Heat pump generator or engine

A heat pump and generator technology, applied in machines/engines, heat pumps, refrigerators, etc., can solve problems such as low thermal energy transfer rate, large amounts of exhaust gas, dust, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

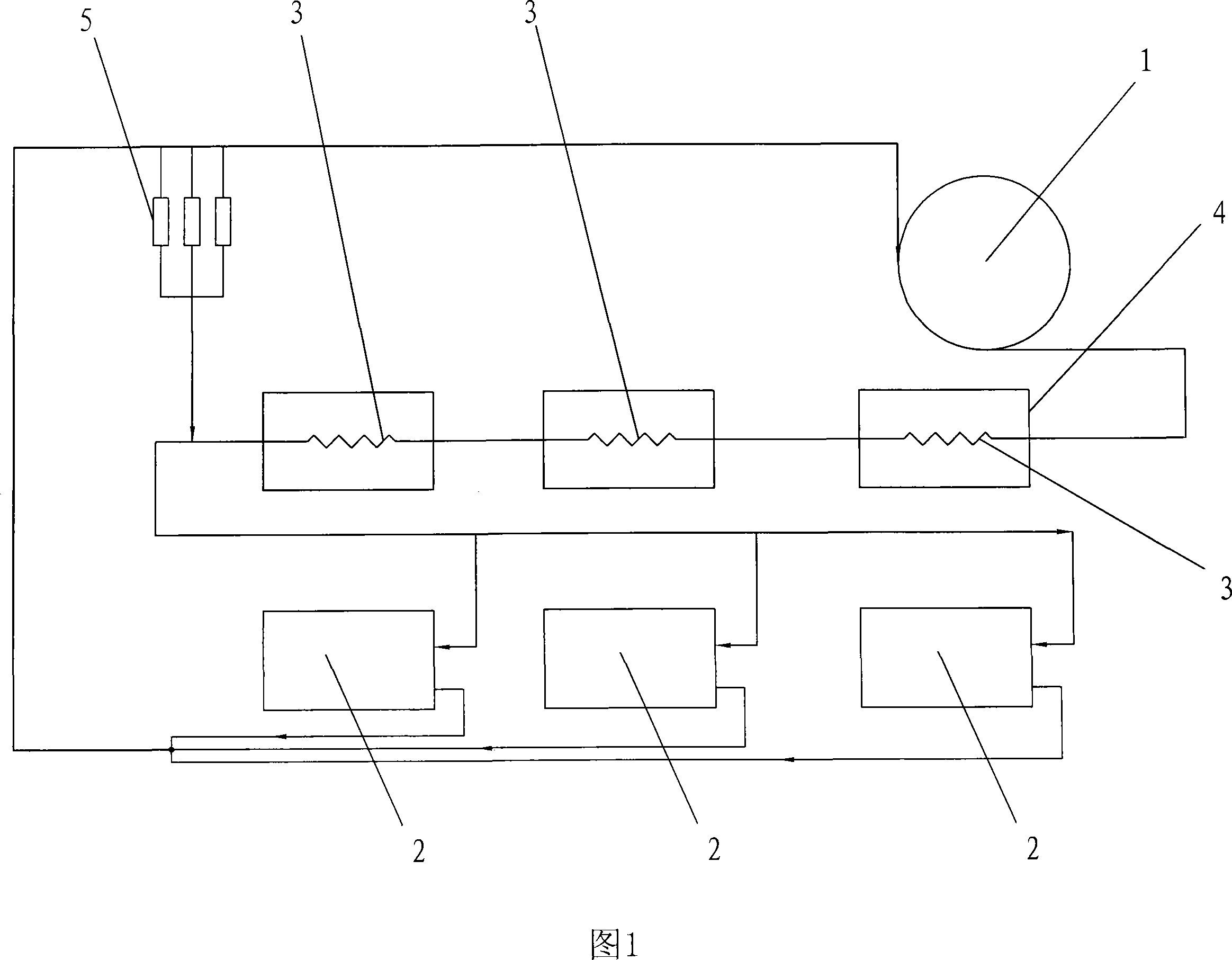

[0011] As shown in Figure 1, a single refrigerant system: a heat pump generator or engine includes a steam turbine 1, a generator or an engine (not shown in the figure), three condensers 3, three condensate tanks 4, and three heat pumps Or the unit 2 and the oil separation device 5, the steam turbine 1 and the condenser 3, the condenser 3 and the heat pump or unit 2, the heat pump or unit 2 and the steam turbine 1 are connected by pipes, and the refrigerant is carried in the pipes; the condenser 3 is immersed in the condensing In the water tank 4 , the oil separation device 5 is connected to the pipeline between the heat pump machine or unit 2 and the steam turbine 1 , and between the condenser 3 and the heat pump machine or unit 2 .

[0012] The condensers 3 are connected in series, and each condenser 3 is individually immersed in the water of the condensed water tank 4; the three heat pump machines or units 2 are connected in parallel.

[0013] Heat pump machine or unit 2, c...

Embodiment 2

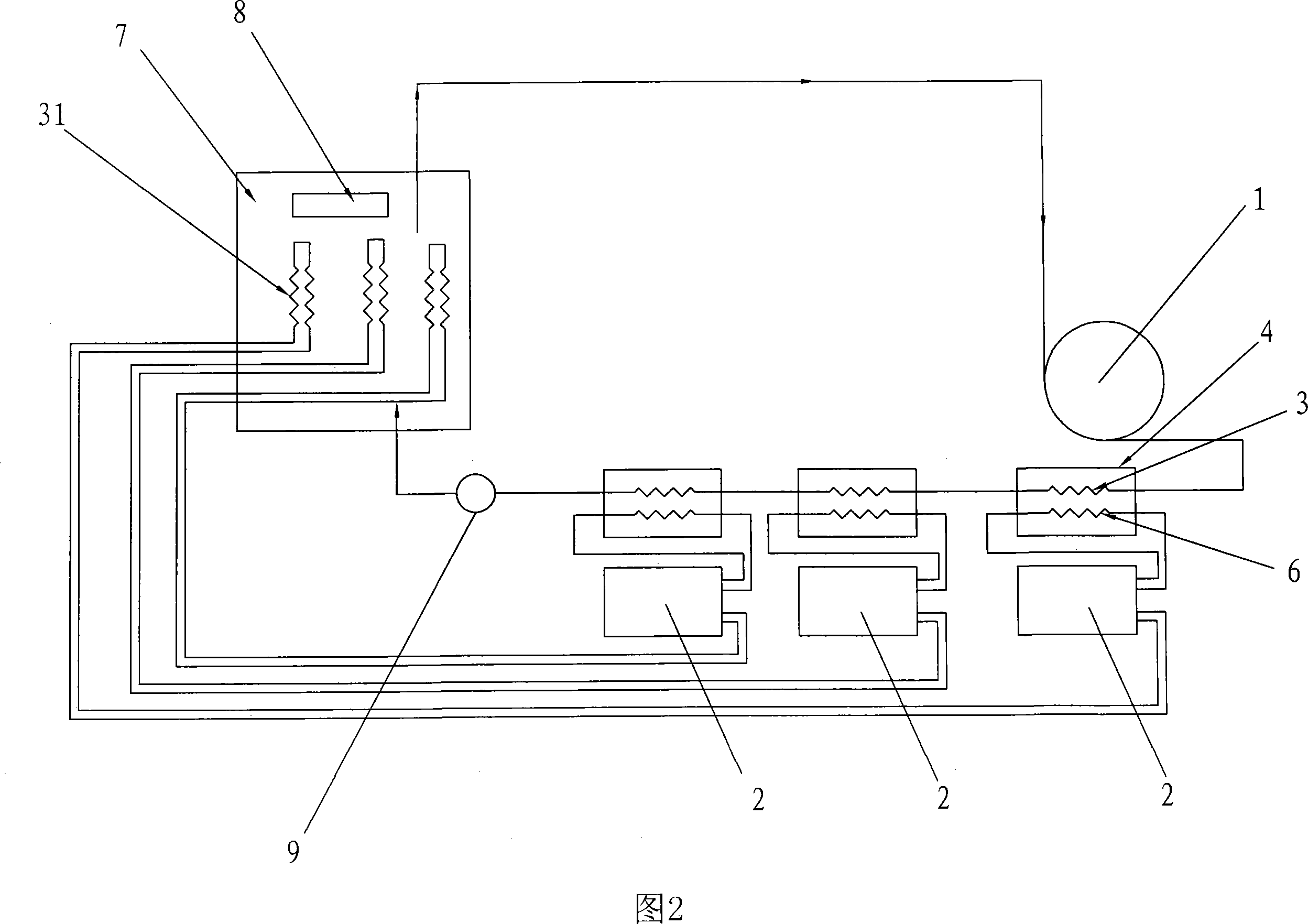

[0016] As shown in Figure 2, dual refrigerant system: this heat pump generator or engine includes a steam turbine 1, a generator or engine (not shown in the figure), three condensers 3, three condensate water tanks 4, and three evaporators 6. Three heat pumps or units 2 and steam boiler 7, steam turbine 1 and condenser 3, condenser 3 and steam boiler 7, steam boiler 7 and steam turbine 1 are connected by pipes, and steam boiler 7 uses refrigerant; condenser 3 Immersed in the water in the condensed water tank 4, a refrigerant pressure pump 9 is connected between the steam boiler 7 and the condenser 3; the condenser 31 and the evaporator 6 of the heat pump system are connected to the heat pump machine or unit 2, and the evaporator 6 is immersed in the condensed water tank 4, the heat pump system condenser 31 is installed in the steam boiler 7.

[0017] Three condensers 3 are connected in series, and each condenser 3 is individually immersed in a condensed water tank 4; there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com