Refrigerating circuit for use in a motor vehicle

A technology for refrigeration circuits and motor vehicles, which is applied in the direction of refrigerators, refrigeration components, vehicle parts, etc., and can solve problems such as increased refrigerant mass flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

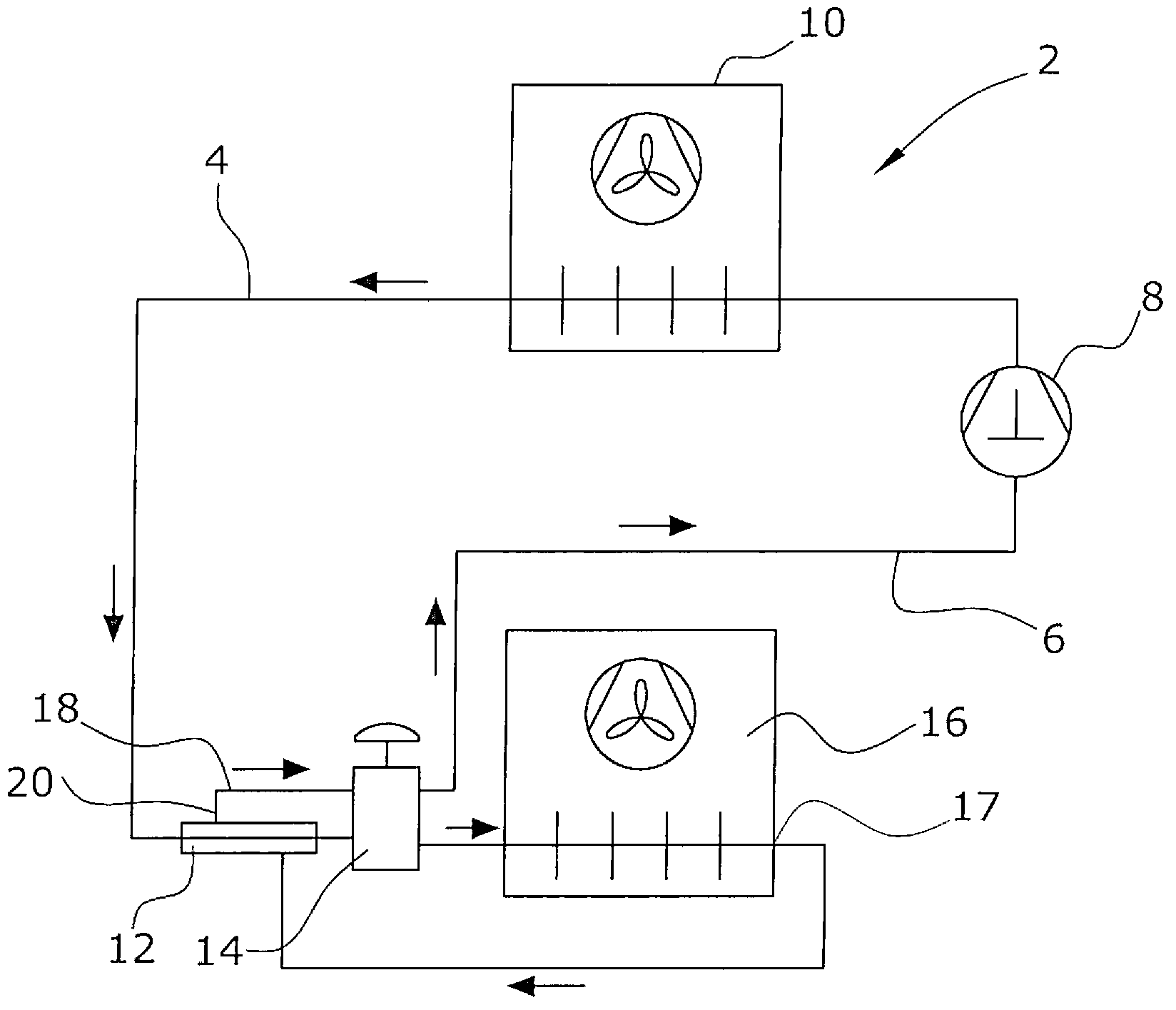

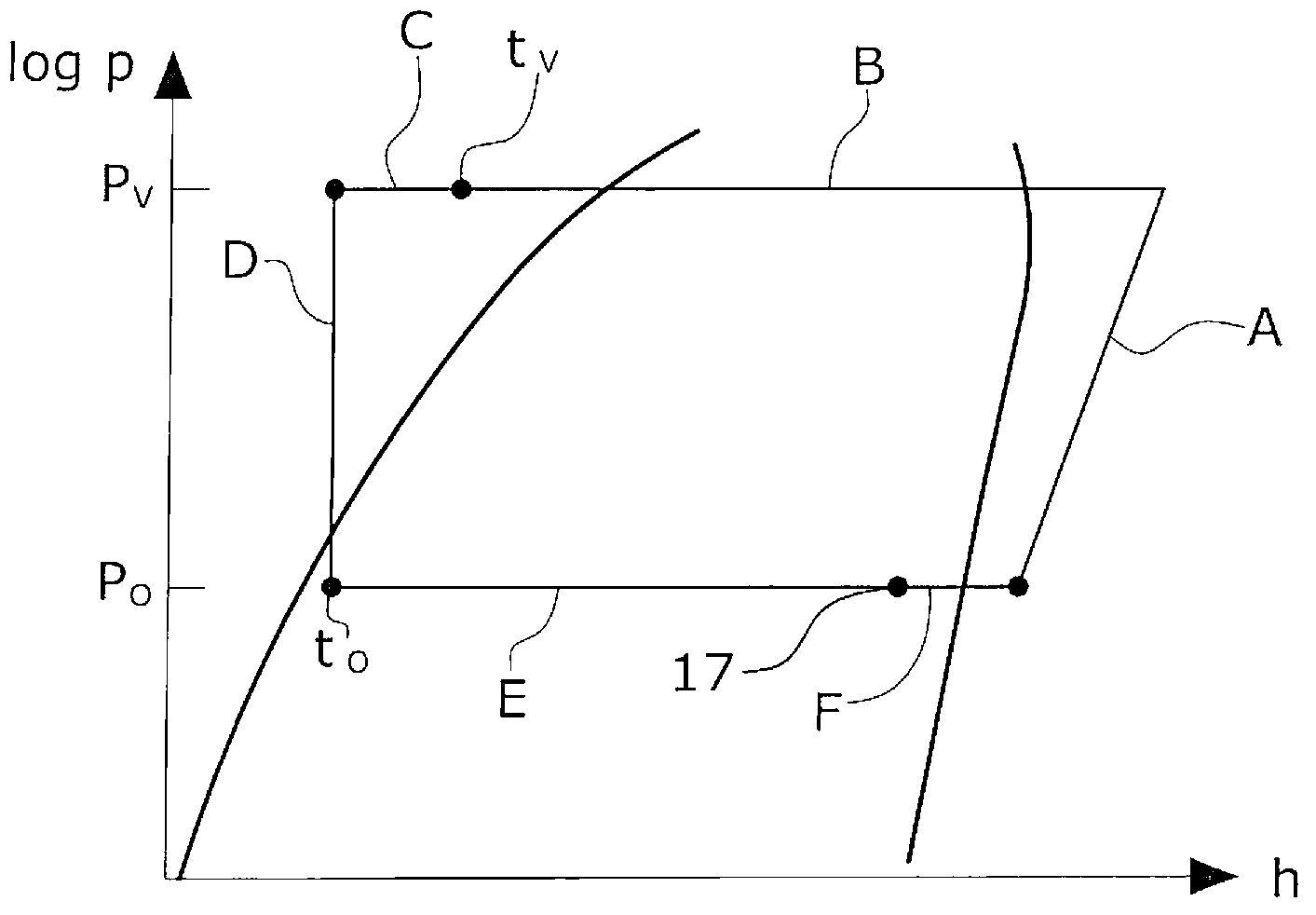

[0011] figure 1 A refrigeration circuit according to the invention is schematically shown and see now figure 2 The pressure-enthalpy diagram in is explained in more detail. The refrigeration circuit has a pressure line 4 and a suction line 6 . Pressure line 4 starts at the output of compressor 8 . Compressor 8 compresses the refrigerant to a liquefaction pressure P V , which in figure 2 is indicated by a state change A. Refrigerant at liquefaction pressure P V is transferred to the condenser 10, where the refrigerant releases heat, with the result that the refrigerant is in liquid state at the output of the condenser 10 and it has a liquefaction temperature t V . This state change in figure 2 Indicated by B.

[0012] From the condenser 10, the refrigerant is passed to the internal heat exchanger 12, in which the refrigerant in the pressure line 4 releases heat to the refrigerant in the suction line 6, which is shown by the pressure-enthalpy diagram The state chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com