Efficient automatic de-icing system

A de-icing and automatic technology, which is applied in ice making, ice making, ice storage/distribution, etc., can solve the problems of exhaust waste heat evaporator cooling waste, affecting unit efficiency, unstable system operation, etc., to avoid refrigerant The state is unstable, the system is stable, and the cooling effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

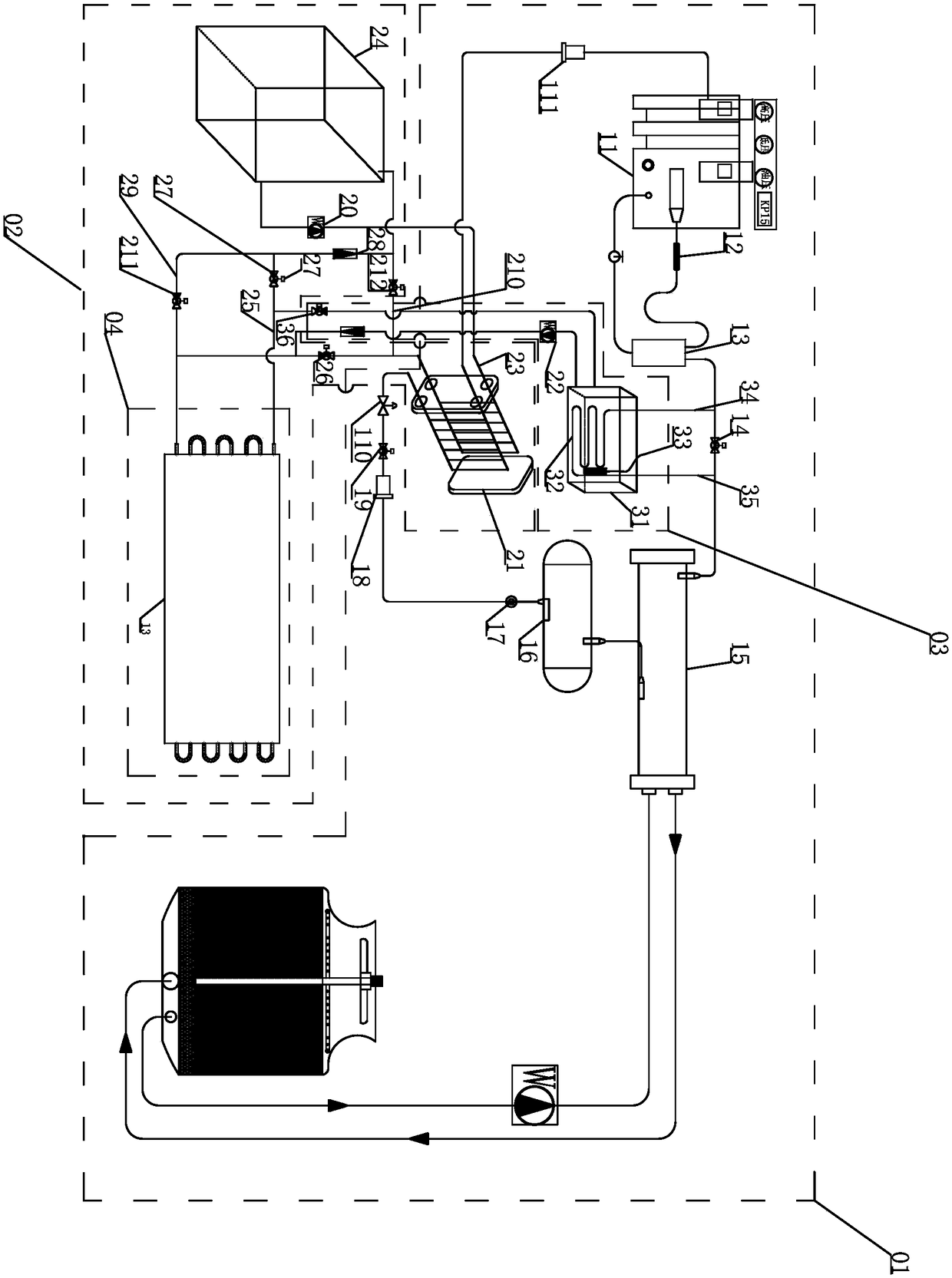

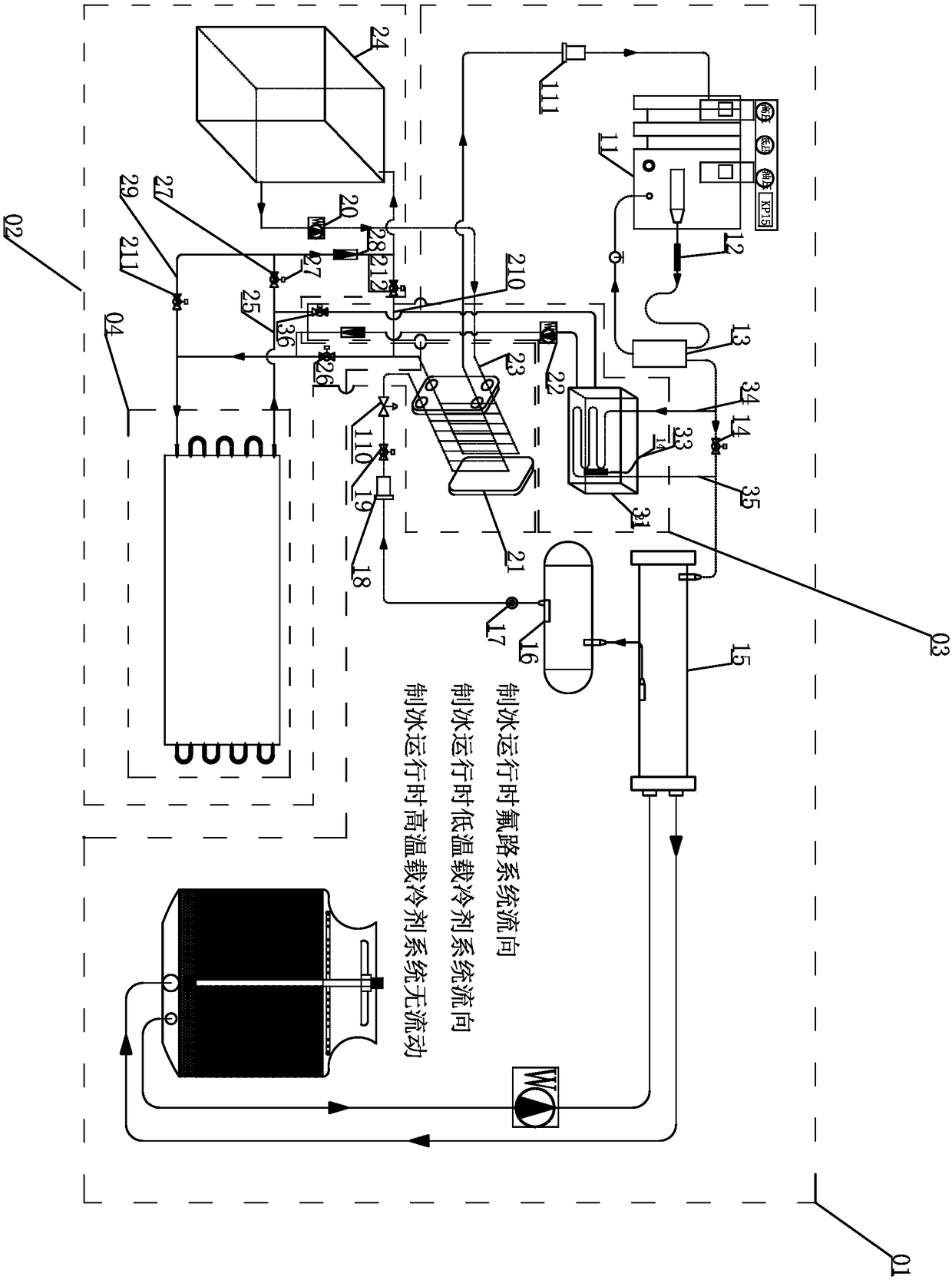

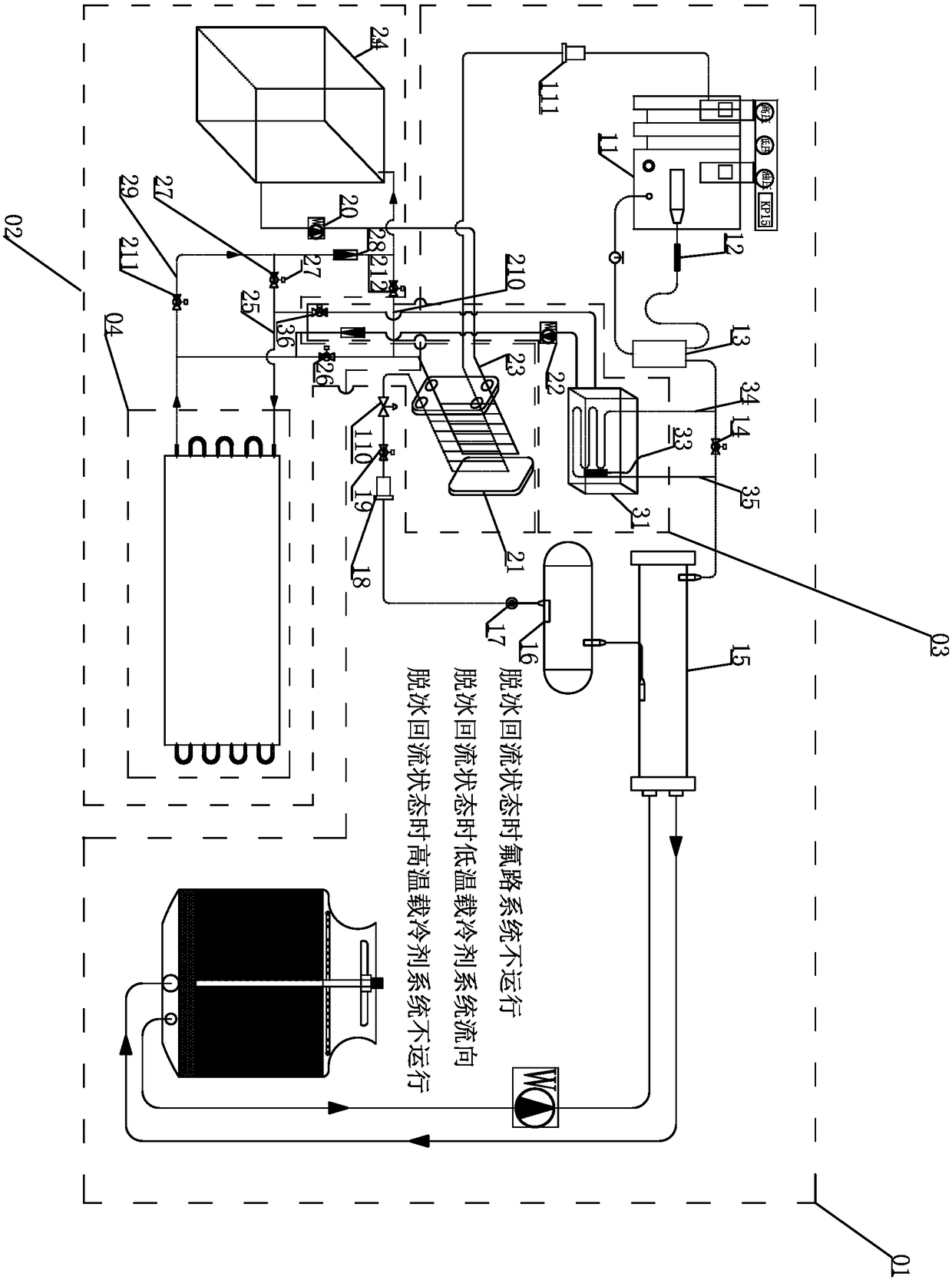

[0027] Below in conjunction with accompanying drawing, invention is described in further detail.

[0028] Such as Figure 1-7 As shown, a high-efficiency automatic deicing system includes an ice-making mechanism 01, a low-temperature brine mechanism 02 and a high-temperature brine mechanism 03 that perform heat exchange with the ice-making mechanism 01, and a low-temperature brine mechanism 02 and a high-temperature brine mechanism. The high-temperature brine mechanism 03 communicates with the ice-making and de-icing mechanism 04. The ice-making mechanism 01 can provide cooling capacity and heat to the low-temperature brine mechanism 02 and the high-temperature brine mechanism 03 for ice-making or de-icing, and the cold brine mechanism 02 and the high-temperature brine mechanism 03 generate cold The amount and heat are supplied to the ice-making and de-icing mechanism 04 to make ice or de-ice through the brine. The ice-making mechanism 01 includes a compressor 11, a shock ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com