Thermal management system and control method thereof and auto

A thermal management system and heat pipe technology, applied in the thermal management system and its control method and the automotive field, can solve problems such as inability to cool, complex heating and cooling system pipelines, etc., achieve simple pipelines, improve system reliability and operating efficiency , the effect of reducing the operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

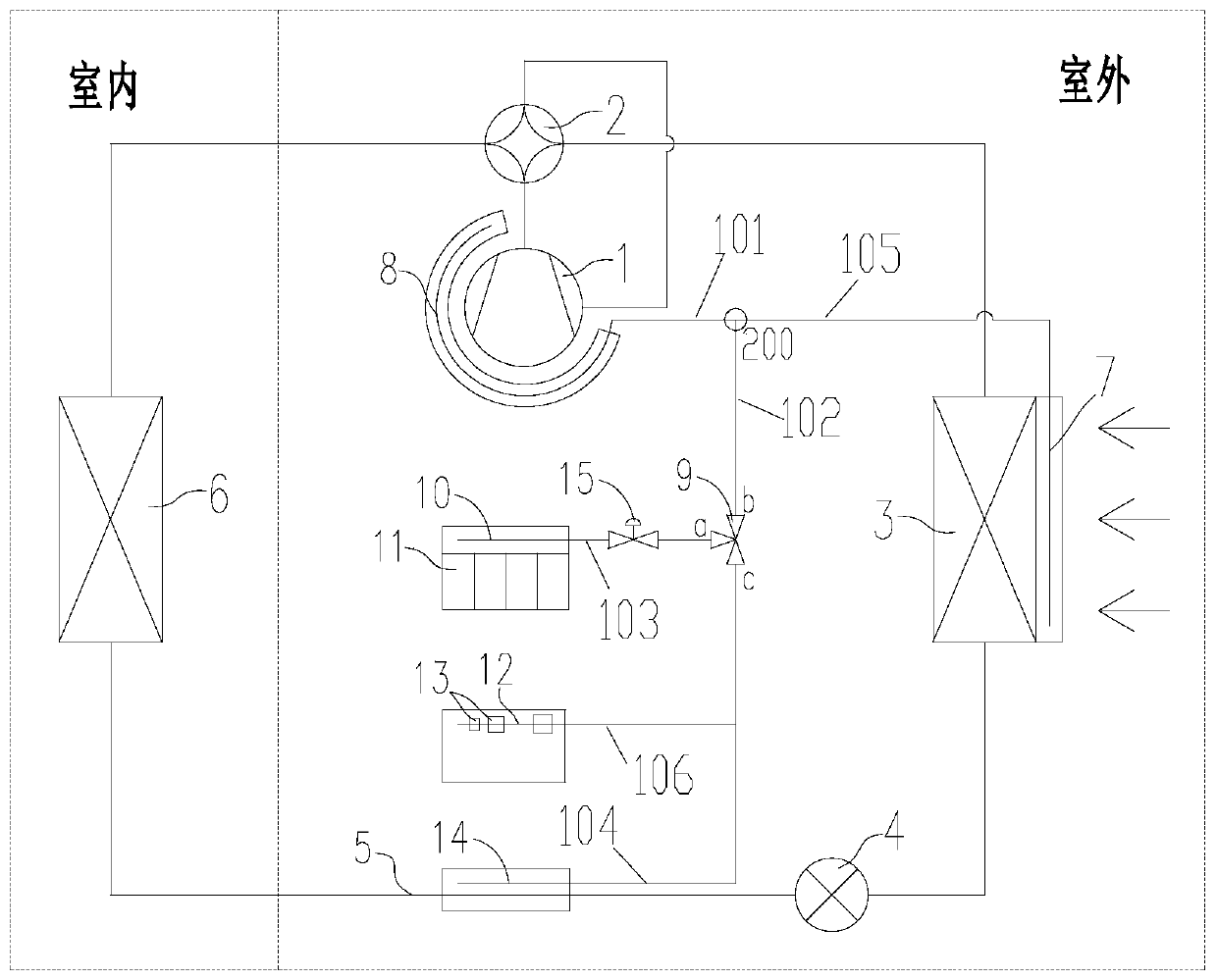

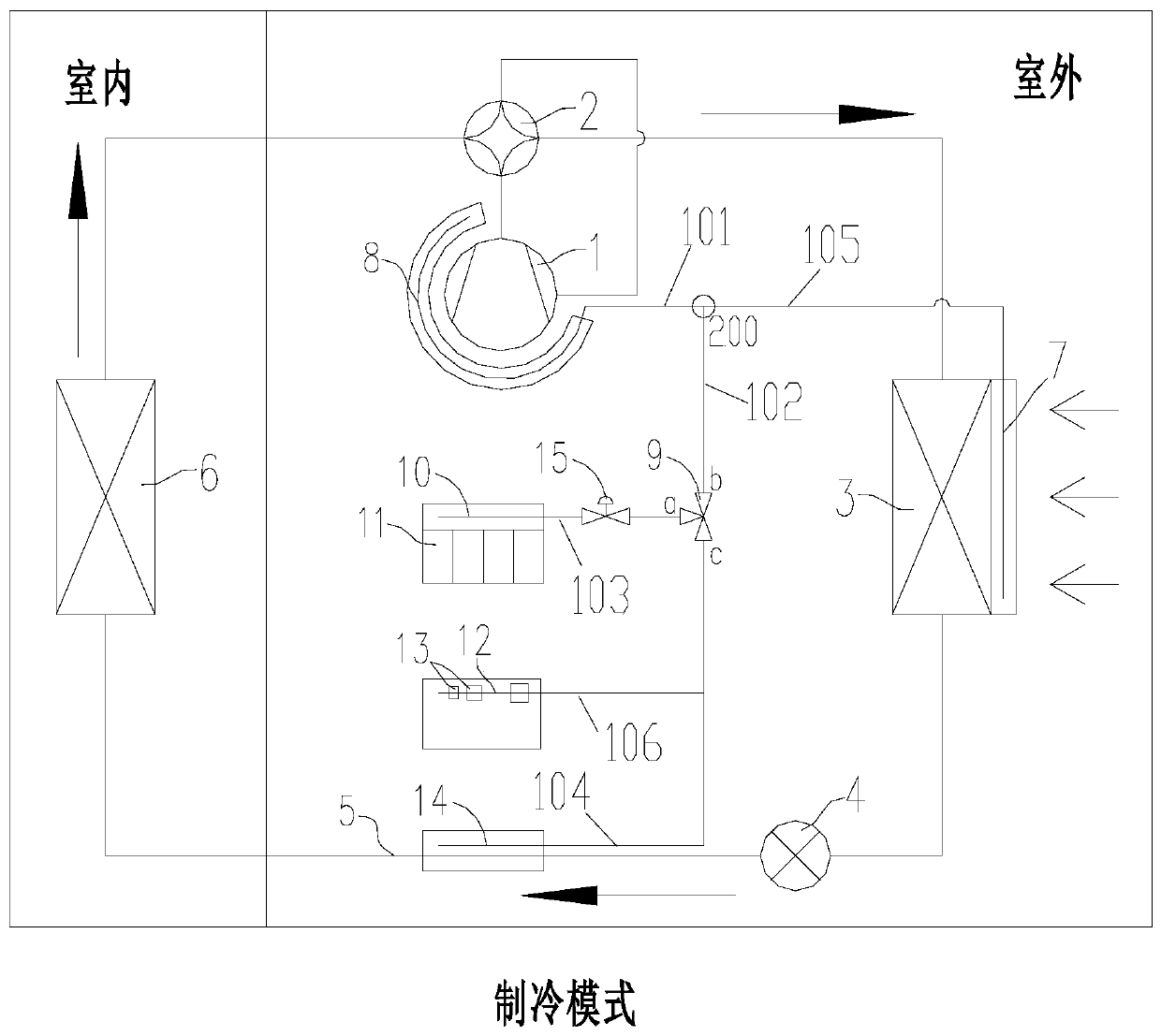

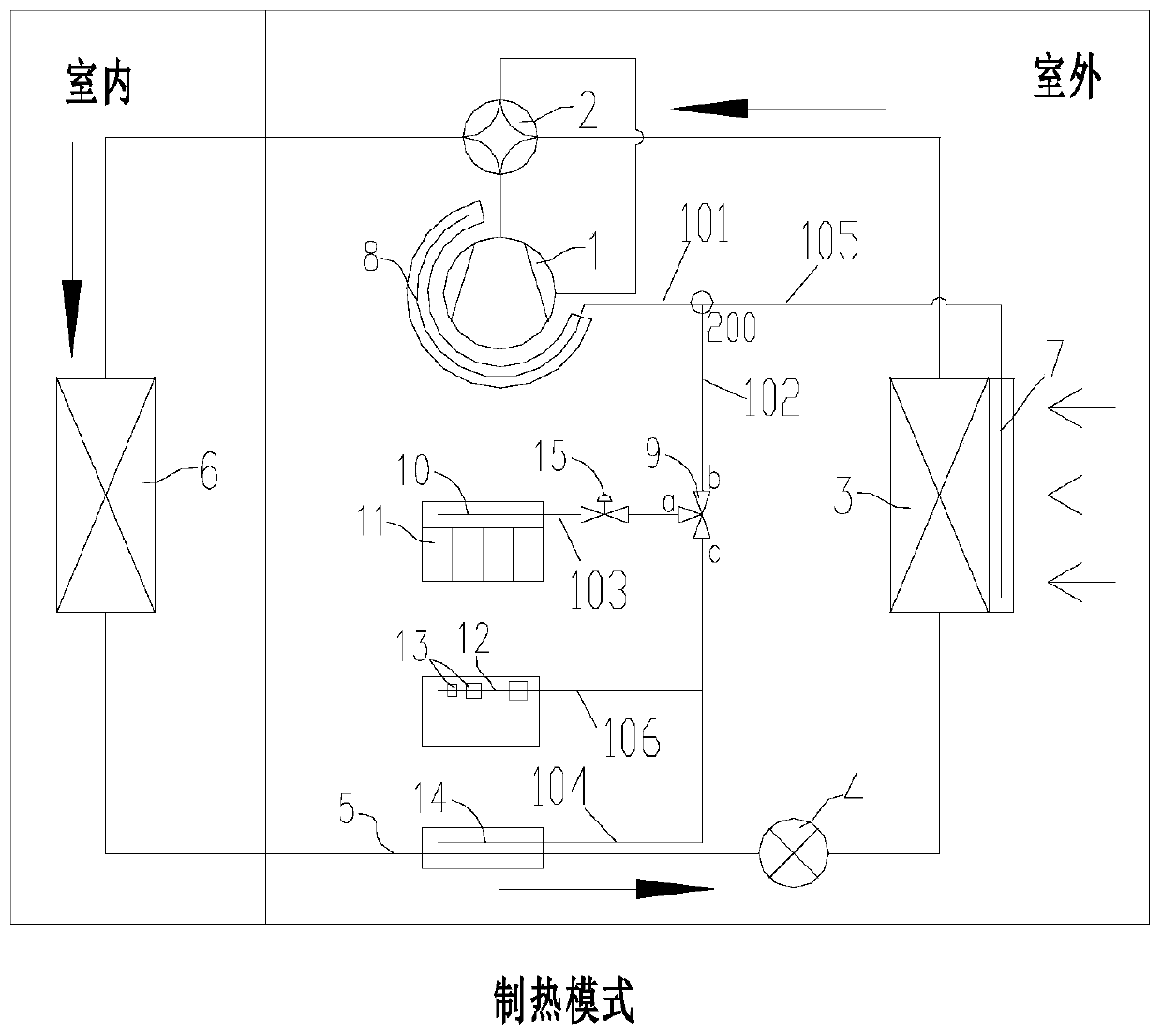

[0063] Such as Figure 1-3 As shown, the present invention provides a thermal management system, which includes:

[0064] Battery pack 11 (preferably accumulator);

[0065] It also includes a heat pipe assembly, which includes a first evaporation end 8 of the heat pipe, a heat exchange end 10 of the heat pipe, and a second condensation end 14 of the heat pipe;

[0066] And the heat exchange end 10 of the heat pipe is arranged at the position of the battery assembly 11. When the battery assembly 11 needs to be heated, the heat exchange end 10 of the heat pipe can communicate with the first evaporation end 8 of the heat pipe, so that Heat is absorbed from the first evaporation end 8 of the heat pipe to heat the battery assembly 11; and when the battery assembly 11 needs cooling, the heat exchange end 10 of the heat pipe can also be condensed with the second heat pipe The end 14 is connected to release heat toward the second condensing end 14 of the heat pipe to cool the batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com