Patents

Literature

95results about How to "Raise the inlet air temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

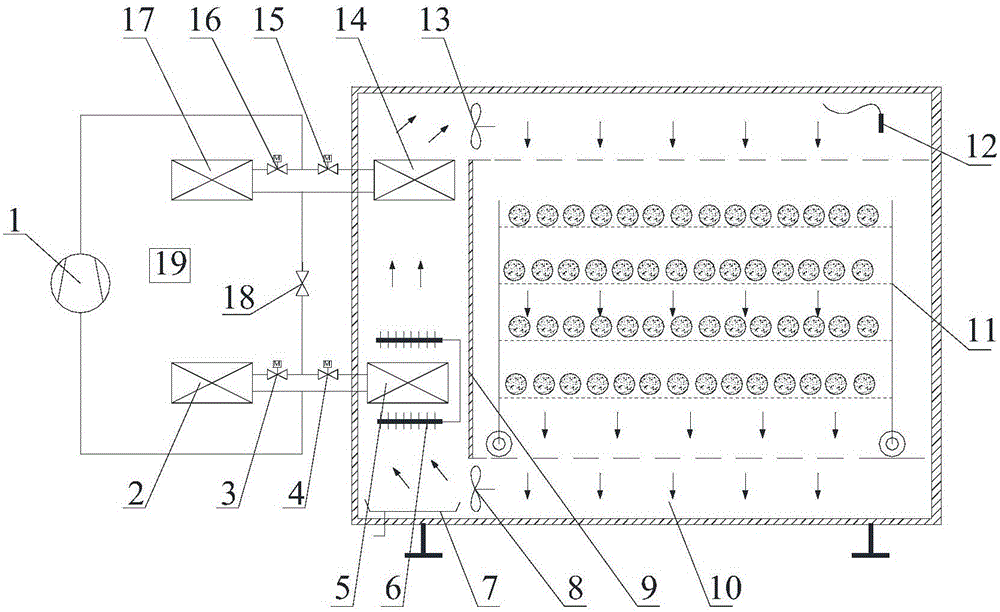

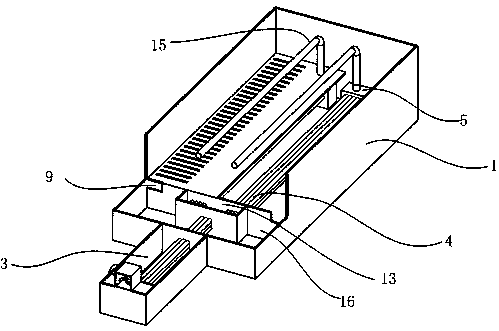

Data center water-cooling heat pipe cooling system and method

InactiveCN104833029AIncrease the display densityLarge temperature difference between inlet and outlet airLighting and heating apparatusAir conditioning systemsData centerProcess engineering

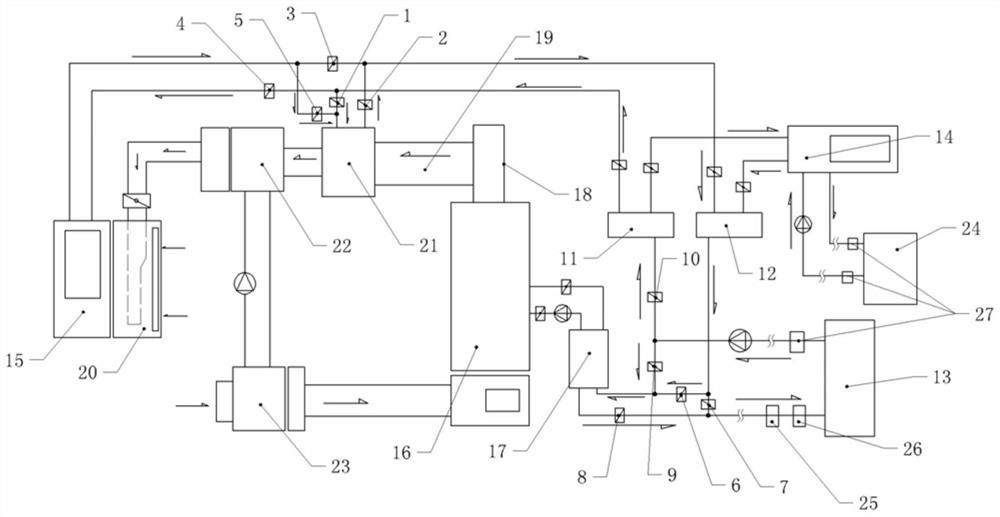

The invention discloses a data center water-cooling heat pipe cooling system and method. The system and the method aim to overcome the defects that the cooling efficiency is low and the air-conditioning power consumption is large in the using process of a data center in the prior art. The cooling system partitions a data center into an upper equipment cabinet space and a lower refrigerating space through an elevated floor. Equipment cabinets are arranged in columns. Closed cold channels and closed hot channels are sequentially formed among the equipment cabinets in a repeated mode. A hot pipe heat exchange unit is arranged in the corresponding equipment cabinet lower refrigerating space and exchanges heat with a chilled water unit through a cold liquid distributor. As the hot pipe heat exchange unit does not occupy the equipment cabinet space, the equipment cabinet density can be improved; meanwhile, by closing the cold channels and the hot channels, the equipment cabinets are directly cooled, the air inlet temperature of a hot pipe is improved, the refrigerating efficiency is improved, the energy-saving effect is achieved, and the system is suitable for the environment like a data center machine room where heat needs to be dissipated.

Owner:CHANGSHA MAXXOM HIGH TECH CO LTD

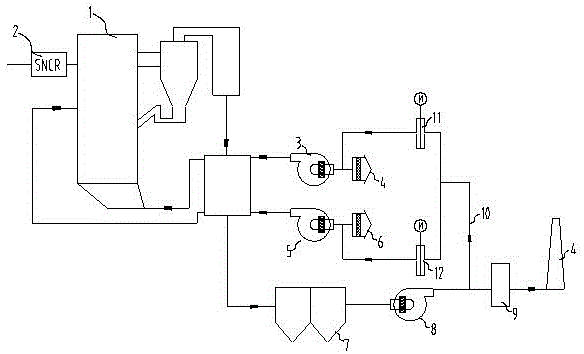

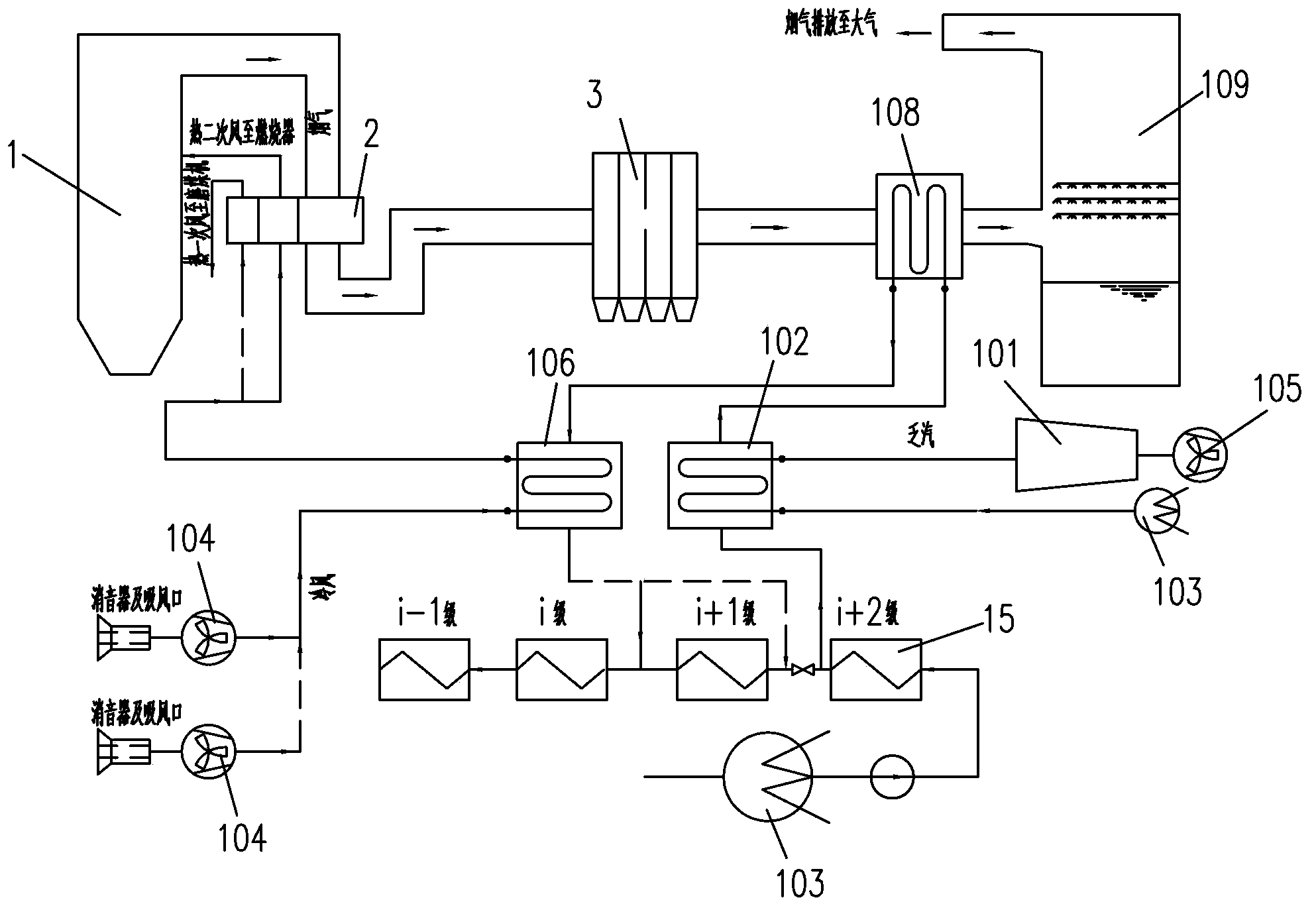

Flue gas recirculation-based wide load-wide coal deep denitrification system for CFB (circulating fluidized bed) boiler

InactiveCN105570883ALower combustion temperatureEmission reductionFluidized bed combustionFluegas recirculationCombustion chamberFlue gas

The invention provides a flue gas recirculation-based wide load-wide coal deep denitrification system for a CFB (circulating fluidized bed) boiler. The system comprises the boiler, an SNCR (selective non-catalytic reduction) system, a primary air blower, a secondary air blower, an induced draft fan, a recirculation flue, a primary air recirculation adjusting valve, a secondary air recirculation adjusting valve and the like. One end of the recirculation flue is connected with an outlet of the induced draft fan, the other end is connected with an inlet of the primary air blower and an inlet of the secondary air blower by the aid of the primary air recirculation adjusting valve and the secondary air recirculation adjusting valve, low-temperature flue gas is led out of the outlet of the induced draft fan, the low-temperature flue gas with the proper flow is sent to different positions of a combustion chamber by the blowers through control by the adjusting valves, distribution of temperature fields in the boiler is optimized by fine controlling content of oxygen of primary air and content of oxygen of secondary air on the basis of SNCR, pollutant emission is reduced, and the CFB boiler can realize low emission of NOx under wide load-wide coal conditions.

Owner:SICHUAN CHUANGUO BOILER

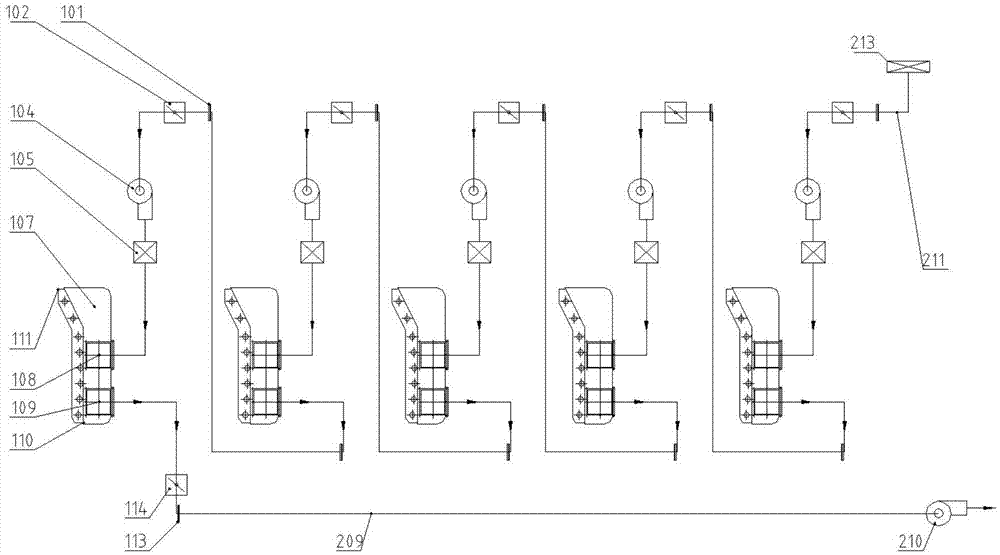

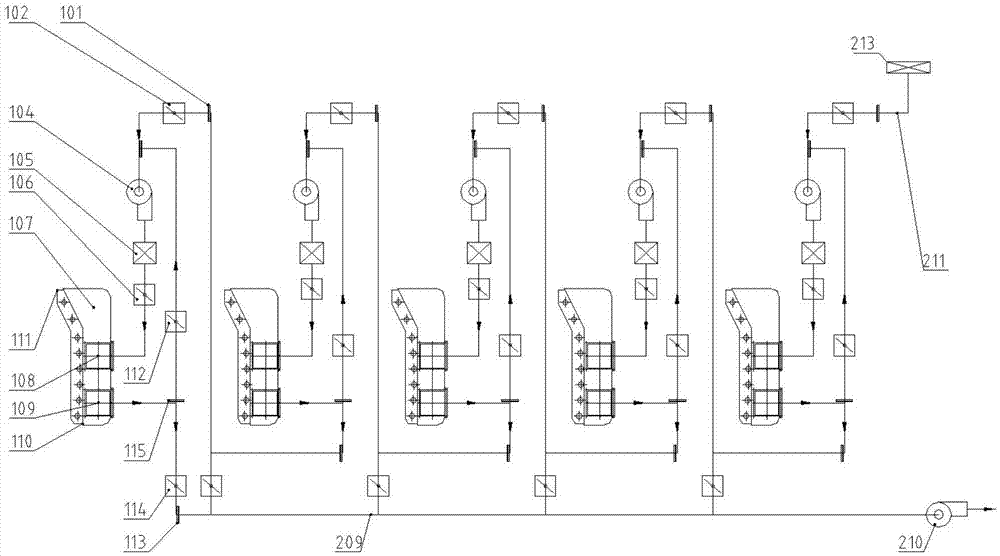

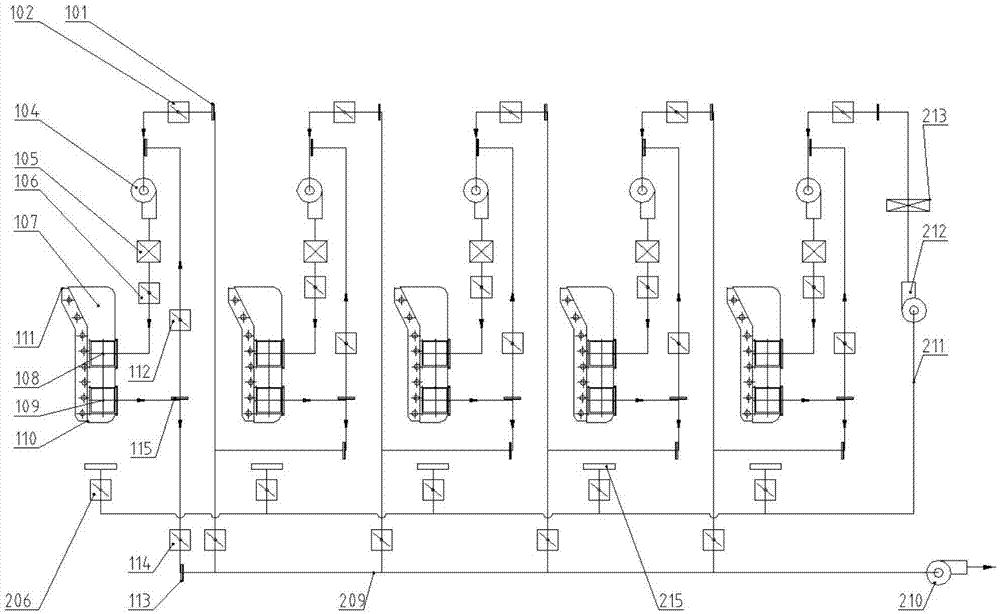

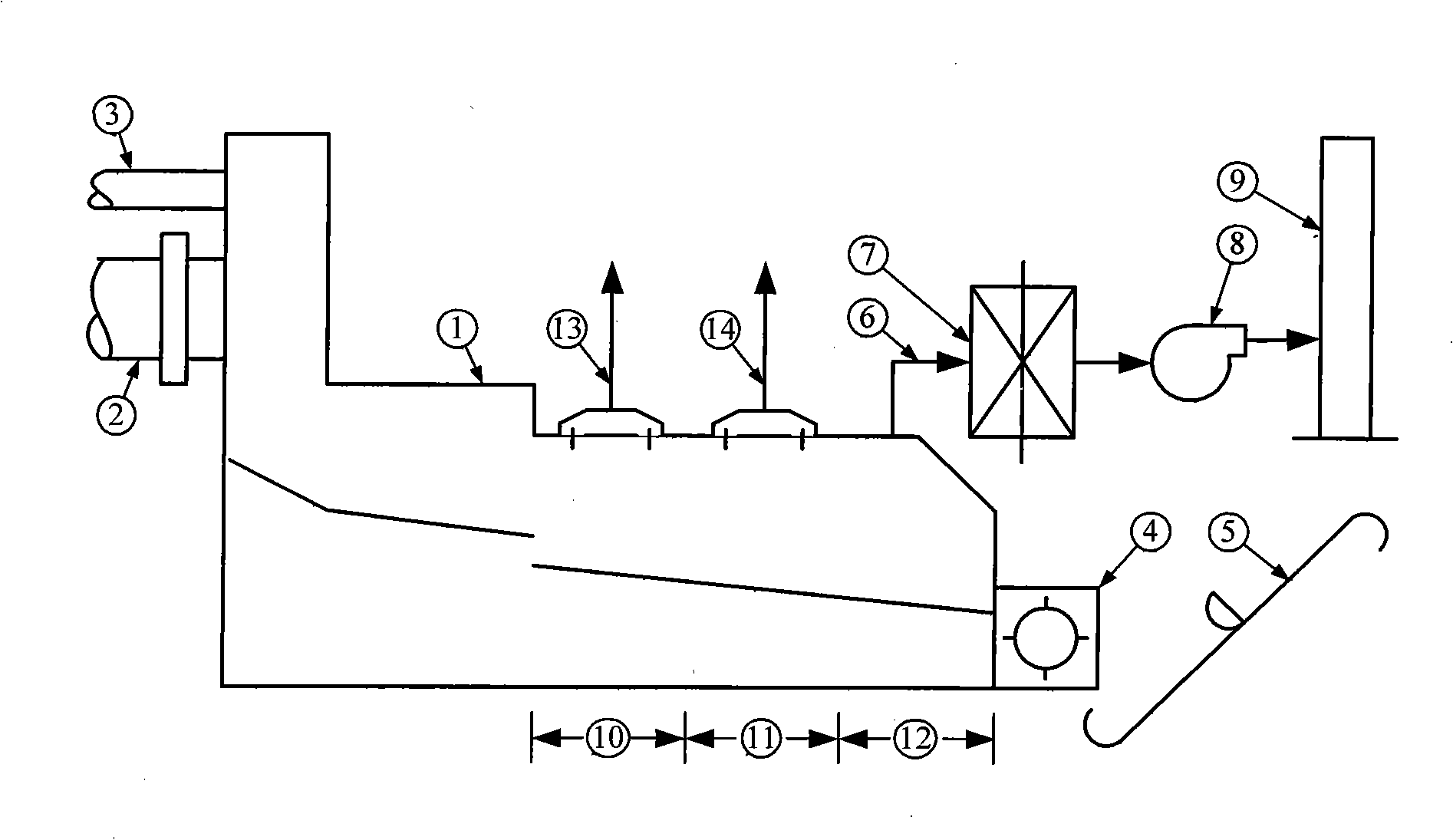

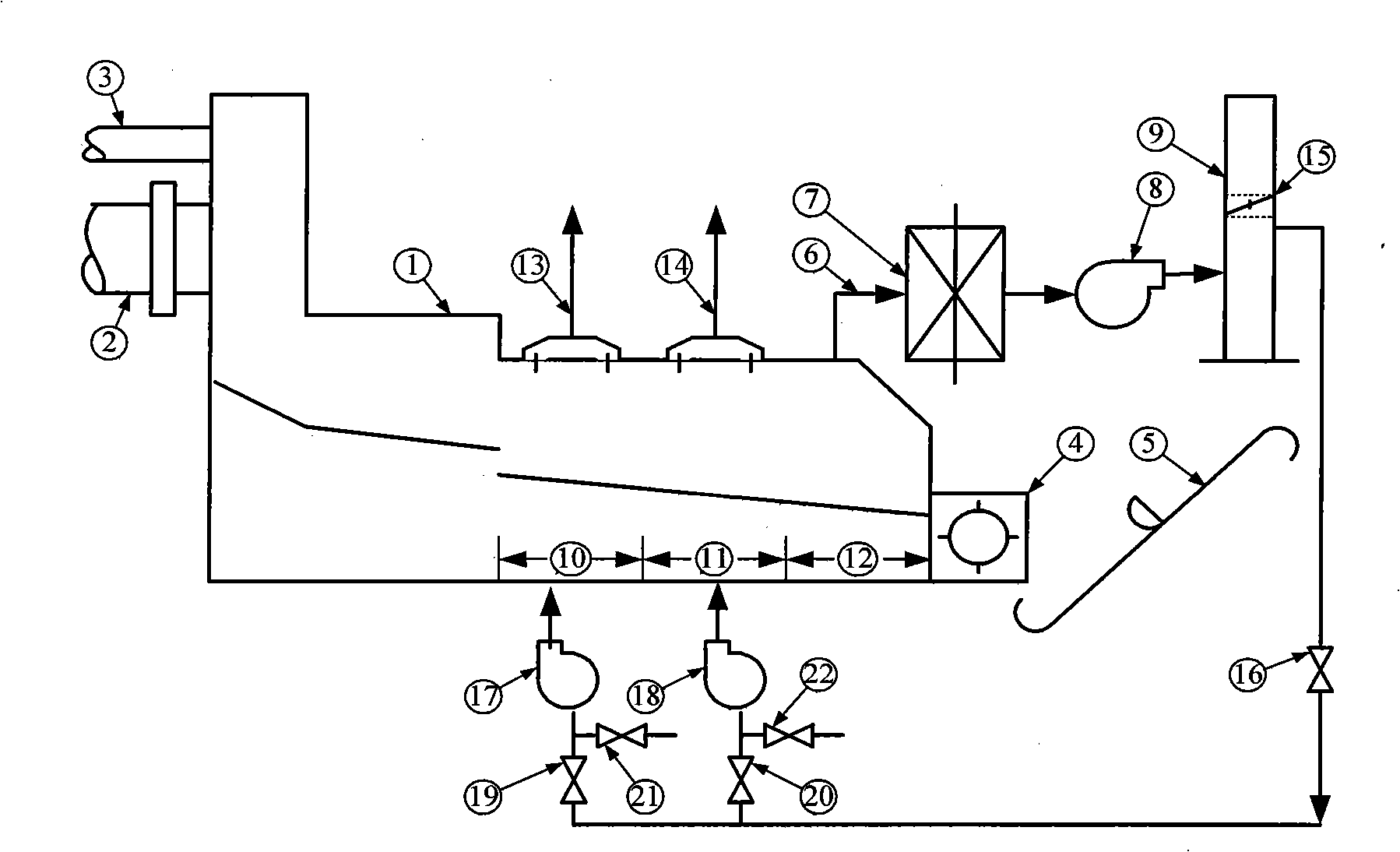

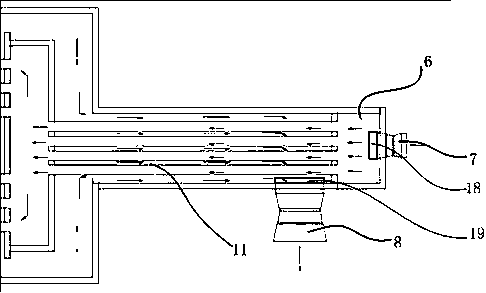

Tandem drying system

ActiveCN105444536AEasy to set upReduce exhaust air volumeDrying gas arrangementsPretreated surfacesWaste management

The invention provides a tandem drying system. The tandem drying system comprises at least two drying units, wherein each drying unit comprises a unit air supply fan and a drying box; a unit air inlet and a unit air outlet are formed in each drying unit; a drying box air inlet and a drying box air outlet are formed in each drying box; each unit air inlet is connected with the corresponding drying box air inlet; each unit air outlet is connected with the corresponding drying box air outlet; an exhaust air inlet which is connected with the unit air outlet of the last drying unit is formed in an exhaust air header pipe; a supply air outlet which is connected with the unit air inlet of the first drying unit is formed in a supply air header pipe; in every two adjacent drying units, the unit air outlet of the former drying unit is connected with the unit air inlet of the latter drying unit; each unit air supply fan is arranged between the corresponding unit air inlet and the corresponding drying box air inlet; and an exhaust air fan is arranged on the exhaust air outlet of the exhaust air header pipe. The tandem drying system has the advantages of simplicity and stability, easiness in adjustment, small exhaust air amount, low energy consumption, no potential safety hazards, low environment protection cost and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

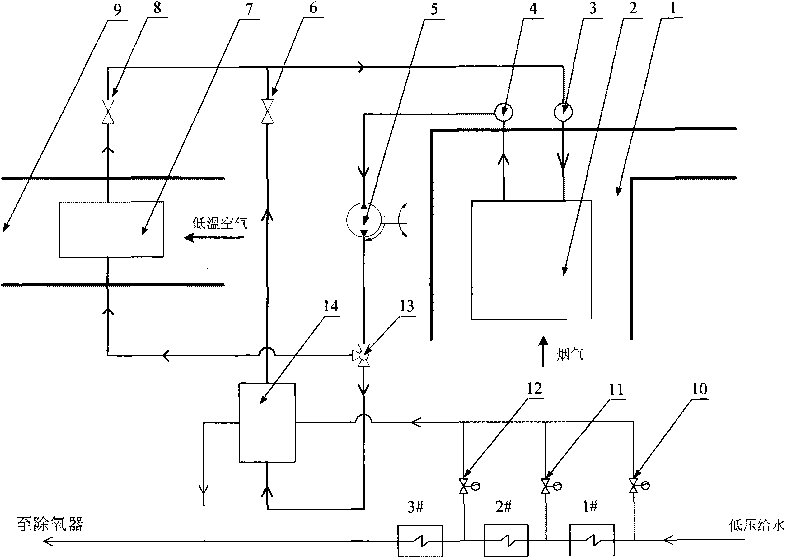

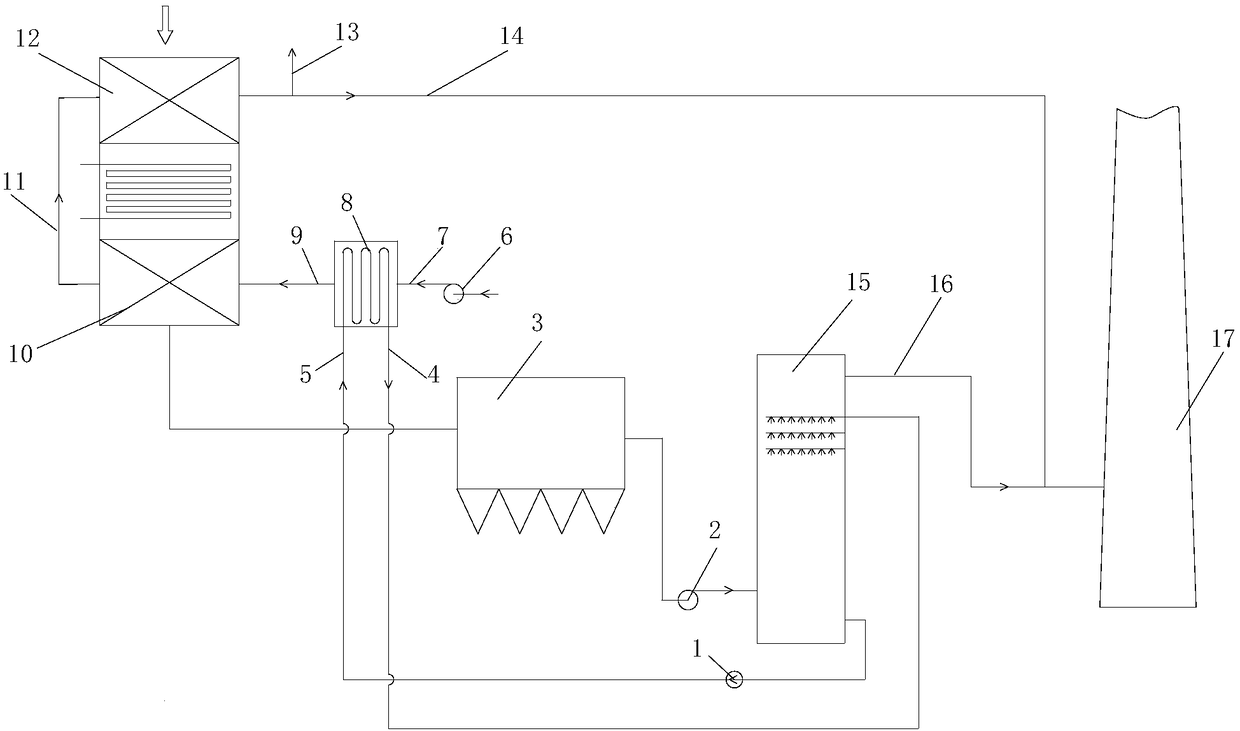

Coal-water boiler exhaust gas residual heat recovery device

InactiveCN101737766ARaise the inlet air temperatureGuaranteed safe operationCombustion technology mitigationFeed-water heatersAir preheaterEngineering

A coal-water boiler exhaust gas residual heat recovery device is characterized in that a cyclic heat exchange system using water as the heat transfer medium separates a boiler exhaust gas cooler from a residual heat utilization device, thus avoiding the safety problem caused by heating surface leakage and simultaneously realizing seasonal change of the exhaust gas residual heat utilization device. Specifically, a gas cooler is arranged in a gas flue behind an air preheater (or dust catcher), the water is used as the heat transfer medium, firstly the water is heated in the gas cooler to reduce the exhaust gas temperature, and then the heat absorbed by the water in the gas cooler is released in another heat exchanger to be used for heating the main condensed water to raise the temperature of the low pressure feed water or heating the cold air to raise the inlet air temperature of the boiler. After the system is adopted, the boiler exhaust gas residual heat can be fully and effectively recovered, the steam extraction capacity of the heat regenerative system can be reduced, the generated output of the set can be increased and the coal consumption in power generation can be reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

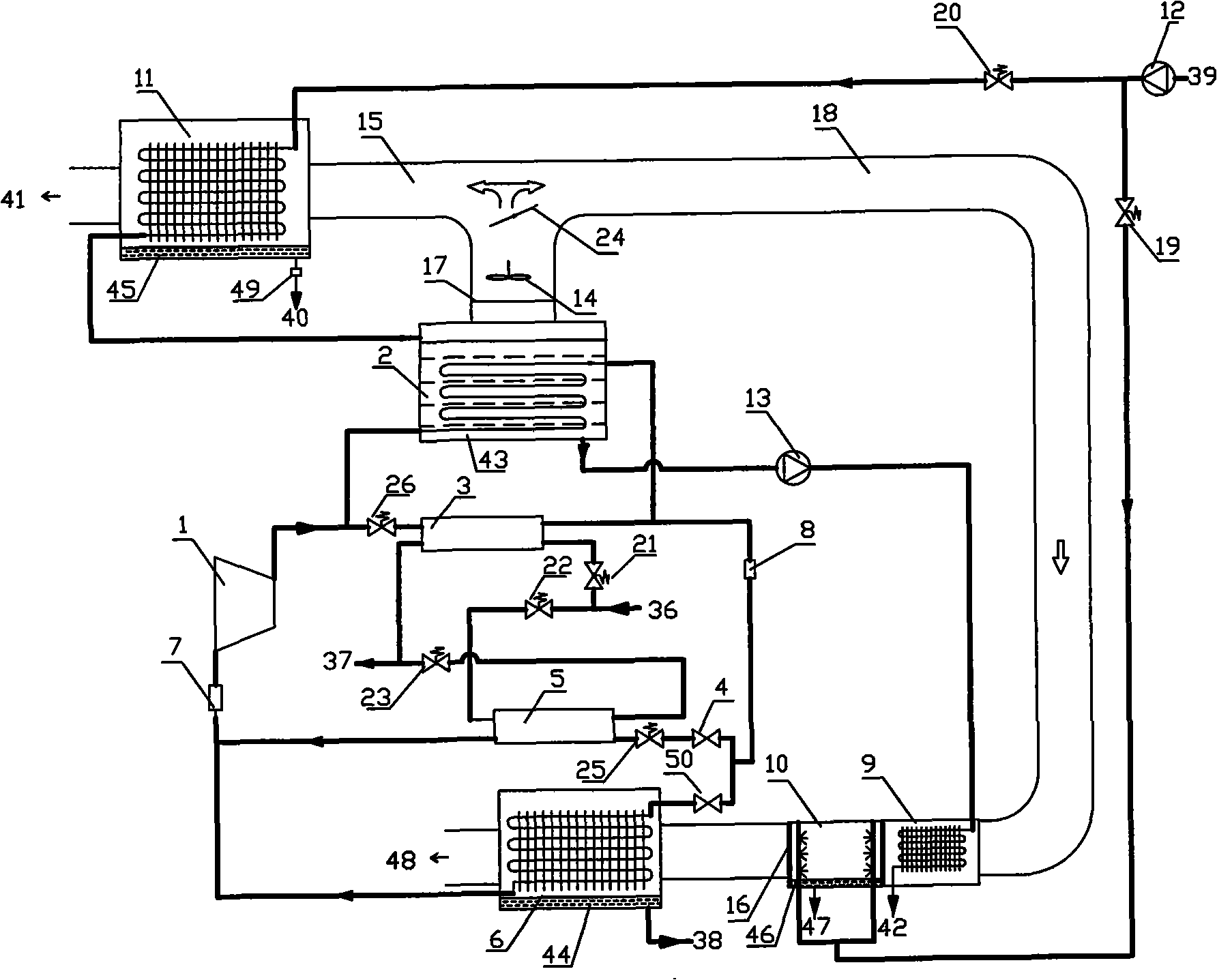

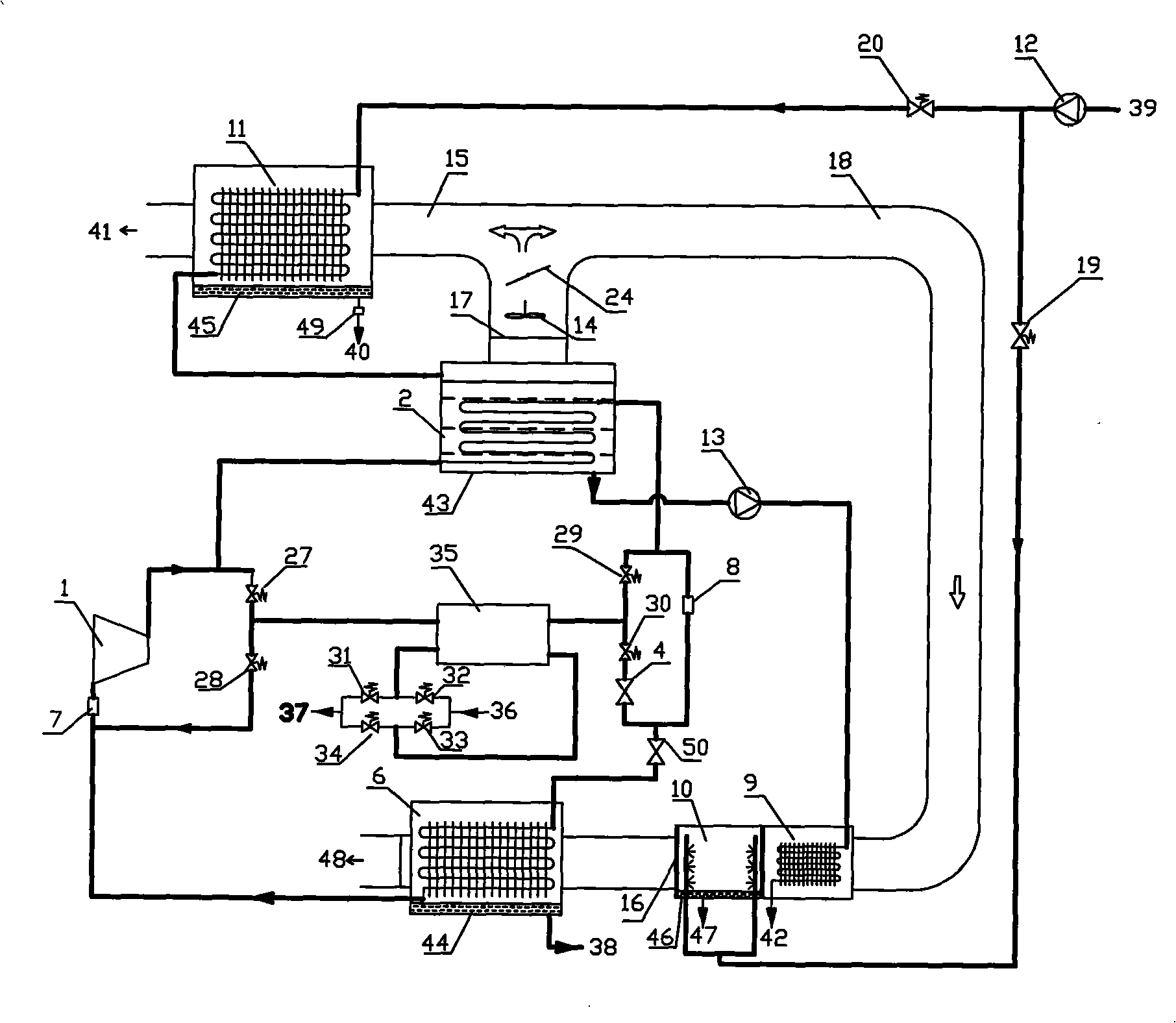

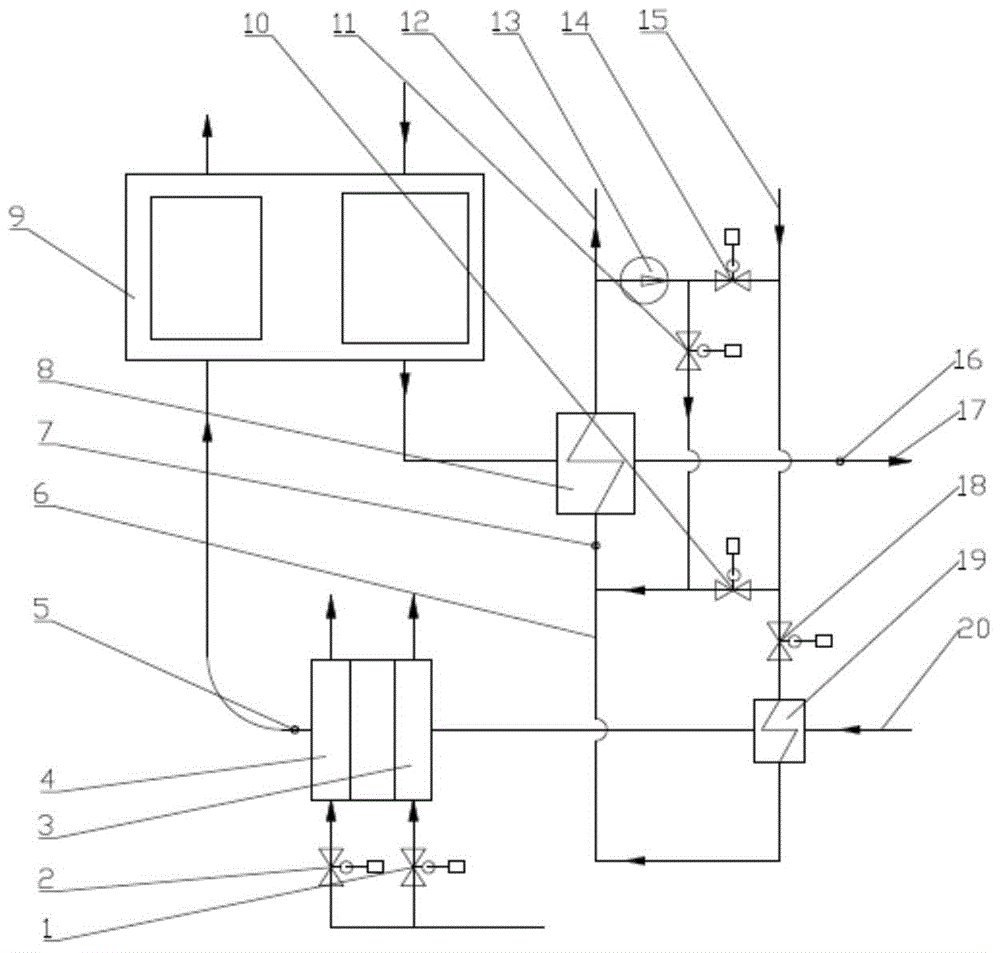

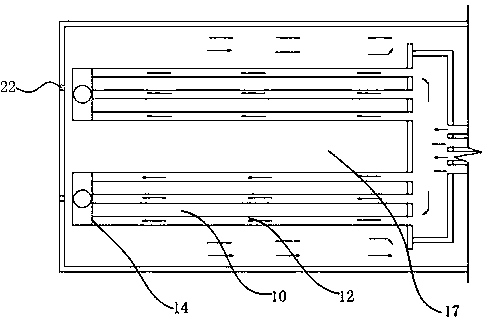

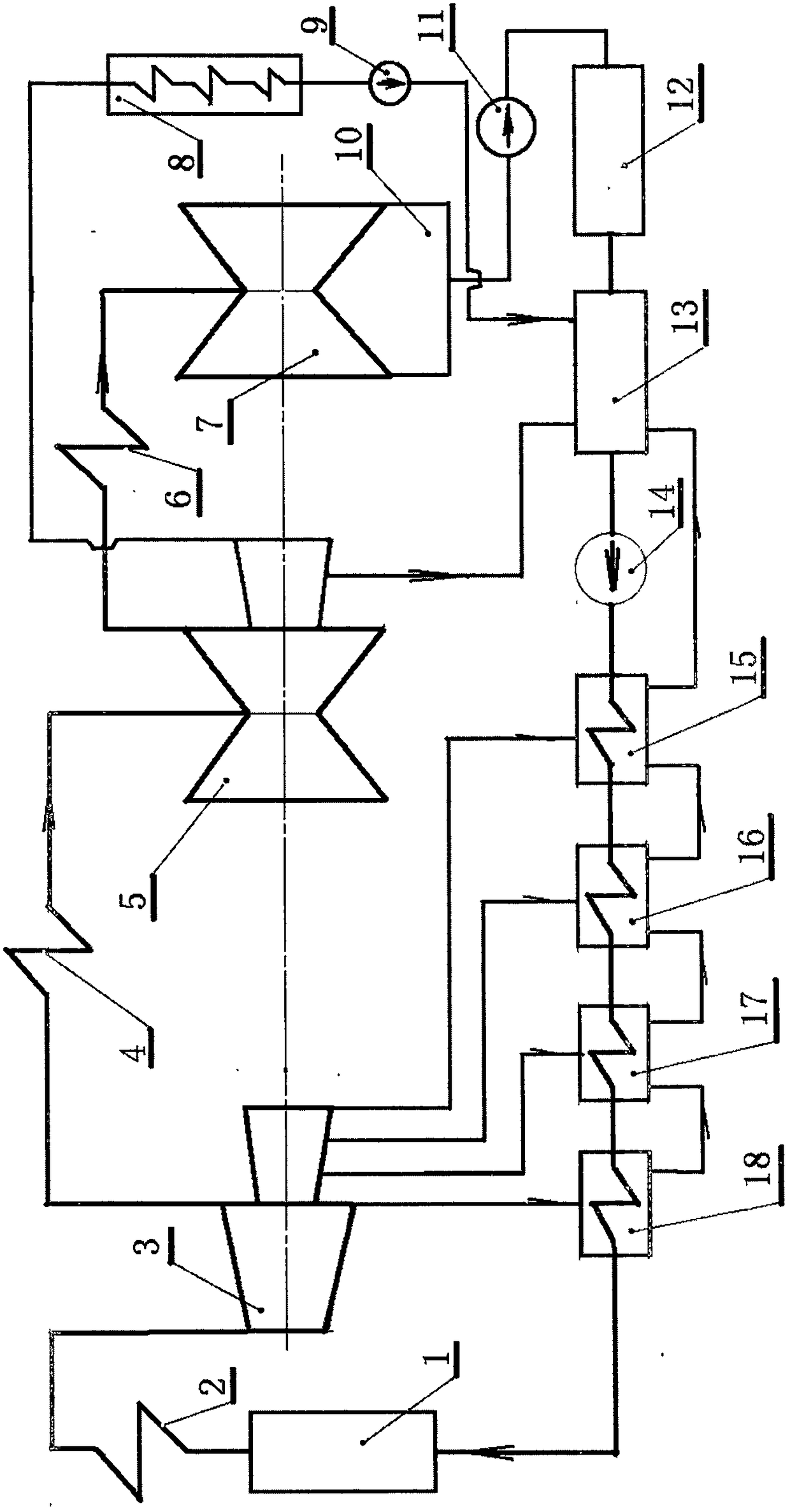

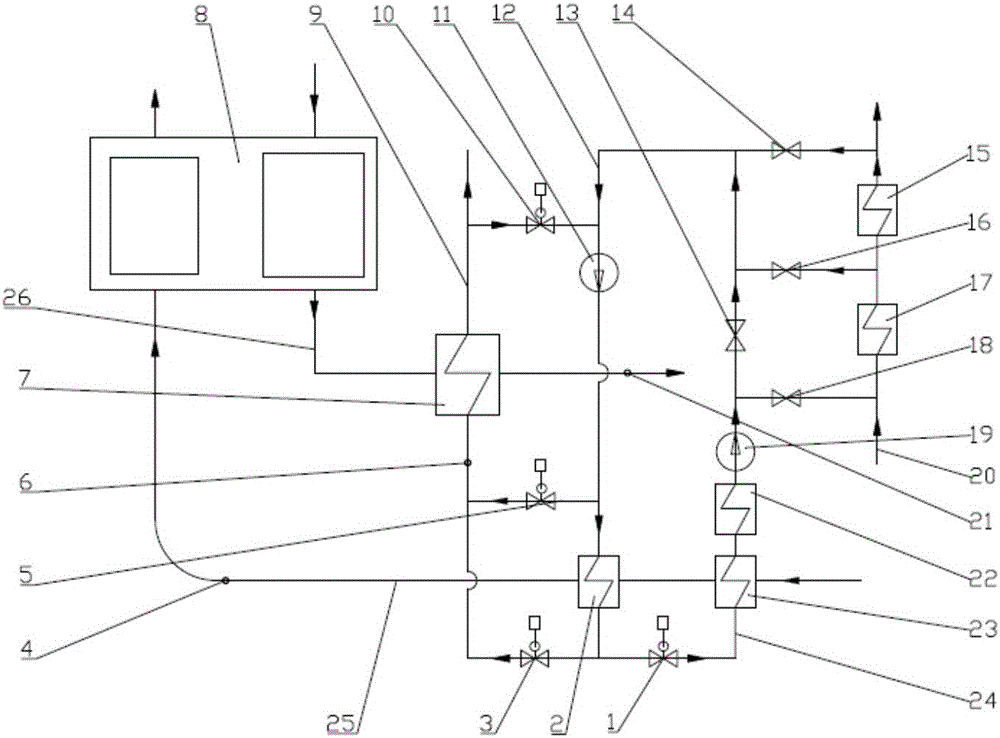

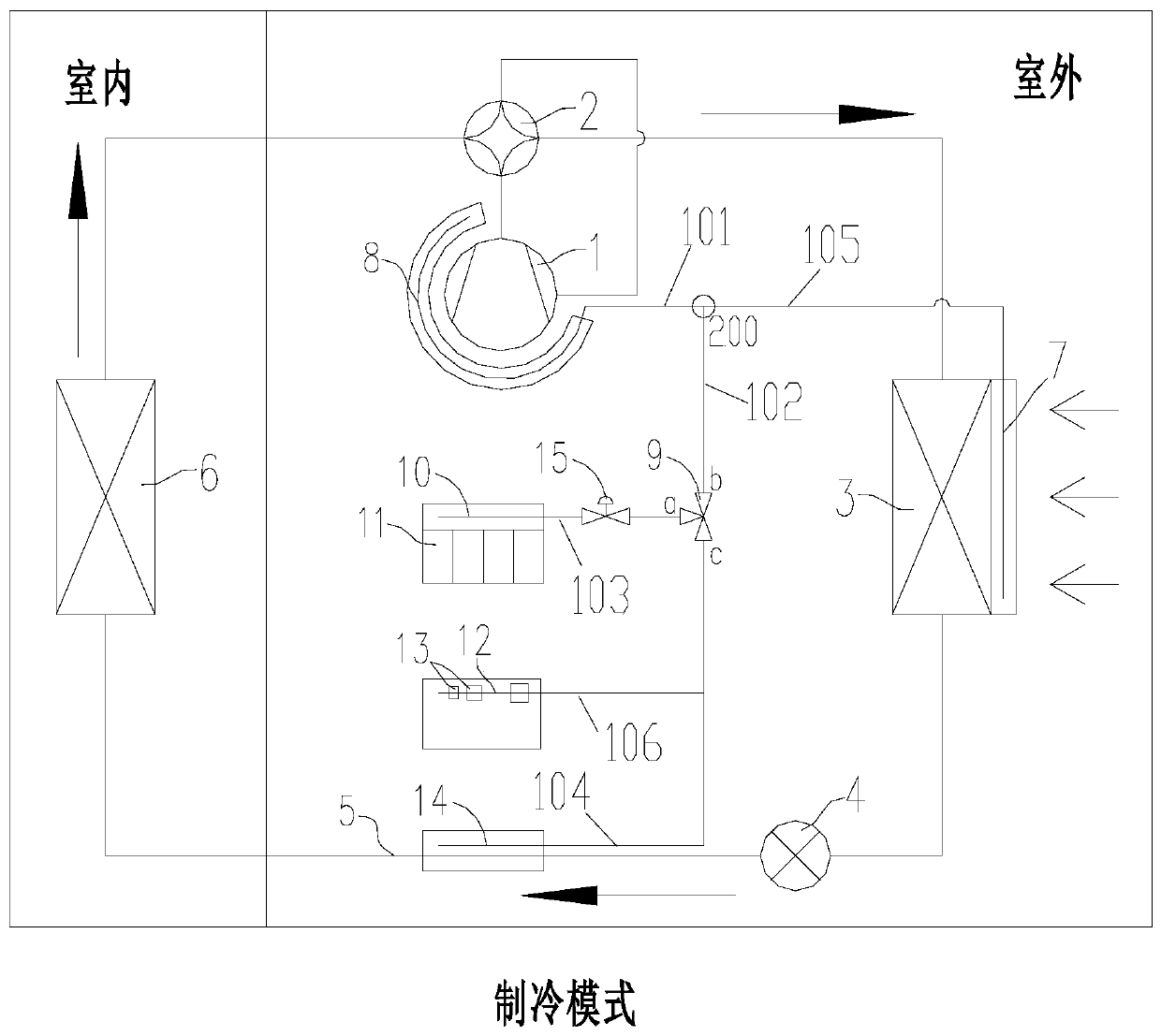

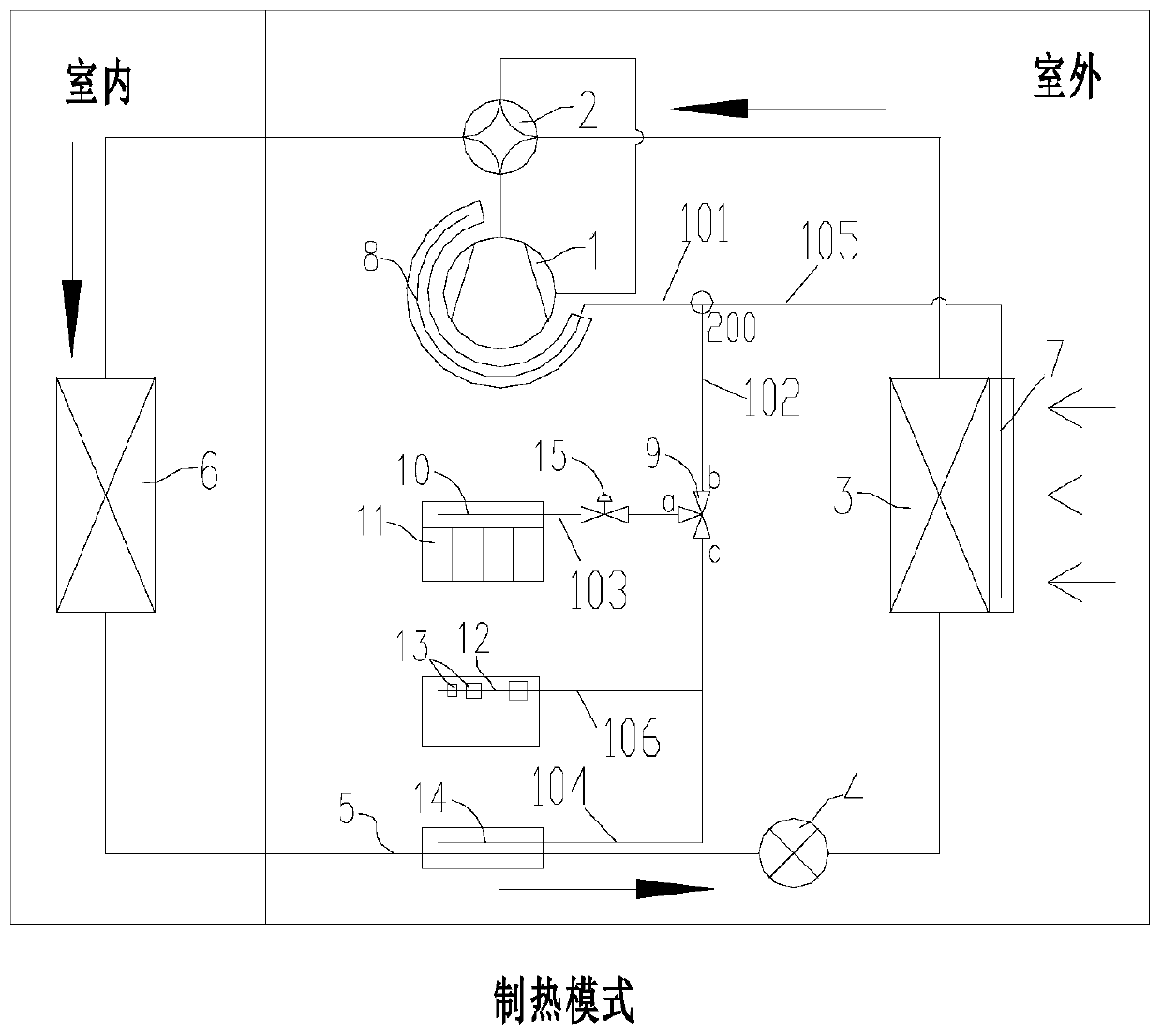

Novel sea water heat pump cold, heat, hot water and fresh water tetrad feed system

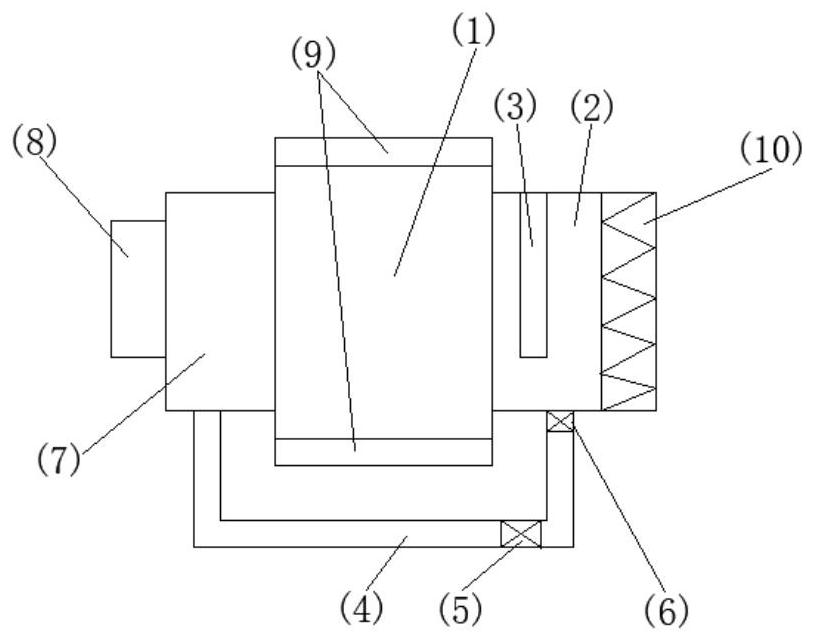

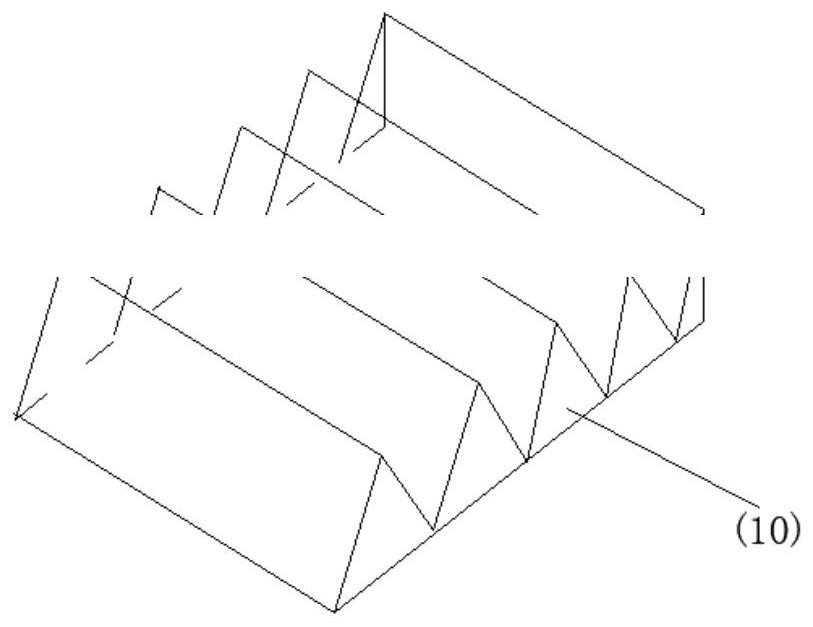

InactiveCN101324383AImprove operational efficiencySmall temperature differenceFluid heatersHeat pumpsVapor–liquid separatorMagnetic valve

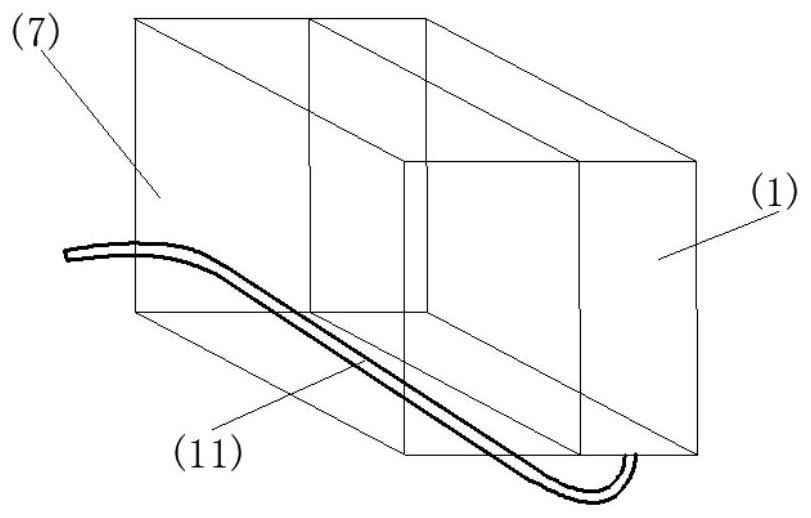

The invention discloses a novel four-purpose system capable of cooling, heating and providing hot water and fresh water by using a heat pump of seawater. The novel four-purpose system is characterized in that the system comprises a heat pump system, a fresh water preparation system and a hot water preparation system, wherein the heat pump system includes a compressor (1), a heating condenser (3), a first throttle valve (4), a refrigerating evaporator (5), a gas-liquid separator (7), a liquid reservoir (8), a refrigerant loop solenoid and a water side loop solenoid. The fresh water preparation system comprises a coil condenser (2), a first air channel (18), an inlet air pre-heating heat exchanger (9), a spraying room (10), a water baffle (16), an evaporator (6) for desalting, a second throttle valve (50), and a solenoid (19). The hot water preparation system includes a heat exchanger (11) for preparing hot water, a first air channel (15) and a solenoid (20). The system has the advantages of compact structure, multiple purposes, high-efficiency utilization of waste heat, lowered cost and reduced space.

Owner:YANTAI UNIV

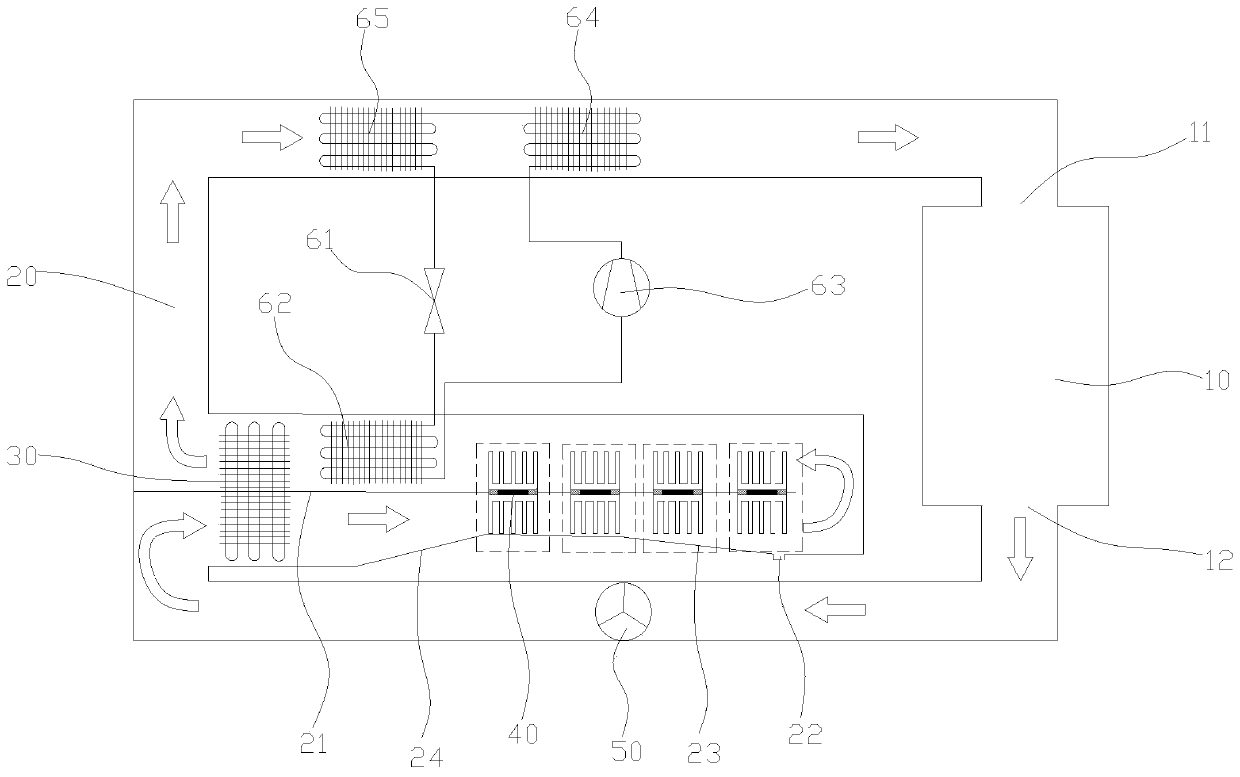

Energy-saving type garden staff heat pump drying device

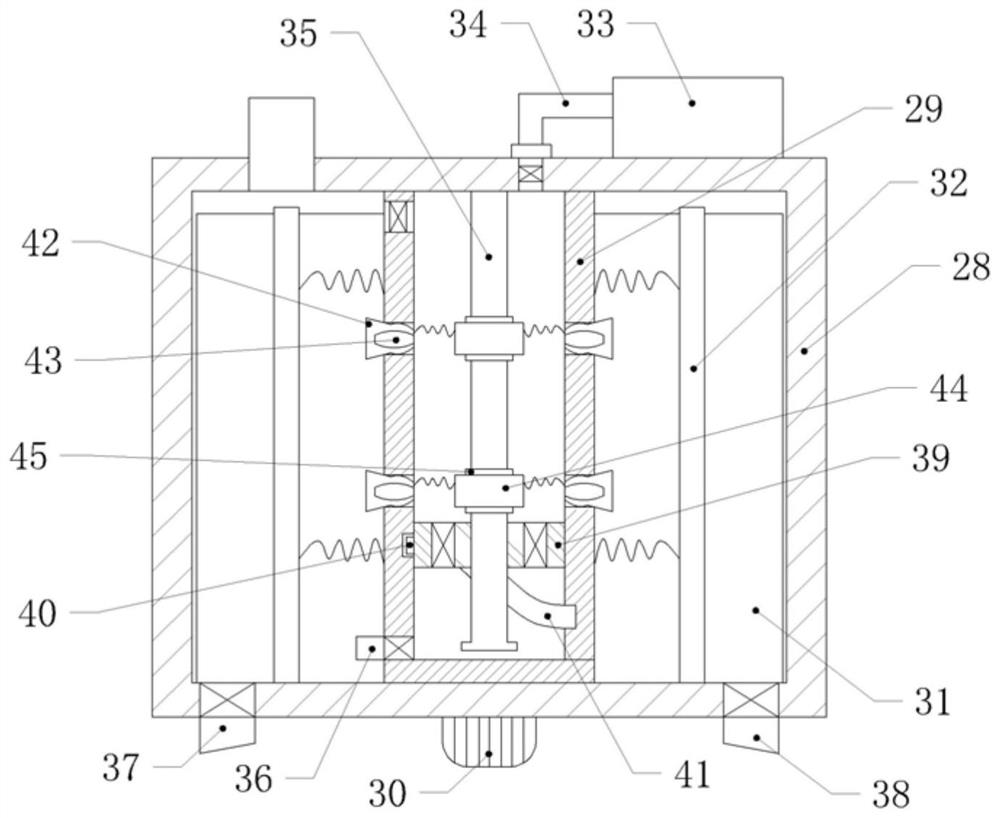

InactiveCN105029655AHeating up fastGuaranteed drying qualityFood processingDrying machines with local agitationEngineeringMoisture sensor

The invention discloses an energy-saving type garden staff heat pump drying device. The energy-saving type garden staff heat pump drying device is composed of a compressor, a first evaporator, a first electromagnetic stop valve, a second electromagnetic stop valve, a second evaporator, heat pipes, a water pan, a return fan, a partition plate, a drying box, a garden staff rack, a temperature and humidity sensor, an air feeder, a first condenser, a third electromagnetic stop valve, a fourth electromagnetic stop valve, a second condenser, a throttling valve and a controller. The energy-saving type garden staff heat pump drying device has the advantages that heat can be absorbed from the environment in the drying starting stage, inlet air sensible heat of the evaporators in the drying box is directly used for heating circulating air, and excessive heat in the drying box in the drying later stage can be discharged out of the drying box; starting heating is quick, the temperature is controllable, the heat efficiency is high, the drying quality is good, and environmental friendliness and sanitation are achieved.

Owner:TIANJIN AOLV AGRI & SIDELINE PROD GRP

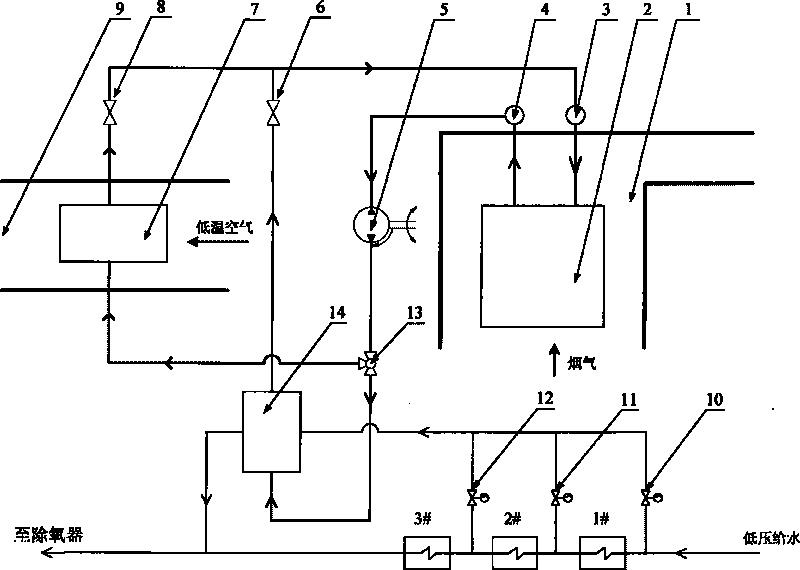

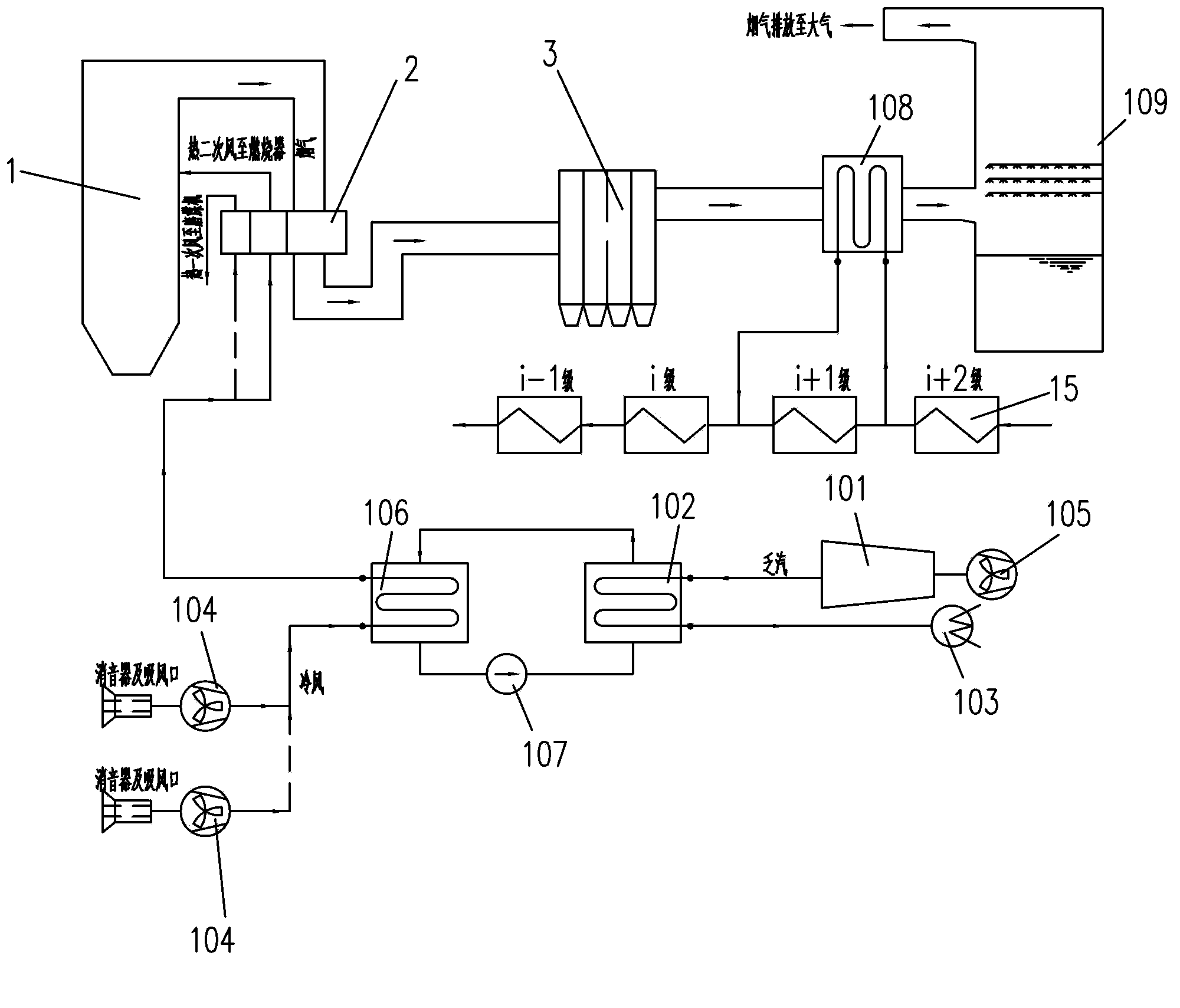

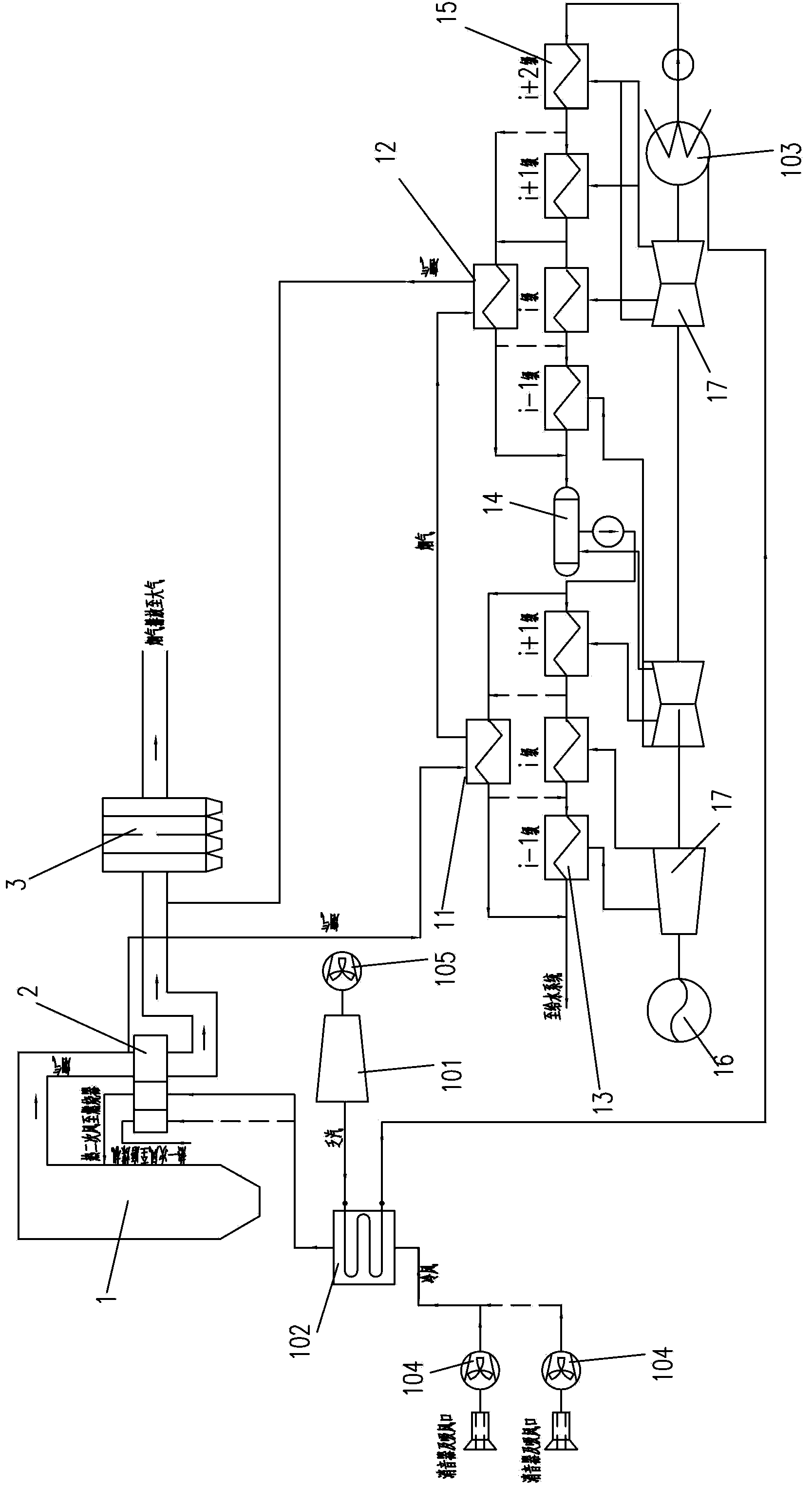

Waste heat utilizing system of thermal power plant and thermal power unit

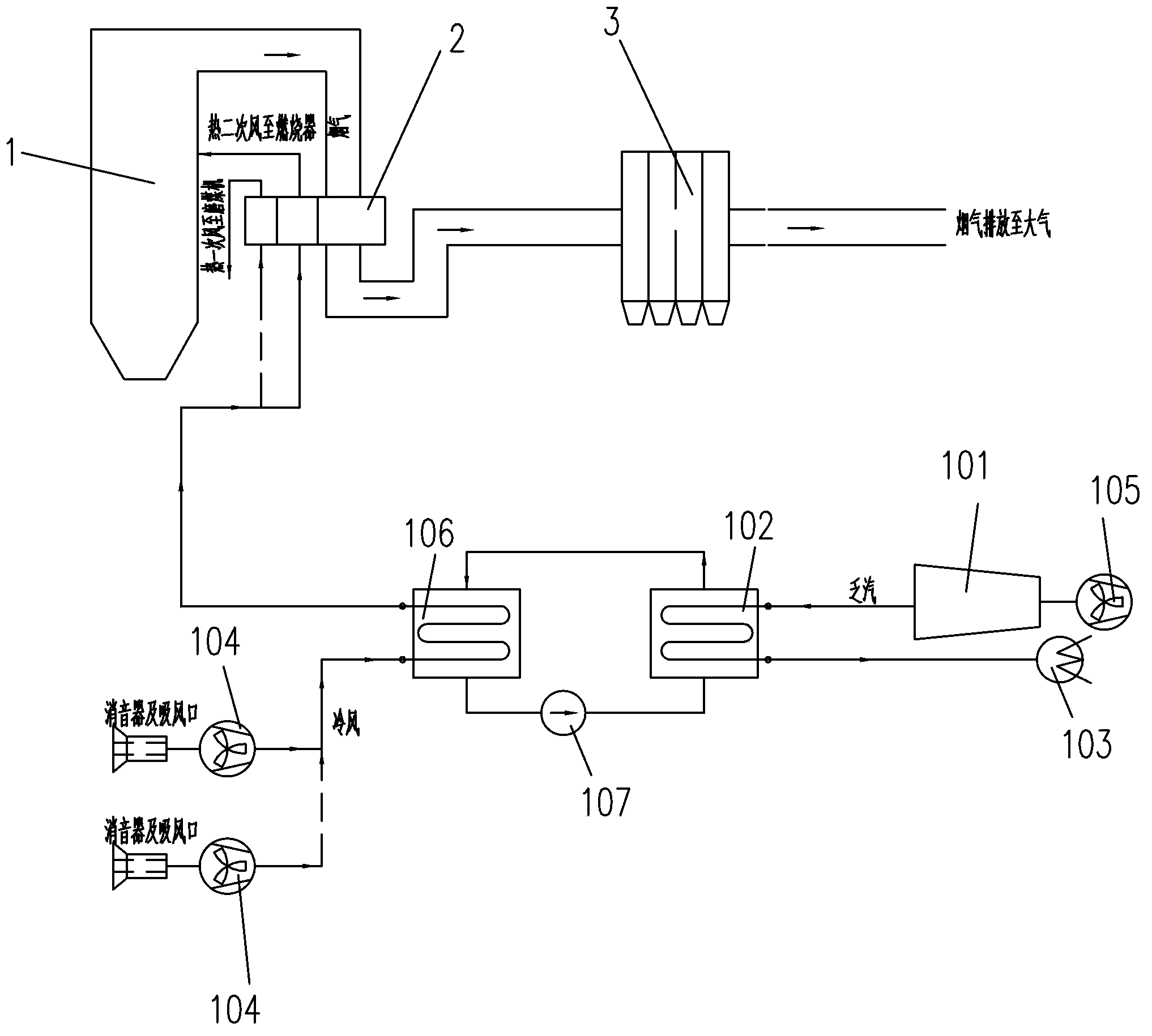

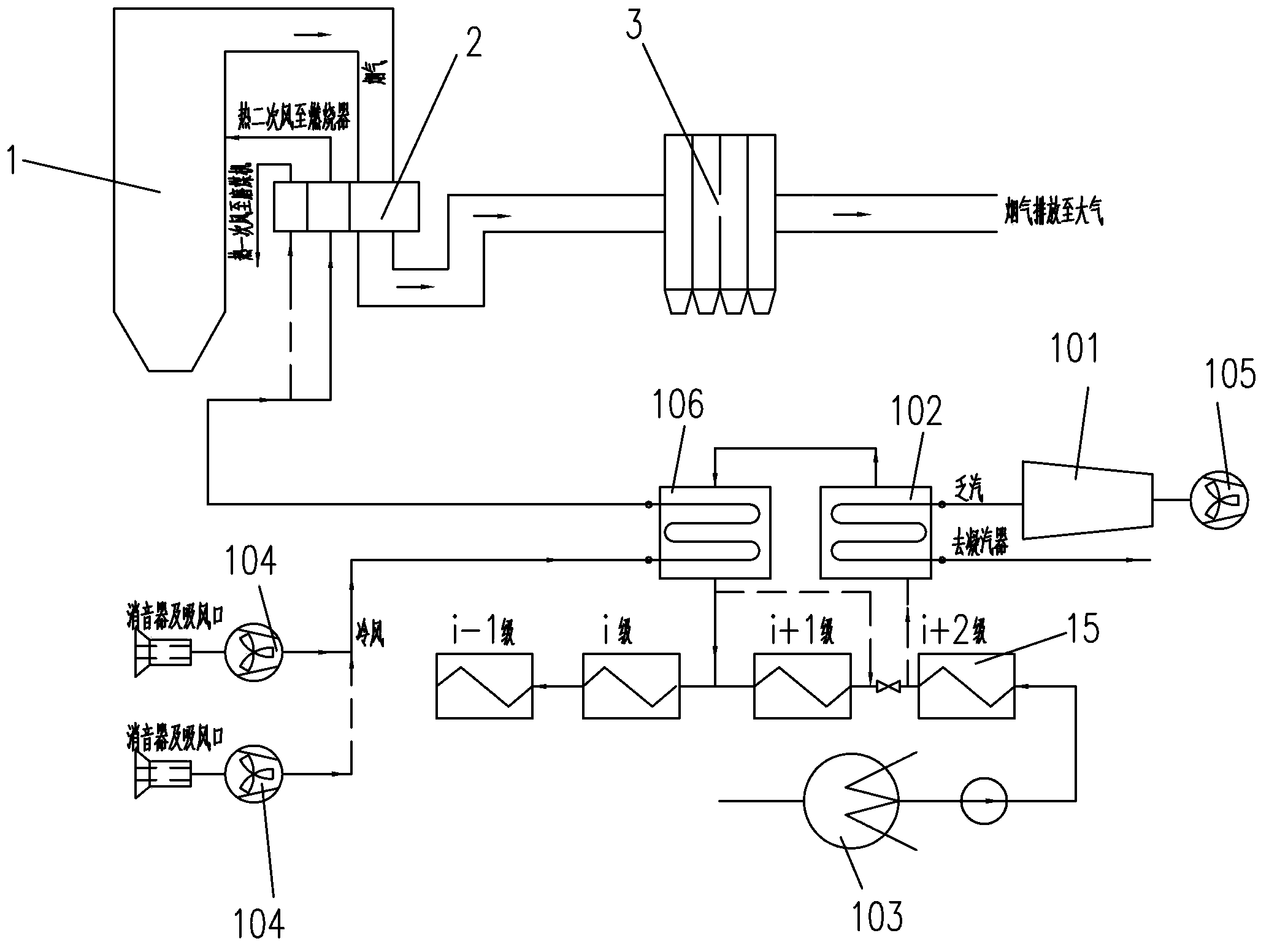

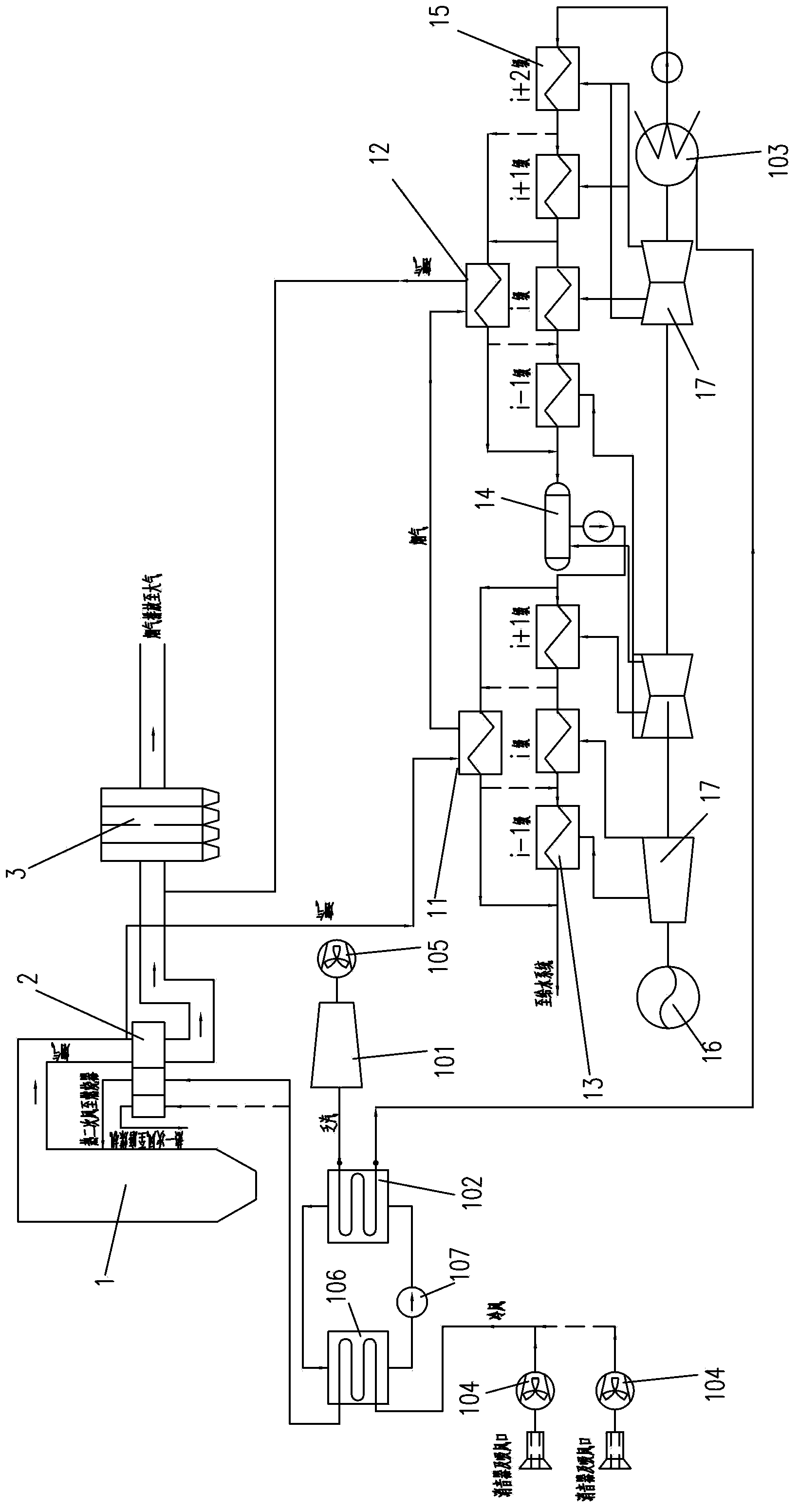

ActiveCN103574587AReduce coal consumptionReduce steam extractionLiquid degasificationFeed-water heatersAir preheaterEngineering

The invention provides a waste heat utilizing system of a thermal power plant and a power unit. The waste heat utilizing system of the thermal power plant comprises a boiler outlet flue gas waste heat utilizing system, an air preheater outlet flue gas waste heat utilizing system and a driving steam turbine steam exhaust waste heat utilizing system; the flue gas of the air preheater outlet is used for heating the condensed water from a low-pressure heater; the driving steam turbine steam exhaust waste heat utilizing system comprises a steam-water heat exchanger and an air-water heat exchanger which are formed into a steam-water-air heat exchange system; primary air and or secondary air of the air preheater inlet are or is heated by the steam exhaust of a driving steam turbine through the steam-water-air heat exchange system; the feed water and the condensed water are heated by part of high temperature flue gas of the boiler outlet. According to the waste heat utilizing system of the thermal power plant and the thermal power unit, the waste heat energy of the thermal power plant is effectively utilized and accordingly the efficiency of the thermal power plant is improved, meanwhile the coal consumption is reduced, and emissions of pollutants are reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

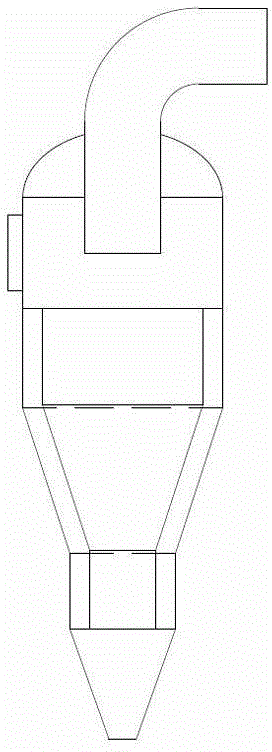

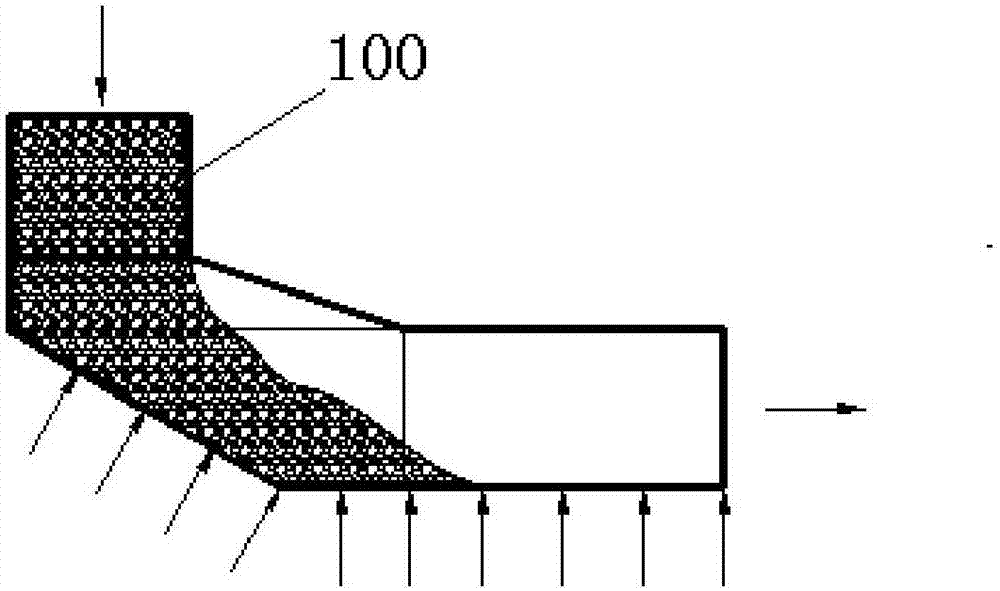

Gasification process system for fine particle biomass or solid fossil fuel

ActiveCN104449872AWell mixedReduce dust accumulationEnergy inputGasification processes detailsCyclonic separationSeparation technology

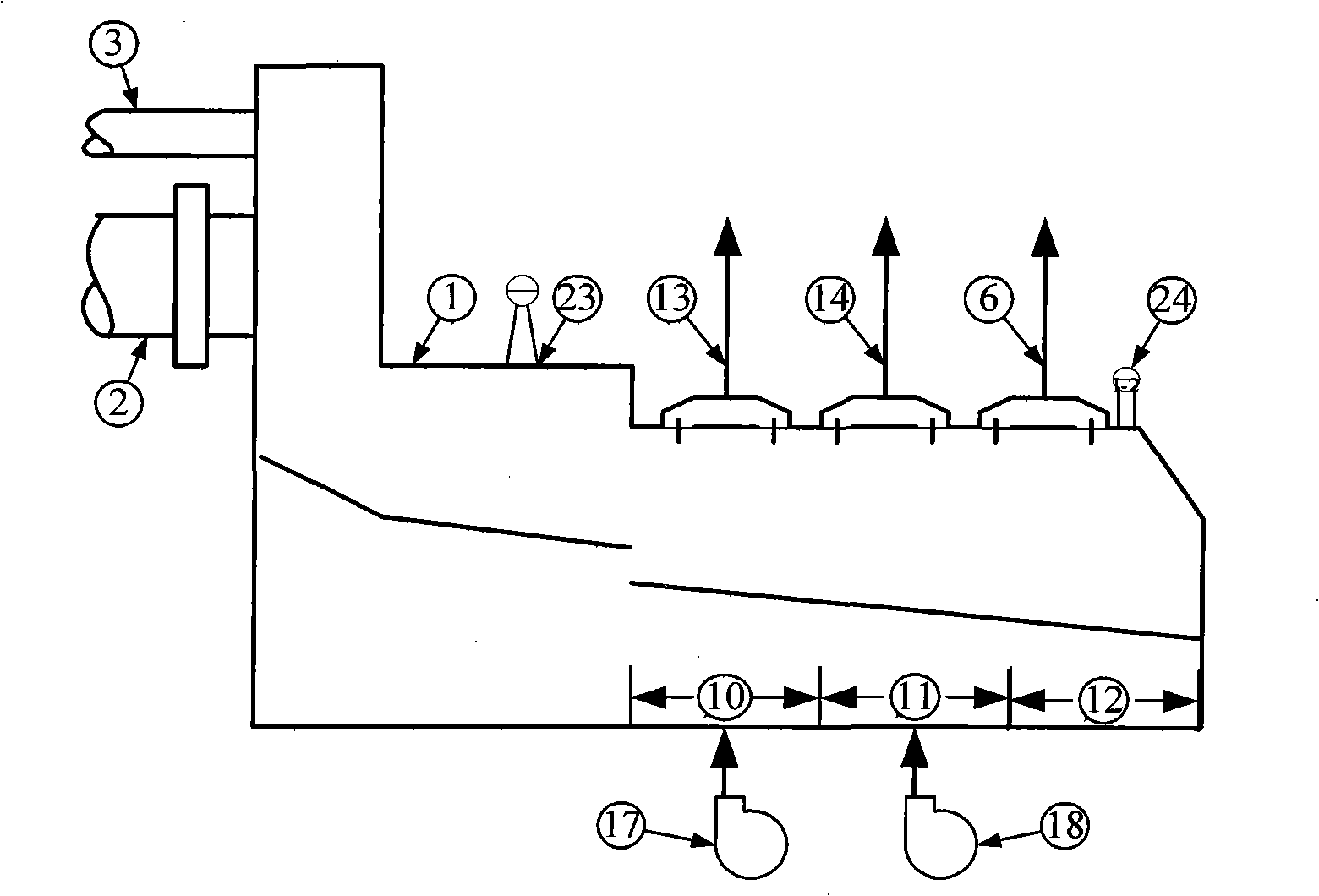

The invention discloses a gasification process system for fine particle biomass or solid fossil fuel. A combustion system adopts a circulating fluidized bed combustion technology and an efficient cyclone separation technology of the fine particle biomass or solid fossil fuel. The fine-particle circulating fluidized bed combustion technology adopts a flat-plate directional wind cap, so that refining combustion of coal particles is achieved; a fluidized bed gasification reactor system of the fine particle biomass or solid fossil fuel adopts a fine-particle gasification technology, and the fine-particle gasification technology adopts the flat-plate directional wind cap, so that the problems of low gas production rate and low gas production heat value in an existing coal gasification process system are solved; by virtue of an afterheat utilization system, the heat carried in the gasification process is transformed into steam, and is supplied to the fluidized bed gasification reaction system of the fine particle biomass or solid fossil fuel, so that the cost is reduced by using self-energy sources; and the gasification process system also comprises an ash treatment system and a gasification process gas purification system, so that the problem of waste of the heat carried in ash, and the problem that sulfide and dust carried in the gasification process are not thoroughly treated are solved.

Owner:大连科林能源工程技术开发有限公司

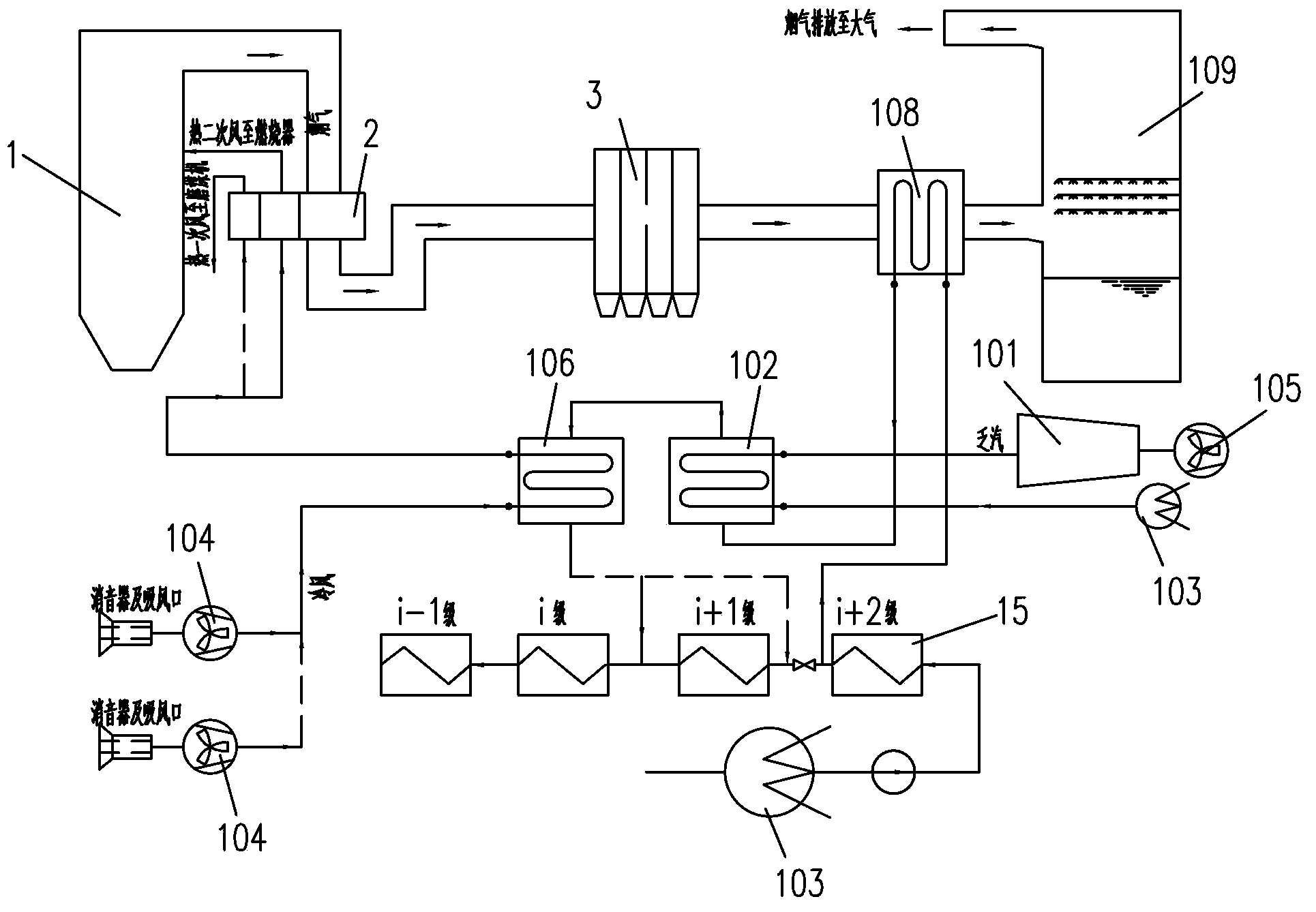

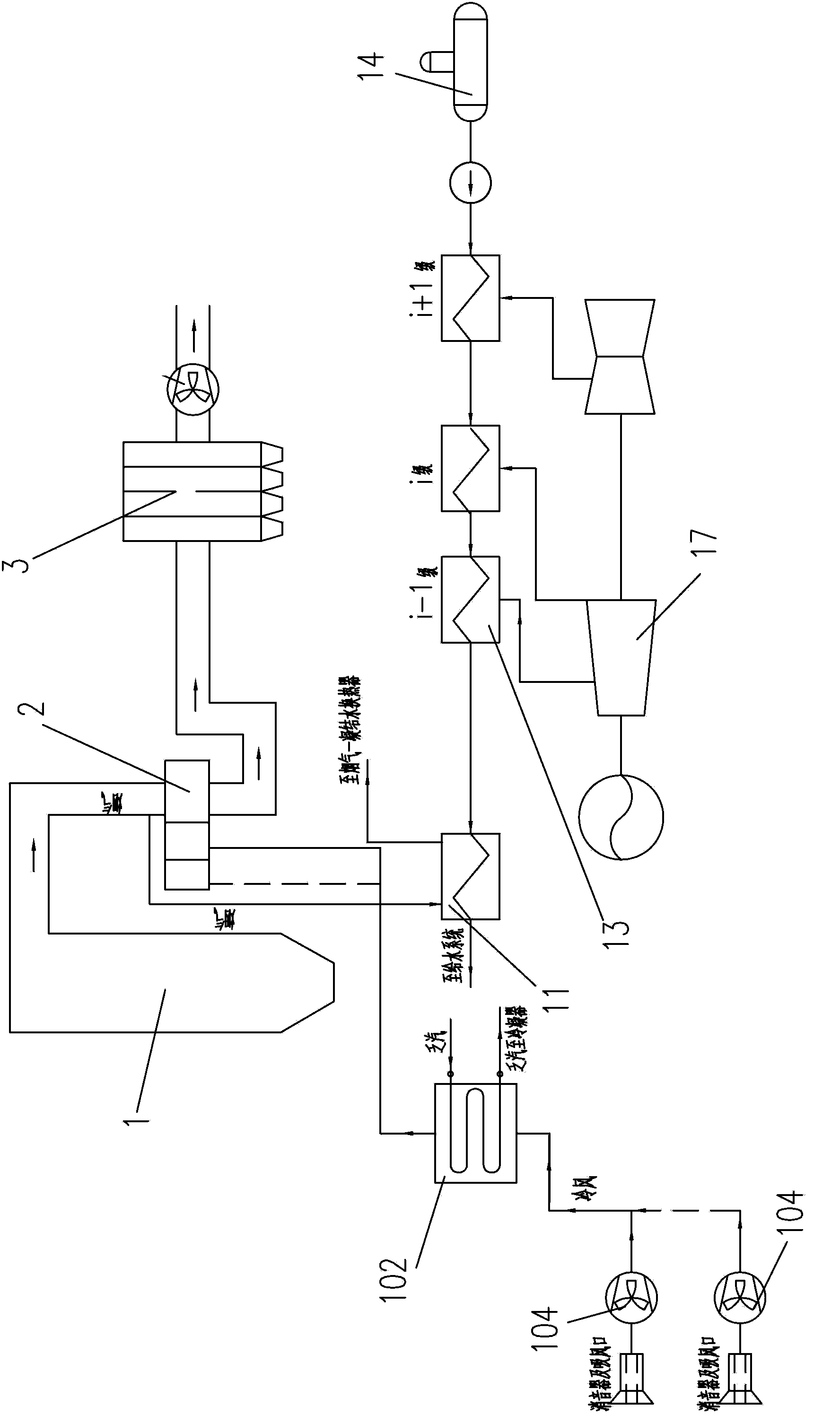

Air preheating and flue gas waste heat utilizing system and method

InactiveCN104807035ASolve the existing disadvantagesRaise the inlet air temperatureFeed water supplyCombustion processAir preheaterFlue gas

The invention particularly aims to the technical field of boiler air preheating. A disclosed air preheating and flue gas waste heat utilizing system comprises a flue gas channel (17), an air channel (20), an air preheater (9), a condensed water flue heat exchanger (8) and a condensed water air channel heat exchanger (19), and further comprises a condensed water feeding main pipe (15) and a condensed water returning main pipe (12); the flue gas channel (17) and the air channel (20) are connected with the air preheater (9); the condensed water flue heat exchanger (8) is arranged on the flue gas channel (17) at the back of the air preheater (9) in a flue gas flowing direction; the condensed water air channel heat exchanger (19) is arranged on the air channel (20) at the front of the air preheater (9) in an air flowing direction. According to the air preheating and flue gas waste heat utilizing system, flue gas discharge and heat exchange can be automatically adjusted according to change of operation conditions; on the premise of ensuring the safety of a heated surface and the regular operation of the system, the maximization of the heat circulation efficiency and the system economical efficiency is ensured.

Owner:郝江平

Control method for getting wind process for kiln hood waste heat boiler in dry cement residual heat utilization and apparatus thereof

InactiveCN101407382AStabilization and inlet air temperature and steam productionIncrease the inlet air temperature and steam productionClinker productionCement kilnEngineering

The invention relates to the fields of the recycle and application to electricity generation of waste gas and residual heat of a kiln head clinker cooler of a novel dry method cement production line. On the basis that at the kiln head cooler, the temperature of the cooled clinker is 600-200 DEG C of a cooling grate bed area and the discharging temperature of the cooler is ensured to meet the requirement, the invention controls and improves the temperature of hot air at the upper part of a clinker layer after heat exchange with the clinker, through utilizing first-discharging waste gas discharged to air and with temperature of 80-120 DEG C as cooling air which is corresponding to the area and used for cooling the clinker, effectively controlling the thickness of the clinker layer in the cooler and improving the temperature of the cooling air which is corresponding to the area and used for cooling the clinker. According to the temperature of hot air at the upper part of the corresponding clinker layer, the thickness of the clinker layer in the cooler and the temperature of the cooling air can be regulated in real time. The invention has the advantages of further stabilizing and improving the temperature of inlet air and steam production of residual heat boilers, stabilizing and improving generated energy of residual heat generation, and simultaneously improving the rate of multipurpose utilization of cement kiln residual heat resources.

Owner:昆明阳光基业股份有限公司

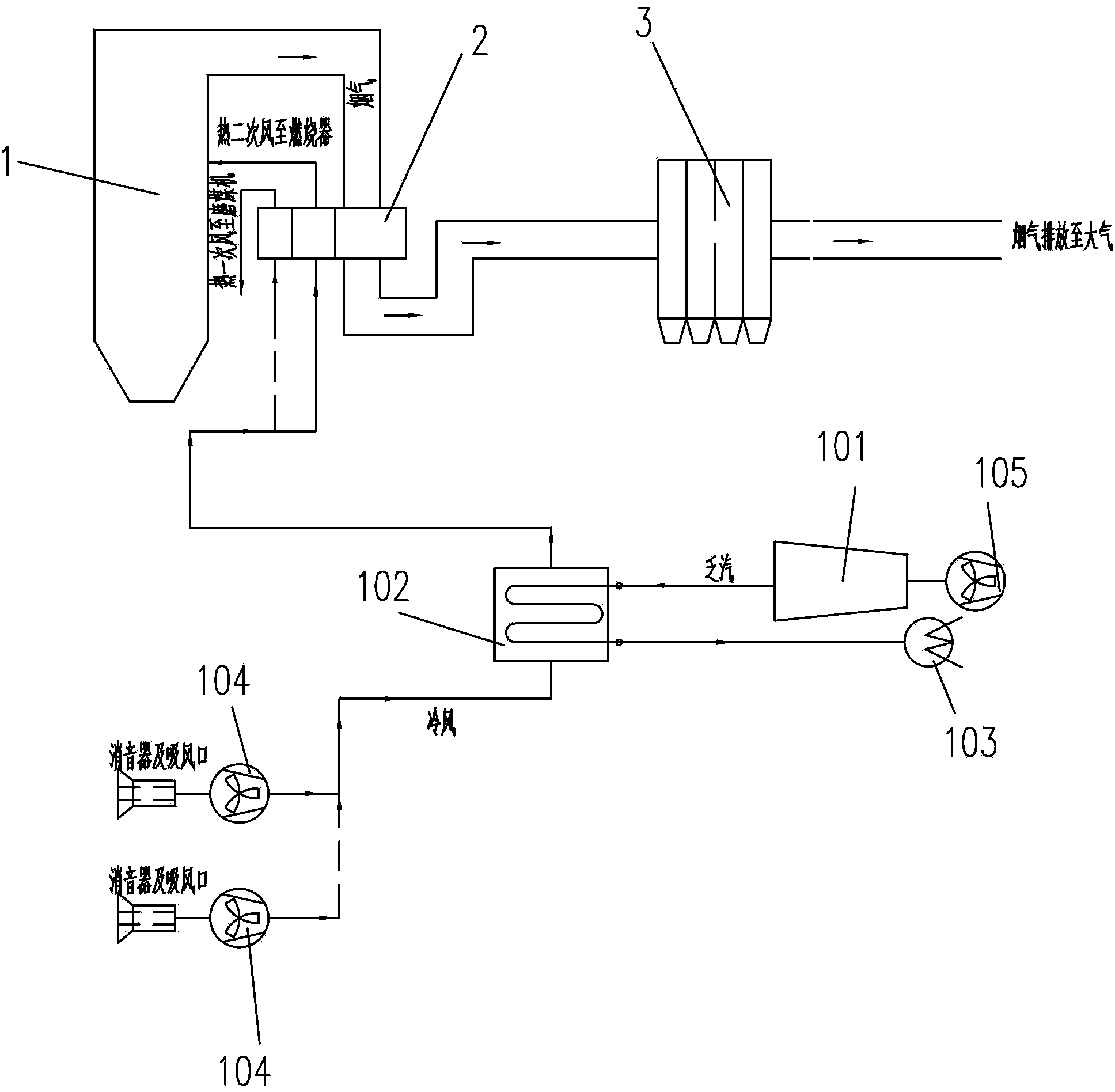

Steam exhaust energy utilizing system of driving steam turbine of thermal power plant and thermal power unit

ActiveCN103573311AReduce steam extractionReduce heat consumptionSteam useIncreasing energy efficiencyAir preheaterEngineering

The invention provides a steam exhaust energy utilizing system of a driving steam turbine of a thermal power plant and a thermal power unit. The steam exhaust energy utilizing system of the driving steam turbine comprises the driving steam turbine, an air preheater and a fan and also comprises a steam-water heat exchanger and an air-water heat exchanger which are formed into a steam-water-air heat exchange system; primary air and or secondary air of the air preheater inlet are or is heated by the steam exhaust of the driving steam turbine through the steam-water-air heat exchange system. According to the steam exhaust energy utilizing system of the driving steam turbine of the thermal power plant and the thermal power unit, the steam exhaust energy of the driving steam turbine is effectively utilized and accordingly the efficiency of the thermal power plant is improved, meanwhile the coal consumption is reduced, and emissions of pollutants are reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

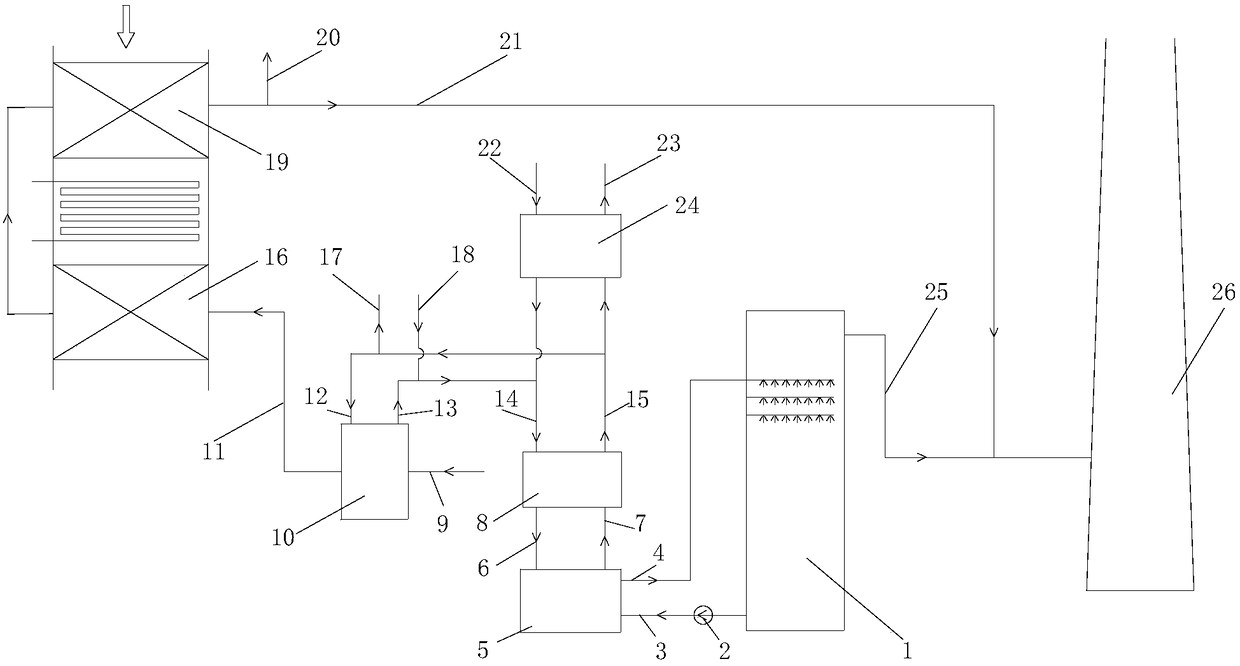

System and technology capable of utilizing waste heat of desulfurated slurry to prevent chimney from emitting white smoke

InactiveCN108592068ANo adverse effect on efficiencyEfficiency impactEmission preventionIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention discloses a system and a technology capable of utilizing waste heat of desulfurated slurry to prevent a chimney from emitting white smoke. The system comprises a desulfurizing tower, anair heater, a high temperature air preheater and a low temperature air preheater, wherein the desulfurizing tower is connected with the air heater; desulfurated slurry from the desulfurizing tower exchanges heat with the cold air of the air heater, and the desulfurated slurry after temperature reduction returns to the desulfurizing tower; the air heater is further connected with the low temperature air preheater; the cold air passing through the air heater is heated by the desulfurated slurry and then enters the low temperature air preheater; the low temperature air preheater is connected withthe inlet of the high temperature air preheater through a pipeline; the outlet of the high temperature air preheater communicates with a boiler and the outlet flue of the desulfurizing tower; most ofhigh temperature air out of the high temperature air preheater is supplied to the boiler via a boiler hot air pipeline and provides oxygen for fuel combustion; and other small part of high temperature air enters the outlet flue of the desulfurizing tower and is mixed with wet flue gas from the desulfurizing tower in the flue to prevent the chimney from emitting white smoke.

Owner:烟台羽林节能科技有限公司

Steam exhaust cooling system of driving steam turbine of thermal power plant and thermal power unit

InactiveCN103575124ASimple systemIncrease profitCombustion processFeed water supplyPollutantPower unit

The invention discloses a steam exhaust cooling system of a driving steam turbine of a thermal power plant and a thermal power unit. The steam exhaust cooling system of the driving steam turbine comprises the driving steam turbine, an air preheater and a fan and also comprises an air cooler; the steam exhaust of the driving steam turbine is cooled by the air cooler through the inlet air from the fan; the steam exhaust inlet of the air cooler is connected with the steam exhaust outlet of the driving steam turbine; the air inlet of the air cooler is connected with the fan; the air outlet of the air cooler is connected with the air inlet of the air preheater. According to the steam exhaust cooling system of the driving steam turbine of the thermal power plant and the thermal power unit, the steam exhaust energy of the driving steam turbine is effectively utilized and accordingly the efficiency of the thermal power plant is improved, meanwhile the coal consumption is reduced, and emissions of pollutants are reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Livestock and poultry house fresh air preheating system suitable for cold region

PendingCN108684535ASolve ventilation consumptionVentilation consumption is not affectedAnimal housingHerdFresh air

The invention discloses a livestock and poultry house fresh air preheating system suitable for a cold region. A fresh air preheating system body is arranged in a livestock and poultry house body. A first-stage preheating module comprises an out-house heat exchanging chamber, and a gas inlet device and a gas exhaust device are arranged in the out-house heat exchanging chamber; the gas inlet devicecomprises an gas inlet fan, and the gas exhaust device comprises a gas exhaust fan, and is communicated with a second-stage preheating module through in-house waste gas outlets; a second-stage preheating system comprises an in-house manure pit, the in-house manure pit is internally provided with a preheating ventilating channel, and the two ends of the preheating ventilating channel are connectedwith a first fresh air collecting chamber and a third-stage preheating module respectively; the third-stage preheating module comprises a second fresh air collecting chamber, an air inlet pipeline isarranged at the top of the second fresh air collecting chamber, leads into a ceiling of the livestock and poultry house, and penetrates through the livestock and poultry house front and back, and airoutlets are uniformly formed the air inlet pipeline. By means of the fresh air preheating system, the purposes of helping existing animal houses to lower the consumption for ventilating while the ventilation of pig houses is not influenced, and increase the air inlet temperature for pig herds while the heating cost is lowered are achieved.

Owner:青岛大牧人机械股份有限公司

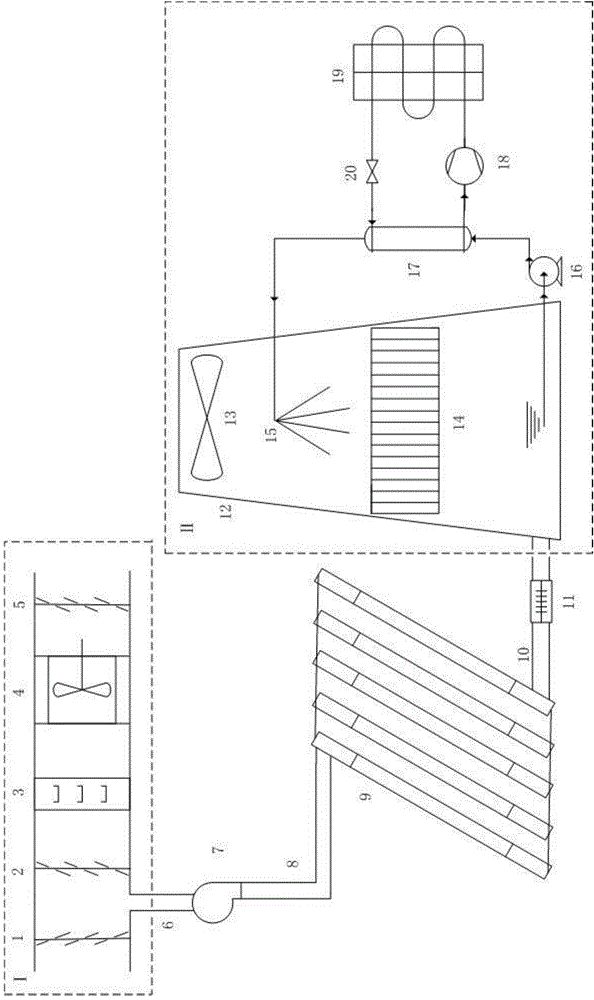

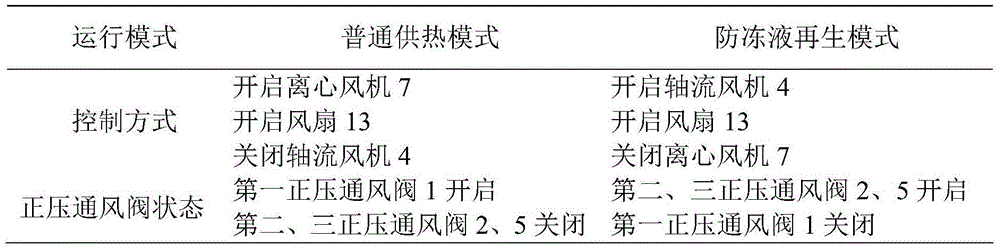

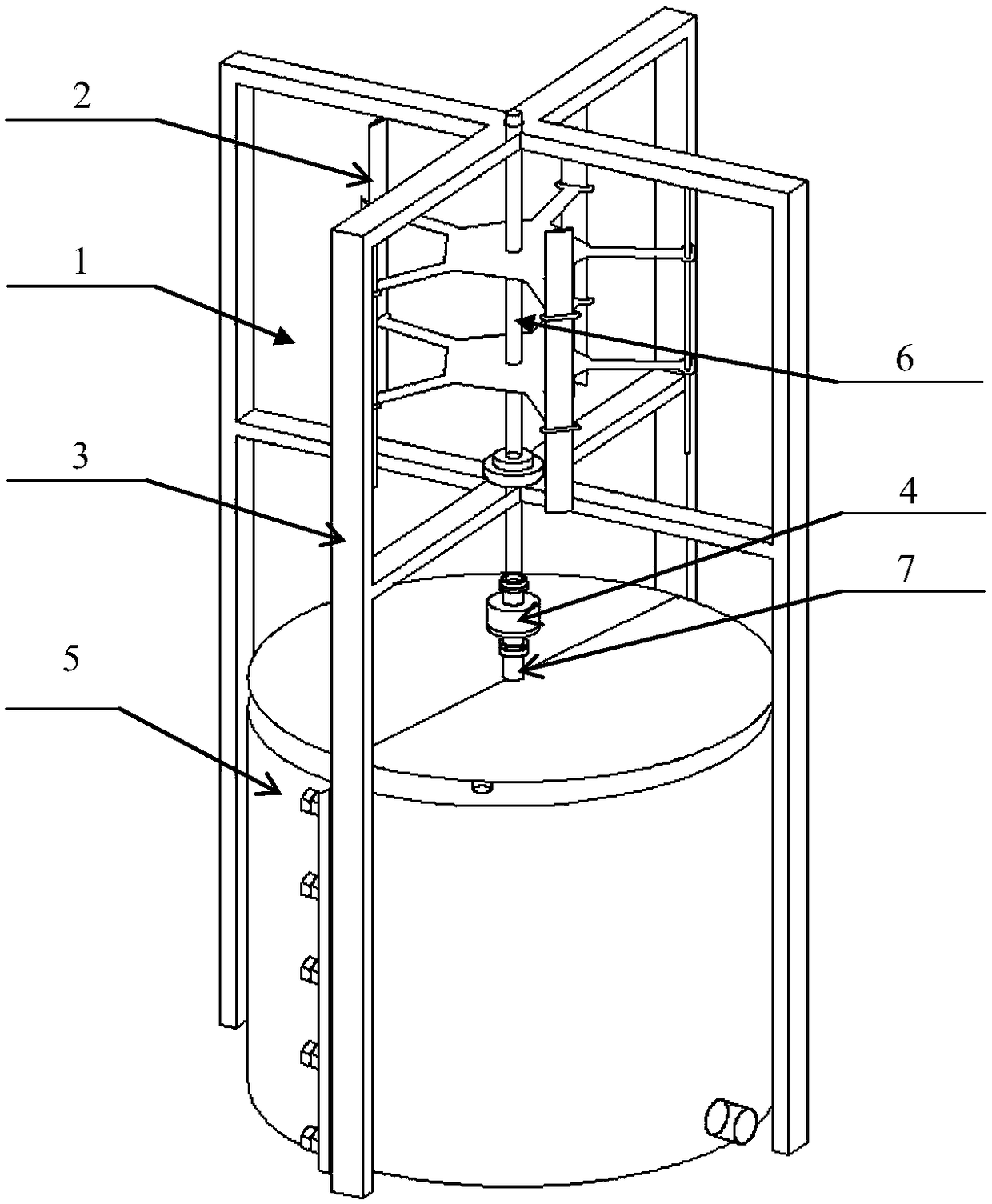

Solar-assisted real-time regeneration system for anti-freezing solution of open heat-source tower

ActiveCN104864736ASolving the practical problem of freezing point riseAchieve instant regenerationHeat recovery systemsSolar heat devicesEngineeringHeat pump

The invention discloses a solar-assisted real-time regeneration system for an anti-freezing solution of an open heat-source tower. The system comprises an air inlet pipe I, a centrifugal fan, a solar air heat collector and an open heat-source tower heat pump system II. The air inlet manner is controlled, the anti-freezing solution in the open heat-source tower can be regenerated, and problems that the concentration of the anti-freezing solution gradually decreases and the freezing point rises during operation of a heat pump of the open heat-source tower are solved; real-time regeneration of the anti-freezing solution is realized, the heat pump is not required to be shut down, and the continuity of heat supply of the heat pump of the open heat-source tower in winter is kept. The solar air heat collector is added in the system, so that sensible heat exchange between air and the anti-freezing solution can be improved. An air type solution regeneration manner is adopted, the requirement of regeneration of the anti-freezing solution for high-grade energy sources is met, and complex equipment is avoided. The solar-assisted real-time regeneration system for the anti-freezing solution is integrated on the basis of the open heat-source tower, renewable energy sources are fully utilized, and large-scale application of solar and heat-source tower heat pump technologies is promoted.

Owner:TIANJIN UNIV

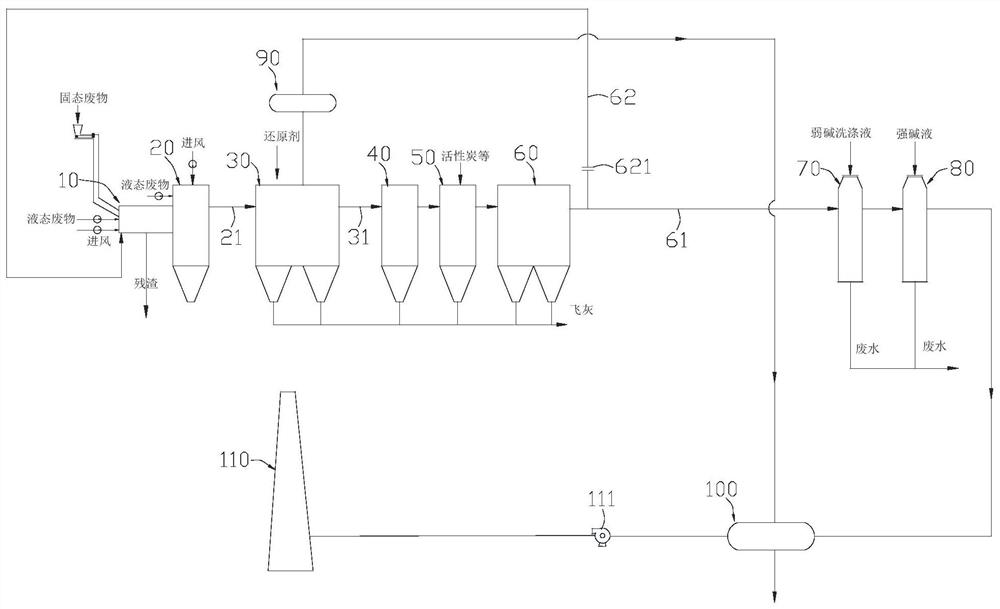

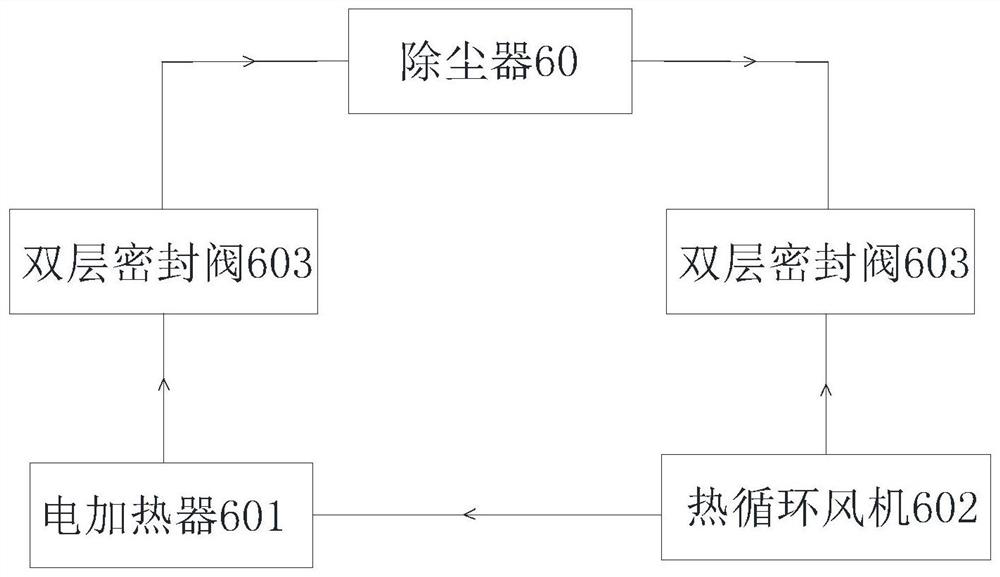

Hazardous waste incineration flue gas treatment system and hazardous waste incineration flue gas treatment method

PendingCN112460604ARaise the inlet air temperatureReduce oxygen concentrationCombustion technology mitigationIncinerator apparatusCombustion chamberTreatment system

The invention discloses a hazardous waste incineration flue gas treatment system and a hazardous waste incineration flue gas treatment method. The hazardous waste incineration flue gas treatment system comprises a rotary kiln, a secondary combustion chamber, a waste heat boiler, a quench tower, a dry deacidification tower, a dust remover, a washing tower, a wet deacidification tower and a flow dividing flue, wherein the rotary kiln, the secondary combustion chamber, the waste heat boiler, the quench tower, the dry deacidification tower, the dust remover, the washing tower and the wet deacidification tower are sequentially connected in the advancing direction of flue gas; and the flow dividing flue is connected between an outlet of the dust remover and the rotary kiln. The flue gas generated by incineration of the rotary kiln is treated, the flue gas meets the low-nitrogen emission requirement, and meanwhile the problem about flue gas heat recovery after incineration of the rotary kilnis solved; and part of the flue gas is guided into the rotary kiln through the flow dividing flue to be recycled in the subsequent treatment process, the air inlet temperature of the rotary kiln is increased, the oxygen concentration of the rotary kiln is reduced, and then the emission concentration of nitric oxide is reduced.

Owner:中广核工程有限公司 +3

Secondary reheating unit with ultrahigh pressure cylinder and high-intermediate pressure cylinder both provided with additional heat regeneration stages

ActiveCN108643980ARaise the inlet air temperatureReduce heat consumptionSteam usePower stationEngineering

The invention discloses a secondary reheating unit with an ultrahigh pressure cylinder and a high-intermediate pressure cylinder both provided with additional heat regeneration stages, and relates toa secondary reheating unit in the fire coal power station ultra-supercritical stage. In particular, the ultrahigh pressure cylinder and the high-intermediate pressure cylinder are both provided with the additional heat regeneration stages, a heat regeneration system is further optimized, main steam, primary reheating steam and secondary reheating parameters are further optimized, the heat consumption of the secondary reheating unit in the ultra-supercritical stage can be obviously reduced, and the greenhouse gas discharge can be obviously reduced.

Owner:章礼道

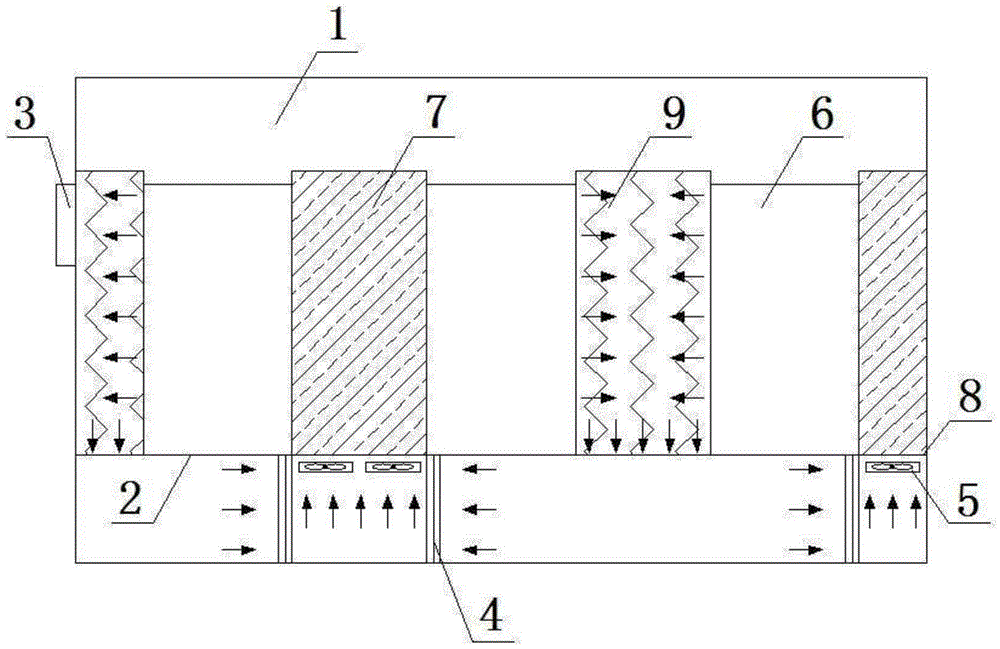

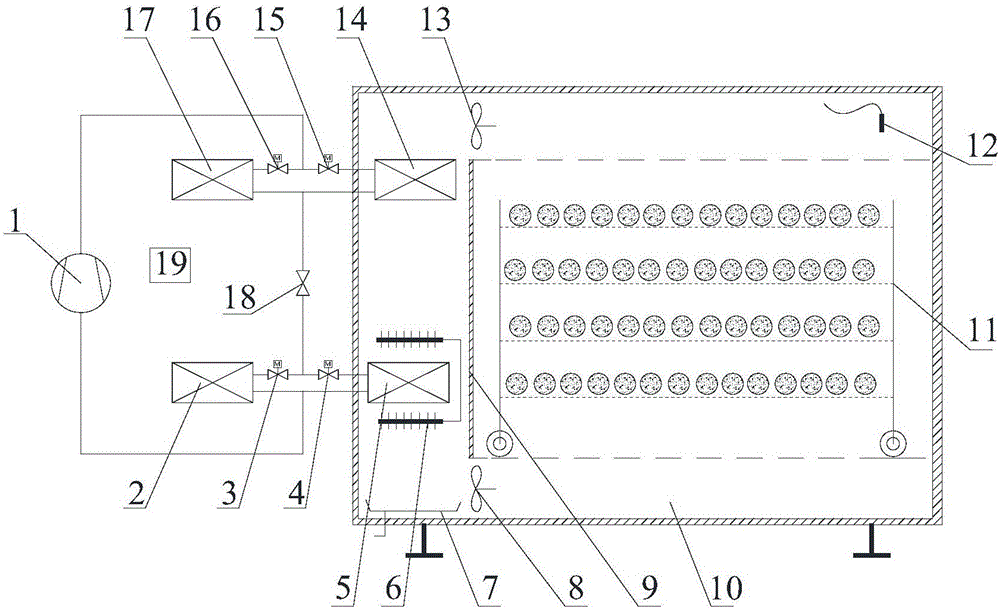

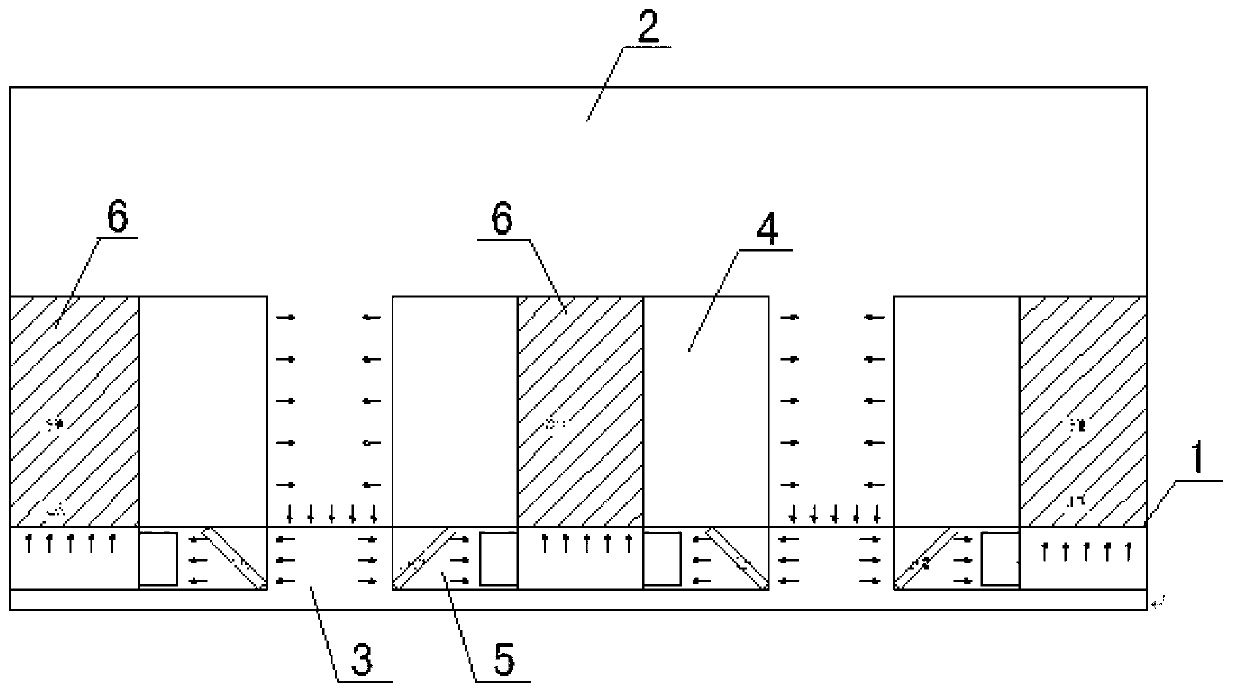

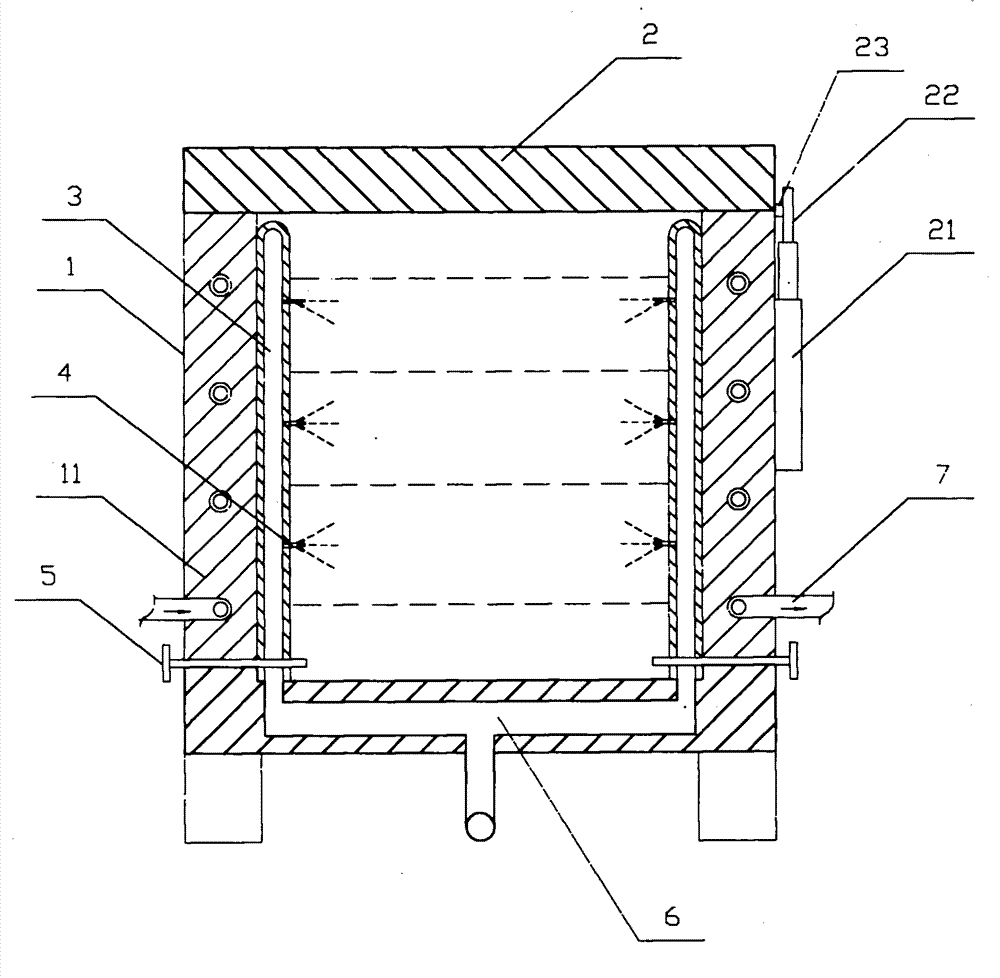

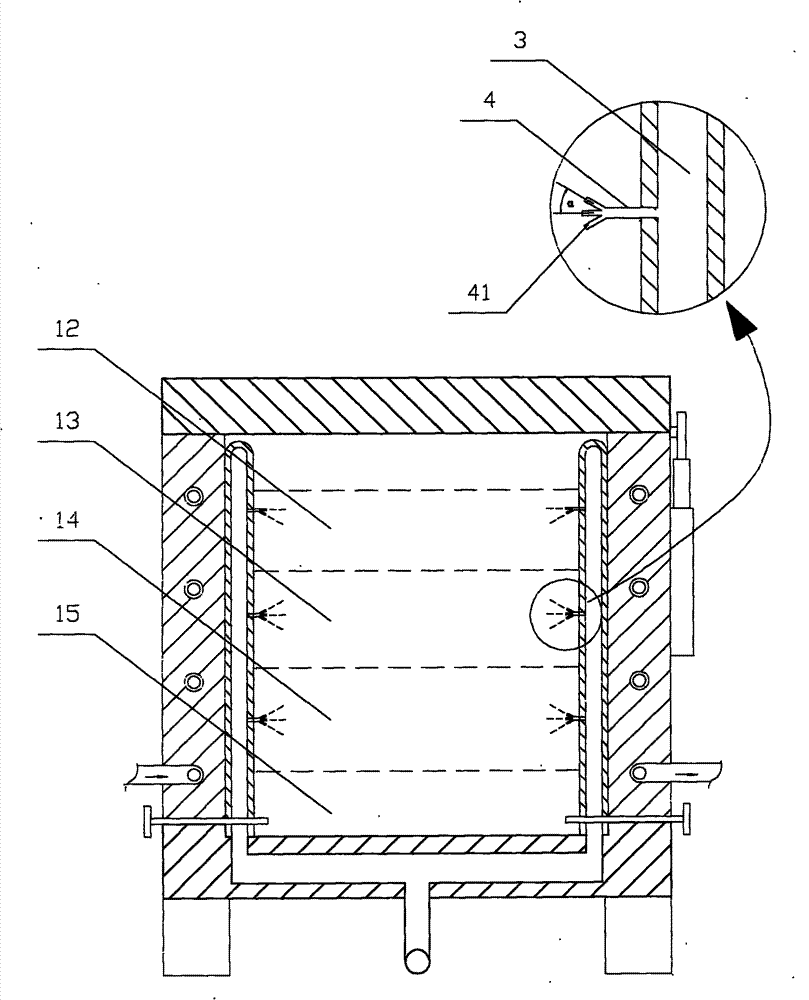

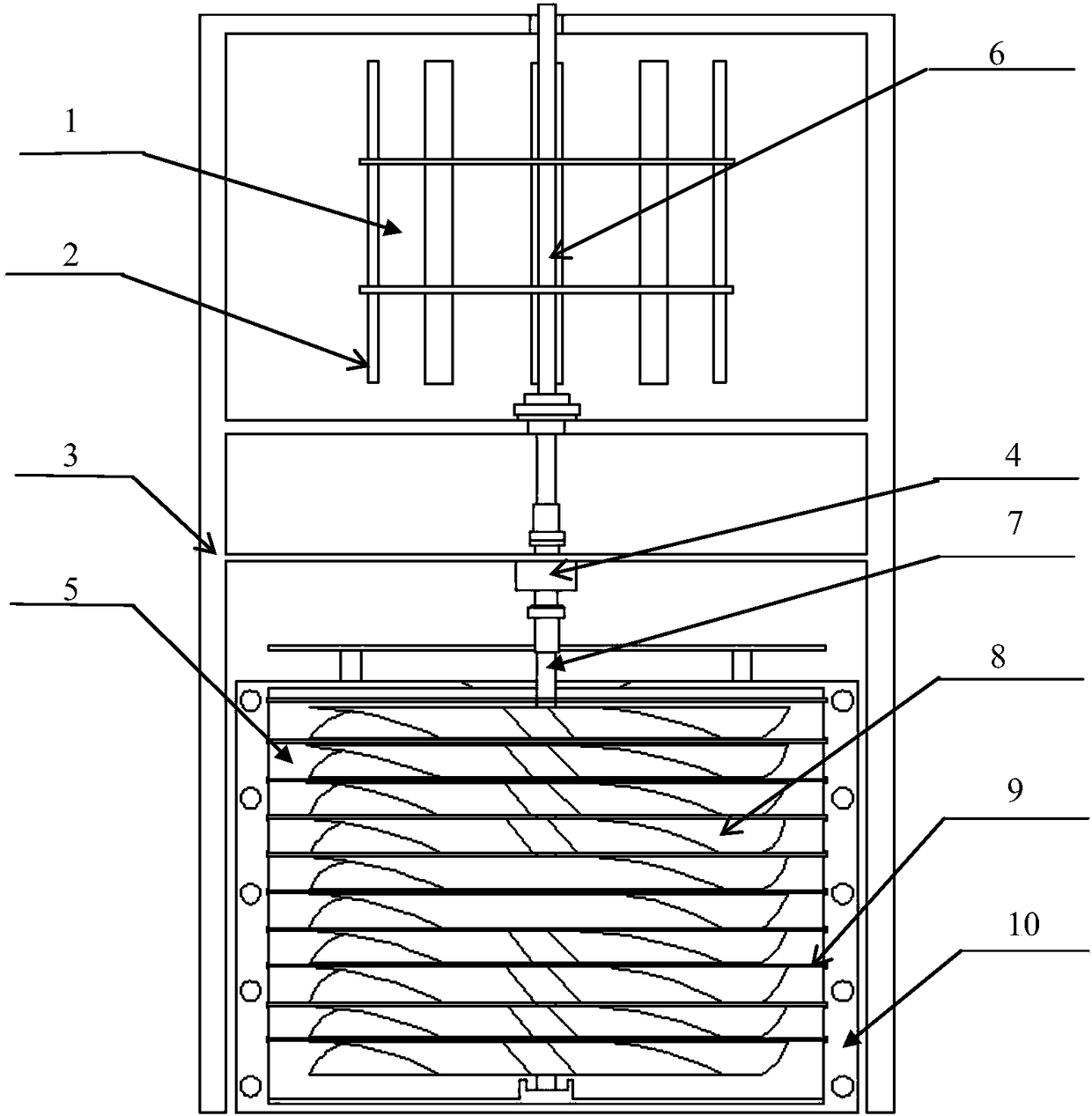

Closed cold channel data center with cold region and hot region

InactiveCN103344020ARaise the inlet air temperatureImprove heat transfer efficiencyDucting arrangementsLighting and heating apparatusChannel dataEngineering

The invention discloses a closed cold channel data center with a cold region and a hot region. A plurality of cabinets are arranged in a machine room of the data center. The machine room is divided by a floor into a machine room space above the floor and a refrigeration equipment space below the floor. The cabinets are arranged on the floor in rows, and each row of cabinets is provided with a closed cold channel. Refrigeration equipment is arranged in the refrigeration equipment space, wherein the refrigeration equipment comprises a hot air inlet and a cold air outlet, the hot air inlet is communicated with the machine room space, and the cold air outlet is communicated with one corresponding closed cold channel. According to the closed cold channel data center with the cold region and the hot region, the refrigeration equipment does not occupy floor space of the machine room so that all the floor space can be used for the placement of the cabinets as needed; moreover, the machine room is divided into the cold region and the hot region, inlet air temperature of the refrigeration equipment is raised, therefore, heat exchange efficiency is improved, and the effect of energy conservation is achieved; meanwhile, the closed cold channels are adopted to enable the refrigeration equipment to supply cold air to each row of cabinets, the cold air of the refrigeration equipment is distributed to each cabinet after being transmitted to the closed cold channels, and therefore the closed cold channel data center can be adapted to various models of cabinets.

Owner:NANJING CANATAL DATA CENT ENVIRONMENTAL TECH CO LTD

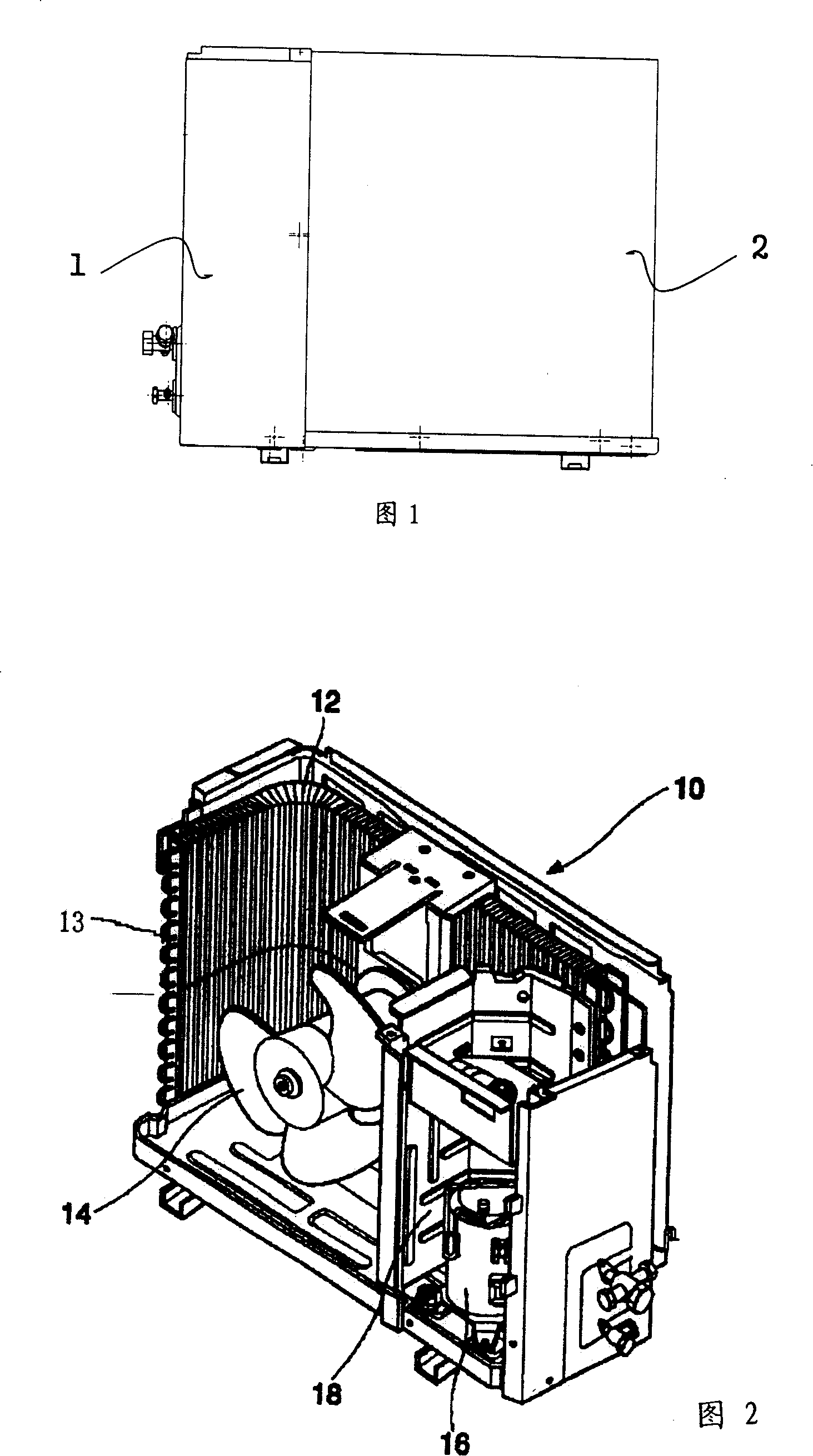

Cabinet air-conditioner outdoor machine defrosting device

InactiveCN101187514ARaise the inlet air temperatureImprove defrosting effectCorrosion preventionRefrigeration componentsFiberCarbon fibers

The invention discloses a defrosting device of an outdoor cabinet type air conditioner, which is applied to the defrosting field of an air conditioner. The outdoor cabinet type air conditioner comprises a heat exchanger which is constituted by brass pipes which are arrayed in parallel, the outer side of the heat exchanger is provided with a heating wire which is arranged on a frame, the frame is directly fixed on the heat exchanger through a screw bolt, and the frame is a square brandreth. A plurality of holes are arranged on the left and right sides of the frame, the heating wire which is wound in S-shape is penetrated into the hole, simultaneously, the heating wire is composed of carbon fibers, the trend of the heating wire is coincident with the trend of the brass pipe in the heat exchanger, and row number of the heating wires are approximately equal to the row number of the brass pipes in the heat exchanger. Further, a switch is controlled by the heating wire through an outdoor printed circuit board, and a power supply is arranged on the printed circuit board. The invention raises air inlet temperature of an outdoor machine, delays frost formation, and accelerates defrosting speed.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

High-temperature pyrolysis incineration equipment

The invention discloses high-temperature pyrolysis incineration equipment. The high-temperature pyrolysis incineration equipment comprises a combustion chamber, wherein a combustion device and an air supply device are arranged in the combustion chamber; the combustion device comprises a plurality of air supply tubes arranged on a side wall of the combustion chamber; and each air supply tube is provided with a plurality of sprayers with multidirectional nozzles. A first combustion region and a second combustion region in the combustion chamber are combined into a whole structure, the incineration equipment is small in size and moves conveniently, different regions in the combustion chamber can be subjected to air supply combustion supporting and wind-proof partitioning respectively through the sprayers, treated objects are combusted sufficiently, noxious substances and black smoke which are generated due to the fact that the treated objects are not combusted completely are eliminated completely, and pollution on the environment is avoided.

Owner:义乌市中雄箱包有限公司

Adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization

InactiveCN105091020AIncrease independenceBest Cascade UtilizationCombustion processSteam useEngineeringRecuperator

The invention belongs to the fields of thermal power generation and the like and particularly relates to an adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization. According to the adjustable boiler air preheating system and method, air preheating, waste heat utilization and regenerative heat cycling are made to be combined organically; heat-transmission cycling condensate water is divided into a large open cycle in which a bypass low-pressure heater extrudes a steam turbine to perform high-parameter steam extraction and a small closed cycle in which the low-pressure heater (or an added heat exchanger) is used for absorbing heat to increase low-parameter steam extraction; heat flow is divided according to the temperature level difference, heat source and cold source resources are dynamically and sufficiently used, optimal gradient utilization of heat energy in the power generation thermodynamic cycle is achieved, the energy use quality is improved, and energy losses are reduced. According to the adjustable boiler air preheating system and method, the operation mode of the system can be optimized and adjusted automatically according to the change of the operation condition so that gradient utilization of energy of different qualities can be achieved and energy losses can be reduced, and the thermodynamic cycle efficiency and the system economy are maximized.

Owner:郝江平

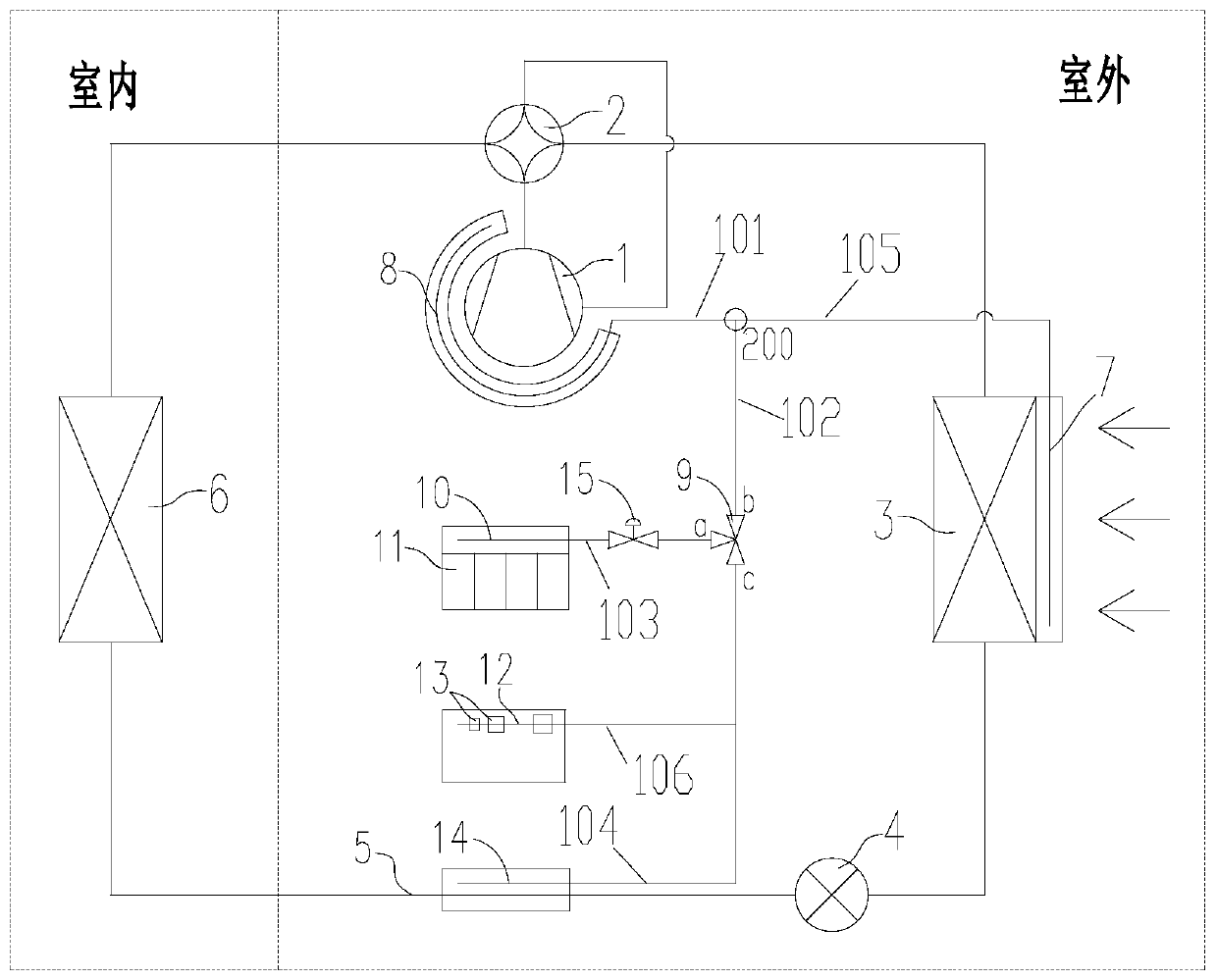

Thermal management system and control method thereof and auto

ActiveCN109910550ASimple pipingImprove reliabilityAir-treating devicesVehicle heating/cooling devicesEvaporationThermal management system

The invention provides a thermal management system and a control method thereof and an auto. The thermal management system comprises a battery assembly (11) and a heat pipe assembly, wherein the heatpipe assembly comprises a first heat pipe evaporation end (8), a heat pipe heat exchange end (10) and a second heat pipe condensation end (14); the heat pipe heat exchange end (10) is arranged in theposition of the battery assembly (11), and the heat pipe heat exchange end (10) may be communicated with the first heat pipe evaporation end (8) to absorb heat from the first heat pipe evaporation end(8) to heat the battery assembly (11); the heat pipe heat exchange end (10) may also be communicated with the second heat pipe condensation end (14) to release heat to the second heat pipe condensation end (14) to cool the battery module (11). The invention cannot only cool the battery, but also heat the battery, realizing a wider range of application, and the heating and cooling system pipelineis simple, improving the reliability and operating efficiency of the system.

Owner:GREE ELECTRIC APPLIANCES INC

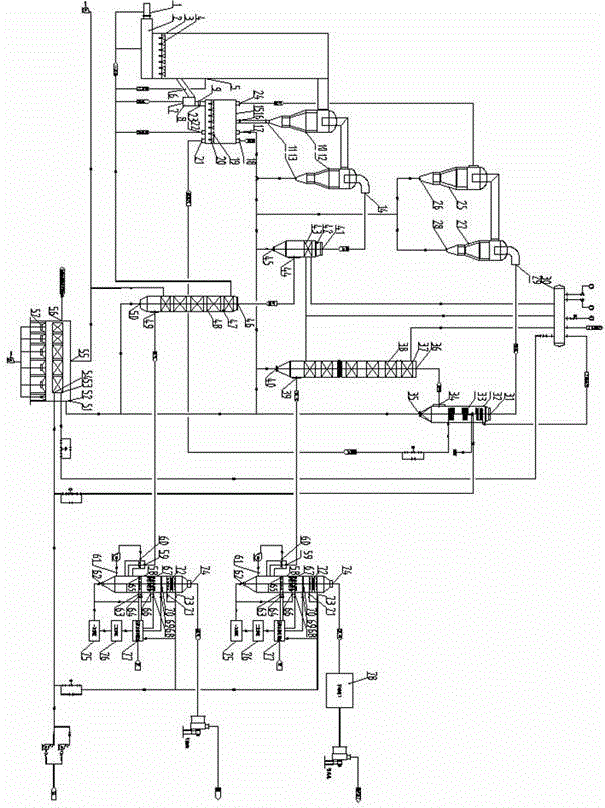

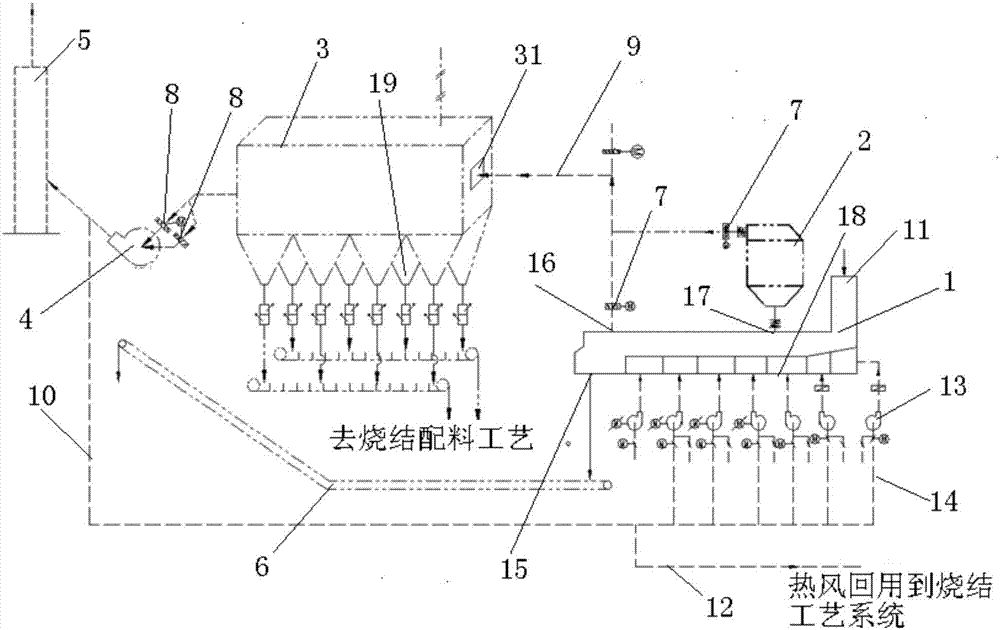

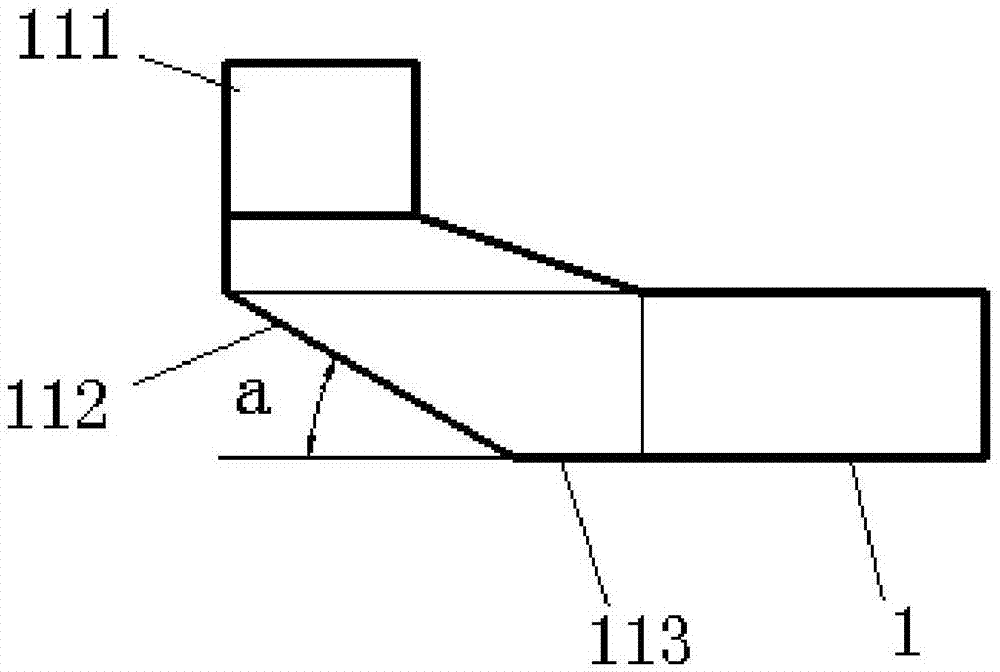

System for cooling heat ore deposits and recycling waste heat

PendingCN108007219AImprove cooling effectImprove waste heat recovery efficiencyIncreasing energy efficiencyCombustion technology mitigationFlue gasAir blower

The invention discloses a system for cooling heat ore deposits and recycling waste heat. The system comprises a sintered heat ore cooler, wherein a perpendicular material pre-storage section of the sintered heat ore cooler is equipped with a sintered ore distributing and air-locking device; a horizontal cooling section which communicates with the material pre-storage section is arranged in the sintered heat ore cooler; the cooling section is equipped with a cooler trolley; the bottom of the cooling section is provided with a sectional air supply system for supplying air through an air blower;the upper end of the cooling section is integrated with a waste heat boiler which utilizes waste heat generated in a heat ore deposit cooling process to generate power; the waste heat boiler and the sintered heat ore cooler are connected with a dust remover through a low-temperature flue gas pipeline; a flue gas outlet of the dust remover is connected with an inlet of an induced draft fan; an outlet of the induced draft fan is connected with a flue gas recycling pipeline; and the flue gas recycling pipeline is connected with the sectional air supply system. The system radically solves the airleaking problem of an existing equipment system.

Owner:SINOMA ENERGY CONSERVATION

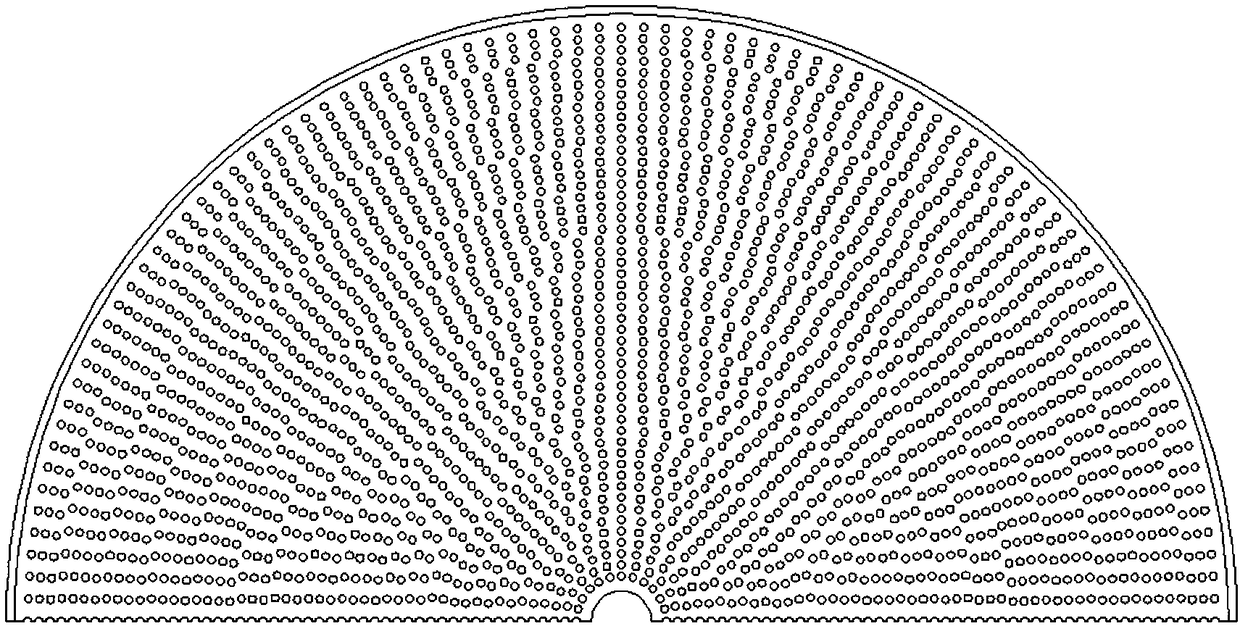

Novel wind energy heating system

PendingCN108374762AExpand the form of useAvoid consumptionWind motor combinationsRenewable energy generationThermal energyEngineering

The invention provides a novel wind energy heating system which comprises a wind energy collecting device, an air power heating furnace and a speed increase unit. The wind energy collecting device comprises a first rotating shaft and rotary blades fixed to the first rotating shaft in the circumferential direction, and the rotary blades rotate under the effect of wind energy to drive the first rotating shaft to rotate; the air power heating furnace comprises a furnace wall, a second rotating shaft arranged in the furnace wall, a plurality of restriction orifices and a plurality axial flow blades fixed to the second rotating shaft; center holes of the multiple axial flow blades are arranged on the second rotating shaft in a sleeving manner and are arranged in the axial direction of the second rotating shaft, the restriction orifices are arranged between every two corresponding adjacent axial flow blades, and the speed increase unit is connected between the first rotating shaft and the second rotating shaft. By means of the novel wind energy heating system, other unnecessary waste generated by conversion from wind energy to electric energy to heat energy is saved, and the energy resource using rate is improved; and the inlet air temperature of the air energy using equipment can be improved, the energy conversion efficiency of the air energy using equipment is improved, and the application scope of the system is expanded.

Owner:XUHAI COLLEGE CHINA UNIV OF MINING & TECH +1

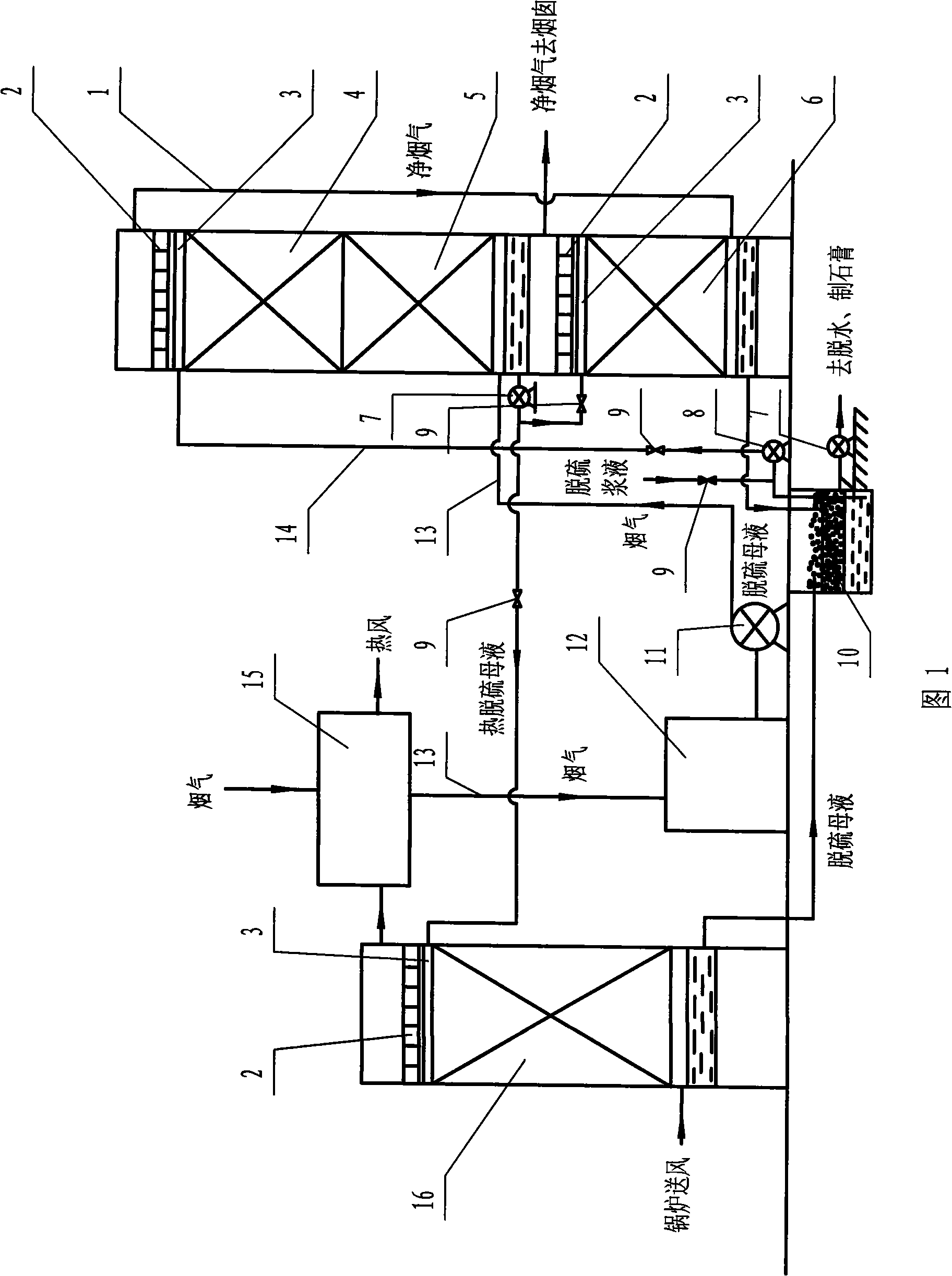

Gas-liquid contact type non-phase-change middle medium heat exchange wet-type desulfuration method and apparatus

InactiveCN101298021AEliminate acid dew corrosion on the heating surfaceSolving Corrosion ProblemsDispersed particle separationAir preheaterEngineering

The invention discloses a gas-liquid contact type non phase transition intermediate medium heat transfer wet desulfurization method and a device thereof. Flue gas enters a flue gas cooling section through an air preheater to carry out pre-desulfurization and release heat towards desulfurization liquid to bring down temperature, and then enters a desulfurization section; the desulfurization liquid absorbs the heat of the flue gas to cause the temperature to rise to 90 to 95 DEG C and then enters a purified flue gas heating section and an air preheating section to release heat again; the lower part of the desulfurization section of the device is connected with the flue gas cooling section which is respectively connected with the purified flue gas heating section and the air preheating section; the air preheating section is connected with the air preheater and the air preheater is connected with the flue gas cooling section; an outlet at the top of the desulfurization section is connected with the purified flue gas heating section; the bottoms of the air preheating section and the purified flue gas heating section are connected with a sedimentation tank which is connected with a spray device at the upper part of the desulfurization section. The method and device greatly improve the heat efficiency of boilers; meanwhile, the minimum wall temperature of the air preheater is greatly increased and far away from a flue gas acid dew point, thereby guaranteeing the safe operation of boilers and preventing heating surfaces from acid dew corrosion.

Owner:苏州全大节能环保科技有限公司

System and technology for removing white smoke exhausted from boiler and industrial kiln chimneys

InactiveCN108518700AReduce the temperatureIncrease temperatureHeat pumpsEmission preventionHeating seasonHeat pump

The invention discloses a system and technology for removing white smoke exhausted from boiler and industrial kiln chimneys. The system comprises a heat pump, a desulfurization process water heat exchanger, an air heater, a supplemental water heater, a plurality of water feeding and discharging pipelines and a plurality of smoke ducts, wherein the heat pump is used for generating low-temperature water and absorbing heat from low-temperature heat source desulfurization process water, accordingly, the temperature of smoke exhausted from an outlet of a desulfurization tower is lowered, and the amount of water contained in the smoke exhausted from the outlet of the desulfurization tower is decreased; meanwhile, the heat pump can generate high-temperature water which is used for serving as a heat source of the air heater to heat cold air, and surplus heat can be recovered, used for outside heating in winter and used for heating supplemental water in non-heating seasons; and the dual functions of smoke waste heat recovery and white smoke removing are achieved, and under the condition that operation of a boiler is not influenced, zero-cost operation of the white smoke removal process is achieved.

Owner:ZIBO INNOVATION ENERGY TECH CO LTD

Small-size heat pump drying device realizing high-efficiency dehumidification

PendingCN110595196AAchieve dehumidificationReduce humidityDrying gas arrangementsHeating arrangementEvaporationEngineering

The invention discloses a small-size heat pump drying device realizing high-efficiency dehumidification. The device comprises a sealed drying chamber, a heat pipe heat exchanger, a thermoelectric module and a heat pump, wherein the heat pump comprises an expansion valve, an evaporator, a compressor, a first condenser and a second condenser which sequentially communicate with one another through apipeline so as to form a loop; the drying chamber is provided with an air inlet and an air outlet, wherein the air inlet and the air outlet mutually communicate through a drying channel, and a circulating fan is arranged in the drying channel; the evaporator is arranged in the portion, close to one side of the air outlet, in the drying channel, and the first condenser and the second condenser arearranged in the portion, close to one side of the air inlet, in the drying channel; a baffling plate is arranged in the drying channel, a heat pipe heat exchanger evaporation section, a thermoelectricmodule cold end, a thermoelectric module hot end and a heat pipe heat exchanger condensing section are arranged sequentially in the air advancing direction, and the evaporator is arranged between thethermoelectric module hot end and the heat pipe heat exchanger condensing section; and the drying channel is provided with a drainage port below the thermoelectric module cold end. According to the small-size heat pump drying device realizing high-efficiency dehumidification, air is dehumidify, the relative humidity of the air is reduced, and therefore the purpose of high-efficiency dehumidifyingand drying can be realized.

Owner:GUANGDONG UNIV OF TECH +1

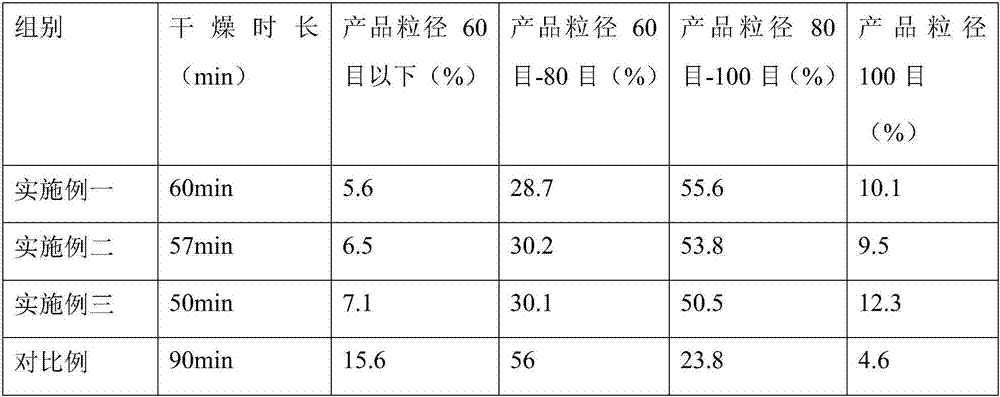

316 titanium fluidized bed drying-cooling process applied to potassium salt

ActiveCN107477982AEvenly heatedReduce cakingDrying solid materials with heatDrying gas arrangementsExhaust gasTitanium

The invention discloses a 316 titanium fluidized bed drying-cooling process applied to potassium salt. The 316 titanium fluidized bed drying-cooling process comprises the following steps: (1) primary drying: injecting hot flue gas into a drying machine till cold air in the drying machine is exhausted, feeding the wet material of potassium salt to the drying machine, spraying an anti-caking agent in liquid form to the drying machine at a spraying rate of 30 min / L by utilizing a spraying gun, waiting for the sufficient mixing of the wet material of potassium salt and the anti-caking agent in the drying machine, and drying to form first potassium salt dust; (2) secondary drying; (3) cooling: mixing second potassium salt dust with the first potassium salt dust, feeding the mixture to a fluidized bed for cooling so as to obtain a finished product of potassium salt and second off gas, and recovering the second tail gas by utilizing a bag-type dust collector, so that only the finished product of potassium salt is obtained; and (4) emptying. The 316 titanium fluidized bed drying-cooling process applied to potassium salt disclosed by the invention has the advantages that the drying time is short and the particle size of the finished product is small, and can be widely applied to the technical field of the drying of potassium salt.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Energy-saving comprehensive heat supply system

ActiveCN112923424AAvoid wastingImprove utilization efficiencyHeating fuelHeat recovery systemsWater source heat pumpThermodynamics

The invention relates to the technical field of heating equipment, and particularly discloses an energy-saving comprehensive heat supply system. The energy-saving comprehensive heat supply system comprises a heat consumer unit, a boiler heating unit, a water source heat pump heating unit, an air energy heat pump heating unit, a heat recovery circulating unit, a water return tank and a water supply tank. The heat recovery circulating unit is connected with a exhaust pipe of a boiler through a smoke pipe. The water supply tank is separately connected with the boiler heating unit, the water source heat pump heating unit and the air energy heat pump heating unit through a boiler water supply pipe, a water source heat pump water supply pipe and an air energy heat pump water supply pipe, and the heat recovery circulating unit is connected with the air energy heat pump water supply pipe through a heat recovery water supply pipe. The heat recovery circulating unit is connected with an air energy heat pump water return pipe through a heat recovery water return pipe. The energy-saving comprehensive heat supply system aims to solve the problems that in the prior art, central heating equipment is single, the utilization rate of heating heat energy is low, and more heat energy is wasted.

Owner:贵州中能投科技有限公司

Hydrogen fuel cell low-temperature operation support device

PendingCN114171754AImprove uniformityGuaranteed uptimeFuel cell heat exchangeThermal insulationHydrogen fuel cell

The invention relates to the technical field of hydrogen fuel cells, in particular to a hydrogen fuel cell low-temperature operation supporting device. A hydrogen fuel cell low-temperature operation supporting device is suitable for an air cooling hydrogen fuel cell stack and comprises an air inlet cover, an air inlet heating device, a backflow air duct, a backflow heating device, a backflow fan, an exhaust cover, a main fan and an end plate heating device. Waste heat and water are utilized by refluxing high-temperature tail gas, the inlet air temperature is improved through the inlet air heating device, the uniformity of the stack temperature is improved through the end plate heating device, and the temperature of hydrogen entering the stack is improved through the high-temperature tail gas, so that the purpose of maintaining stable operation of the hydrogen fuel cell stack in a low-temperature environment is achieved; the heat reflection material and the thermal insulation material greatly reduce heat loss during low-temperature operation of the hydrogen fuel cell stack, so that the normal working temperature of the stack can be maintained, and the environment temperature lower limit of stable operation of the hydrogen fuel cell can be reduced.

Owner:张家口市氢能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com