An adjustable wheelbase fan cooling structure

A heat dissipation structure and fan technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of different heat dissipation pressures of motor fans, unfavorable energy conservation and environmental protection, and the inability of fans to move easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

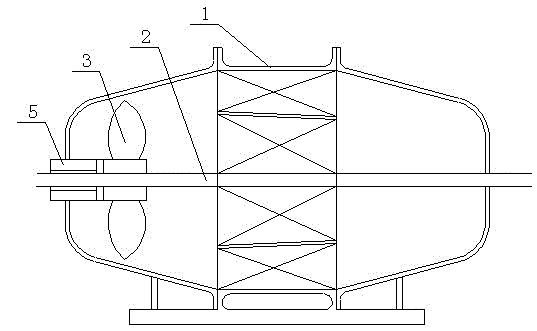

[0009] Such as figure 1 As shown, the heat dissipation structure of the adjustable wheelbase fan according to the embodiment of the present invention includes a motor body 1, a drive shaft 2 is provided in the center of the motor body 1, and inside the motor body 1 at the non-power output end of the drive shaft 2 A cooling fan 3 is installed. The cooling fan 3 and the drive shaft 2 are connected by a spline groove and slidably fitted. An adjustment sleeve 5 is installed on the housing of the motor body 1 at the non-power output end of the drive shaft 2. The adjusting sleeve 5 is connected with the drive shaft 2 through a screw thread, and the inner side of the adjusting sleeve 5 is in contact with and slidingly connected with the heat dissipation fan 3.

[0010] In the heat dissipation structure of the adjustable wheelbase fan of the present invention, the position of the heat dissipation fan on the drive shaft can be adjusted by adjusting the sleeve, thereby achieving different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com