System and method for realizing machine starting denitration operation

A denitrification and steam technology, which is applied in separation methods, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems that the denitrification facilities cannot be put into operation at the start-up stage, lack of SCR inlet flue temperature adjustment means, and boiler efficiency decline, etc. , to achieve the effect of wide application range, convenient implementation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

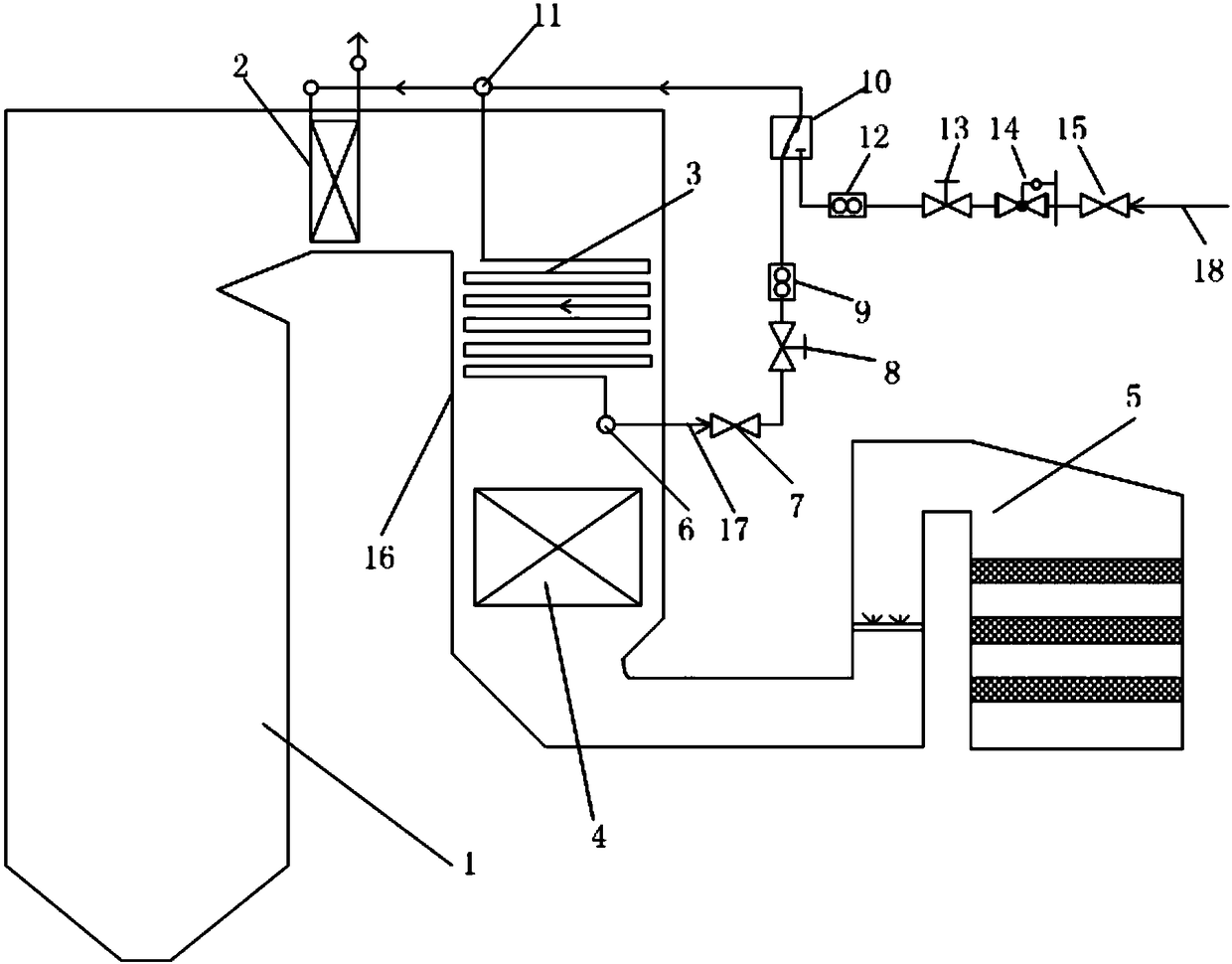

[0030] Such as figure 1 As shown, a start-up and denitrification system is put into operation, including a boiler 1, a final reheater 2, a low-temperature reheater 3, an economizer 4 and an SCR reactor 5.

[0031] A boiler flue 16 is provided on the boiler 1; in the boiler flue 16, a final reheater 2, a low-temperature reheater 3, an economizer 4 and an SCR reactor 5 are arranged in sequence according to the flow direction of the flue gas. The flue gas generated after the combustion of boiler 1 passes through the final reheater 2, low-temperature reheater 3, and economizer 4 successively. After heat release, the flue gas meets the requirements for denitrification and put into operation, and then passes through the SCR reactor 5 to reduce NO X emissions.

[0032] The final reheater 2 is a heat exchange device that uses the steam from the low-temperature reheater 3 to absorb the heat of the high-temperature flue gas generated by the combustion of the boiler 1 to reduce the temp...

Embodiment 2

[0037] According to Embodiment 1, the only difference is that on the low-temperature reheater 3, a low-temperature reheater outlet header 11 and a low-temperature reheater inlet header 6 are arranged in sequence according to the flow direction of the flue gas; The header 6 is a device for uniform distribution of steam flow, and the outlet header 11 of the low-temperature reheater is a device for mixing multiple streams of steam.

[0038] The low-temperature reheater 3 is also provided with a low-temperature reheat steam bypass pipe 17 connecting the low-temperature reheater inlet header 6 and the low-temperature reheater outlet header 11, that is, according to the direction of steam flow, the low-temperature reheater inlet Header 6, low temperature reheat steam bypass pipe 17, low temperature reheater outlet header 11.

[0039] In the present invention, the steam flow direction is opposite to the flue gas flow direction.

Embodiment 3

[0041] According to Embodiment 2, the only difference is that the low-temperature reheat steam bypass pipe 17 is provided with a bypass steam gate valve 7 . The bypass steam gate valve 7 is used to open or close the low-temperature reheat steam bypass pipe 17; when the flue gas passes through the final reheater 2, low-temperature reheater 3 and economizer 4 to cool down, the temperature of the flue gas meets the denitrification According to the requirements of commissioning, the low-temperature reheat steam bypass pipeline 17 is no longer needed at this time, and the low-temperature reheat steam bypass pipeline 17 can be closed at this time, so that steam cannot pass through the low-temperature reheat steam bypass pipeline 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com