Patents

Literature

38results about How to "Improve heat conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

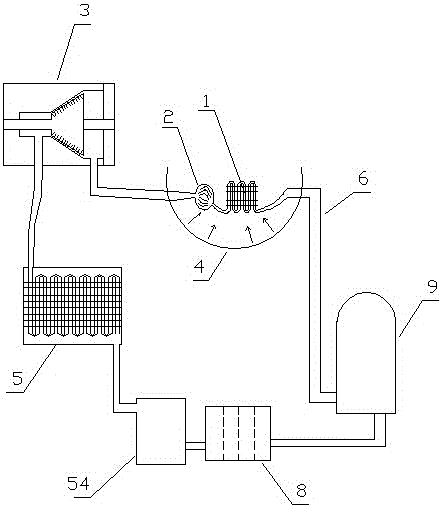

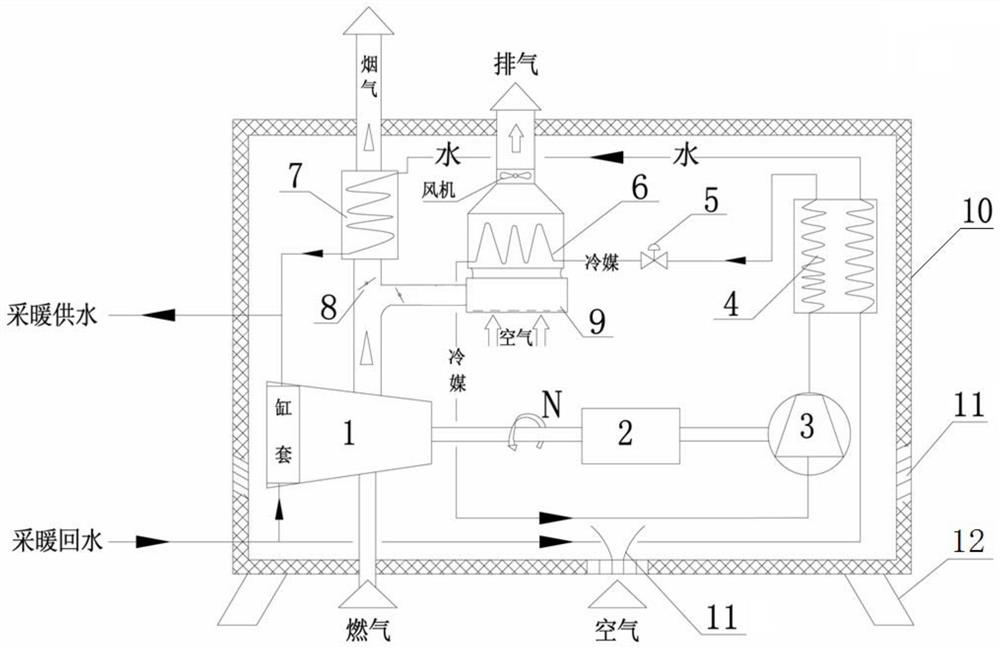

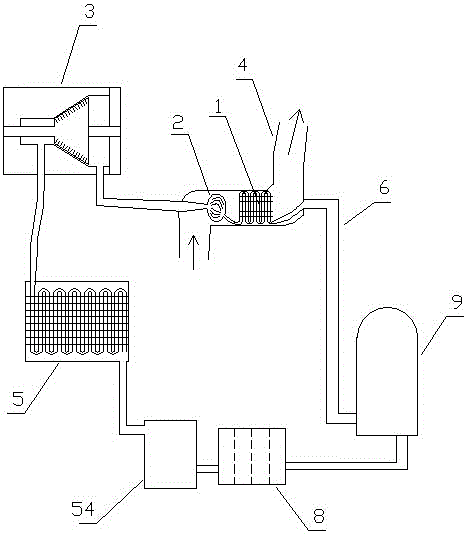

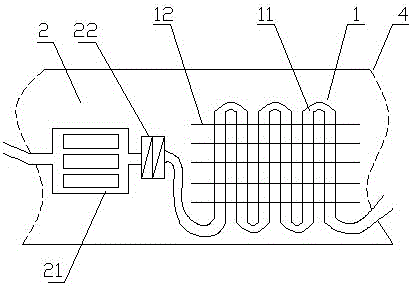

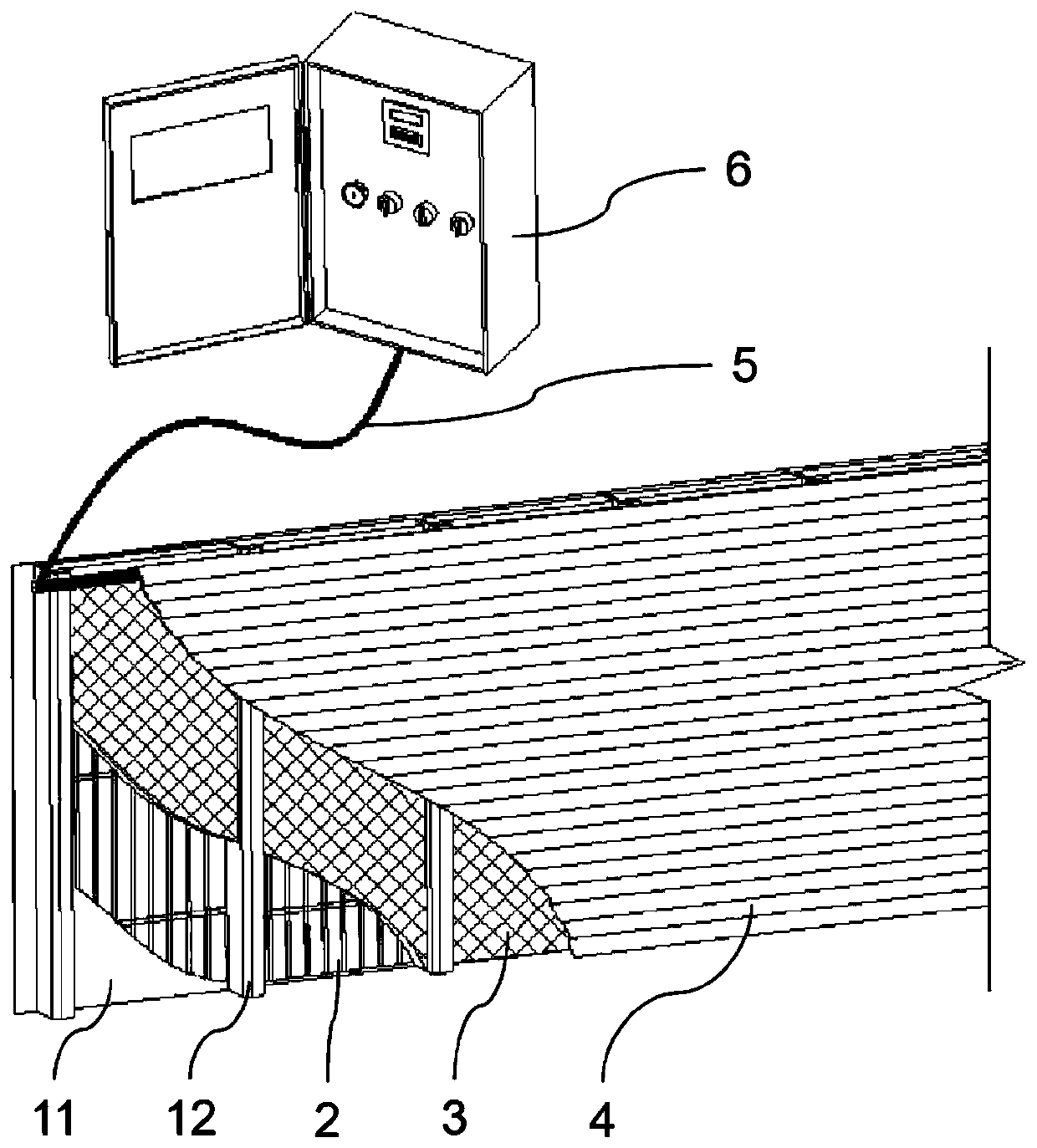

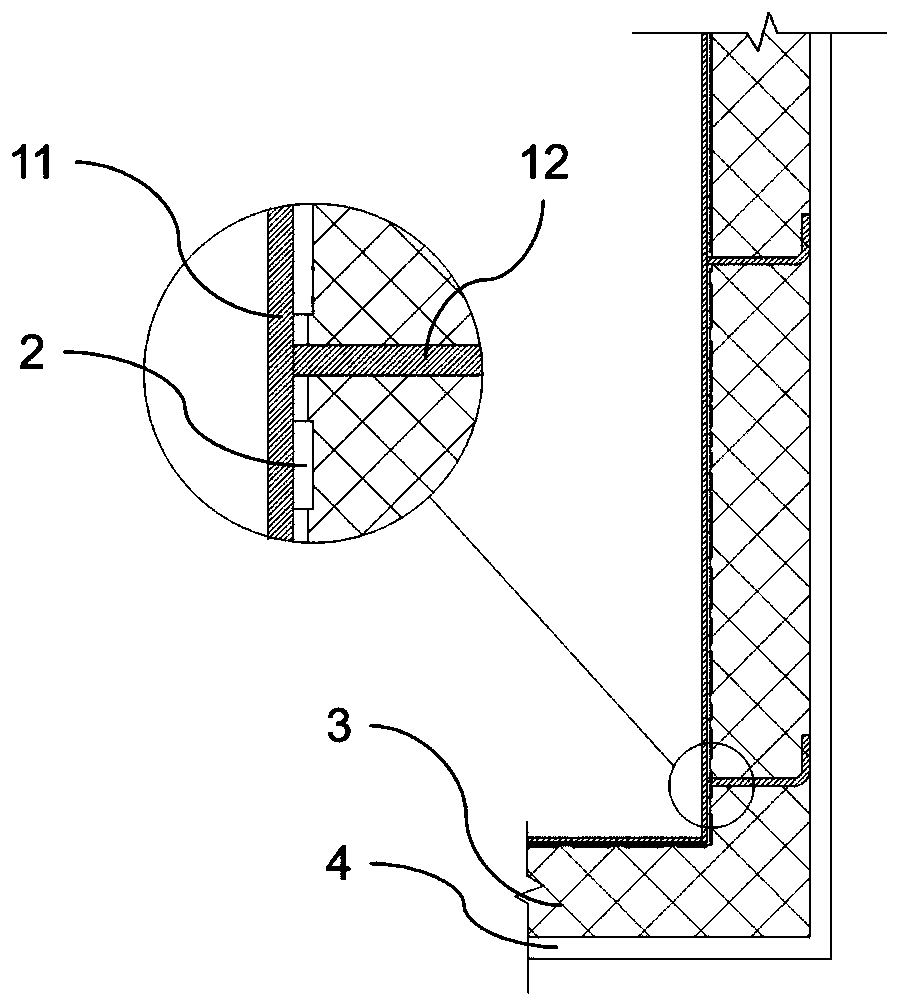

Gas-driven air source heat pump heat supply unit for central heating system

ActiveCN105841390AImprove heat conversion rateReduce pollutionFluid heatersMechanical apparatusEngineeringInternal combustion engine

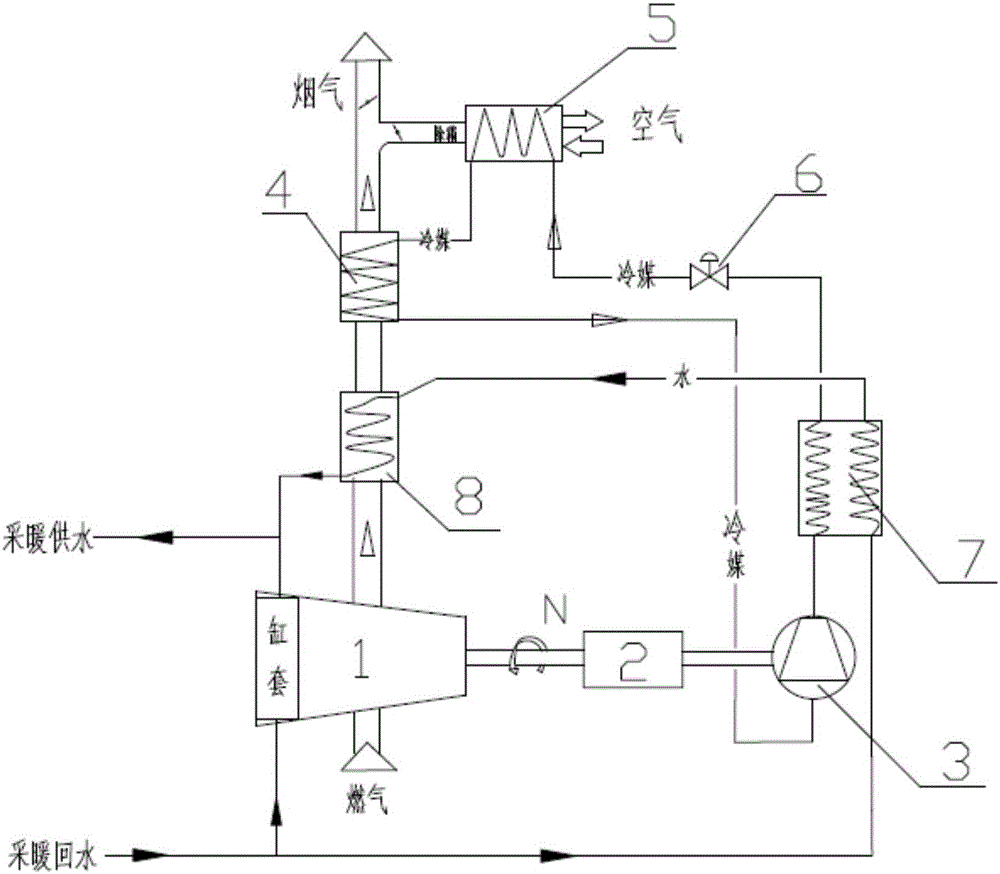

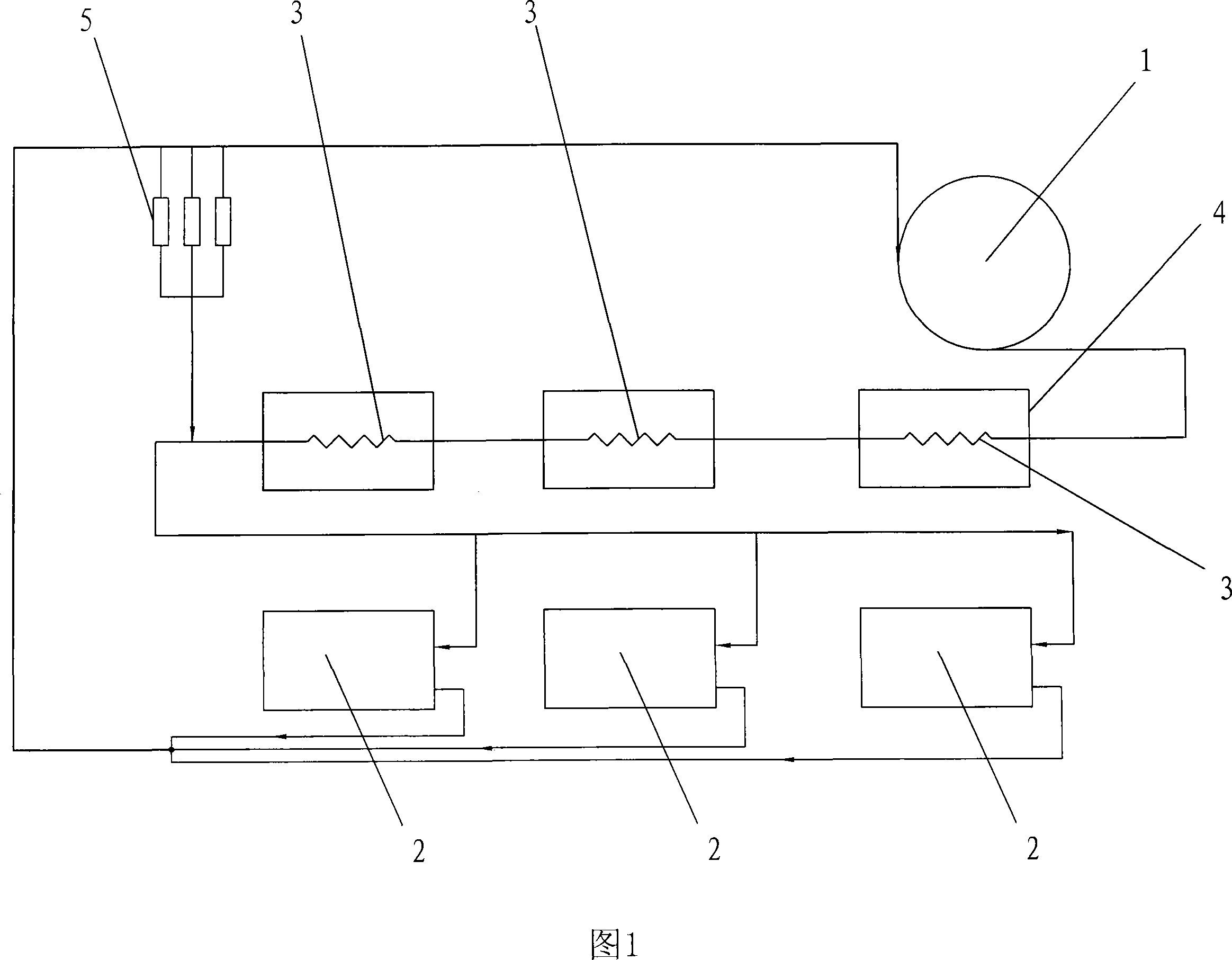

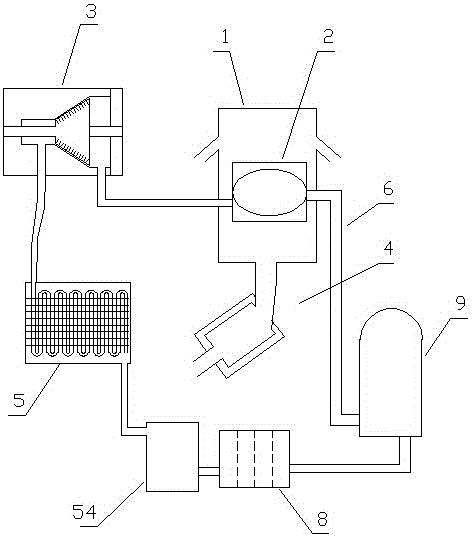

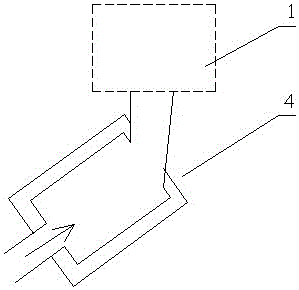

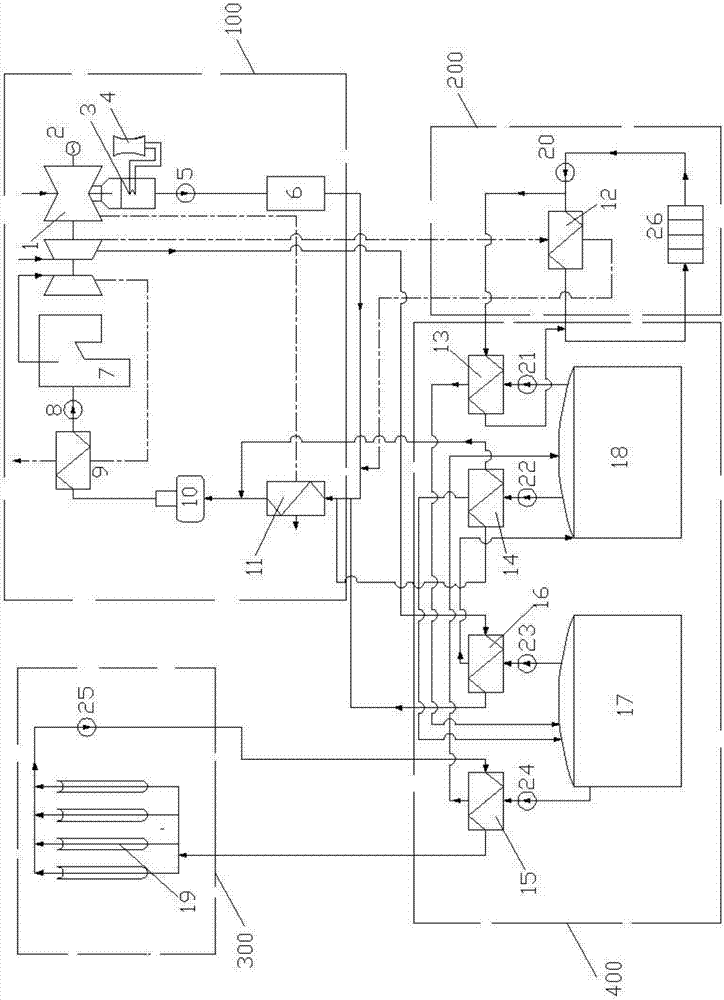

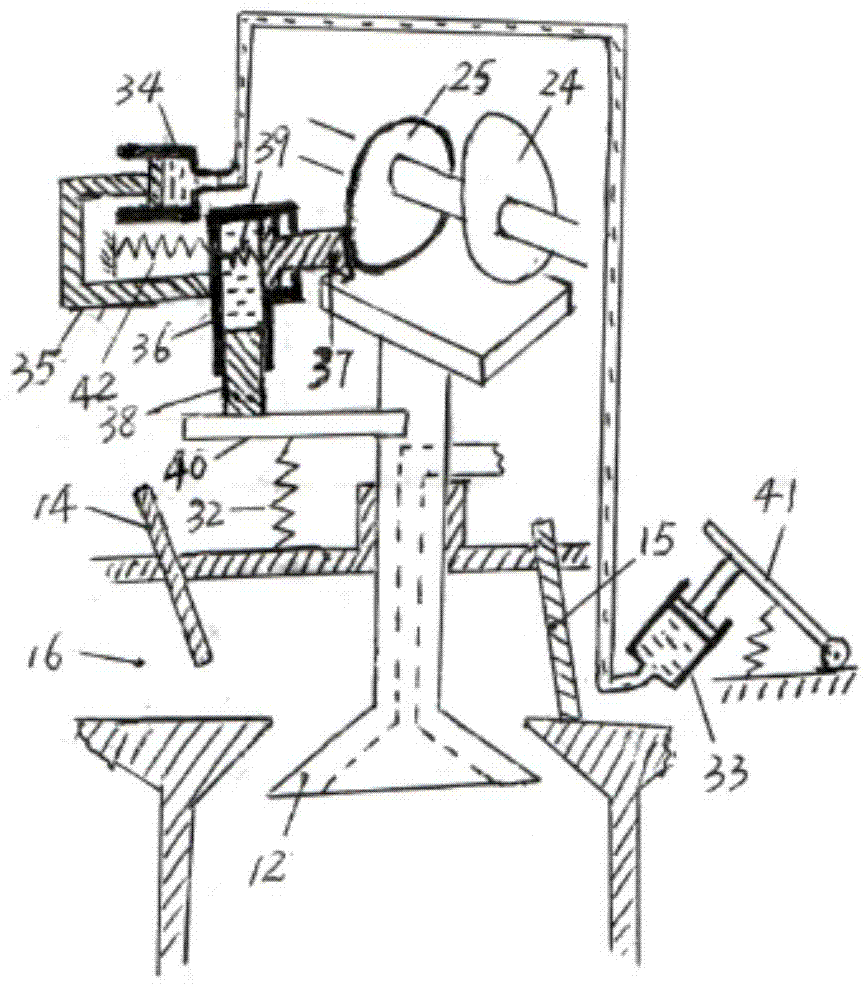

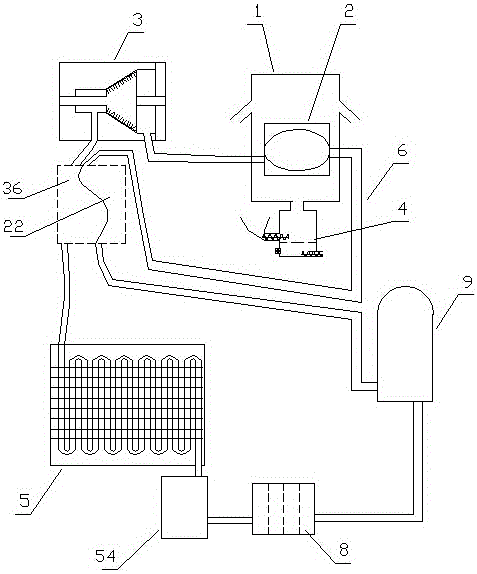

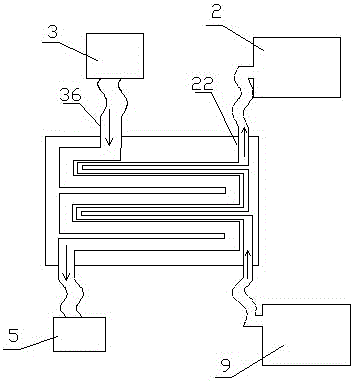

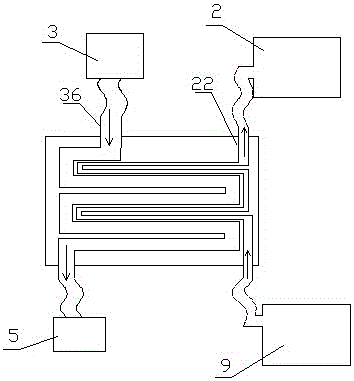

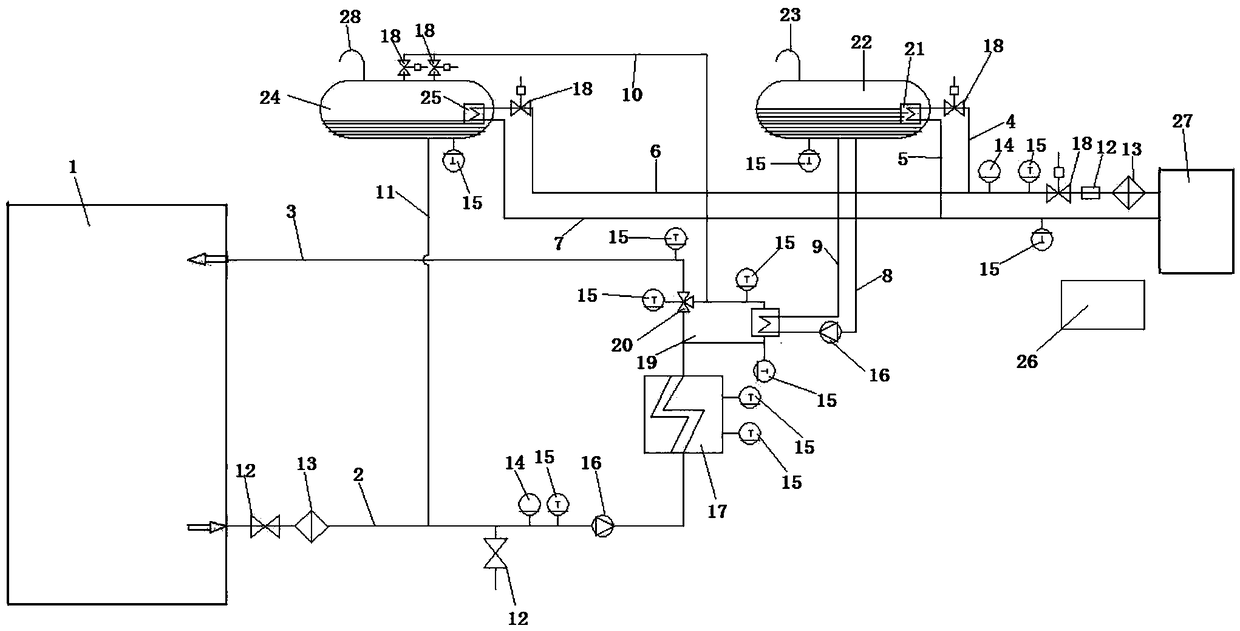

The invention discloses a gas-driven air source heat pump heat supply unit for a central heating system. The gas-driven air source heat pump heat supply unit for the central heating system comprises an internal combustion engine. The internal combustion engine, a compressor, a condenser and a flue gas waste heat recoverer are connected in sequence, so that a gas-heating hot water system is formed. The condenser is further connected with a first evaporator which is connected back to the compressor, so that an air source heat pump refrigerant system is formed. The flue gas waste heat recoverer is arranged on a flue gas pipeline of the internal combustion engine. A water outlet pipeline of the flue gas waste heat recoverer is connected with a water supply pipeline of a heat supply system, and the heat supply system supplies circulating high-temperature water to users. The internal combustion engine is adopted to drive a heat pump to pump heat in air, then waste heat continues to be applied to the heat supply system, the integral heat energy conversion rate can be 200%, and the heat energy conversion rate is high. The outlet water temperature of the condenser can be 60 DEG C or over by increasing the condensation pressure, water discharged out of the condenser further absorbs flue gas heat through the flue gas waste heat recoverer arranged on the exhaust pipeline of the internal combustion engine, and the water supply temperature can be up to 85 DEG C.

Owner:山东生态家园环保股份有限公司

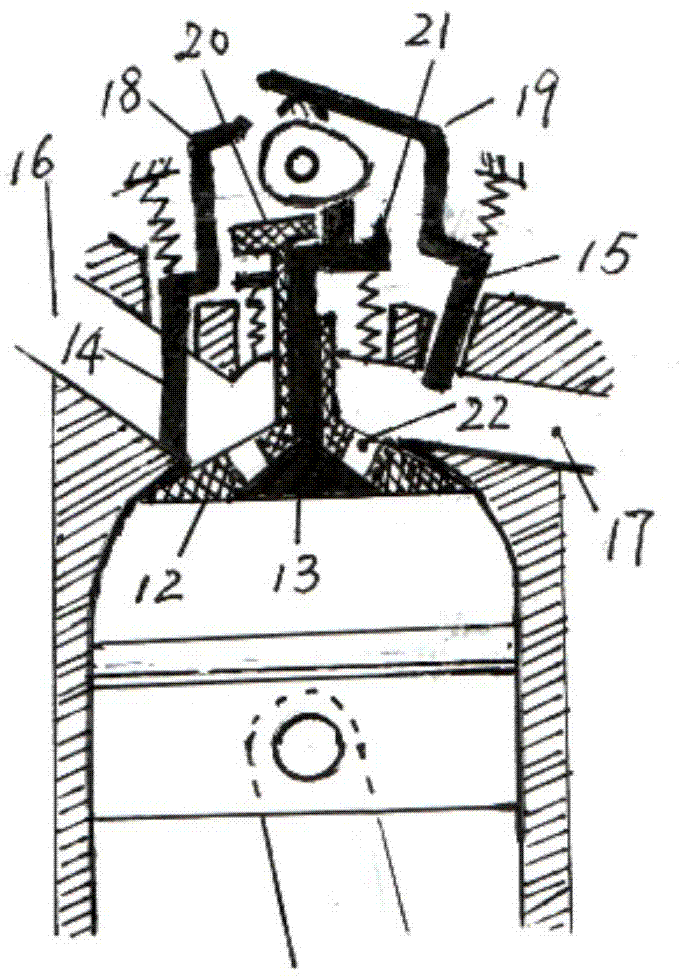

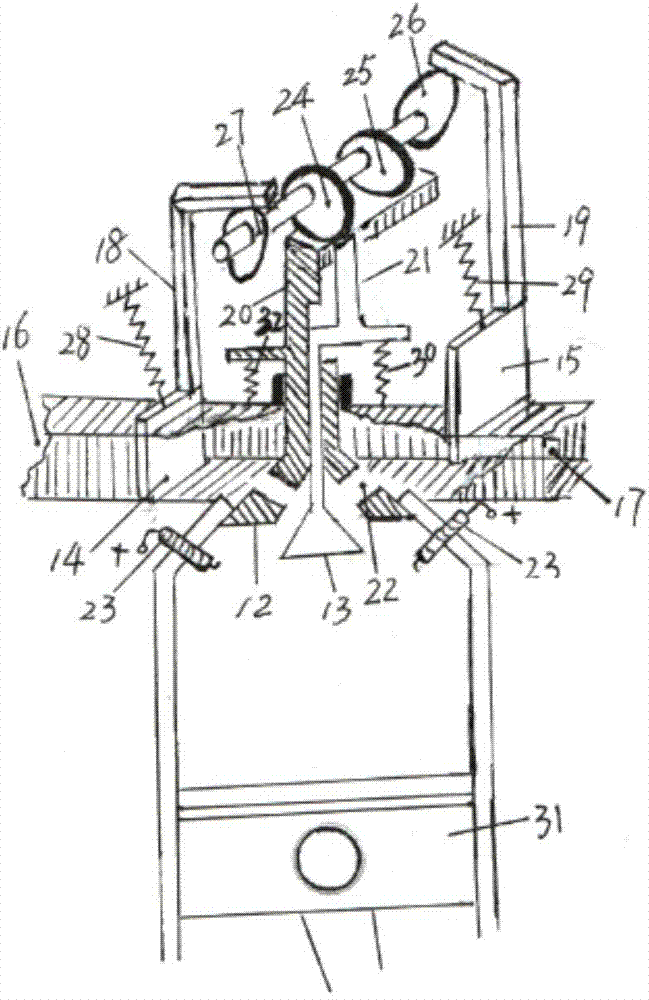

High-efficiency engine

InactiveCN101042069AReduce high temperature and high pressure holding timeReduce lossesMachines/enginesCombustion chamberEngineering

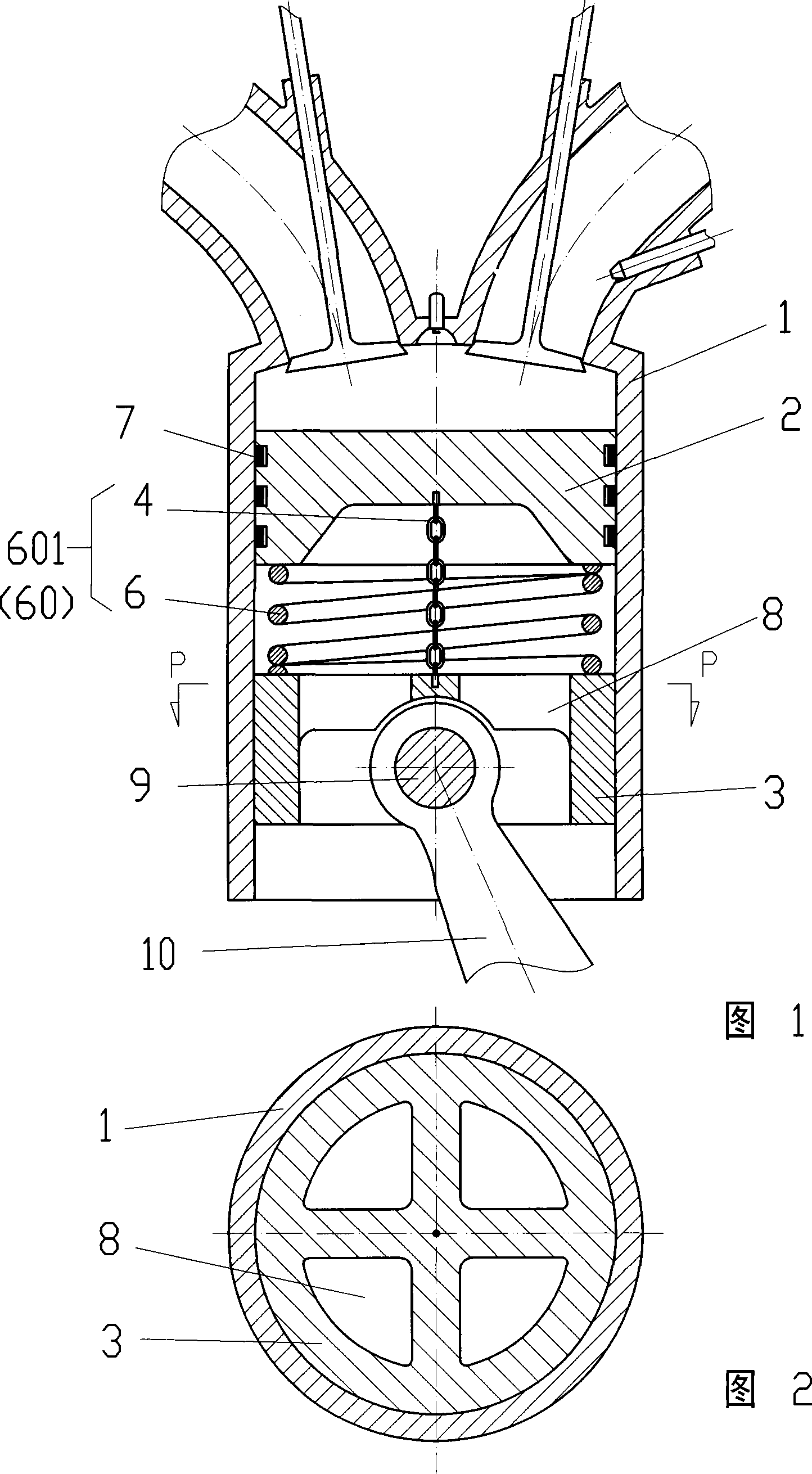

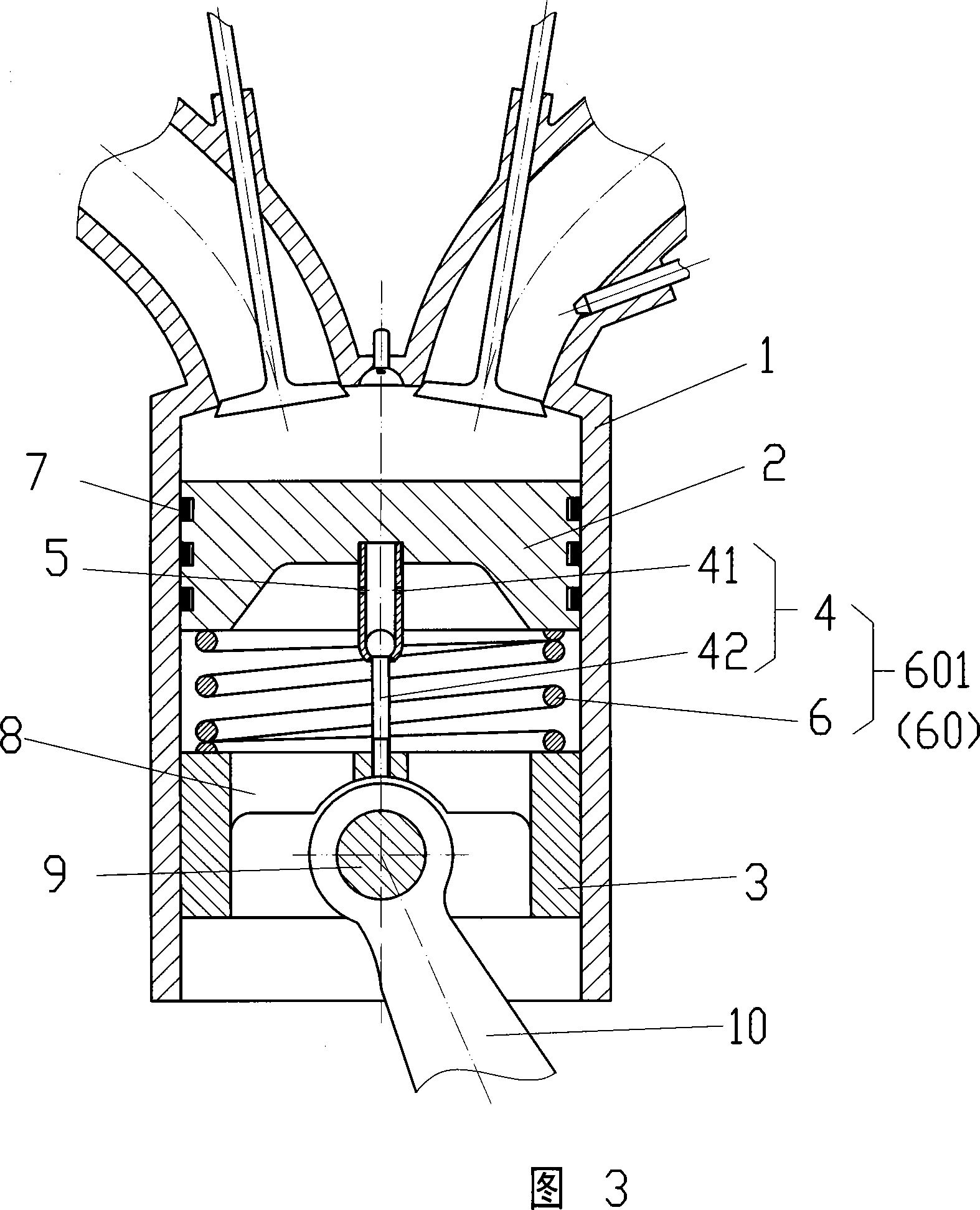

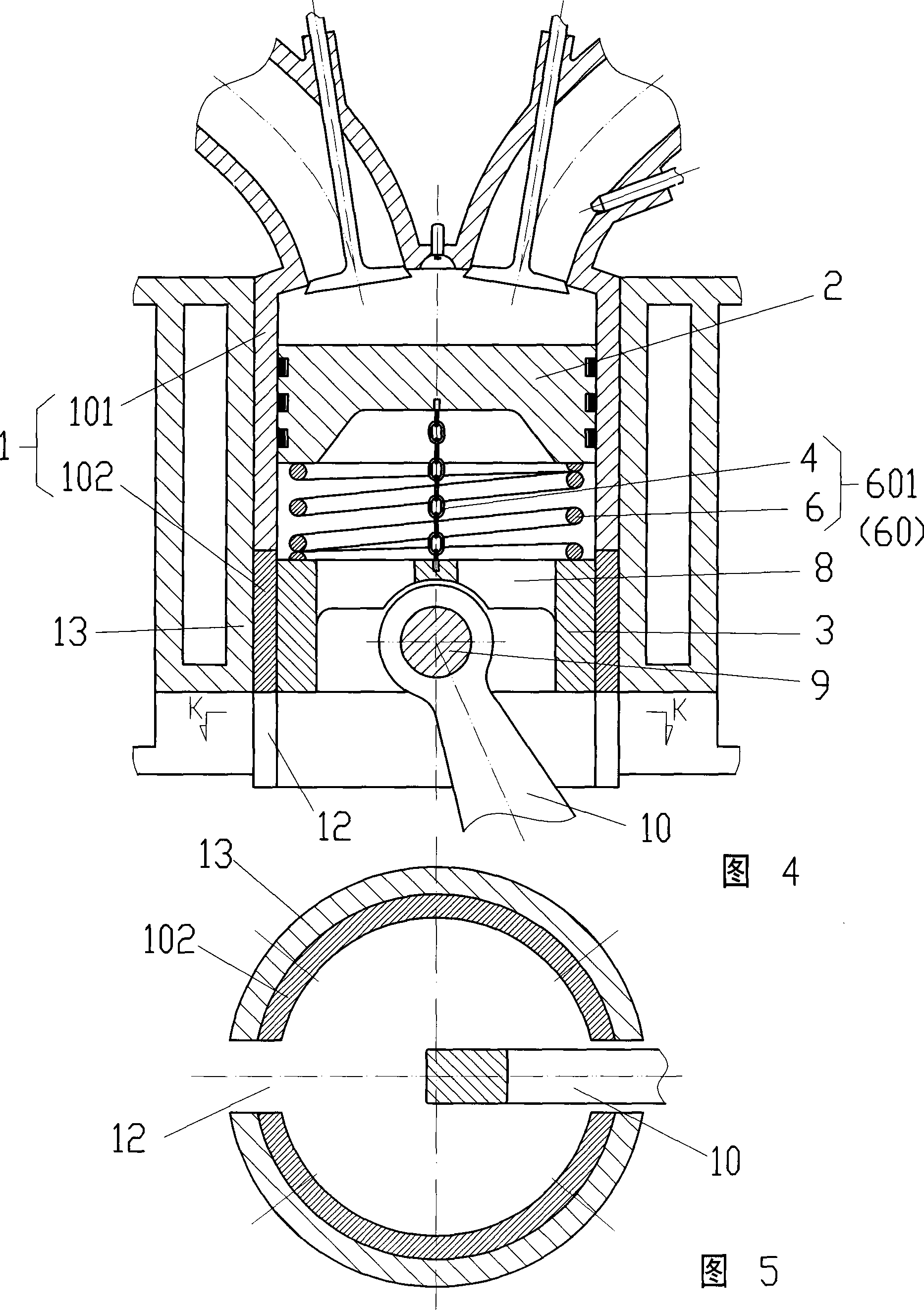

A highly efficient engine comprises the cylinder, piston, guide, piston pin and linking lever with active linking device between the piston and the guide, with the linking device setting as prepressure shrinkable spring or nonspring linking device with the guide connecting with the linking lever. With better location of the guide having low temperature and better lubrication, and the piston bearing up and down forces, it can greatly reduce the friction and wearing between the piston and the cylinder. Apart from that, it can quickly reduce the top dead end high temperature and pressure retain time, with greatly reduced shock, improved torque, with higher, more efficient, energy saving and environment protective design.

Owner:靳宇男

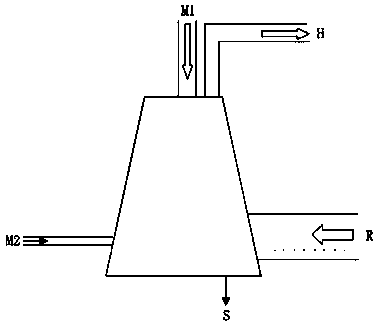

Bypass power generation process and system of dry-process rotary kiln cooperative processing of wet garbage

ActiveCN103939912AThe process is simple and reliableFlexible processDispersed particle separationIncinerator apparatusHydrocotyle bowlesioidesCo-processing

The invention discloses a bypass power generation process and system of dry-process rotary kiln cooperative processing of wet garbage. According to the process, the wet garbage is fed into a C5 discharge pipe, high-temperature alkali powder inside the C5 discharge pipe rapidly dries and alkalifies the garbage, the dry and combustible garbage enters a kiln tail smoke chamber along with the powder to be rapidly gasified and combust, high-temperature steam and combustion emissions generated by combustion are pumped into a bypass settlement flue, are processed by the bypass settlement flue and a bypass draught fan and are mixed into exhaust gas waste heat of a grate cooler head, then the blast capacity and the blast temperature are adjusted, then a steam boiler produces steam power for power generation, garbage not combusting out in time and ash combusting out enter a rotary kiln along with raw power materials to be combusted to be clinker, and hydrocarbon not combusting out in time ascends into a decomposing furnace to continue to combust out. The invention further discloses the bypass power generation system of the dry-process rotary kiln cooperative processing of the wet garbage. The method and system can solve the problems that urban life garbage affects the kiln condition and coal consumption is increased, and can effectively eliminate the problem that a kiln system is blocked by water and chlor-alkali in the garbage.

Owner:长沙紫宸科技开发有限公司

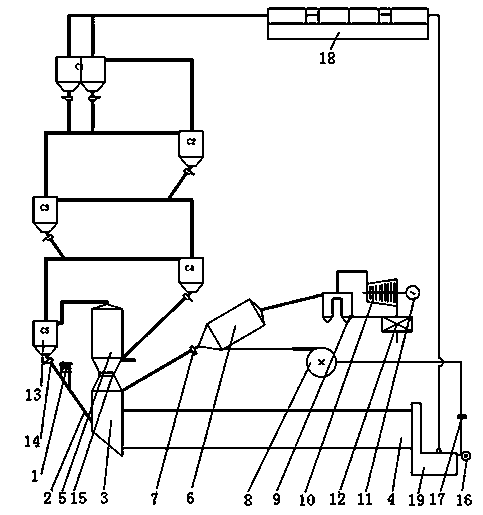

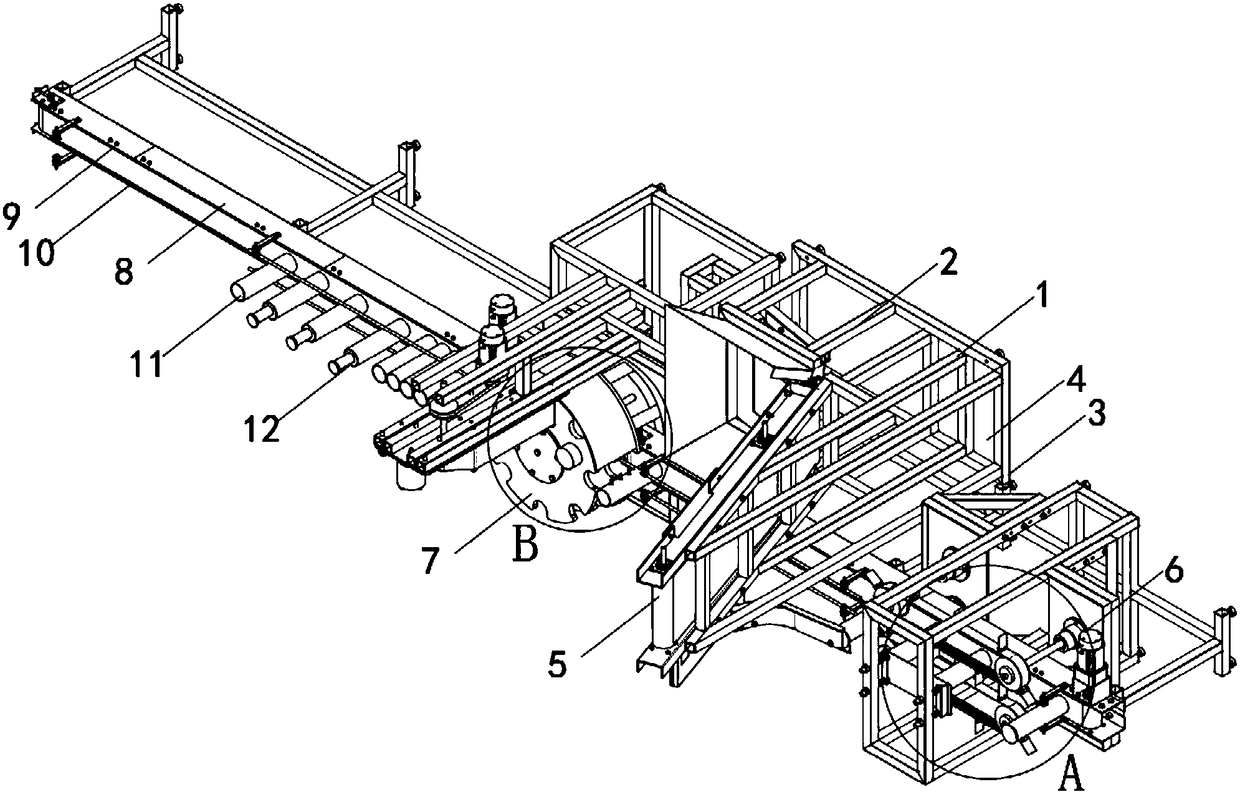

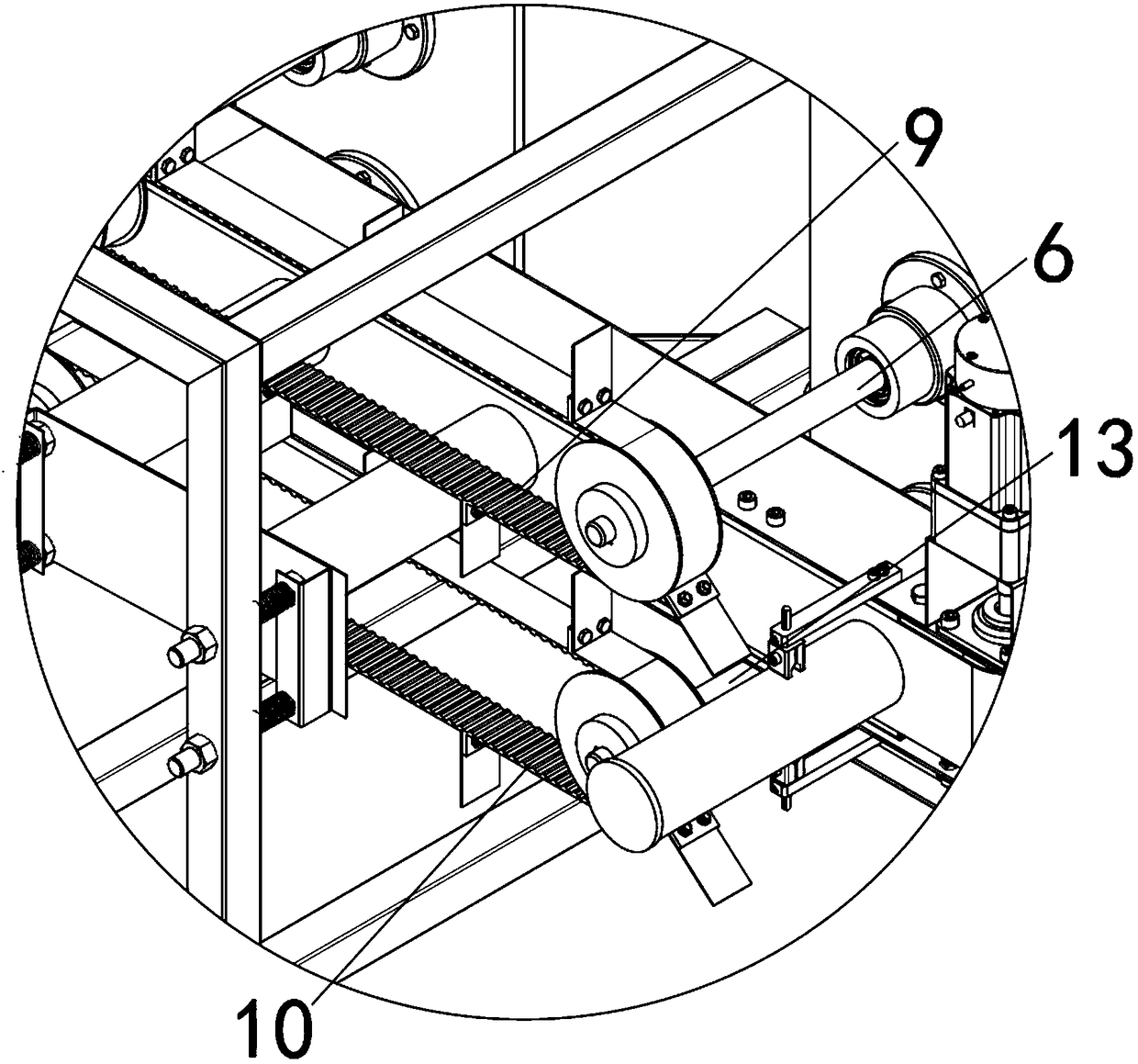

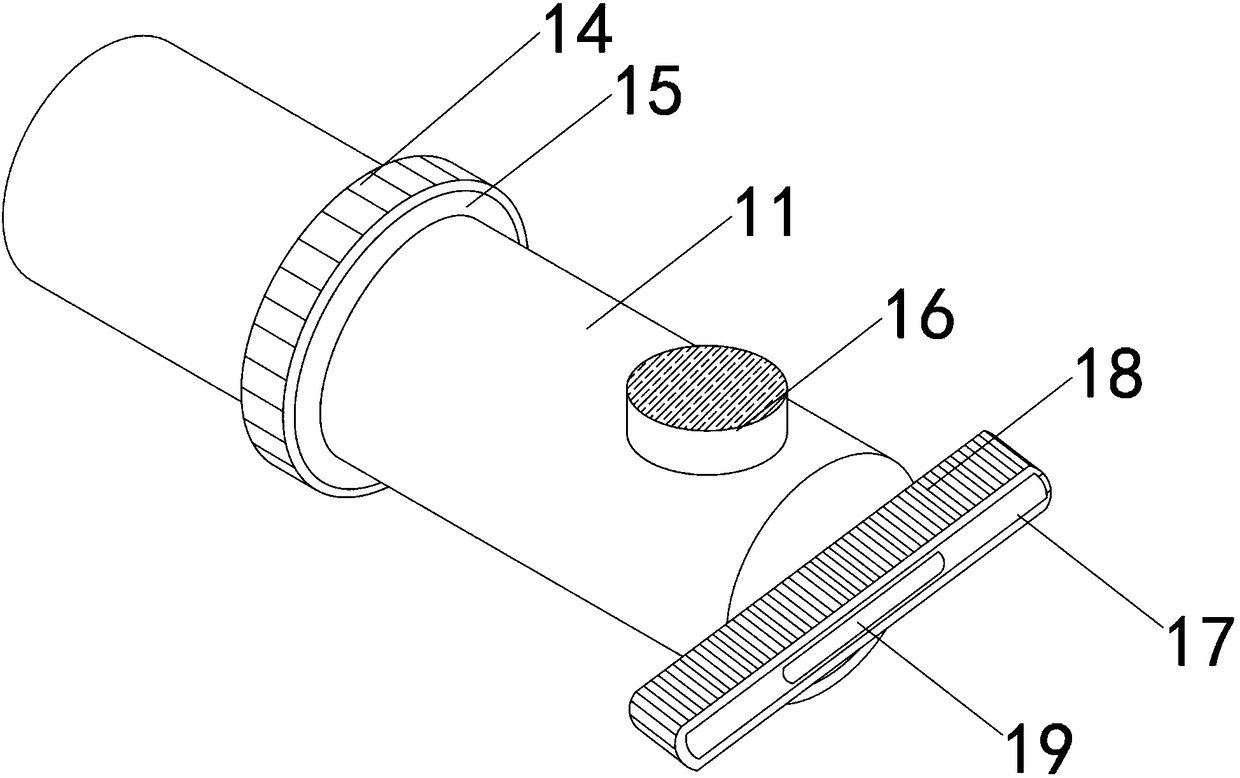

Biomass fuel energy-saving supply system for thermal power plant boiler and supply method thereof

InactiveCN109237507ACrushed fullyCrushed completelyFuel feeding arrangementsSolid fuel pretreatmentThermal energyCombustion

The invention discloses a biomass fuel energy-saving supply system for a thermal power plant boiler. The system comprises an assembling and connecting frame, an aggregate crushing box, a conveying bin, a supply cylinder and a first hydraulic pump. A plurality of transverse partition plates are arranged in the middle of the assembling and connecting frame in parallel, and one ends of the transversepartition plates are each perpendicularly provided with a longitudinal partition. The system has the advantages that fuel is scraped and cut through cutter edges, the fuel and a scraper are oppositein rotating direction, the collision probability of the fuel and the scraper is increased, the fuel crushing efficiency and crushing degree of the scraper are improved, the fuel is crushed more thoroughly, fuel combustion is more sufficient and more thorough, the fuel thermal energy conversion rate is increased, when the boiler generates the equivalent electric quantity, less biomass fuel is adopted, and working energy conservation of the supply system is ensured; a pressing plate moves up and down to extrude the biomass fuel, the density is larger when the fuel is put into the boiler, the fuel containing amount in the boiler is increased, and the phenomenon that the boiler is blocked by the fuel is avoided.

Owner:王幼林

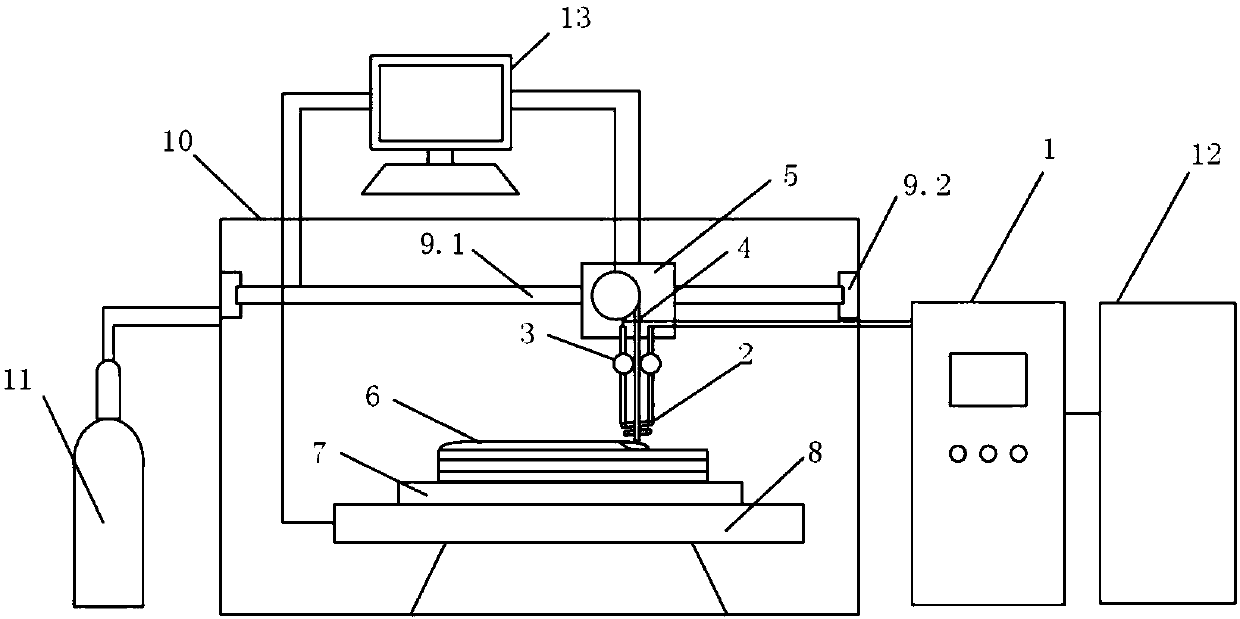

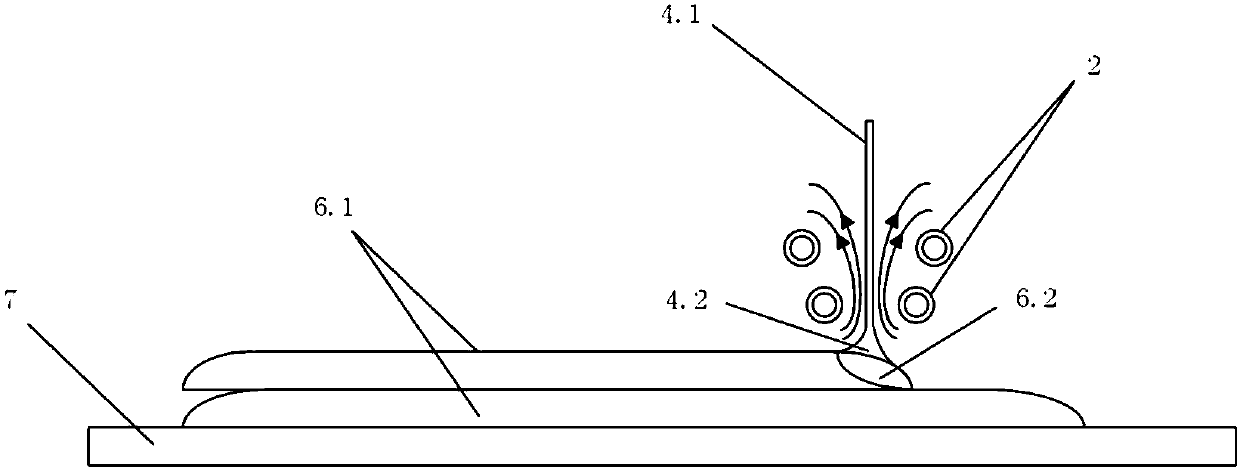

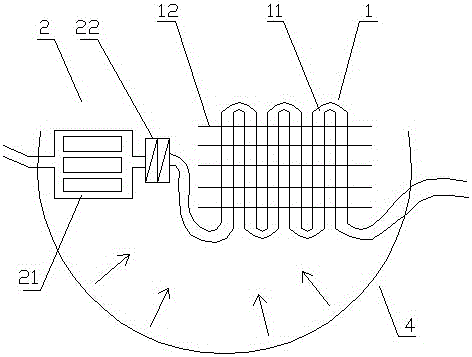

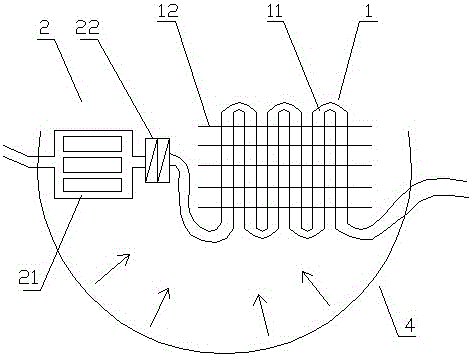

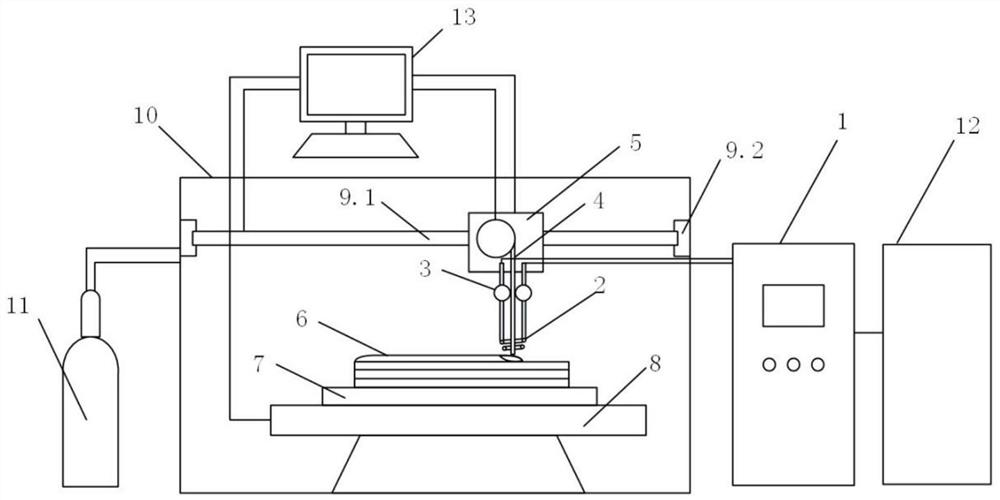

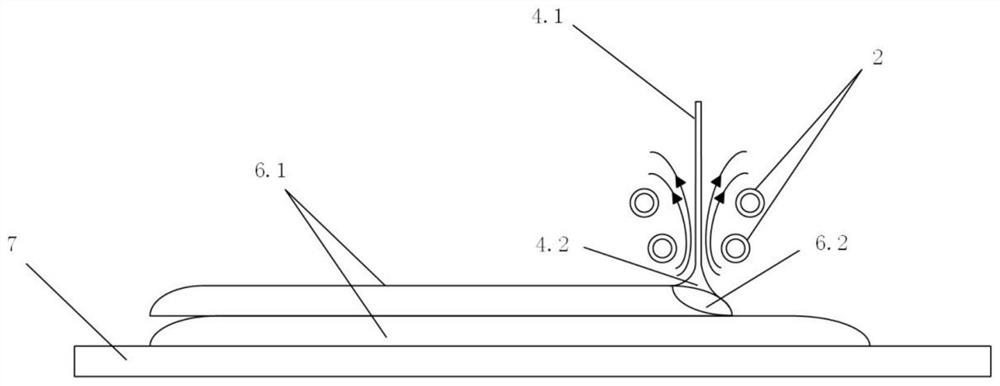

Metal deposition forming method and device based on ultra-high frequency induction heating technology

InactiveCN109550947AImprove heat conversion rateLow costAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyGas cylinder

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Internal combustion engine

InactiveCN1851252AImprove heat conversion rateExtend your lifeNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberEngineering

The invention discloses a novel internal combustion engine, comprising mineral-free water heating device, crank-driven high pressure pump and in-combustion chamber nozzle on the engine body, where the heating device, high pressure pump and nozzle are connected in series. And the invention can raise heat conversion of the engine and reduce energy source consumption by the engine.

Owner:刁久新

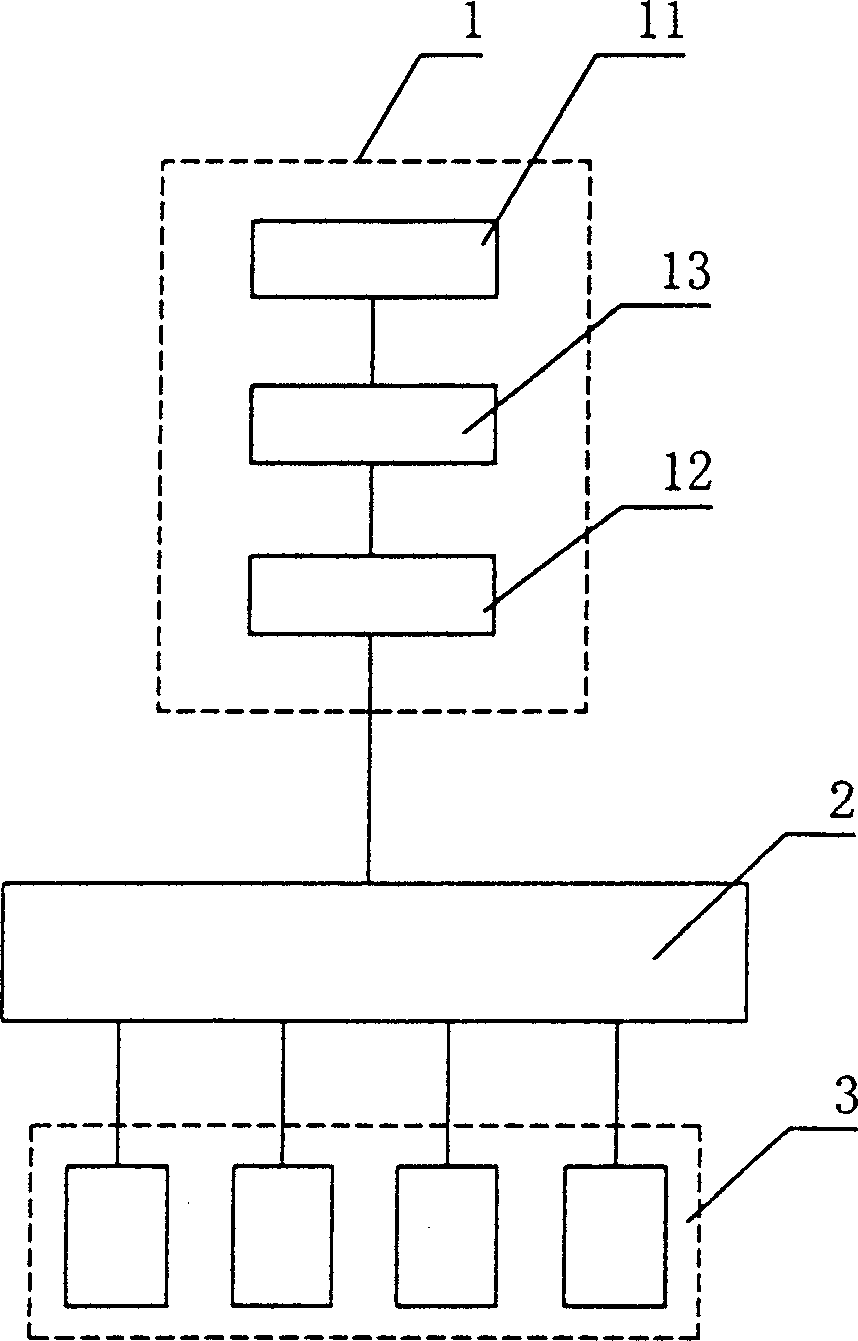

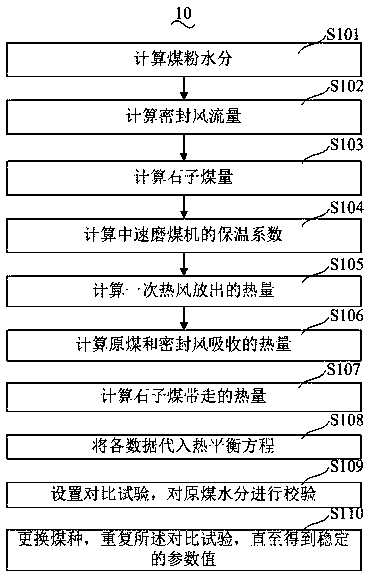

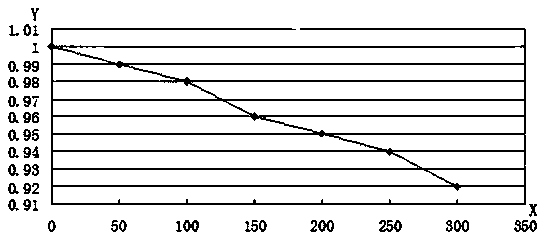

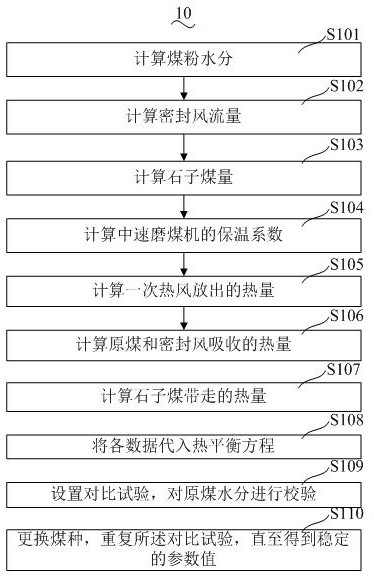

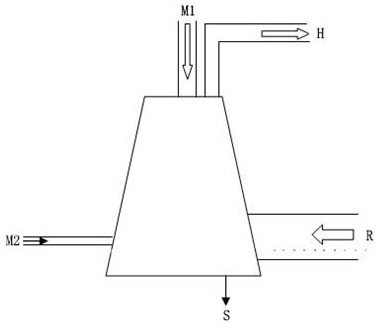

Method for calculating moisture of raw coal in medium-speed coal mill online

ActiveCN110568018AReasonable control of outlet temperatureRealize online accurate calculationMolecular entity identificationMaterial moisture contentCalculation errorProcess engineering

The invention discloses a method for calculating the moisture of raw coals in a medium-speed coal mill online. The method comprises the steps of calculating the moisture of pulverized coals, calculating sealing air flow, calculating a pebble coal amount, calculating a heat preservation coefficient of the medium-speed coal mill, calculating heat released by primary hot air, calculating heat absorbed by the raw coals and sealing air, calculating heat taken away by pebble coals, plugging each data into a heat balance equation, setting a contrast test and verifying the moisture of the raw coals, and replacing a coal type and repeating the contrast test until a stable parameter value is obtained. The invention discloses the method for calculating moisture of the raw coals in the medium-speed coal mill online. A ground product of the medium-speed coal mill is sampled and tested, the moisture of the raw coals is calculated through a heat balance equation, multiple sets of contrast test verification are set, a calculation error of the raw coal moisture is reduced, the accurate judgment on the coal type is facilitated to reasonably control the outlet temperature of the coal mill, boiler operation parameters are adjusted to optimal values, and therefore the heat energy conversion rate of the raw coals is improved.

Owner:广东红海湾发电有限公司 +1

Long-acting anti-icing wind power blade coating and preparing method thereof

InactiveCN105111907AEvenly dispersedGuaranteed decentralizationPolyurea/polyurethane coatingsElectrical conductorDefoaming Agents

The invention discloses a long-acting anti-icing wind power blade coating and a preparing method thereof. According to a formula, the coating is prepared from a component A and a component B, wherein the component A is prepared from resin, dispersant, titanium dioxide, carbon black, a conducting material, a defoaming agent, a leveling agent, a rheological additive, a flatting agent, an adhesion promoter, an initiating agent, butyl acetate and propylene glycol monomethyl ether; the component B is prepared from an HDI tripolymer and a prepolymer made of HDI or IPDI, and the curing agent component with the -NCO content of 5-15%. The preparing method of the coating and a preparing method of the component A are provided. On the premise that a paint film has excellent performance for daily use, the film serves as a resistor while being changed into a conductor, the problem that blades ice during operation in snowy weather in winter is solved thoroughly, and long-term safe and stable operation and service life of a wind power unit are guaranteed.

Owner:文庆武

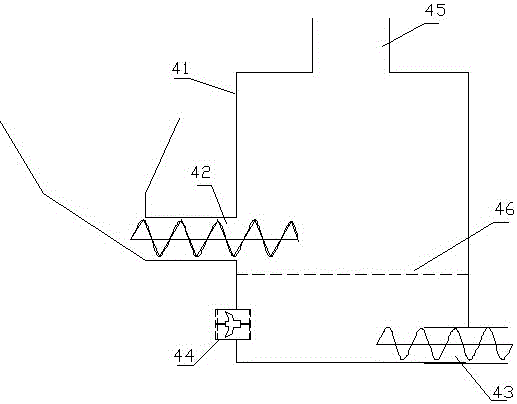

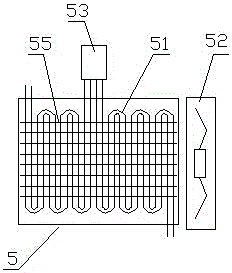

Solar heat energy power system based on multistage pressurization condensation

InactiveCN106438239AImprove heat conversion rateReduce pressureFrom solar energySteam engine plantsThermal energySolar light

The invention discloses a solar heat energy power system based on multistage pressurization condensation. The solar heat energy power system based on multistage pressurization condensation comprises a heat collecting device, a gasifying device, a turbine, a condensing device and a one-way hydraulic pump for realizing circulating communication through circulating pipes; circulating working mediums are filled in the circulating pipes; the heat collecting device and the gasifying device are mounted in a solar light collecting cover; the condensing device is mounted out of the solar light collecting cover, and includes a condensing pipe, a cooling fan and multiple pressurization mechanisms; the cooling fan is mounted above or below the condensing pipe; and the pressurization mechanisms are uniformly distributed at the middle part of the condensing pipe stage by stage. The solar heat energy power system based on multistage pressurization condensation is quicker in condensing speed, can reduce the condensation energy discharge and improve the heat energy conversion efficiency, and is stable in operation and adjustable in power.

Owner:郭远军

Heat pump generator or engine

The invention relates to a generator or engine of heating pump, comprising condenser, condensing water tank, heating pump machine or heating pump unit and oil separation device. The steam turbine is connected with the condenser by pipes. The condenser is connected with the heating pump machine or heating pump unit by pipes. The heating pump machine or heating pump unit is connected with the steam turbine by pipes. Cool medium is injected in the pipe. The oil separation device is connected with the heating pump machine or heating pump unit and the steam turbine by pipes. The condenser is connected with the heating pump machine or heating pump unit by pipes. Because of adopting the structure, when it is used cool medium with high temperature and high pressure drives generator or engine by the steam turbine. Cool medium enters into the condenser. Heat energy from condenser makes the temperature of water in condensing water tank rise so as to produce hot water. In working process of heating pump machine or heating pump unit. Heat energy in air is absorbed and cool air is generated. So not only conversion rate of heat energy is high but also hot water and cool air can be generated and exhaust gas and dust can not be generated.

Owner:成坚强

Internal combustion engine tail gas utilization heat energy power system based on multistage pressurization condensation

InactiveCN106437908AIncrease the amount of workIncrease the differential pressureSteam/vapor condensersStationary conduit assembliesHydraulic pumpEngineering

The invention discloses an internal combustion engine tail gas utilization heat energy power system based on multistage pressurization condensation. The system comprises a gasifying device, a turbine, a condensing device and a one-way hydraulic pump for realizing circular communication through circulating pipes in sequence; circulating working mediums are filled in the circulating pipes; a heat collecting device is mounted at the external of the gasifying device, and is communicated with an internal combustion engine tail gas pipe; the condensing device includes a condensing pipe, a cooling fan and multiple pressurization mechanisms; the cooling fan is mounted above or below the condensing pipe; and the pressurization mechanisms are uniformly distributed at the middle part of the condensing pipe stage by stage. The internal combustion engine tail gas utilization heat energy power system based on multistage pressurization condensation has the advantages of quicker condensing speed, capability of reducing the condensation energy discharge and improving the heat energy conversion efficiency, stable operation and power adjustability.

Owner:郭远军

High-efficient, energy-saving and environment-friendly thermal power generating unit

InactiveCN101893252AImprove combustion efficiencySave resourcesNon-combustible gases/liquids supplyThermal energyCombustion chamber

The invention discloses a high-efficient, energy-saving and environment-friendly thermal power generating unit and relates to the field of the thermal power generating units which can burn solid, liquid or gas fuel, convert chemical energy of fuel into thermal energy, further convert the thermal energy into pressure potential energy of water vapor, further convert the pressure potential energy into mechanical energy of a steam turbine, and further convert the mechanical energy into electrical energy of a power generator; such as a coal-fired thermal power generating unit, a fuel-fired thermal power generating unit, a gas-fired thermal power generating unit and the like. Pure oxygen (or pure liquid oxygen) which is separated from the air through an air separation device is directly supplied into a burning chamber of the thermal power generating unit for replacing the original air in an excessive manner, thereby leading the fuel to be fully and completely burned, and leading the instantaneous effective burning rate of the fuel to achieve the highest limit value. The high-efficient, energy-saving and environment-friendly thermal power generating unit can save energy from three aspects: 1) the thermal power generating unit can lead the fuel to be fully and completed burned, thereby saving the energy; 2) the thermal power generating unit can reduce the exhaust emission by 79% and reduce the heat taken away by exhaust by 79%, thereby saving the energy; and 3) the thermal power generating unit can reduce nitrogen in a burning resistant agent by 79% and greatly reduce nitrogen oxides in the exhaust, thereby greatly reducing the loss of the thermal energy of the exhaust and further improving the thermal-power conversion rate. Therefore, the thermal power generating unit can improve the burning efficiency of the thermal power generating unit, save the energy, reduce the emission and reduce the consumption.

Owner:赵军政

Solar thermal and thermal power plant coupled power generation and thermal energy storage combined system and implementation method

InactiveCN106523053BIncrease profitMaximize UtilizationSolar heating energySolar heat devicesSeasonal thermal energy storageThermal energy storage system

The invention discloses a solar heat and thermal power plant coupling power generation and heat storage energy combination system and a realization method. The combination system comprises a thermoelectric production module, a thermoelectric heating module, a solar heat module and a heat energy storage module. The solar heat module heats condensated water of the thermoelectric production module to participate in power generation in non heating seasons, so that the coal consumption of the thermoelectric production module is reduced, and the emission is reduced; and in heating seasons, the heat energy storage module and the thermoelectric heating module are coupled to directly supply heat to a heat user pipe network, so that the energy form conversion link is reduced, and the utilization rate of solar energy is increased. The heat energy storage device needed by the solar heat module is shared with the heat energy storage device needed by low-trough electric peak adjustment of the thermoelectric production module, and is lower in unit investment compared with single thermoelectric production module using the low-trough electric peak heat energy storage device; the heat utilization stability of solar energy is enhanced; and meanwhile, the flexibility of the thermoelectric heating module and the peak adjusting capacity of the thermoelectric production module are greatly improved.

Owner:DATANG LUOYANG CO GENERATION POWER

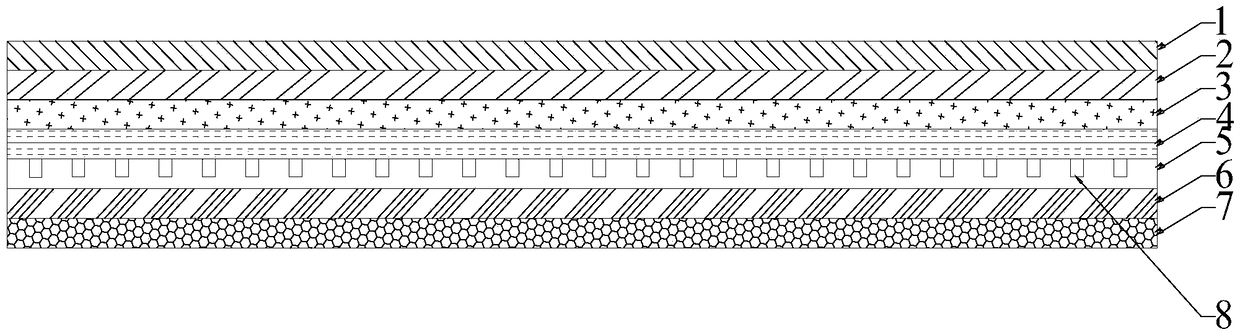

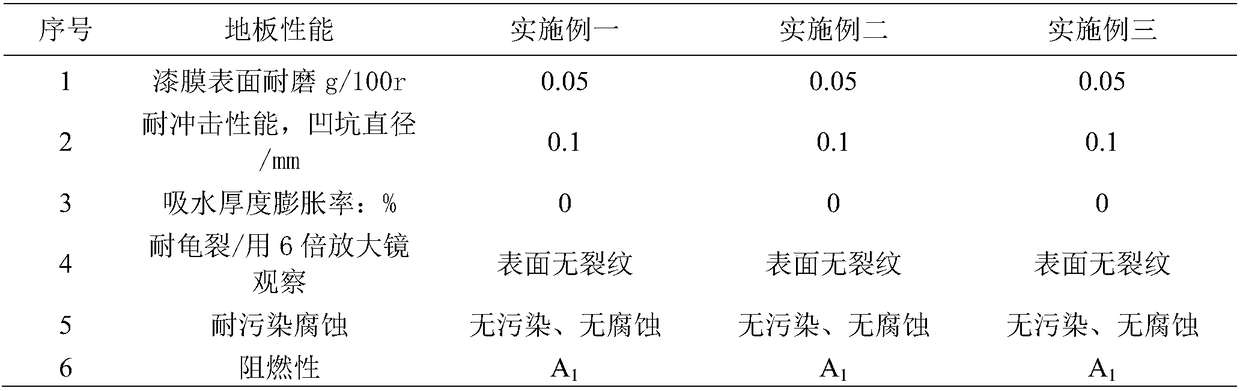

Novel thermal floor and preparation process thereof

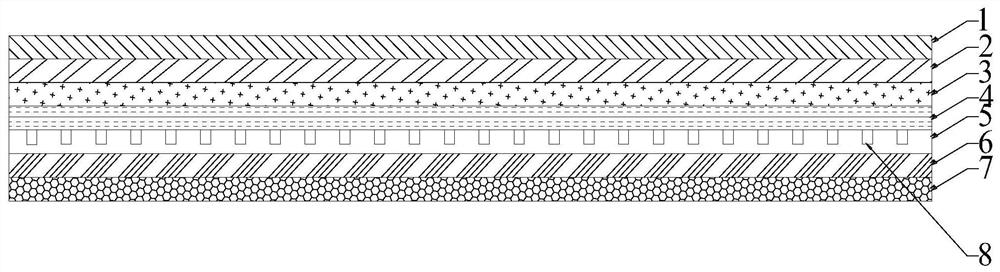

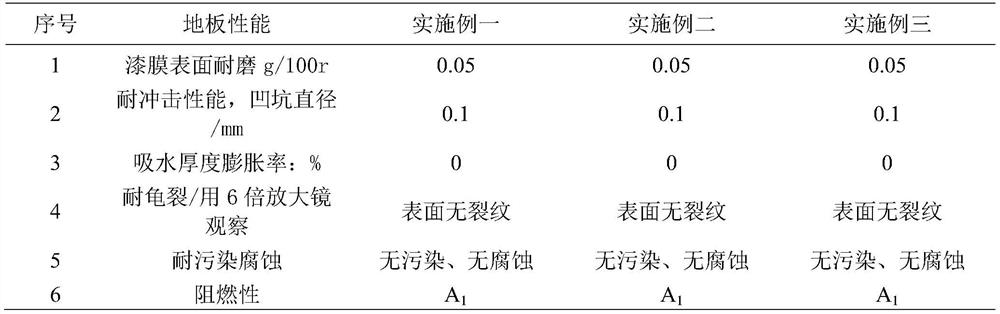

ActiveCN108979055AImprove surface wear resistanceImprove impact resistanceFlooring insulationsCrack resistanceThermal insulation

The invention belongs to the technical field of floors and discloses a preparation method and a paving process of a novel thermal floor. The novel thermal floor is composed of, sequentially from top to bottom, a UV (ultraviolet) curing layer, a wearing layer, a pattern layer, floor base materials, a bottom wire layer, a reflecting layer and a sound insulating layer, wherein the surface of the bottom wire layer is uniformly provided with a plurality of grooves filled with soft materials. The novel thermal floor is good in surface wearing resistance, impact resistance, waterproofness, cracking resistance, pollution and corrosion resistance, fire resistance and the like, and meanwhile achieves good thermal insulation to meet the demands of practical application.

Owner:HEBEI KENUO RUBBER PROD CO LTD

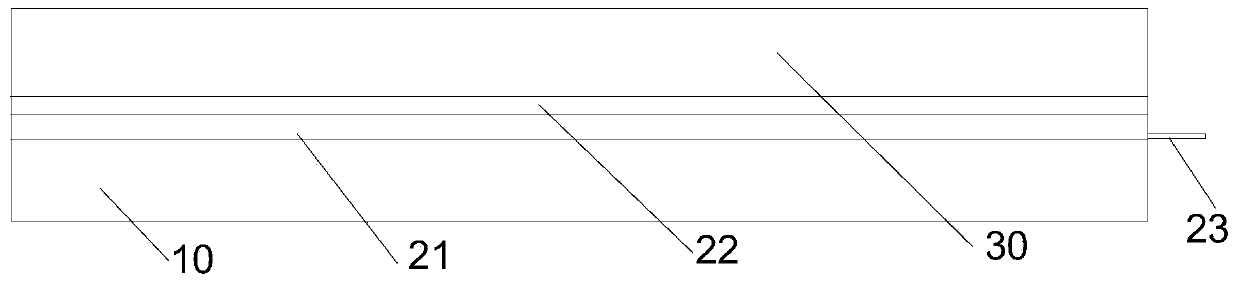

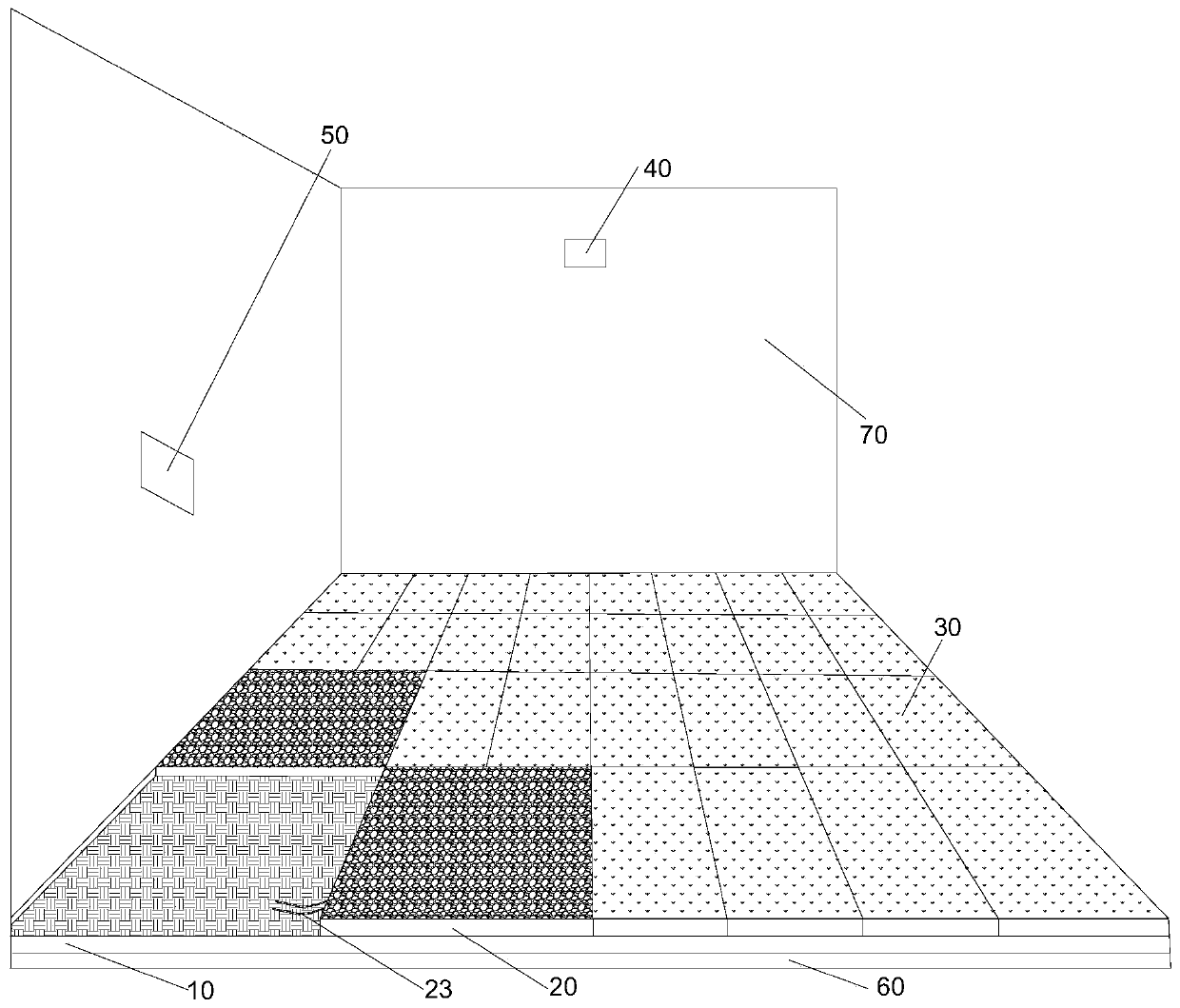

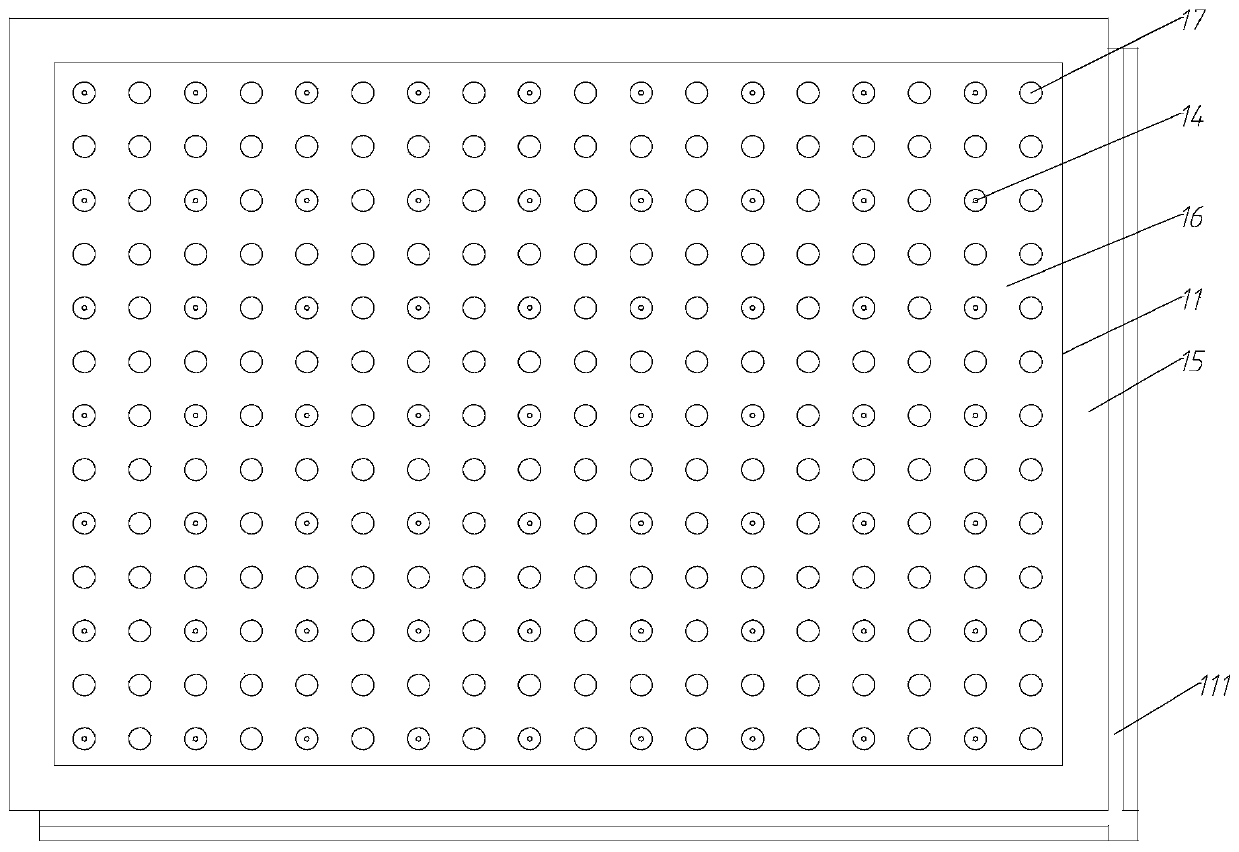

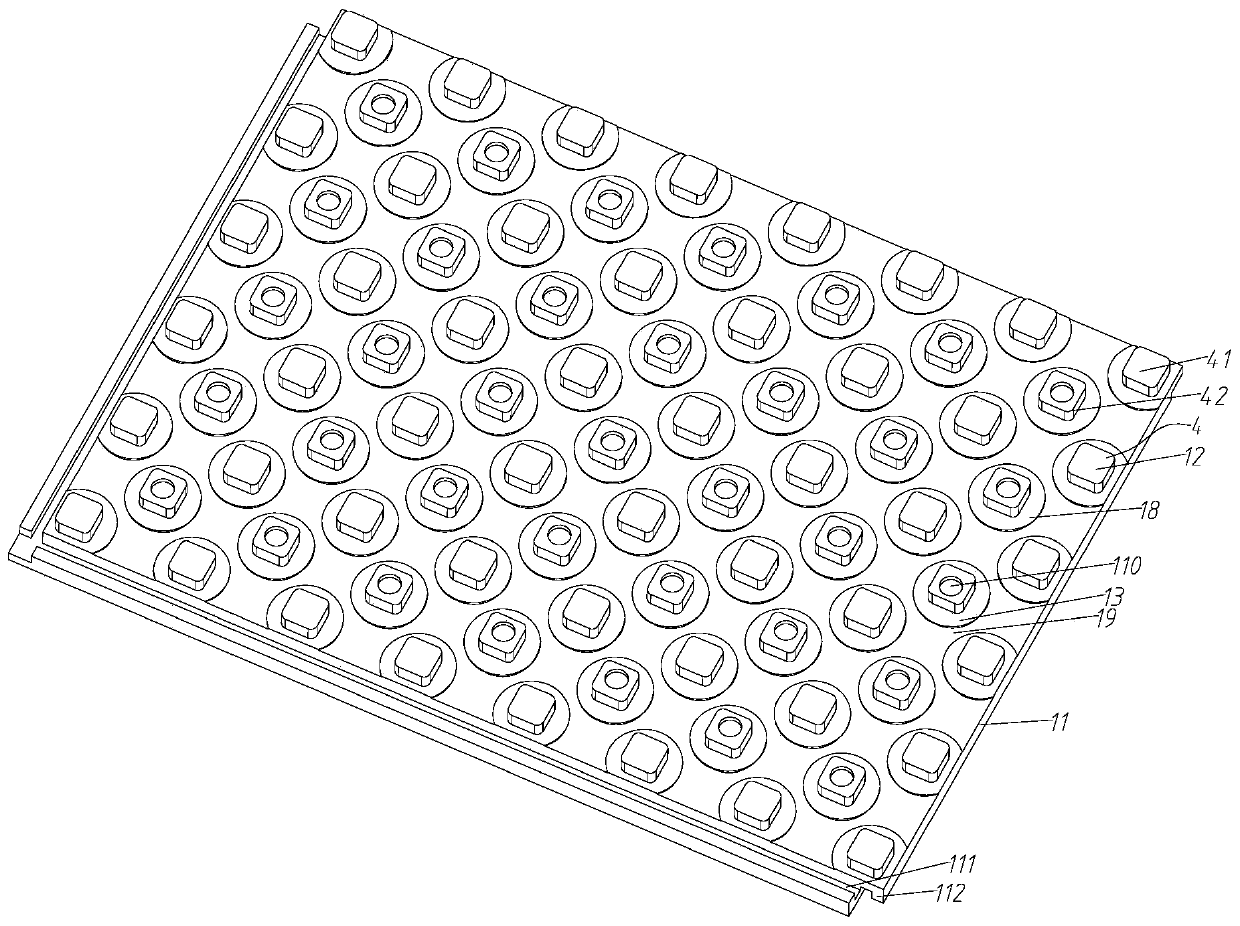

Composite material floor heating plate

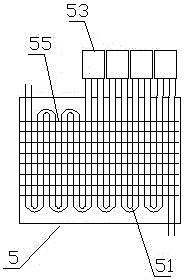

PendingCN110762594APrevent heat from dissipatingImprove heat conversion rateHeating fuelLighting and heating apparatusHeating filmHeating system

This application embodiment provides a composite material floor heating plate. The composite material floor heating plate comprises a heat insulation layer, a heating system and a floor decoration layer which are sequentially arranged from bottom to top, wherein the heating system comprises a heating layer and a heat dissipation layer arranged above the heating layer; the heating layer is a carbonfiber heating film; the heat dissipation layer is basalt fiber cloth; and the floor decoration layer is made of a basalt fiber composite material. According to the composite material floor heating plate, the heat insulation layer, the heating system and the floor decoration layer are integrated into the composite material floor heating plate, basalt rock wool is adopted for heat preservation, andheat energy is prevented from being dissipated outwards; the carbon fiber heating film is adopted for heating, and the basalt fiber cloth and the basalt composite material are adopted for dissipatingheat energy into a room; and through a whole set of synergistic effect, the heat energy conversion rate of the composite material floor heating plate is high, and then the utilization rate of the heat energy is greatly increased.

Owner:SICHUAN QIANYI COMPOSITE MATERIAL CO LTD

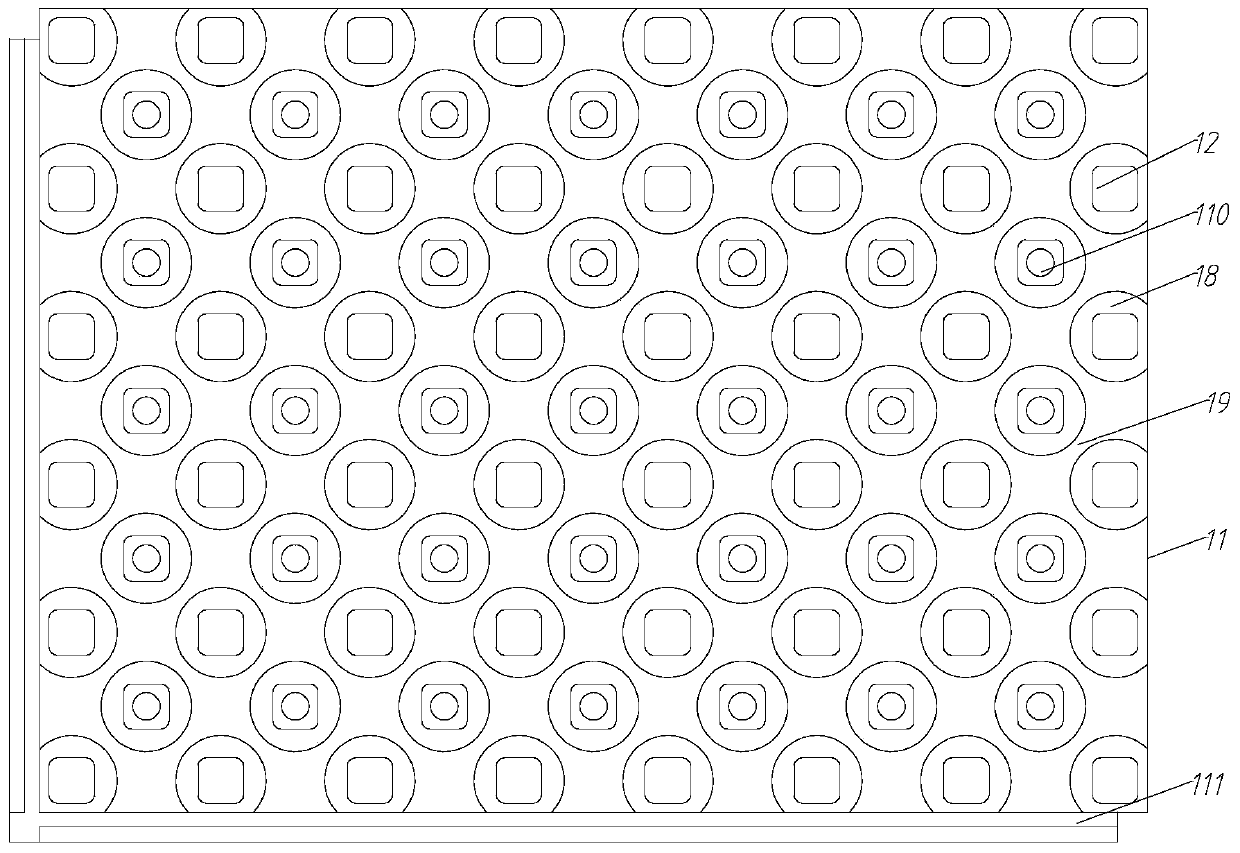

Novel floor heating module and processing process

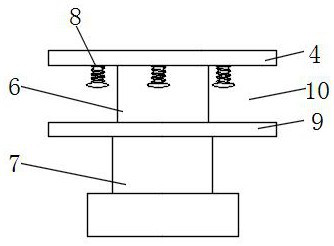

PendingCN110318516AImprove heat conversion rateSmooth tube spacingFlooring insulationsThermal insulationComputer module

The invention belongs to the technical field of building materials, and discloses a novel floor heating module and a processing process thereof. The novel floor heating module comprises a thermal insulation layer, wherein the thermal insulation layer comprises a thermal insulation layer body, a plurality of limiting columns and a plurality of adsorbing holes, the limiting columns are uniformly arranged on the upper surface of the thermal insulation layer body; a first channel for allowing a floor heating tube to pass through is formed between the adjacent two limiting columns; and the adsorbing holes are formed in the lower surface of the thermal insulation layer to form an air channel during positive and negative pressure forming. Aluminum is firstly coated on a flame retardant layer in aprocessing process, and the flame retardant layer is formed on the thermal insulation layer through positive and negative pressure forming, so that the novel floor heating module is obtained. The technical scheme solves the problems that the floor heating module in the prior art is not high in strength and damages are easily caused in a using process.

Owner:张佩佳

Energy-saving engine and exhaust control method for same

InactiveCN103470327BIncrease the cross-sectional areaReduce consumptionOutput powerMachines/enginesExhaust valveInlet valve

Owner:汪辉

Biomass heat energy power system based on working medium circulation condensation

InactiveCN106437896AReduce the temperatureReduce pressureSteam/vapor condensersStationary conduit assembliesThermal energyHydraulic pump

The invention discloses a biomass heat energy power system based on working medium circulation condensation. The biomass heat energy power system comprises a gasification device, a turbine, a condensing unit and a one-way hydraulic pump which circularly communicate with one another sequentially through circulating pipelines. The circulating pipelines internally contain a circulating working medium. A heat collection device is installed outside the gasification device and communicates with a biomass furnace. The gasification device comprises a gasification cavity and a preheating cavity pipe. A pre-condensation cavity is arranged at the exhaust port position of the turbine, and the preheating cavity pipe makes parallel contact with the pre-condensation cavity. The biomass heat energy power system based on working medium circulation condensation can accelerate condensation, improve the efficiency of the turbine and reduce the heat energy exhaust amount, and therefore the heat energy conversion efficiency is improved.

Owner:郭远军

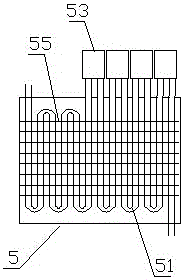

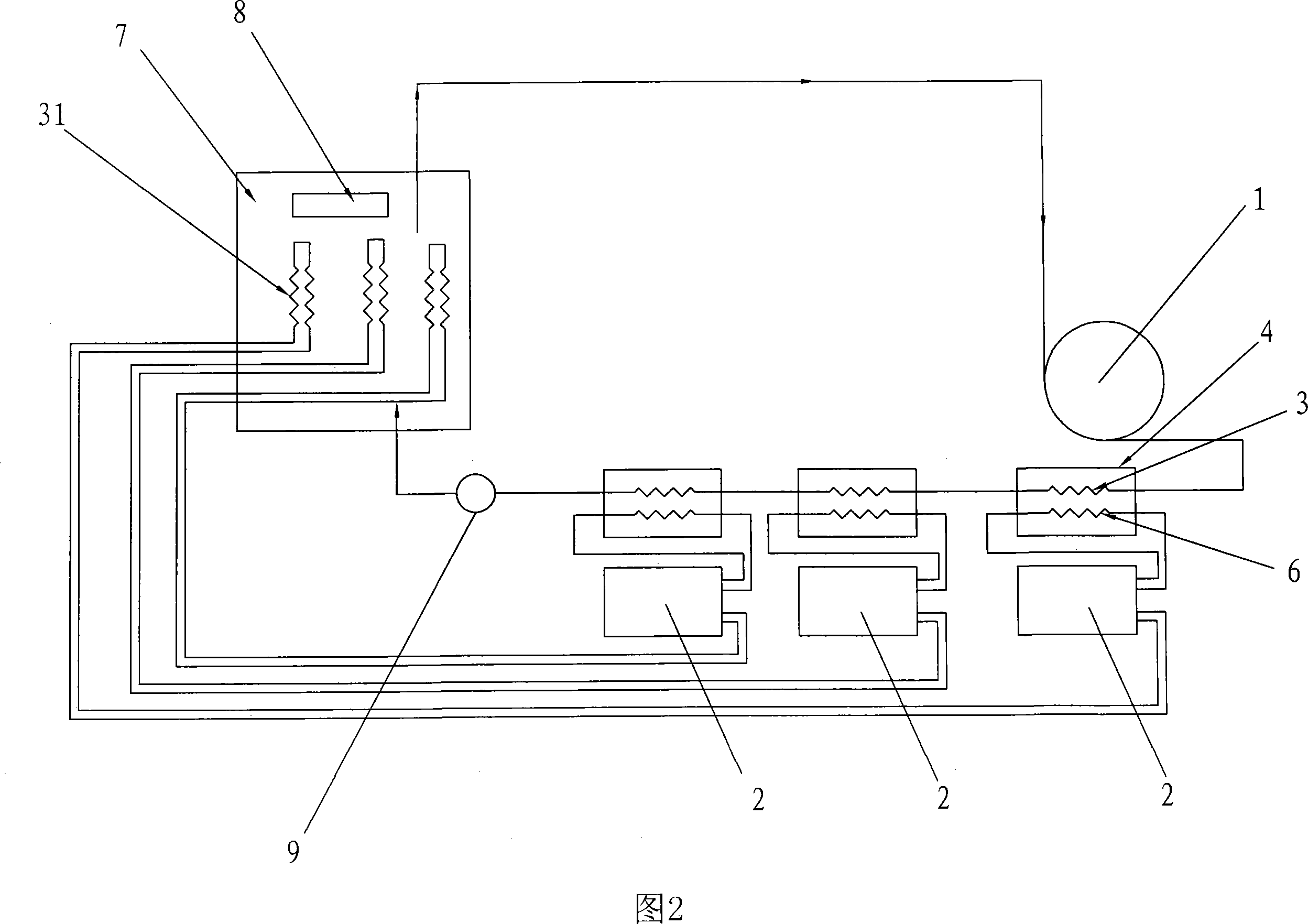

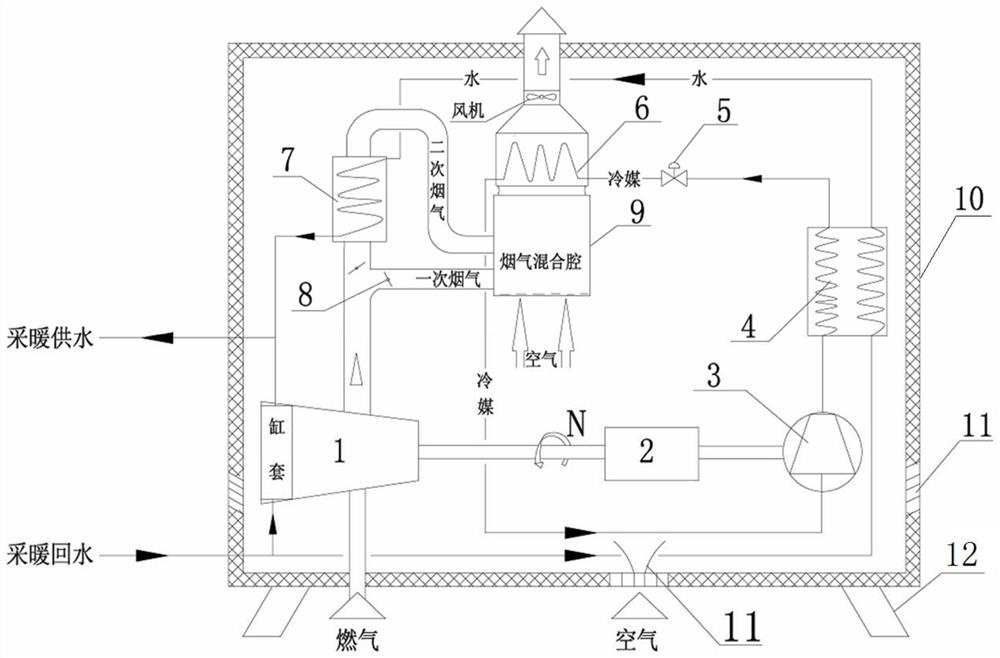

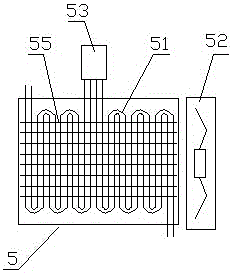

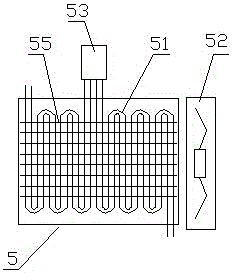

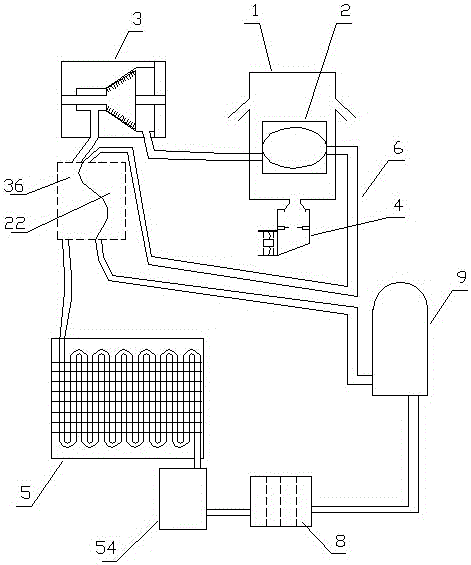

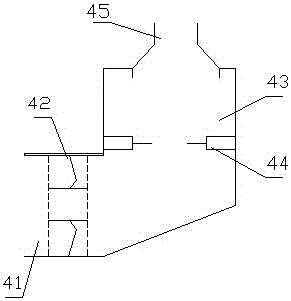

A full heat recovery integrated gas heat pump heating unit and its application

ActiveCN110173751BImprove securitySolve pollutionFluid heatersHeat pumpsInternal combustion engineVariator

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Solar thermal energy power system based on pressurization condensation

InactiveCN106246485AGood condensation effectImprove heat conversion rateFrom solar energySteam engine plantsPressure regulatorThermal energy

The invention discloses a solar thermal energy power system based on pressurization condensation. The solar thermal energy power system comprises a heat collecting device, a gasification device, a turbine, a condensing device and a unidirectional hydraulic pump which are in circulation communication through a circulation pipe. A circulating working medium is contained in the circulation pipe. The heat collecting device and the gasification device are installed in a solar snoot, and the condensing device is installed outside the solar snoot and comprises a condensing pipe, a cooling fan and a pressurization mechanism. The pressurization mechanism is installed at the middle end of the condensing device. The pressurization mechanism comprises a pressurization turbine and a turbine pressure regulator, and the turbine pressure regulator controls and is connected with the pressurization turbine. The solar thermal energy power system based on pressurization condensation has quick condensation efficiency, can reduce condensation energy discharge, improve thermal energy conversion efficiency and run stably, and is adjustable in power.

Owner:郭远军

Pressurization and condensation thermal energy power system utilizing thermal drained water of nuclear power station

InactiveCN106224042AImprove heat conversion rateReduce pressureSteam engine plantsThermal energyNuclear power

The invention discloses a pressurization and condensation thermal energy power system utilizing thermal drained water of a nuclear power station. The pressurization and condensation thermal energy power system comprises a heat collecting device, a gasifying device, a turbine, a condensing device and a one-way hydraulic pump, wherein the heat collecting device, the gasifying device, the turbine, the condensing device and the one-way hydraulic pump circularly communicate in sequence through a circulating pipeline. Circulating working media are contained in the circulating pipeline. The heat collecting device and the gasifying device are mounted in a thermal drained water channel of the nuclear power station. The condensing device is mounted in a low-temperature deep-water zone and comprises a condensing pipe, a cooling fan and a pressurization mechanism, wherein the pressurization mechanism is mounted at the middle end of the condensing pipe and comprises a pressurization turbine and a turbine pressure regulator, and the turbine pressure regulator is connected with the pressurization turbine in a controlling mode. The pressurization and condensation thermal energy power system utilizing thermal drained water of the nuclear power station has a high condensing rate and can reduce condensation energy discharge and improve thermal energy conversion efficiency, operation is stable, and power is adjustable.

Owner:郭远军

Electric heating film curing prefabricated component die

PendingCN111409181AReduce manufacturing costReduce shipping costsCeramic shaping apparatusHeat energyElectric heating

An electric heating film curing prefabricated component die comprises a concrete prefabricated component forming template, an electric heating film and a heat preservation layer. The concrete prefabricated component forming template comprises a panel making direct contact with the concrete surface. The electric heating film is attached to the outer side of the panel. The outer side of the electricheating film is provided with the heat preservation layer. After concrete is poured in the die and formed, temperature rise can be directly conducted on the surface of the die, operation is simple, construction is convenient, the heat energy conversion rate is high, the curing speed is high, the die circulation efficiency is high, and the electric heating film curing prefabricated component die can be used for manufacturing prefabricated components in any site.

Owner:宁波优造建筑科技有限公司

Thermal energy dynamic system of oil field exhaust gas based on cyclic condensation of working medium

InactiveCN106246256AReduce the temperatureReduce pressureSteam engine plantsThermal energyCombustion chamber

The invention discloses a thermal energy dynamic system of oil field exhaust gas based on cyclic condensation of working medium comprising a gasification device, a turbine, a condensation device and a one-way hydraulic pump which are successively cycled and communicated through a circulating pipeline; circulating work medium is contained in the circulating pipeline; a thermal-arrest device which is installed outside the gasification device is communicated with an oil field exhaust gas burner comprising an exhaust gas inlet, an oil field exhaust gas induced draught fan, an exhaust gas combustion chamber, a continuous fire guider and a hot gas discharge pipe; the gasification device comprises a gasification chamber and a preheating chamber; an exhaust port of the turbine is provided with a pre-condensing chamber which is in touch with the preheating chamber in parallel. The thermal energy dynamic system of oil field exhaust gas based on cyclic condensation of working medium can accelerate the condensation, improve the efficiency of the turbine, reduce the heat expelled outside, and thereby enhance the heat energy conversion efficiency.

Owner:郭远军

A new type of heating floor and its preparation process

ActiveCN108979055BImprove surface wear resistanceImprove impact resistanceFlooring insulationsCrack resistanceThermal insulation

The invention belongs to the technical field of floors and discloses a preparation method and a paving process of a novel thermal floor. The novel thermal floor is composed of, sequentially from top to bottom, a UV (ultraviolet) curing layer, a wearing layer, a pattern layer, floor base materials, a bottom wire layer, a reflecting layer and a sound insulating layer, wherein the surface of the bottom wire layer is uniformly provided with a plurality of grooves filled with soft materials. The novel thermal floor is good in surface wearing resistance, impact resistance, waterproofness, cracking resistance, pollution and corrosion resistance, fire resistance and the like, and meanwhile achieves good thermal insulation to meet the demands of practical application.

Owner:HEBEI KENUO RUBBER PROD CO LTD

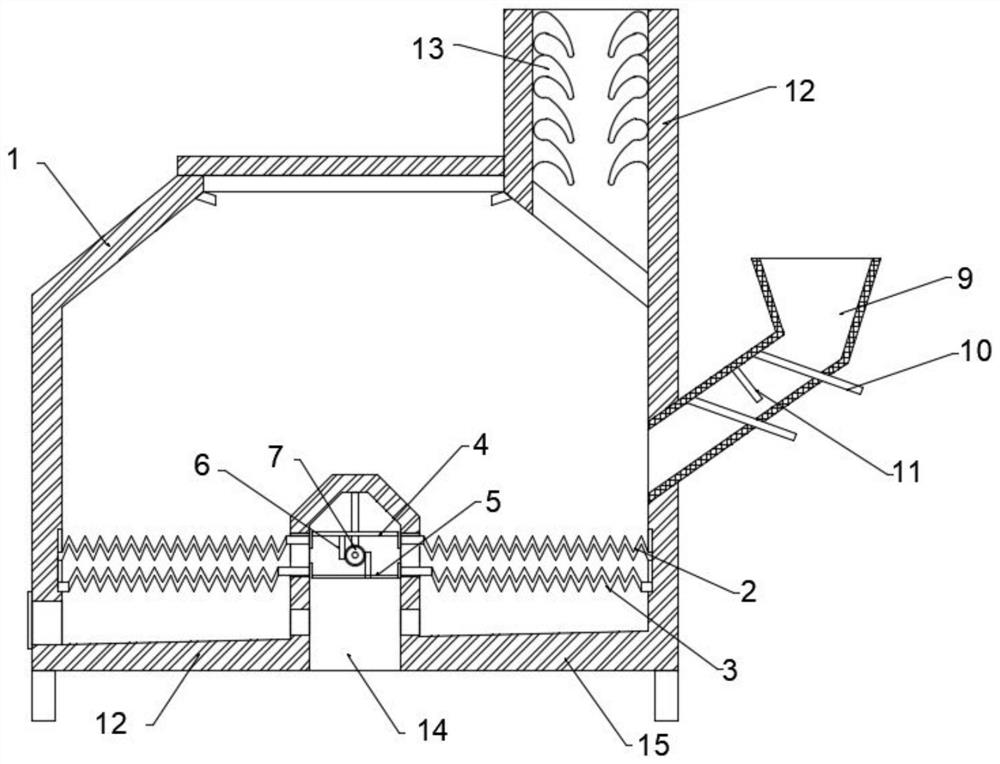

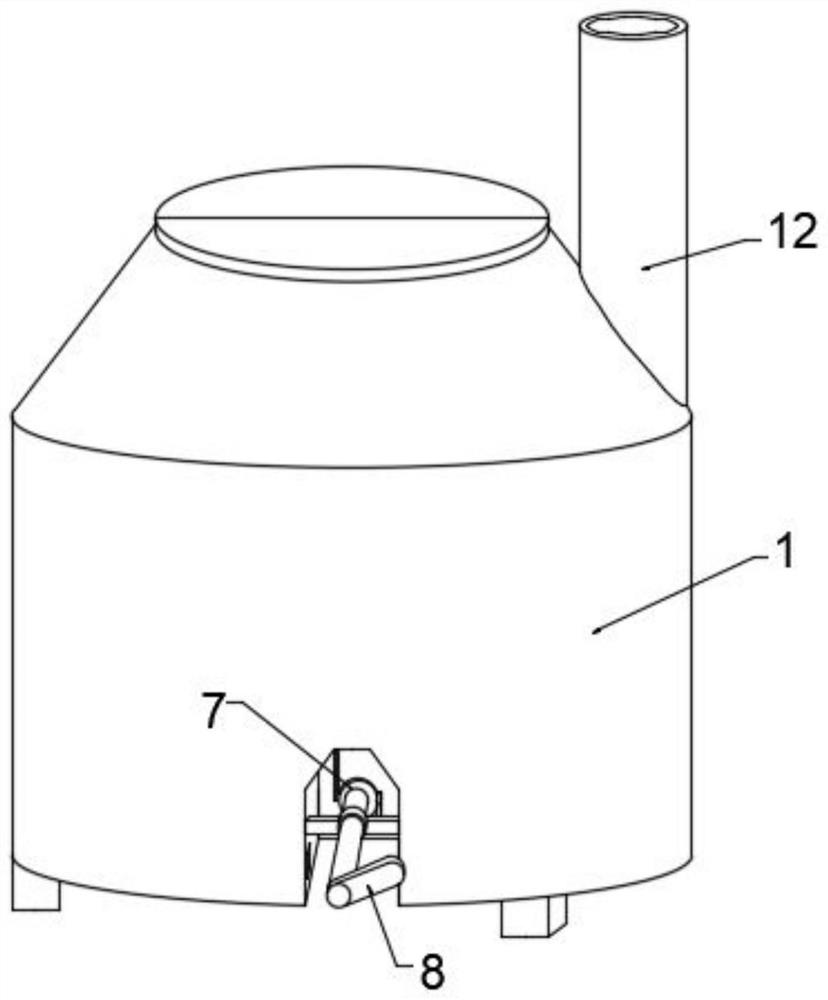

Heating device for winter construction of construction project and using method

ActiveCN113623717ABurn fullyImprove conversion rateDomestic stoves or rangesLighting and heating apparatusThermodynamicsSolid fuel

The invention discloses a heating device for winter construction of a construction project and a using method, and belongs to the technical field of indoor heat preservation of buildings. The heating device comprises a furnace body, a first fire grate and a second fire grate which are installed in the furnace body, and an adjusting mechanism installed in the furnace body and used for adjusting the first fire grate and the second fire grate to move up and down, wherein the mesh size of the second fire grate is smaller than that of the first fire grate. The first fire grate and the second fire grate are adjusted up and down through the adjusting mechanism, meshes of the second fire grate are smaller than those of the first fire grate, and fine particles of solid fuel on the first fire grate fall onto the second fire grate to continue to play a combustion effect, so that sufficient combustion of the solid fuel in the device is achieved, the heat energy conversion rate of the device is increased, and the energy-saving effect of the device is further achieved.

Owner:CHINA MCC17 GRP

A metal deposition forming method and device based on ultra-high frequency induction heating

InactiveCN109550947BImprove heat conversion rateLow costAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyMetallurgy

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

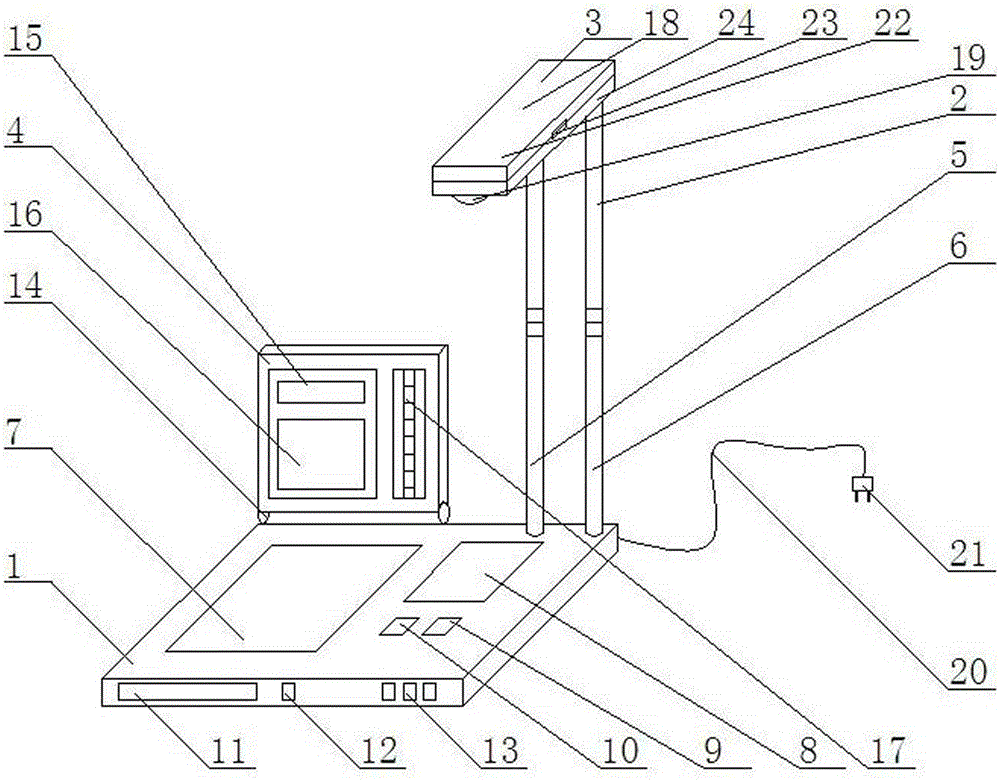

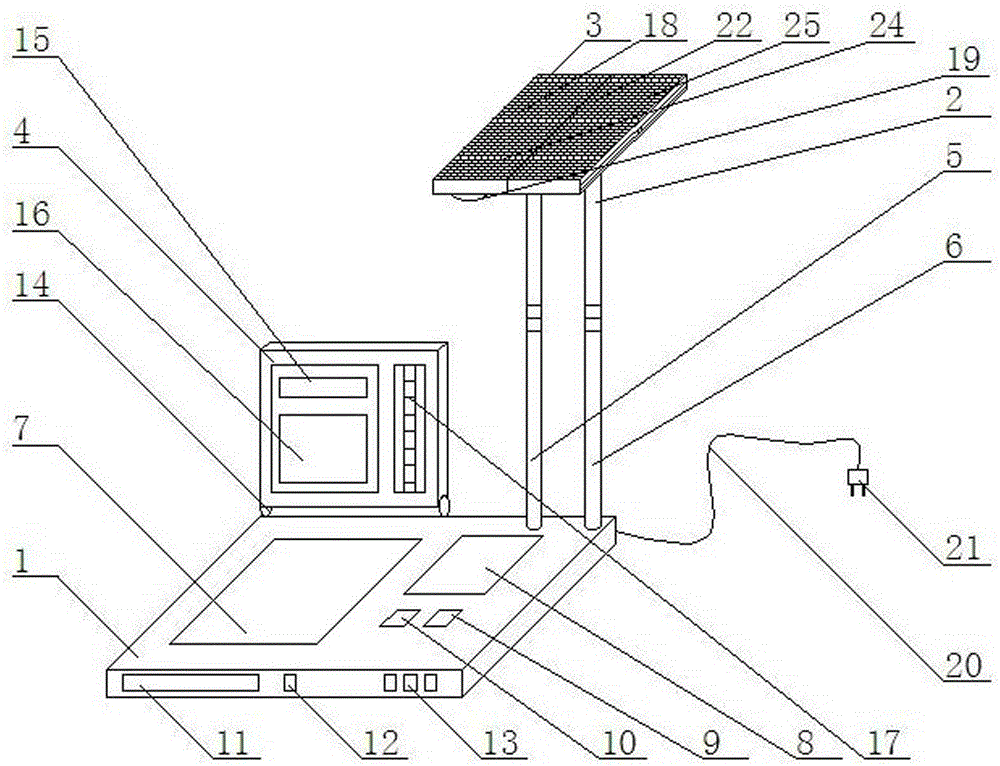

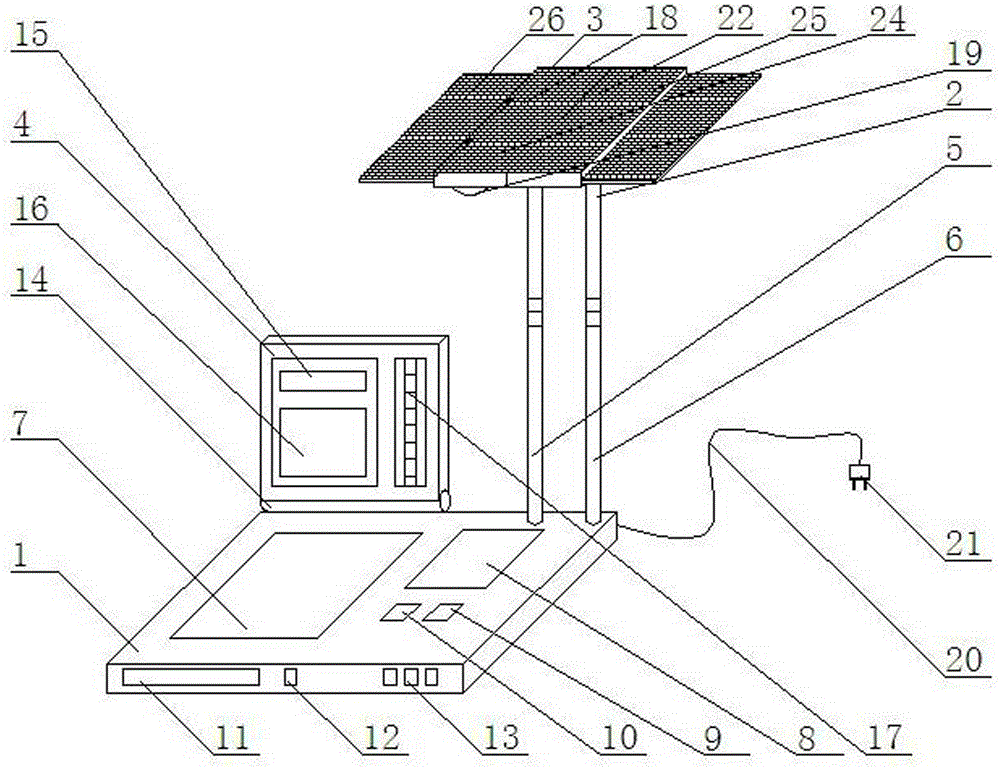

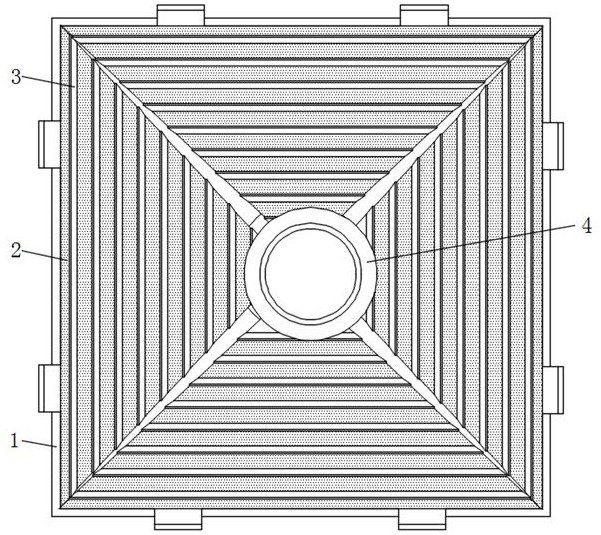

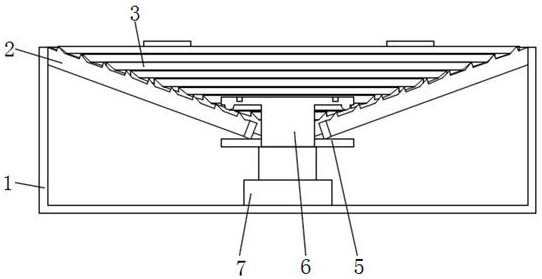

Solar table lamp

InactiveCN106402782AImprove protectionImprove heat conversion rateLighting support devicesLighting elementsEngineeringUSB

A solar table lamp comprises a lampholder, a supporting rod, a lamp cap and a turnover screen. The lampholder is a rectangular lampholder, and the supporting rod is composed of a left supporting rod body and a right supporting rod body and arranged at the rear right end of the top surface of the lampholder. A video and audio playing screen is arranged at the left end of the top surface of the lampholder, a calculator is arranged at the rear side of the right end of the top surface of the lampholder, and a lighting lamp switch and a video and audio playing screen switch are arranged at the front side of the right end of the top surface of the lampholder. The front surface of the lampholder is provided with a storage battery, a video and audio playing screen USB interface and three USB mobile phone charging interfaces. The turnover screen is connected to the rear left end of the top surface of the lampholder through a rotating shaft and can be overturned forwards to be buckled on the lampholder. The turnover screen is provided with a time display module, a calendar module and a temperature display module. A charging wire and a plug are arranged at the rear end of the lampholder. The solar table lamp has the advantages that energy is saved, the environment is protected, the functions are abundant, practicability is high, and the appearance is fashionable.

Owner:HARBIN JINDU SOLAR ENERGY TECH

Concentrating solar cell device

PendingCN113300671AImprove spotlight effectImprove practicalityPhotovoltaic supportsPhotovoltaic energy generationElectrical batteryEngineering

A concentrating solar cell device disclosed by the present invention comprises a device body, solar panel bearing tables, a pressing table and an electric telescopic rod, the top end of the device body is hinged with four groups of solar panel bearing tables, and the top end of each solar panel bearing table is fixedly provided with three-edged refraction strips at equal intervals; an electric telescopic rod is installed at the center position in the device body, a bearing platform is fixed to the top end of the electric telescopic rod, a moving tray moving up and down is concentrically fixed to the top end of each bearing platform, a connecting short column is welded to the center position of the top end of each moving tray, and a pressing table is installed at the top end of each connecting short column. And an extrusion cavity for preventing the solar panel bearing table is arranged between the pressing tables and the movable trays. The novel structural design is adopted, the condensation effect is enhanced, the heat energy conversion rate is increased, the practicability of the device is enhanced, the stable clamping function is achieved when the device is used, and therefore the stability of the device is enhanced when the device is used.

Owner:TSINGHUA UNIV +1

A high temperature heat transfer oil thermal energy conversion system

ActiveCN108120025BRealize the heating effectAchieve coolingStorage heatersCorrosion preventionThermal energySolenoid valve

Owner:珠海国能复合材料科技有限公司

On-line Calculation Method of Raw Coal Moisture in Medium Speed Coal Mill

ActiveCN110568018BReasonable control of outlet temperatureRealize online accurate calculationMolecular entity identificationMaterial moisture contentProcess engineeringHot blast

The invention discloses an online method for calculating the moisture content of raw coal in a medium-speed coal mill, which includes calculating the moisture content of coal powder; calculating the sealing air flow rate; calculating the amount of pebble coal; calculating the thermal insulation coefficient of the medium-speed coal mill; Calculate the heat absorbed by the raw coal and the sealed air; Calculate the heat taken away by the pebble coal; Substitute each data into the heat balance equation; Set up a comparison test to check the moisture content of the raw coal; Change the coal type and repeat the comparison test until you get stable parameter values. The method for online calculation of the raw coal moisture in the medium-speed coal mill is to sample and test the grinding product of the medium-speed coal mill, calculate the moisture of the raw coal through the heat balance equation, and set up multiple comparison tests to verify, which reduces the calculation error of the raw coal moisture. It is beneficial to make an accurate judgment on the coal type, to reasonably control the outlet temperature of the coal mill, and adjust the boiler operating parameters to the optimal value, thereby improving the thermal energy conversion rate of the raw coal.

Owner:广东红海湾发电有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com