Power unit

A technology of power unit and engine, applied in the direction of motor vehicles, transmissions, electric scooters, etc., can solve the problems of buffering and operation stability, large moving range, etc., to improve driving performance, ensure maintenance, and suppress vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

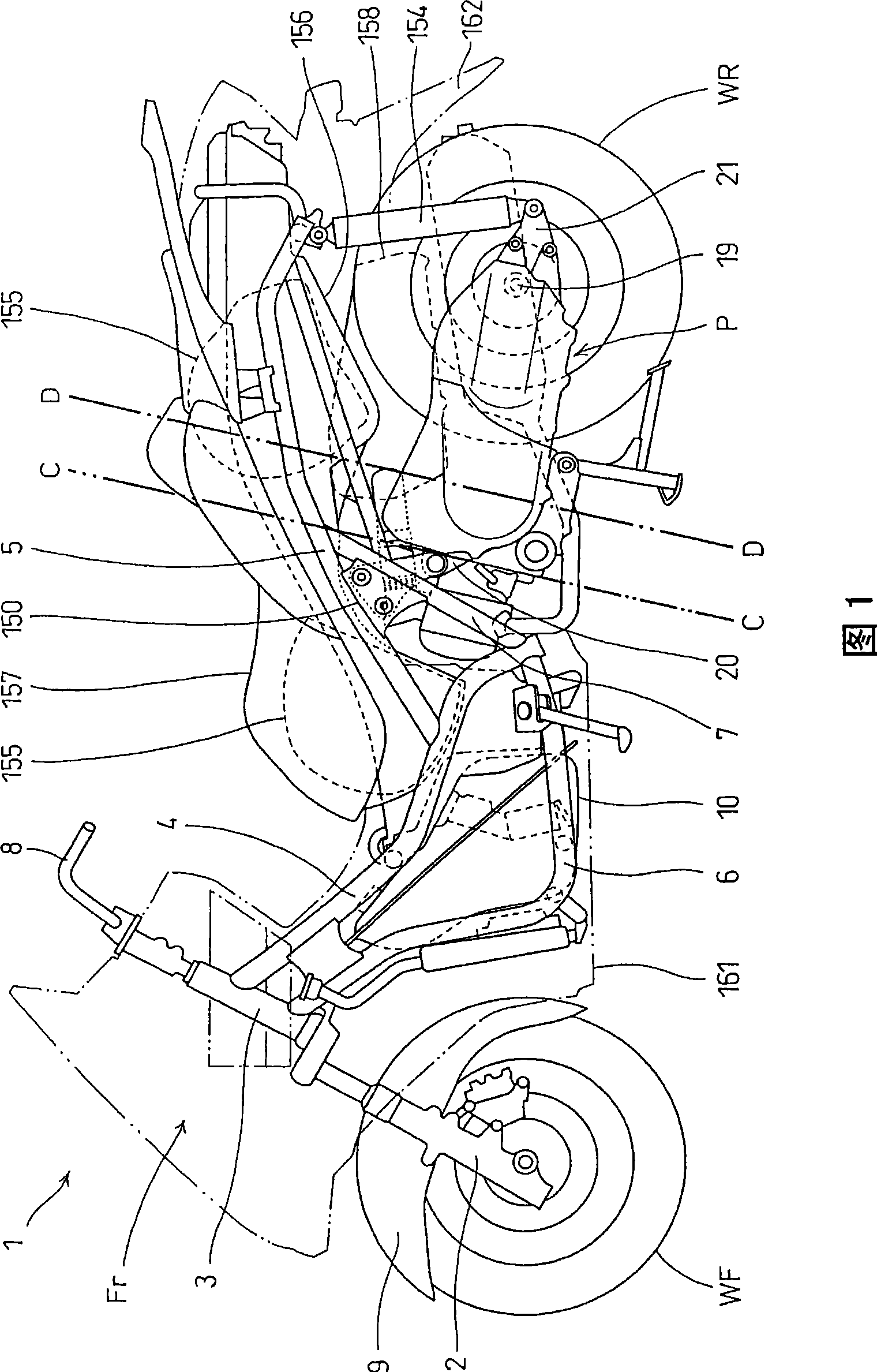

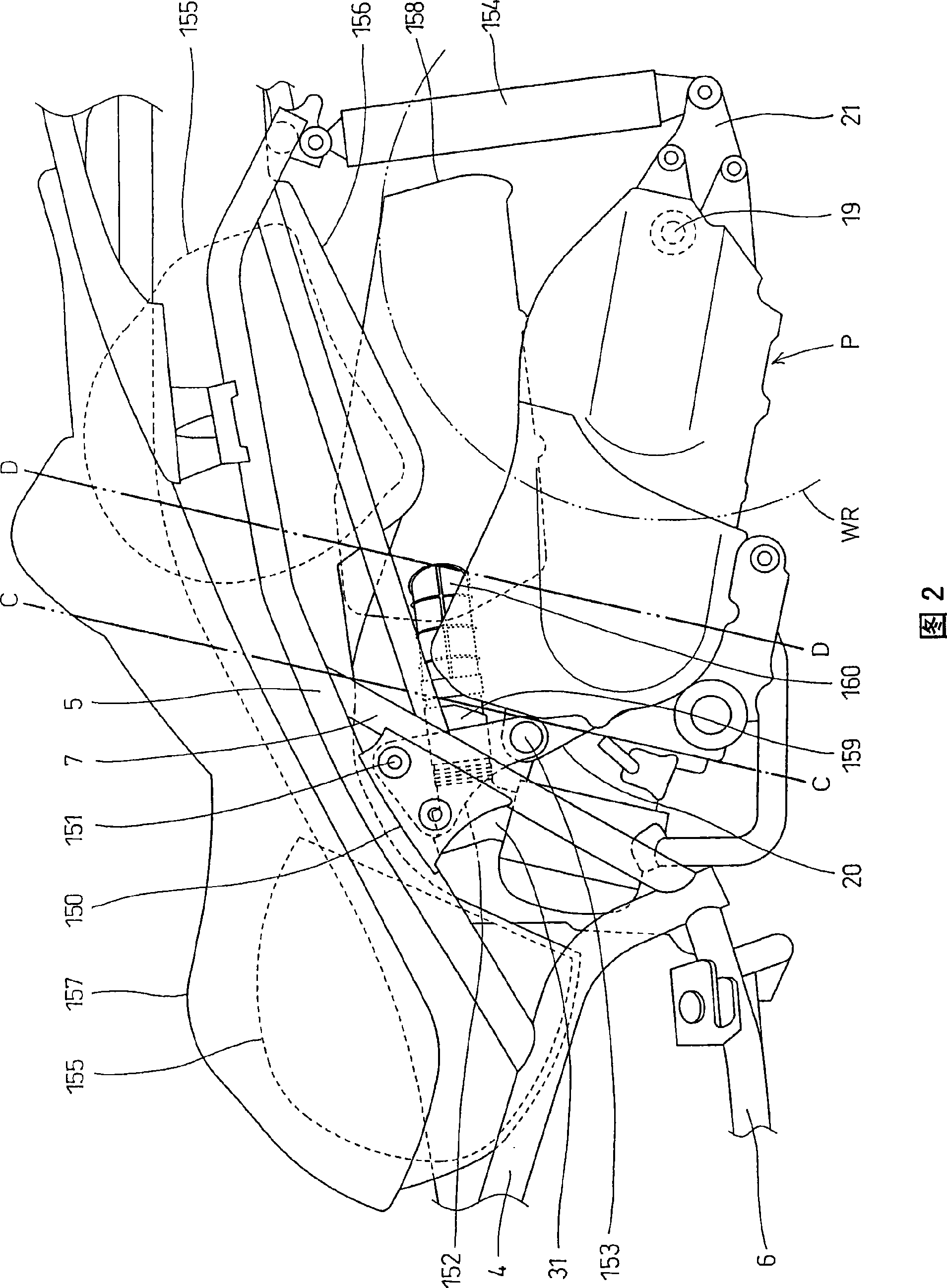

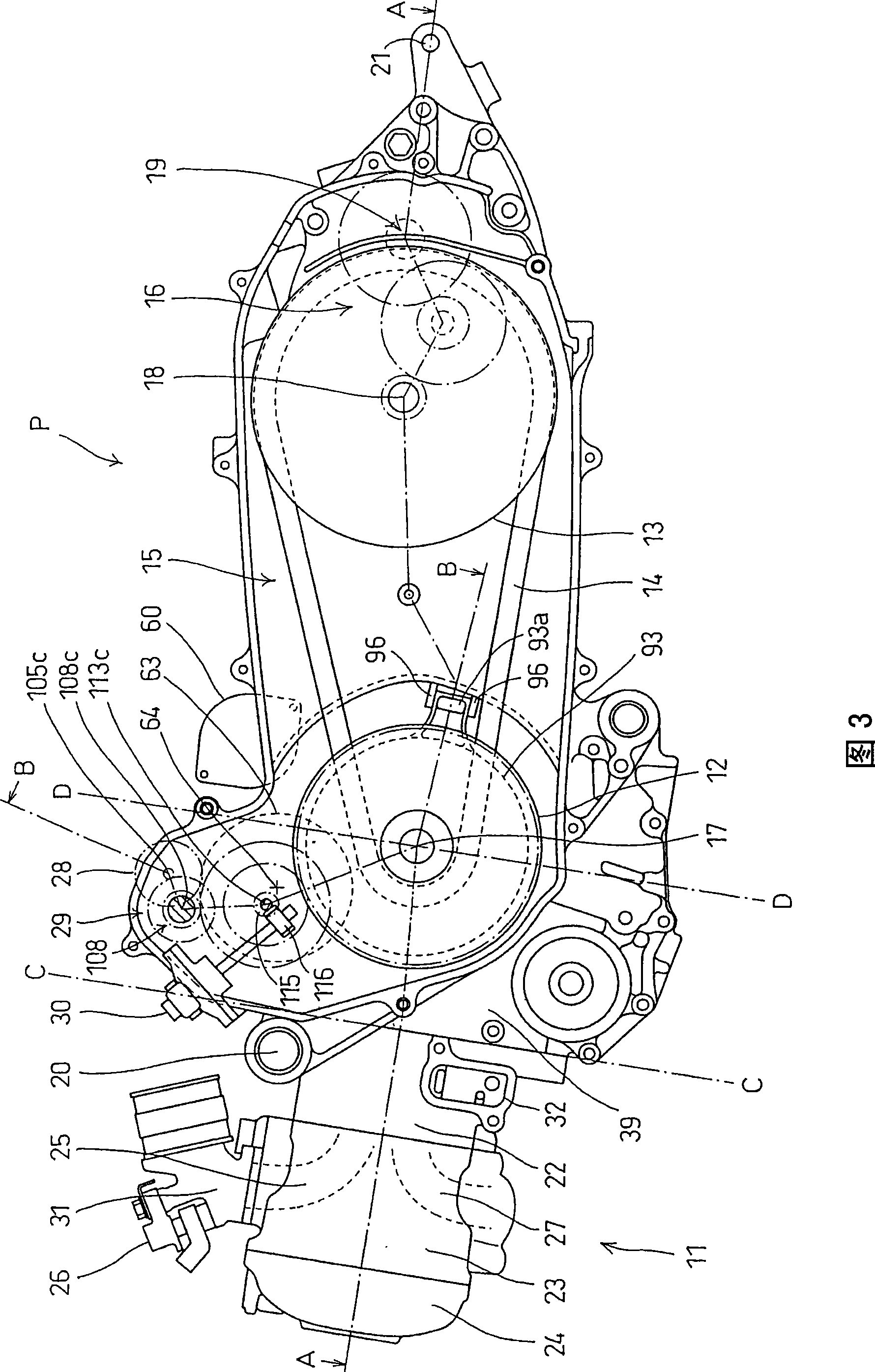

[0057] FIG. 1 is a side view of a motorcycle 1 equipped with a power unit P according to an embodiment of the present invention, and FIG. 2 is an enlarged rear view of the motorcycle 1 . In FIG. 1 , the frame Fr of the motorcycle 1 includes: a head tube 3 that rotatably supports a front fork 2 ; a main frame 4 extending rearward and downward from the head tube 3 ; A pair of left and right rear frames 5 connected in parts and extending rearward and upward; a lower frame 6 extending downward from the head pipe 3 and bent backward and connected to the lower end of the main frame 4; The middle frame 7 of the middle part. The front wheel WF is pivotally supported on the lower end of the front fork 2 , the steering handle 8 is connected to the top of the front fork 2 , and the front fender 9 covering the top of the front wheel is supported by the front fork 2 . A fuel tank 10 is provided between the main frame 4 and the lower frame 6 .

[0058] Referring to FIG. 2 together, pivot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com