Patents

Literature

73results about How to "Efficiency impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

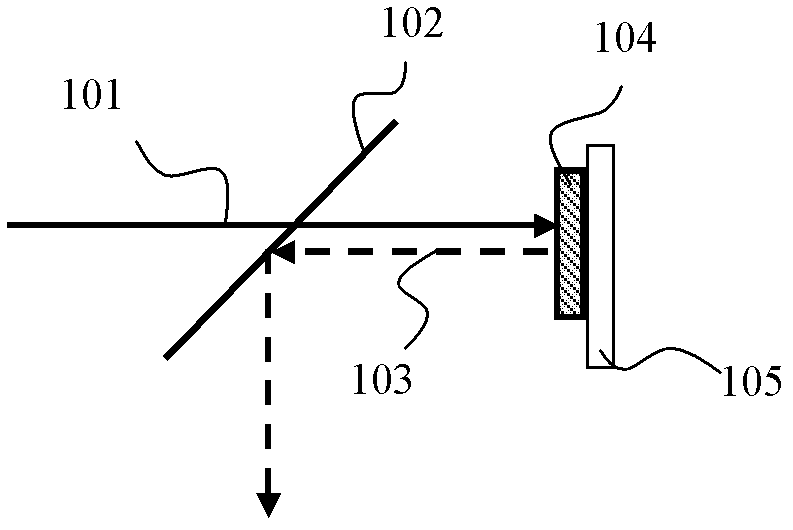

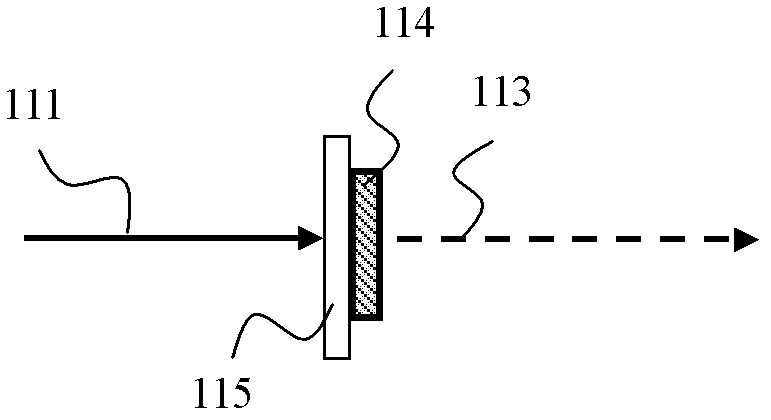

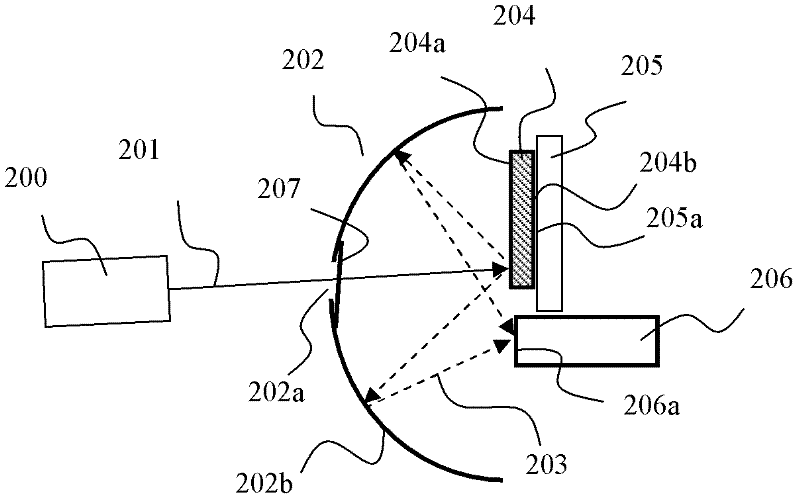

Light emitting device, projection device and lighting device

ActiveCN102563410AEfficiency impactEfficient collectionPoint-like light sourceProjectorsLight guideEffect light

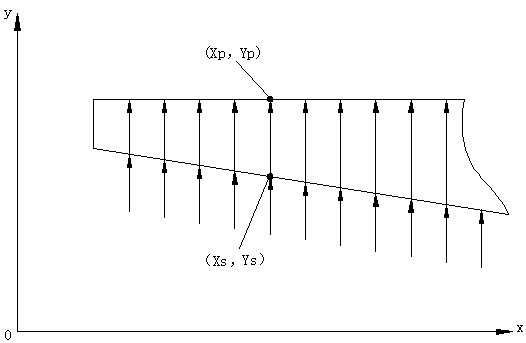

The invention provides a light emitting device, a projection device and a lighting device. The light emitting device comprises a wavelength conversion material layer and a light guiding device, wherein the wavelength conversion material layer with a first surface and a second surface comprises a wavelength conversion material and a scattering material, and the light guiding device is positioned on one side of the first surface of the wavelength conversion material layer and used for guiding exciting light into the first surface of the wavelength conversion material layer, and guiding stimulated light and residual exciting light to enter a light emitting channel, wherein the stimulated light is emitted by the first surface of the wavelength conversion material layer, and the residual exciting light is absorbed by the wavelength conversion material layer. By the aid of the light emitting device, the light guiding device positioned on one side of the first surface of the wavelength conversion material layer is effectively positioned can be used for effectively collecting the exciting light reflected by the wavelength conversion material layer, so that the efficiency of the light emitting device cannot be affected by the scattering material added by the scattering material, and the contradiction between color uniformity and light emitting efficiency is solved.

Owner:APPOTRONICS CORP LTD

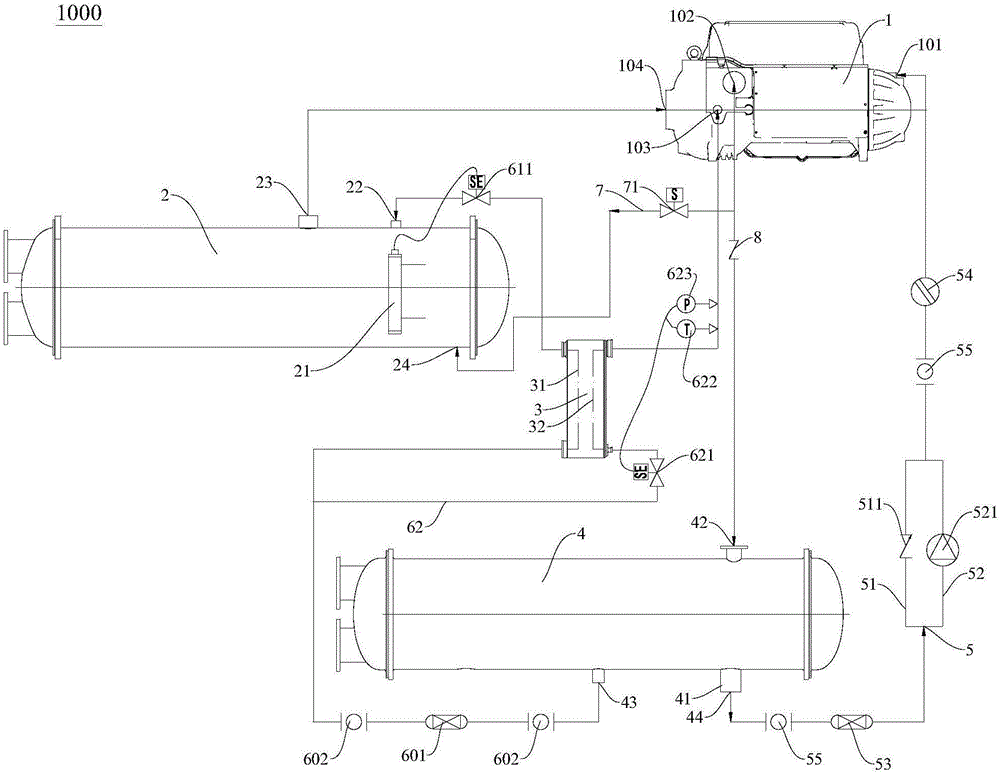

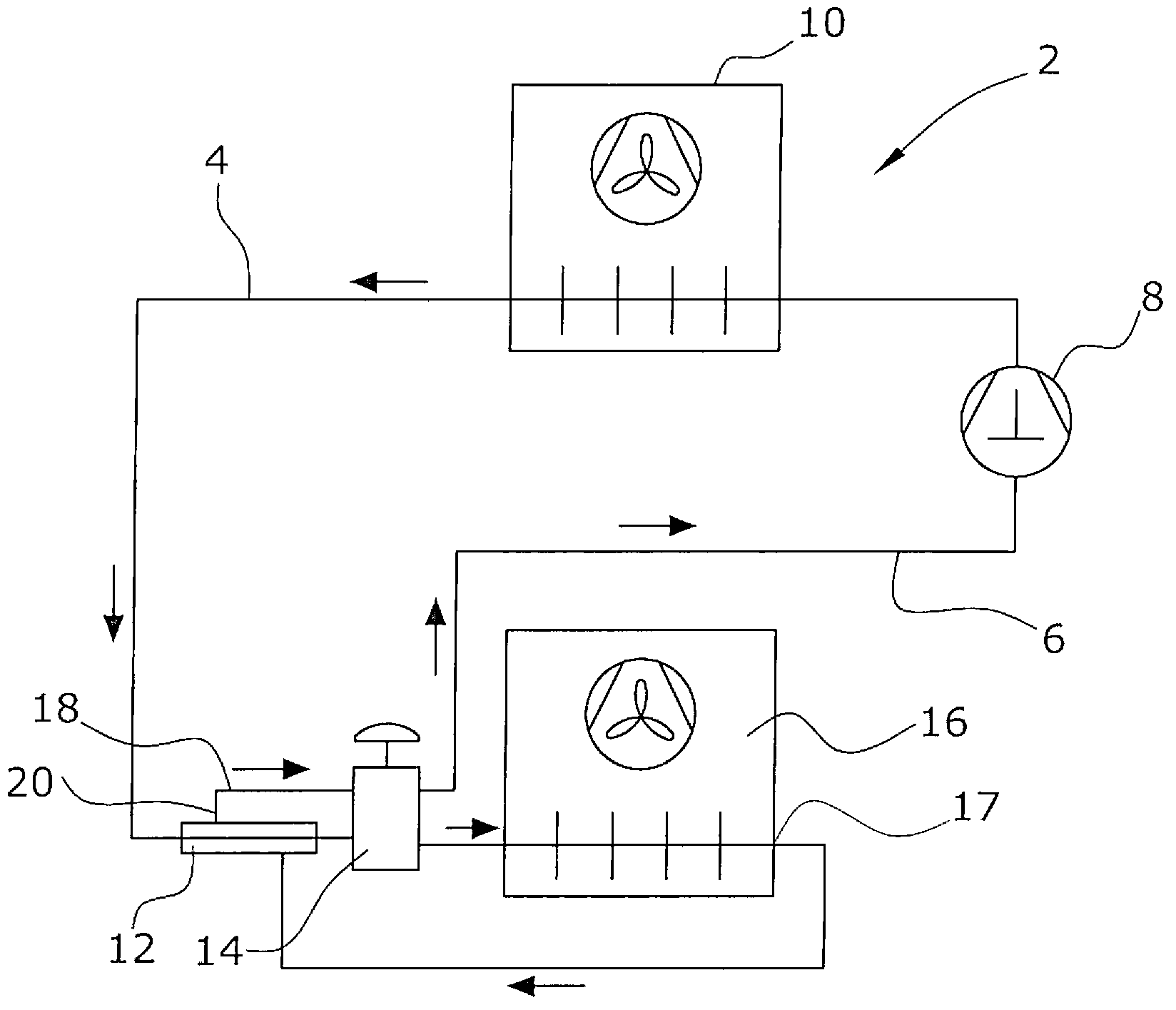

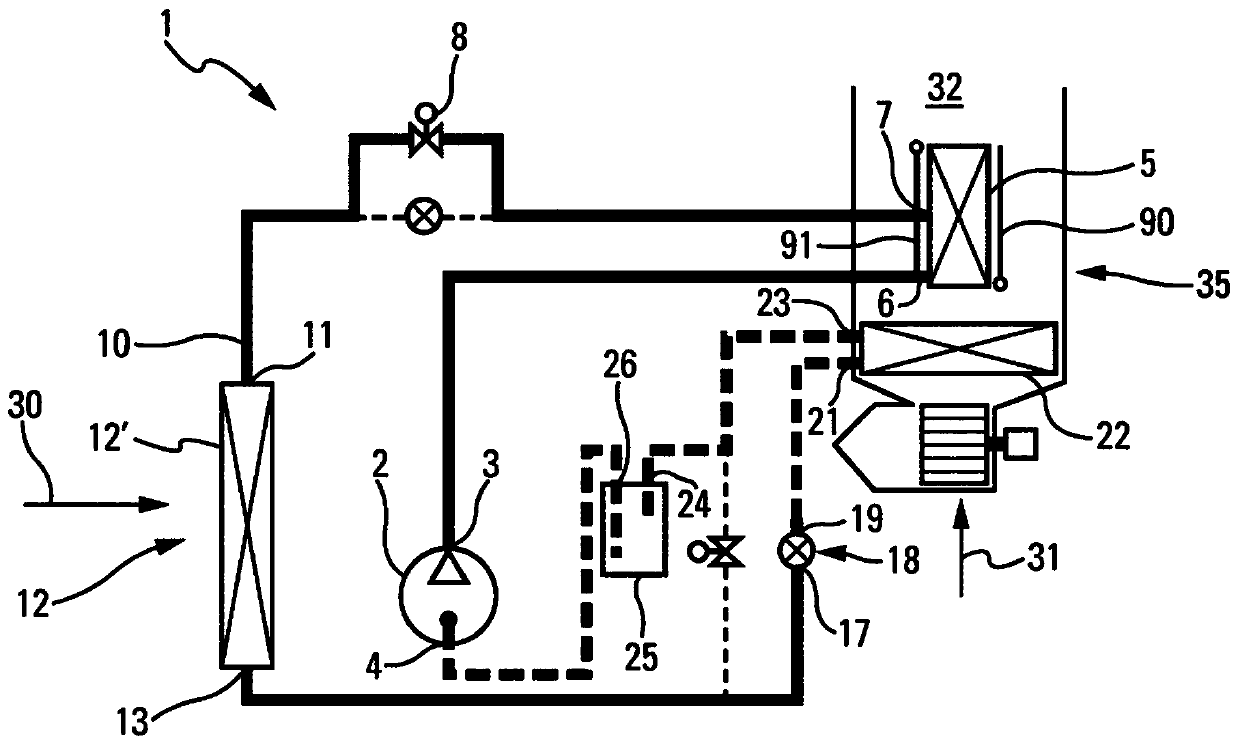

Oilless water chilling unit and air conditioning system

InactiveCN106642778ASimple structureImprove energy efficiencyCompressorCompression machines with non-reversible cycleRefluxLiquid state

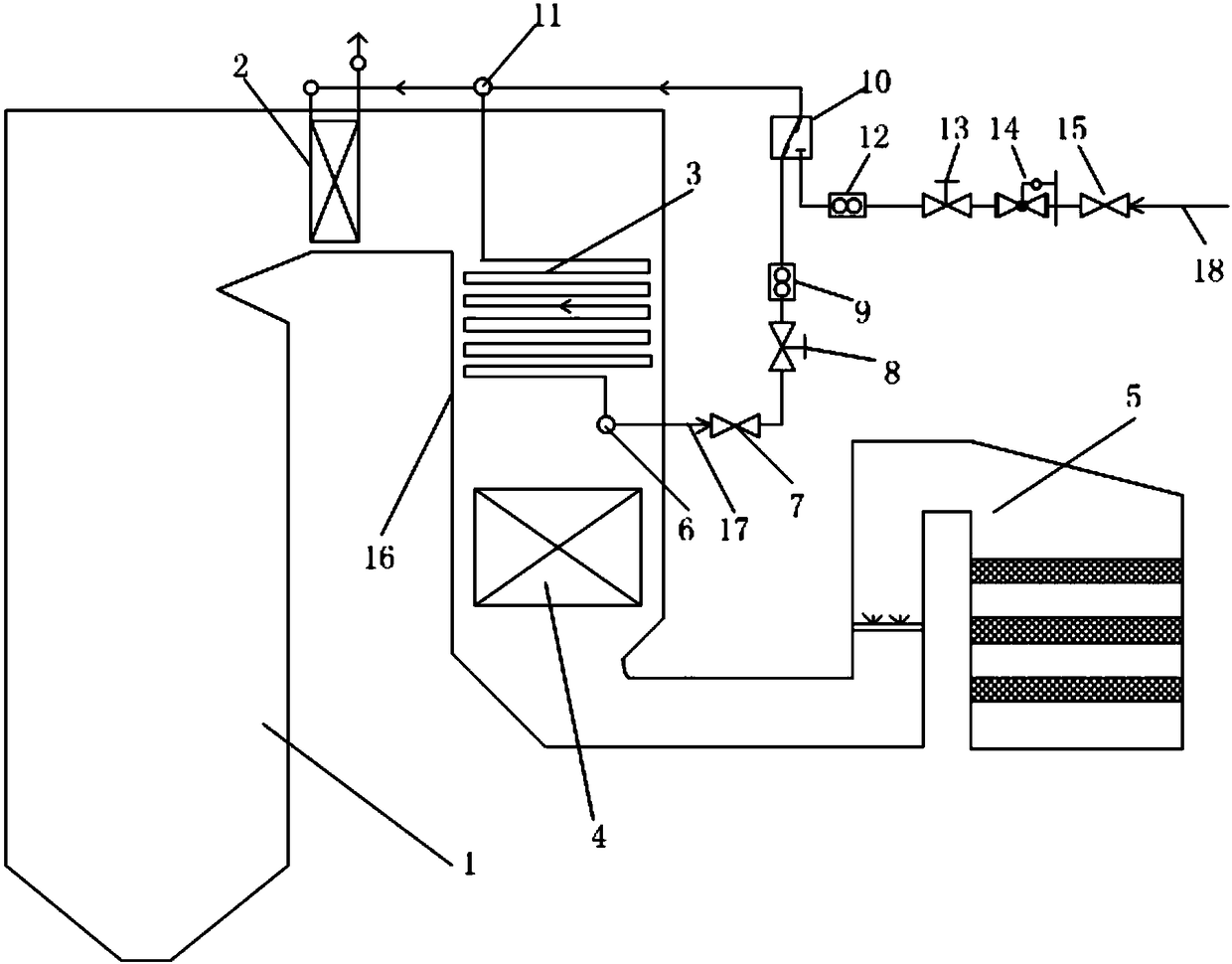

The invention discloses an oilless water chilling unit and an air conditioning system. The oilless water chilling unit comprises a compressor, a condenser, an evaporator, a first throttling element and double refrigerant reflux pipelines, wherein the compressor is provided with a refrigerant inlet; the condenser is provided with a liquid outlet; the double refrigerant reflux pipelines are in series connected between the liquid outlet and the refrigerant inlet; the double refrigerant reflux pipelines comprise a first cooling branch and a second cooling branch which are connected in parallel; a first one-way valve is in series connected on the first cooling branch; and a drive device is in series connected on the second cooling branch. According to the oilless water chilling unit disclosed by the invention, refrigerant cooling is adopted inside the compressor, and liquid-state refrigerant separated out from the condenser flows back into the compressor through the double refrigerant reflux pipelines, so that the structure is simple, and maintenance cost is low. Meanwhile, the system avoids influences, on efficiency of a heat exchanger, of lubricating oil, so that efficiency and life cycle of the heat exchanger are not attenuated, unit energy efficiency is high, and an operation range is wide.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

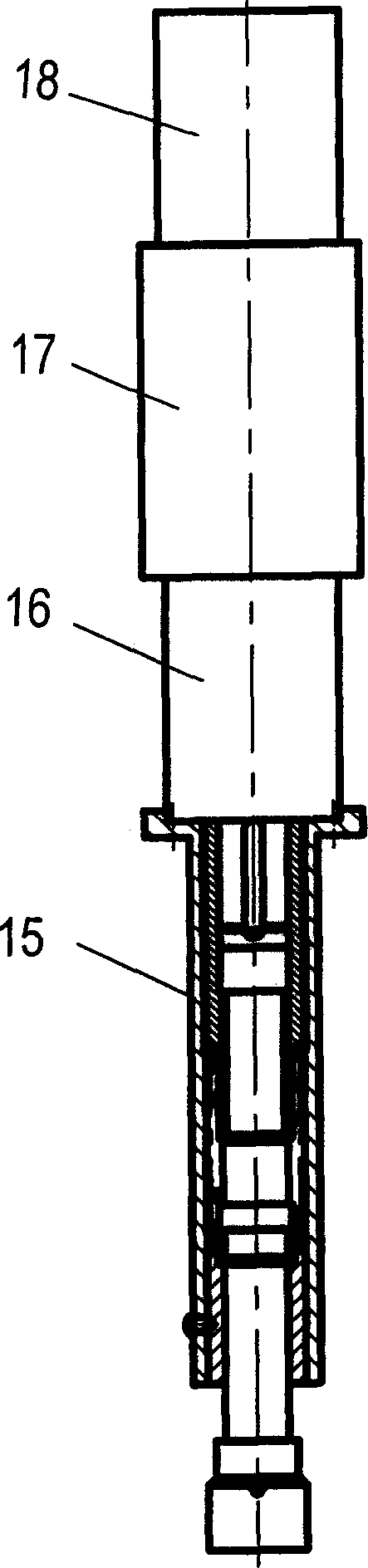

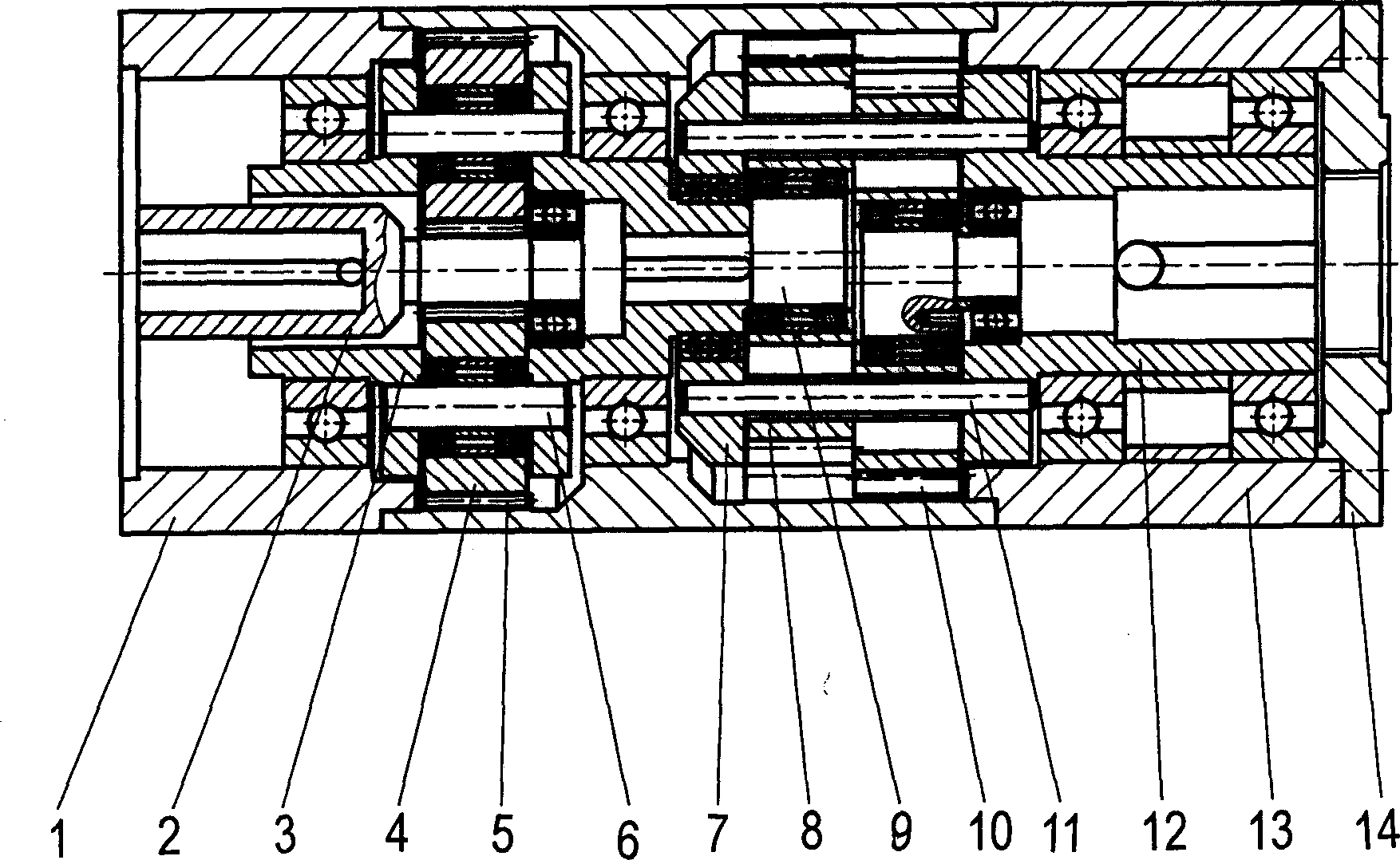

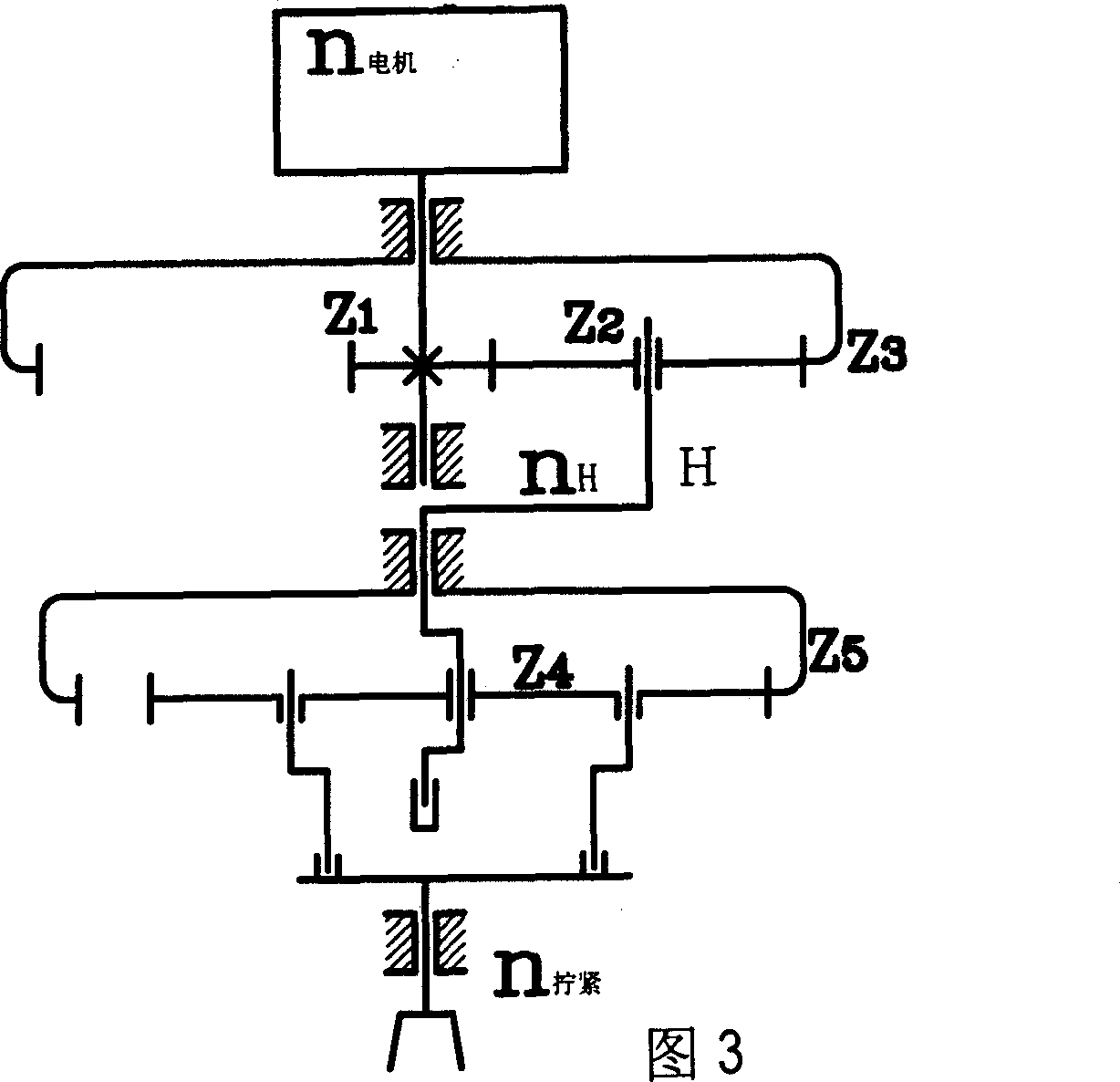

Screwing machine based on servo system

The invention relates to screw thread screw-up machine based on servo system. Its features are that the servo motor is used as the driving mechanism. Reducing mechanism and toque sensor are set between the driving and output mechanism. The reducing mechanism is adopted two grade reducing; the first grade is planet gear train; the second grade is low tooth difference driving. It is adopted dynamic toque sensor; one end of the strain axis of the sensor is directly connected to the output end of the reducing mechanism; the other end is directly connected to the spline housing used as the driving input in the output mechanism. The invention possesses high assembling efficiency and high assembling precision, especially suits to motor dom, can realize relatively precise control to the screwing up of the bolt.

Owner:HEFEI UNIV OF TECH

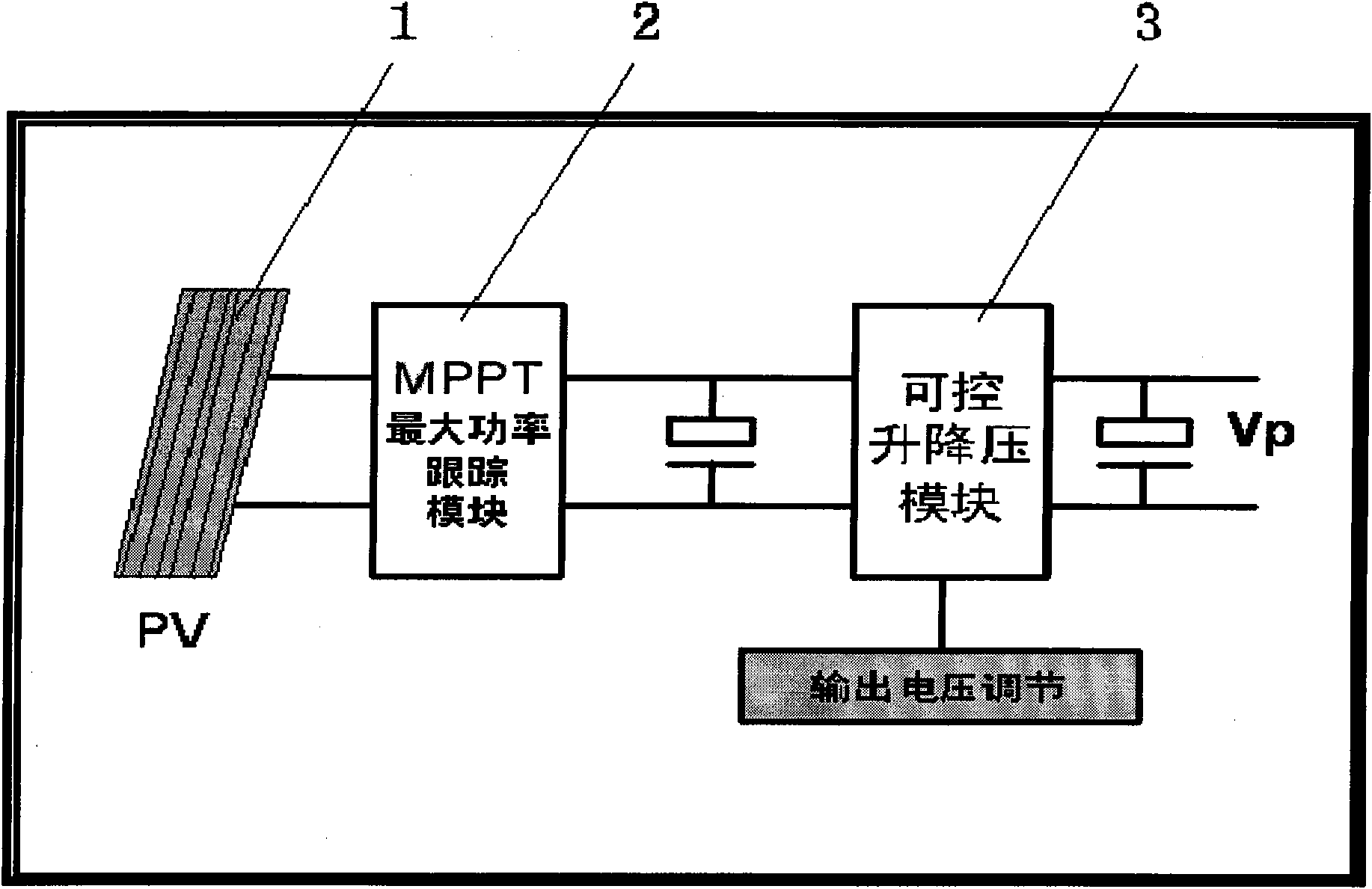

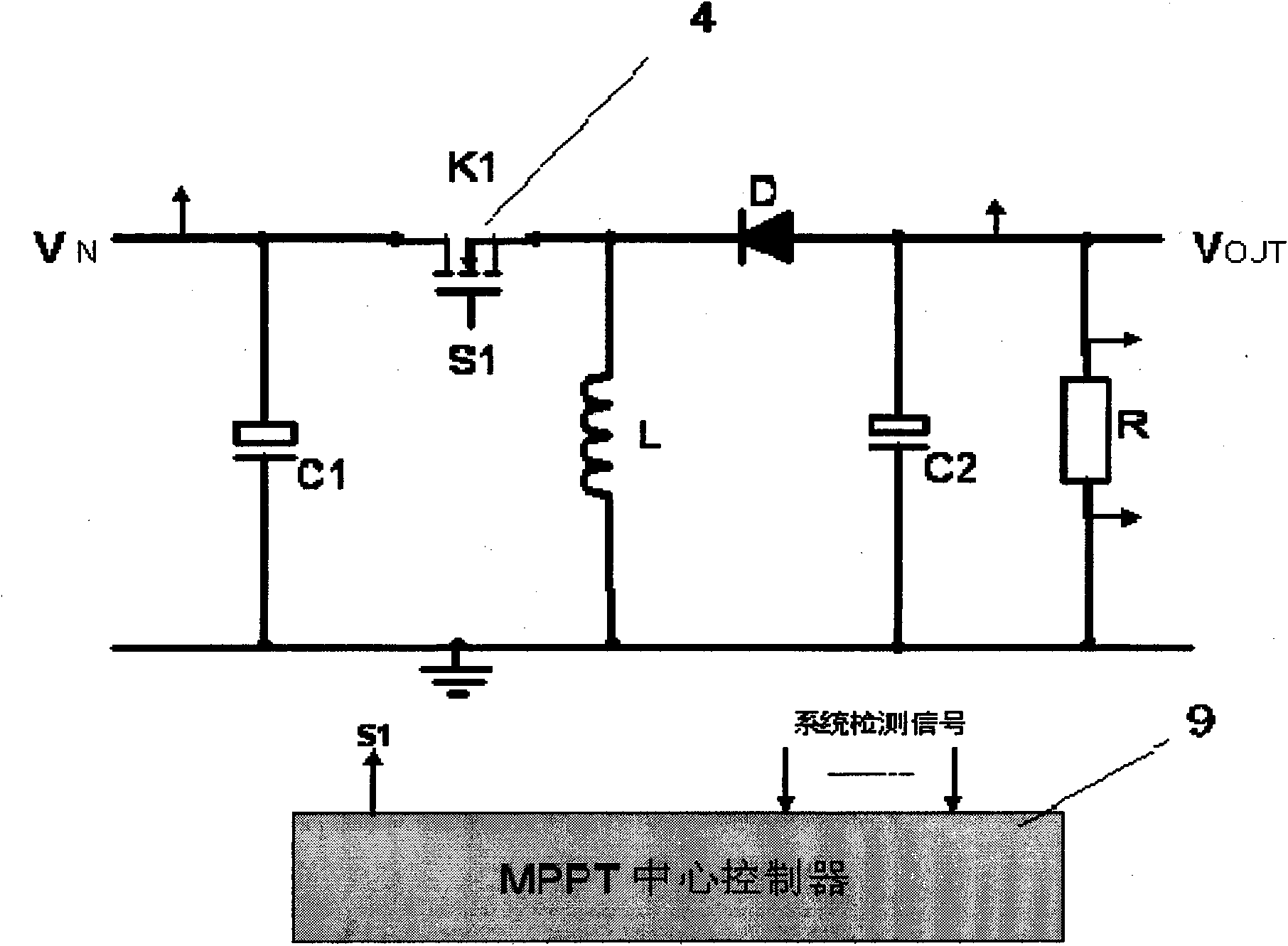

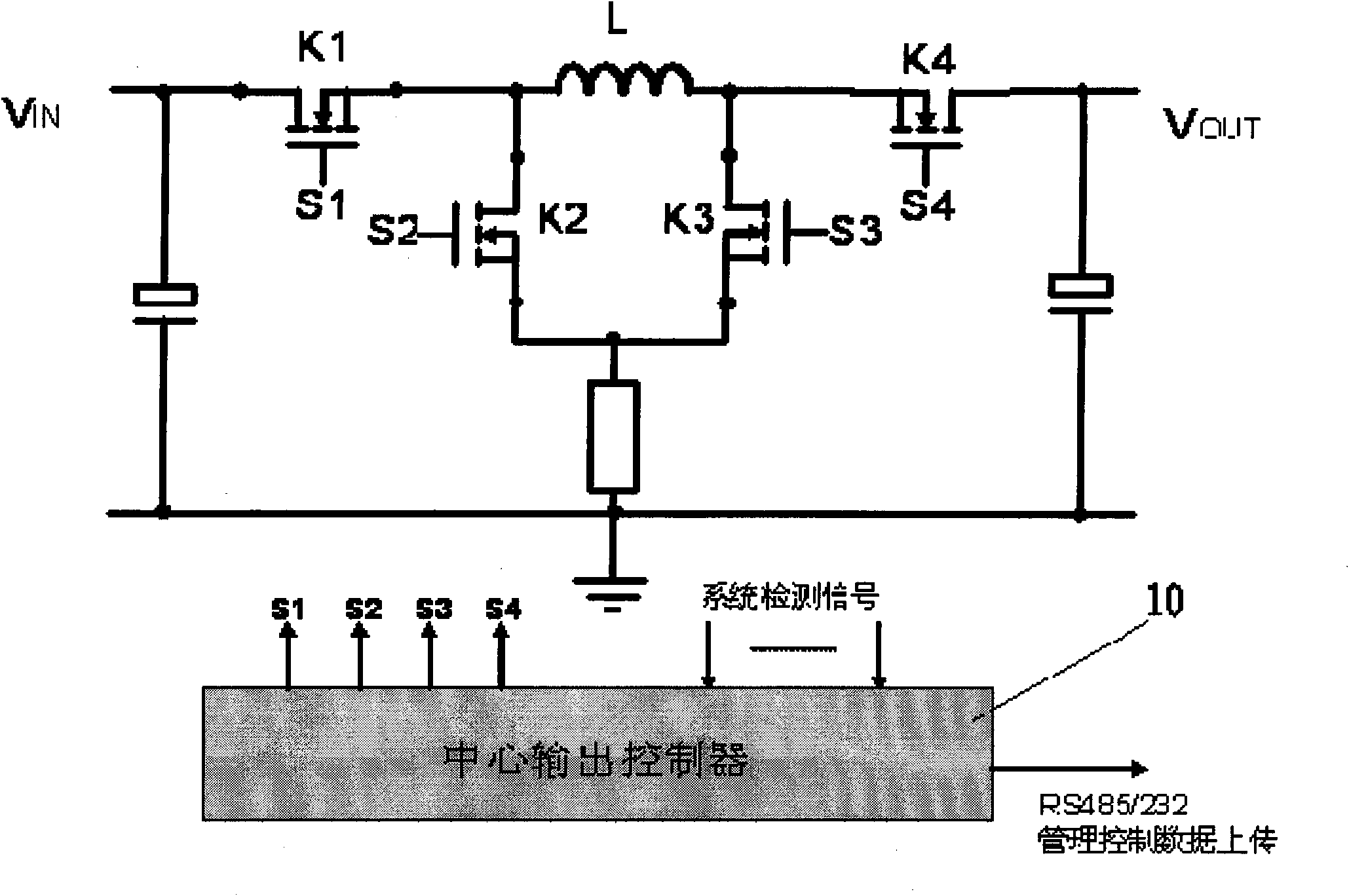

Photovoltaic component DC grid-connection controller

InactiveCN101938136AVoltage will not dropEfficiency impactSingle network parallel feeding arrangementsPhotovoltaic energy generationGrid-tie inverterComputer module

The invention relates to a photovoltaic component DC grid-connection controller. The invention is characterized in that the photovoltaic component DC grid-connection controller (5) is composed of an MPPT (Maximum Power Point Tracking) circuit module (2) and a controllable boost circuit module (3). The invention has the functions of keeping the photovoltaic component to be in the maximum power point tracking mode at any time and maintaining the output voltage at a stable preset value Vp. The invention enables the output of the photovoltaic component to be worked in the maximum available power state, and can be conveniently combined with other photovoltaic components to form a high-efficiency matrix. The invention effectively reduces the influence on the photovoltaic matrix from shielding, and simplifies the structure of a grid-connection inverter.

Owner:KUNMING PROMEE ENERGY TECH

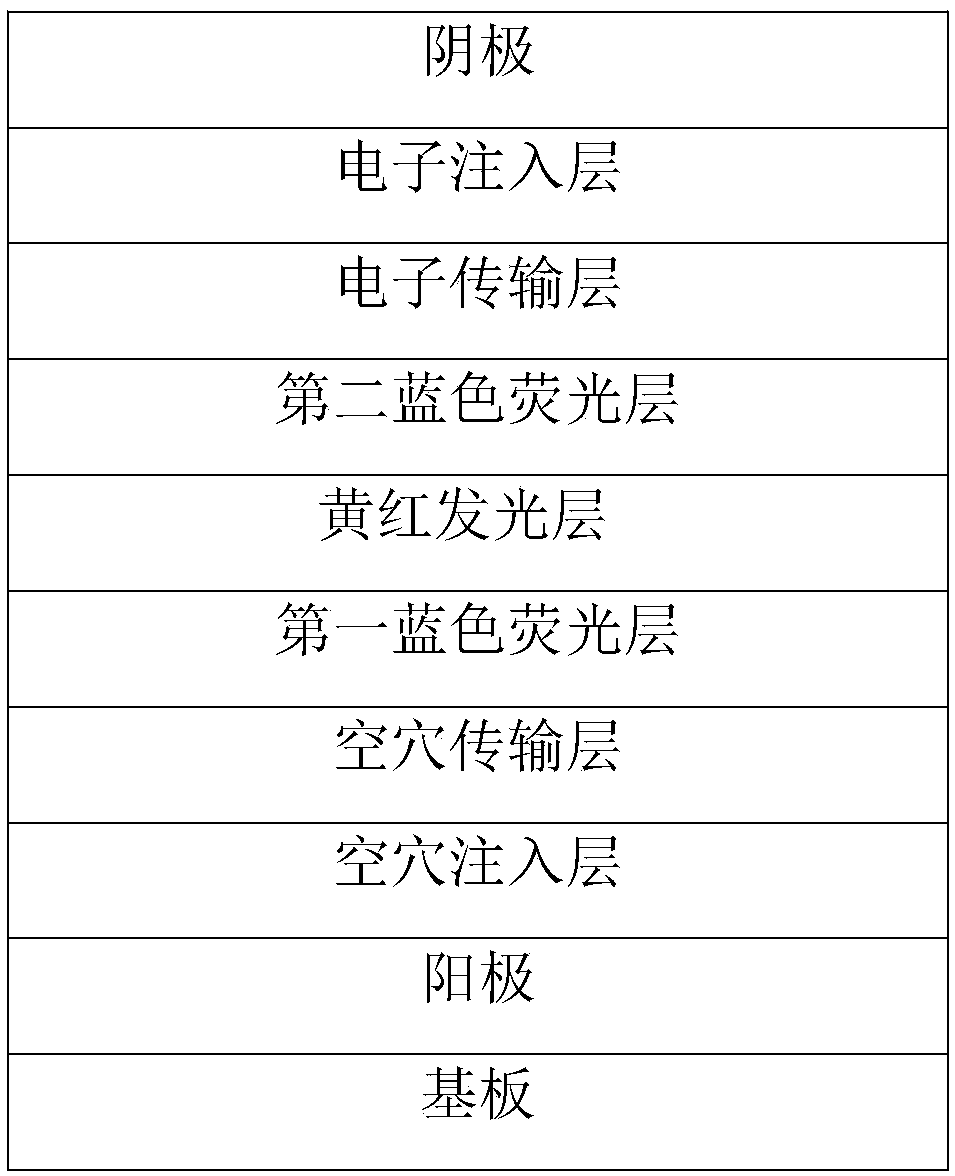

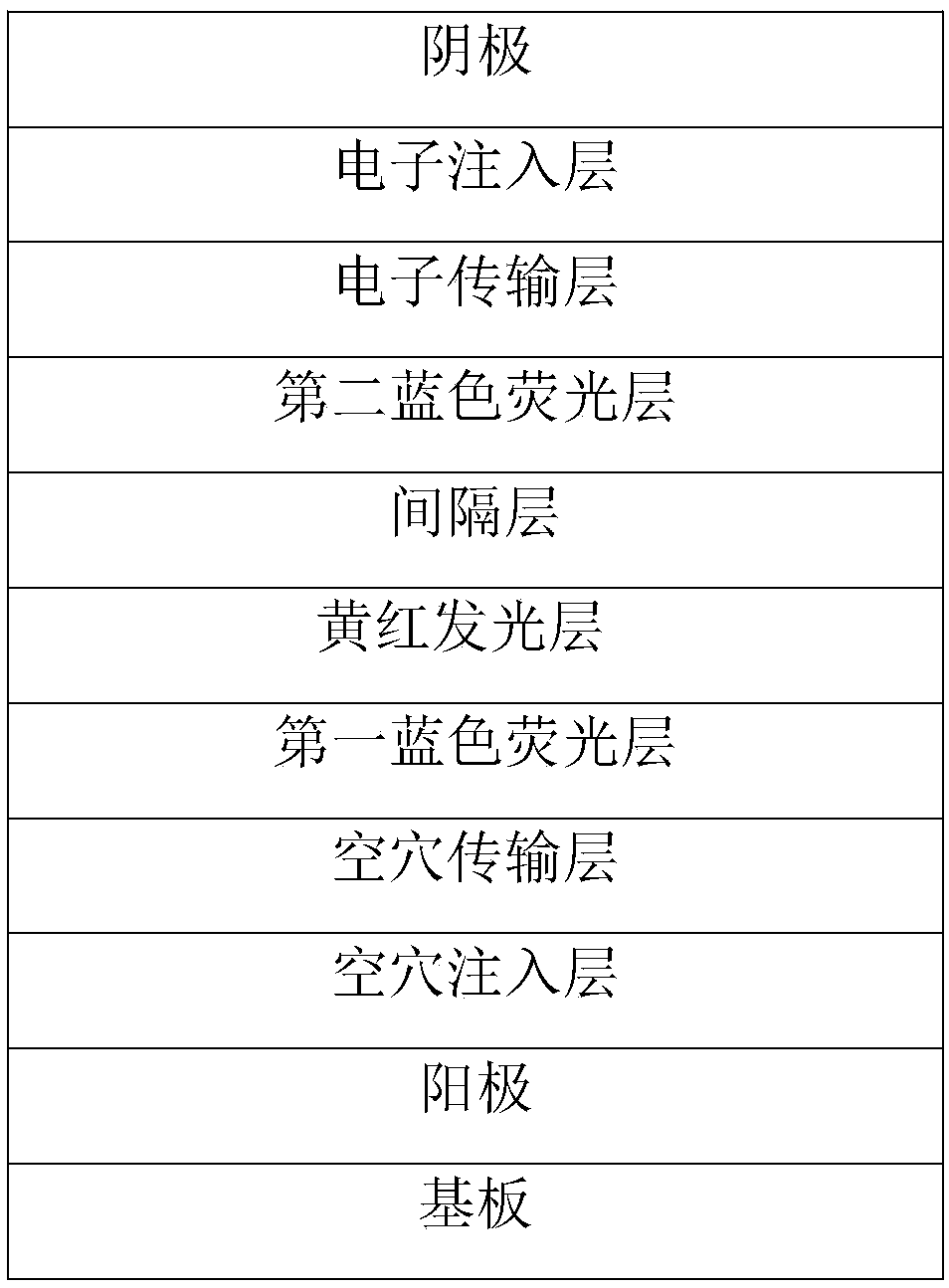

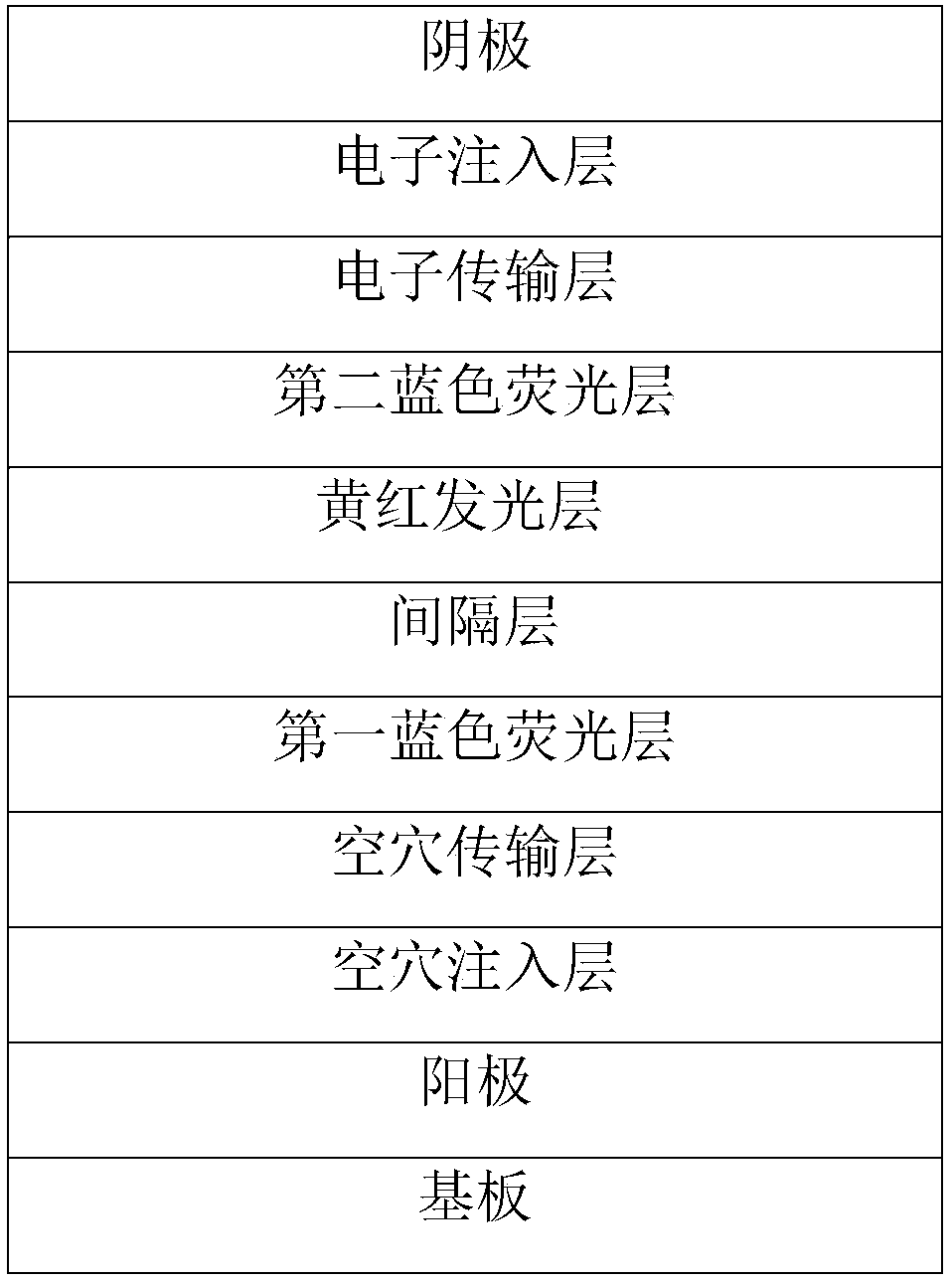

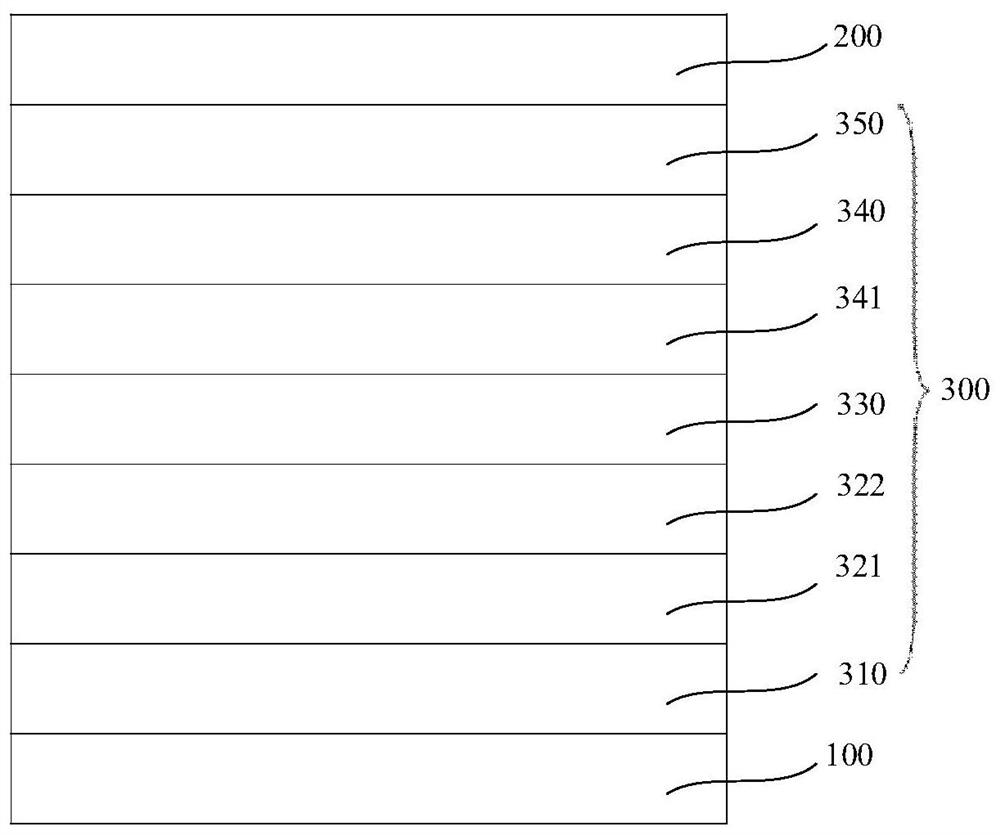

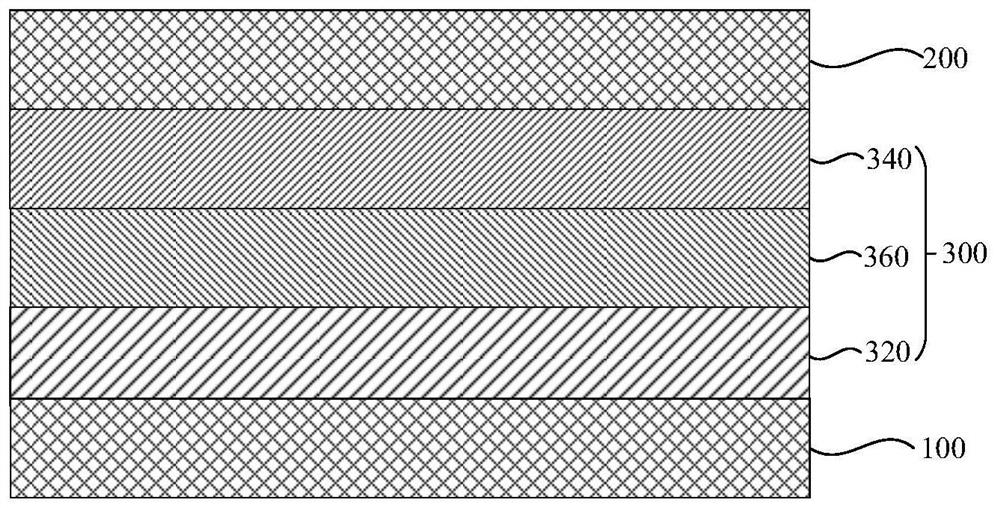

High-efficiency hybrid white OLED (Organic Light Emitting Diode) with high color rendering index

InactiveCN108269937AImprove device efficiencyReduce the numberSolid-state devicesSemiconductor/solid-state device manufacturingElectron transmissionRed light

The invention discloses a high-efficiency hybrid white OLED with a high color rendering index. The OLED comprises a substrate, an anode, a cavity implantation layer, a cavity transmission layer, a first blue fluorescent layer, a yellow and red phosphorescent layer, a second blue fluorescent layer, an electron transmission layer, an electron implantation layer and a cathode which are laminated successively from bottom to top; the yellow and red phosphorescent layer is formed by locating a yellow light material and a red light material in the same light emission layer; the first blue fluorescentlayer is arranged adjacent to the yellow and red light emission layer and separated from the yellow and red light emission layer by a spacing layer, the yellow and red phosphorescent layer is arranged adjacent to the second blue fluorescent layer and separated from the second blue fluorescent layer by a spacing layer, the concentration of red light emitted by the red light material is lower thanthe concentration of yellow light emitted by the yellow light material in the yellow and red light emission layer, and each of the first and second blue fluorescent layer is a non-doped or doped lightemission layer. The hybrid white OLED is high in efficiency and color rending index, simple in structure and convenient to popularize, can be popularized commercially, and has good market prospects.

Owner:GUANGDONG UNIV OF TECH

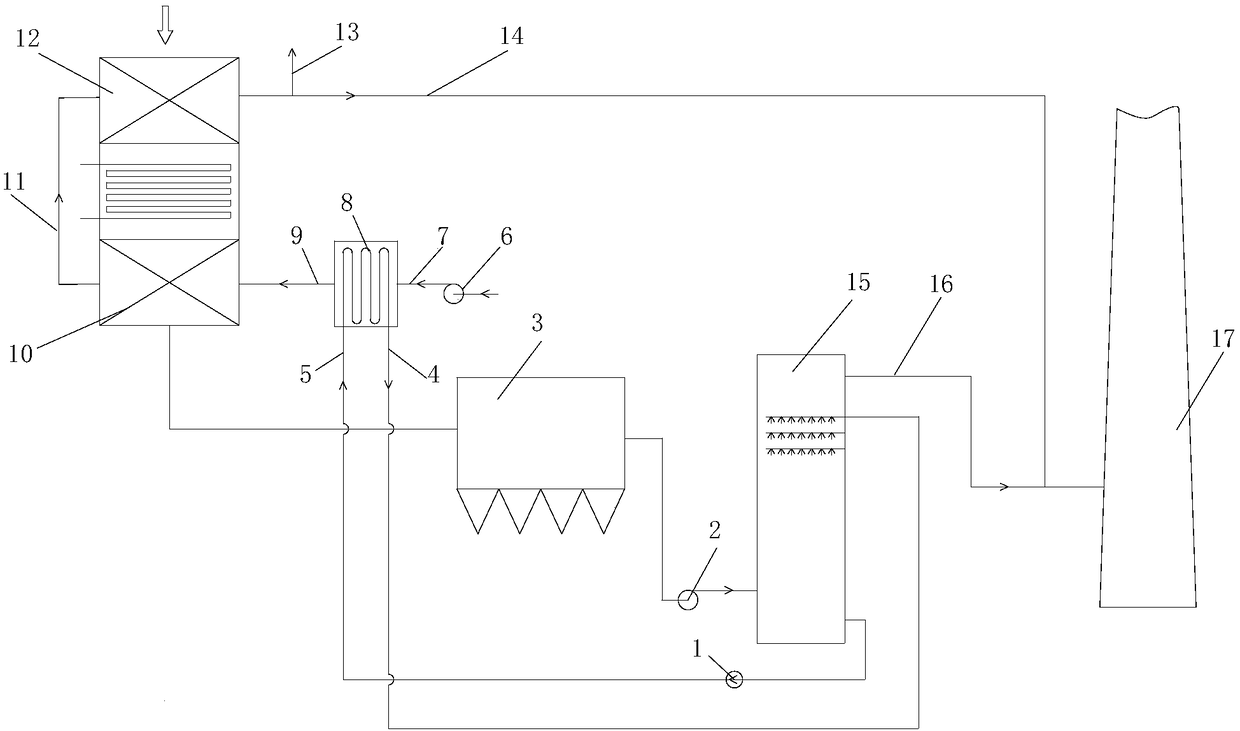

System and technology capable of utilizing waste heat of desulfurated slurry to prevent chimney from emitting white smoke

InactiveCN108592068ANo adverse effect on efficiencyEfficiency impactEmission preventionIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention discloses a system and a technology capable of utilizing waste heat of desulfurated slurry to prevent a chimney from emitting white smoke. The system comprises a desulfurizing tower, anair heater, a high temperature air preheater and a low temperature air preheater, wherein the desulfurizing tower is connected with the air heater; desulfurated slurry from the desulfurizing tower exchanges heat with the cold air of the air heater, and the desulfurated slurry after temperature reduction returns to the desulfurizing tower; the air heater is further connected with the low temperature air preheater; the cold air passing through the air heater is heated by the desulfurated slurry and then enters the low temperature air preheater; the low temperature air preheater is connected withthe inlet of the high temperature air preheater through a pipeline; the outlet of the high temperature air preheater communicates with a boiler and the outlet flue of the desulfurizing tower; most ofhigh temperature air out of the high temperature air preheater is supplied to the boiler via a boiler hot air pipeline and provides oxygen for fuel combustion; and other small part of high temperature air enters the outlet flue of the desulfurizing tower and is mixed with wet flue gas from the desulfurizing tower in the flue to prevent the chimney from emitting white smoke.

Owner:烟台羽林节能科技有限公司

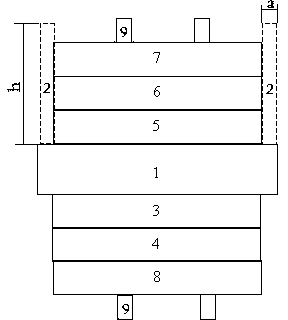

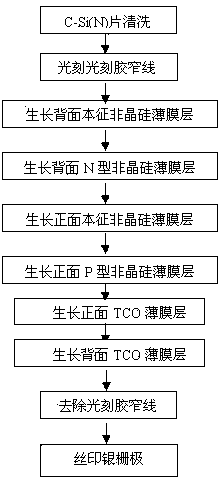

Method for isolating films on two sides of substrate layer and preparing process for heterogenous junction solar cell

ActiveCN103426973APrevent leakageNo damageFinal product manufactureSemiconductor devicesEngineeringElectrical connection

The invention discloses a method for isolating films on the two sides of a substrate layer. The method comprises the following steps of 1, photoetching photoresist narrow lines at the periphery of the front side and / or the back side of the substrate layer and at the portion close to the edge of the substrate layer, 2, respectively and correspondingly producing film layers on the front side and the back side of a substrate, 3, using organic solvent to remove the photoresist narrow lines in the step 1 before the work procedure for forming a silver grid electrode of the solar cell, and 4, using low-temperature silver paste silk screen to print the silver grid electrode and drying the low-temperature silver paste to enable the organic solvent used in the step 3 to be volatized. The method can effectively avoid the phenomenon of cell electric leakage or cell short circuit caused by electrical connection between the films on the two sides of the substrate layer. Furthermore, the method can avoid damage of laser isolation methods, mechanical isolation methods and the like to the cell and guarantee that the efficiency of the cell is not affected.

Owner:TRINASOLAR CO LTD

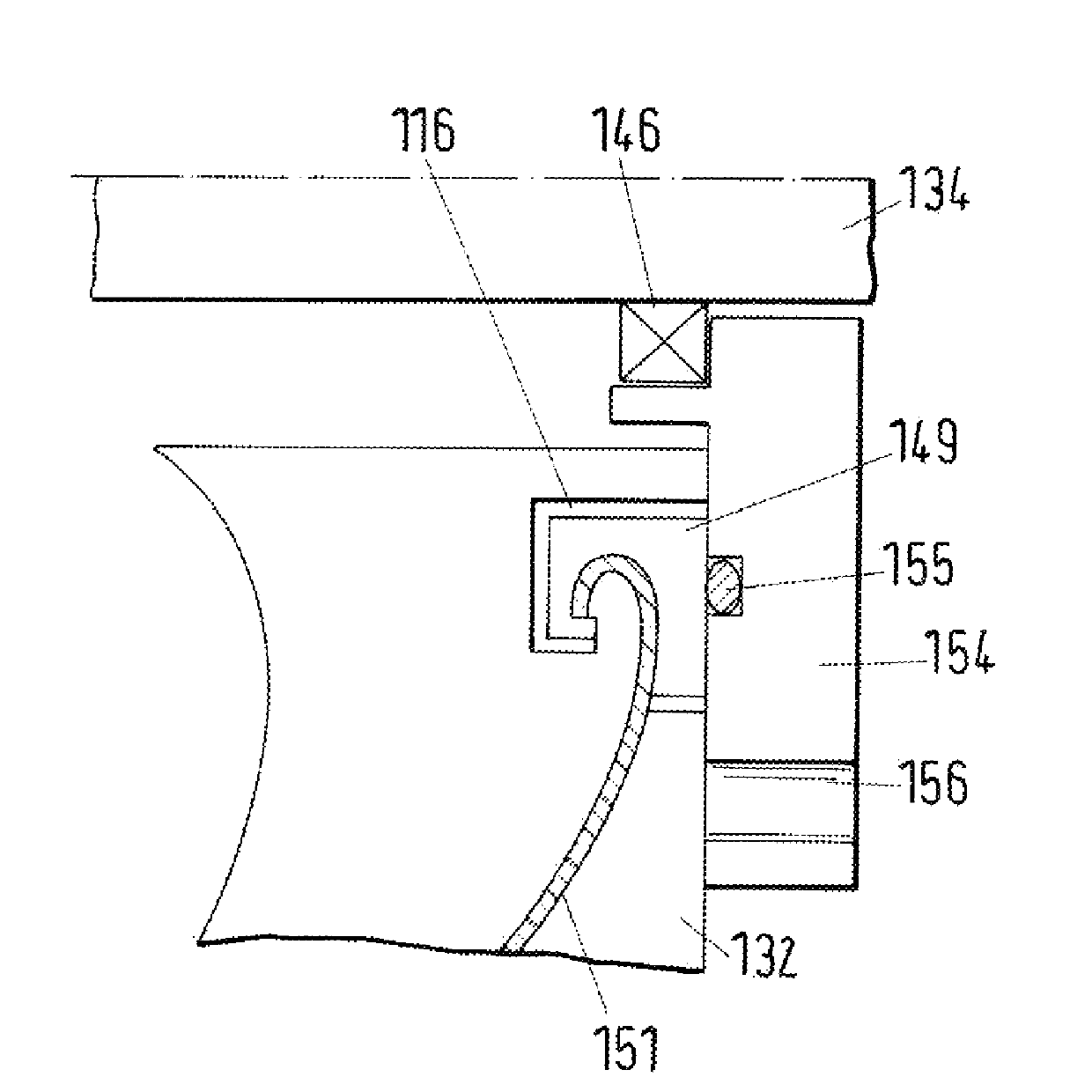

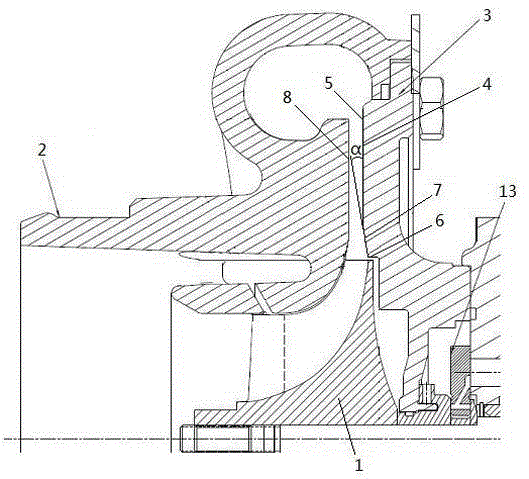

Sealing assembly and pump with a sealing assembly

InactiveCN103321943AImprove sealingEfficiency is not adversely affectedEngine sealsPump componentsEngineeringMechanical engineering

Owner:SULZER MANAGEMENT AG

Mixed-flow water turbine runner blade outlet edge trimming method

ActiveCN108661840AGuaranteed mechanical strengthAvoid crackingHydro energy generationGrinding machinesMixed flowWater turbine

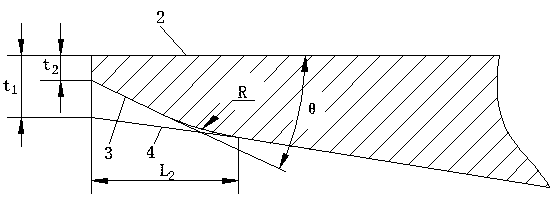

The invention discloses a mixed-flow water turbine runner blade outlet edge trimming method. The mixed-flow water turbine runner blade outlet edge trimming method comprises the following steps of: step a. cutting to obtain a blade wing profile, and determining a blade outlet edge trimming area; step b. enabling a molded line of the back of a blade after edge trimming and a molded line of the backof the blade before edge trimming to be in circular arc transition, wherein the radius R is 4-7 times of the thickness t1 of the outlet edge of the blade before edge trimming; step c. determining thefinal geometric dimension of the outlet edge trimming of the blade; step d. determining the sizes of a child-mother sample plate and a circular arc sample plate of the back of the blade, and integrally machining the child-mother sample plate and the circular arc sample plate of the back of the blade; step e. marking off on the outlet edge of the blade, and determining the final position of the back pressure edge of the outlet of the blade after trimming; step f. adjusting the angle of the outlet edge of the blade till the angle meets the size of the son-mother sample plate; and step g. grinding the circular arc of the black of the blade till the circular arc meets the size of the circular arc sample plate of the back of the blade. The mixed-flow water turbine runner blade outlet edge trimming method can prevent or eliminate water turbine squealing and blade cracks generated by blade hydraulic power elastic resonance induced by the Karman vortex street of a runner outlet, and improves the structure integrality of the mixed-flow water turbine runner and the operation safety of the water turbine.

Owner:DONGFANG ELECTRIC MACHINERY

System and method for realizing machine starting denitration operation

PendingCN108458357AReduce absorptionRaise the inlet steam temperatureGas treatmentDispersed particle separationProcess engineeringFlue

The invention relates to a system and method for realizing machine starting denitration operation and belongs to the technical field of coal-fired power station boiler environmental protection. The system comprises a boiler, the boiler is internally provided with a boiler smoke passage, and the boiler smoke passage is internally provided with a final-stage reheater, a low-temperature reheater, aneconomizer and an SCR (Selective Catalytic Reduction) reactor according to the flowing direction of smoke in sequence. According to the system and method for realizing machine starting denitration operation, at the stage of machine starting, a low-temperature reheater steam bypass is adopted to reduce smoke heat absorbed by the low-temperature reheater, adjacent-boiler high-temperature steam is adopted, bypass reheating steam of the boiler is heated, the inlet steam temperature of the final-stage reheater is raised to reduce the heat absorption quantity of the final-stage reheater, and then the inlet smoke temperature of the SCR reactor is raised, and the effective operation of denitration facilities is realized; at the stage of normal operation, according to the actual production requirements, the low-temperature reheating steam bypass and a high-temperature steam pipeline from an adjacent boiler are closed, energy sources are saved, and influence will not be generated to the efficiency of the boiler; and the system is simple and convenient to carry out, furthermore, the investment and operation cost is low, and the system and method for realizing machine starting denitration operation have wide application range.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

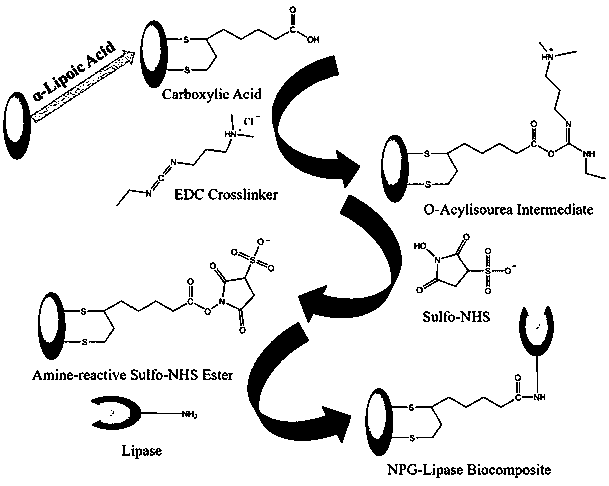

Method for preparing immobilized lipase by using porous nano-gold as carrier, and application of immobilized lipase

InactiveCN108866037AImprove stabilityImprove reuse efficiencyHydrolasesOn/in inorganic carrierAlpha-Lipoic AcidThermal stability

The invention discloses a method for preparing immobilized lipase by using porous nano-gold as a carrier, and application of the immobilized lipase. According to the method, the porous nano-gold material is prepared by using a dealloying method; the method comprises the steps of firstly, modifying by using alpha-lipoic acid so as to form a carboxylated nano-gold material; modifying the carboxylated nano-gold material by using a coupling agent so as to form a nano-gold compound terminated by N-hydroxysulfosuccinimide sodium salt; immobilizing porcine pancreatic lipase onto the nano-gold compound. The immobilized lipase prepared by the method has good catalytic activity, pH stability and thermal stability; compared with resolvase, the immobilized lipase has obviously improved storage stability; furthermore, after being subjected to simple treatment, the carrier can be recycled, so that the cost is lowered.

Owner:TAIYUAN UNIV OF TECH

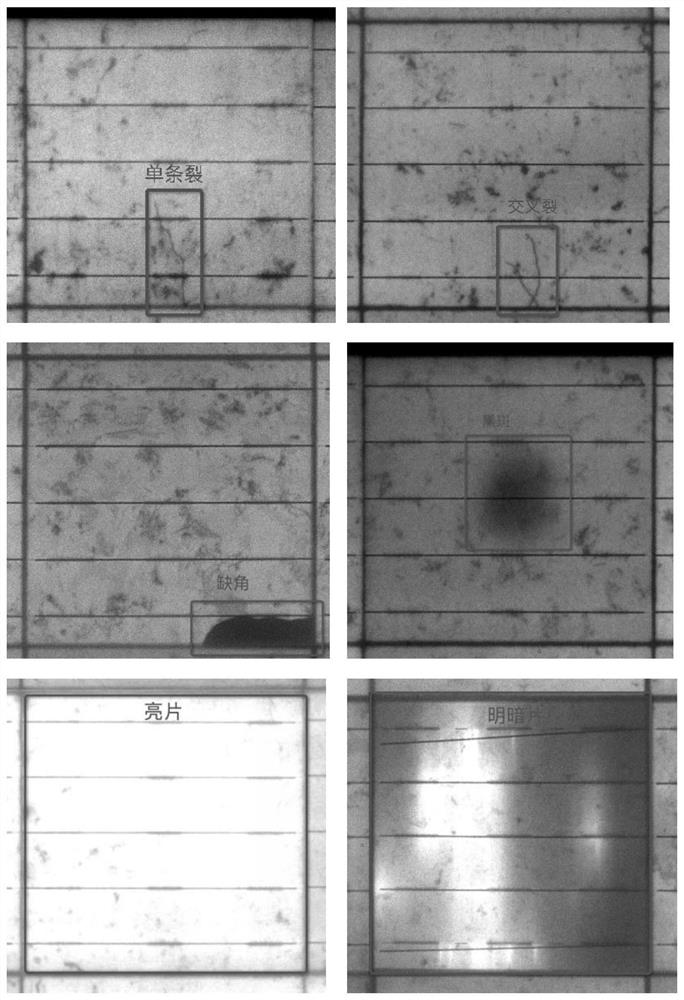

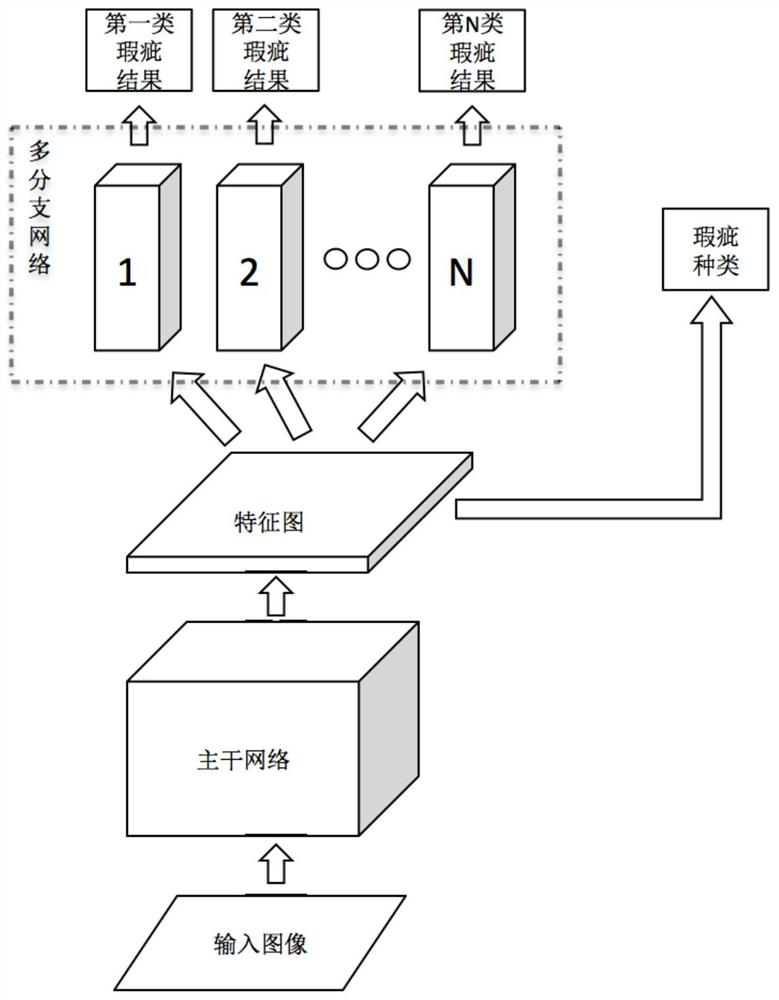

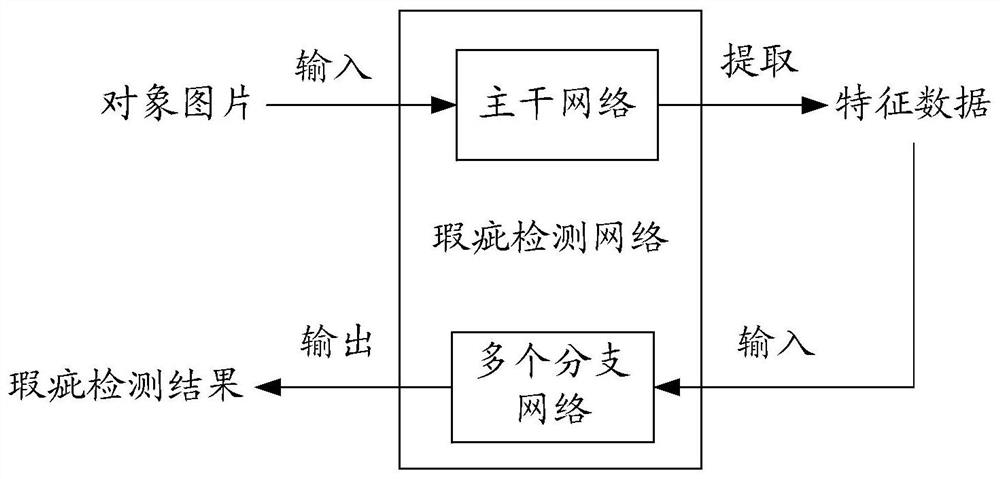

Detection method, computer equipment and storage medium

PendingCN112016575AHigh precisionImprove efficiencyImage enhancementImage analysisFeature extractionAlgorithm

The embodiment of the invention discloses a detection method. The method comprises the following steps of inputting the object picture into a backbone network of a defect detection network for featureextraction; obtaining feature data, inputting the feature data into a plurality of branch networks of the defect detection network, depending on feature data, respectively detecting different types of flaws on the object picture by a plurality of branch networks; and outputting defect detection results. The method is advantaged in that each branch of the neural network can be used for specifically and independently detecting one type of flaws; a problem that the detection precision is low when the neural network learns multiple defect forms at the same time is avoided, on the other hand, lesscomputing resources are consumed compared with the mode that multiple neural networks are adopted for detection, and defect detection precision and efficiency are improved under the condition that the same computing resources are consumed.

Owner:ALIBABA GRP HLDG LTD

Method for detecting tanshinone components, and application thereof

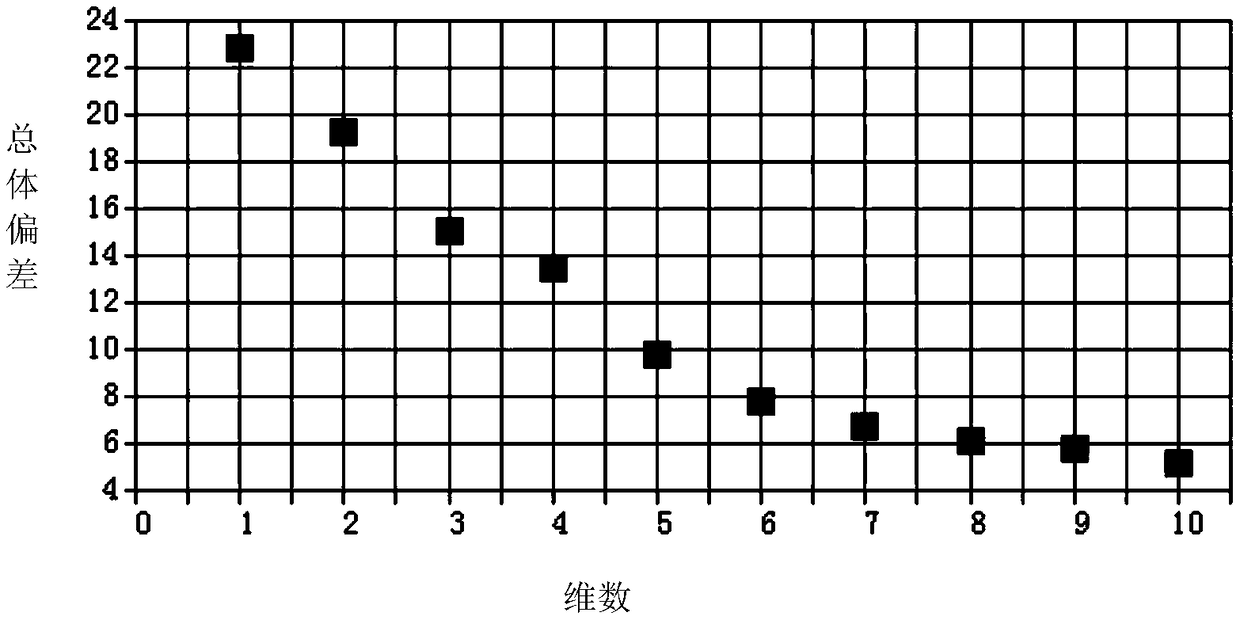

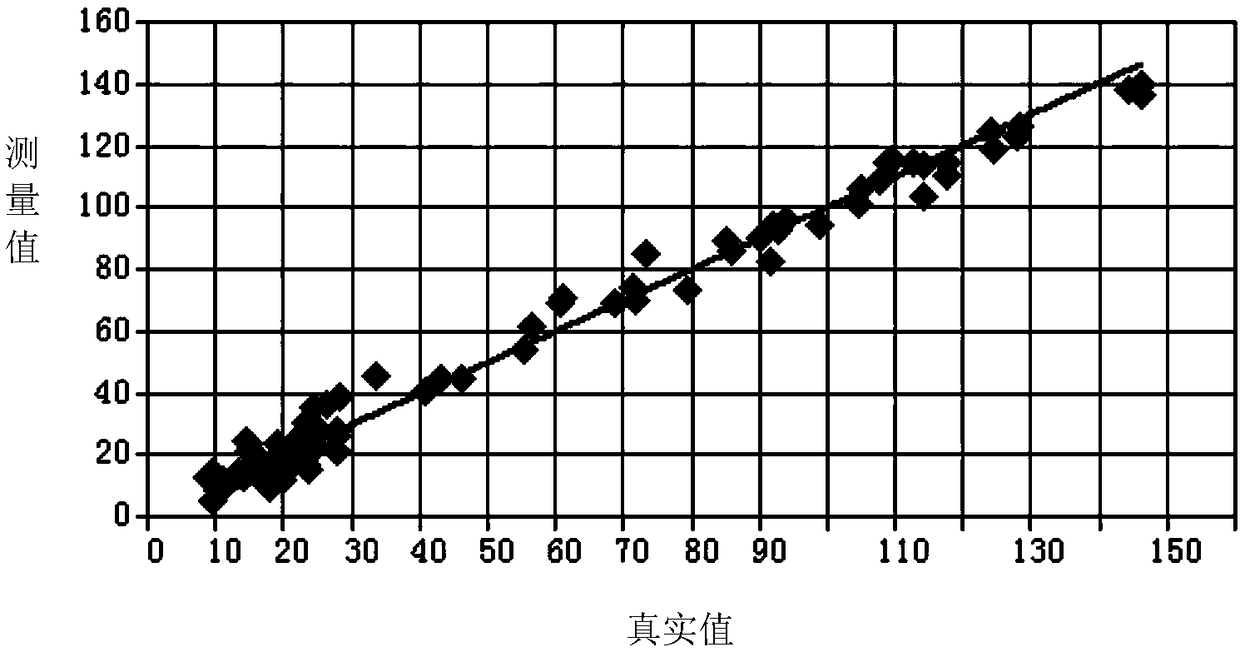

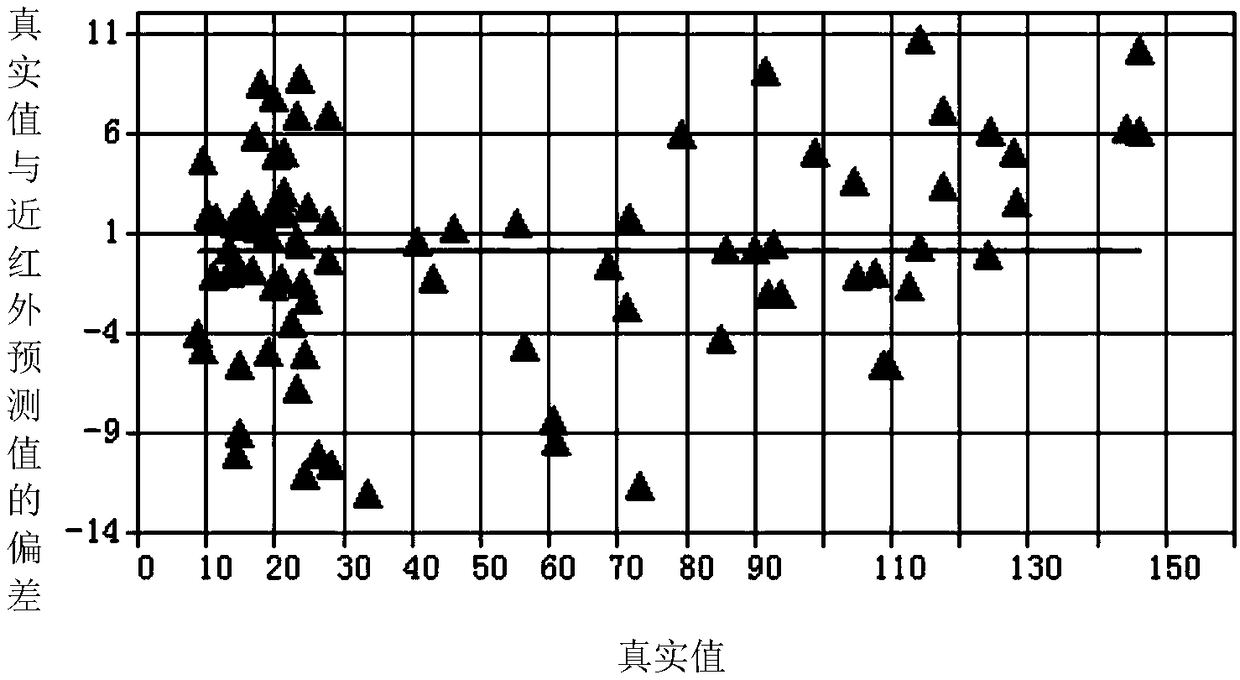

ActiveCN108663337ARapid determination of contentThe assay method is fastComponent separationMaterial analysis by optical meansSpectroscopyTanshinone IIA

The invention relates to a method for detecting tanshinone components, and an application thereof. The tanshinone components are dihydrotanshinone, cryptotanshinone, tanshinone I and tanshinone IIA. The method comprises the following steps: collecting samples to be tested in the extraction and concentration of Salvia miltiorrhiza, collecting the near infrared spectra of the samples to be tested bynear-infrared spectroscopy, and converting the near infrared spectra into the respective content of dihydrotanshinone, cryptotanshinone, tanshinone I and tanshinone IIA in every sample to be tested according to a selected model. The method has the advantages of fastness in detection of the respective content of the tanshinone components in a compound Salvia miltiorrhiza tablet, simplicity in thepreparation of the samples, and realization of online analysis.

Owner:GUANGZHOU BAIYUSN HUTCHISON WHAMPOA CHINESE MEDICINE

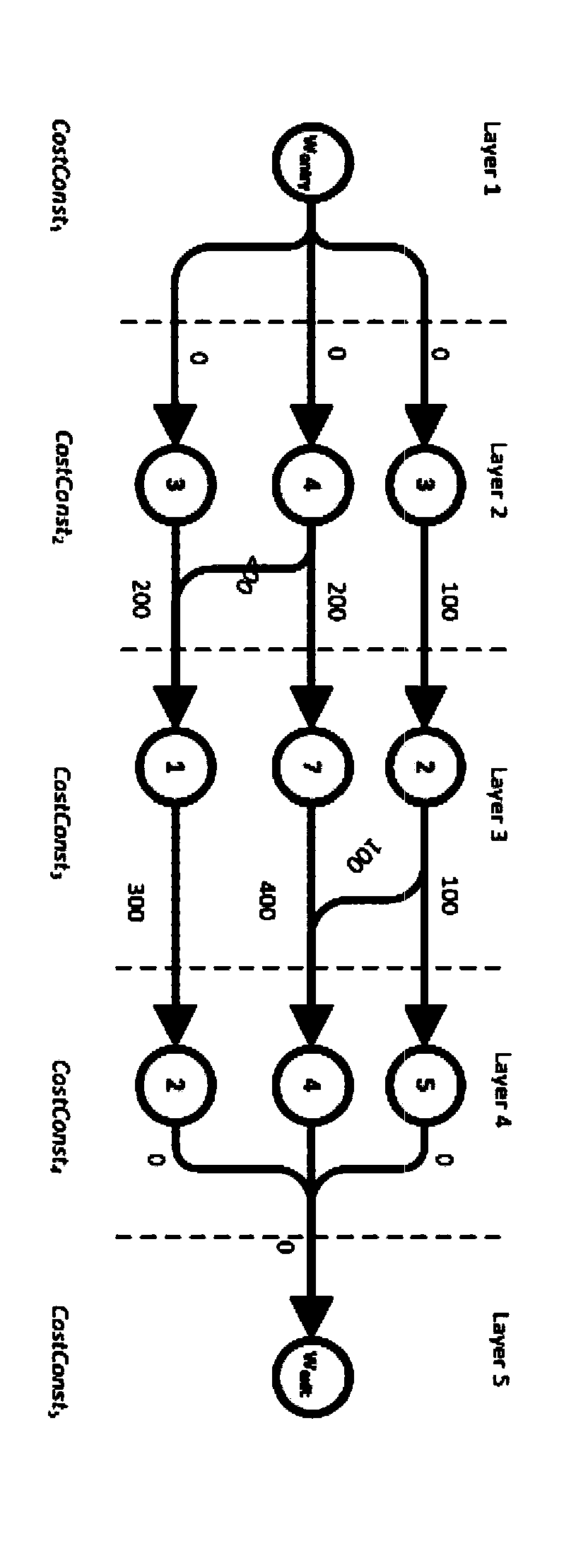

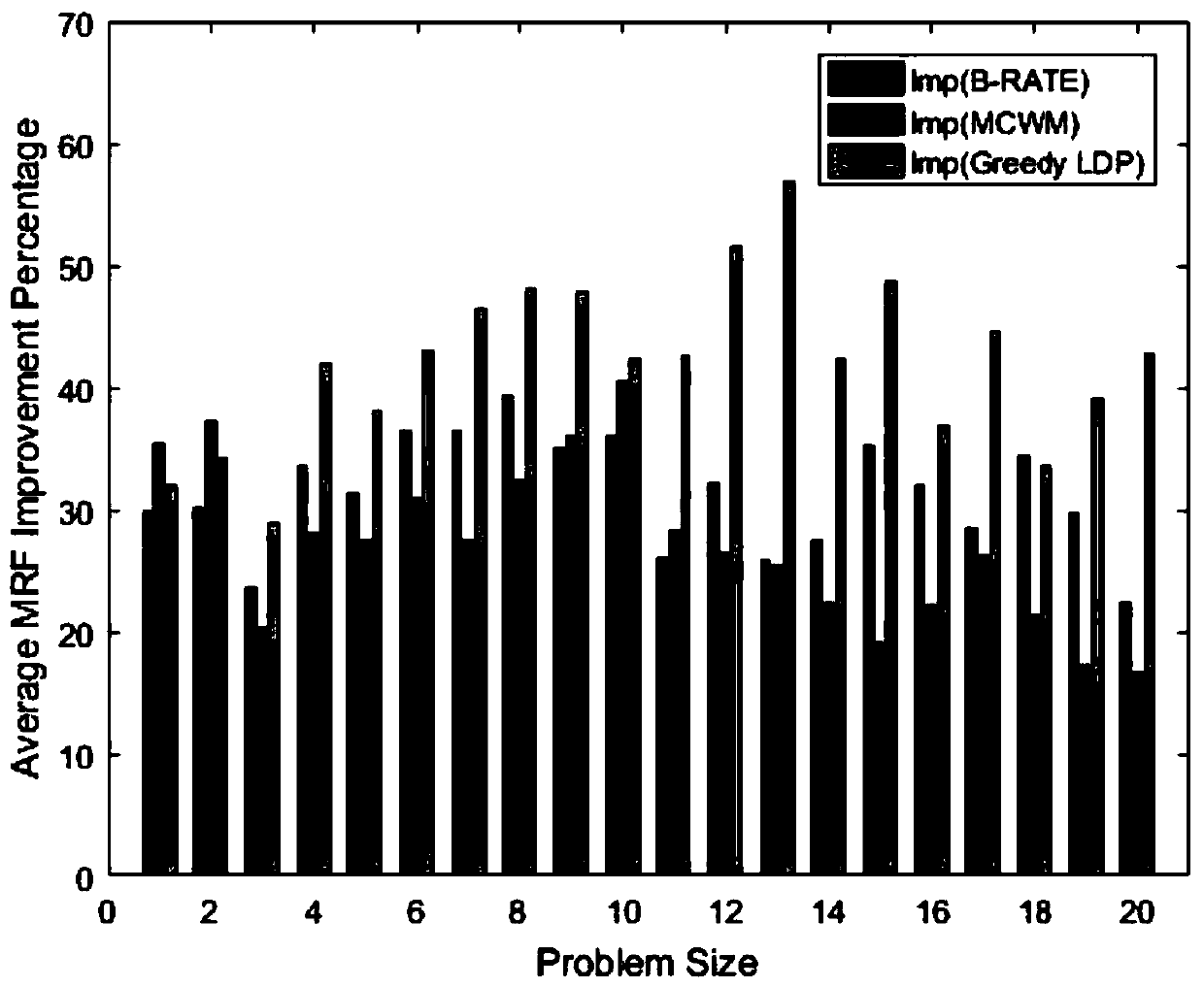

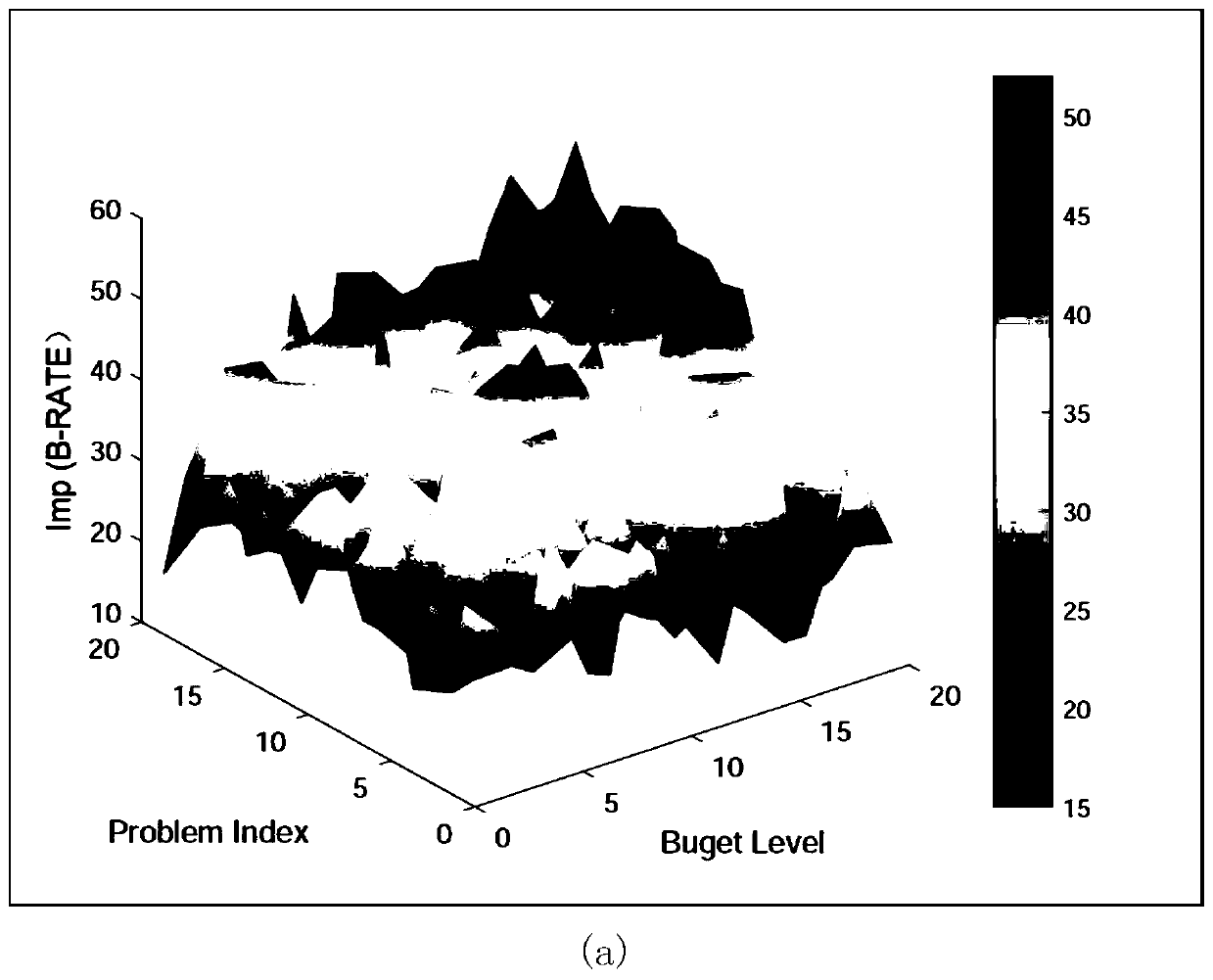

A static workflow scheduling method and device

ActiveCN109783189AImprove work efficiencyShorten the timeSoftware simulation/interpretation/emulationSoftware engineeringWorkflow scheduling

The invention discloses a static workflow scheduling method and device. Hierarchical division is carried out according to the structure of the workflow, for the workflow module of each layer, the typeof the virtual machine is considered based on budget, the virtual machine is distributed, and then mapping scheduling of the physical machine is carried out on the distributed virtual machine. The performance bottleneck of the workflow in the heterogeneous multi-cloud environment is solved, and the defect of insufficient throughput of the workflow in the heterogeneous cloud environment is improved.

Owner:NORTHWEST UNIV

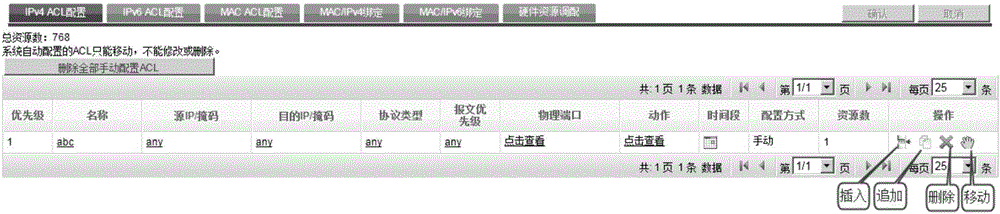

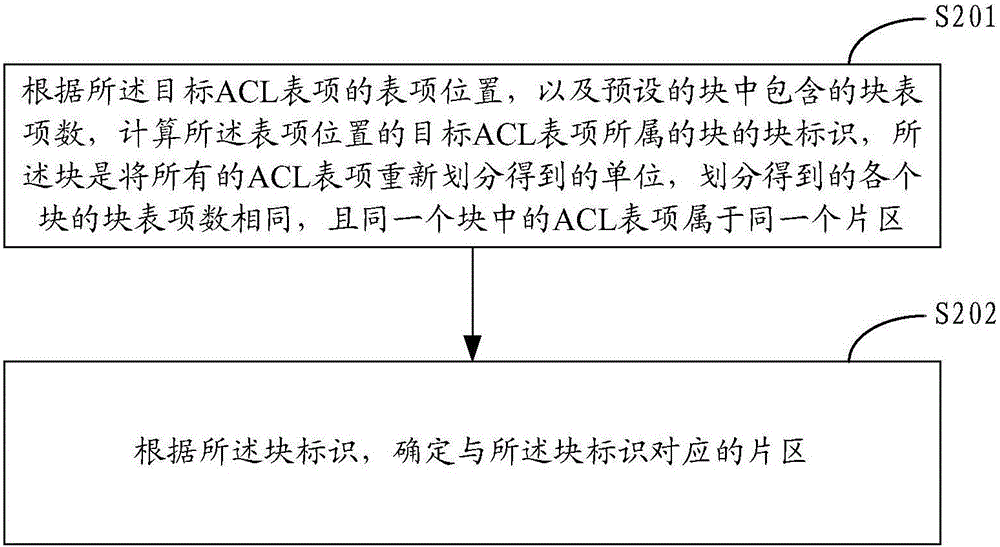

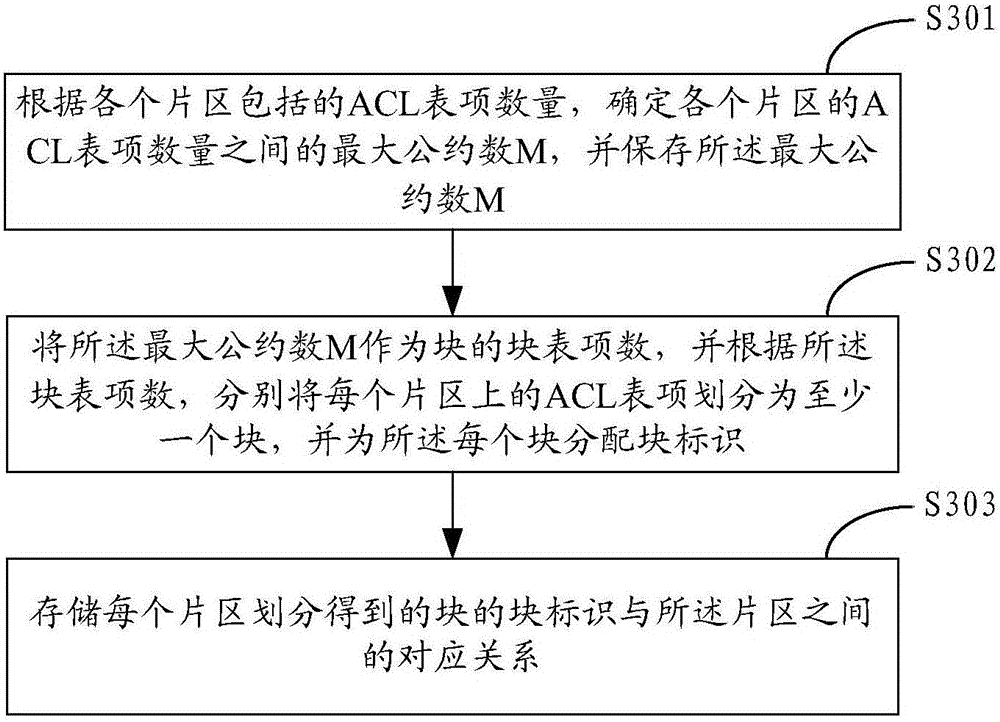

Method and device for searching ACL (Access Control List) list item

ActiveCN105939271AImprove efficiencyEfficiency impactData switching networksNetwork switchData mining

The invention provides a method and a device for searching an ACL (Access Control List) list item. The method is applied to a network switching device; multiple ACL list items are stored at the network switching device; all the ACL list items are divided into multiple areas; each area comprises multiple ACL list items; and the method comprises the steps of calculating a block identification of a block which a target ACL list item at the list item position belongs to based on the list item position of the target ACL list item and the number of block list items contained in a preset block, wherein the block is a unit which is obtained by re-dividing all the ACL list items, and each block obtained through the division has the same number of the block list items, and the ACL list items in the same block belong to the same area; and determining an area corresponding to the block identification based on the block identification. By applying the embodiment of the invention, reduction of time difficulty of an algorithm for determining the belonging area based on the position of each ACL list item is realized, and the efficiency of the network switching device is improved.

Owner:HANGZHOU DPTECH TECH

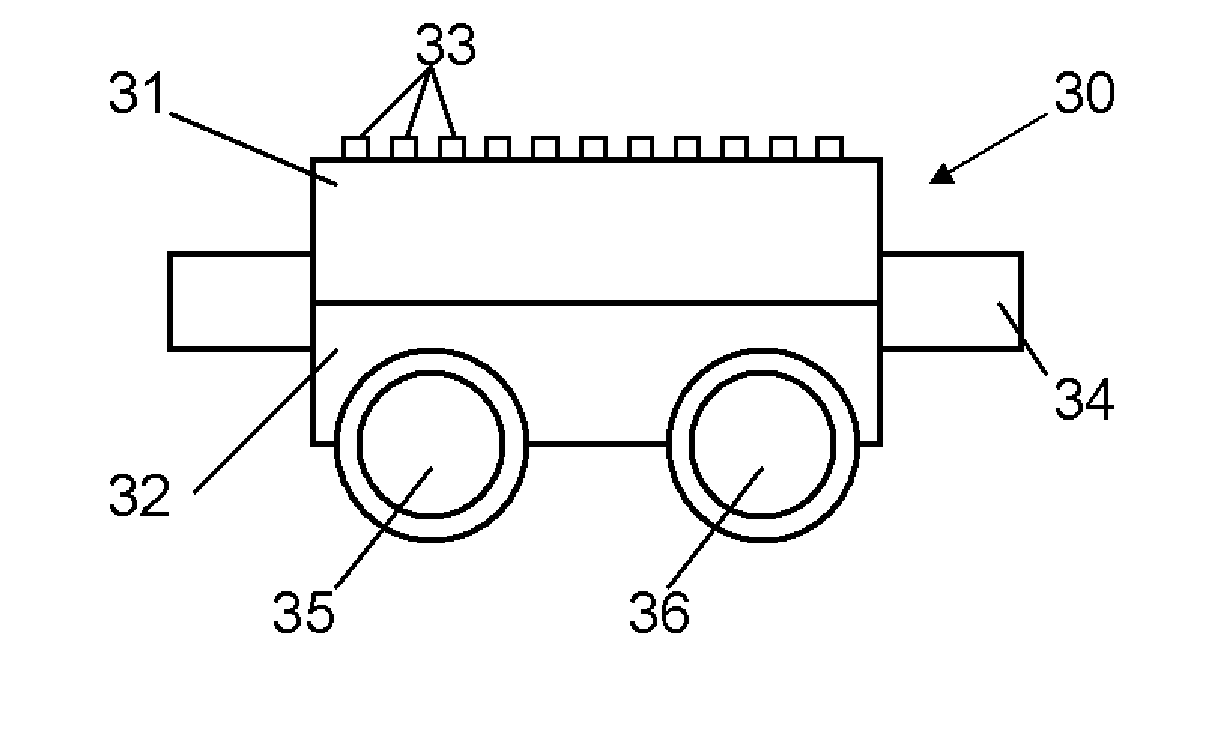

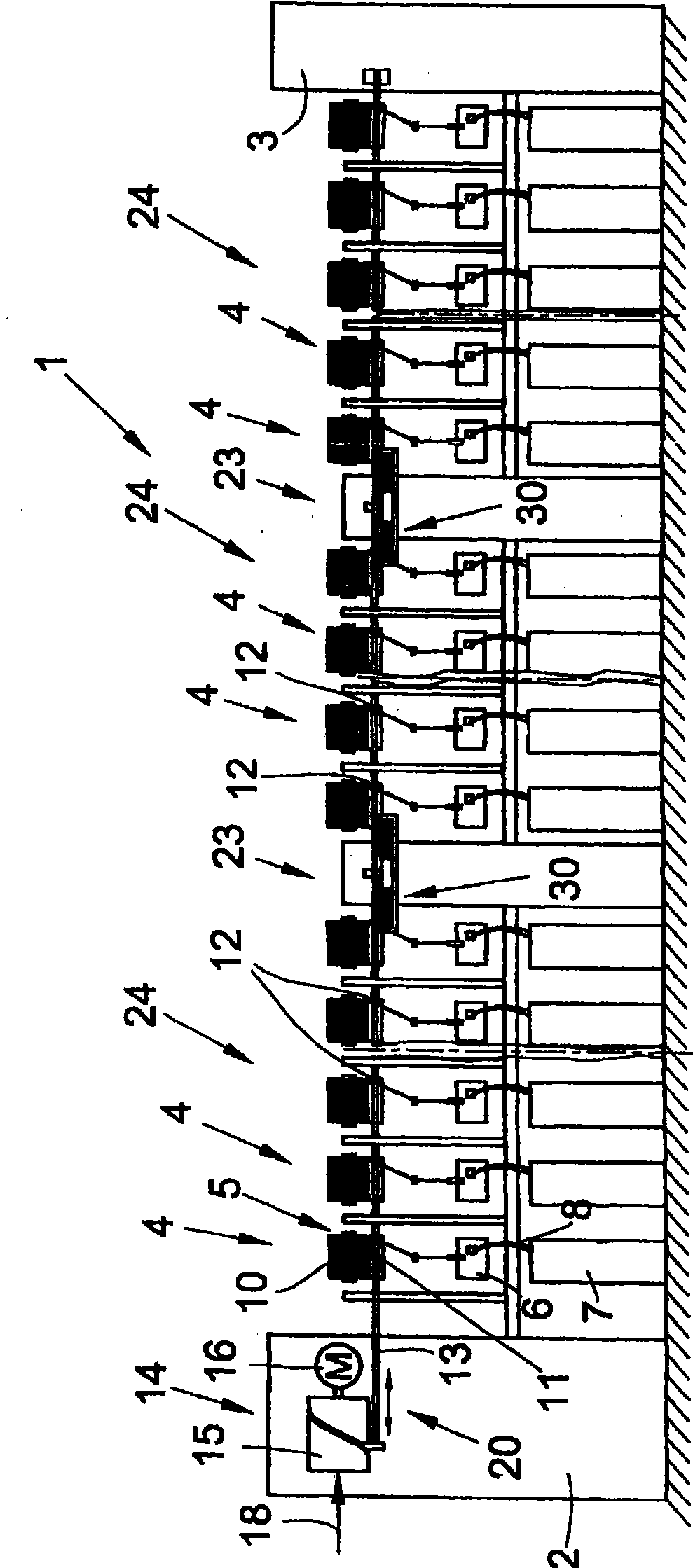

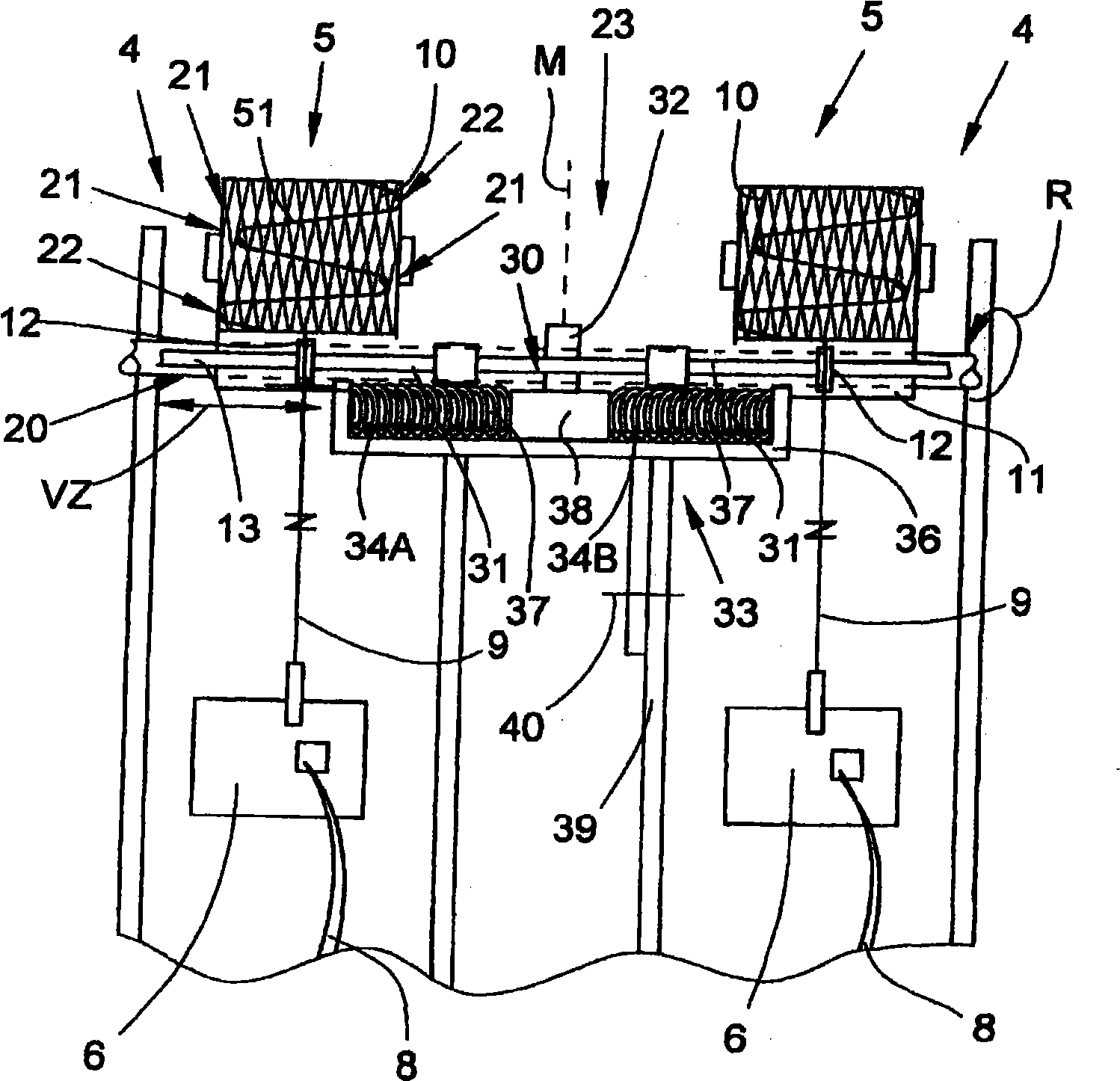

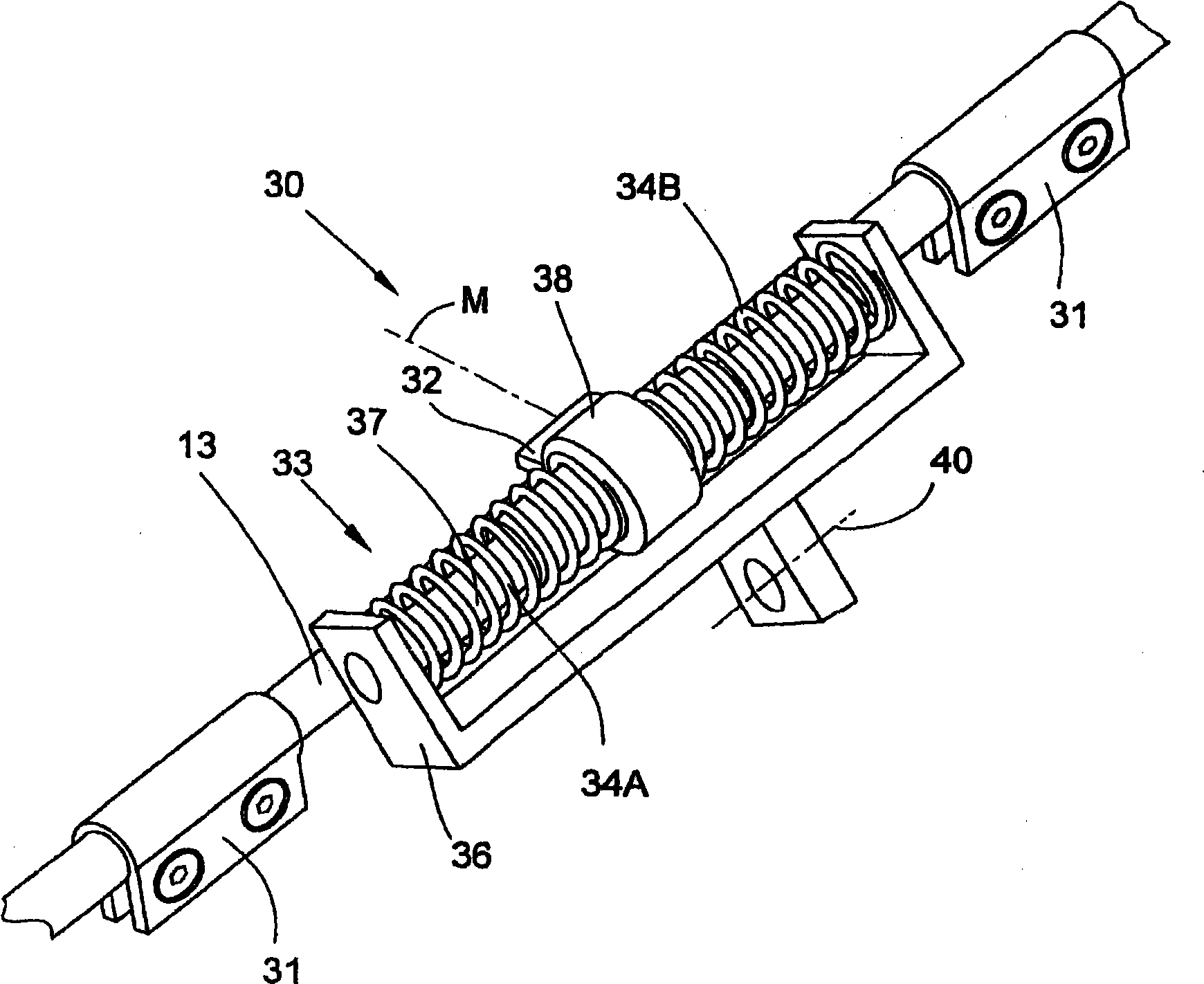

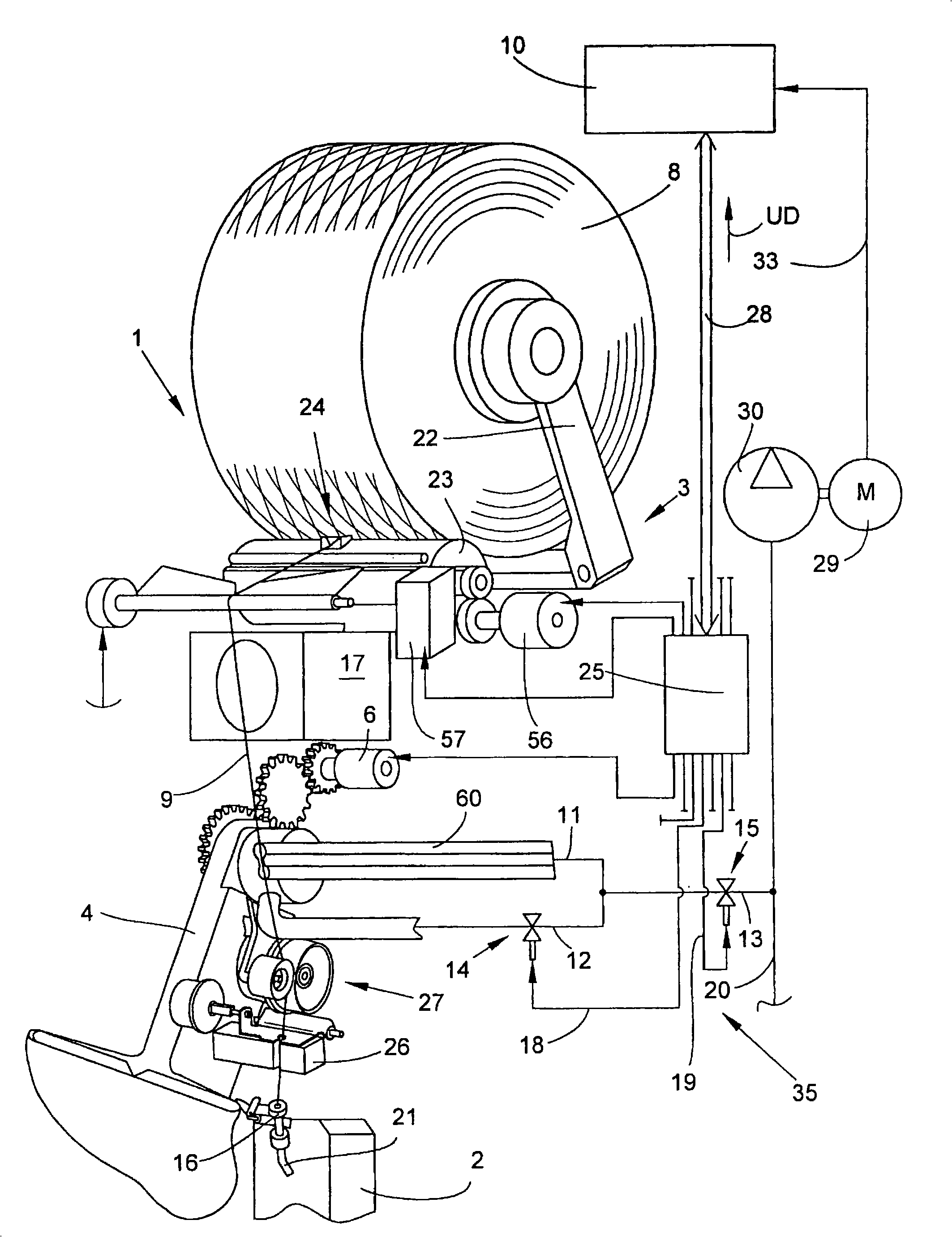

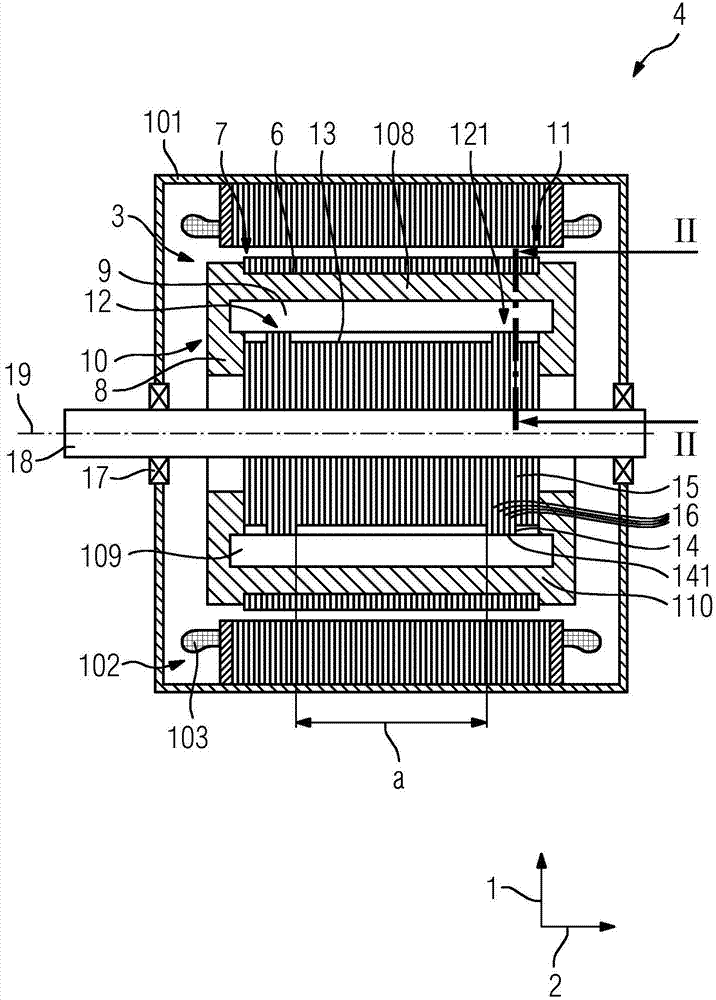

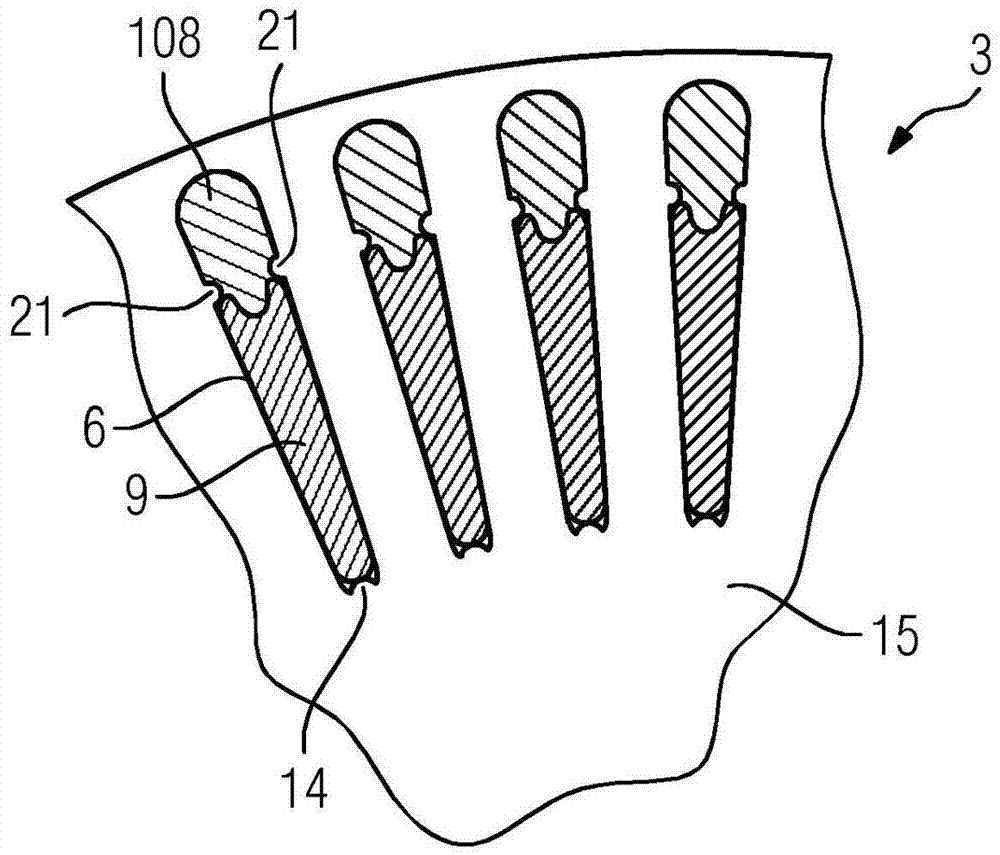

Cross-winding device for a textile machine which produces cross-wound bobbins

ActiveCN101535159ACounteract kinetic energyNo excessive cancellation of the kinetic energy of the yarn feeder rodFilament handlingYarnBobbin

The invention relates to a cross-winding device (20) for a textile machine (1) which produces cross-wound bobbins and which has numerous operating positions (4), and which has a thread carrier rod (13) extending in a longitudinal direction relative to the machine and actuated in a traverse direction and on which cross-winding thread guides (12) are fixed. The cross-winding device (20) is also equipped with a so-called edge transferring device (18) which ensures that the cross-winding thread guides (12) run up to both inner (21) and outer (22) reversal points. In addition, the cross-winding device (20) has at least one energy storage unit (30) which supports the change of direction of the thread carrier rod (13) in the area of the reversal points (21, 22). According to the invention, it is provided that driver elements (31) are arranged on the thread carrier rod (13) which work together alternately in the cross-winding end areas thereof with a mechanical stop (32) of a spring system (33) which is formed as an energy storing unit (30). Said spring system (33) has at least two prestressed spring elements (34A, 34B) which lie on opposite sides of the mechanical stop (32) and which are formed and positioned such that the spring system (33), originating from a fulcrum (M) and going toward both sides, has for each side a decreasing spring characteristic (45, 46).

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

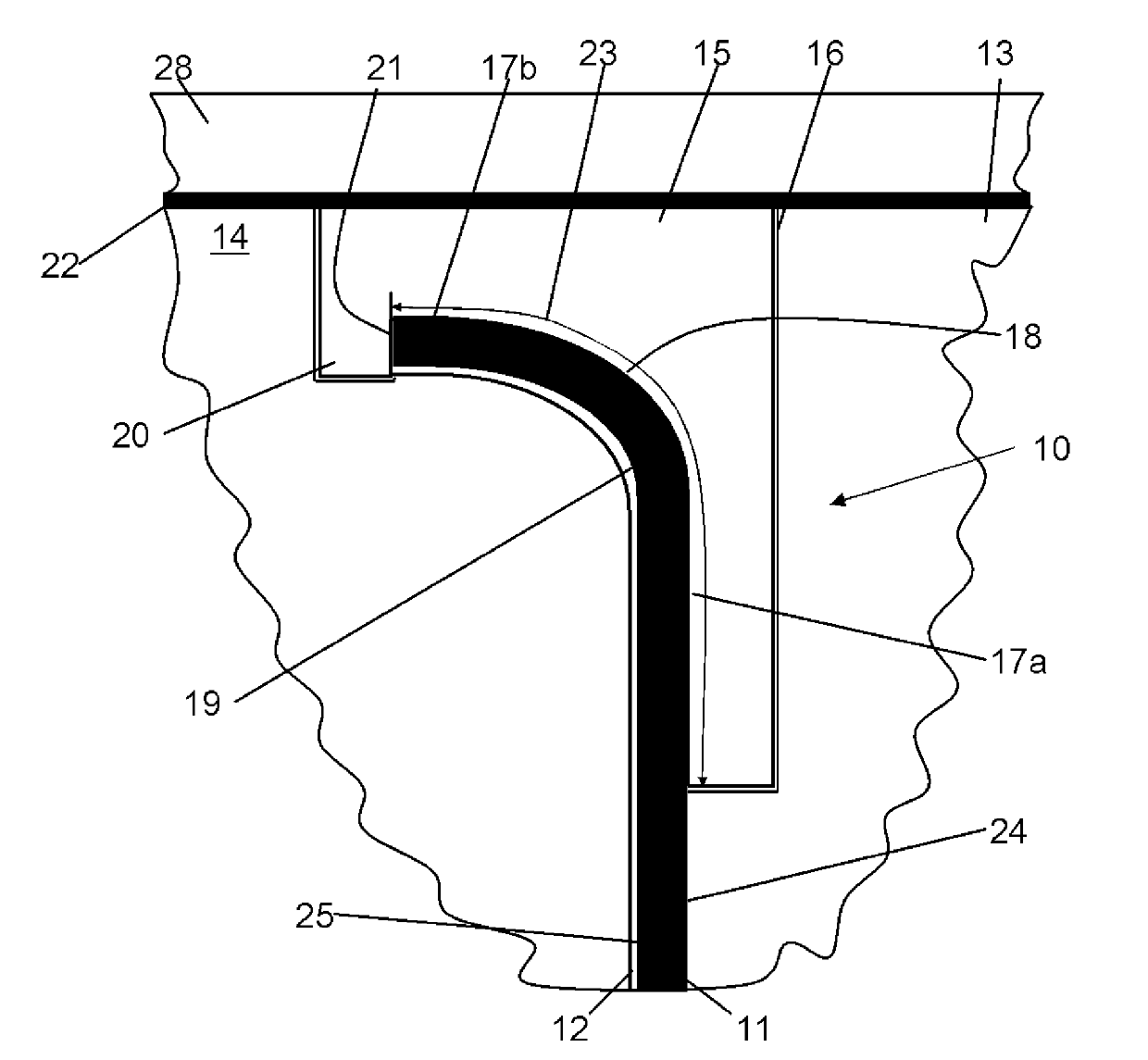

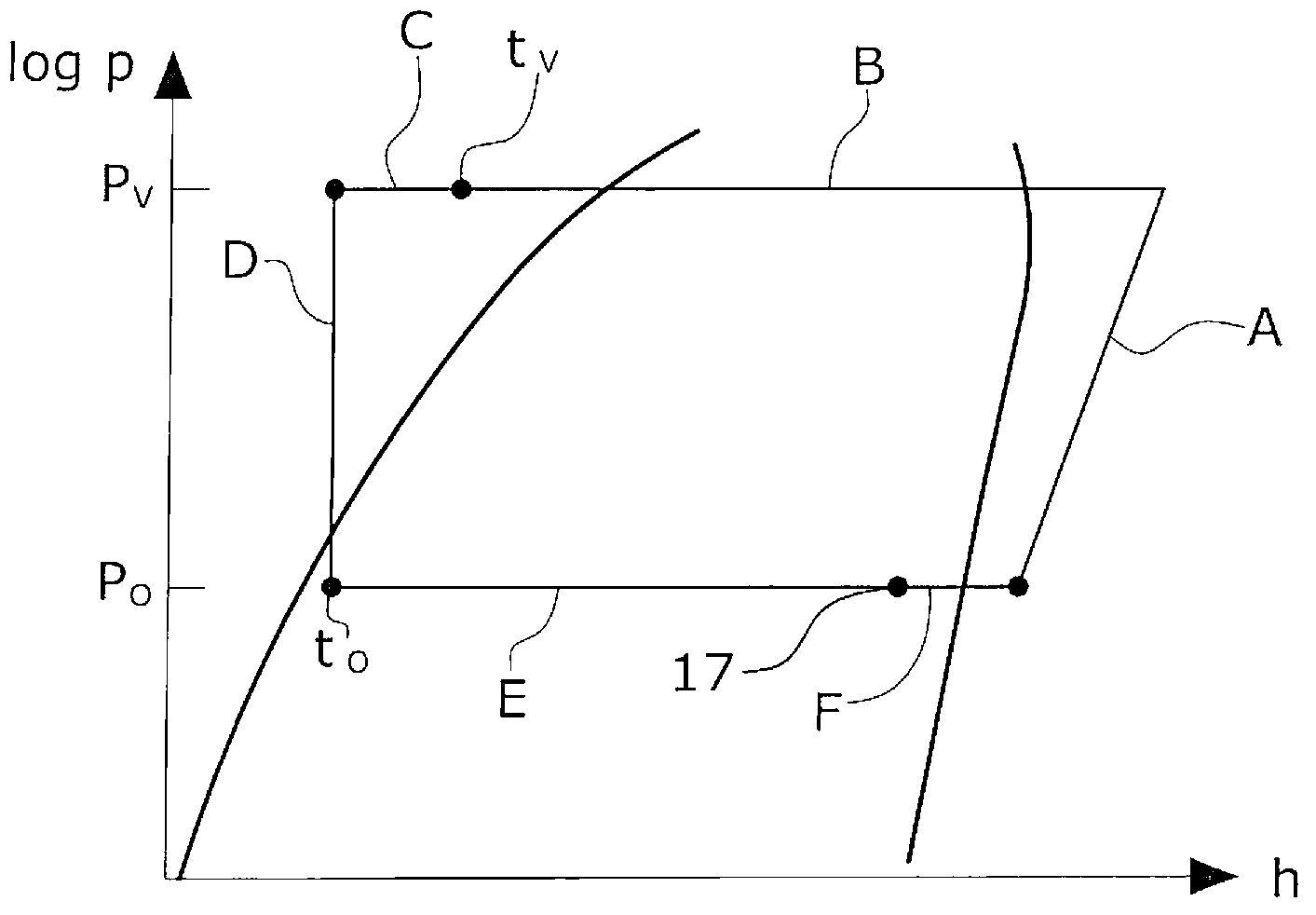

Refrigerating circuit for use in a motor vehicle

InactiveCN102980334AFacilitated releaseEfficiency impactMechanical apparatusCompression machines with non-reversible cycleMobile vehicleRefrigerant

The invention relates to a refrigerating circuit for use in a motor vehicle which has a refrigerant compressor (8) connected on the output side to a pressure line (4) and on the input side to a suction line (6). The refrigerating circuit has at least one condenser (10), at least one regulated expansion valve (14), at least one evaporator (16) and at least one inner heat exchanger (12). The regulated expansion valve (14) has a temperature tE in a detection zone (20) of the suction line (6) as a controlled variable. The detection zone (20) for the regulated expansion valve (14) is arranged at the output of the inner heat exchanger (12).

Owner:DR ING H C F PORSCHE AG

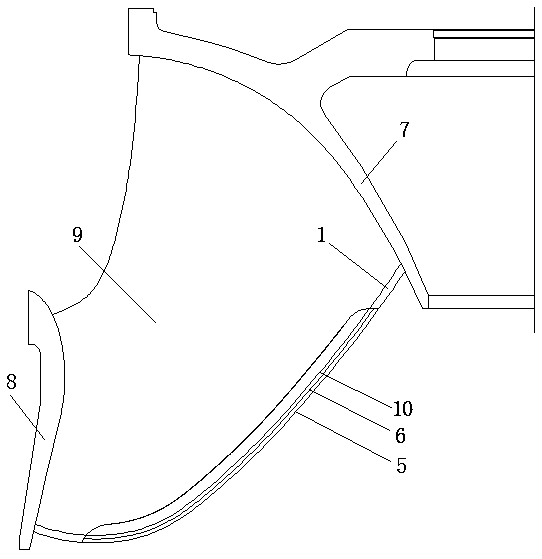

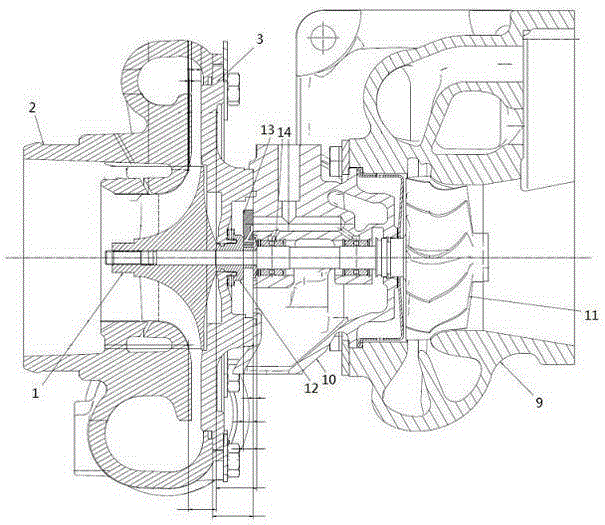

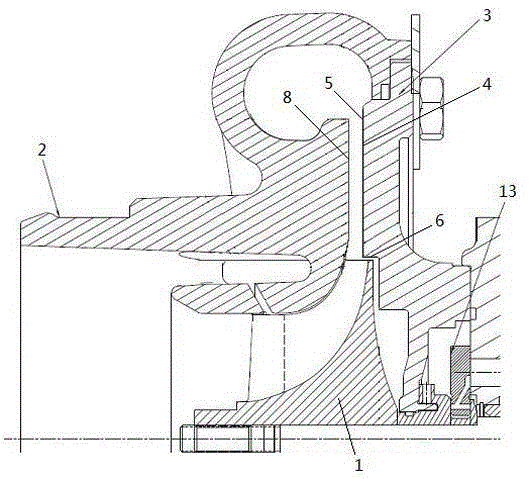

Device and method for reducing oil leakage of supercharger compressor

ActiveCN104819166AReduce oil spillsEfficiency impactEngine manufacturePump componentsImpellerEngineering

The invention relates to a device and method for reducing oil leakage of a supercharger compressor. The device comprises a compressor body mainly composed of an impeller, a compressor volute and a compressor back plate. The device is characterized in that at the outlet position of the impeller, the upper end face of the compressor back plate protrudes outwards, the size of the protruding part has continuous changes of different degrees, and therefore the compressor back plate and the impeller overlap to different degrees at the outlet position of the impeller, and the compressor back plate blocks gas flow the outlet of the impeller to different degrees. By means of the device, the influences on the efficiency of the compressor can be reduced while the oil leakage of the compressor is reduced.

Owner:山东赛马力发电设备有限公司

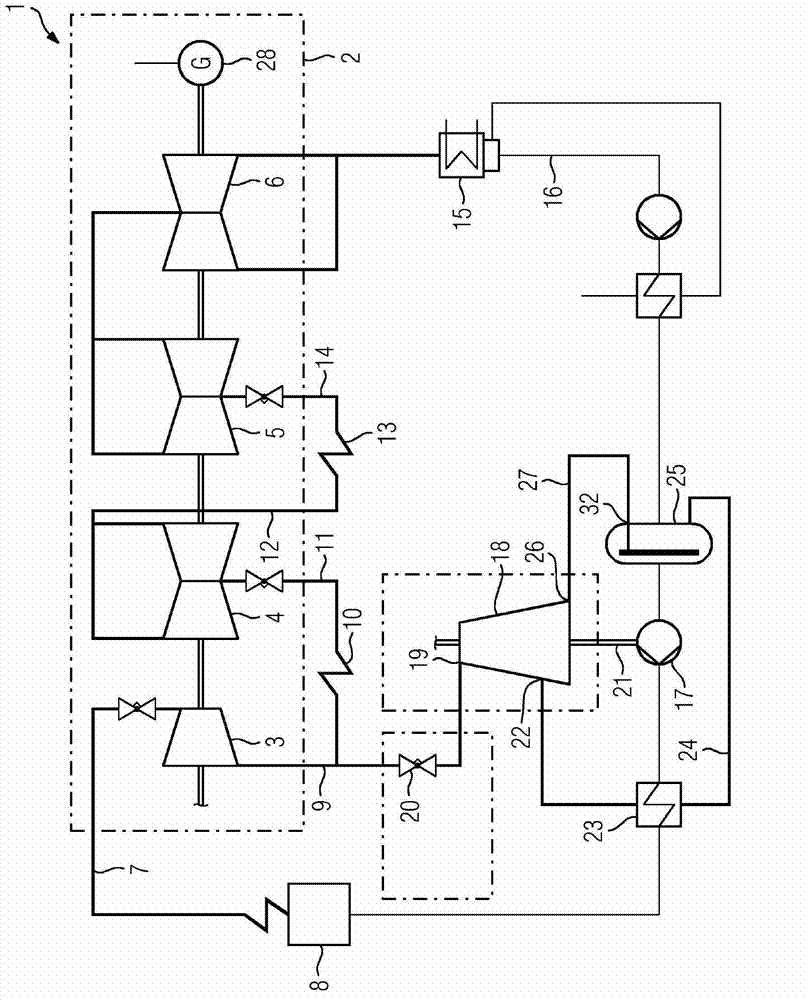

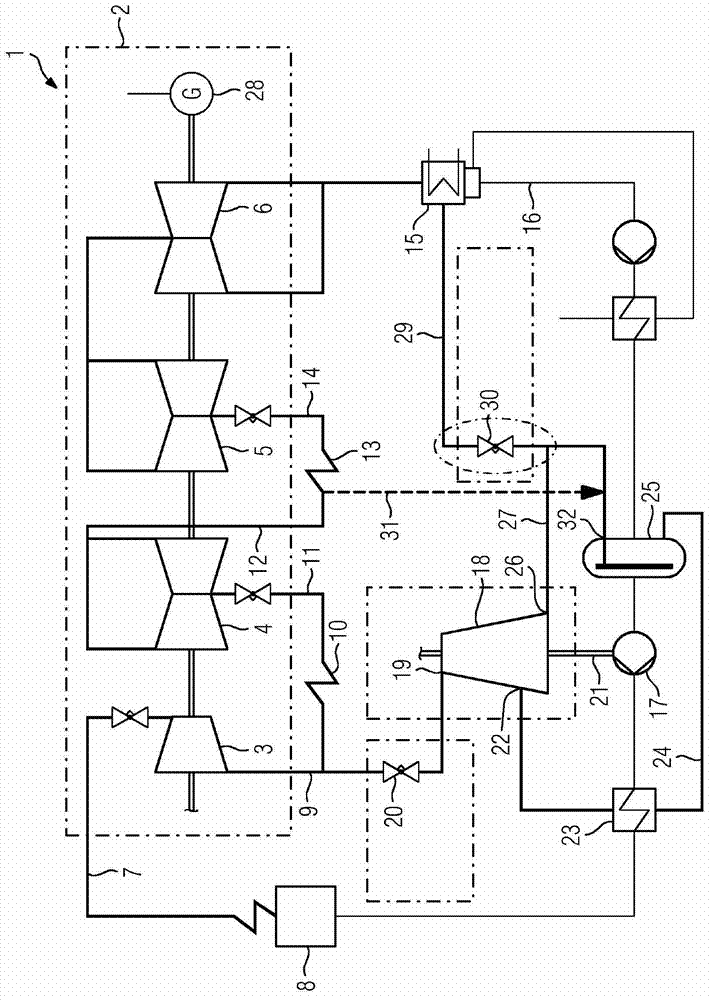

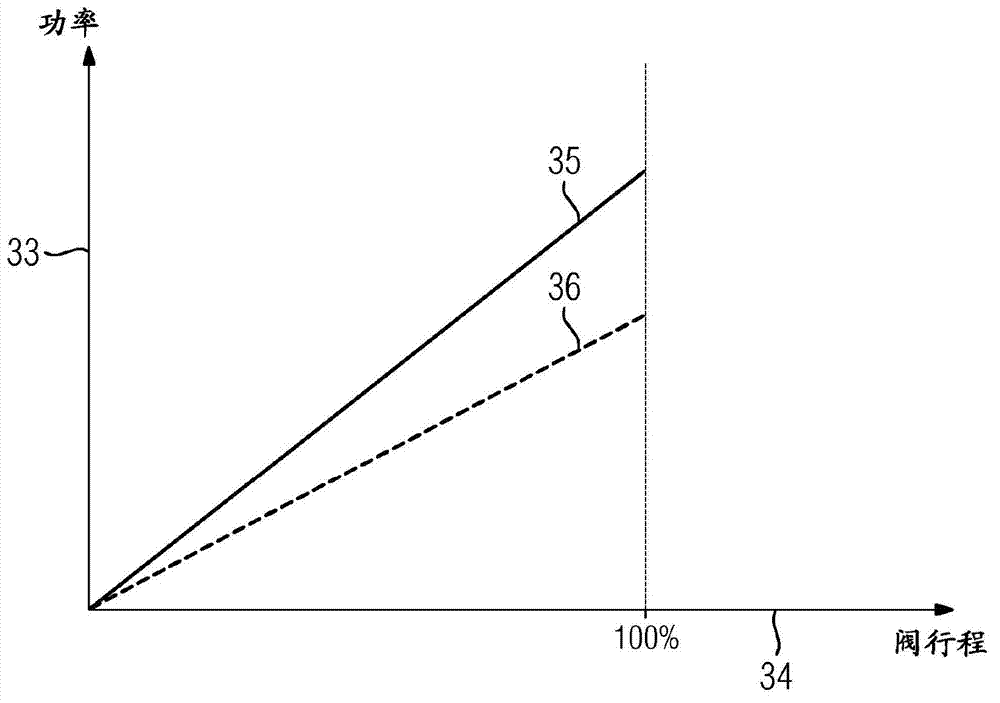

Steam power plant comprising a tuning turbine

The invention relates to a steam power plant (1) having a feed pump drive turbine (18) which at the outlet side is connected additionally to a main condenser (15).

Owner:SIEMENS AG

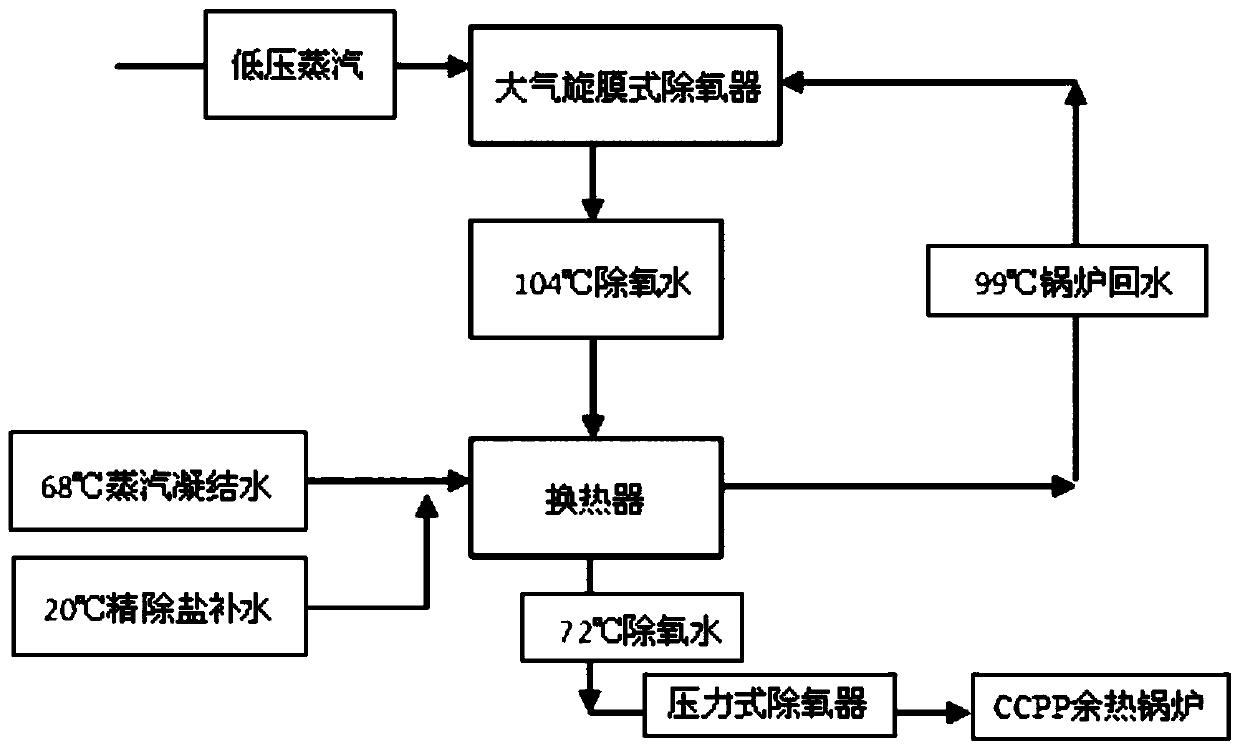

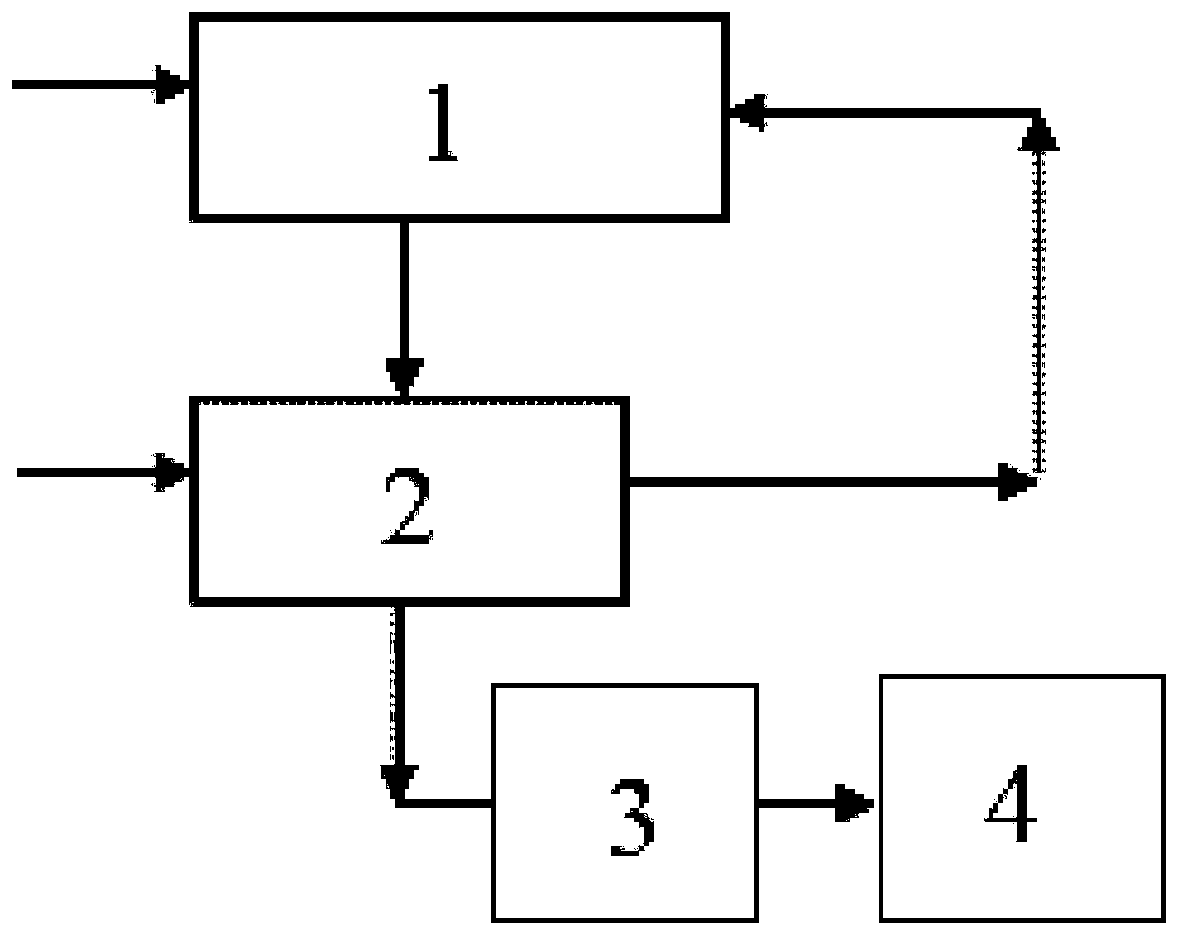

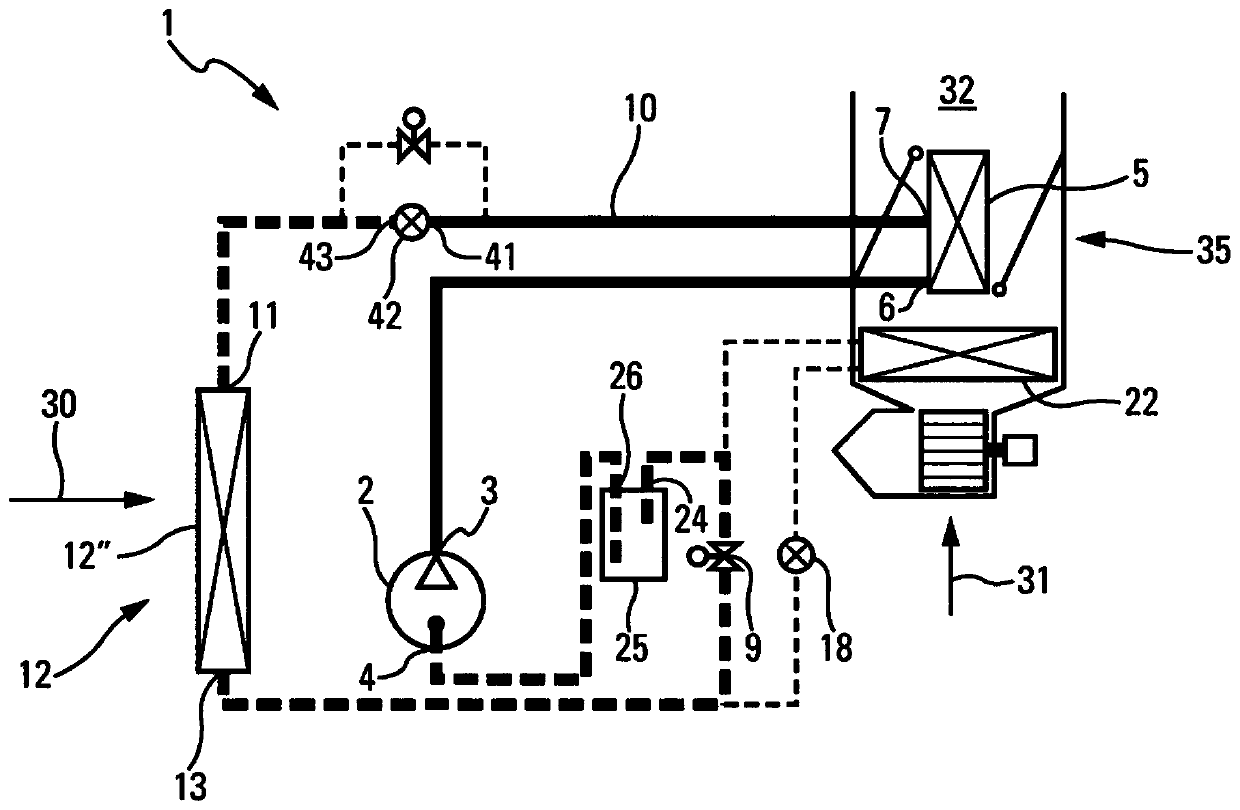

Method and device for reducing feedwater dissolved oxygen of CCPP waste heat boiler

InactiveCN110726133AReduce consumptionEfficiency impactLiquid degasificationCombined combustion mitigationProcess engineeringDeaerator

The invention discloses a method and device for reducing feedwater dissolved oxygen of a CCPP waste heat boiler. A heat exchanger and a first deaerator are introduced on the basis of an existing pressure deaerator, boiler return water at the first temperature is heated to the second temperature through the heat exchanger, the boiler return water at the second temperature is pre-deoxidized throughthe first deaerator, the first deaerator heats and pre-deoxidizes the boiler return water through low-pressure steam, and thus dissolved oxygen of the boiler return water is reduced to meet the process requirement of inlet dissolved oxygen of the original pressure deaerator; deoxidized water heated and pre-deoxidized by the first deaerator serves as a heating medium of the heat exchanger, the deoxidized water is subjected to heat exchanging with the boiler return water at the first temperature through the heat exchanger, the boiler return water at the first temperature is heated, and thus theconsumption of the low-temperature steam of the first deaerator is greatly decreased; meanwhile the inlet temperature of the pressure deaerator is lowered, no influence on the heat balance of a wasteheat boiler system and the efficiency of a turbine system is caused, and the balance of the whole-system heat load is prevented from being broken.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

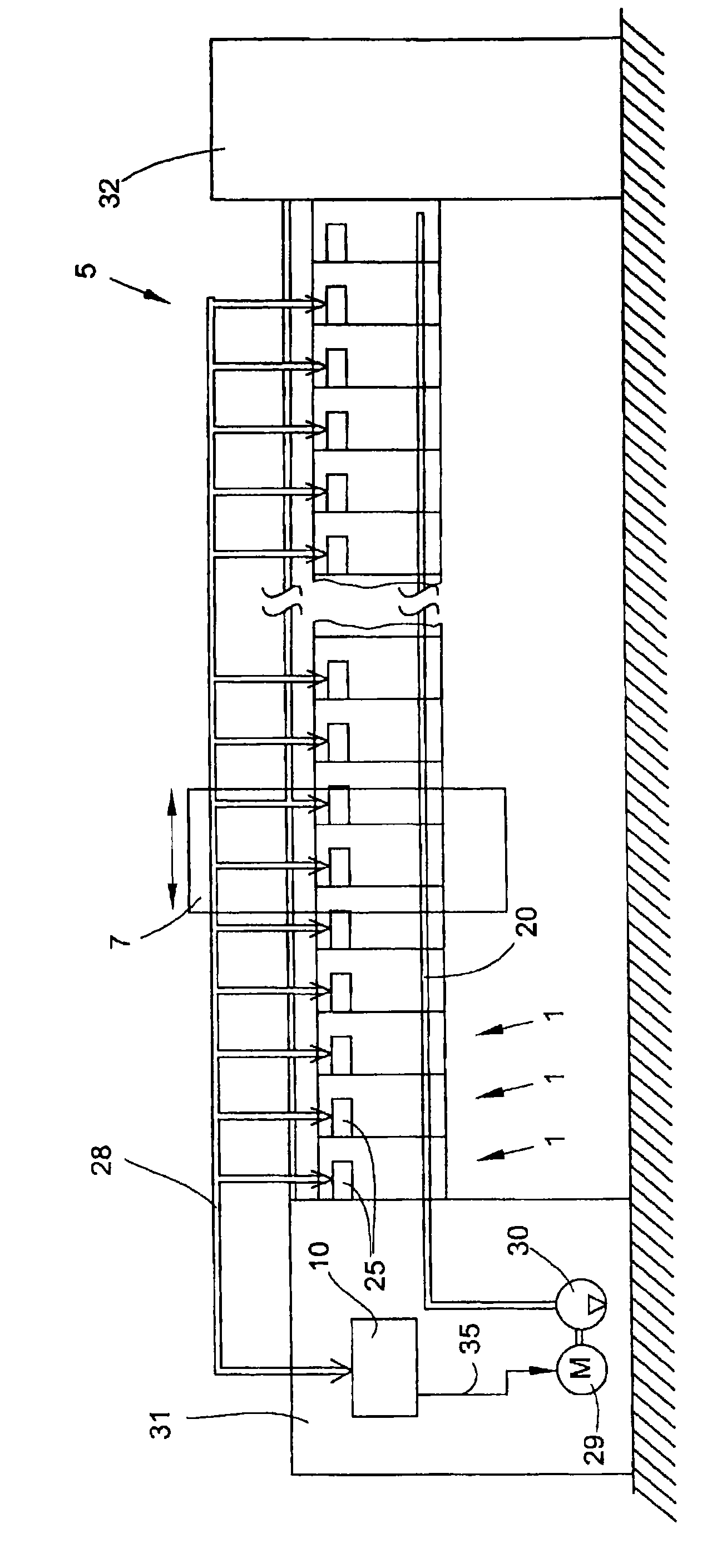

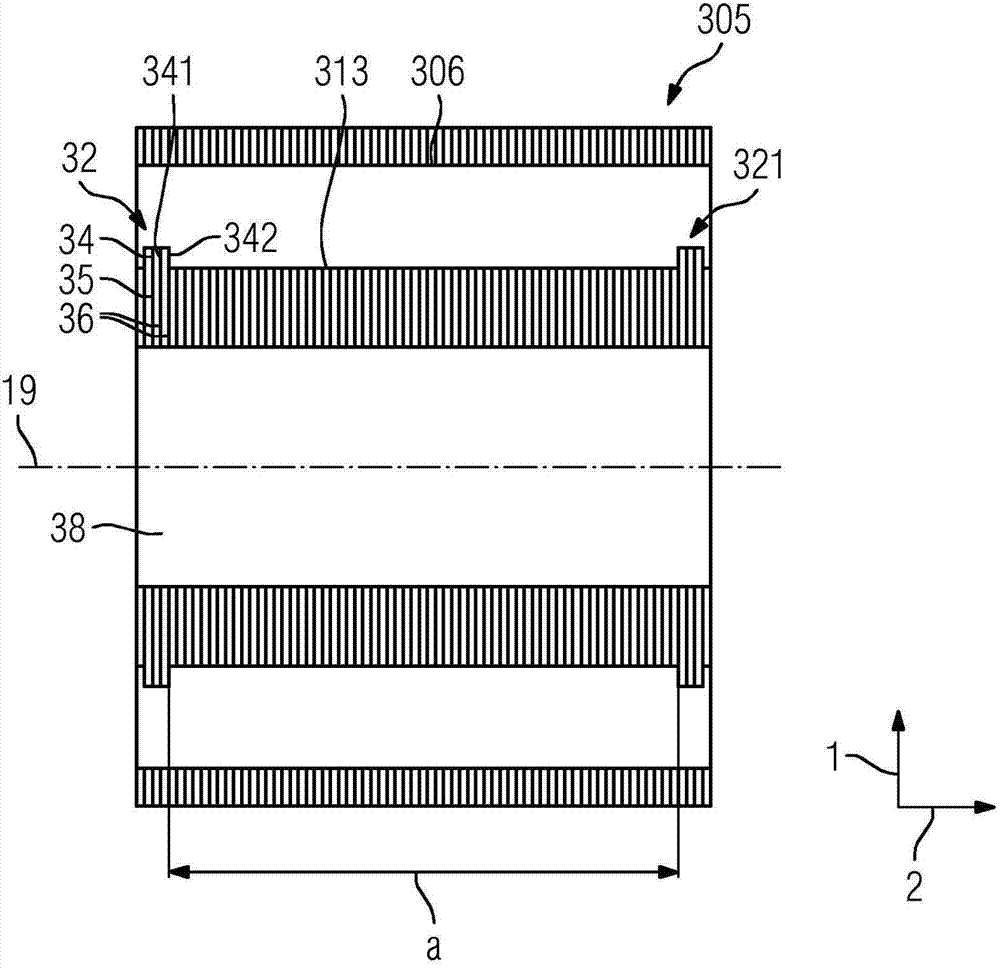

Method and apparatus for operating a textile machine which produces crosswound bobbins

ActiveCN101528574AEfficiency impactRaise priorityFilament handlingContinuous wound-up machinesBobbinWorkstation

The invention relates to a method and an apparatus for operating a textile machine which produces crosswound bobbins, in particular for the distribution as required of vacuum which is provided by a vacuum system of the textile machine to workstations of the textile machine which require vacuum, wherein a central control unit of the textile machine ensures that the vacuum in the vacuum system does not undershoot a defined minimum level. There is provision according to the invention for vacuum requirements (UD) of the workstations (1) which arrive in the central control unit (10) of the textile machine (5) to be distinguished according to at least one first priority class (I) and one second priority class (II), wherein vacuum requirements (UD) which are categorized in the first priority class (I) are always processed with preference.

Owner:SAURER GERMANY GMBH & CO KG

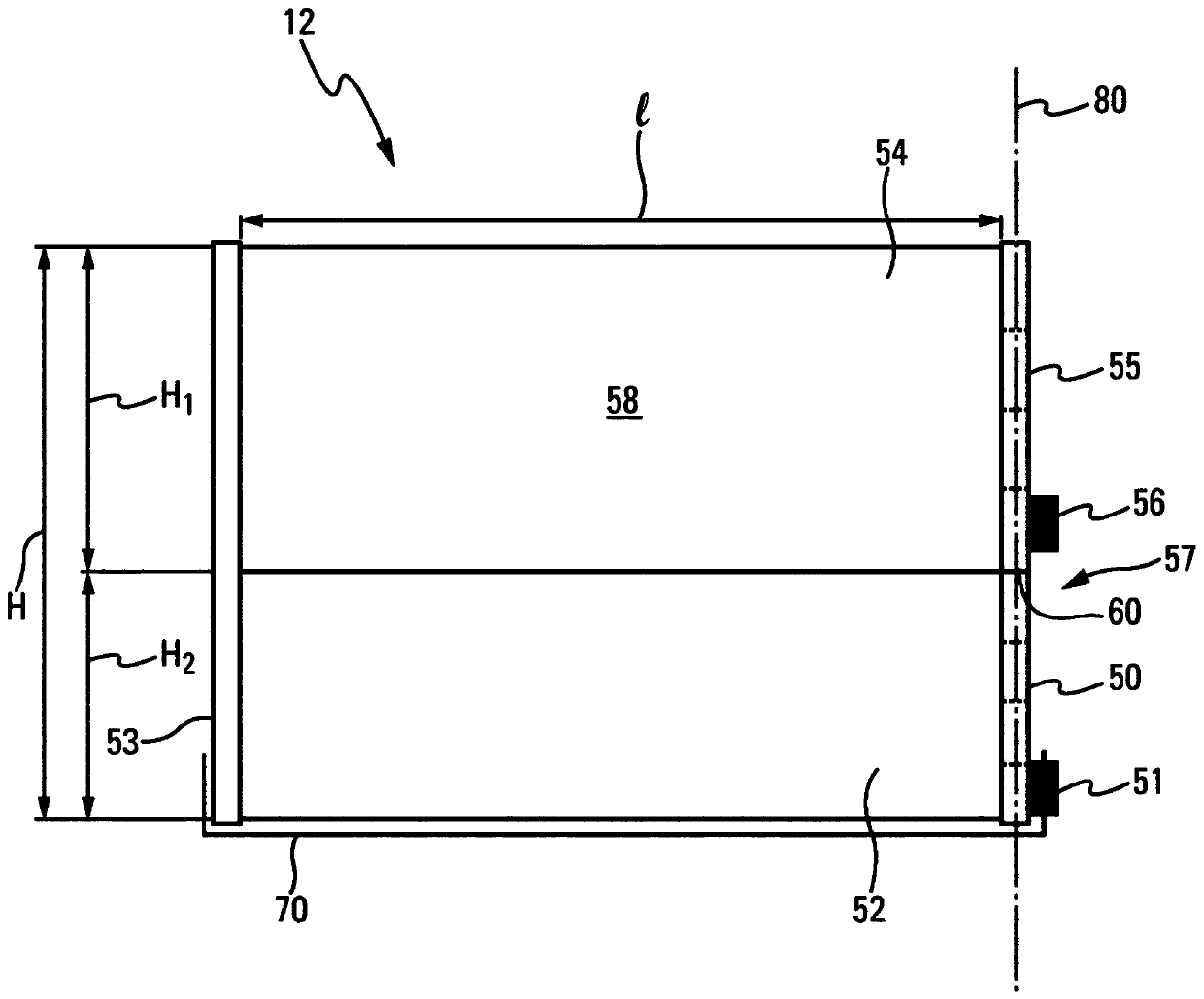

Assembly including a heat exchanger and a mounting on which said exchanger is mounted

InactiveCN110849171AOptimize allocationIncrease mass flowAir-treating devicesVehicle heating/cooling devicesVertical planeEngineering

The invention relates to an assembly including a heat exchanger (12) and a mounting (70) on which said exchanger (12) is mounted, said exchanger (12) including a first channel (52) for circulating a coolant supplied by a first collector (50) provided with a first pipe (51) in which the coolant can circulate, and a second channel (54) for circulating the coolant supplied by a second collector (55)provided with a second pipe (56) in which the coolant can circulate, the first and second channels (52, 54) defining a heat-exchange surface (58) that extends in a substantially vertical plane. According to the invention, the first pipe (51) is located in the lower half of the first collector (50) along a first axis (80) parallel to the plane of the heat-exchange surface (58), the second pipe (56)being located above the first pipe (51) along the first axis (80). The invention further relates to an air-conditioning loop including the above-described assembly.

Owner:VALEO SYST THERMIQUES

Organic compound and electronic element using organic compound and electronic device

ActiveCN113754641AImprove mobilityIncrease polarityGroup 4/14 element organic compoundsOrganic chemistry methodsSimple Organic CompoundsElectron transporting layer

The invention relates to an organic compound, the organic compound has a structure as shown in the following formula (1), in the formula (1), R1 and R2 are the same or different from each other and are respectively and independently a substituted or unsubstituted alkyl group with 1-4 carbon atoms and a substituted or unsubstituted phenyl group; each Y is the same or different and independently has a structure represented by formula (2), X1, X2, X3, X4 and X5 are the same or different and independently are CR4 or N, and at least one of X1, X2, X3, X4 and X5 is N; m is selected from 1 or 2; n is selected from 1 or 2. The organic compound can be used as a hole blocking layer or an electron transport layer of an organic electroluminescent device.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

Cage rotor comprising a deformable bearing

ActiveCN104769822AManufacturing does not affectReduce imbalanceWindingsMagnetic circuit rotating partsEngineeringMechanical engineering

Owner:SIEMENS AG

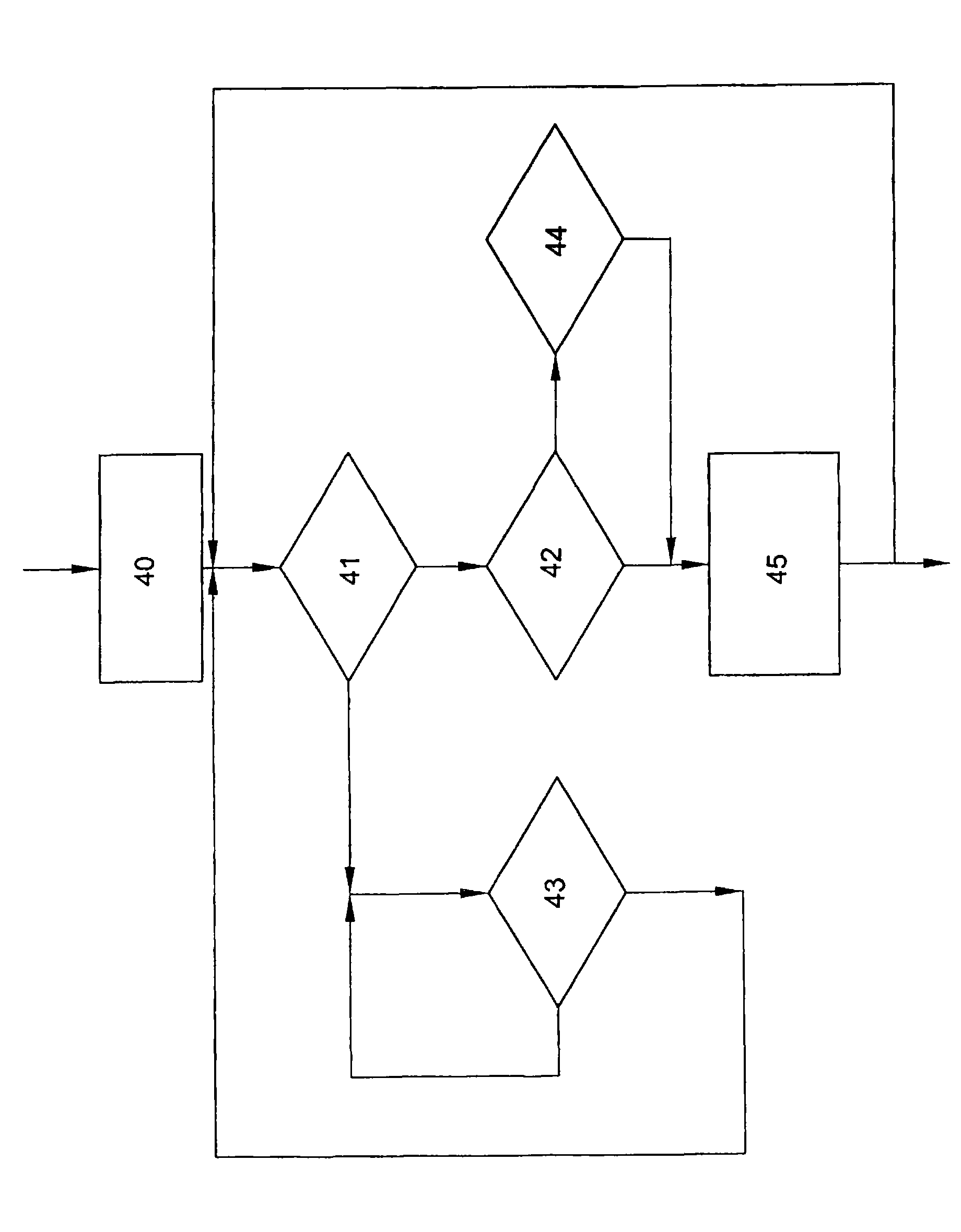

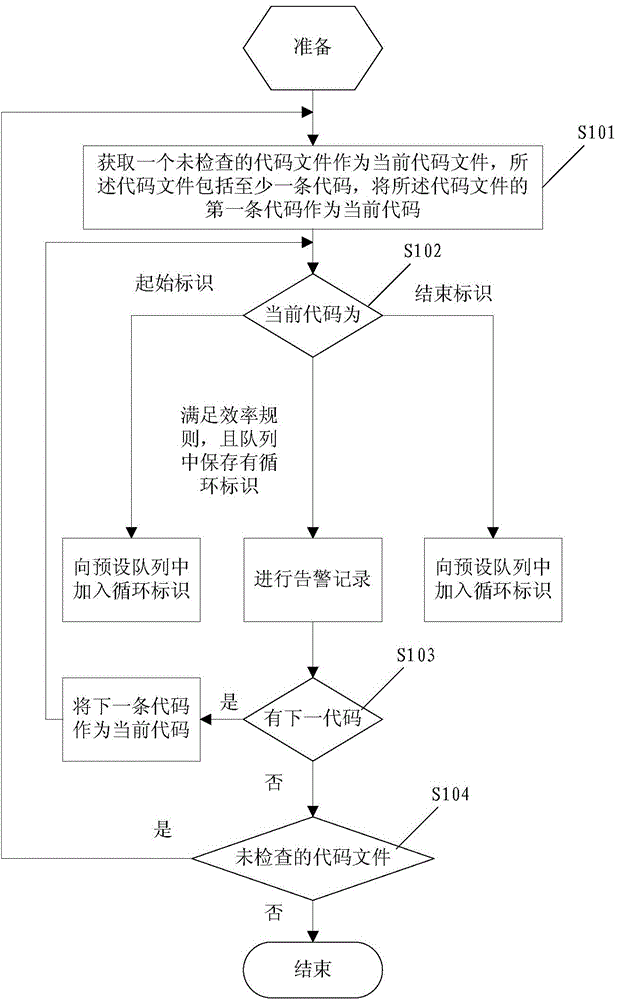

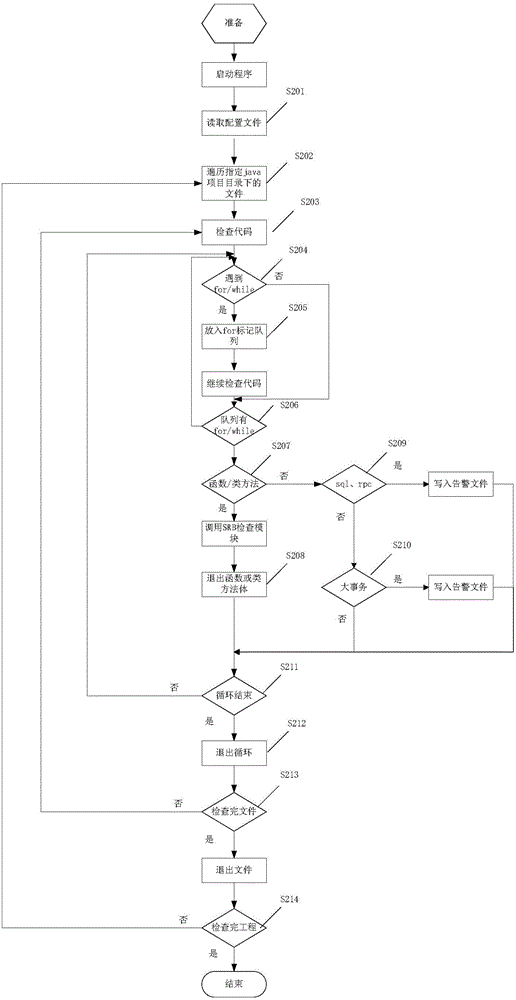

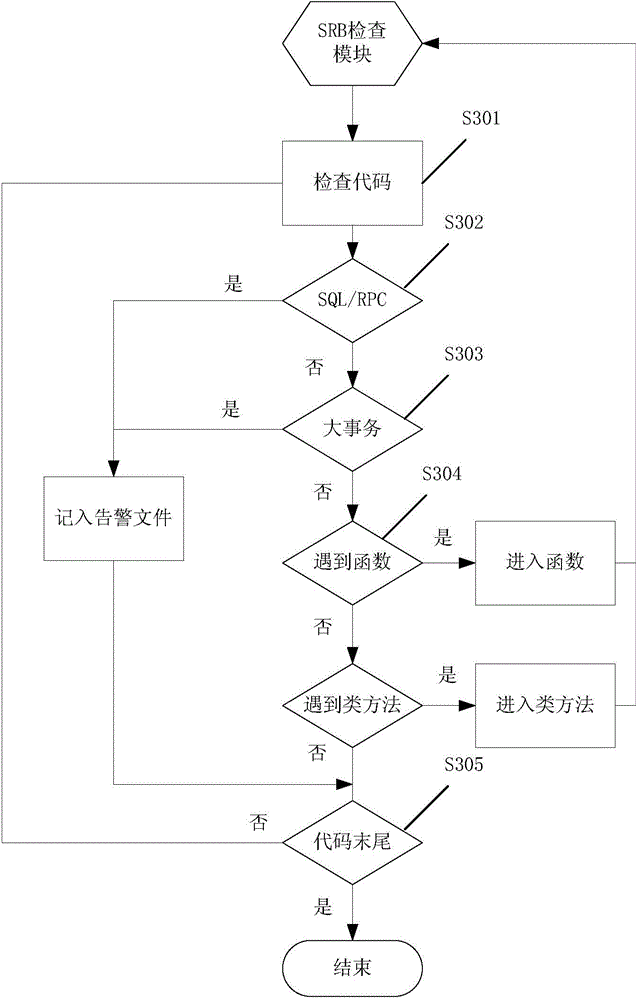

Code efficiency inspection method and code efficiency inspection system

The invention discloses a code efficiency inspection method and code efficiency inspection system. The method includes the following steps: an uninspected code file is obtained as a current code file, and a first code of the code file is adopted as a current code; the current code is inspected: if the current code is an initial identifier of a loop paragraph, then a loop identifier is added into a preset queue; if the current code meets a preset efficiency rule and the loop identifier is still stored in the queue, then alarm logging is carried out; if the current code is an ending identifier of the loop paragraph, then the loop identifier is removed from the queue; if the code file also has a next code, then the next code is adopted as a current code, or else the current code file is set as an inspected code file; if an uninspected code file exists, then the code file is obtained, or else the method is completed. The method can find out codes severely affecting efficiency by scanning codes.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

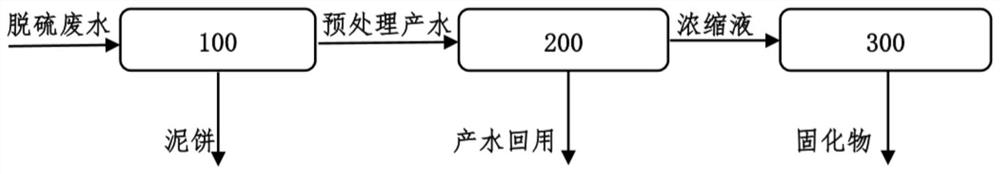

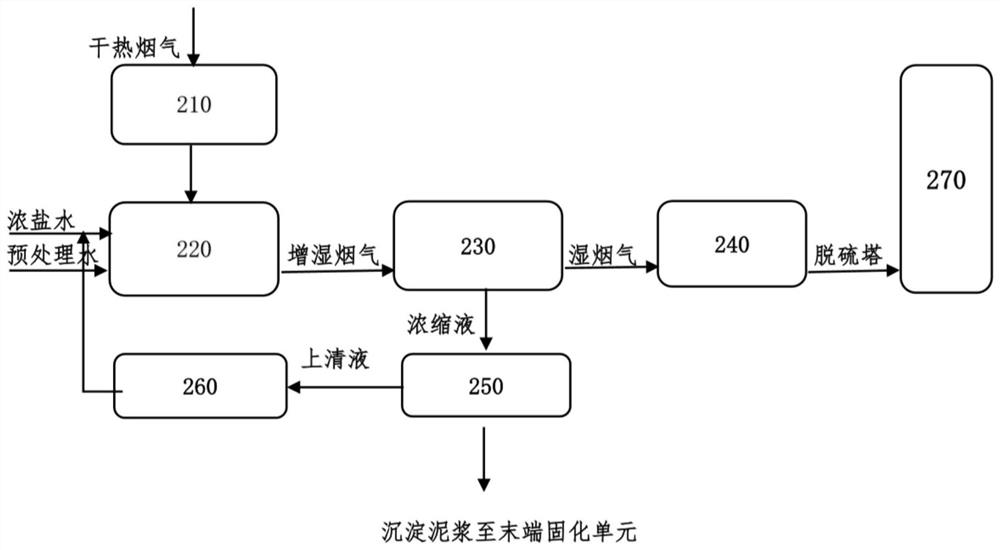

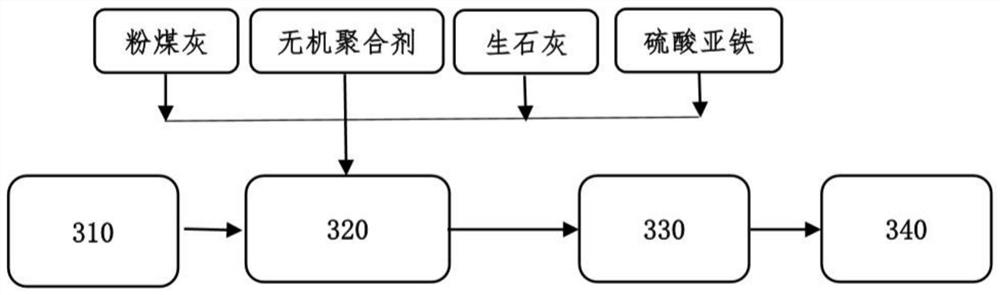

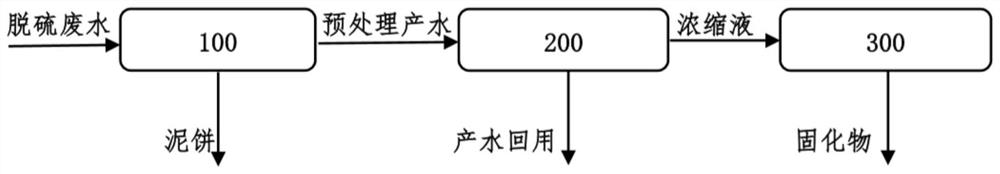

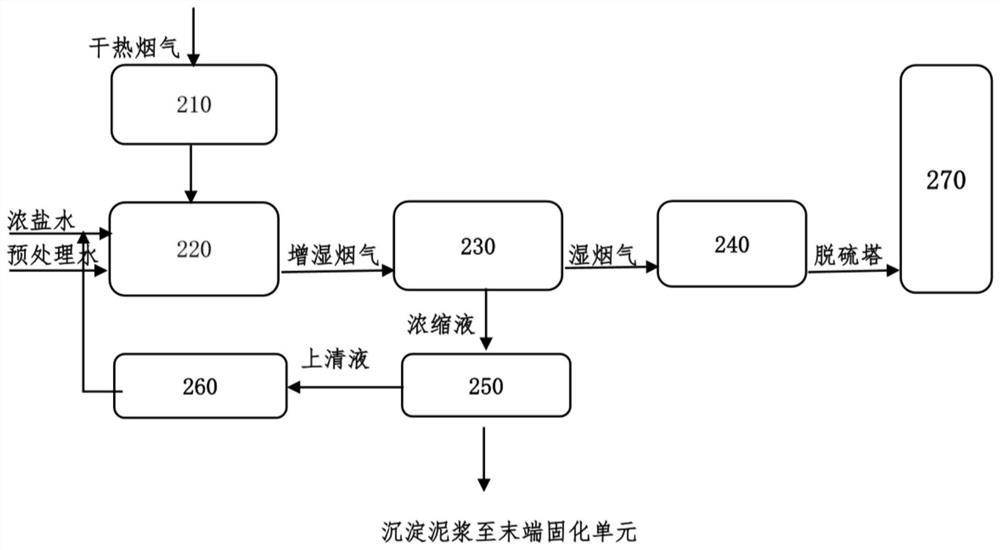

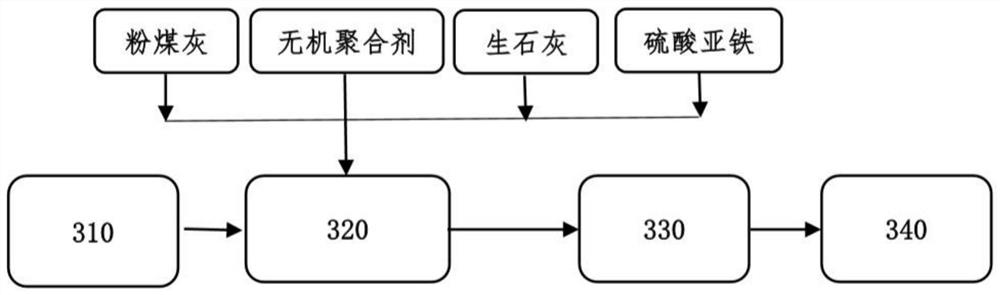

Zero discharge system for high-efficiency low-cost desulfurization wastewater treatment of coal-fired power plant

ActiveCN111892218ASimple crafting systemLow operation and maintenance costsWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSulfideWater treatment

The invention relates to the field of wastewater treatment, in particular to a zero discharge system for high-efficiency low-cost desulfurization wastewater treatment of a coal-fired power plant. Thezero discharge system comprises a pretreatment unit, a concentration reduction unit and a tail end curing unit, the pretreatment unit is used for removing suspended matters, fluoride, sulfide and heavy metal ions in the wastewater through flocculation reaction, reducing chemical oxygen consumption and ammonia nitrogen and effectively adjusting the pH value; pretreated water of the pretreatment unit is treated by the concentration reduction unit in a direct contact type thermal concentration mode, obtained wet flue gas enters a desulfurizing tower to be treated, obtained precipitated mud entersa tail end solidification unit, and obtained mud supernatant strong brine circularly enters the concentration reduction unit to be treated; after mixing of a tail end curing unit precipitated slurrywith fly ash, quick lime, ferrous sulfate and an inorganic polymerizing agent, a low-grade building material if formed. Flue gas waste heat is used for concentrating desulfurization wastewater, the inlet flue gas temperature of the desulfurization tower is reduced, and the evaporation water consumption of the desulfurization tower is reduced; the wastewater recovery rate is high, and the water-saving purpose is achieved.

Owner:张建东

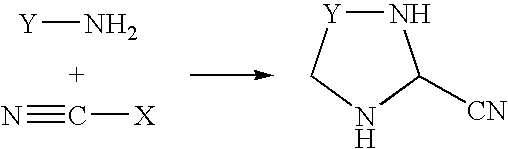

Process for the preparation of cyano-substituted-nitrogen-containing heteroaryl compounds

Owner:AMPAC FINE CHEM

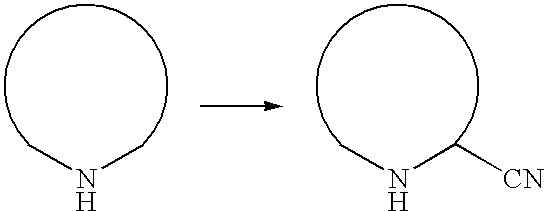

Power circuit, power recovery control circuit and method

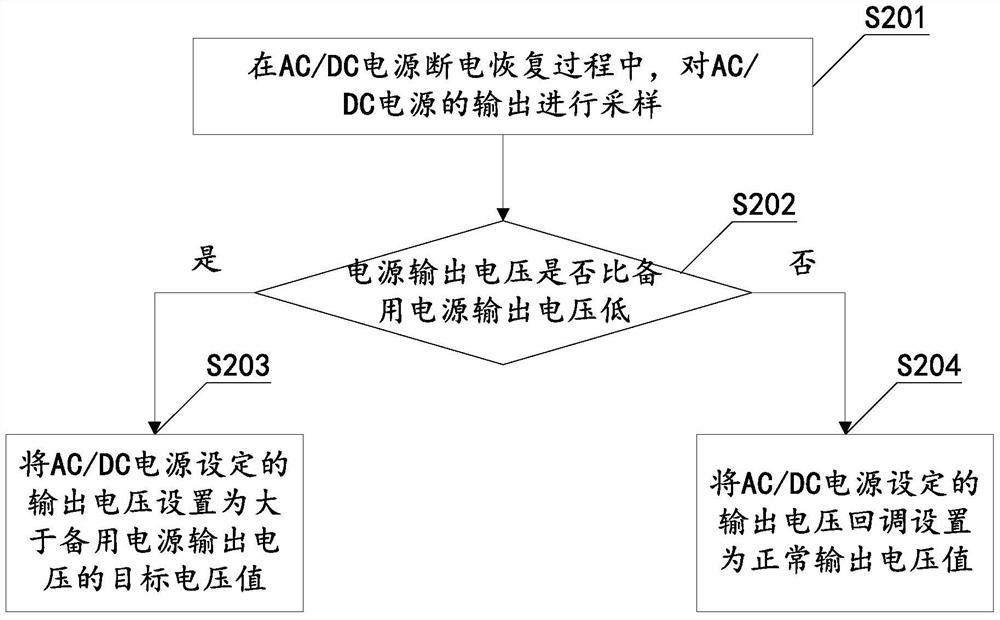

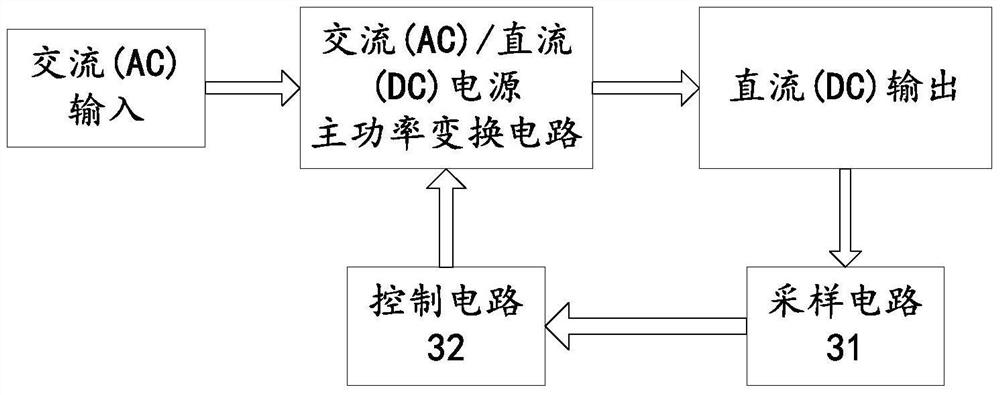

ActiveCN107546838BEfficiency has no significant effectEfficiency impactBatteries circuit arrangementsEmergency power supply arrangementsElectrical batteryHemt circuits

The invention discloses a power supply circuit, a power supply recovery control circuit and a method. A sampling circuit of the power supply recovery control circuit samples the output of the AC / DC power supply during the AC / DC power failure recovery process, and the power supply recovery control circuit controls the power supply recovery control circuit. When the circuit judges that the output voltage of the AC / DC power supply is lower than the output voltage of the current backup power supply according to the sampling result, the output voltage set by the AC / DC power supply is set to a target voltage value greater than the output voltage of the backup power supply (such as a battery). In this way, it can ensure that the output voltage Vout of the power supply is established normally after a short-term power failure of the system, thereby realizing the seamless switching between the backup battery and the AC / DC power supply to the power supply of the system during the recovery process of the AC / DC power failure. Compared with the existing oring circuit control method, the solution provided by the embodiment of the present invention is simpler, the cost is relatively lower, and the efficiency of the power supply is not significantly affected.

Owner:ZTE CORP

A zero-discharge system for high-efficiency and low-cost desulfurization wastewater treatment in coal-fired power plants

ActiveCN111892218BSimple crafting systemLow operation and maintenance costsWaste water treatment from gaseous effluentsMultistage water/sewage treatmentIron sulphateSlurry

The invention relates to the field of waste water treatment, in particular to a zero-emission system for high-efficiency and low-cost desulfurization waste water treatment in coal-fired power plants. It consists of a pretreatment unit, a concentration reduction unit and a terminal solidification unit; the pretreatment unit removes suspended solids, fluoride, sulfide, and heavy metal ions in wastewater through flocculation, reduces chemical oxygen consumption and ammonia nitrogen, and effectively adjusts pH value; the pretreatment water of the pretreatment unit is processed by the direct contact thermal concentration method through the concentration reduction unit, and the wet flue gas obtained enters the desulfurization tower for treatment, and the obtained sedimentation mud enters the terminal solidification unit, and the supernatant brine of the obtained mud The circulation enters the concentration reduction unit for treatment; the sedimentation mud in the terminal solidification unit is mixed with fly ash, quicklime, ferrous sulfate and inorganic polymerizer to form low-grade building materials. Use the waste heat of flue gas to concentrate the desulfurization wastewater, reduce the temperature of the flue gas at the inlet of the desulfurization tower, and reduce the evaporation water consumption of the desulfurization tower; the recovery rate of wastewater is high, and the purpose of water saving is achieved.

Owner:张建东

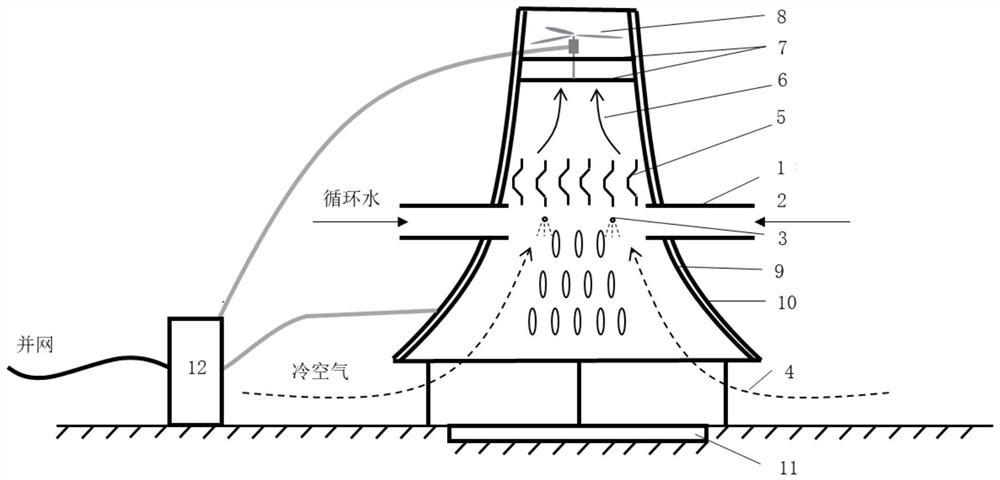

Wind-solar coupled water cooling tower of thermal power station and working method therefor

PendingCN112595140AAchieve coolingRealize multi-level utilizationWind motor with solar radiationMachines/enginesElectrical batteryNew energy

The invention discloses a wind-solar coupled water cooling tower of a thermal power station and a working method therefor, and belongs to the technical field of energy power generation. A water cooling tower body is in a double-curve shape; a spraying device is arranged in the middle of the water cooling tower body and faces the lower portion inside the water cooling tower body; one end of a circulating water pipeline is connected with the spraying device, and the other end is connected with a circulating water system; a support frame is arranged at the throat portion of the water cooling tower body; a wind generating set is arranged on the support frame, and the windward side of a blade of the wind generating set faces downwards; a water removal device is arranged between the spraying device and the wind generating set; a reservoir is arranged at the bottom of the water cooling tower body; a solar film battery is arranged on the outer wall of the water cooling tower body; and the windgenerating set and the solar film battery are respectively connected with a grid-connected assembly through cables. On the basis of original thermal power station facilities, original resources are fully utilized, and meanwhile, new energy is developed in a coupling manner, so that economic and environmental benefits can be improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com