A high temperature heat transfer oil thermal energy conversion system

A technology of thermal energy conversion and heat transfer oil, which is applied in heat storage heaters, heat exchange equipment, indirect heat exchangers, etc., can solve the problem of high temperature heat transfer oil cooling, and achieve the effect of precise temperature control and high heat conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

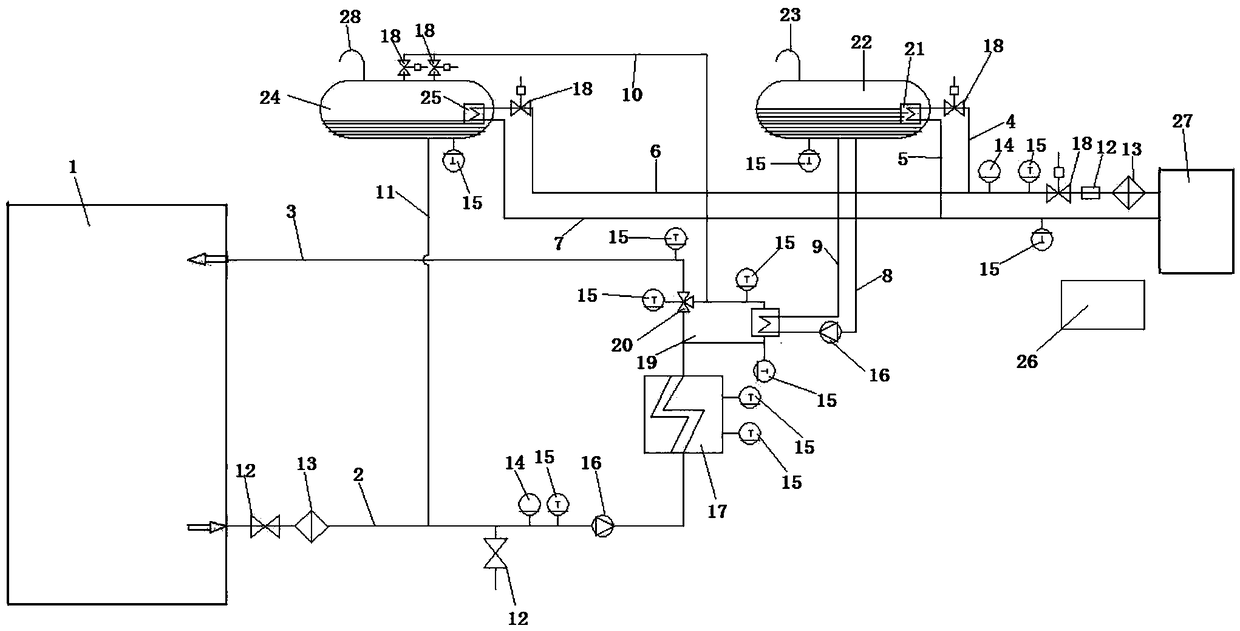

[0031] Embodiment 1, the heat transfer oil outlet of the external device 1 is connected to the heat transfer oil inlet of the heating system 17 through the heat transfer oil return line 2, and the heat transfer oil return line 2 flows from the heat transfer oil outlet of the external device 1 to the direction of the heating system 17. Solenoid valves 12, Filter 13, pressure sensor 14, temperature sensor 15, high temperature heat transfer oil pump 16, solenoid valve 12 and filter 13 are arranged at the intersection point of heat transfer oil return line 2 and expansion heat transfer oil return line 11, close to the heat transfer oil outlet of external device 1 side, the pressure sensor 14, the temperature sensor 15 and the high temperature heat transfer oil pump 16 are arranged at the intersection point of the heat transfer oil return line 2 and the expansion heat transfer oil return line 11 near the side of the heating system 17, and the heat transfer oil in the external equipme...

Embodiment 2

[0032] Embodiment 2, a second heat exchanger 21 is set in the oil storage tank 22, the cooling water inlet of the second heat exchanger 21 is connected to the outlet of the cooling water tower 27 through the cooling water output pipeline 4, and the cooling water outlet is connected to the cooling water outlet through the cooling water return pipeline 5. At the entrance of the water tower 27, a temperature sensor 15 is installed on the oil storage tank 22. The top of the oil storage tank 22 is connected with a first overflow pipe 23. The temperature of the cooling water in the cooling water tower 27 is kept at 15°C. A filter 13, a solenoid valve 12, a flow sensor 18, a temperature sensor 15 and a pressure sensor 14 are sequentially arranged in the direction of the oil storage tank 22; a third heat exchanger 25 is arranged in the expansion oil tank 24, and the third heat exchanger 25 cools the water inlet The cooling water output pipeline 4 is connected to the cooling water outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com