Screwing machine based on servo system

A servo system and tightening machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of incompetence of air guns, large noise and dust, low assembly efficiency, etc., and achieve compact size of tightening device and large reduction ratio , the effect of system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

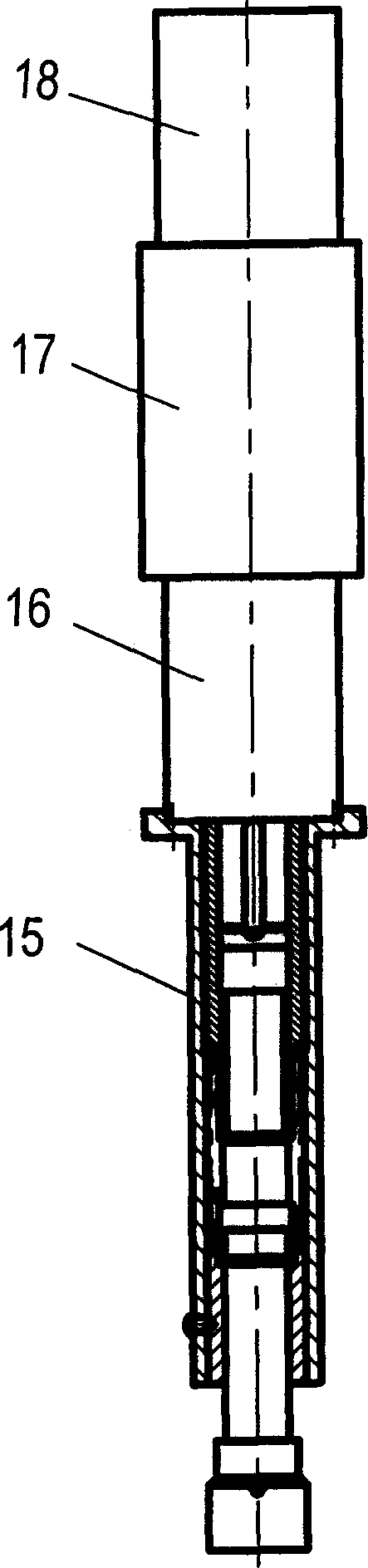

[0018] see figure 1 In this embodiment, a servo motor is used as the driving mechanism 18, and a reduction mechanism 17 and a torque sensor 16 are provided between the driving mechanism 18 and the output mechanism 15.

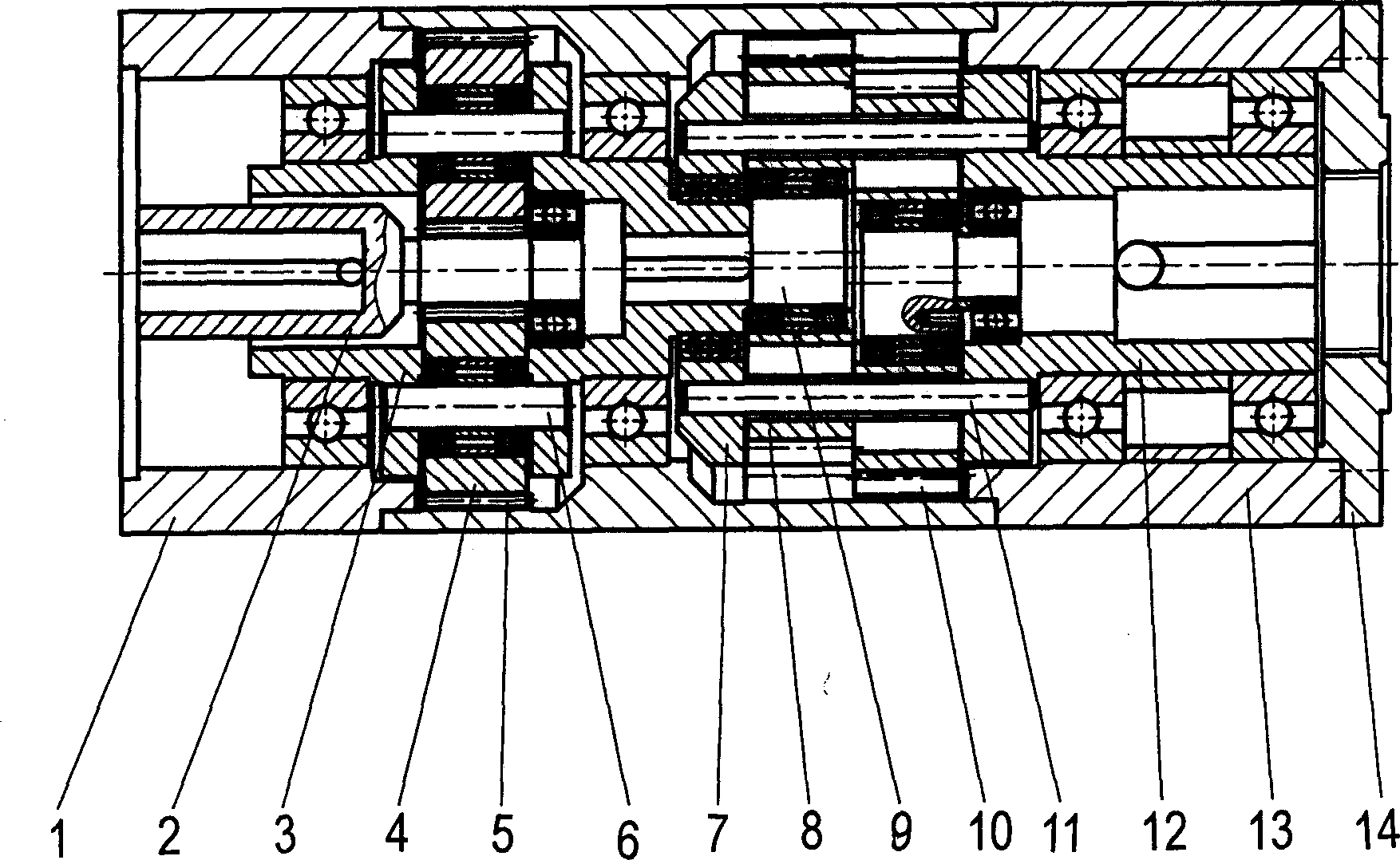

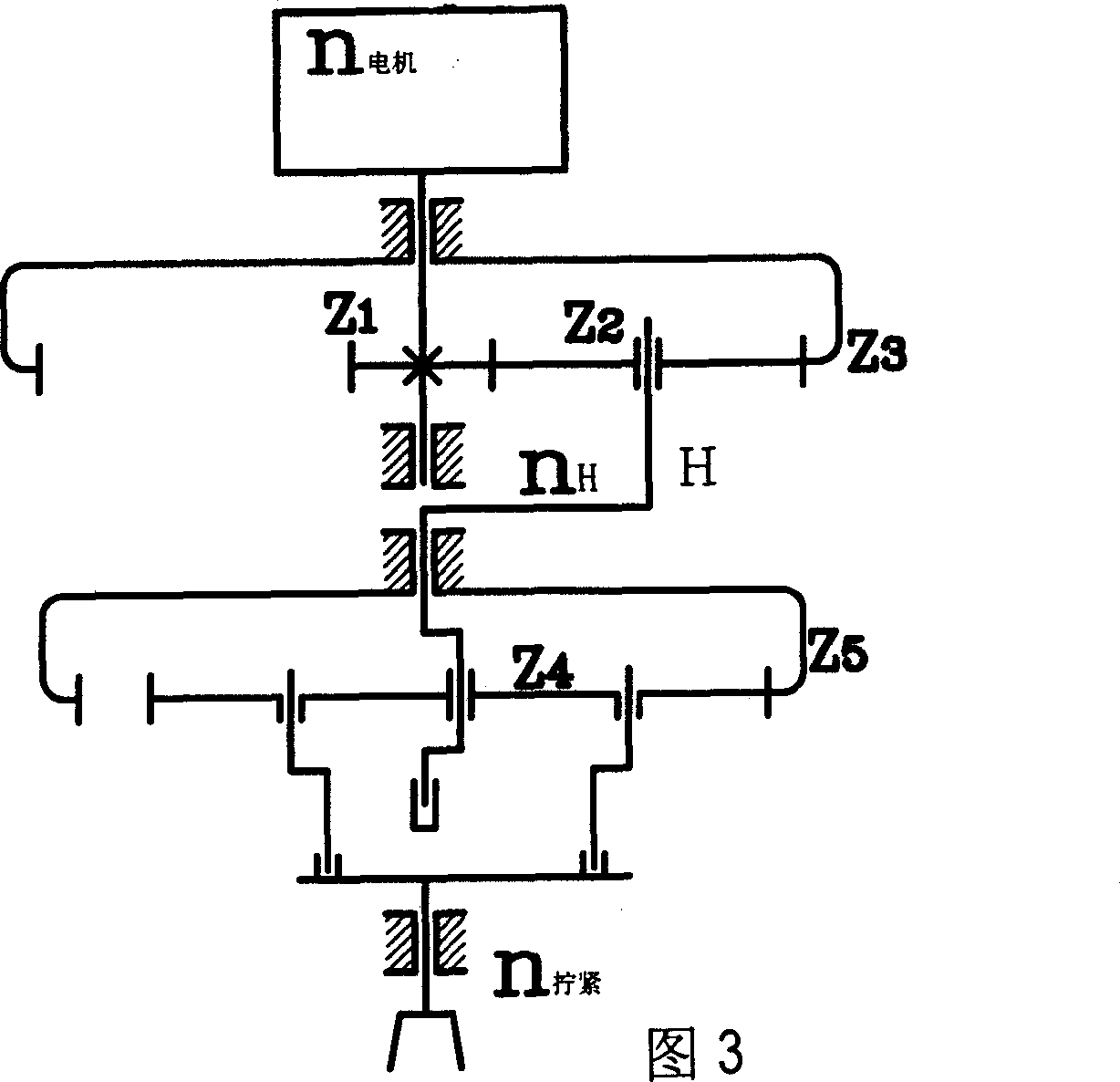

[0019] see figure 2 , Fig. 3, present embodiment deceleration mechanism adopts two-stage deceleration.

[0020] The first stage is a planetary gear train, including a sun gear 2, a planet carrier 3, three planetary gears I4, six pin shafts I6, an internal gear I5 and related bearing components. The wheel shaft of its sun gear 2 is directly connected with the motor, the planetary gear 14 meshes with the sun gear 2 and the internal gear 1, and its planet carrier 3 is output.

[0021] The second stage is transmission with less tooth difference, specifically two-tooth difference transmission, including 1 eccentric shaft 9, 1 support disc 7, 2 planetary gears II 8, 6 pin shafts II 11, and 1 internal gear II 10 and related bearing components. Wherein, the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com