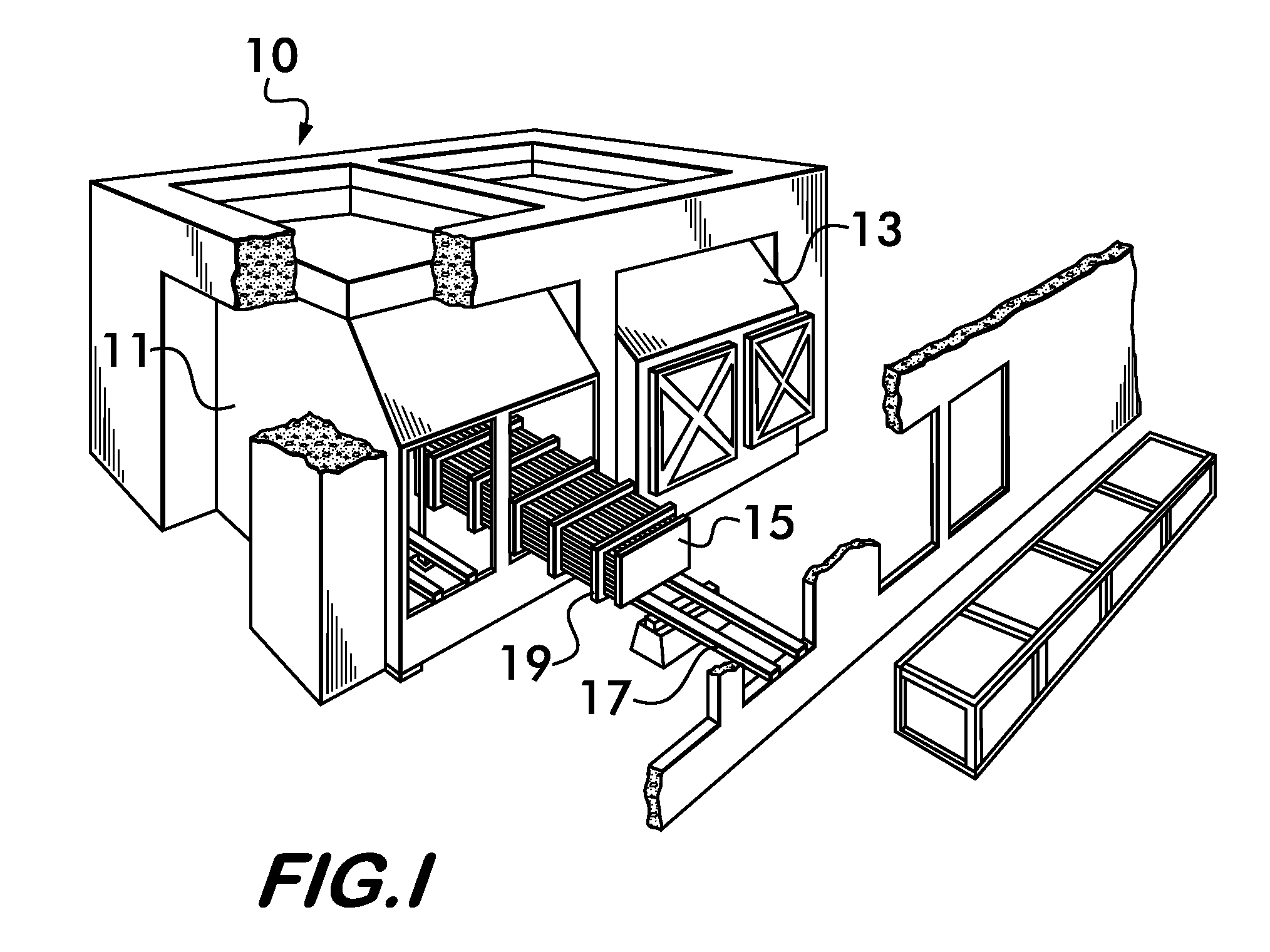

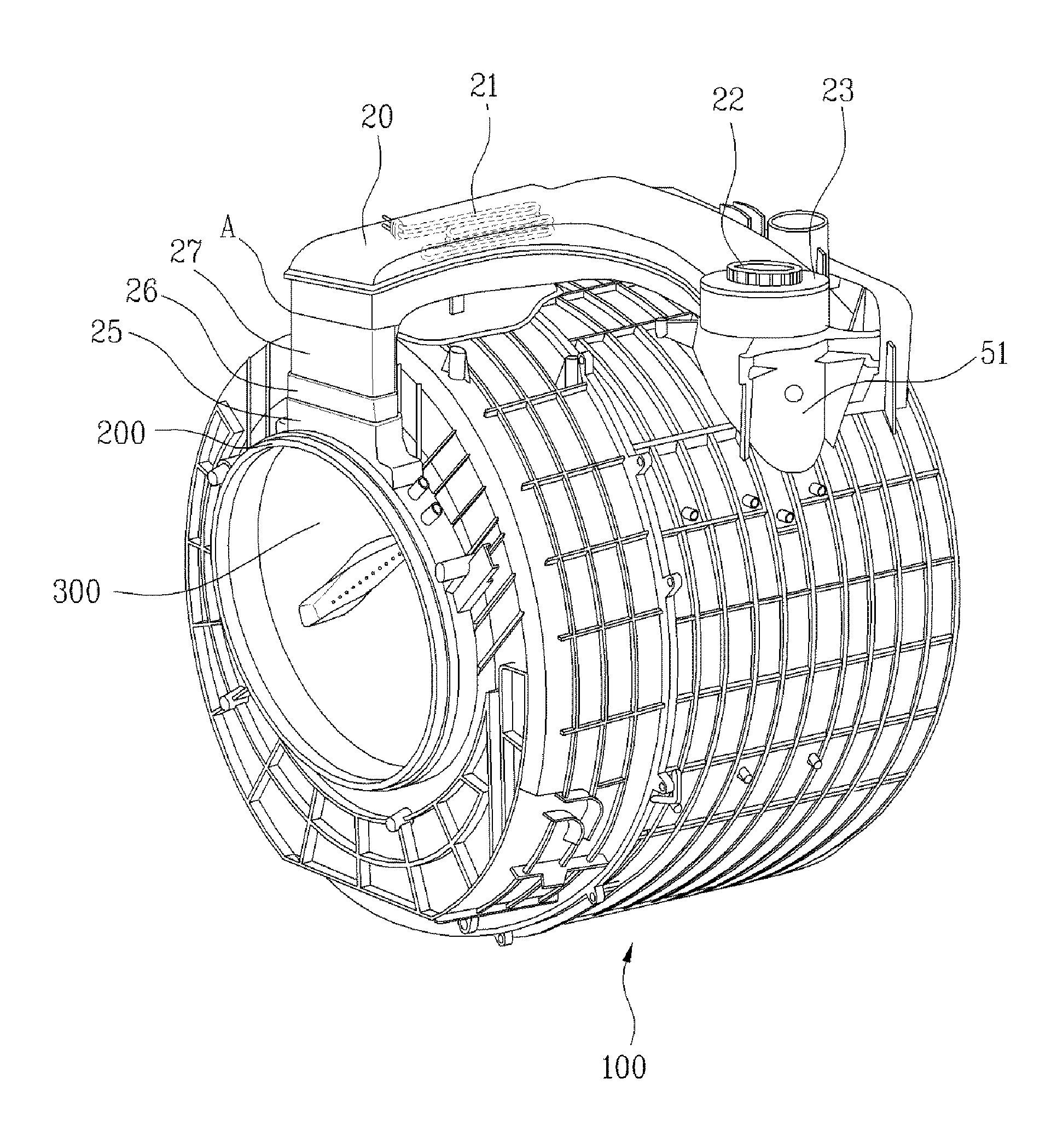

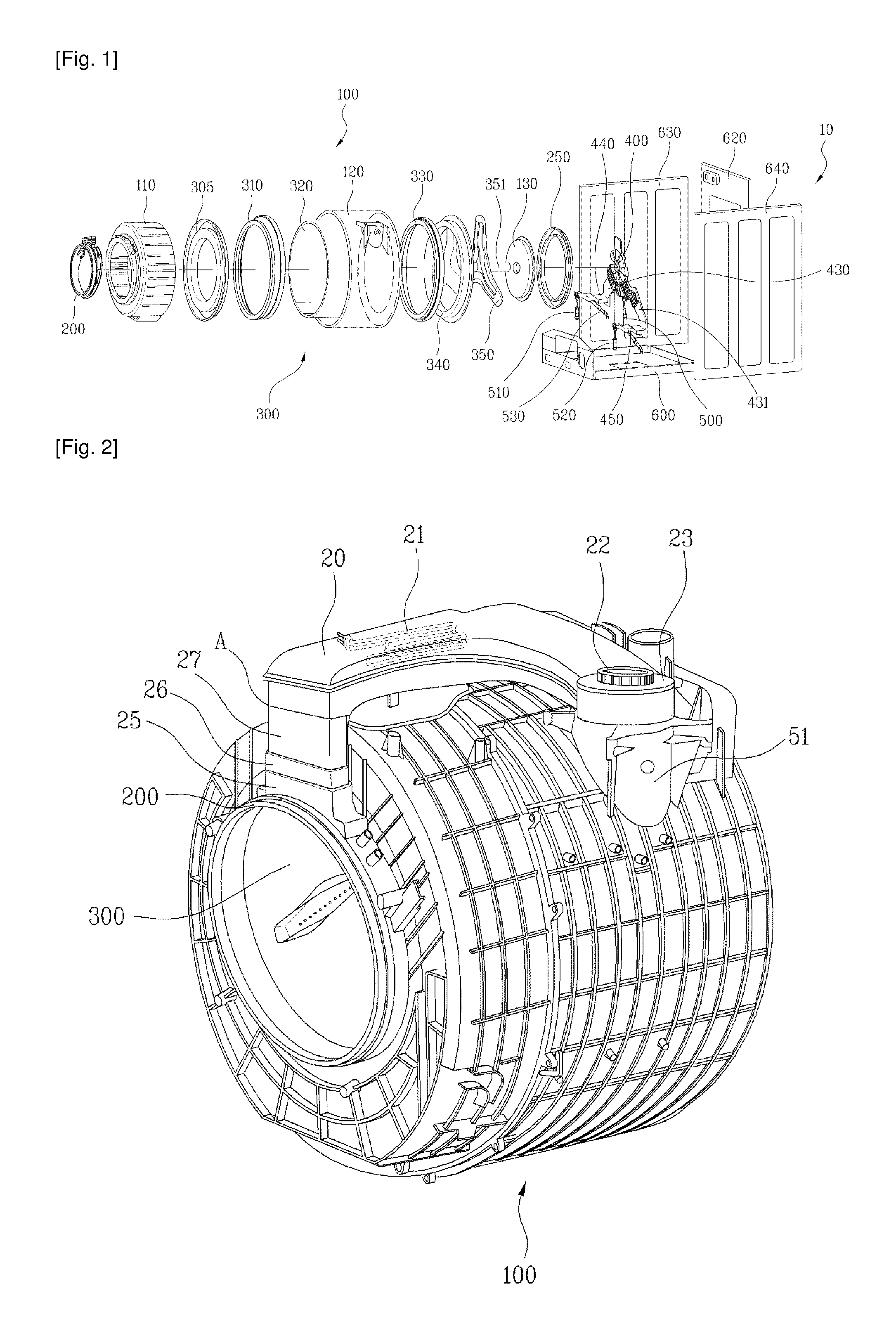

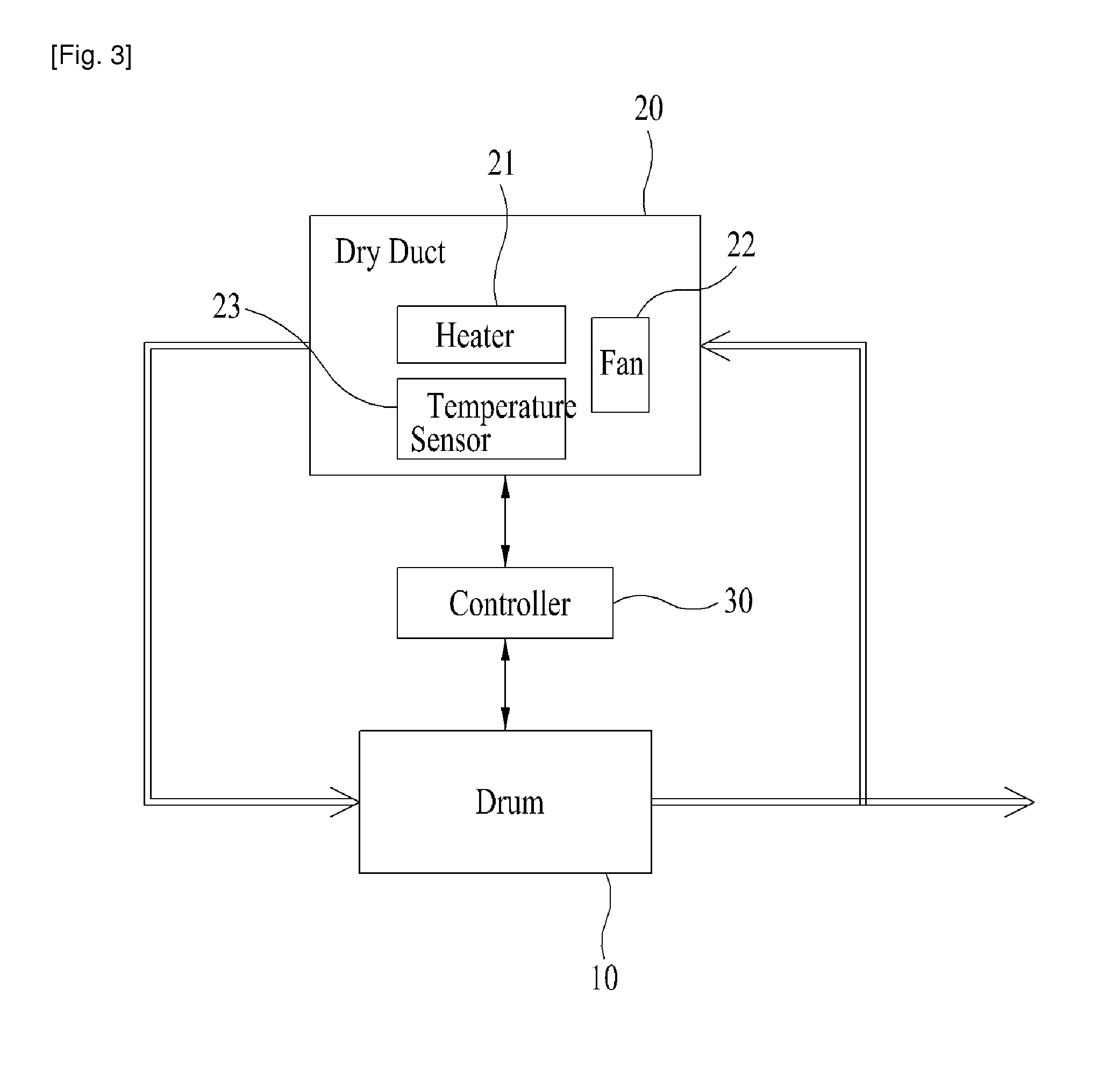

Washing machine and control method thereof

InactiveUS9133575B2Increase capacityAdd support structureDrying solid materials with heatOther washing machinesMechanical engineeringMoisture

A washing machine and a control method therefore are disclosed. The washing machine includes a cabinet (10); a tub (100) fixed to the cabinet (10); a drum (300) rotatably provided in the tub (100); a dry duct (20) which heats air exhausted from the tub (100) a predetermined temperature, to re-supply the heated air to the tub (100); condensation unit (170) which condenses moisture on at least a predetermined area of an inner circumferential surface of the tub (100) by heat-exchanging external air of the cabinet (10) with at least predetermined area of an outer circumferential surface of the tub (100); and sensing unit (410) which senses the amount of condensate generated in the tub (100). A washing machine and a control method thereof are disclosed. The washing machine includes a cabinet; a tub fixed to the cabinet; a drum rotatably provided in the tub; a dry duct which heats air exhausted from the tub a predetermined temperature, to re-supply the heated air to the tub; condensation unit which condenses moisture on at least a predetermined area of an inner circumferential surface of the tub by heat-exchanging external air of the cabinet with at least predetermined area of an outer circumferential surface of the tub; and sensing unit which sense the amount of condensate generated in the tub.

Owner:LG ELECTRONICS INC

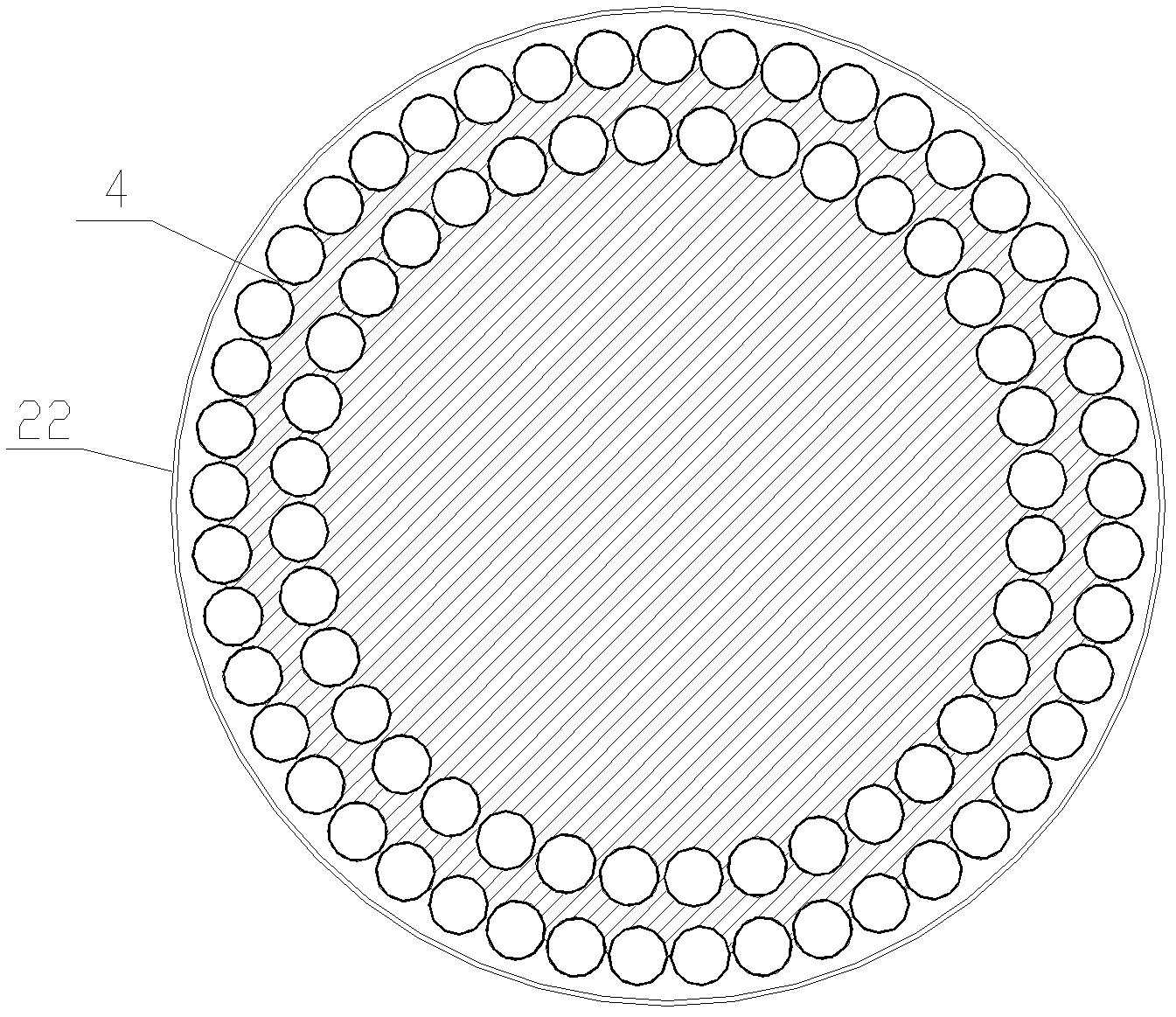

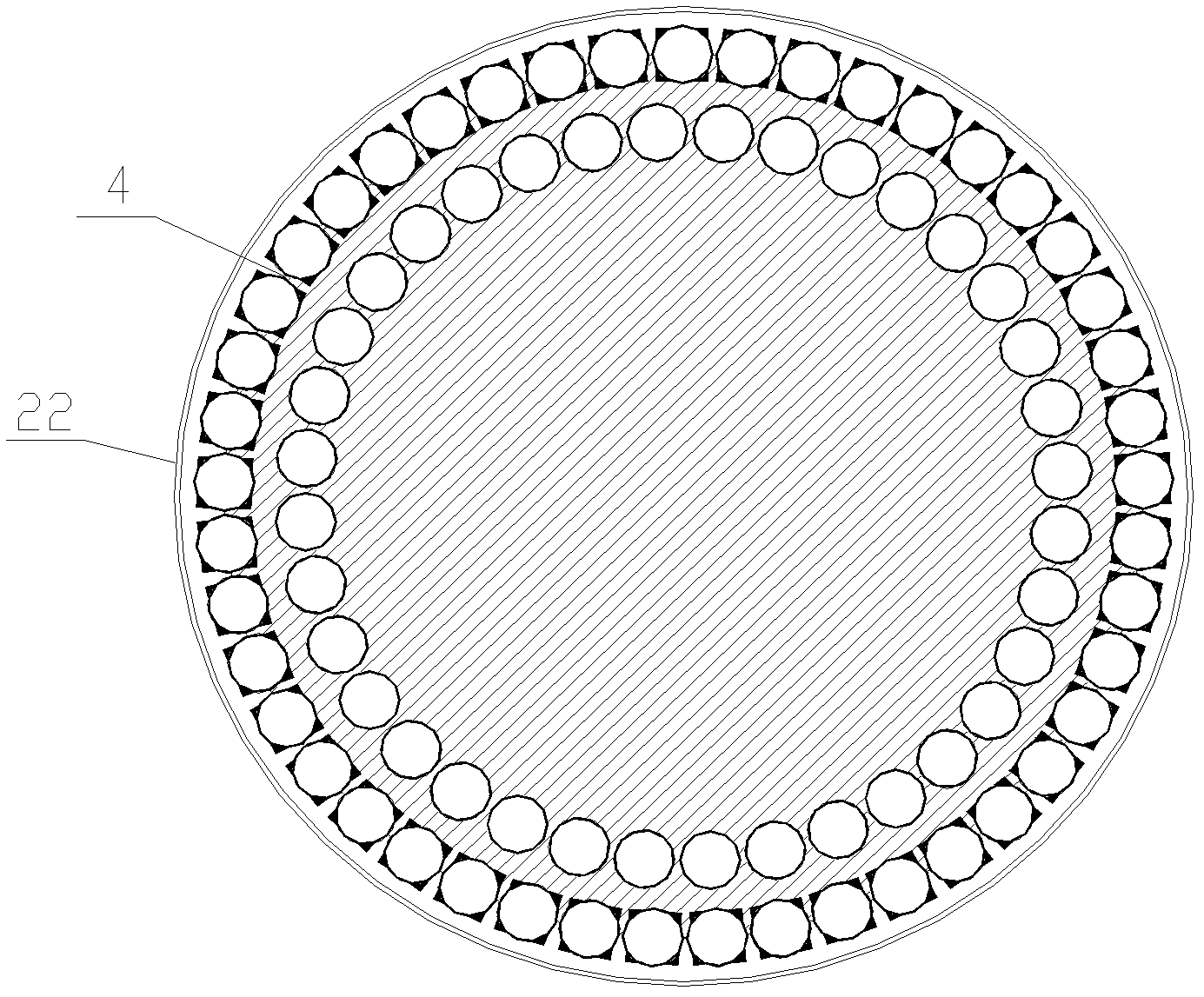

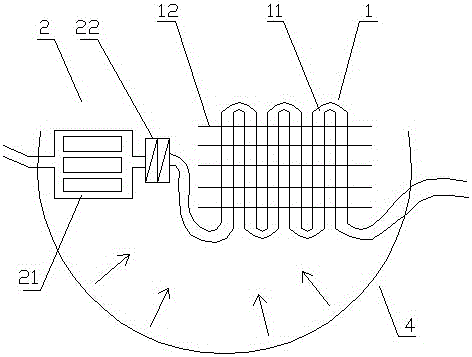

High-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler

PendingCN111141028AFully absorb radiation heat transferEnhanced radiation heat transferAir heatersGaseous fuel burnerCombustorAir blower

The invention provides a high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler comprises a combustor and a heat exchanger, wherein the full-premixed combustor mounted in the center of a boiler top plate consists of a booster fan, a premixing chamber and a water-cooling combustion head; a flame stabilizing pipe and an anti-tempering column of the water-cooling combustion head can realize high-adjustment-ratio water-cooling premixed combustion; the heat exchanger consists of a lap of water-cooling wall and one or more laps of fins uniformly arranged in the peripheral direction by bent edge folding fin pipes; an air blower feedsair into the premixing chamber for fully mixing with gas to enter an inner cavity of a hole plate of the combustion head; the air flows out from a fire hole, and is sprayed out from narrow gaps amongthe water-cooling pipes distributed in the peripheral direction; after the air flows out from the flame stabilizing pipe, the air is ignited to uniformly combust in the peripheral direction and the axial direction, and radiates and releases heat to an inner pipe ring; smoke flushes base pipes and fins of inner and outer ring fin pipes in sequence to reinforce heat exchange; and the smoke downwards flows into a dew bearing disc through gaps between a housing and an outer layer fin pipe, and is exhausted into atmosphere from a smoke outlet. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler is high in combustion load adjustment ratio, compact in heat exchange, low in nitrogen emission and high in heat efficiency.

Owner:XI AN JIAOTONG UNIV +1

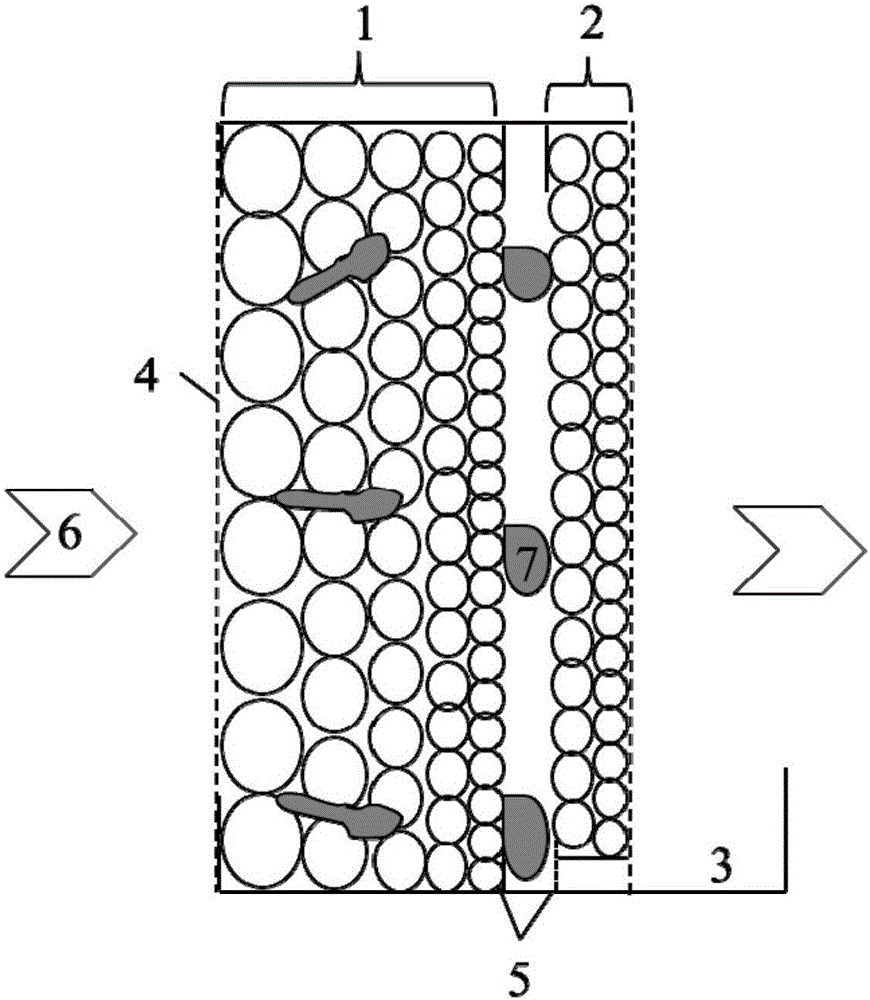

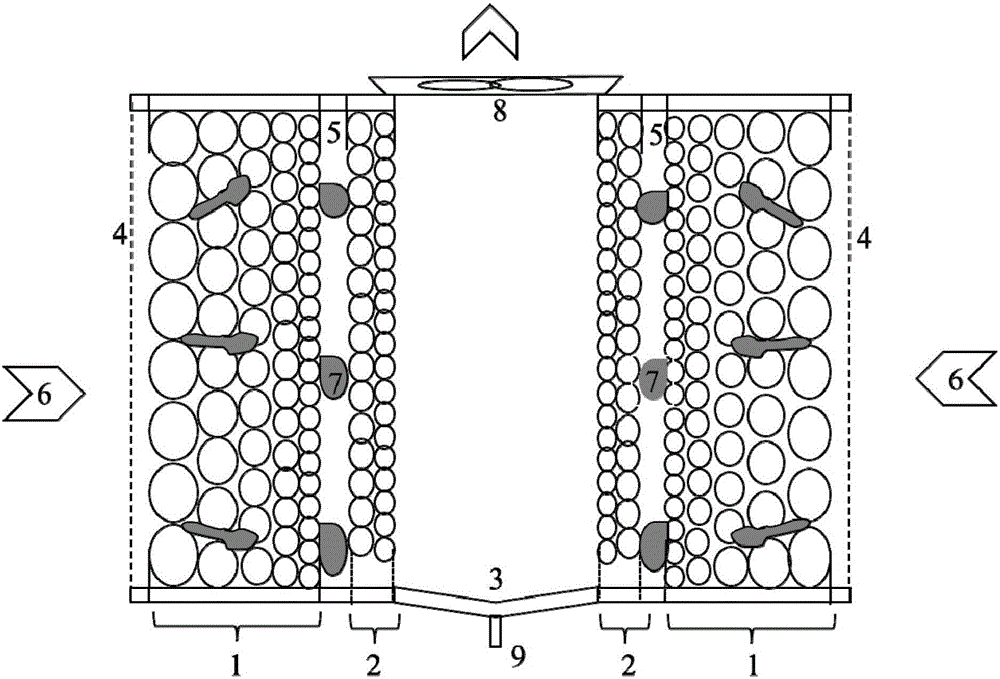

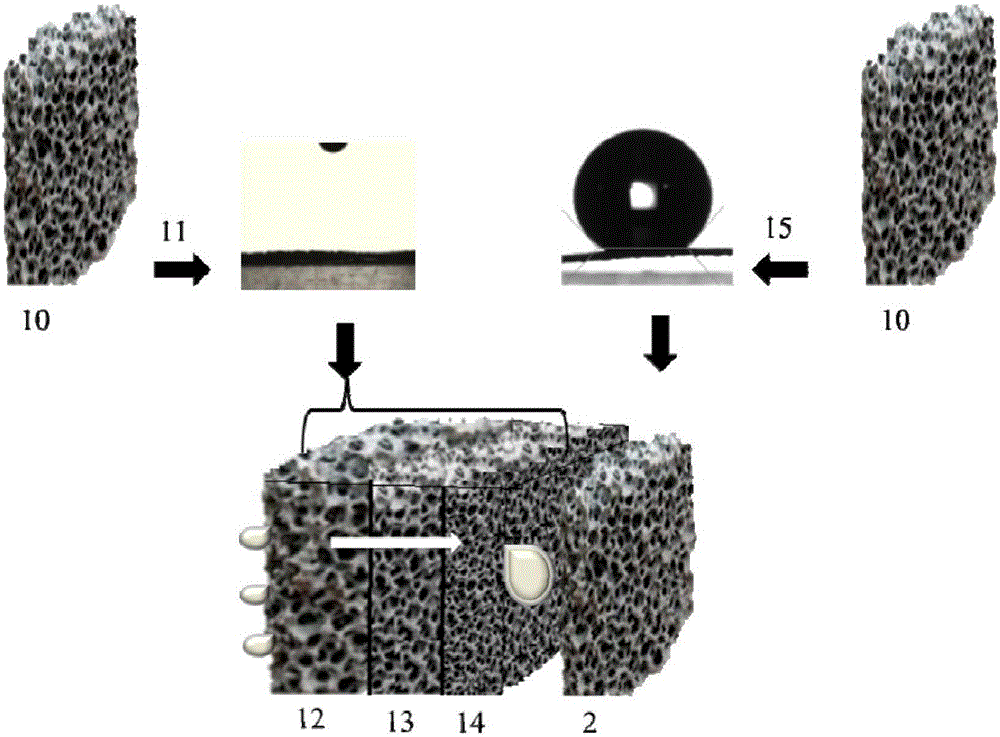

Water collecting device with gradient hydrophilic and hydrophobic performance and application thereof

ActiveCN105973021APromote regenerationSpeed up condensationSteam/vapor condensersDrinking water installationEnergy conservationChemistry

The invention belongs to the technical field of water collecting and energy conservation, and particularly relates to a water collecting device with the gradient hydrophilic and hydrophobic performance and an application thereof. The water collecting device with the gradient hydrophilic and hydrophobic performance comprises gradient pore hydrophilic porous foam, hydrophobic porous foam, a collecting tank, a protective cover and a porous foam fixing structure; wherein the protective cover is filled with the gradient pore hydrophilic porous foam and the hydrophobic porous foam; two spaces are arranged on the two sides of the hydrophobic porous foam correspondingly; the front space is an interval gap between the hydrophobic porous foam and the gradient pore hydrophilic porous foam, and the width of the front space is in a millimeter scale; the rear space is provided with the collecting tank; and the hydrophobic porous foam is suspended through the porous foam fixing structure, so that the interval gap on the front side communicates with the collecting tank.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

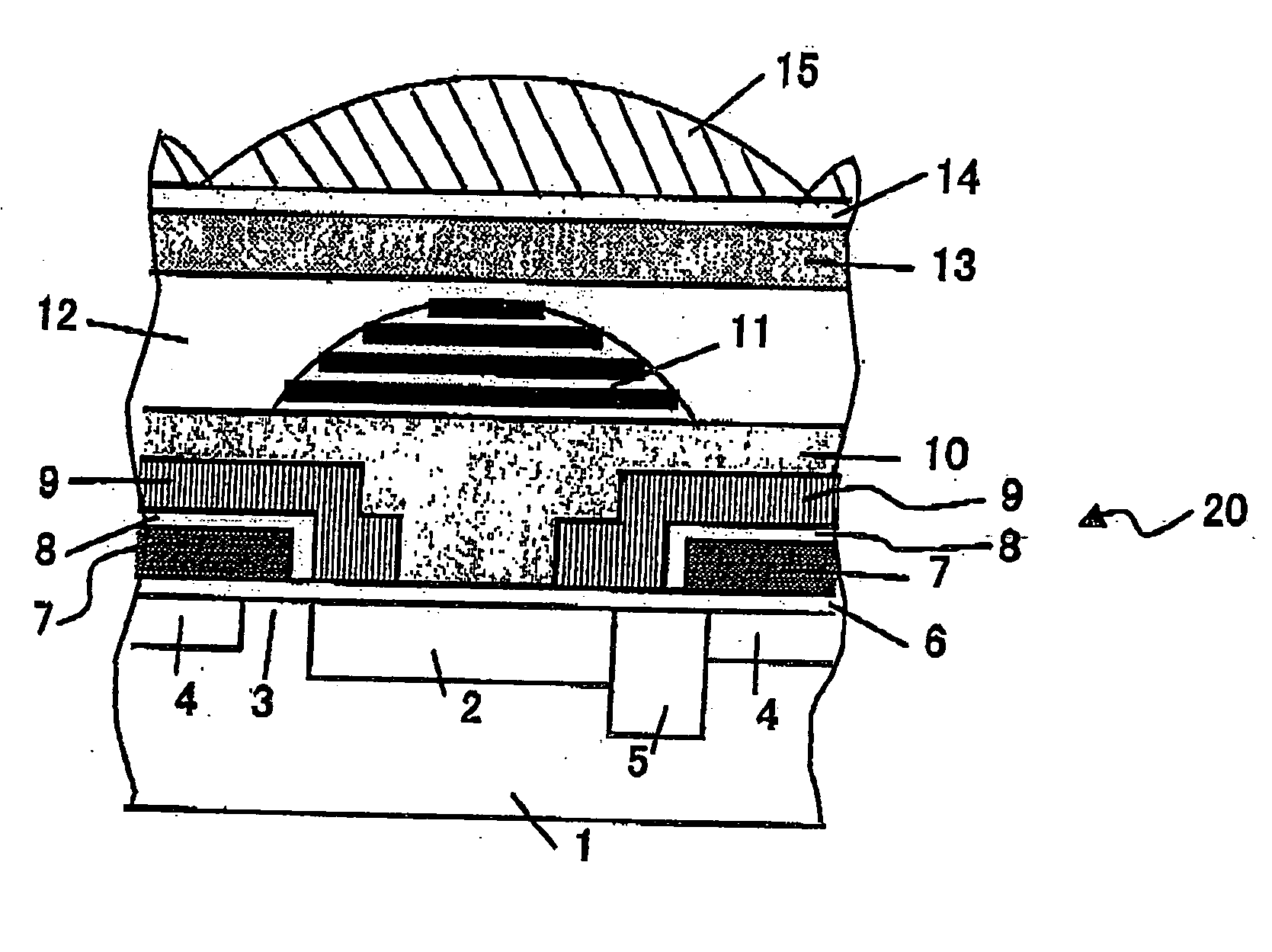

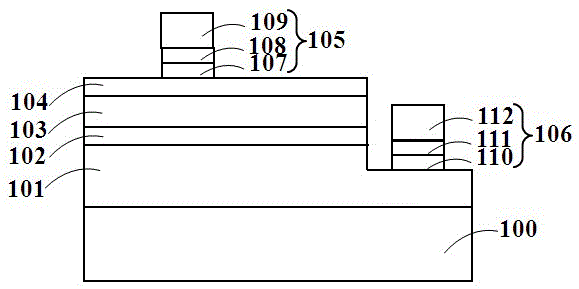

Semiconductor device and method for fabricating the same

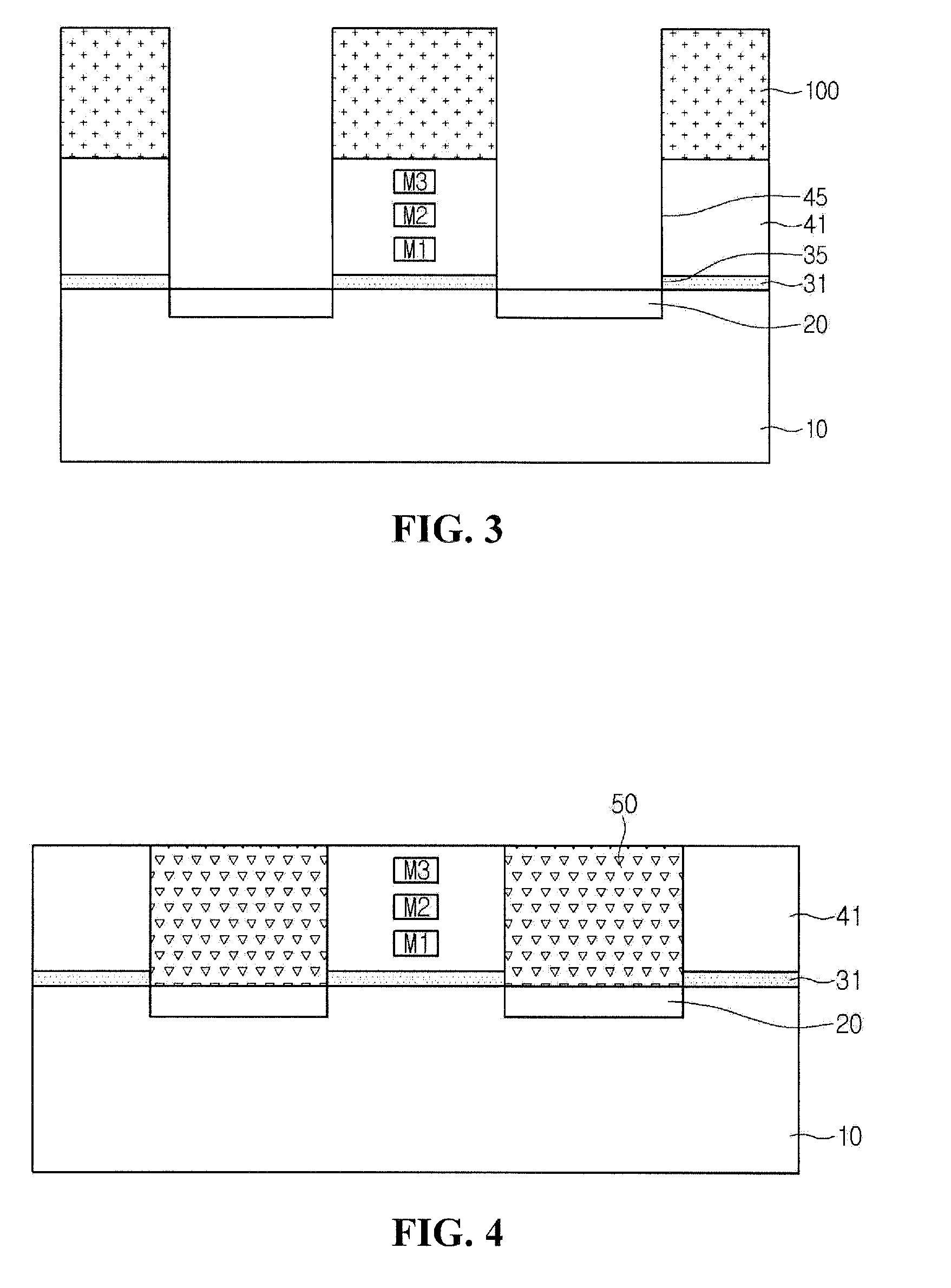

InactiveUS20050179103A1Improve film thickness uniformityAvoid uneven film thicknessSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialRefractive index

A semiconductor device comprises a photoelectric conversion portion formed on a semiconductor substrate, a first transparent film provided on the photoelectric conversion portion, and an interlayer lens provided on the first transparent film at a position corresponding to the photoelectric conversion portion, in which the interlayer lens has a higher refractive index than the first transparent film, and at least one of upper and lower surfaces of a second transparent film formed with a thin film multilayer structure of two or more types of compounds is formed to have a protruded shape.

Owner:SHARP KK

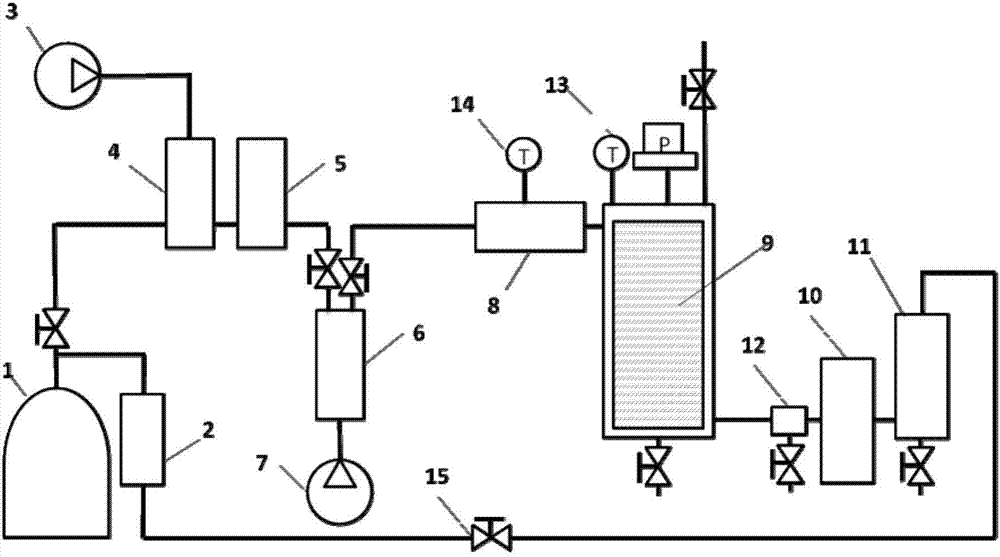

Supercritical carbo dioxide corrosion experimental apparatus

ActiveCN106896054AIncrease condensation rateImprove stabilityWeather/light/corrosion resistanceCorrosion reactionSystem stability

A supercritical carbo dioxide corrosion experimental apparatus comprises a carbon dioxide gas source, a preheating furnace and a corrosion reactor, an outlet of the carbon dioxide gas source is communicated with an inlet of the preheating furnace via a boost pump, an outlet of the preheating furnace is communicated with the corrosion reactor that is used for holding a sample, and an outlet of the corrosion reactor is connected with a cooling system. Through the carbon dioxide gas source, the boost pump, the corrosion reactor and the cooling system, the carbon dioxide gas source is boosted by the boost pump before entering the corrosion reactor; a condensing system is arranged at the rear of the corrosion reactor, gas condensing speed is increased, and system stability and safety are improved; the supercritical carbo dioxide corrosion experimental apparatus is simple in structure, and can provide simple and effective testing for corrosive action of a test material under high-temperature supercritical carbon dioxide (S-CO2).

Owner:HUANENG POWER INT INC +1

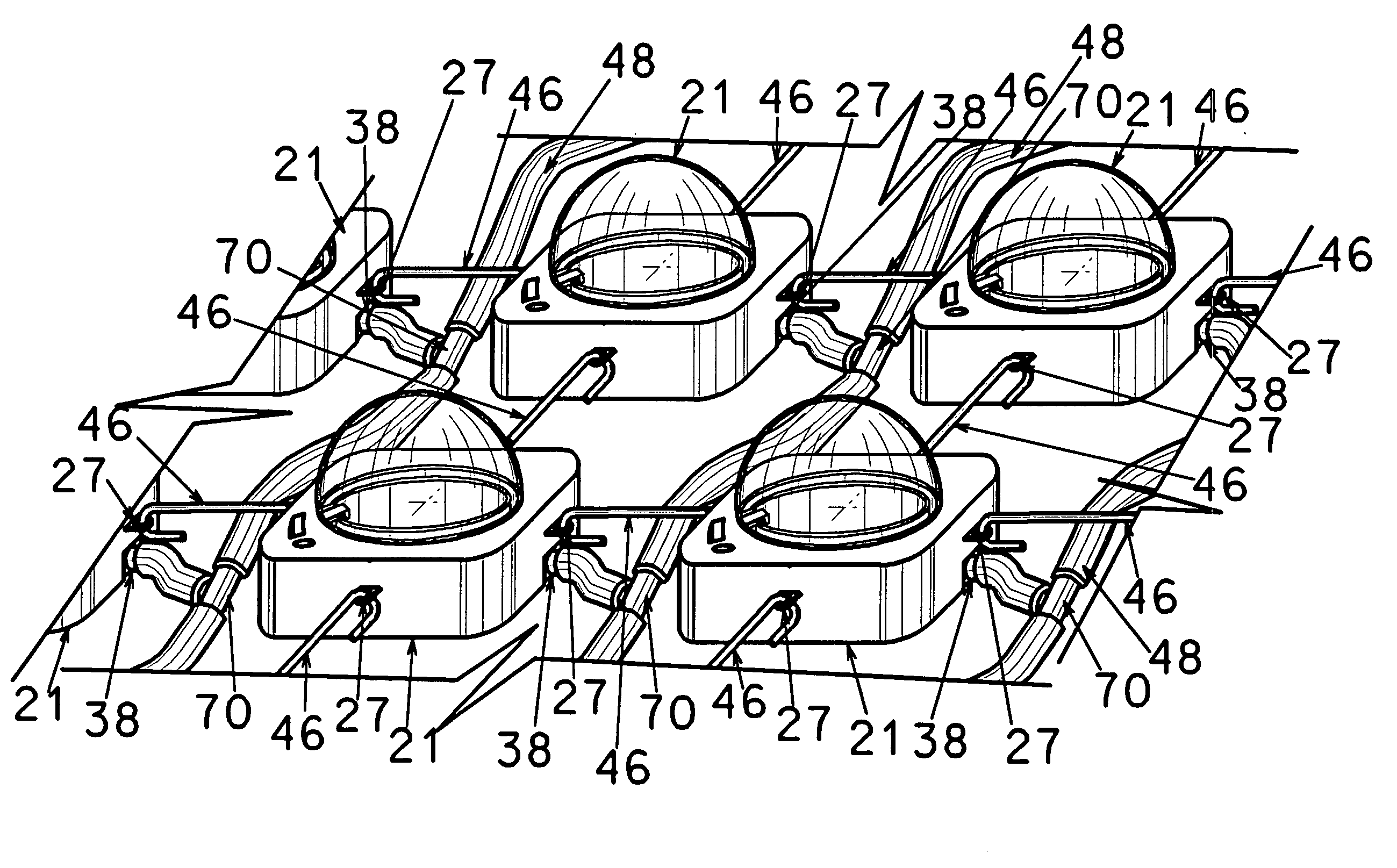

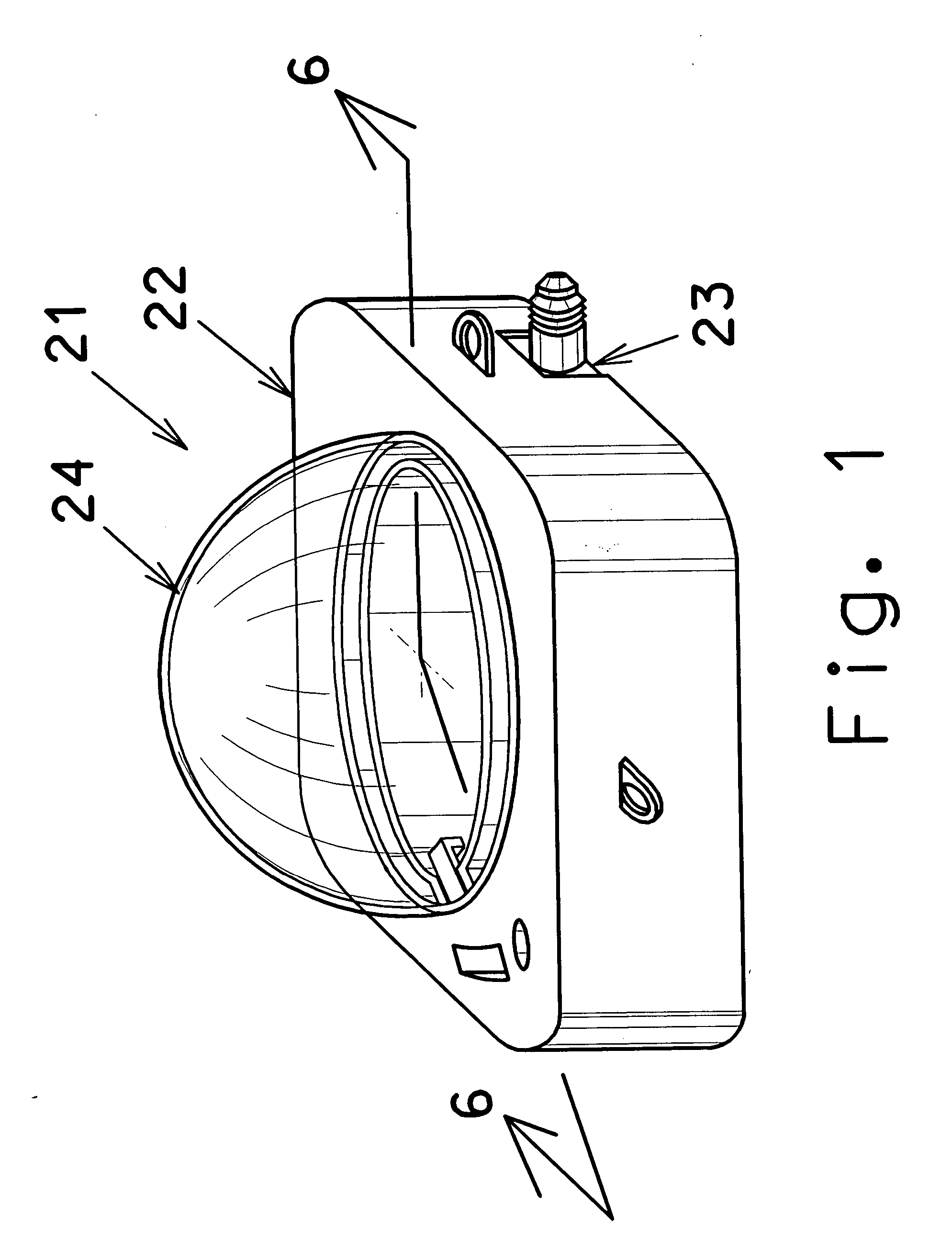

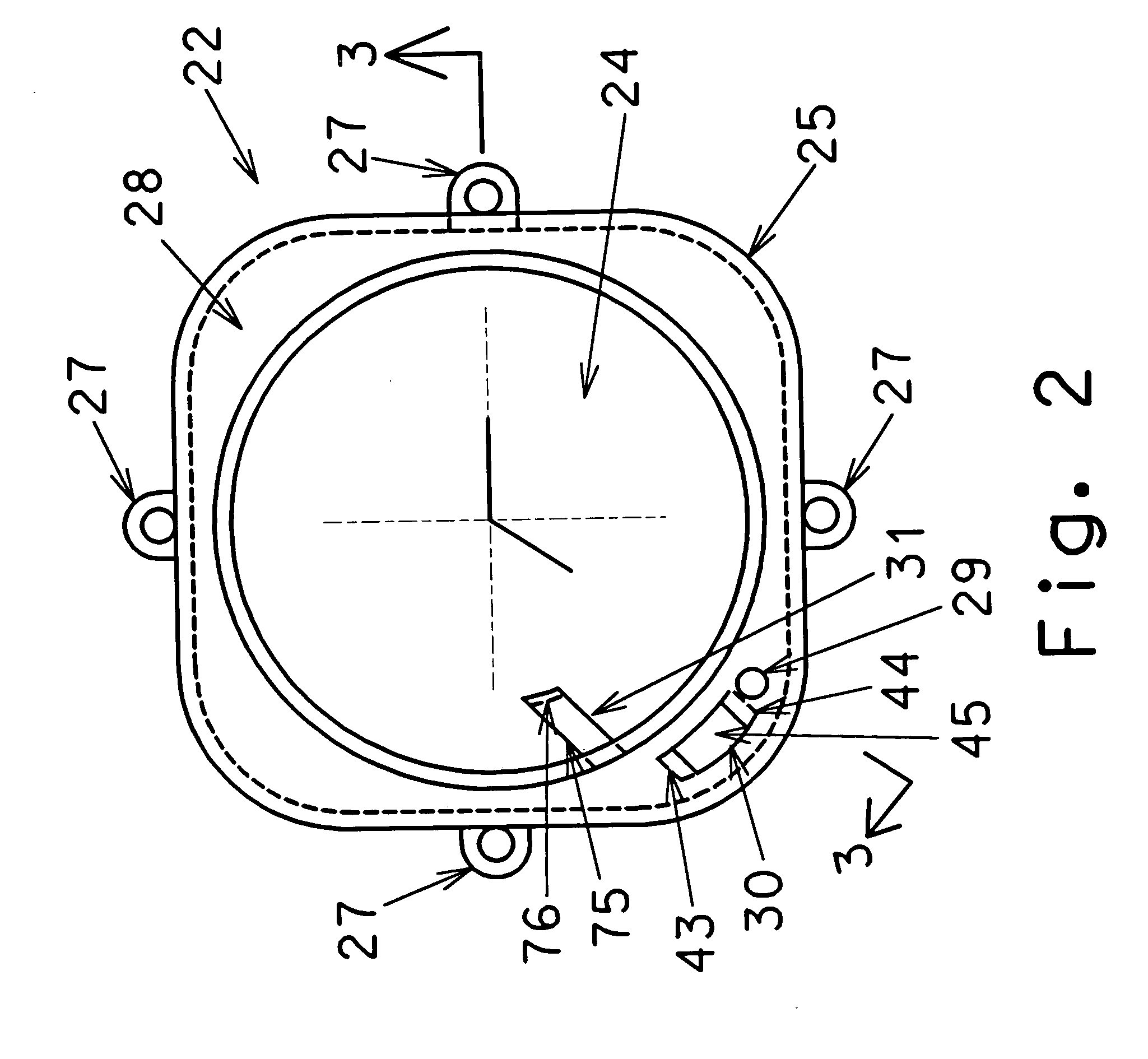

Solar powered water purification system

ActiveUS20120228114A1Increase condensation rateGeneral water supply conservationSeawater treatmentDistillationSolar water

A distillation unit for producing potable water using solar radiation is disclosed. The distillation unit includes a heating chamber defining an interior chamber adapted to contain a non-potable liquid for distillation, and a dome-shaped condensing portion having an inner surface and an outer surface, with the condensing portion disposed over the heating chamber such that the heating chamber and the inner surface of the condensing portion are provided in fluid-transfer communication. The distillation unit also includes a pre-heat jacket having a first surface and a second surface and an interior defined therebetween adapted to receive non-potable liquid for distillation therein. The first surface is disposed adjacent the outer surface of the condensing portion, and the pre-heat jacket defines an access entry for introducing non-potable liquid for distillation into the interior of the heating chamber. The distillation unit also includes a trough adjacent for receiving a potable liquid therein.

Owner:EPIPHANY SOLAR WATER SYST

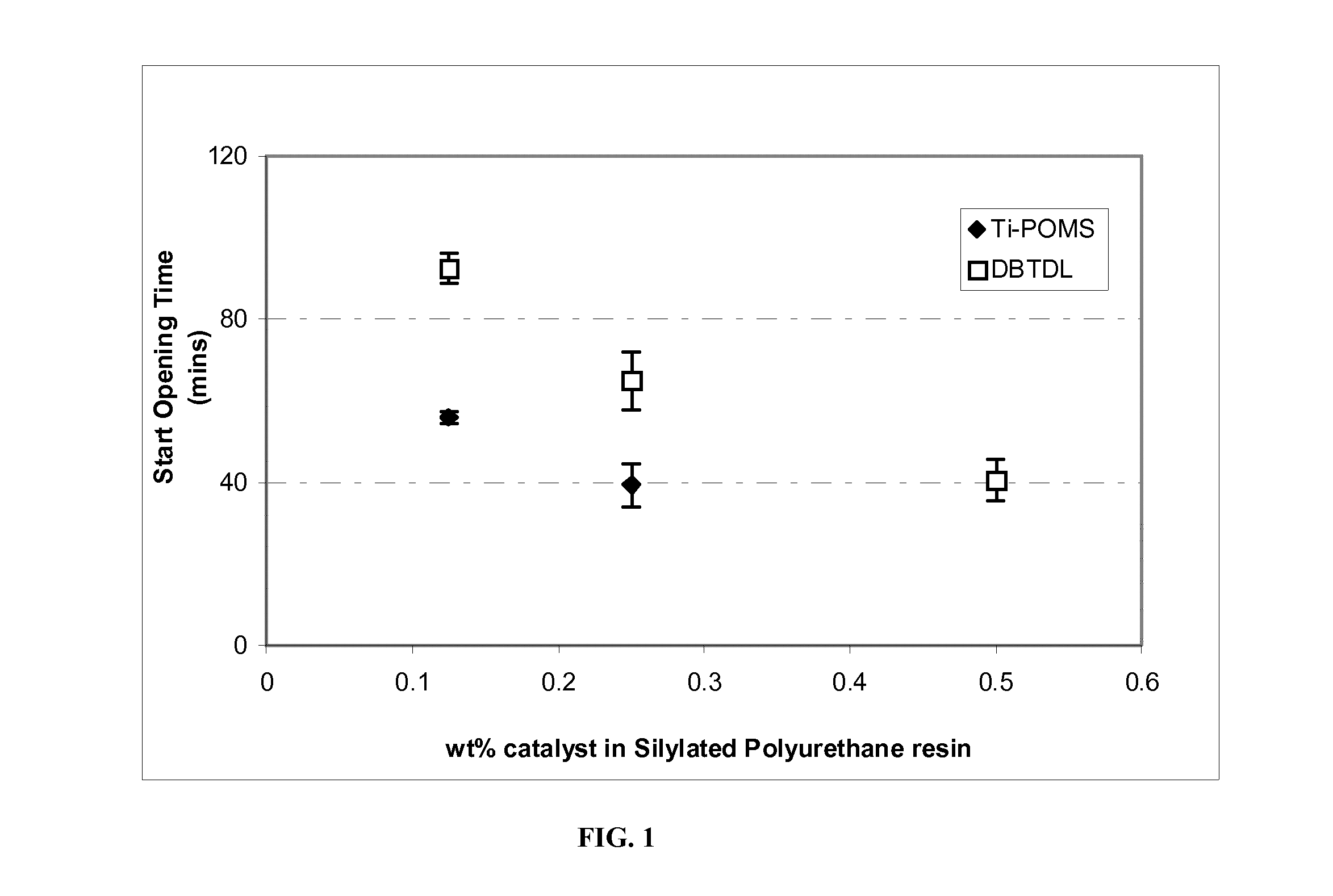

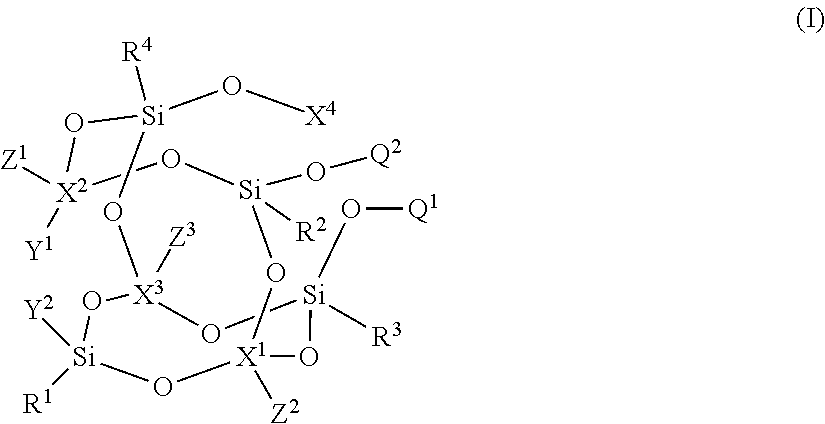

Composition Comprising Silylated Polymers

ActiveUS20160046793A1Increase condensation ratePolyureas/polyurethane adhesivesConductive materialSilylationSilanization

The present invention relates to a tin-free composition comprising at least one silylated polymer and at least one tin-free polyhedral oligomeric metallo silsesquioxane. The present invention also relates to a process of curing a composition comprising a silylated polymer comprising the step of: contacting a silylated polymer with a tin-free polyhedral oligomeric metallo silsesquioxane.

Owner:HUNTSMAN INT LLC

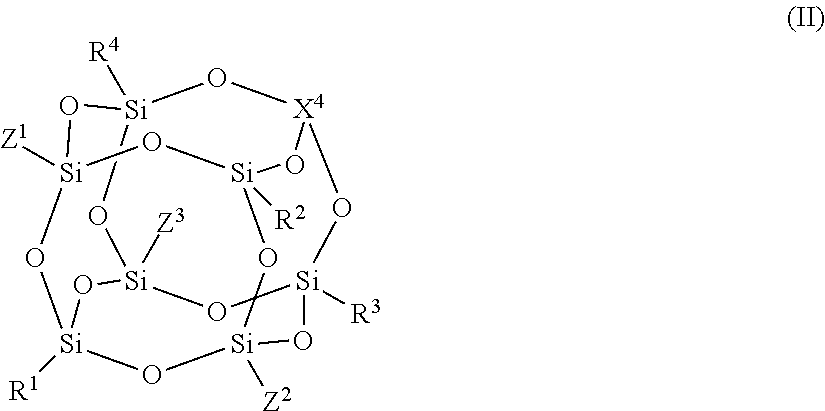

Method for preparing hydrogen-rich fuel gas through high-humidity sludge gasification based on blast furnace slag waste heat recovery

ActiveCN105567327ALow resource efficiencyImprove applicabilitySludge treatmentEnergy inputCatalytic reformingWater vapor

The invention provides a method for preparing hydrogen-rich fuel gas through high-humidity sludge gasification based on blast furnace slag waste heat recovery. The method comprises the steps that high-temperature gas and high-temperature slag particles which are generated in the liquid blast furnace slag air-quenching and granulating processes serve as a high-humidity sludge drying heat source and a sludge gasification heat source respectively, water in sludge is converted into vapor in the drying and gasifying stages, and the vapor serves as a sludge gasifying medium and a catalytic reforming medium for gasifying tar; meanwhile, the catalytic action of blast furnace slag is utilized for catalytically degrading the tar and converting the tar into the fuel gas. According to the method for preparing the hydrogen-rich fuel gas through high-humidity sludge gasification based on blast furnace slag waste heat recovery, blast furnace slag waste heat serves as a heating source for high-humidity sludge drying and dewatering and gasifying, and meanwhile the catalytic action of the blast furnace slag is utilized for degrading and converting the tar; the purpose of using waste for treating waste is achieved, the sludge gasification cost is reduced, and high-efficiency conversion of organic matter in the sludge to high-grade hydrogen energy is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

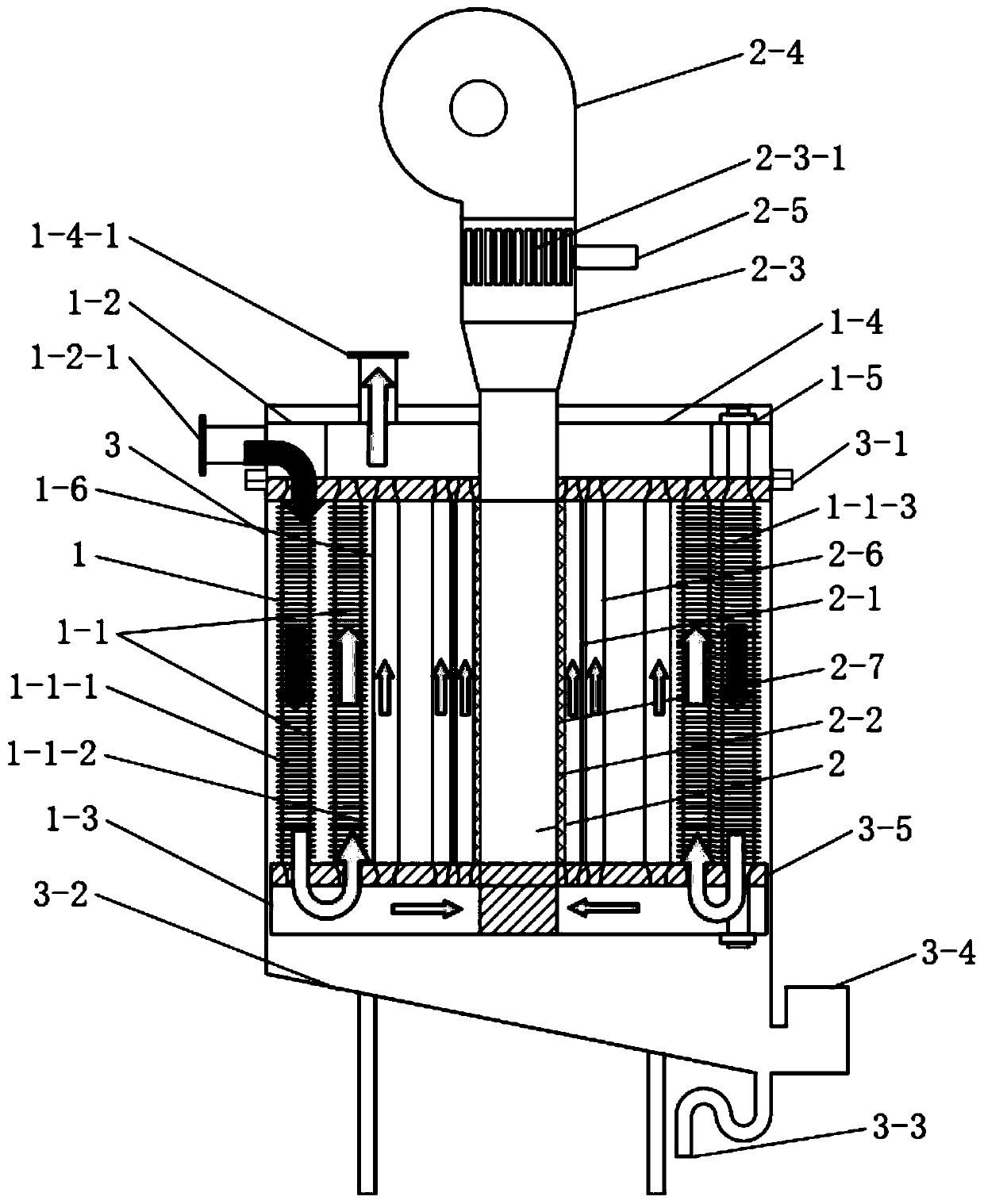

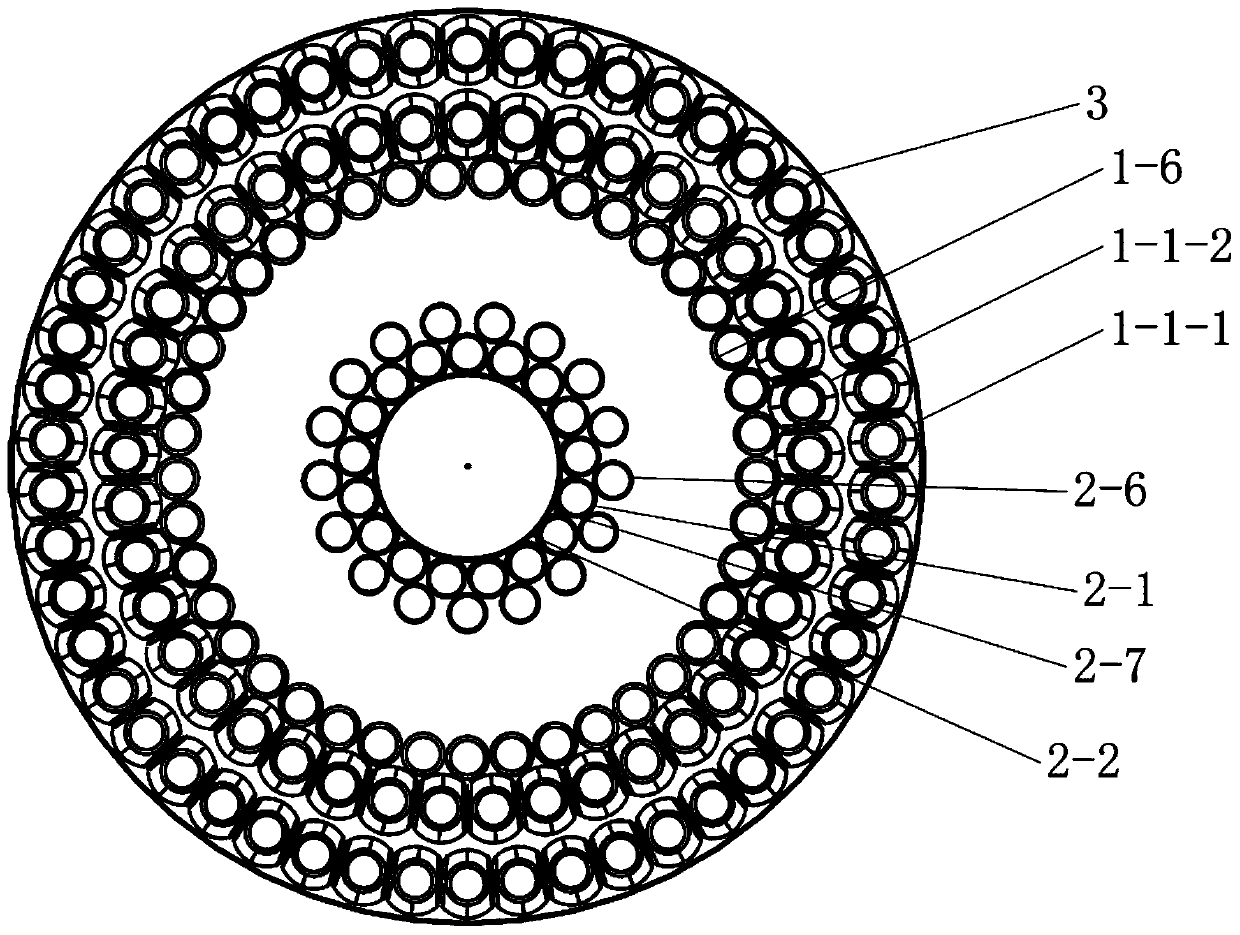

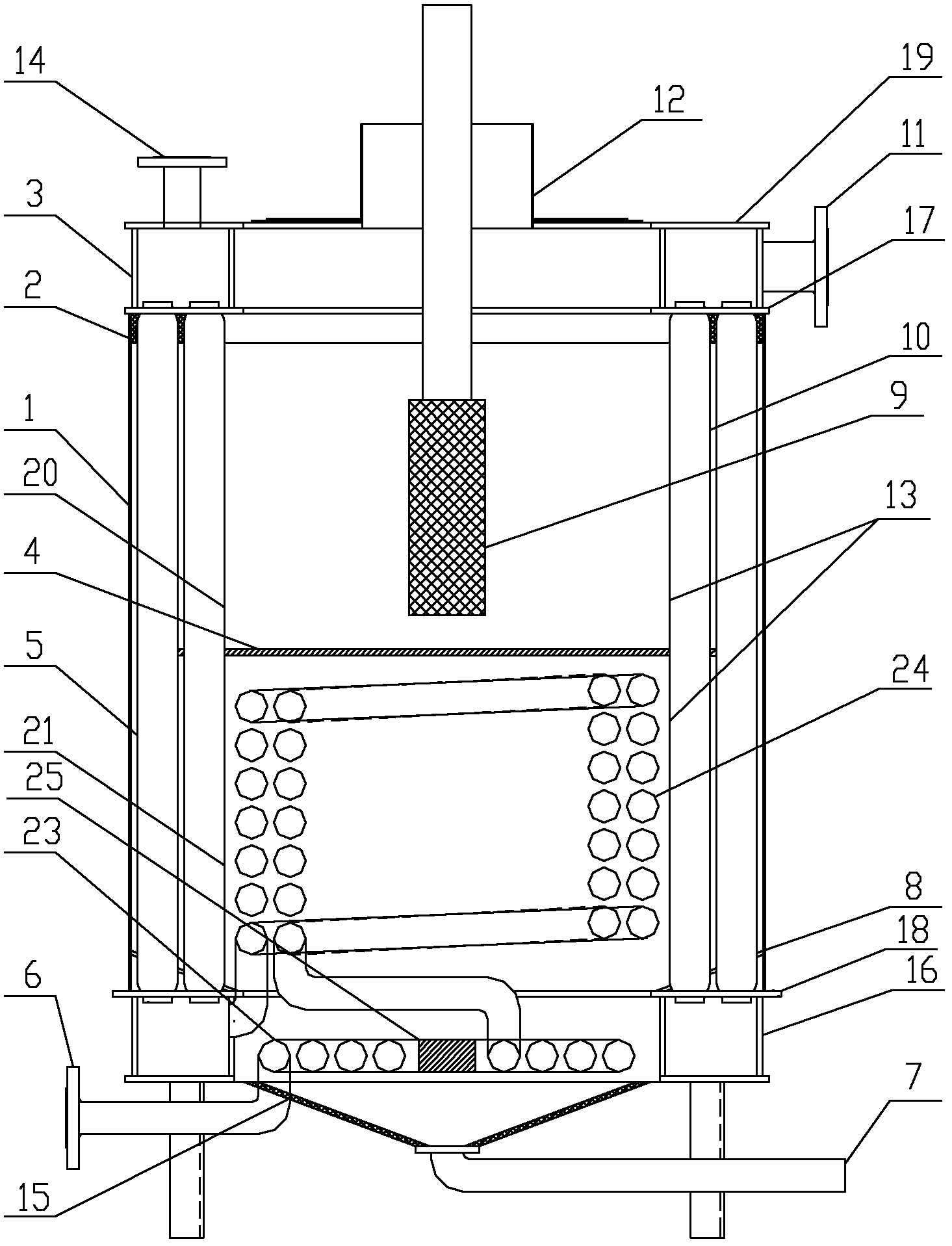

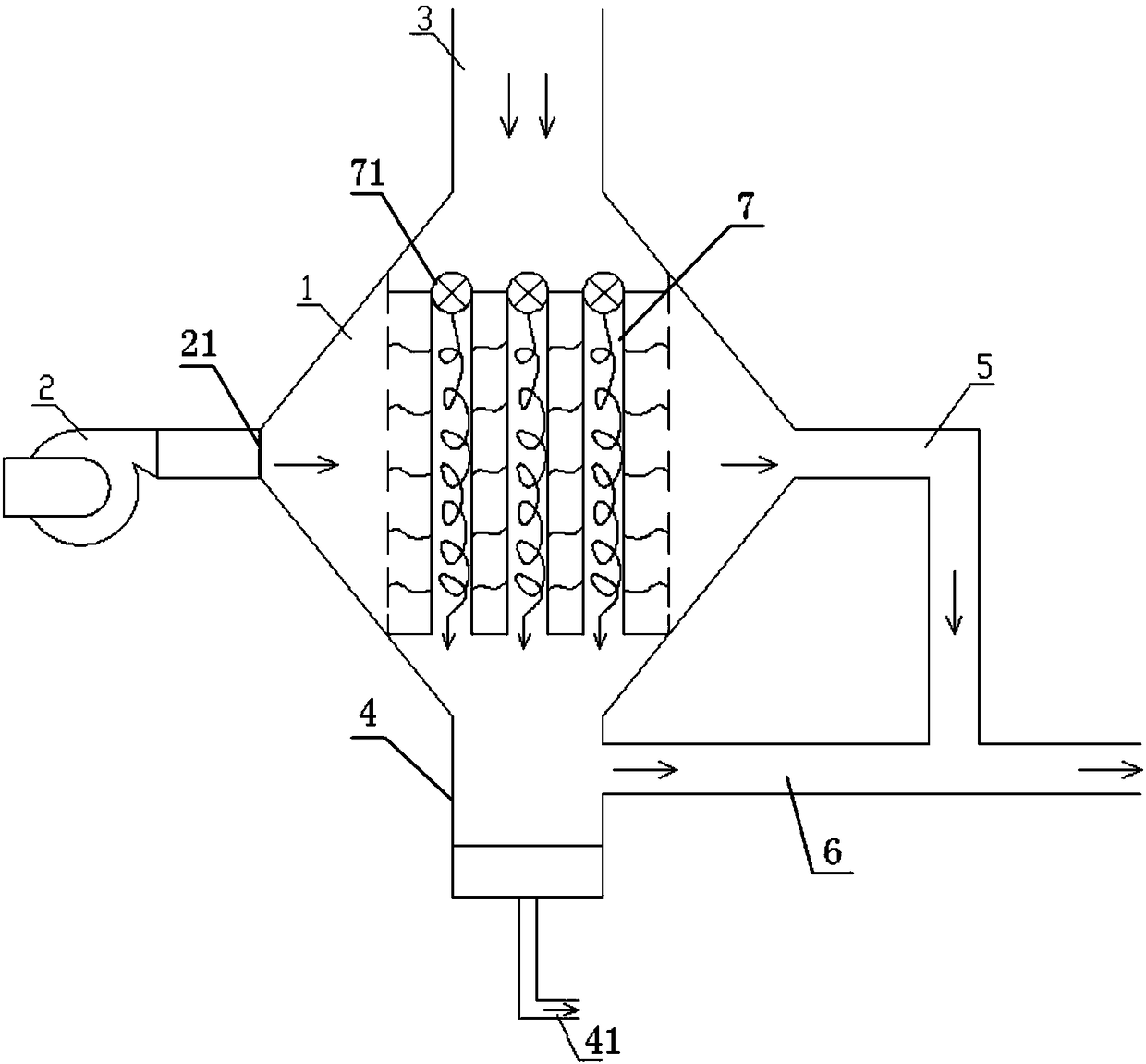

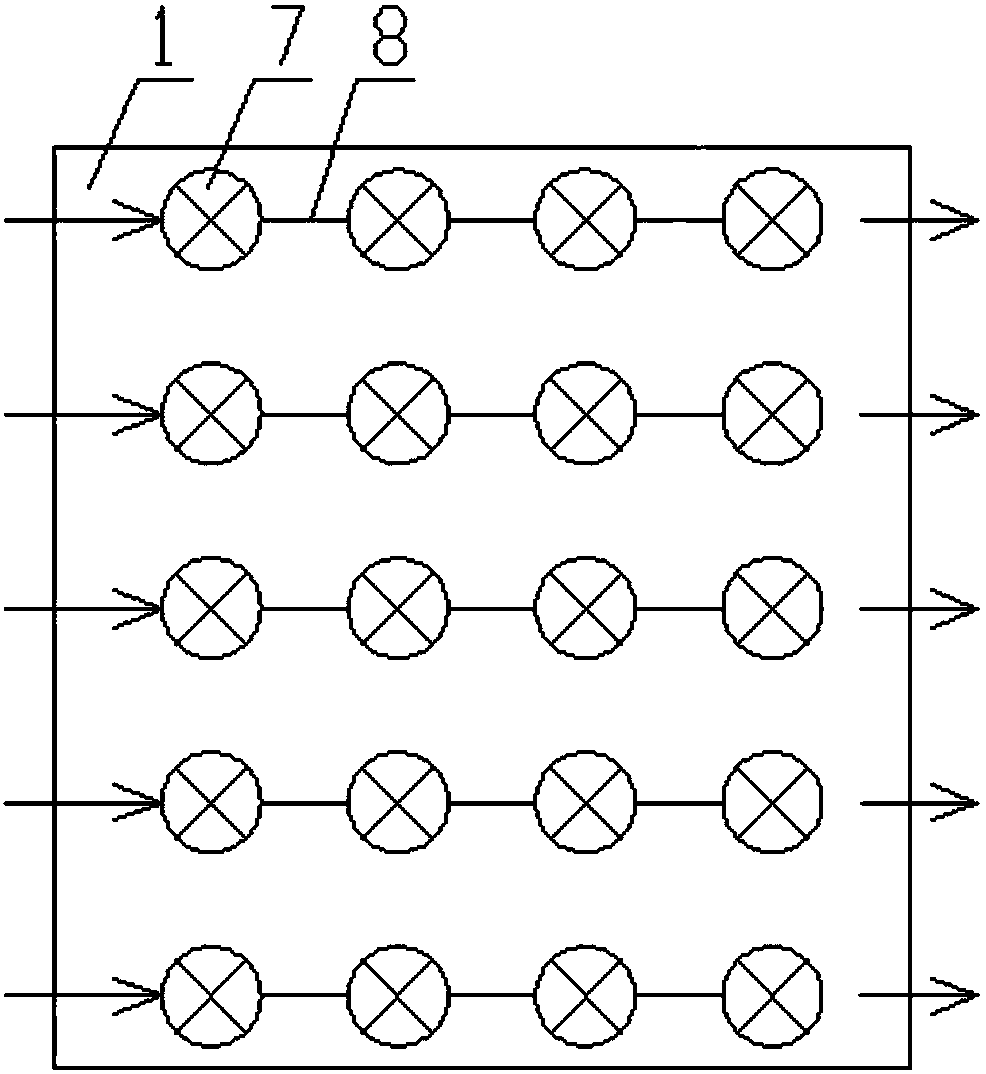

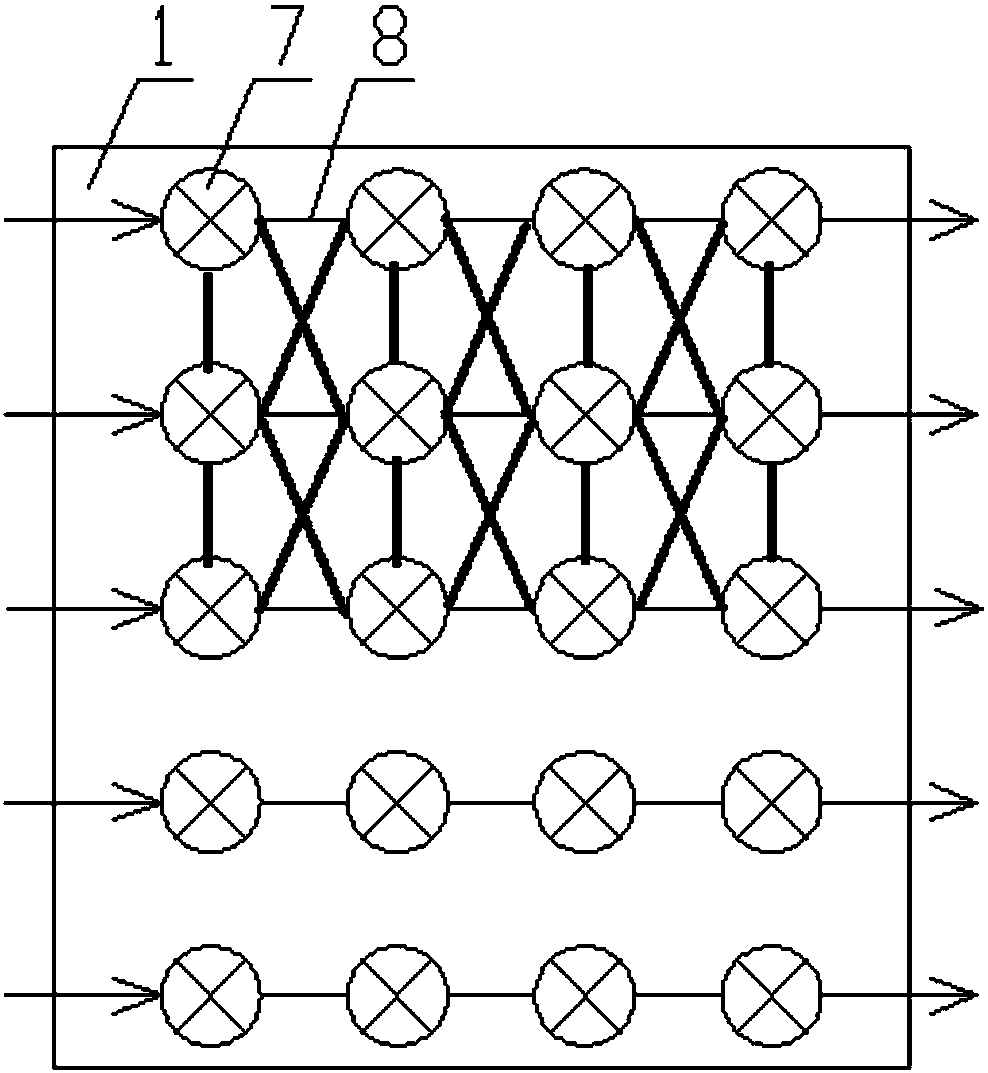

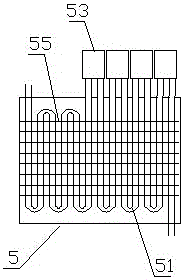

Through-flow type narrow-clearance integral condensation hot-water boiler

InactiveCN102635945ALow investment costAvoid uneven temperature distributionAir heatersSustainable buildingsCombustorEngineering

A through-flow type narrow-clearance integral condensation hot-water boiler comprises a shell. An annular water outlet header is arranged on the upper portion of the shell, an annular water feeding header is arranged on the lower portion of the shell, a deep condensation heat exchange tube bundle and a V-shaped condensation collecting device with a condensate neutralizing treatment device are arranged below the annular water feeding header, an all-premixing metal fiber combustor is arranged on a top plate of a boiler, a metal fiber head of the all-premixing metal fiber combustor penetrates into a radiation heat exchange space so as to realize the characteristic of high radiation heat exchange capacity of the metal fiber head, the annular water outlet header is communicated with the annular water feeding header via inner and outer circles of annular water cooling walls consisting of a plurality of vertical water tubes, a clearance with the size of 1-2mm is reserved between each two adjacent vertical water tubes and is used as a smoke circulation channel, smoke realizes convection heat exchange and condensation heat exchange when flowing among the vertical water tubes, heat is transmitted to working medium water in the vertical water tubes, the deep condensation heat exchange tube bundle deeply cools the smoke, and efficiency of the boiler is improved. In addition, the through-flow type narrow-clearance integral condensation hot-water boiler is simple in structure and convenient in manufacture, and can effectively avoid the harm that tubes are easy to be exploded due to uneven heat load distribution of a traditional through-flow boiler.

Owner:XI AN JIAOTONG UNIV

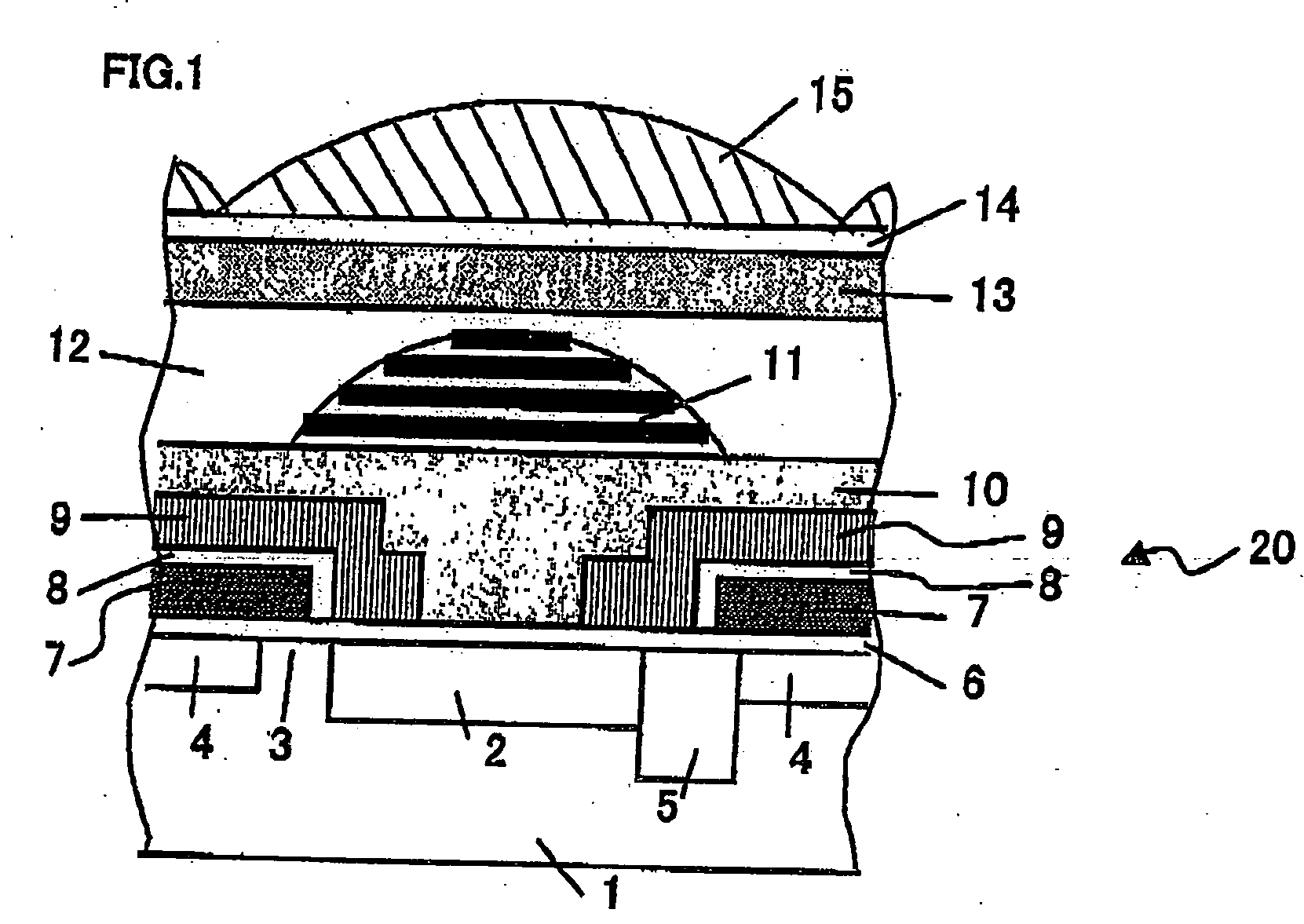

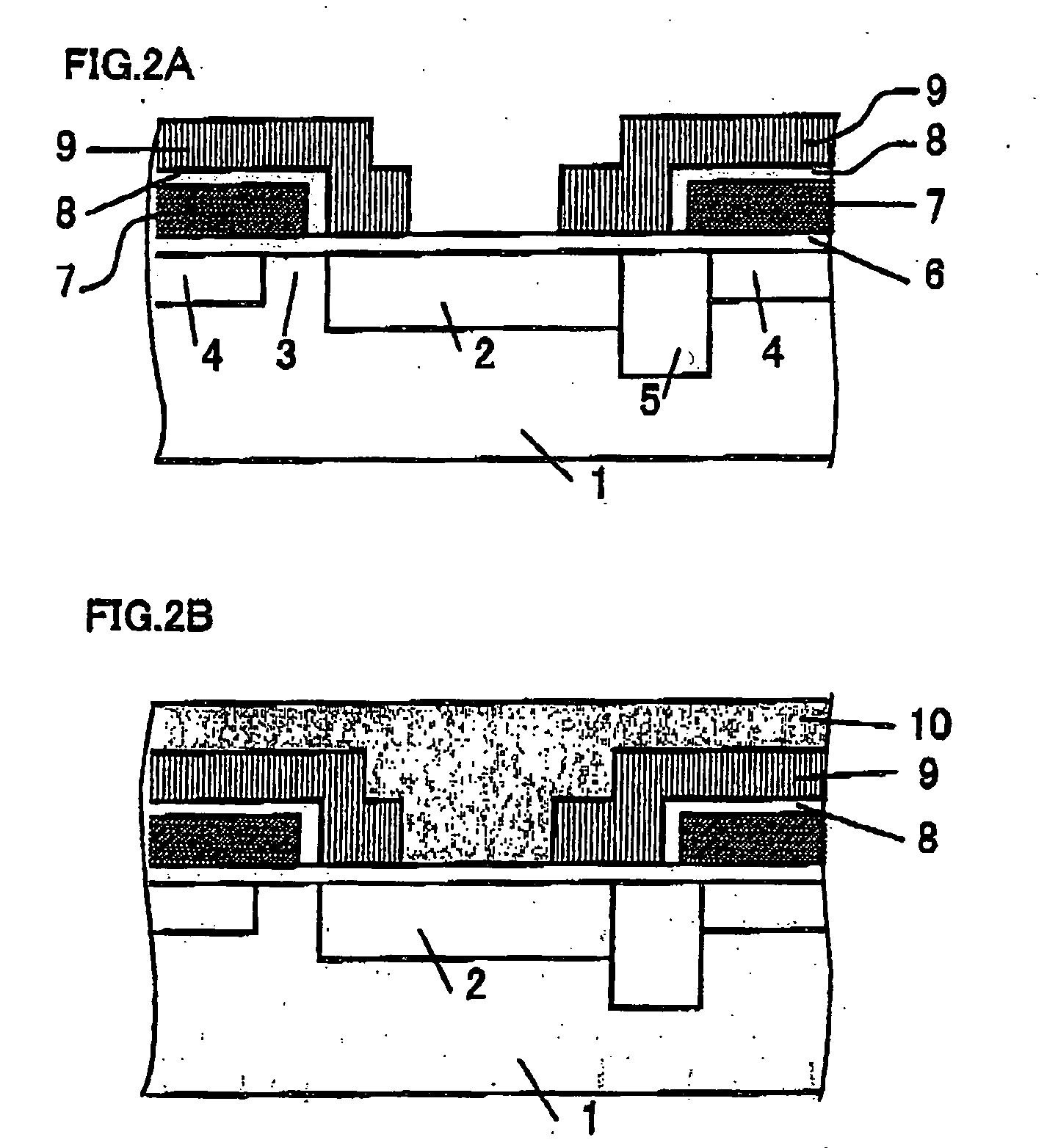

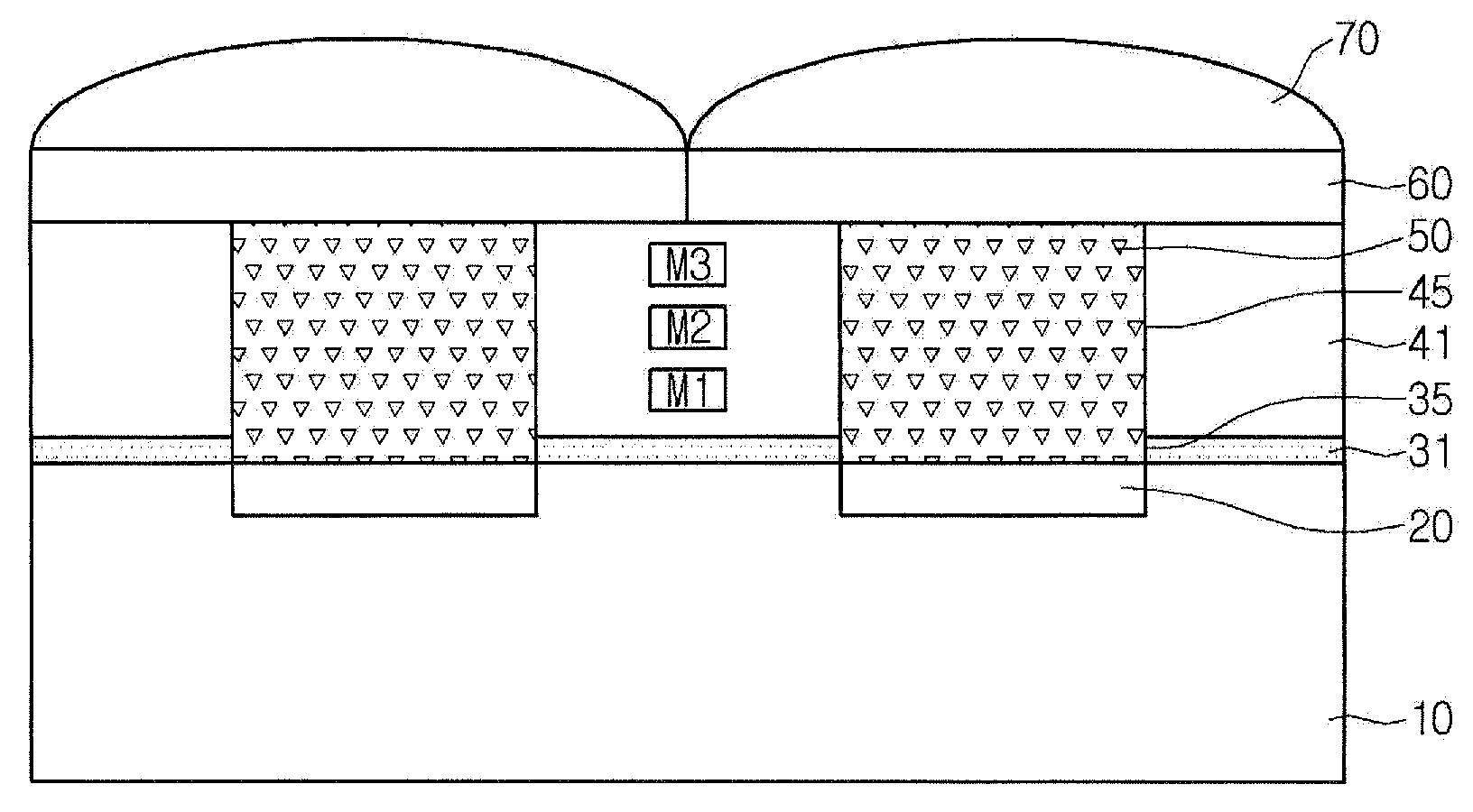

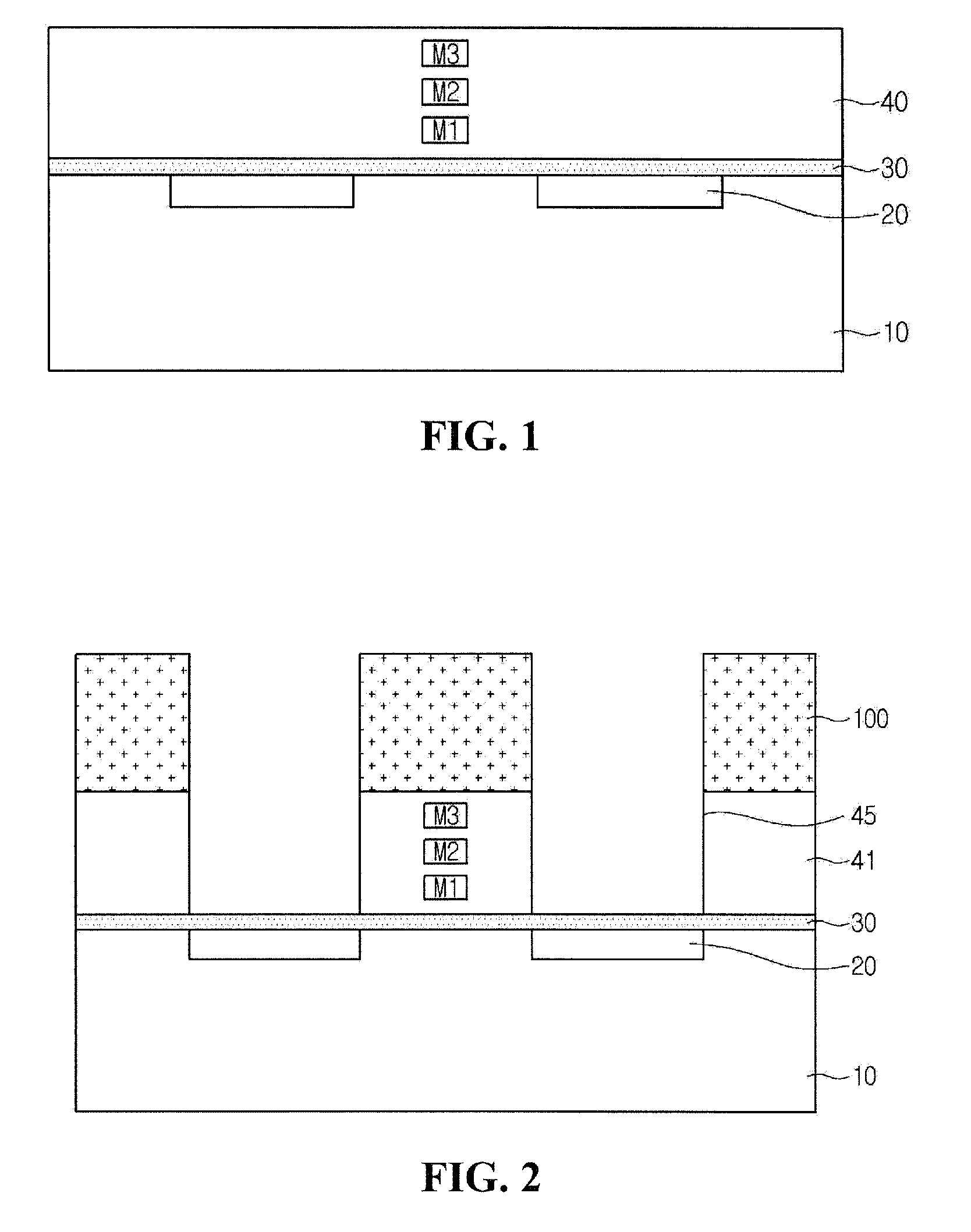

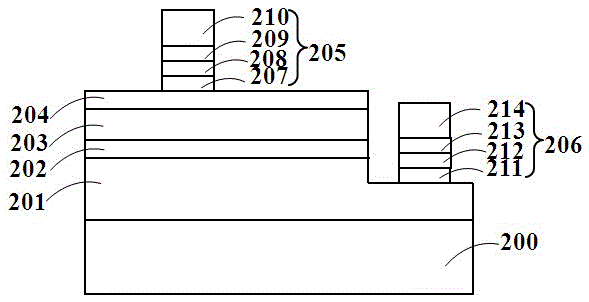

Image Sensor and a Method for Manufacturing Thereof

InactiveUS20090102001A1Improve light concentratingIncrease condensation rateSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPhotodiode

An image sensor according to an embodiment includes a semiconductor substrate including a photodiode; a protective layer pattern having a lower trench that is disposed on the semiconductor substrate to expose the photodiode; an insulating layer pattern having the upper trench that is disposed on the lower trench of the protective layer pattern to expose the photodiode; and a wave guide that is disposed in the lower trench and the upper trench.

Owner:DONGBU HITEK CO LTD

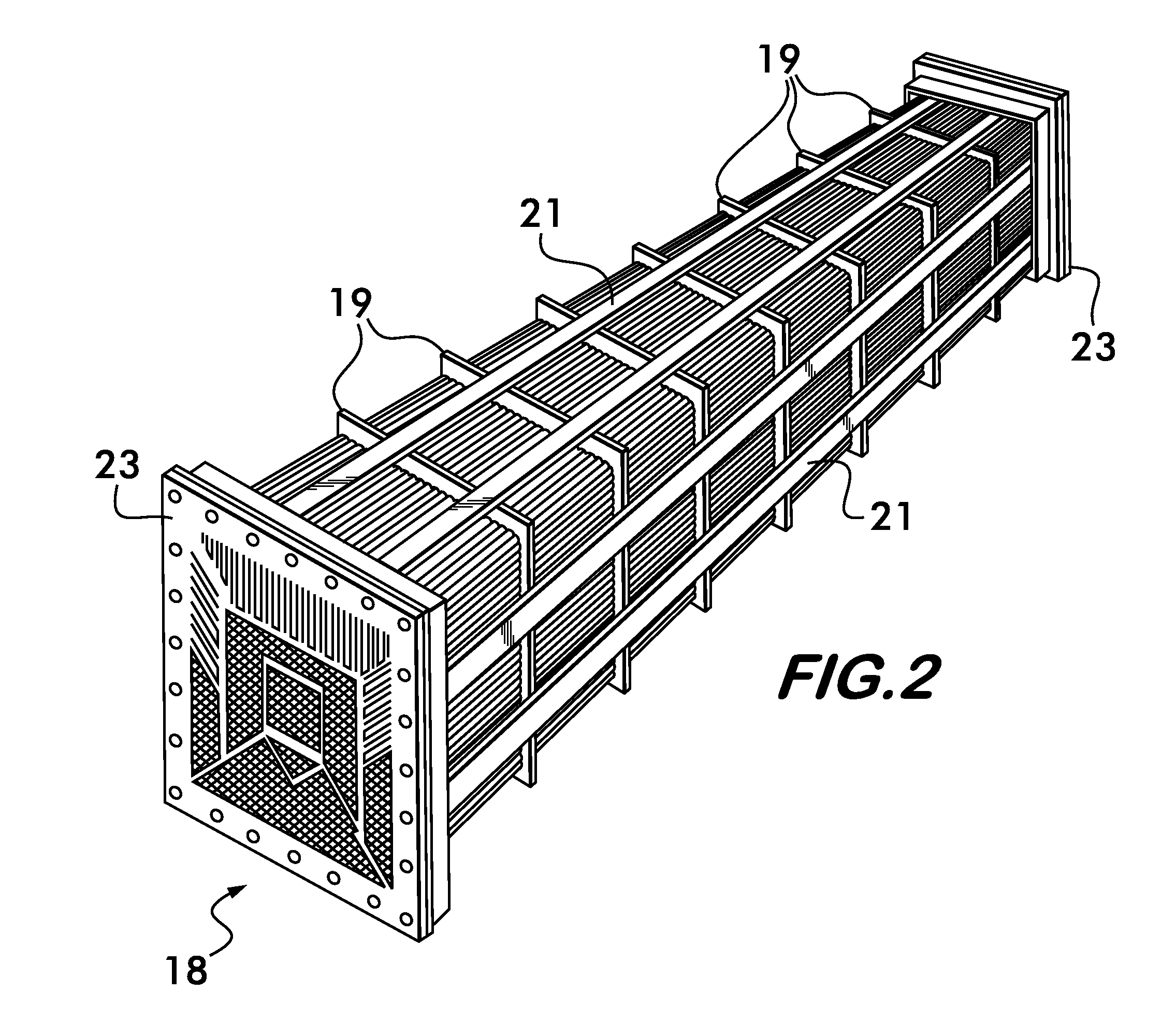

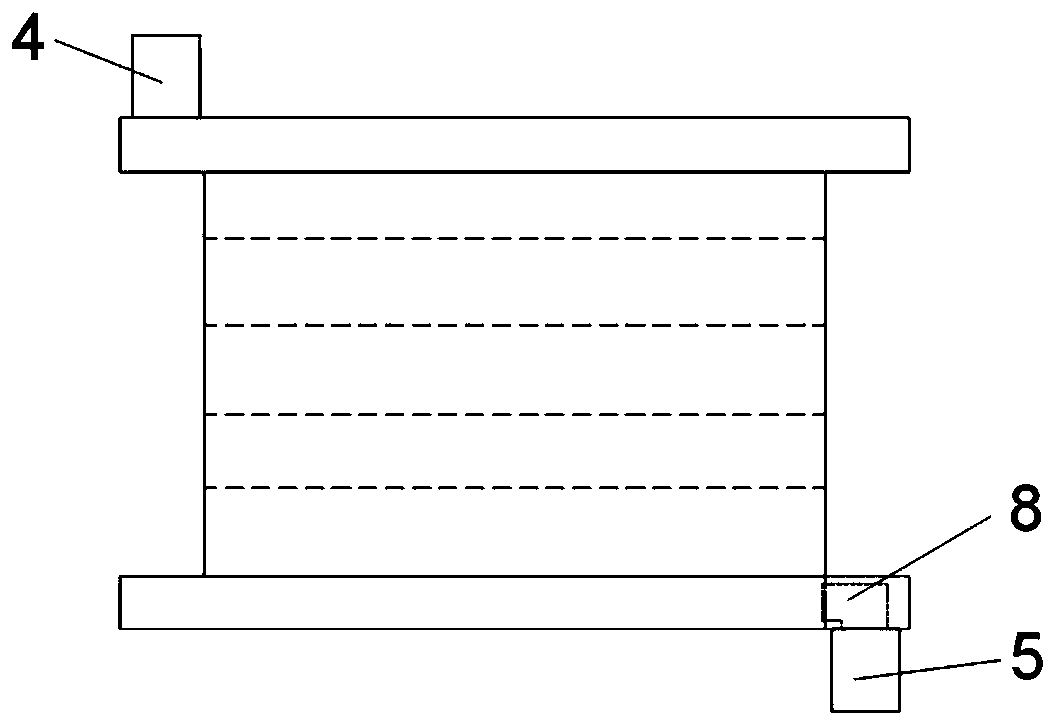

Condenser Shell and Tube Bundle Support Plate Construction

InactiveUS20100314083A1Efficient steam distributionIncrease condensation rateSteam/vapor condensersHeat exchanger casingsEngineeringMechanical engineering

Owner:WILLIAMS GEORGE

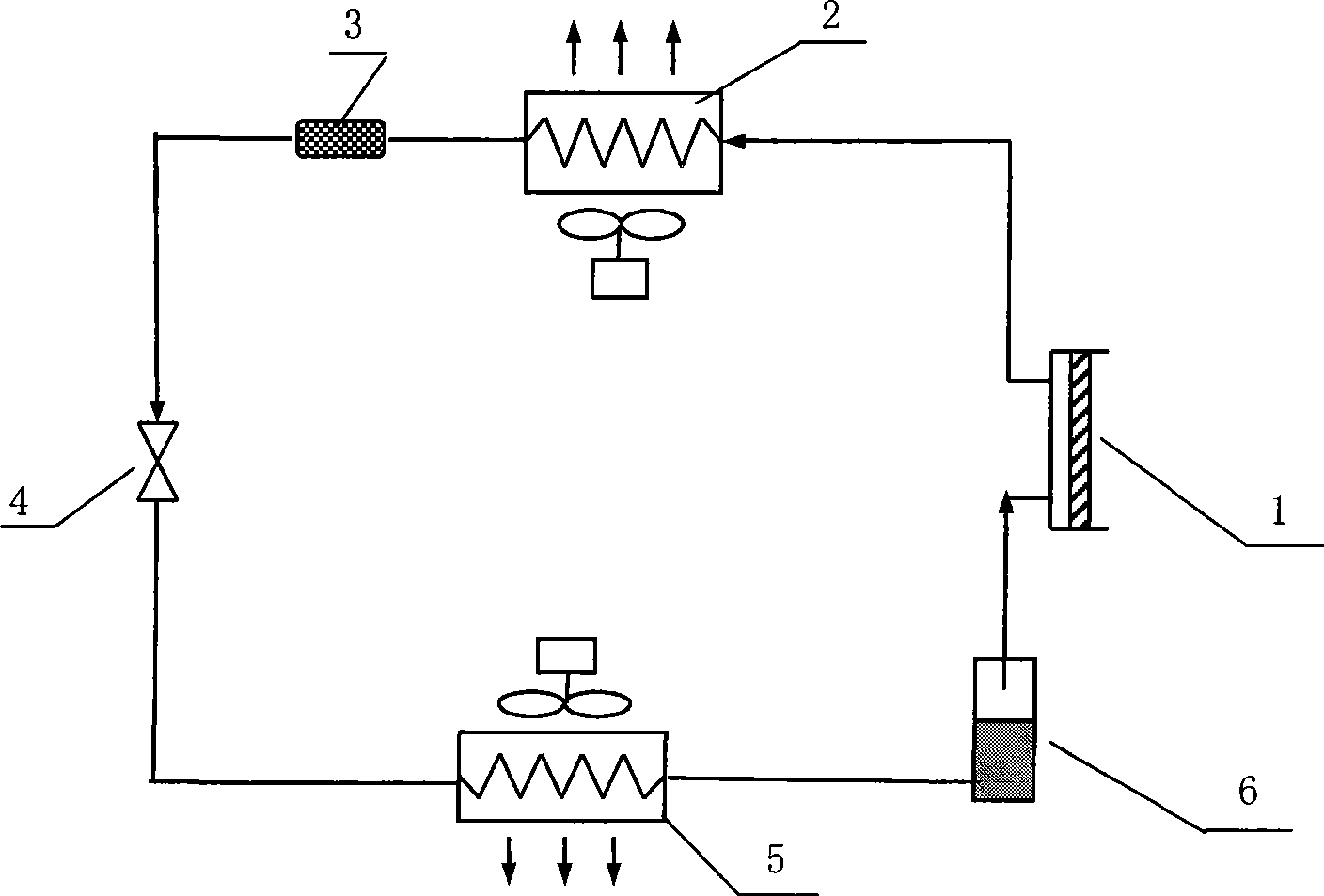

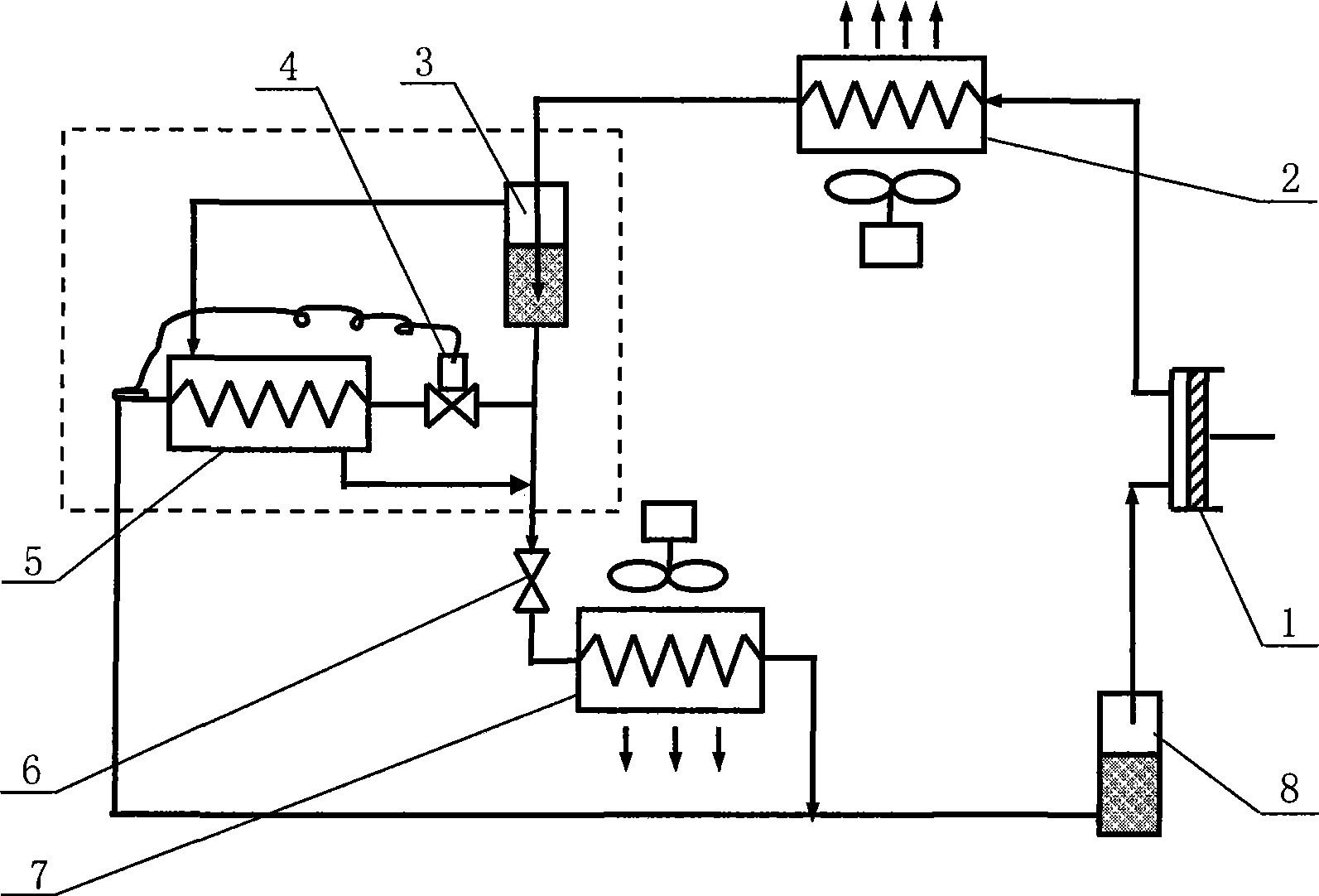

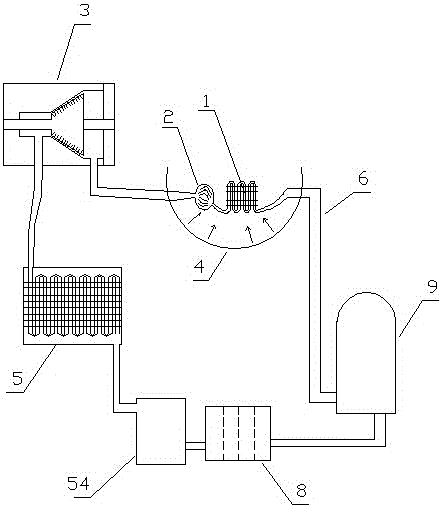

Ultra-high temperature air conditioner cooling cycle system

InactiveCN101476793AReduce working pressure ratioReduce exhaust temperatureCompression machines with several evaporatorsThrottle controlGas phase

The invention provides a refrigeration cycle system for ultrahigh-temperature air conditioners, which adopts a mixed working medium consisting of high-temperature refrigerant and intermediate-temperate refrigerant. The system is characterized in that a compressor, a condenser, a front-end gas-liquid separator, an expansion valve positioned at the liquid-phase outlet end of the front-end gas-liquid separator, an evaporator and a back-end gas-liquid separator are sequentially arranged in a main loop where the compressor is according to the flow direction of the refrigerant; the system is provided with an overlapping loop consisting of an evaporative condenser; an inlet of a condensing branch of the evaporative condenser is communicated with a gas-phase outlet of the front-end gas-liquid separator; an outlet of the condensing branch is connected with an inlet of the expansion valve; an inlet of an evaporation branch of the evaporative condenser is connected with a liquid-phase outlet of the front-end gas-liquid separator through a throttle control valve; an outlet of the evaporative condenser and an outlet of the evaporator are jointly connected to the back-end gas-liquid separator; and an outlet of the back-end gas-liquid separator is communicated with an inlet of the compressor. The system has the advantages that the system adopts the common air-conditioning compressor, can realize large temperature-difference refrigeration in a high-temperature environment, and has good working performance and economic performance in a wide temperature range.

Owner:HEFEI UNIV OF TECH

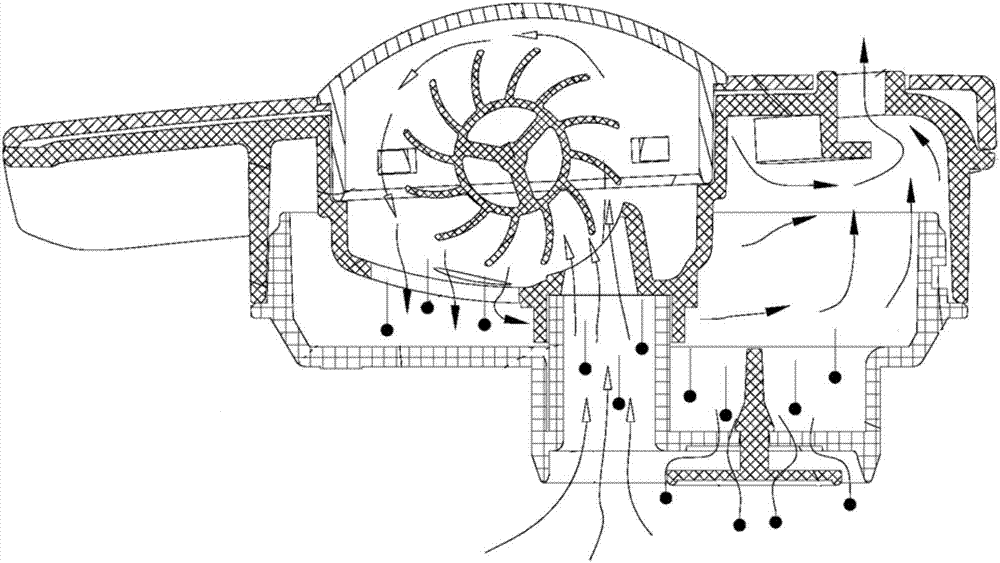

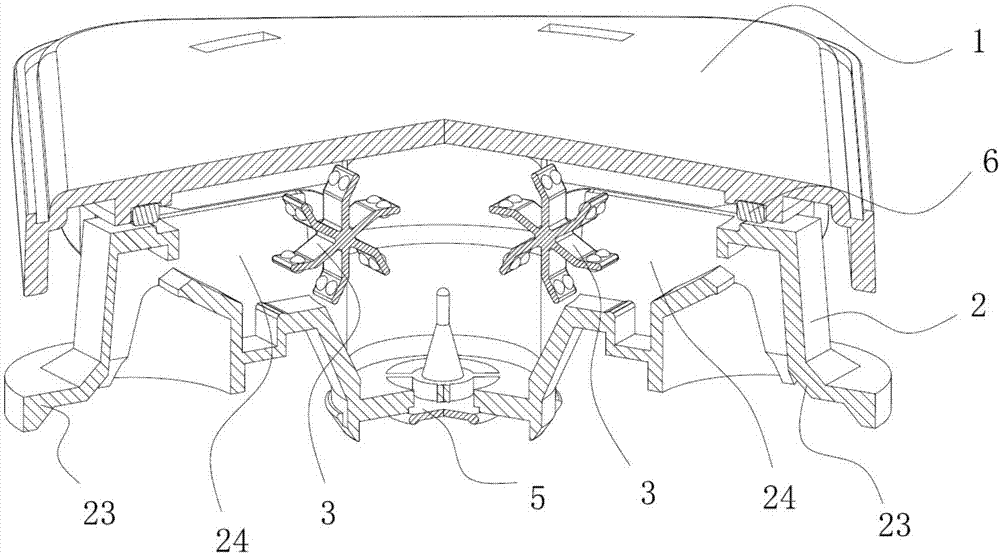

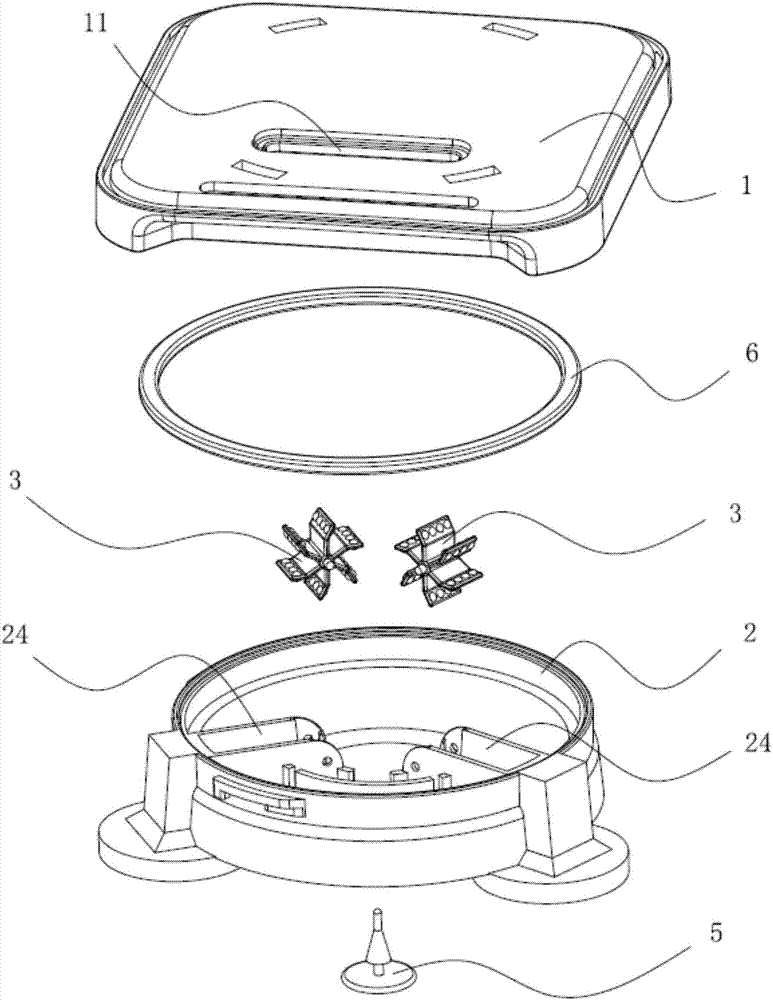

Steam valve assembly and steam heating device

ActiveCN107874600AFully contactedReduce the temperatureSteam cooking vesselsPressure-cookersDischarge efficiencyViscous liquid

The invention discloses a steam valve assembly and a steam heating device, belonging to the technical field of kitchen ware, and being designed aiming at solving the problem of the existing steam valve assembly that viscous liquid is hard to condense to reflow. The steam valve assembly comprises a valve cover, a valve seat and a bubble breaking fan blade, wherein an air outlet is formed in the valve cover, an air inlet communicated with the interior of the steam heating device is formed in the valve seat, the air outlet and the air inlet are respectively communicated with a steam chamber, a steam channel is arranged between the air inlet and the steam chamber, and the bubble breaking fan blade is arranged in the steam channel. The steam heating device comprises the steam valve assembly. According to the bubble breaking fan blade of the steam valve assembly and the steam heating device, formed bubbles in steam with liquid can be broken or crushed, the forming of new bubbles can be prevented, and the temperature of the steam with liquid can be reduced. Gas discharged from the air outlet is mostly common steam instead of steam with liquid, so that the problem that bubbles are formed at the air outlet is solved, the air exhaust temperature is low, the air discharge amount is great and the air discharge efficiency is high.

Owner:GREE ELECTRIC APPLIANCES INC

Method for improving surface light transparency of 3D printing transparent material

InactiveCN106956437AImprove surface light transmissionLow costAdditive manufacturing apparatus3D object support structuresEpoxyViscous liquid

The invention provides a method for improving the light transmittance of the surface of 3D printing transparent materials, which belongs to the technical field of transparent application of 3D printing objects. At normal temperature, the volume ratio of epoxy resin crystal glue and curing agent crystal glue is 2.5~3.5:1 mixing, stirring until the colorless transparent viscous mixed solution; evenly apply the mixed solution obtained in step (1) on the surface of the 3D printed object, the coating thickness is 1mm~3mm; wherein, the 3D printed object Made of transparent material; curing: place the 3D printed object coated in step (2) at a temperature of 60-70°C, and cure for 16-24 minutes, so that the mixed solution is cured on the surface of the 3D printed object. The curable material of the present invention is heated at a high temperature, thereby increasing the coagulation rate and improving the production and processing efficiency. The invention has simple process steps, high processing speed and low cost of raw materials, and is suitable for popularization.

Owner:DALIAN UNIV OF TECH

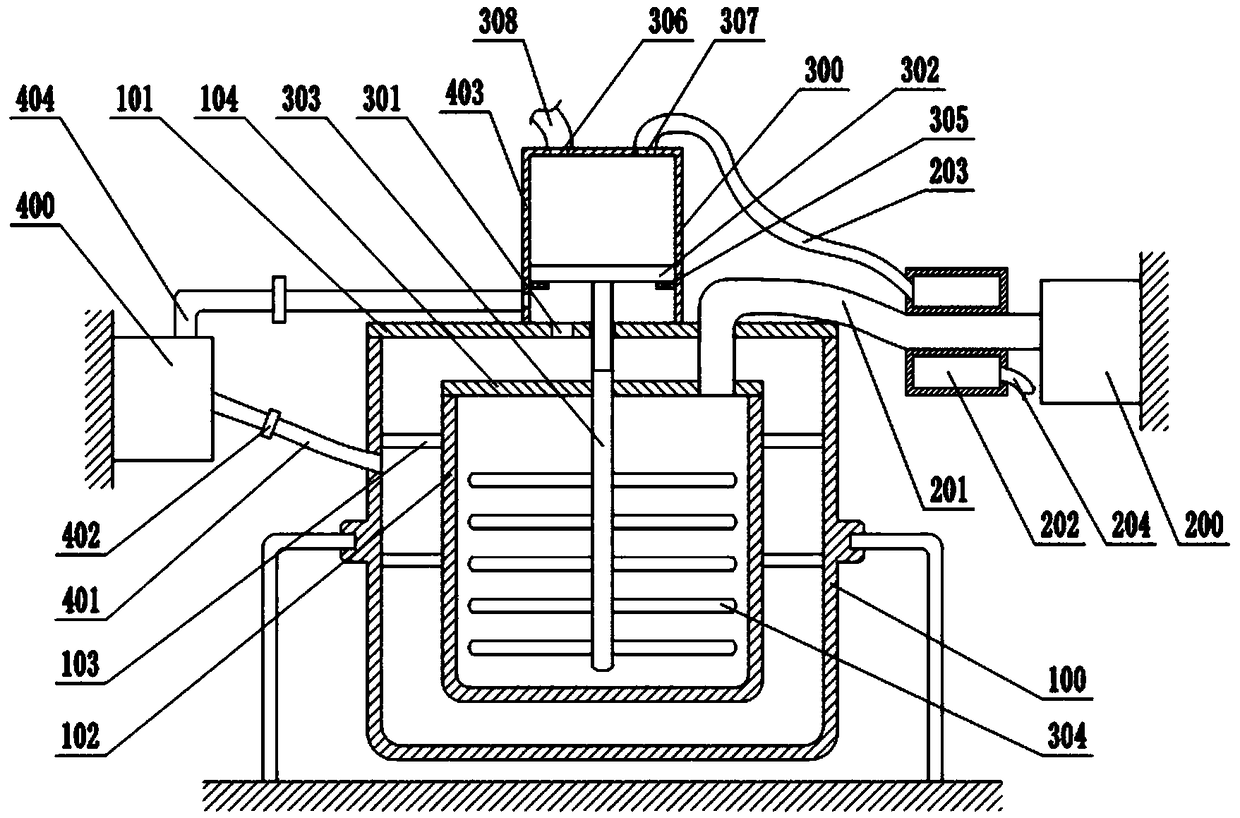

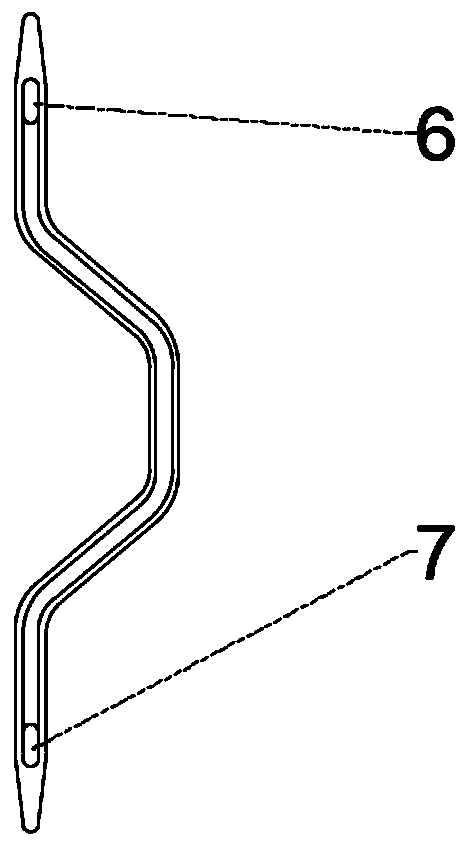

Distilling apparatus for making wine

InactiveCN108660049AIncrease condensation rateHeating evenlyAlcoholic beverage preparationBiochemical engineeringDistillation

The invention relates to the technical field of wine making, and in particular discloses a distilling apparatus for making wine. The distilling apparatus comprises a heating barrel, a wine storage device and a cooling barrel, wherein a first cover body is arranged on the top of the heating barrel, and a heater is arranged at the bottom of the heating barrel; a distillation barrel is fixedly arranged in the heating barrel; a second cover body is arranged on the top of the distillation barrel, and a steam pipe is arranged on the second cover body; a cooling ring is arranged on the steam pipe andis connected with a water inlet pipe and a water outlet pipe; a cylinder body is fixedly arranged on the top of the first cover body; a through hole is formed in the first cover body; the cylinder body is slidably connected with a piston; a piston rod is fixedly arranged at the bottom of the piston; the piston rod extends into the distillation barrel; the piston rod is provided with stirring rods; the cylinder body is provided with a diaphragm, and the bottom of the diaphragm is fixed on the piston; the side wall of the cylinder body is provided with an air outlet hole; the top of the cylinder body is provided with a water inlet one-way valve and a water outlet one-way valve; the water inlet pipe is communicated with the water outlet one-way valve; a drainage pipe is arranged at the waterinlet one-way valve. The distilling apparatus for making wine solves the problem that in the prior art, alcohol in distilled grains is not fully distilled out, so that waste is caused.

Owner:贵州省仁怀市茅台镇永泰酒业股份有限公司

LED chip electrode, LED chip structure and fabrication methods of LED chip electrode and LED chip structure

InactiveCN105633224AExpand coverageIncrease migration rateSemiconductor devicesEngineeringPhotoresist

The invention discloses an LED chip electrode, an LED chip structure and fabrication methods of the LED chip electrode and the LED chip structure. The fabrication method of the LED chip electrode comprises the following steps: forming a negative photoresist on a substrate, defining an electrode pattern and removing the negative photoresist in a pattern region to form an electrode window; forming a reflecting structure on the electrode window; and forming a metal surface layer on the reflecting structure by an ion source-assisted plating method and finishing coating the top surface and the side walls of the reflecting structure. Therefore, the coating range of the reflecting structure is increased; the technological process is effectively simplified; the fabrication cost is saved; and the method is suitable for large-scale production. In further, the metal surface layer is formed by the ion source-assisted plating method to prepare an electrode structure which is compact, small in internal stress and smooth in surface. Therefore, the reliability of an LED is improved.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Washing machine and control method thereof

ActiveUS20130219741A1Increase capacityAdd support structureDrying solid materials with heatOther washing machinesEngineeringMechanical engineering

A washing machine and a control method therefore are disclosed. The washing machine includes a cabinet (10); a tub (100) fixed to the cabinet (10); a drum (300) rotatably provided in the tub (100); a dry duct (20) which heats air exhausted from the tub (100) a predetermined temperature, to re-supply the heated air to the tub (100); condensation unit (170) which condenses moisture on at least a predetermined area of an inner circumferential surface of the tub (100) by heat-exchanging external air of the cabinet (10) with at least predetermined area of an outer circumferential surface of the tub (100); and sensing unit (410) which senses the amount of condensate generated in the tub (100). A washing machine and a control method thereof are disclosed. The washing machine includes a cabinet; a tub fixed to the cabinet; a drum rotatably provided in the tub; a dry duct which heats air exhausted from the tub a predetermined temperature, to re-supply the heated air to the tub; condensation unit which condenses moisture on at least a predetermined area of an inner circumferential surface of the tub by heat-exchanging external air of the cabinet with at least predetermined area of an outer circumferential surface of the tub; and sensing unit which sense the amount of condensate generated in the tub.

Owner:LG ELECTRONICS INC

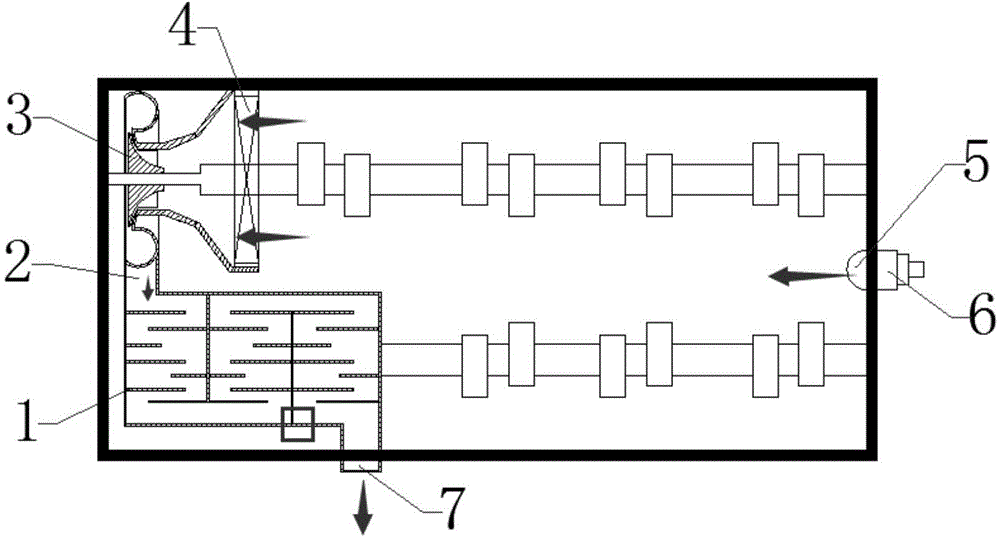

Low energy consumption water-saving type flue gas de-whitening device and method

PendingCN108434922AReduce energy consumptionReduce the temperatureGas treatmentLighting and heating apparatusCold airWater saving

The invention provides a low energy consumption water-saving type flue gas de-whitening device. The device comprises a heat exchanger, a fan, a flue gas duct, a hot air tube, a mixed air duct and centrifugal separation tubes, the two sides of the heat exchanger are respectively connected with the fan and the hot air tube, and the centrifugal separation tubes are vertically arranged in the heat exchanger; the flue gas duct communicated with the centrifugal separation tubes is arranged at the top of the heat exchanger, the mixed air duct communicated with the centrifugal separation tubes is arranged at the bottom of the heat exchanger, the hot air tube is communicated with the mixed air duct and then communicated with a chimney, and inlet vanes are arranged at the tops of the centrifugal separation tubes. The invention further provides a low energy consumption water-saving type flue gas de-whitening method. The method comprises the following steps that flue gas enters the centrifugal separation tubes in the heat exchanger from the flue gas duct, cold air is transported to the heat exchanger through the fan, and heat exchange is conducted on the flue gas and the cold air. The device utilizes natural air (cold air) for heat exchange to achieve the purpose of saving energy consumption; the device adopts a cyclone centrifugal pipeline, and the de-whitening efficiency is improved.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD +1

Labyrinth type oil-gas separation chamber with additionally mounted turbine

ActiveCN104131860AReduce the temperatureIncrease flow rateMachines/enginesCrankcase ventillationEngineering plasticCrankcase

The invention relates to a labyrinth type oil-gas separation chamber with an additionally mounted turbine. The labyrinth type oil-gas separation chamber comprises a labyrinth oil-gas separator, a pressure adjusting valve, a non-woven filter element and the turbine. The pressure adjusting valve is arranged on the wall of the labyrinth type oil-gas separation chamber, and mixed oil mist from a crankcase enters the labyrinth type oil-gas separation chamber through the pressure adjusting valve and a mixed oil mist inlet. The turbine is assembled at a free end of a camshaft, the nonwoven filter element capable of filtering oil and water in mixed gas is arranged in an inlet of the turbine, and an outlet of the turbine is connected with the labyrinth type oil-gas separation chamber through a connector. An indented baffle made of engineering plastics is arranged in the labyrinth type oil-gas separator. The temperature of flowing oil mist in a labyrinth is effectively decreased by rotation of the turbine, flow rate of the oil mist is increased, condensation speed of elaioplast is increased, and pressure at a gas outlet is increased.

Owner:HANGZHOU DIANZI UNIV

Methods and means to collect water vapors

InactiveUS20070090202A1Increase water evaporation rateIncrease condensation rateLiquid surface applicatorsGeneral water supply conservationSprinkler systemCollection system

Owner:HSIA CHIH YU

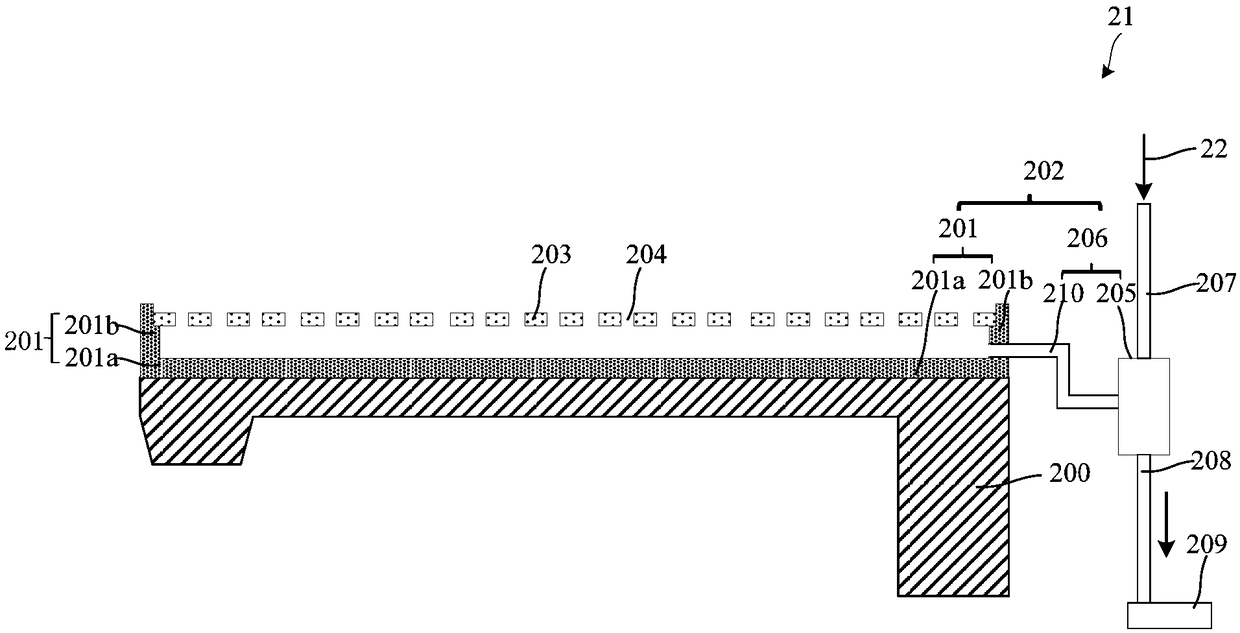

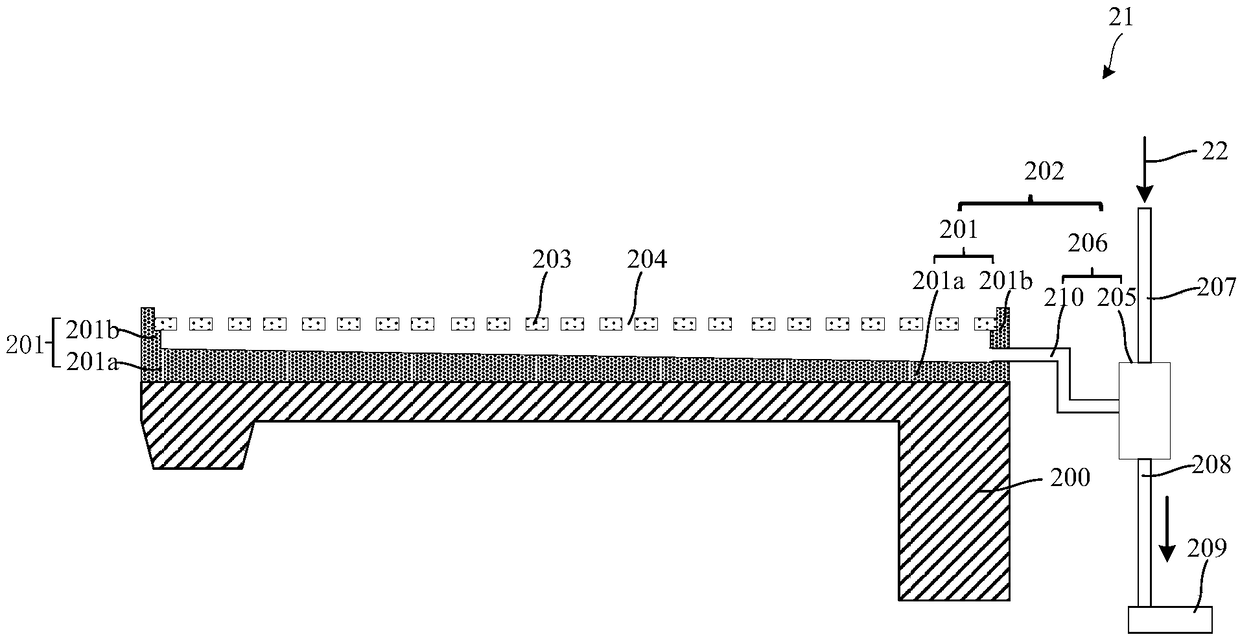

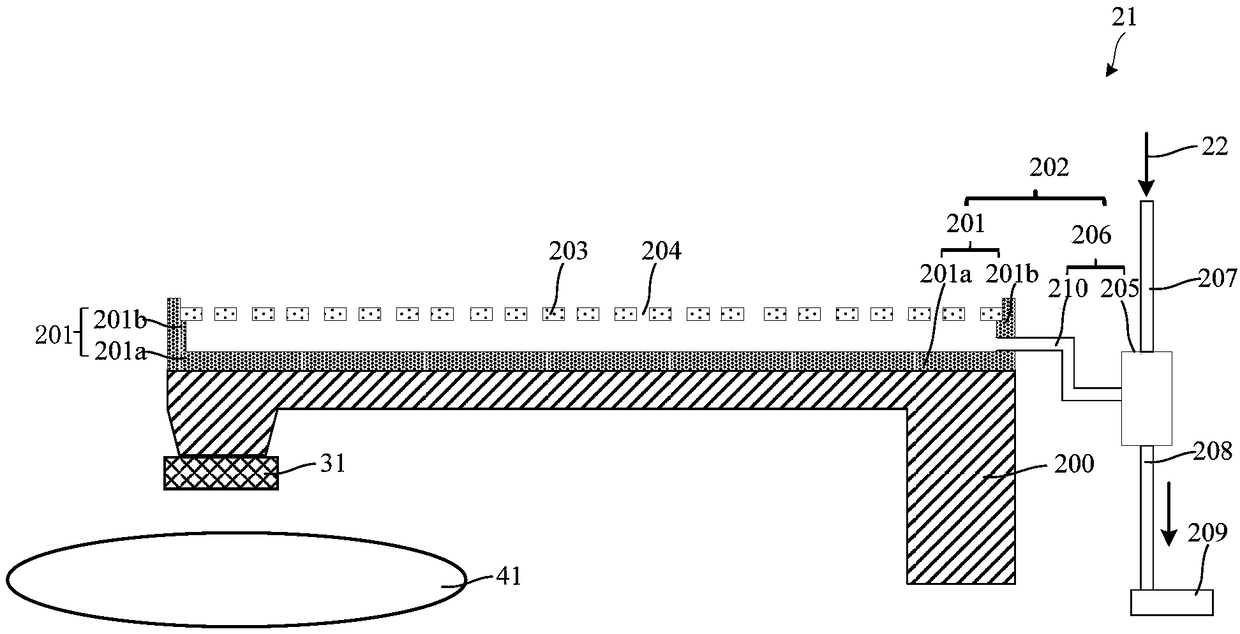

Moving arm, chemical mechanical grinding trimmer and grinding equipment

InactiveCN109333335APrevent fallingAvoid contaminationLapping machinesGrinding/polishing apparatusEngineeringLiquid drop

Disclosed are a moving arm, a chemical mechanical grinding trimmer and grinding equipment. The moving arm comprises a shell wrapping an arm body, and a liquid storage device located on the surface ofthe shell. The liquid storage device is used for storing liquid drops accumulating on the shell and for discharging the stored liquid drops into a lower discharge pipe. According to the moving arm, the liquid drops on the arm can be prevented from dropping onto a lower grinding pad.

Owner:YANGTZE MEMORY TECH CO LTD

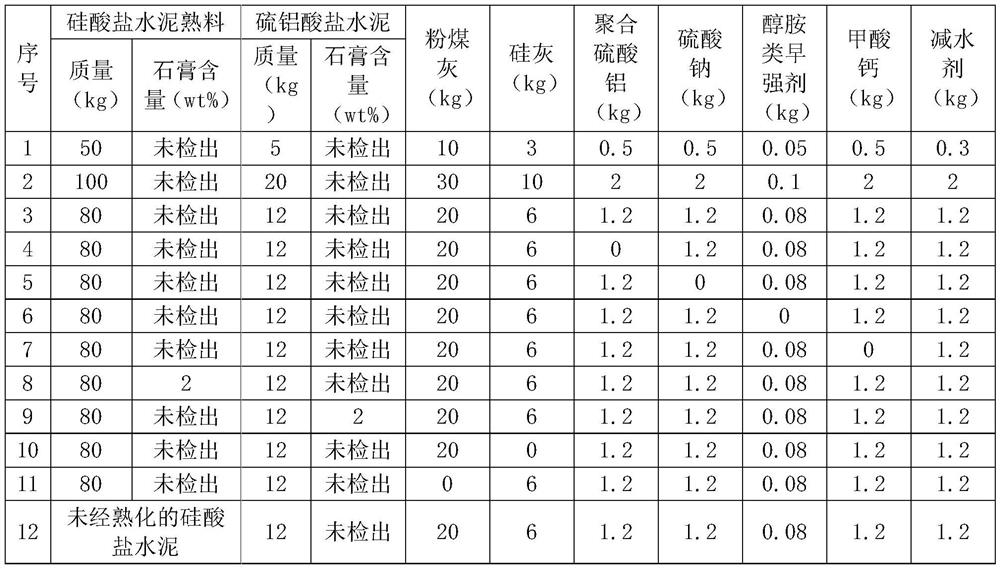

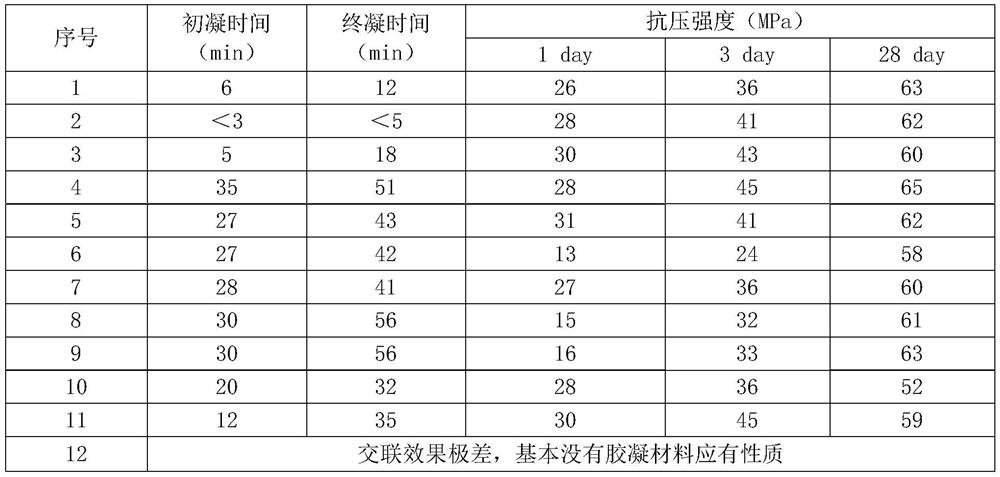

Quick-hardening cementing material as well as preparation method and application thereof

PendingCN112876180AIncreased condensation rateImprove compactnessBuilding repairsSilica fumeMineralogy

The invention relates to a quick-hardening cementing material and a preparation method and application thereof. The quick-hardening cementing material comprises the following raw materials in parts by mass: 50-100 parts of Portland cement; 10 to 30 parts of fly ash; 3 to 10 parts of silica fume; 5 to 20 parts of sulphoaluminate cement; 0.5 to 2 parts of an accelerator; 0.5 to 3 parts of an inorganic early strength agent; 0.05 to 0.1 part of an alcohol amine early strength agent; 0.5 to 2 parts of calcium formate; and 0.3-2 parts of a water reducing agent. The Portland cement and the sulphoaluminate cement basically do not contain gypsum. In order to control the setting rate within a proper range, the Portland cement without gypsum and the sulphoaluminate cement are matched, and the accelerator, the inorganic-organic early strength agent and the calcium formate are matched, so that the initial setting time can be shortened and relatively high strength can be achieved as soon as possible under the condition that the later strength is not influenced.

Owner:山东晟世达科技有限公司

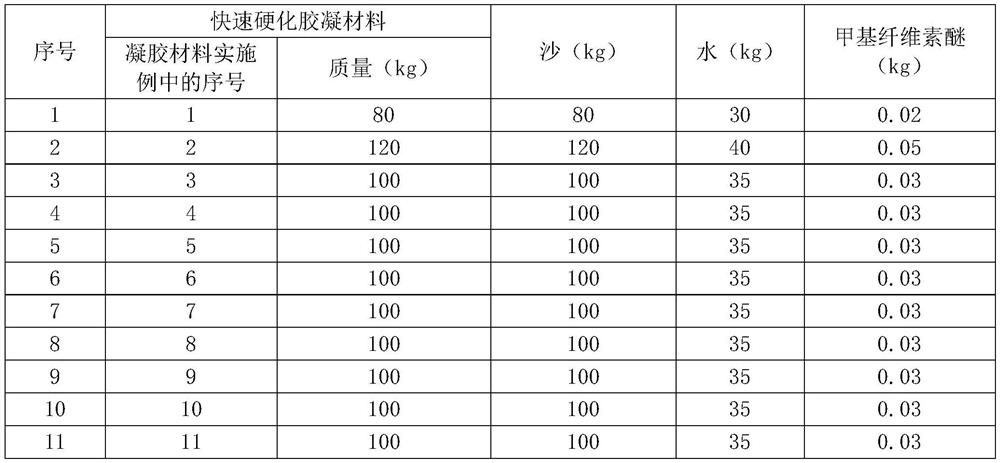

Process for improving SO2 desorption efficiency of desulfurization absorbent

ActiveCN112452109AReduce loadImprove desorption efficiencyGas treatmentDispersed particle separationThermodynamicsPhysical chemistry

The invention discloses a process for improving SO2 desorption efficiency of a desulfurization absorbent. The process comprises the following steps: a, heating amine-rich liquid absorbing SO2 gas, andfeeding the heated amine-rich liquid into a low-pressure desorption tower for pre-desorption; b, feeding the pre-desorbed secondary lean amine solution into a high-pressure desorption tower for desorption; c, reducing SO2 contained in the lean amine output after desorption of the high-pressure desorption tower to be belower than 5g / L, or increasing the total desorption efficiency of SO2 in the amine-rich liquid input in the step a to be greater than 90%; pressurizing the high-pressure desorption steam output by the high-pressure desorption tower, and adopting as a heat source of steam required by steam stripping of SO2 in the desorption amine-rich liquid of the low-pressure desorption tower. According to the invention, a double-tower double-effect and low-pressurization two-time deep desorption process is adopted, the content of SO2 contained in the output lean amine liquid is less than 5g / L or the total desorption efficiency of SO2 in the amine-rich liquid is more than 90%, the operation is stable, the power consumption is low, the live steam consumption is saved by 30-50%, the desorption efficiency is improved by 4-12%, and the investment operation comprehensive cost is reducedby 20-40%; and ultra-low emission of desulfurization can be realized.

Owner:双盾环境科技有限公司

Solid phase synthesis method for adrenomedullin (27-52)

InactiveCN101165067AMild reaction conditionsLess side effectsHormone peptidesPeptide preparation methodsReaction rateTarget peptide

The present invention discloses solid phase synthesis process of adrenal medullarin (27-52). The synthesis process includes the first solid phase Fmoc polypeptide synthesis to graft protective amino acid Fmoc-Ala-OH onto resin, connecting the rest protective amino acids successively, cutting down the synthesized coarse peptide with peptide cutting reagent, and final separating and purifying to obtain the adrenal medullarin (27-52) as the target peptide. The present invention has mild reaction condition, high reaction rate, less side reactions, easy purification, high yield, no corrosion to the equipment and no environmental pollution.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

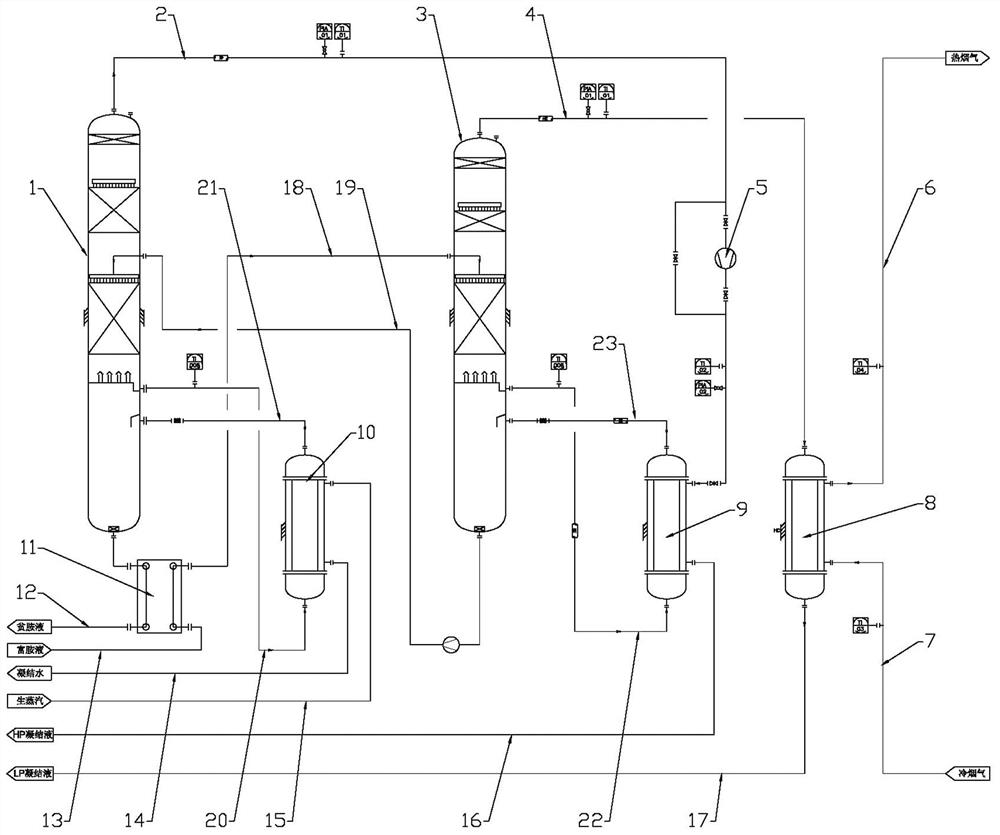

Condensation type demister having vanes with non-uniform wettability and preparation method of vanes

ActiveCN110772925AAmplify tiny dropletsUp to sizeGas treatmentUsing liquid separation agentMetal alloyDemister

The invention discloses a condensation type demister having vanes with non-uniform wettability and a preparation method of vanes. The condensation type demister comprises multiple sets of condensationdemisting vanes arranged at intervals, an upper frame, a lower frame, a cooling water inlet welded to the lower frame and a cooling water outlet welded to the upper frame, wherein the upper frame andthe lower frame are used for fixing the vanes and providing cooling water channels; the vanes are each of a hollow corrugated structure; and through holes connected with a cooling water outlet pipe and a cooling water inlet pipe are formed in the upper portions and the lower portions of the vanes respectively; and the vanes are metal or metal alloy vanes. According to the invention, the surfacesof the vanes are covered with mask plates; the exposed surfaces of the vanes are modified with a low-surface-energy substance for treatment after rough structures are constructed on the exposed surfaces, so the exposed surfaces have super-hydrophobicity and the covered parts have hydrophilicity; and therefore, the vanes have the characteristic of hydrophilicity-hydrophobicity combined non-uniformwettability.

Owner:XI AN JIAOTONG UNIV

Solar heat energy power system based on multistage pressurization condensation

InactiveCN106438239AImprove heat conversion rateReduce pressureFrom solar energySteam engine plantsThermal energySolar light

The invention discloses a solar heat energy power system based on multistage pressurization condensation. The solar heat energy power system based on multistage pressurization condensation comprises a heat collecting device, a gasifying device, a turbine, a condensing device and a one-way hydraulic pump for realizing circulating communication through circulating pipes; circulating working mediums are filled in the circulating pipes; the heat collecting device and the gasifying device are mounted in a solar light collecting cover; the condensing device is mounted out of the solar light collecting cover, and includes a condensing pipe, a cooling fan and multiple pressurization mechanisms; the cooling fan is mounted above or below the condensing pipe; and the pressurization mechanisms are uniformly distributed at the middle part of the condensing pipe stage by stage. The solar heat energy power system based on multistage pressurization condensation is quicker in condensing speed, can reduce the condensation energy discharge and improve the heat energy conversion efficiency, and is stable in operation and adjustable in power.

Owner:郭远军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com