Livestock and poultry house fresh air preheating system suitable for cold region

A technology for fresh air preheating and cold areas, applied in the field of livestock breeding buildings, can solve the problems of frosting of preheating pipes, easy rupture of pipes, etc., and achieve the effect of reducing ventilation consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

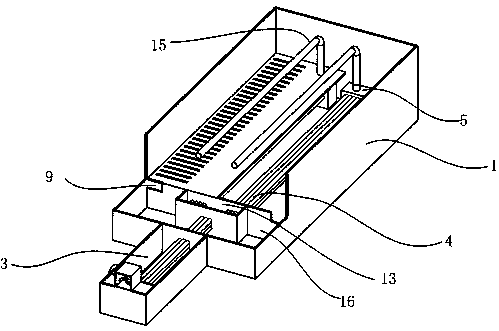

[0050] see Figure 1-Figure 4 In the fresh air preheating system shown, the livestock and poultry house includes a livestock and poultry house body 1 and a suspended ceiling 2 for the livestock and poultry house. Preheating module 3, secondary preheating module 4 and tertiary preheating module 5;

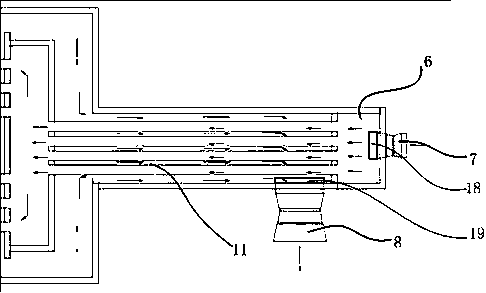

[0051] The primary preheating module 3 includes an external heat exchange chamber 6, and an air intake device and an exhaust device are arranged in the external heat exchange chamber 6;

[0052] Described air intake device comprises air intake blower 7, and described air intake blower 7 is connected with the first fresh air collecting chamber 13 by heat exchange pipeline 11, and described exhaust device comprises exhaust fan 8, and described exhaust device passes through house interior The exhaust gas outlet 9 communicates with the secondary preheating module 4;

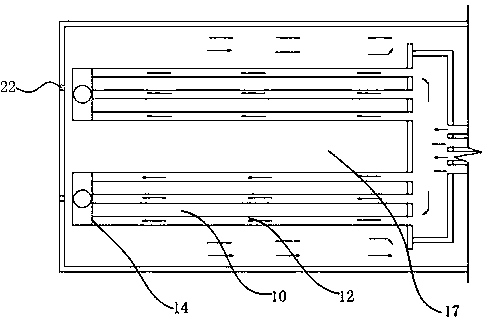

[0053] The secondary preheating module 4 includes a septic tank 10 in the house, and a preheating ventilation channel ...

Embodiment 2

[0067] Such as Figure 2-4 As shown, during the air intake process, the outdoor air is filtered by the air intake fan and introduced into the heat exchange pipe through the air intake filter in the first step. Because the heat exchange pipe is surrounded by the exhaust gas discharged from the house, during the air intake process, the temperature of the cold air outside the house is relatively low. High exhaust heat exchange, the temperature rises and collects in the first fresh air collection chamber to complete the first-level preheating.

[0068] The fresh air in the first fresh air collection chamber enters the septic tank preheating air channel under the action of negative pressure, and enters the second fresh air collection chamber after being heated by the heat in the septic tank to complete the secondary preheating.

[0069] The fresh air preheated by the septic tank enters the top of the pig house through the air inlet pipe. Because the hot air in the pig house gathers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com