Gasification process system for fine particle biomass or solid fossil fuel

A technology of fossil fuels and process systems, which is applied in granular/powder fuel gasification, gasification process, petroleum industry, etc., can solve the problems of incomplete combustion, high carbon content in fly ash, low calorific value, etc. Dust accumulation and corrosion, prolong residence time, and ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

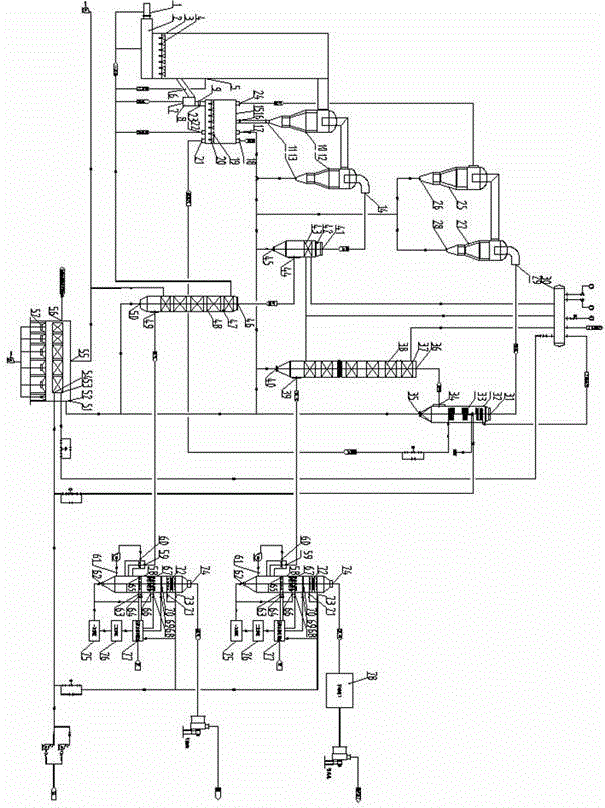

[0024] Such as figure 1 As shown, a circulating fluidized bed combustion system for the gasification process system of fine particle biomass or solid fossil fuels, including a circulating fluidized bed combustion system, a fluidized bed gasification reactor system for fine particle biomass or solid fossil fuels , waste heat utilization system, ash treatment system and gasification process gas purification system.

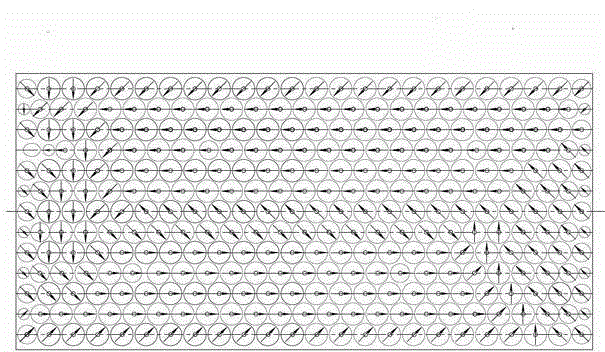

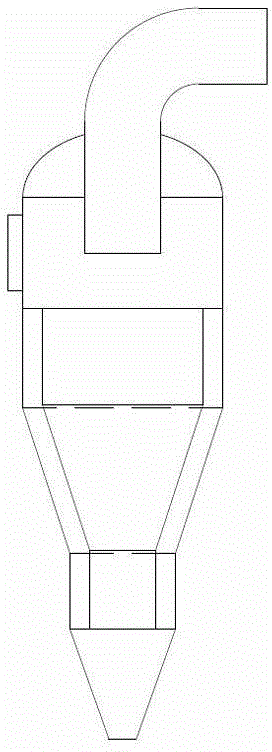

[0025] combine figure 1 , figure 2 and image 3 Illustrate that the circulating fluidized bed combustion system of the embodiment includes: a burner (1), a primary air chamber (2), a water-cooled horizontal air distribution plate I (3), a flat-plate directional air cap I (4), a secondary air nozzle ( 5), the return pipe (6), the return device (7), the loose wind chamber (8) located at the lower part of the return device (7), the return inlet of the return device (7) located at the top of the return device (7) 9), the first-stage cyclone separator (10) on the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com