Radiator with adjustable vertical distance and working method thereof

A heat sink and adjustable technology, applied in energy-saving calculation, cooling/ventilation/heating transformation, climate sustainability, etc., can solve problems such as inability to adjust, and achieve the effect of ensuring normal use, avoiding overheating, and reasonable structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

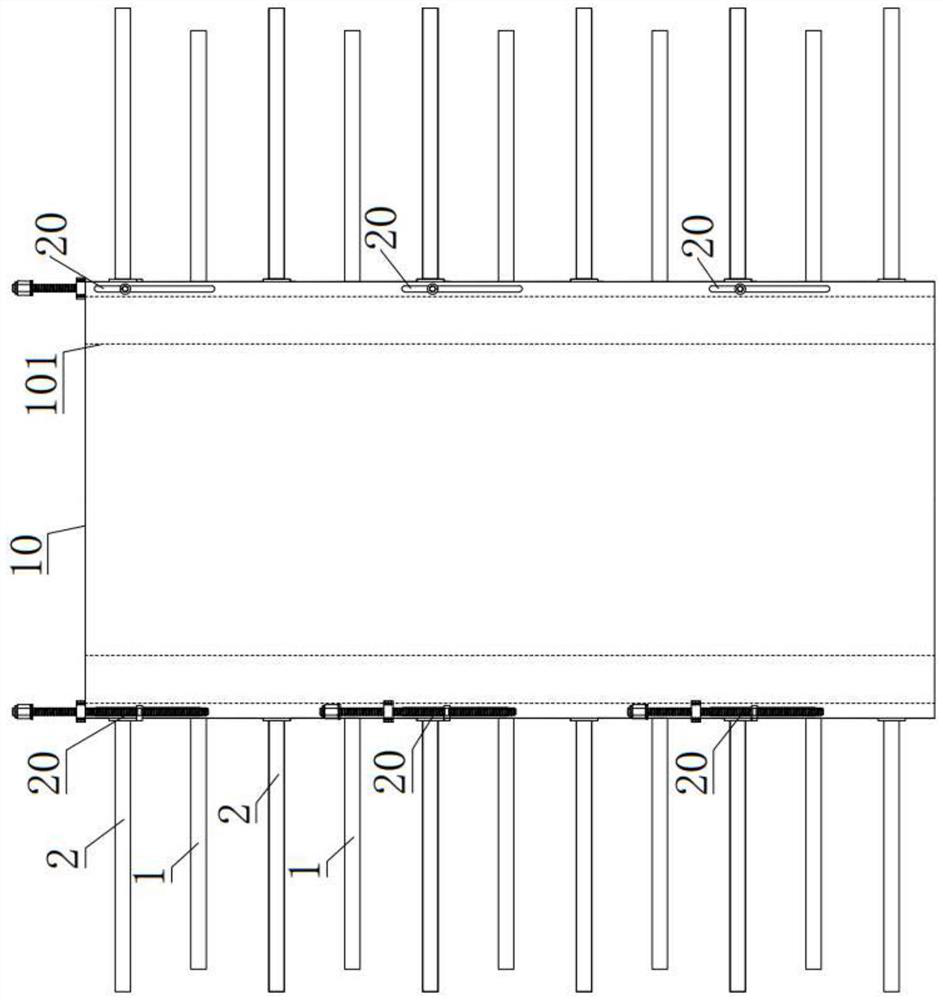

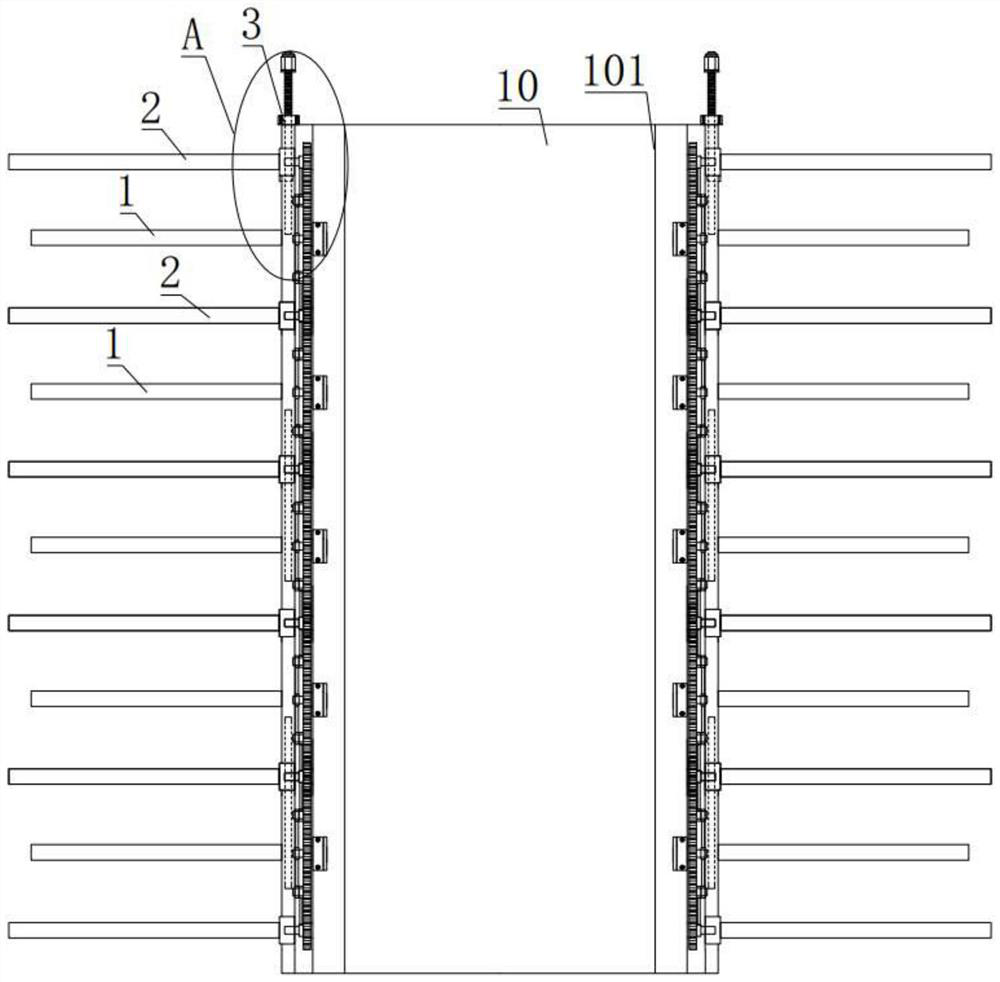

[0034] like figure 1 , 2 The shown radiator with adjustable upper and lower spacing includes a radiator base 10 and two oppositely staggered radiating fin units 20. The radiator base 10 has a rectangular cylindrical structure, and two relatively staggered radiating fins The units 20 are respectively arranged on two opposite outer side walls of the radiator base 10; wherein, the heat dissipation fin units 20 are all composed of a set of heat dissipation fin spacing adjustment modules, and a set of heat dissipation fin spacing adjustment modules along the heat sink The length direction of the base body 10 is arranged in a row. The cooling fin spacing adjustment module includes two fixed cooling fins 1 , two movable cooling fins 2 and a fin spacing adjustment device 3 . The two fixed cooling fins 1 and the two movable cooling fins 2 are spaced apart, and the two fixed cooling fins 1 and the two movable cooling fins 2 are on the same line, the fin spacing adjustment device 3 is a...

Embodiment 2

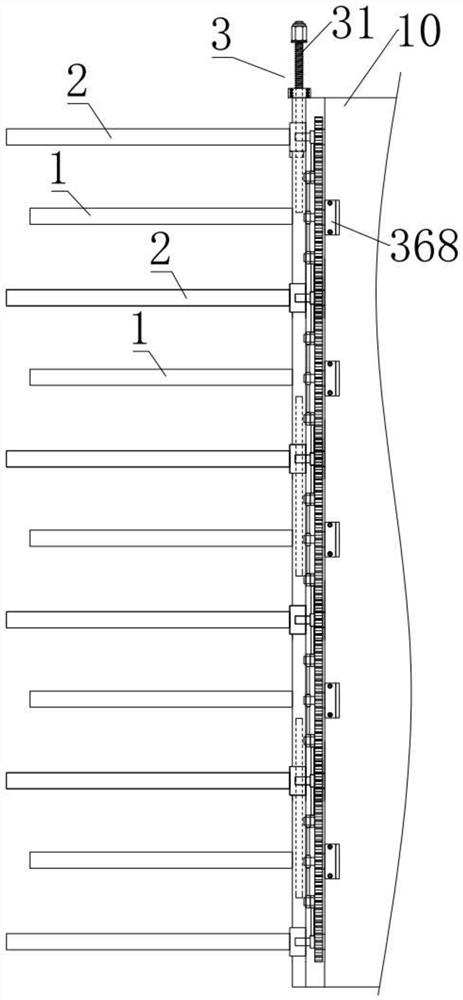

[0041] like Figure 5 , 6 The shown fin spacing adjustment assembly 36 includes a spacing adjustment driving wheel 361, a fixed rotating wheel 362, a spacing adjustment driving wheel 2 363, a spacing adjustment driving wheel 364, a spacing adjustment slider 365, a rotating rod 366, and a spacing adjustment drive pendulum. Rod 367, gear support seat 368, shaft one 369, shaft two 3610, shaft three 3611 and shaft four 3612, the distance adjustment drive wheel one 361 is connected with the shaft one 369, the active swing rod 34 is away from the end of the driving shaft 33 and one end of the rotating rod 366 are sleeved on the first rotating shaft 369, the middle position of the rotating rod 366 is sleeved on the second rotating shaft 3610, the second rotating shaft 3610 is set on the gear support seat 368, the gear support seat 368 It is arranged in the radiator base 10, the fixed rotating wheel 362 is connected with the second rotating shaft 3610, the other end of the rotating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com