Inkjet head cleaning device

A cleaning device and inkjet head technology, applied in printing and other directions, can solve problems such as increased pressure loss, obstruction of liquid delivery, damage to liquid delivery path, etc., to achieve the effects of reduced contact area, reduced flow resistance, and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0113] figure 1 The ink jet head liquid feeding device according to the first embodiment of the present invention is exemplified. like figure 1 As shown, in the ink jet head liquid feeding device according to the first embodiment, the ink tank 1 storing the liquid material is communicated with a common liquid feeding pipeline 2 extending in the horizontal direction at a position below the ink tank 1, and in the common liquid feeding pipe 2 The liquid feeding pipeline 2 is connected with a plurality of independent liquid feeding pipelines 3 at equal intervals. These independent liquid feeding pipes 3 extend downward from the common liquid feeding pipe 2, and the lower ends of the respective independent liquid feeding pipes 3 are respectively connected to the ink jet heads 4 (the liquid reservoirs inside thereof), and these independent liquid feeding pipes 3 are arranged in the vertical direction. On the way, degassing units 5 for degassing air bubbles such as air in the liq...

no. 2 approach

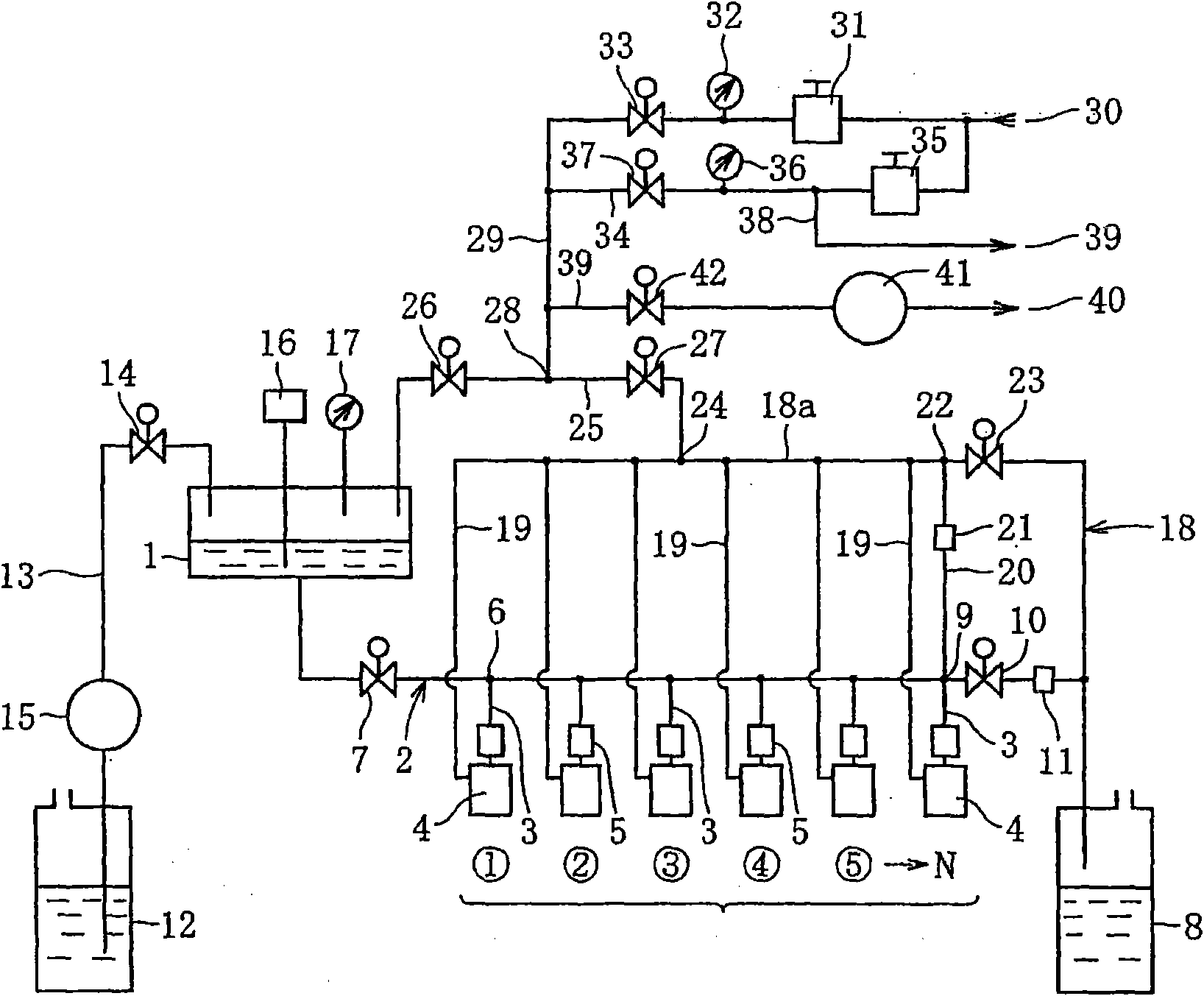

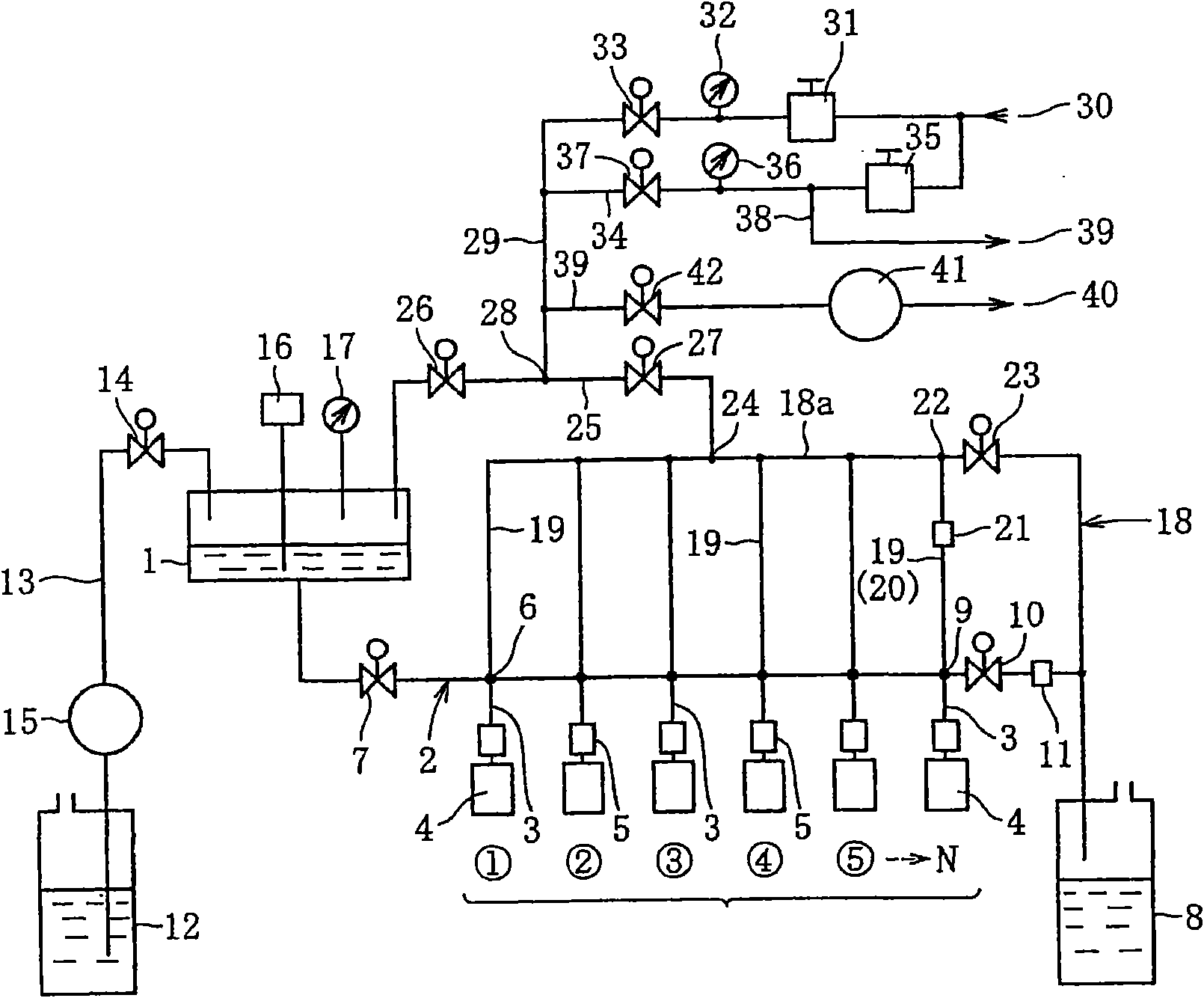

[0124] figure 2 The ink jet head liquid feeding device according to the second embodiment of the present invention is exemplified. like figure 2 As shown, the difference between the inkjet head liquid feeding device of the second embodiment and the inkjet head liquid feeding device of the above-mentioned first embodiment has two points: one is the bypass pipe from the common air diffusing pipe 18 Each lower end of each independent air-diffusing pipeline 19 extending downward from 18a is communicated with each connection part of the public liquid-feeding pipeline 2 and each independent liquid-feeding pipeline 3; the second is that the independent air-diffusing pipeline 19 at the most downstream end is also used as a liquid-feeding and air-diffusing pipe. Road 20. The other components are the same as those of the inkjet head liquid feeding device of the first embodiment described above, and therefore the same reference numerals are used for the common components in both of t...

no. 3 approach

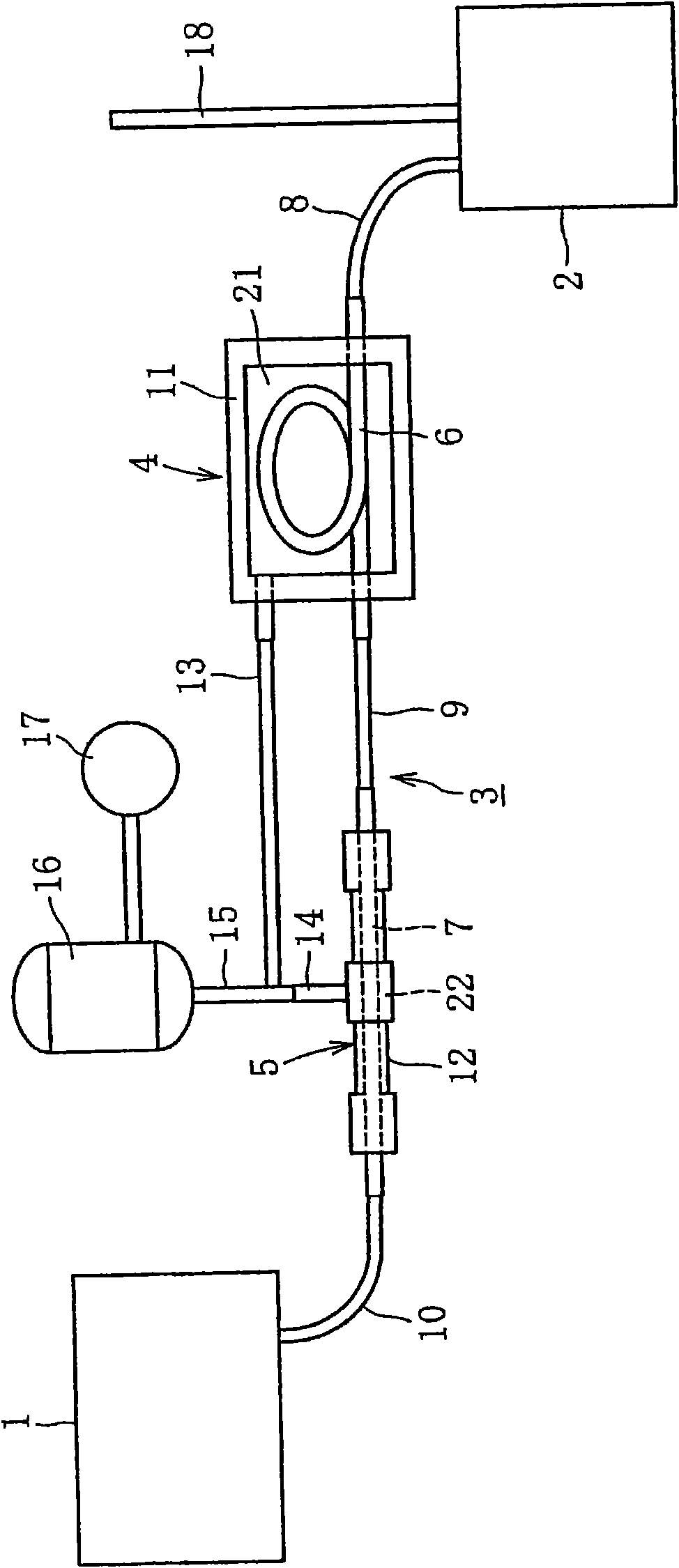

[0128] Figure 3 to Figure 5 The ink jet head liquid feeding device according to the third embodiment of the present invention is exemplified. like image 3 As shown, the inkjet head liquid feeding device of the third embodiment has a liquid feeding path 3 for feeding the liquid material from the ink reservoir 1 storing the liquid material to the inkjet head 2 (internal liquid reservoir), The first degassing unit 4 and the second degassing unit 5 are provided at two places in the middle of the liquid feeding path 3 . The liquid supply path 3 is composed of two degassing pipes (hereinafter referred to as first and second degassing pipes 6 and 7) made of synthetic resin having air permeability and having a single internal flow path, and two degassing pipes having no air permeability and having a single internal flow path. It is formed by connecting three liquid feeding pipes (hereinafter referred to as the first to third liquid feeding pipes 8, 9 and 10) made of metal or the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Vertical size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com