Condenser Shell and Tube Bundle Support Plate Construction

a technology of condenser shell and support plate, which is applied in the direction of indirect heat exchangers, steam/vapor condensers, lighting and heating apparatus, etc. it can solve the problems of tube damage, support plate which promotes longitudinal flow, and does not possess adequate strength to withstand stresses, so as to reduce maintenance costs, improve the efficiency of steam distribution, and enhance the effect of condensate ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

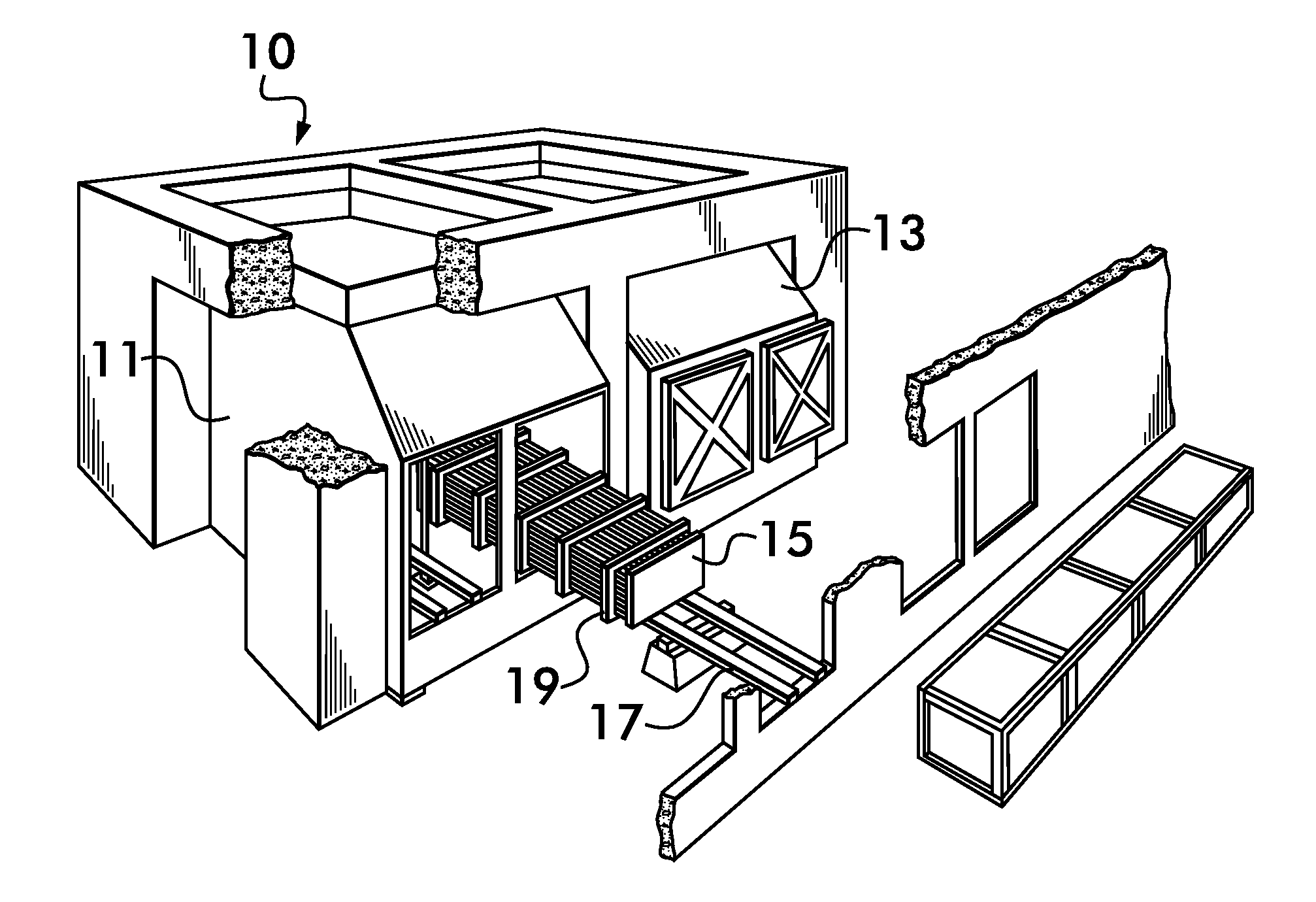

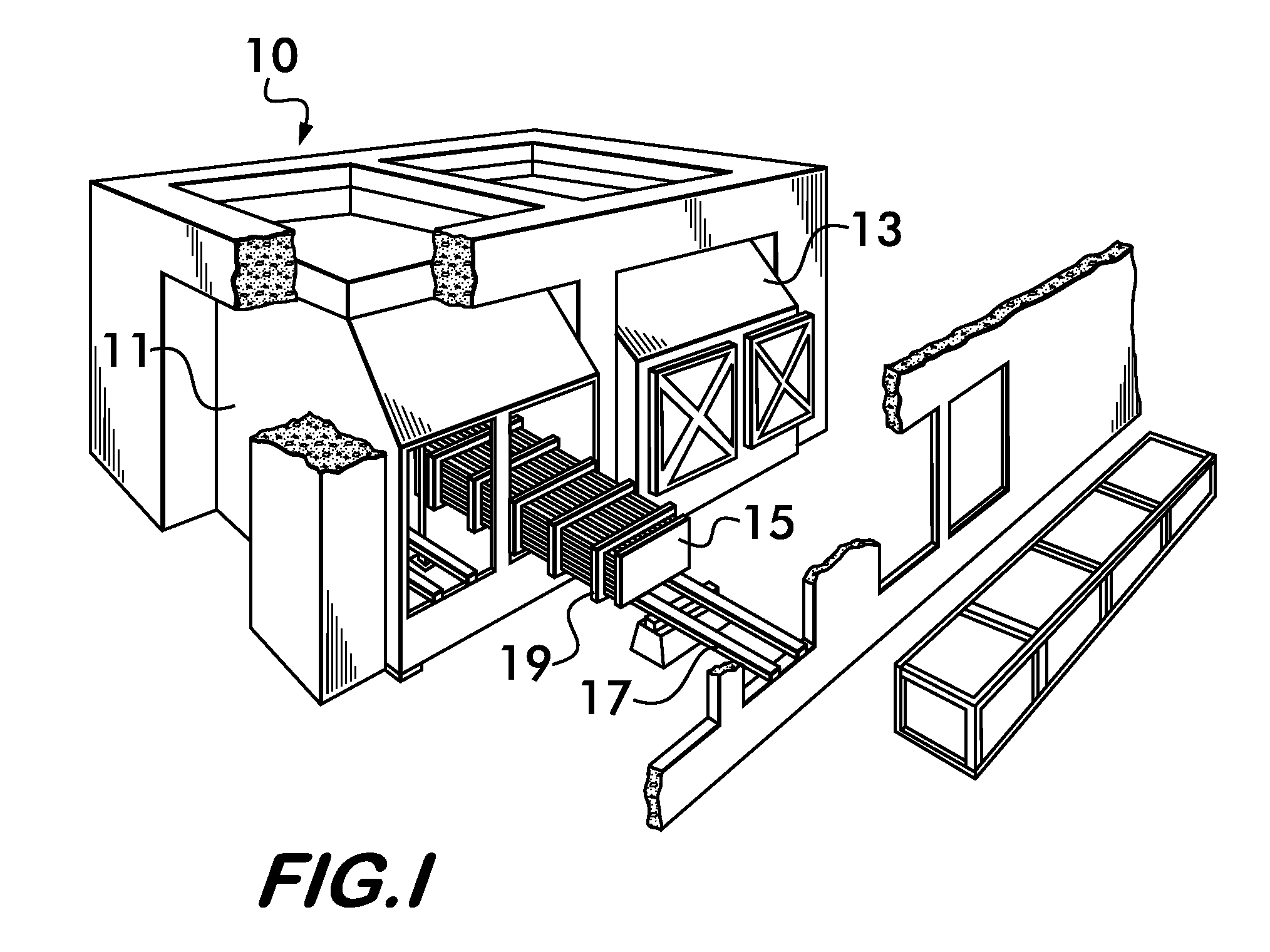

[0015]Referring now to FIG. 1, an exterior view of the installation 10 which includes two steam surface condenser shells 11 and 13 utilizing the support system of the present invention is shown. This Figure depicts the tube bundle 15 being slidably removed from one of the condenser shells 11 with the tube bundle 15 riding on rails 17 which carry the tube bundles by their support plates 19.

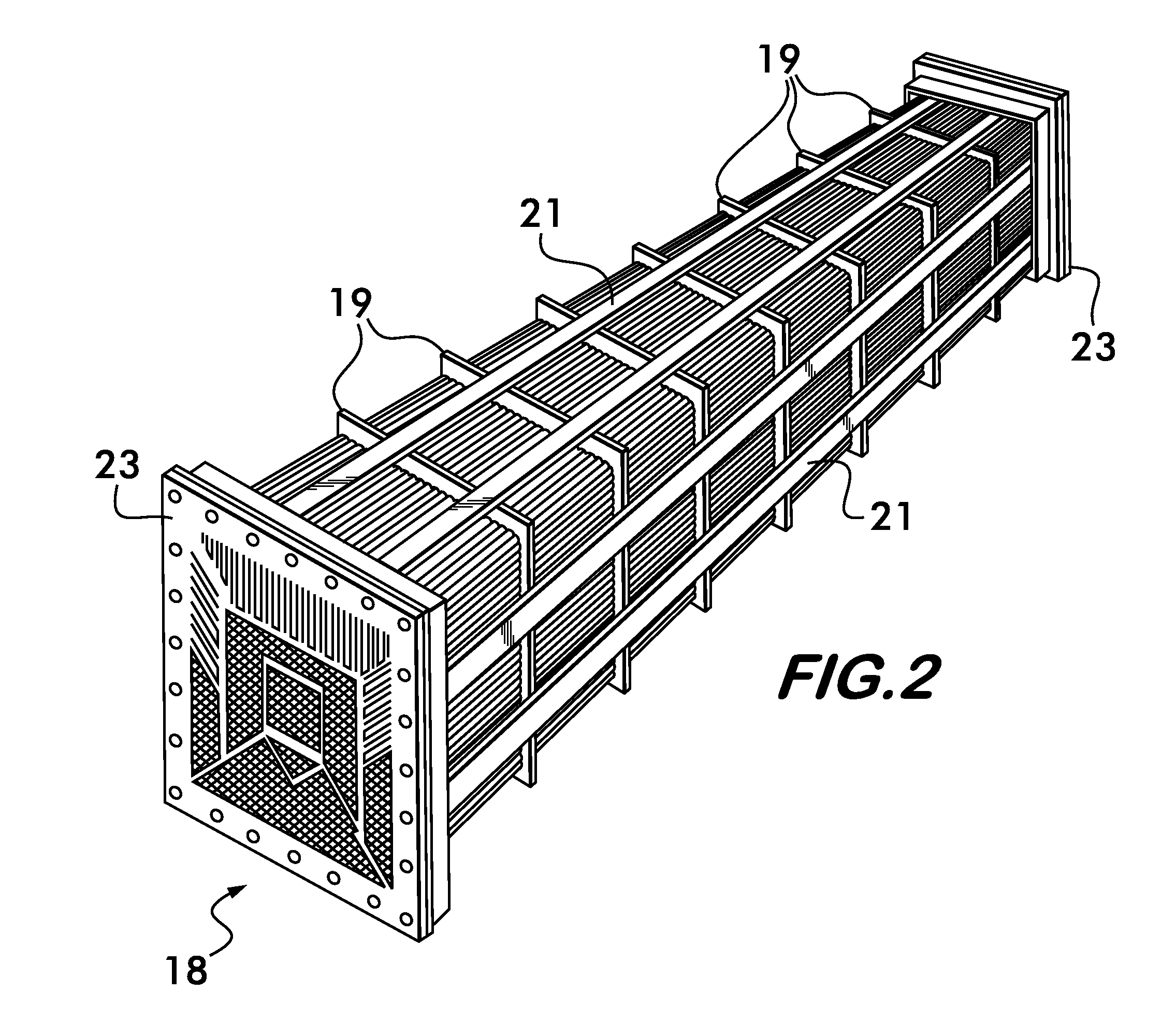

[0016]Referring now to FIG. 2, a typical tube bundle module is shown with the individual tube support plates 19 being supported by a pair of longitudinal framework members 21 along each side. The framework members extend between end plates 23 so that the individual tubes are supported along their entire length.

[0017]Regarding FIG. 3, the need in the art for high performance steam condensers with proper internal support of the shell sidewalls 31 (shown in phantom), is provided by the framework shown. The shell reinforcement of the invention keeps the shell sidewalls from collapsing inwardly due to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com