Internal combustion engine

An internal combustion engine, engine technology, applied in the direction of internal combustion piston engine, combustion engine, engine operation, etc., can solve the problems of increasing engine energy ineffective consumption, increasing energy consumption, reducing pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

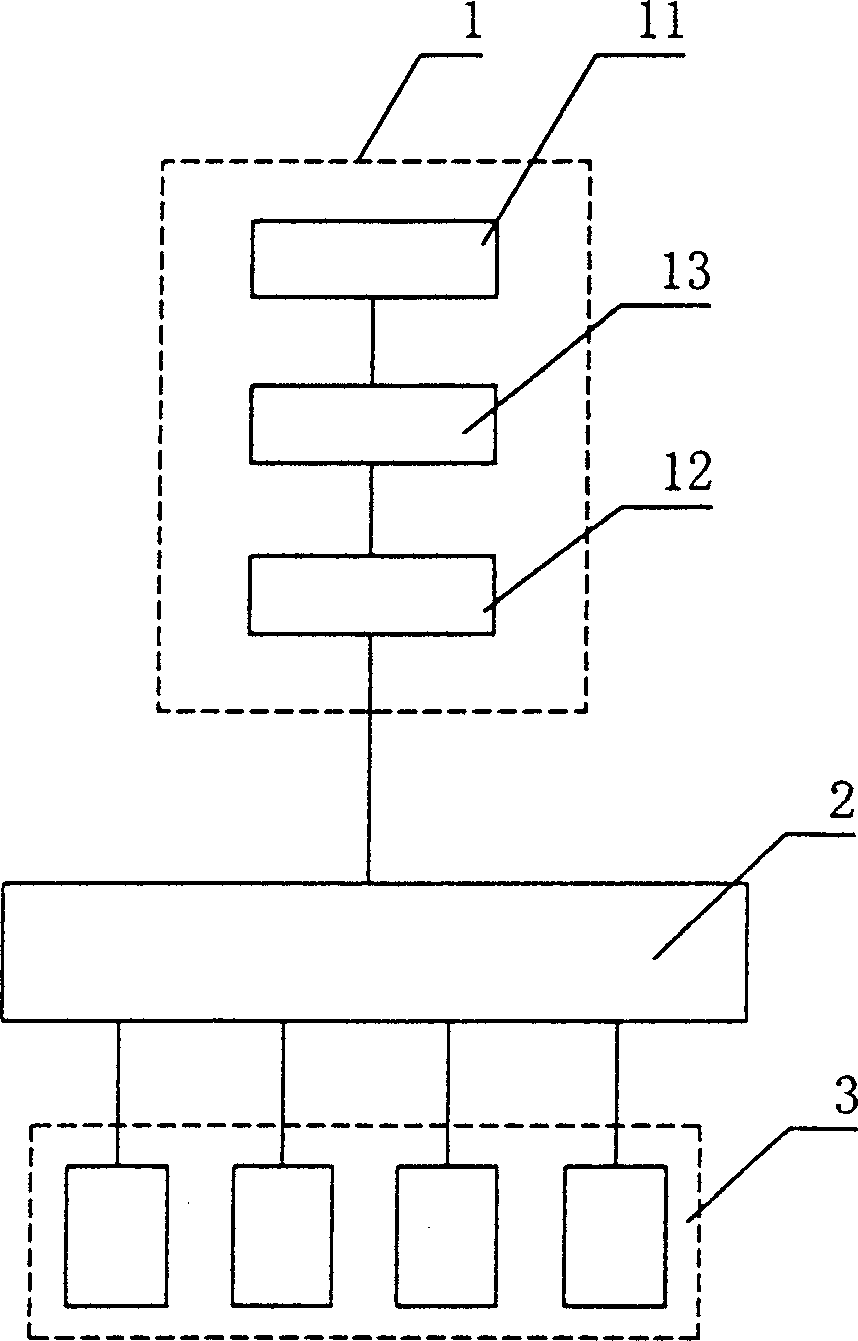

[0011] With reference to accompanying drawing, a kind of novel internal combustion engine of the present invention is: the body of engine is provided with fuel supply injection system, is provided with fuel injector (or spark plug) in the combustion chamber of engine, and this internal combustion engine adopts mineral-free water as auxiliary For the working medium, the engine body is also provided with a heating device 1 capable of heating mineral-free water, a high-pressure pump 2, and nozzles 3 are provided in the combustion chamber of the engine. If it is a multi-cylinder internal combustion engine, nozzles 3 are provided in each combustion chamber; The heating device 1, the high-pressure pump 2 and the nozzle 3 communicate in sequence through a conduit. The mineral-free water is heated by the heating device 1, and the heating device 1 adopts a heat exchanger 11 arranged on the engine body to exchange heat with high-temperature components on the engine body and a heater usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com