Safety testing system used for reactor pressure vessel under serious accident condition

A technology for safety testing and severe accidents, which is applied in the field of reactor pressure vessel safety testing systems, to achieve the effects of flexible temperature adjustment, real test data, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

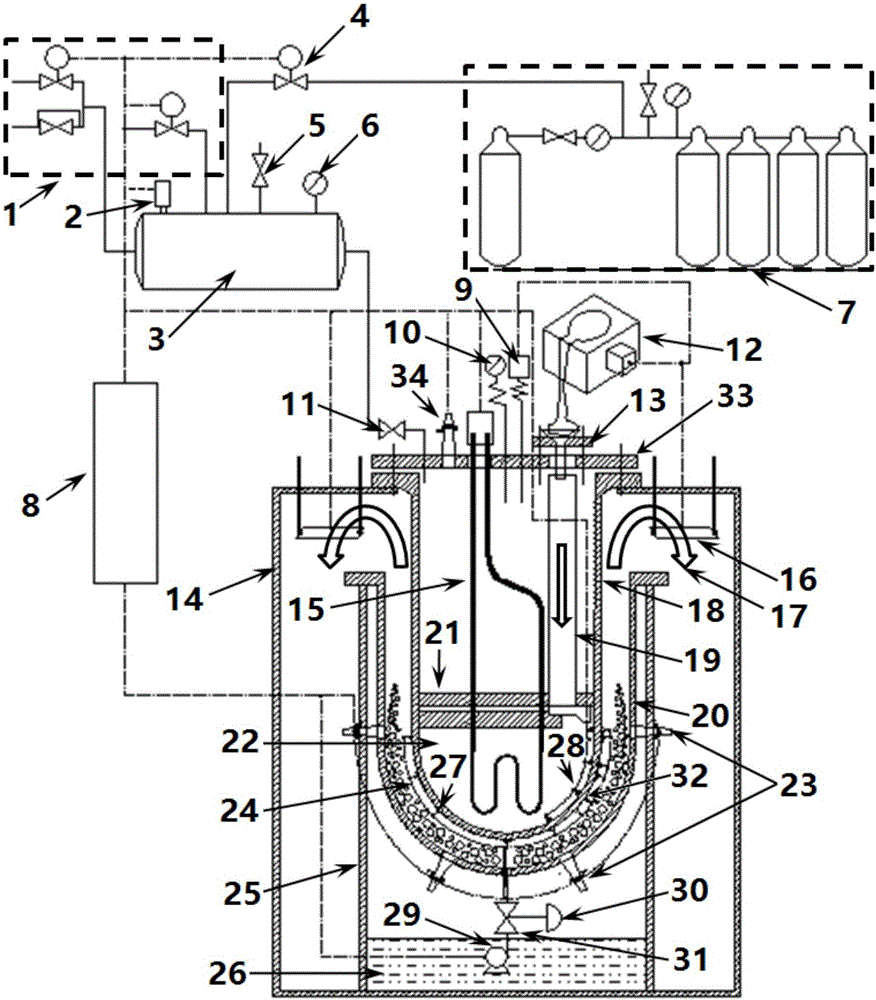

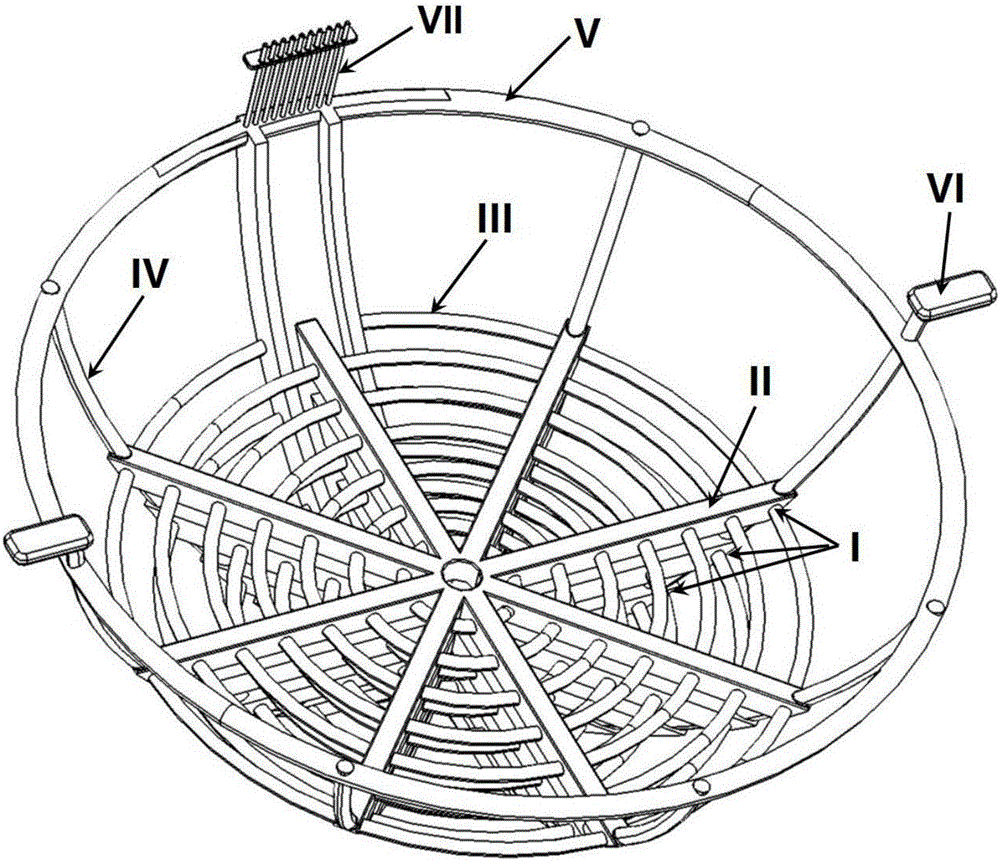

[0033] refer to figure 1 and figure 2 , the reactor pressure vessel safety test system under severe accident conditions, including a heater 15 and a containment shell 18, the upper part of the containment shell 18 is fixed on the top of the outer support wall 14, and the lower head of the containment shell 18 is suspended State; the bottom of the containment vessel 18 is provided with an overflow tower 20, the top of the overflow tower 20 is fixed on the top of the inner support wall 25, and the spherical head of the overflow tower 20 is in a suspended state; The bottom of the overflow tower 20 is provided with a reservoir 26 for storing cooling water, the reservoir 26 provides cooling water for the overflow tower 20, and the lower head of the entire containment vessel 18 is submerged in the cooling in the water;

[0034] A heater 15 is arranged in the containment vessel 18, and the heater 15 is used to uniformly heat the molten material 22 in the containment vessel 18 at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com