Solar heat energy power system based on multistage pressurization condensation

A solar thermal energy and power system technology, which is applied in the direction of using solar energy to generate mechanical power, solar thermal power generation, and mechanisms for generating mechanical power, etc. problems, to achieve the effect of improving gasification efficiency and condensation efficiency, stabilizing gasification temperature and working fluid flow rate, and avoiding unstable turbine speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

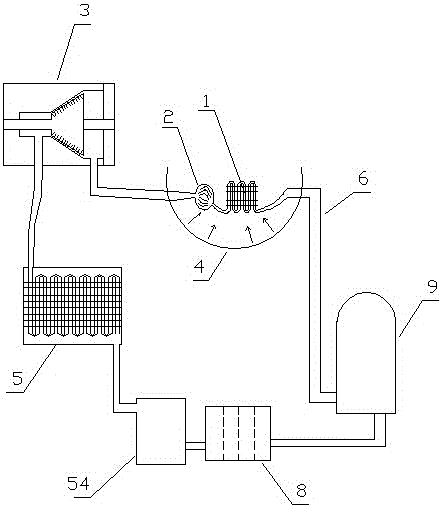

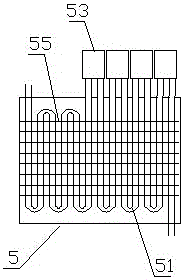

[0076] Embodiment one (such as figure 1 Shown): a solar thermal power system based on multi-stage pressurized condensation, including a heat collector 1, a gasification device 2, a turbine 3, a solar concentrator 4, a condensation device 5, a circulation pipeline 6, and a circulation medium 7 and the one-way hydraulic pump 9, the heat collecting device 1, the gasification device 2, the turbine 3, the condensing device 5 and the one-way hydraulic pump 9 realize circulation communication through the circulation pipeline 6 in sequence, and the circulation pipeline 6 contains a circulating working medium 7 for Gasification heating of the working fluid in the gasification device 2;

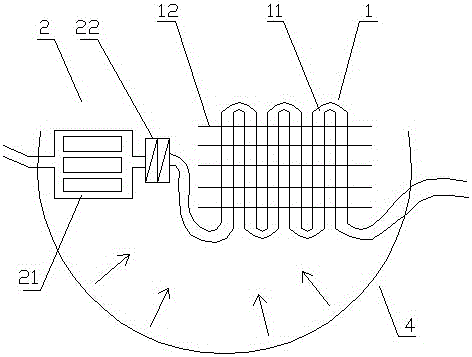

[0077] (Such as figure 2 As shown), the heat collecting device 1 and the gasification device 2 are installed in the solar concentrating cover 4, and the heat collecting device 1 includes solar heat collecting tubes 11 and solar heat collecting fins 12, and the solar heat collecting fins 12 are distri...

Embodiment 2

[0087] Embodiment two (such as Figure 6 shown): The difference from Embodiment 1 is that the solar heat collecting sheet 12 of the heat collecting device 1 is in the shape of a curved sheet.

[0088] By conducting experiments on the solar thermal power system based on multi-stage pressurized condensation in the above-mentioned embodiment two, the gasification temperature of the working fluid reaches 50°C, 55°C, 60°C, 65°C, At 70°C, when the temperature of the cold source is 18°C, the flow rate of the working medium in the circulation pipe is adjusted according to the operation stability of the solar thermal power system based on multi-stage pressurized condensation; the experimental results are: the gasification temperature of the working medium is 50°C When the gasification temperature of the working fluid is about 55℃, the thermal energy conversion efficiency is about 8%. When the gasification temperature of the working fluid is about 60℃, the thermal energy conversion eff...

Embodiment 3

[0089] Embodiment three (such as Figure 7 shown): The difference from Embodiment 1 is that the solar heat collecting fins 12 of the heat collecting device 1 are distributed in a staggered manner.

[0090] By conducting experiments on the solar thermal power system based on multi-stage pressurized condensation in the above-mentioned embodiment three, the gasification temperature of the working fluid reaches 50°C, 55°C, 60°C, 65°C, At 70°C, when the temperature of the cold source is 18°C, the flow rate of the working medium in the circulation pipe is adjusted according to the operation stability of the solar thermal power system based on multi-stage pressurized condensation; the experimental results are: the gasification temperature of the working medium is 50°C When the gasification temperature of the working fluid is about 55°C, the heat energy conversion efficiency is about 8.4%, and when the gasification temperature of the working fluid is about 60°C, the heat energy conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com