A full heat recovery integrated gas heat pump heating unit and its application

A gas-fired heat pump and total heat recovery technology, applied in heat recovery systems, heat pumps, applications, etc., can solve problems such as unsatisfactory efficiency, complex structure, and poorly resolved defrosting control problems, so as to improve the ability to prevent frosting , High thermal energy conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

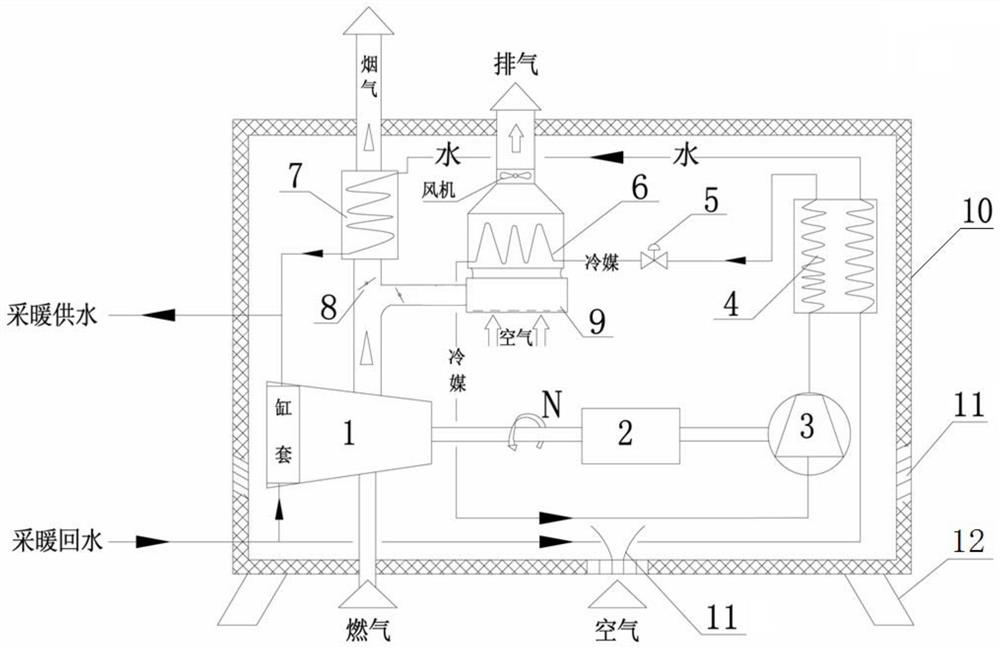

[0038] A full heat recovery type integrated gas heat pump heating unit, refer to figure 1 , including: internal combustion engine 1, transmission coupling 2, compressor 3, condenser 4, expansion valve 5, evaporator 6, flue gas waste heat recovery device 7, smoke exhaust control valve 8, flue gas and air mixing chamber 9, inlet Windshield 10 and shell 11.

[0039] The internal combustion engine 1, transmission coupling 2, compressor 3, and condenser 4 are sequentially connected, and the exterior of the internal combustion engine 1 is provided with a cylinder liner; the expansion valve 5 is arranged between the condenser 4 and the evaporator 6 On the communication pipeline, and the evaporator 6 is connected back to the compressor 3 to form an air source heat pump refrigerant system; the flue gas waste heat recovery device 7 is arranged on the flue gas pipeline of the internal combustion engine 1, and the flue gas and air mixing chamber 9 and The air inlet of the evaporator 6 is...

Embodiment 2

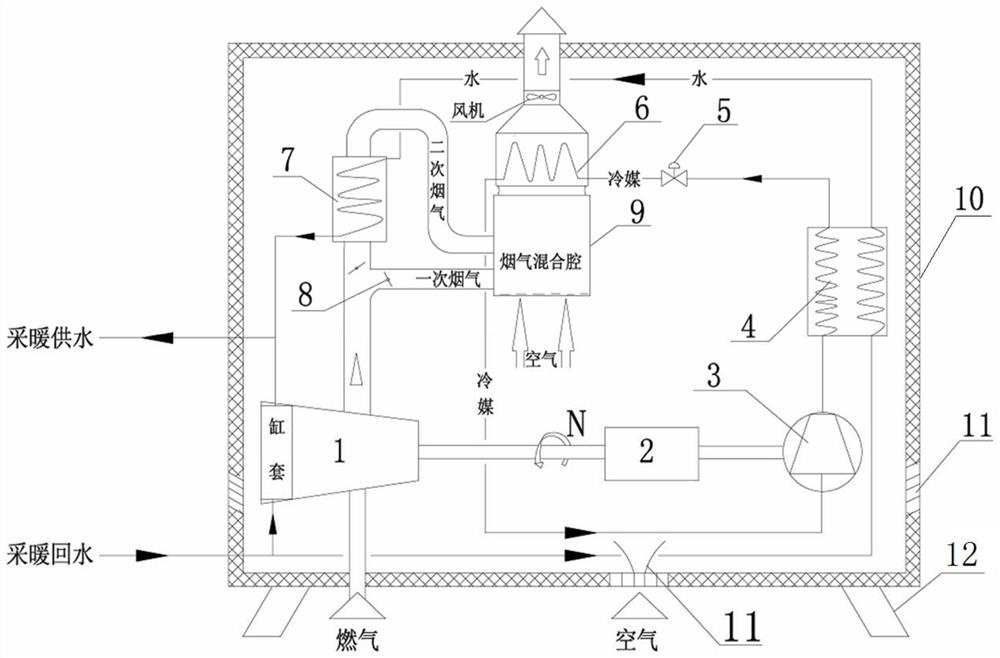

[0042] A full heat recovery type integrated gas heat pump heating unit, the same as the embodiment 1, the difference is: refer to figure 2 , the outlet of the flue gas waste heat recovery device 7 communicates with the flue gas and air mixing chamber 9, and the flue gas enters the air mixing chamber 9 again after exchanging heat with the heating water in the flue gas waste heat recovery device 7 for reuse.

[0043] The characteristics of the heating unit in this embodiment are: due to the large condensation pressure of this model, the temperature of the water outlet from the condenser or the heating circulating water entering the flue gas waste heat recovery device is relatively high, resulting in the flue gas discharged from the flue gas waste heat recovery device ( Secondary flue gas) has a high temperature, so it should all enter the evaporator for further full utilization. The heating unit in this embodiment can provide hot water for heating at a temperature above 55°C, a...

Embodiment 3

[0045] A full heat recovery type integrated gas heat pump heating unit, the same as Embodiment 1 or 2, the difference is that: the air inlet window 11 is provided with a deflector; the deflector can ensure that the air intake passes through the internal combustion engine, coupling Heat dissipation components such as heat exchangers, compressors, heat exchangers, pipelines, etc., so that the waste heat can be fully absorbed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com