Method for isolating films on two sides of substrate layer and preparing process for heterogenous junction solar cell

A technology for solar cells and preparation processes, applied in sustainable manufacturing/processing, circuits, electrical components, etc., which can solve problems affecting battery efficiency, battery leakage, and thin film contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

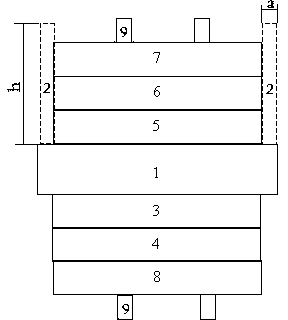

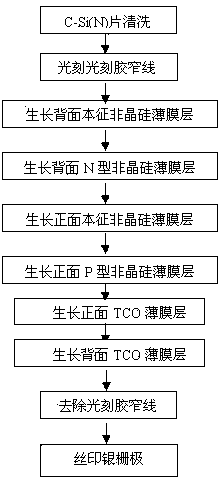

[0030] like Figure 1~2 As shown, a heterojunction solar cell preparation process, the steps of the process are as follows:

[0031] a) Using a C-Si(N) sheet as the substrate layer 1, and cleaning the substrate layer 1;

[0032] b) On the periphery of the front surface of the substrate layer 1 and near the edge of the substrate layer 1, photoresist narrow lines 2 protrude outward; wherein, the width a of the photoresist narrow lines 2 is 0-1 mm, and the height h is greater than 1 μm. Certainly, the photoresist narrow lines 2 may also be photoetched on the back side or both sides of the substrate layer 1 .

[0033] c) On the back of the substrate layer 1, the PECVD method is used to sequentially deposit and grow the back intrinsic amorphous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com