High-efficiency engine

An engine and high-efficiency technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of large lateral force on the piston, serious friction and wear, etc., to reduce knocking, improve thermal power conversion rate, and reduce the amount of formation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

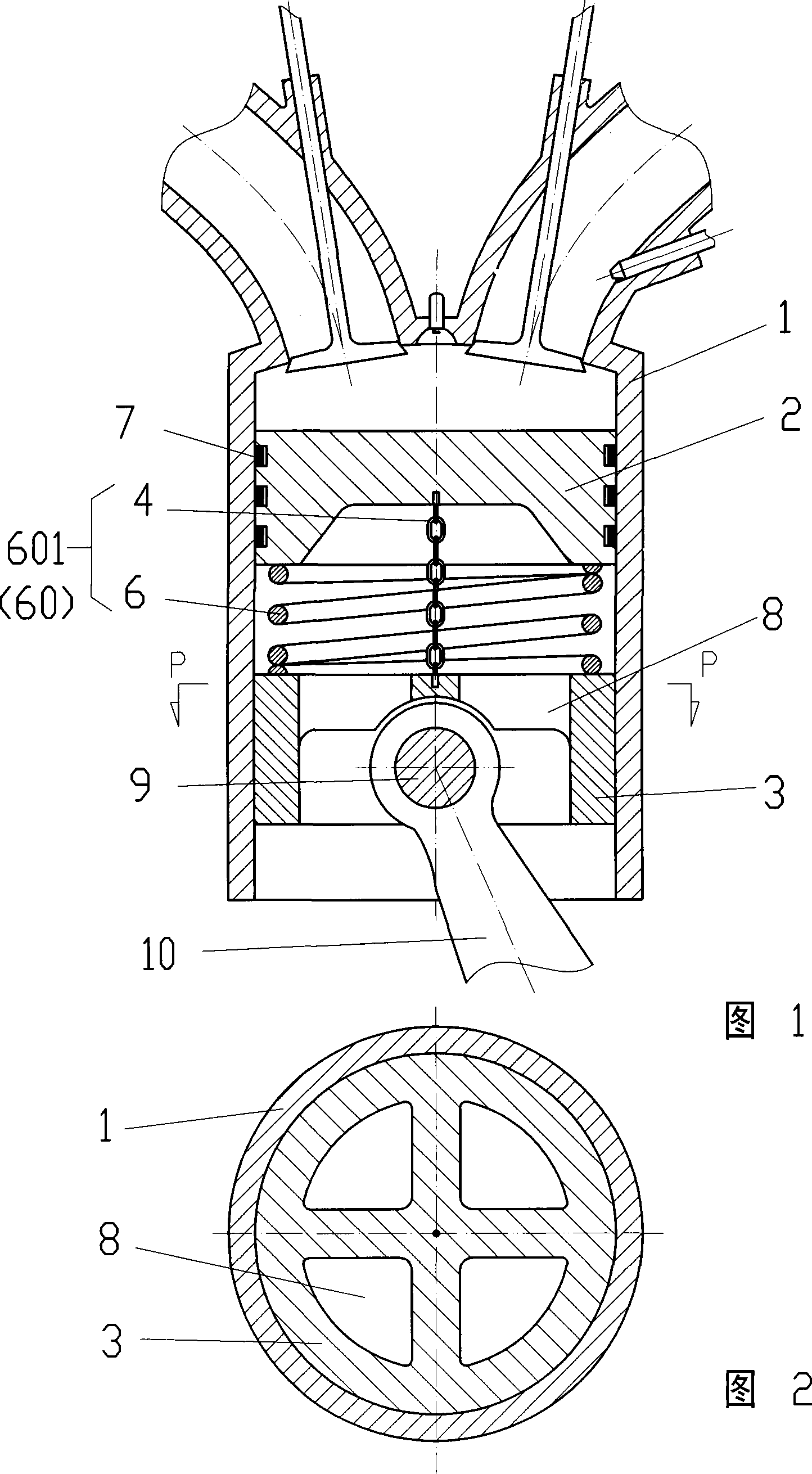

[0022] The high-efficiency engine shown in Figure 1 and Figure 2 includes a cylinder 1, a piston 2, a guide body 3, a piston pin 9 and a connecting rod 10, and a movable connection device 60 is arranged between the piston 2 and the guide body 3, The movable connection device 60 is configured as a pre-compressed spring 601 , and the guide body 3 is movably connected with the connecting rod 10 .

[0023] The guide body 3 is set as a slider structure 3 that is in sliding contact with the lower section of the cylinder 1 and is connected with the connecting rod 10 through the piston pin 9. The slider structure 3 is provided with a fluid channel 8, and the piston 2 In sealing and sliding contact with the upper section of the cylinder 1, the precompression spring 601 is composed of a spring 6 and a stretch limiting cable chain 4, one end of the stretch limiting cable chain 4 is connected to the piston 2, and the other end is connected to the slider structure The body 3 is connected, ...

Embodiment 2

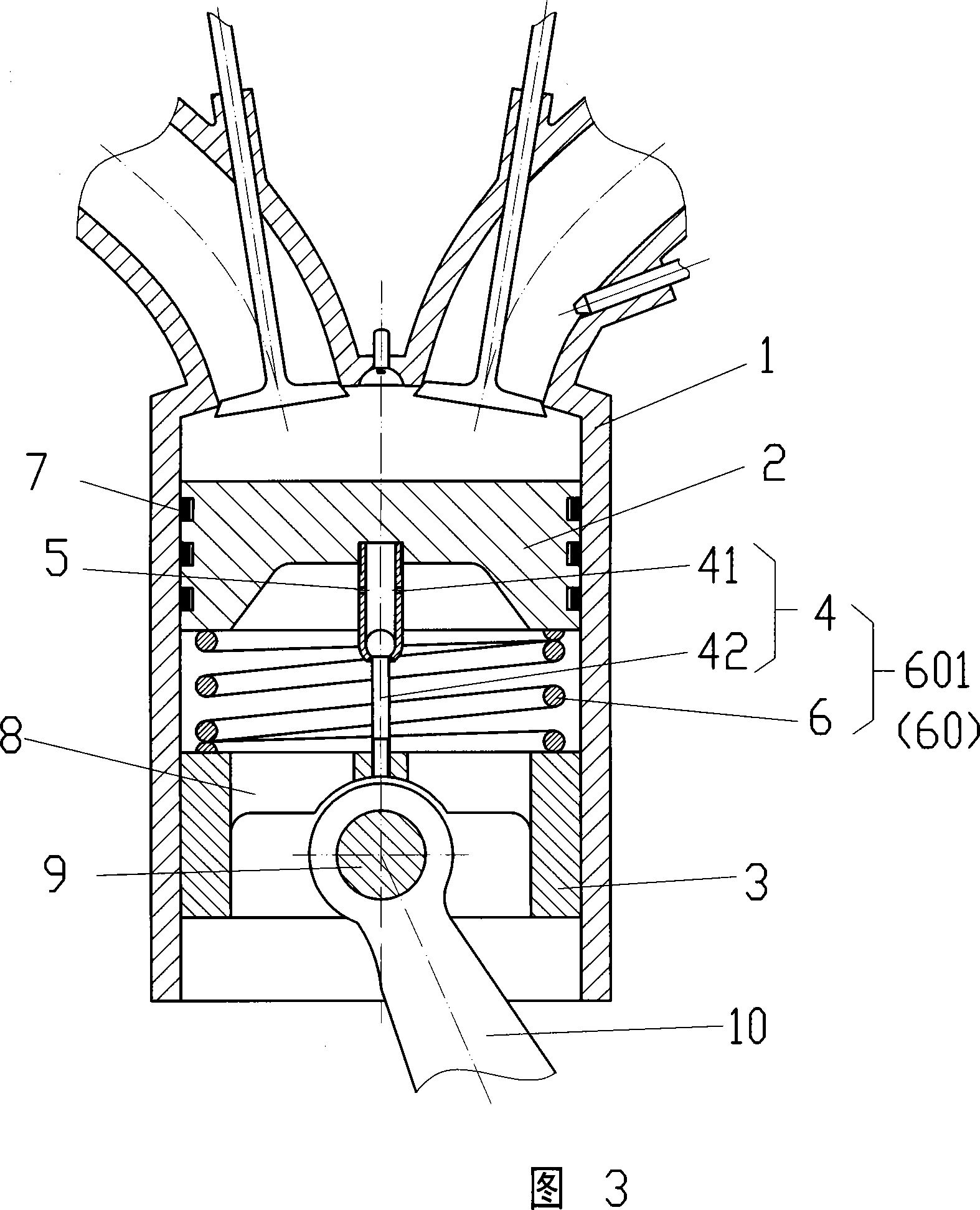

[0025] In the high-efficiency engine shown in Figure 3, the precompression spring 601 is composed of a spring 6 and a stretch limiter 4, one end of the stretch limiter 4 is connected to the piston 2, and the other end is connected to the slider structure 3 connection, the extension-limiting sleeve rod 4 is composed of a ball-end bushing 41 and a ball-end rod 42, the ball-end bushing 41 is provided with an oil hole 5, and the rest of the structure is the same as in Embodiment 1.

Embodiment 3

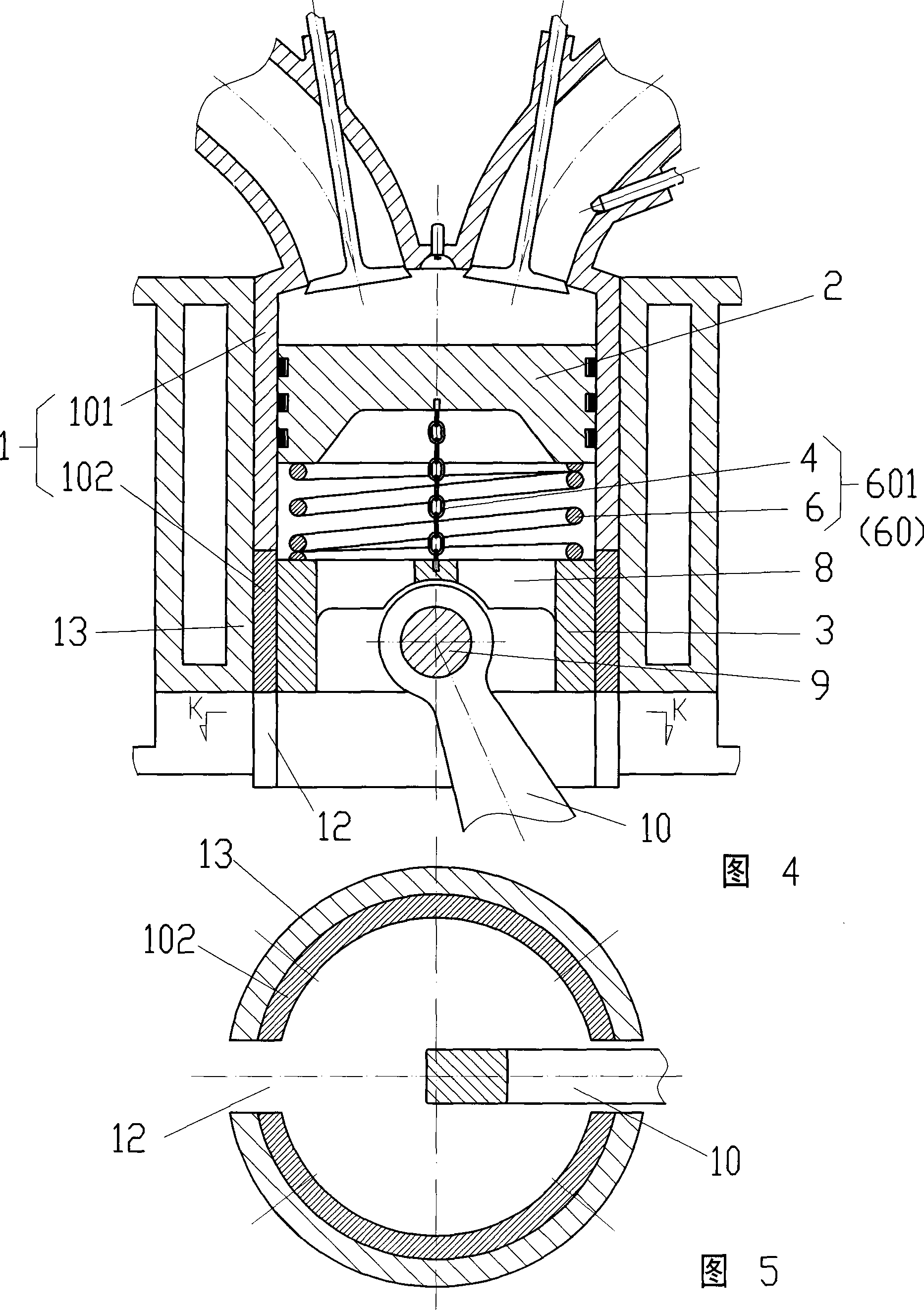

[0027] As for the high-efficiency engine shown in Figures 4 and 5, the cylinder 1 is set as an upper cylinder 101 and a lower slide 102, and the lower slide 102 can be set to be equal or unequal to the upper cylinder 101, or Can be made as non-drum type, also can be provided with opening 12, all the other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com