Composite material floor heating plate

A technology of composite materials and floor heating panels, applied in heating element materials, heating fuels, central heating components, etc., can solve the problems of complex installation process of floor heating, low heat conversion rate of heating system, high energy consumption, etc., to reduce indoor and outdoor air Pollution, prevention of heat energy from being emitted to the outside, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

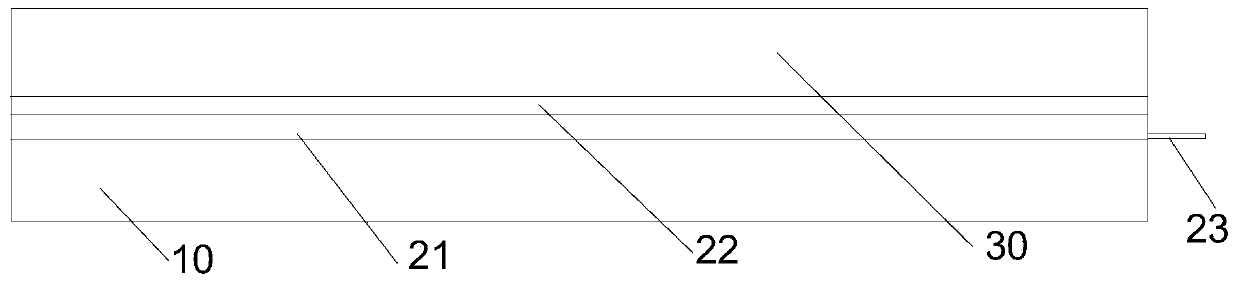

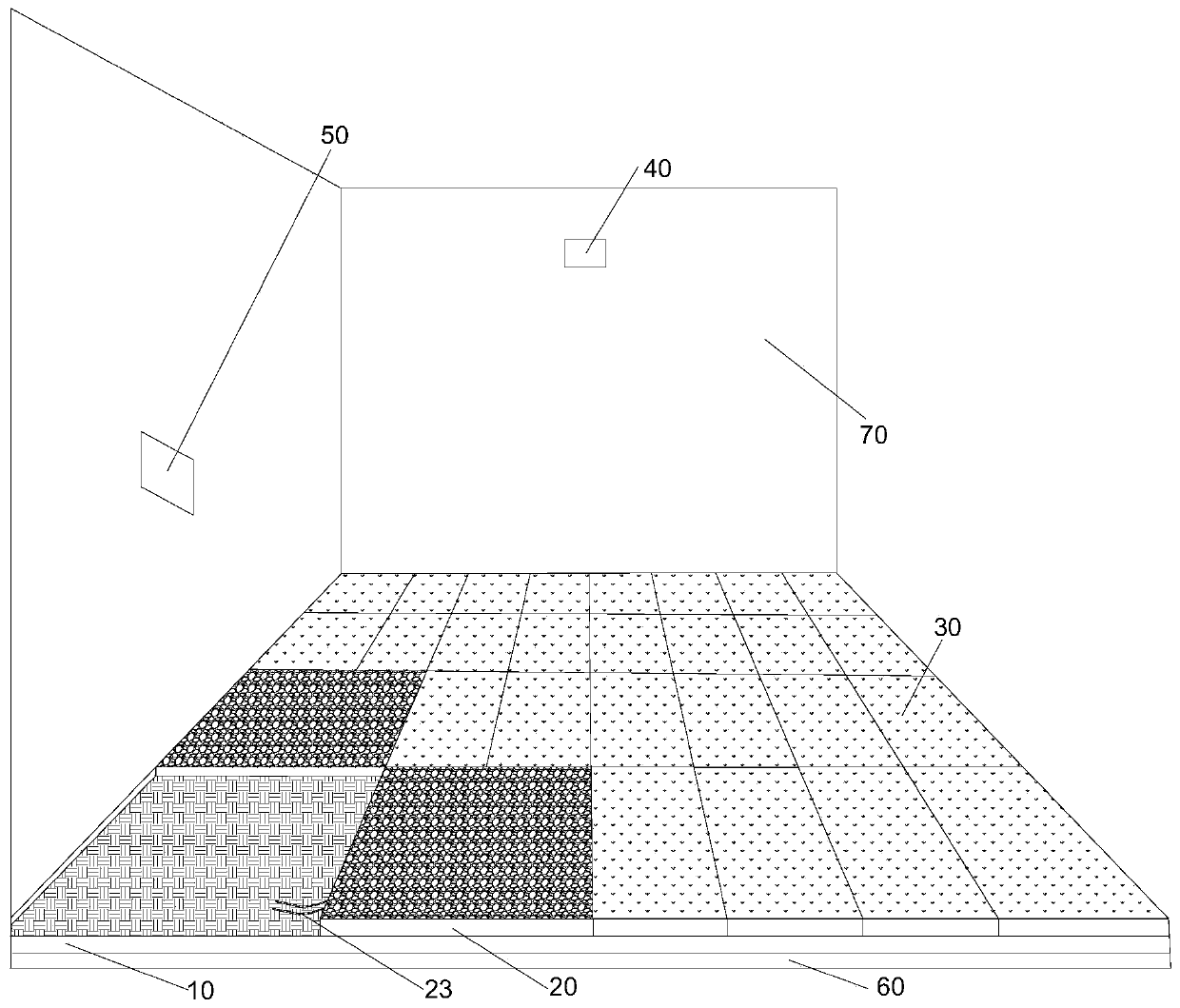

[0032] Please see Figure 1~2 , the embodiment of the present application provides a composite material floor heating panel, which mainly includes a thermal insulation layer 10, a heating system 20 and a ground decoration layer 30, wherein the thermal insulation layer 10 is preferably basalt rock wool, and the heating system 20 includes a heating layer and a heat dissipation layer, the further heating layer is carbon fiber heating film 21, the heat dissipation layer is basalt fiber cloth 22, and the ground decoration layer 30 is basalt fiber composite material.

[0033] Basalt rock wool is made of high-quality basalt as the main raw material, which is melted in a high-temperature furnace to form discontinuous fibers, and then made by solidification, cutting and other processes. The specifications of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com