Patents

Literature

244 results about "Coal fired power stations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coal-fired power station or coal power plant is a thermal power station which burns coal to generate electricity. Coal-fired power stations generate over a third of the world's electricity but cause hundreds of thousands of early deaths each year, mainly from air pollution.

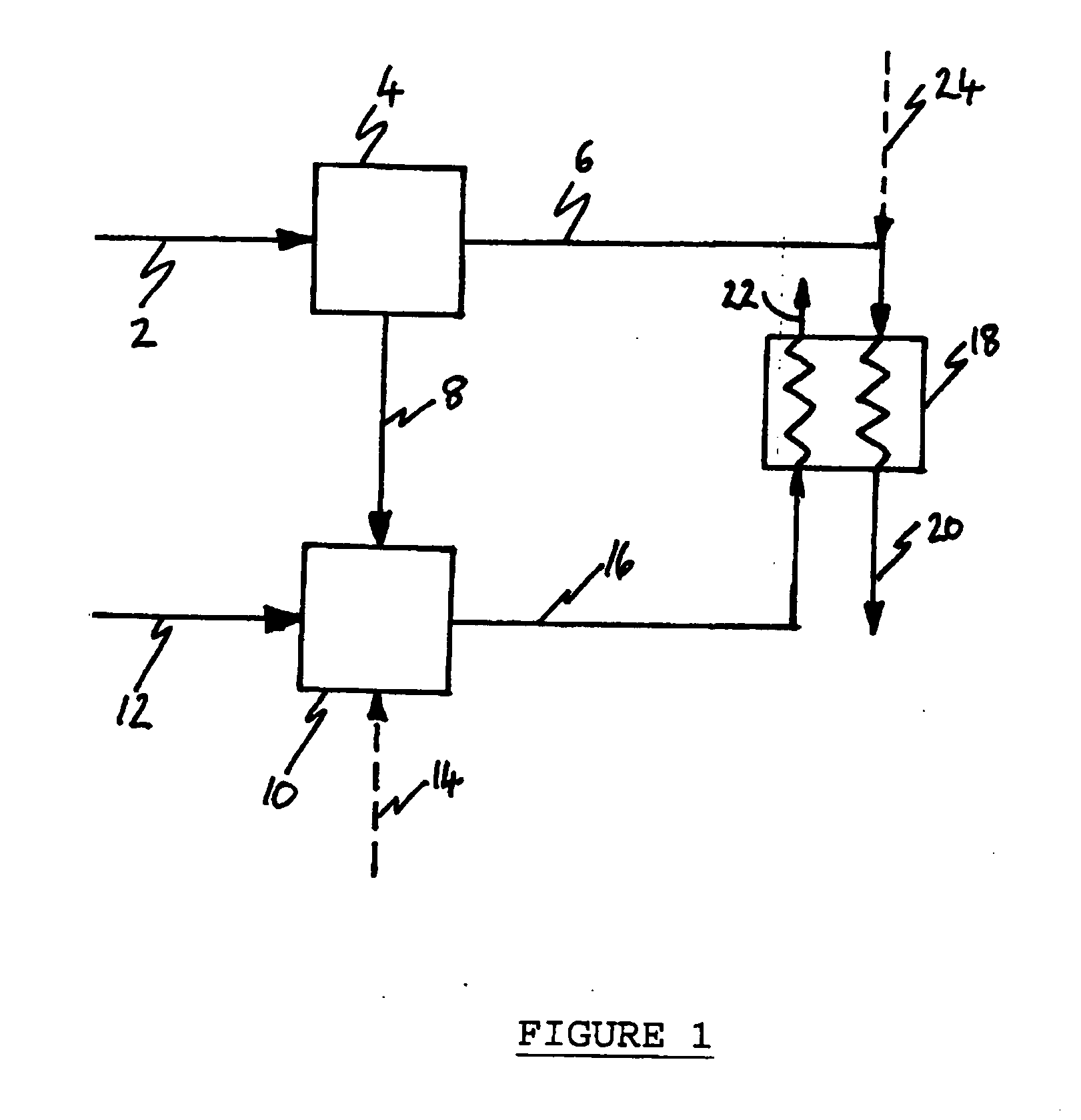

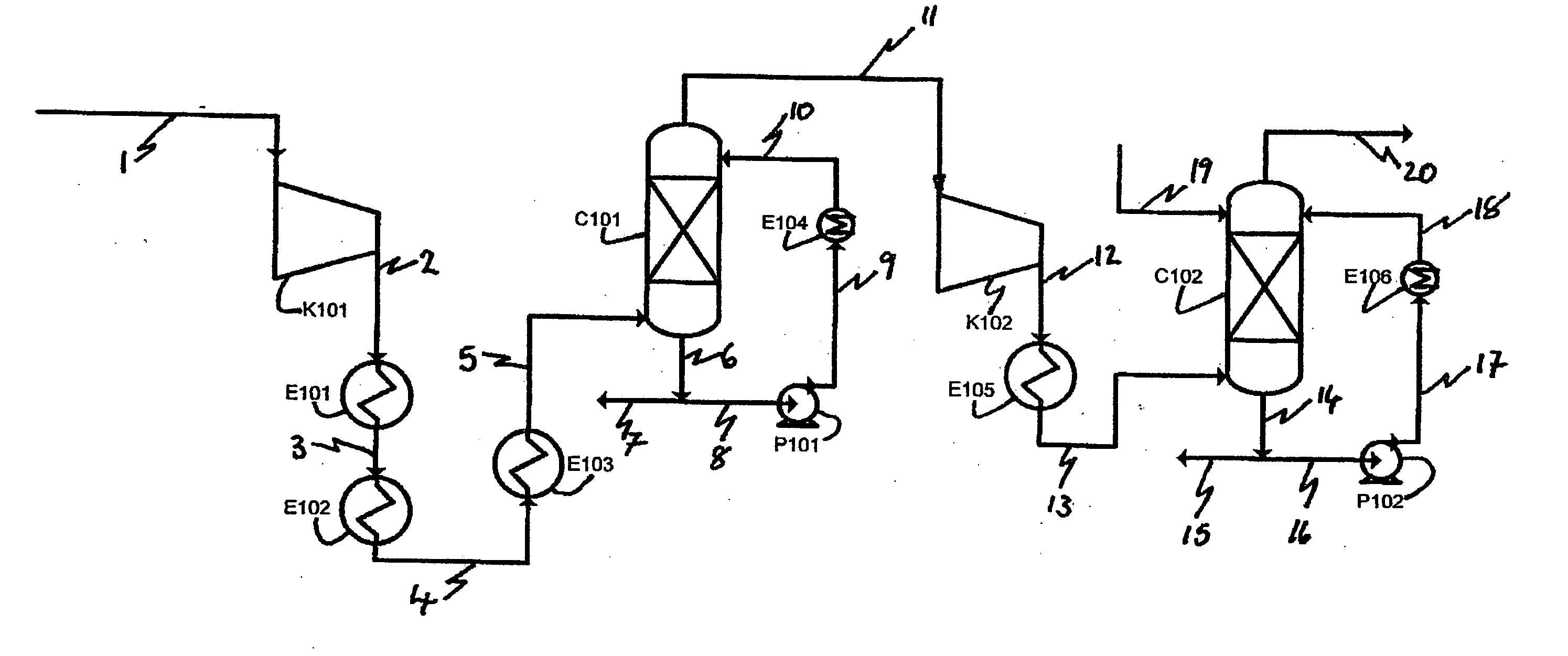

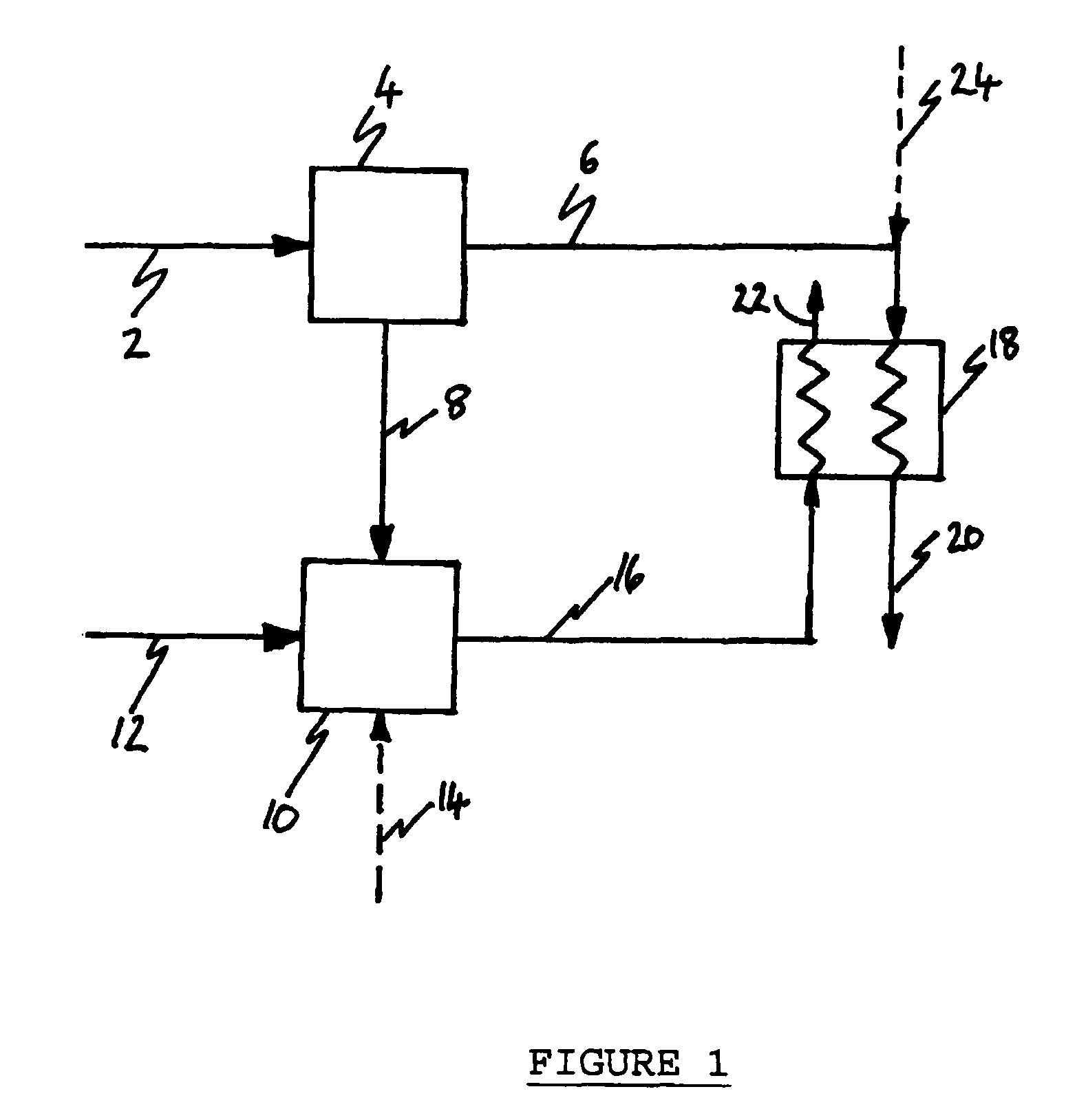

Method of treating a gaseous mixture comprising hydrogen and carbon dioxide

Hydrogen (H2) gas and crude carbon dioxide (CO2) gas are separated from a gaseous mixture thereof. Combustible gas(es) in the crude CO2 gas are combusted to produce heat, at least a portion of which is recovered by indirect heat exchange with at least a portion of the separated H2 gas or a gas derived therefrom. The invention may be integrated with coal-fired power stations to reduce or eliminate emission of harmful components into the atmosphere.

Owner:AIR PROD & CHEM INC

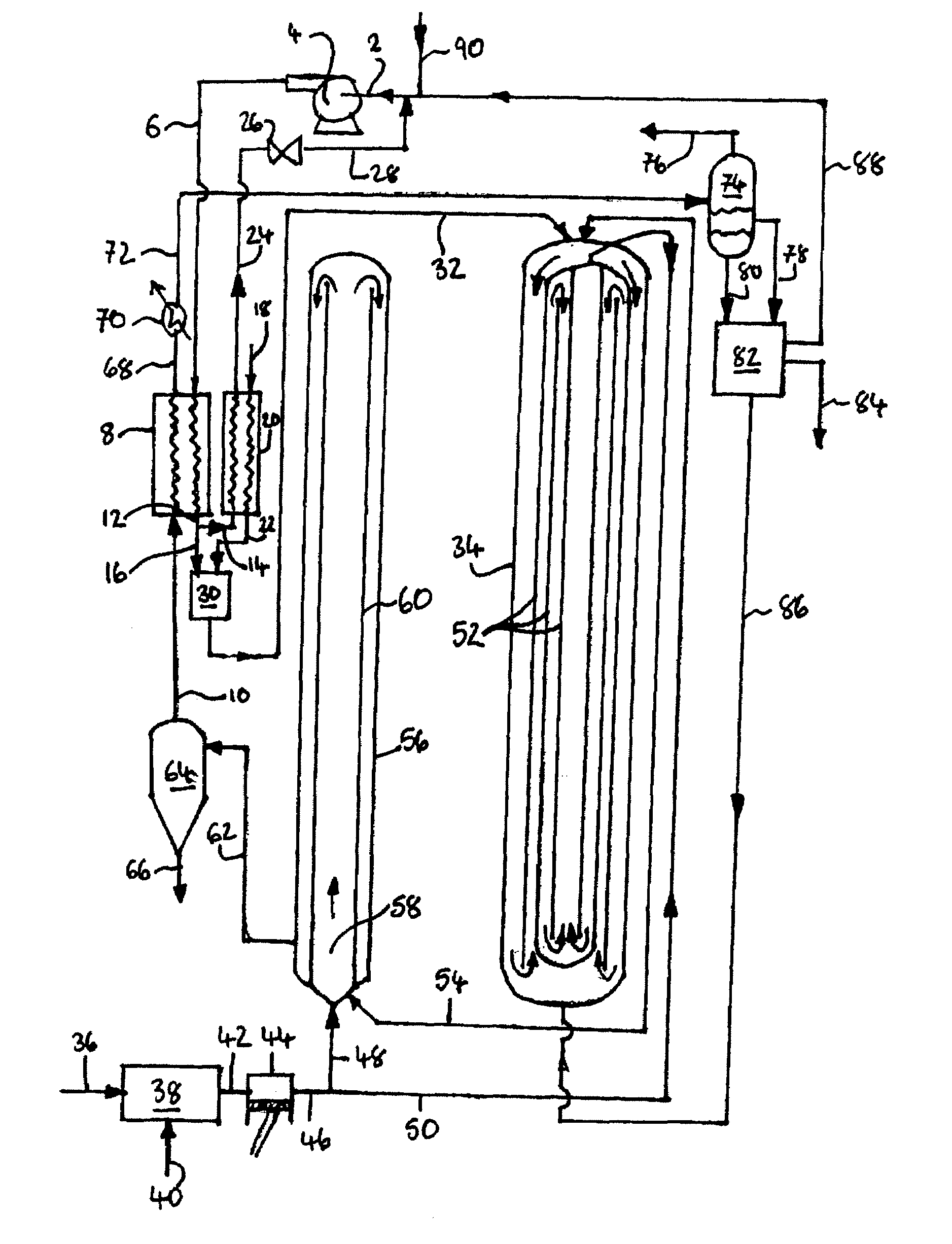

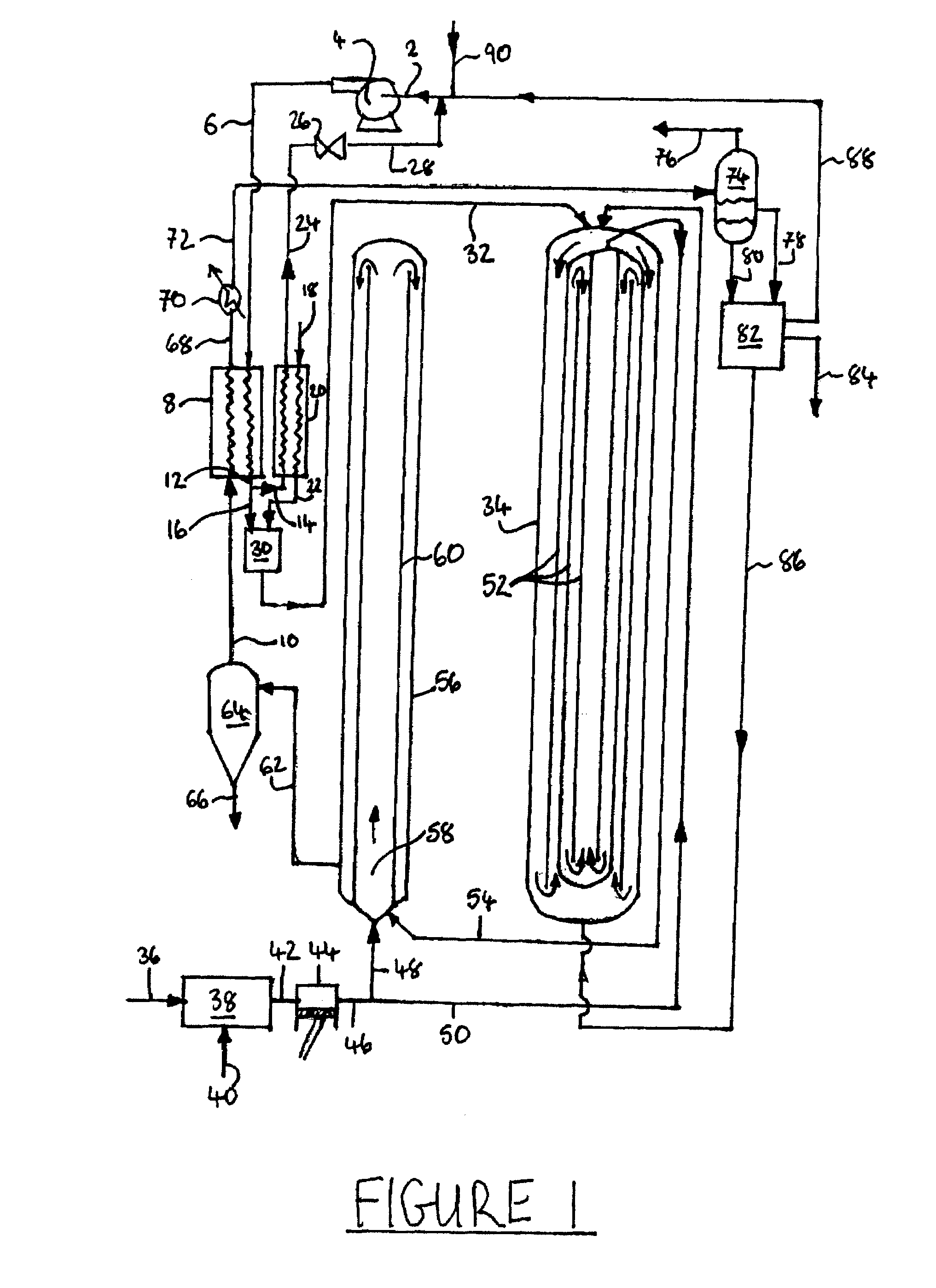

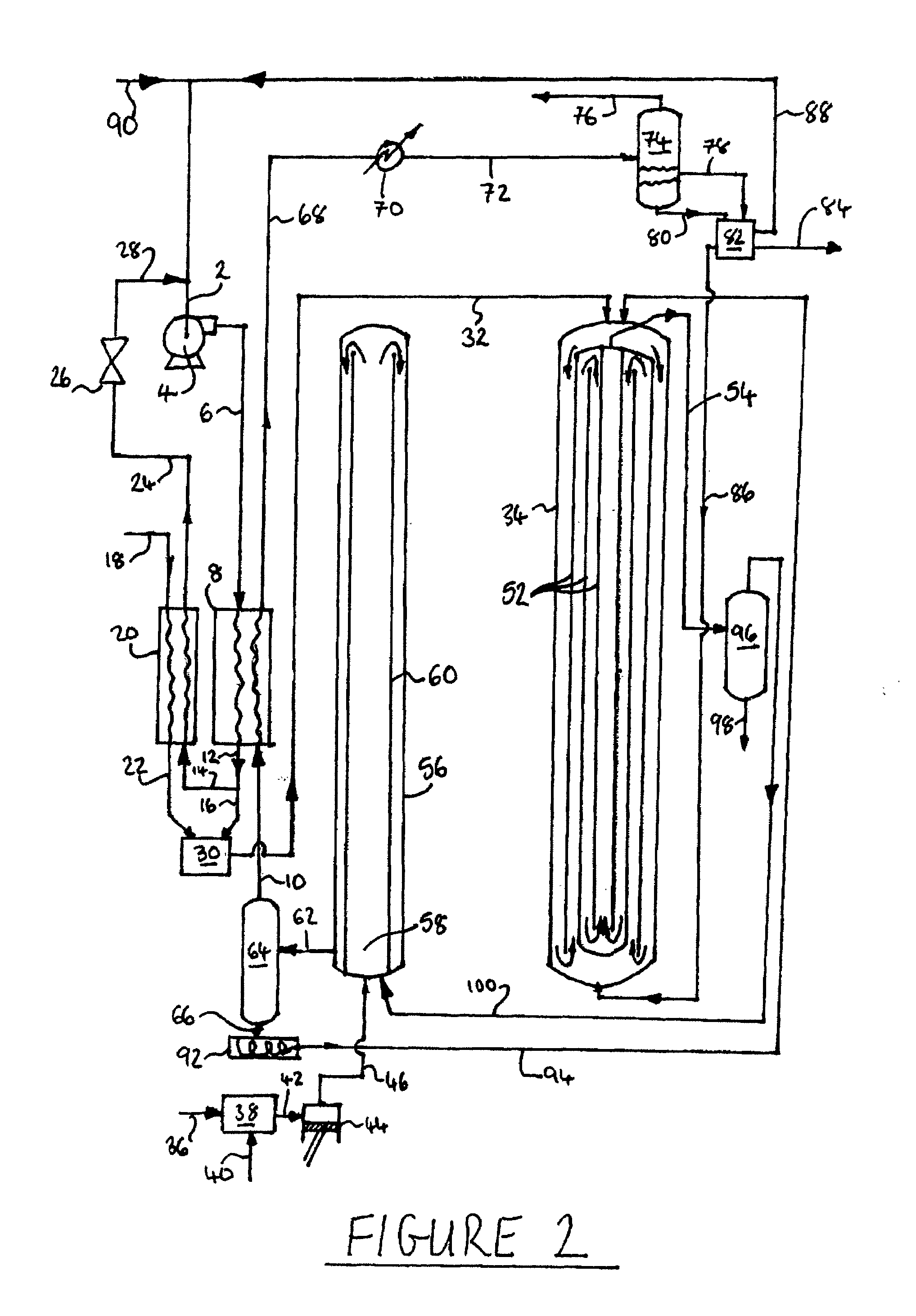

Process and apparatus for upgrading coal using supercritical water

Coal is converted into hydrocarbon compounds using supercritical water. The process involves two stages; a first stage in which carbonaceous material is reacted with supercritical water at above 850K to produce a first supercritical fluid reaction mixture comprising hydrocarbon compounds; and a second stage in which hydrocarbon compounds are extracted from coal mixed with at least a portion of the first supercritical fluid at a temperature within a range of from the supercritical temperature of water to about 695K. Char from the second stage is finely divided and may be either be used outside the process, e.g. in a coal fired power station or a gasifier, or used as at least a portion of the carbonaceous material used in the first stage.

Owner:AIR PROD & CHEM INC

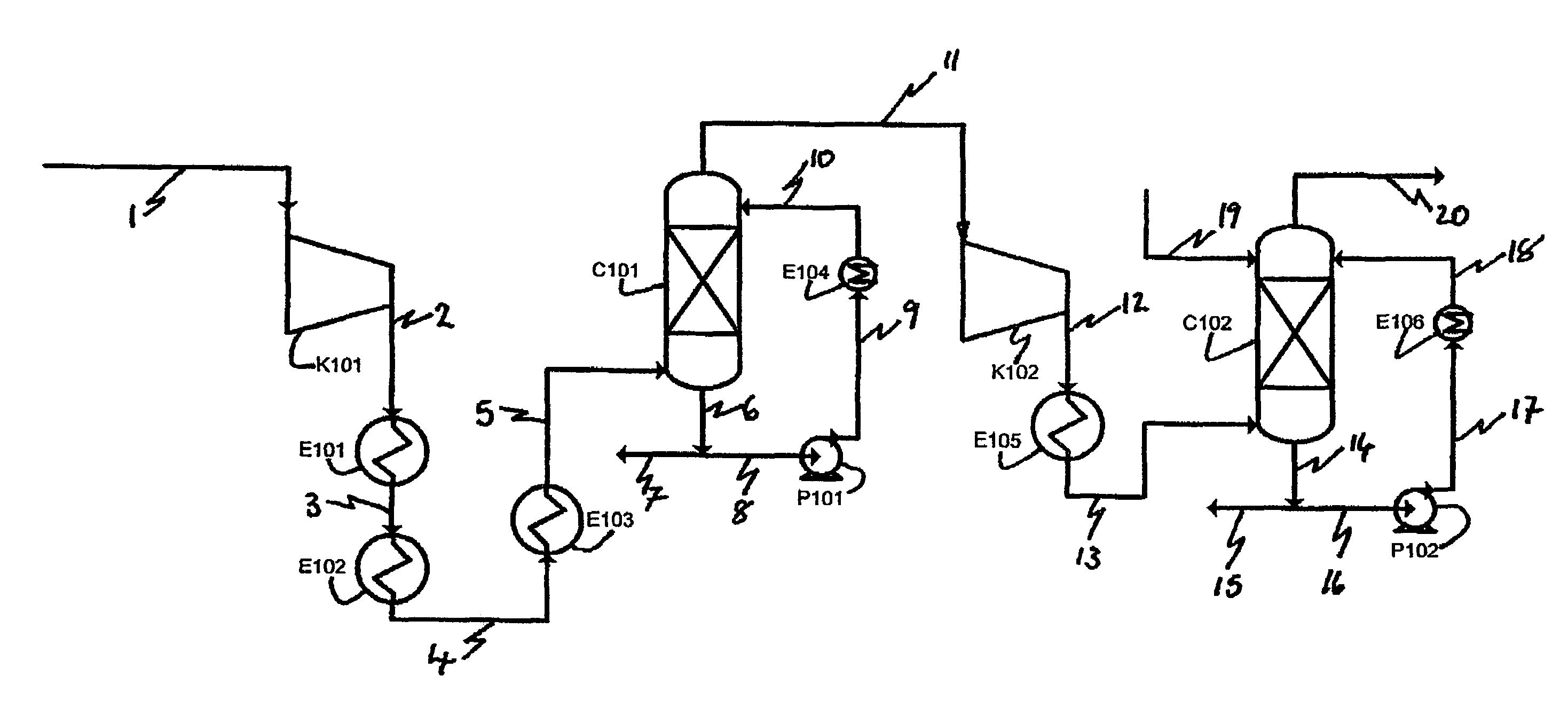

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

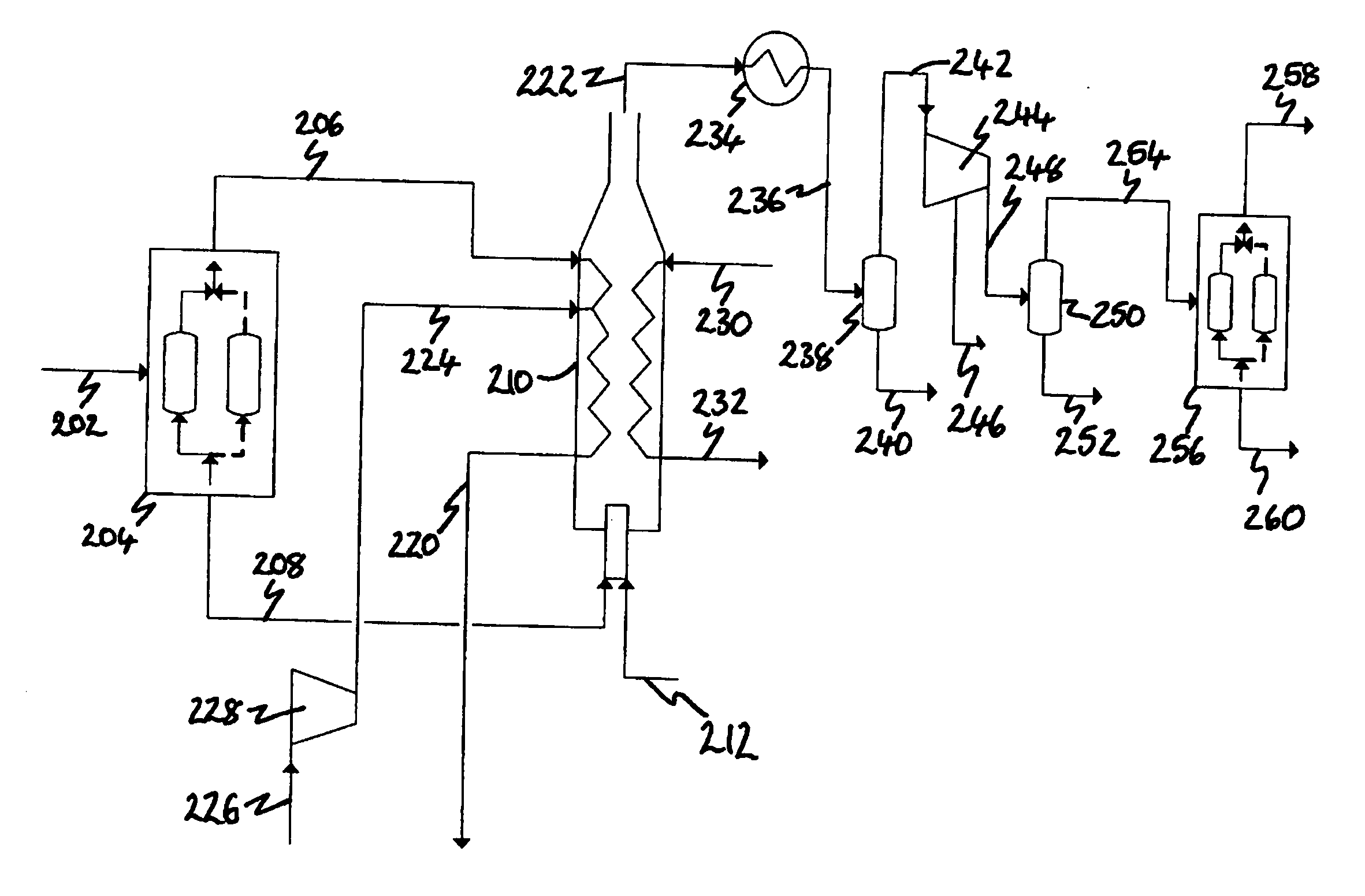

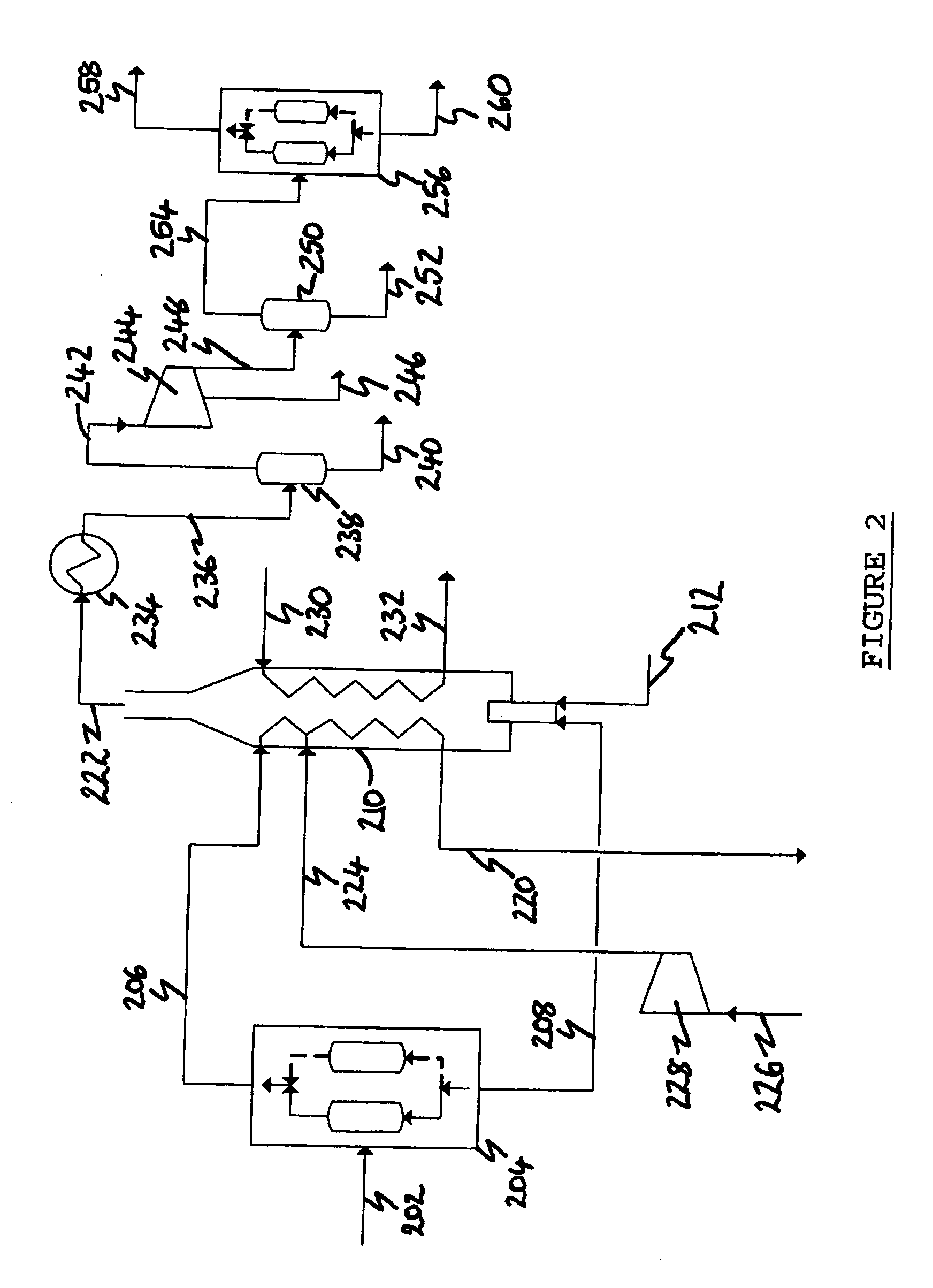

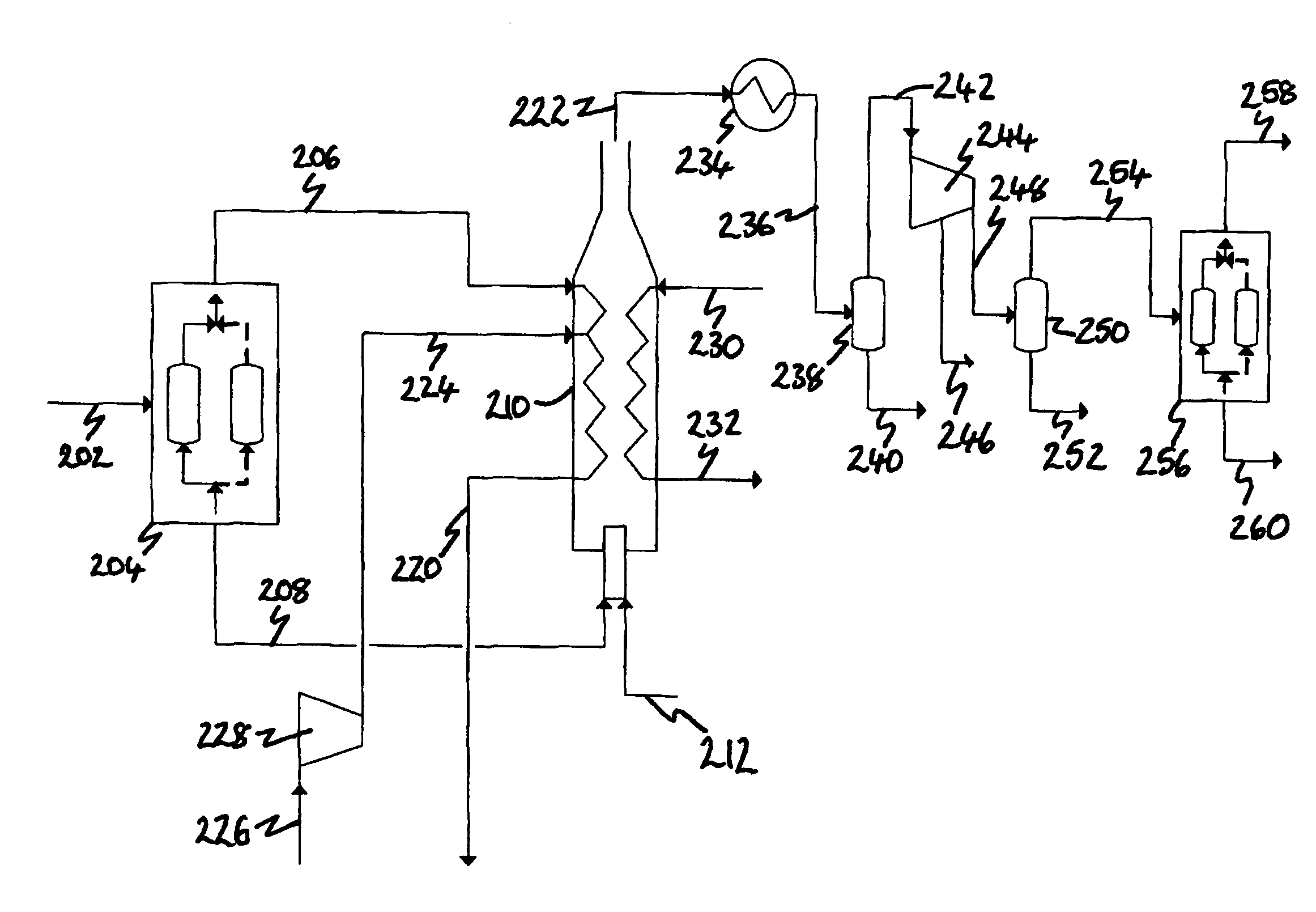

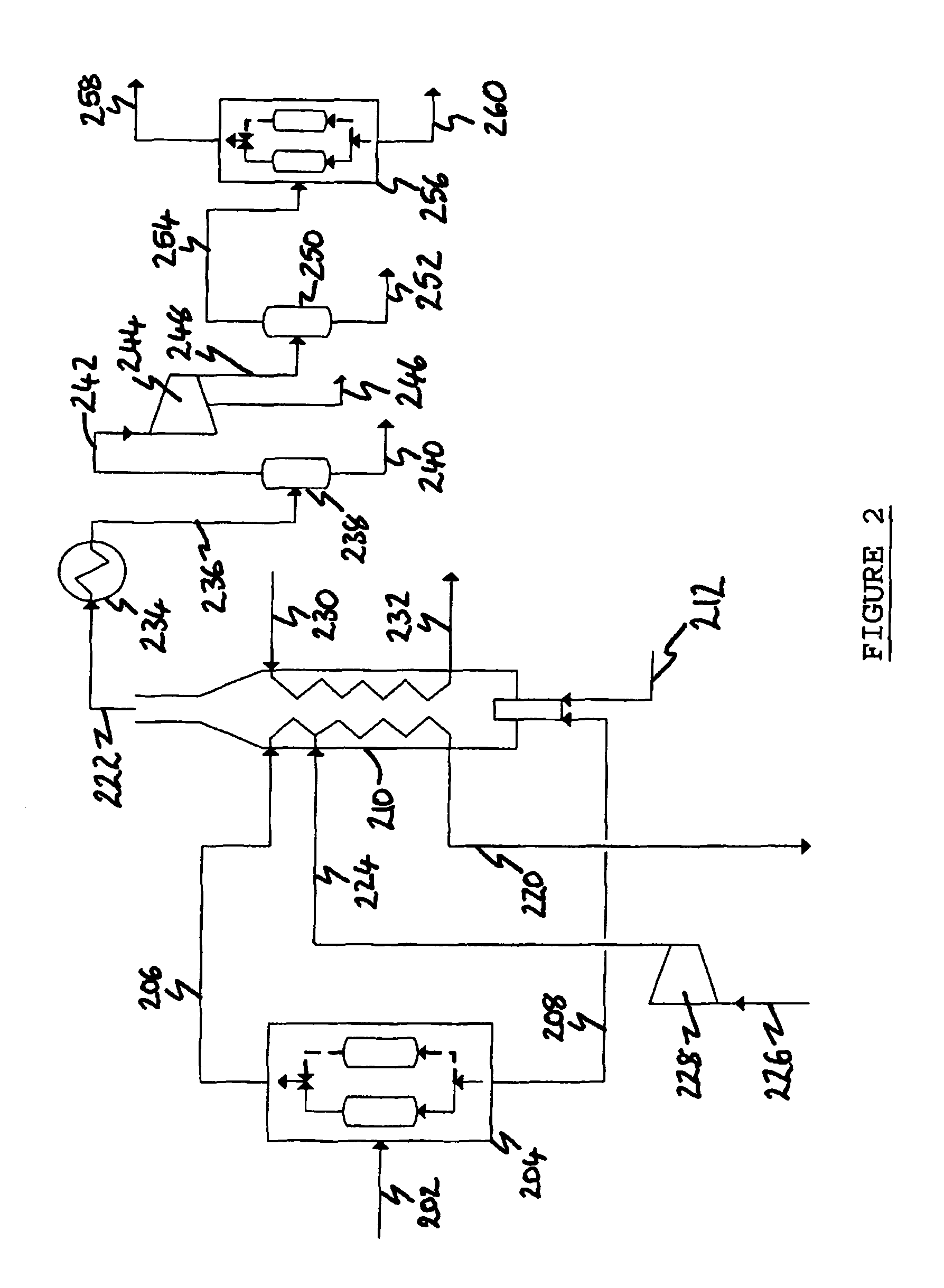

Method of treating a gaseous mixture comprising hydrogen and carbon dioxide

Hydrogen (H2) gas and crude carbon dioxide (CO2) gas are separated from a gaseous mixture thereof. Combustible gas(es) in the crude CO2 gas are combusted to produce heat, at least a portion of which is recovered by indirect heat exchange with at least a portion of the separated H2 gas or a gas derived therefrom. The invention may be integrated with coal-fired power stations to reduce or eliminate emission of harmful components into the atmosphere.

Owner:AIR PROD & CHEM INC

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

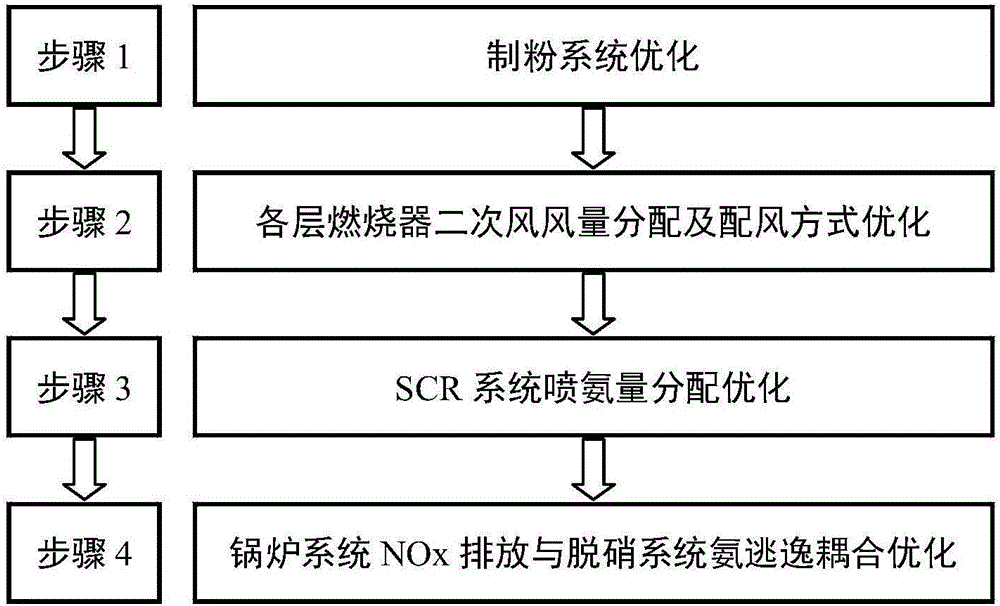

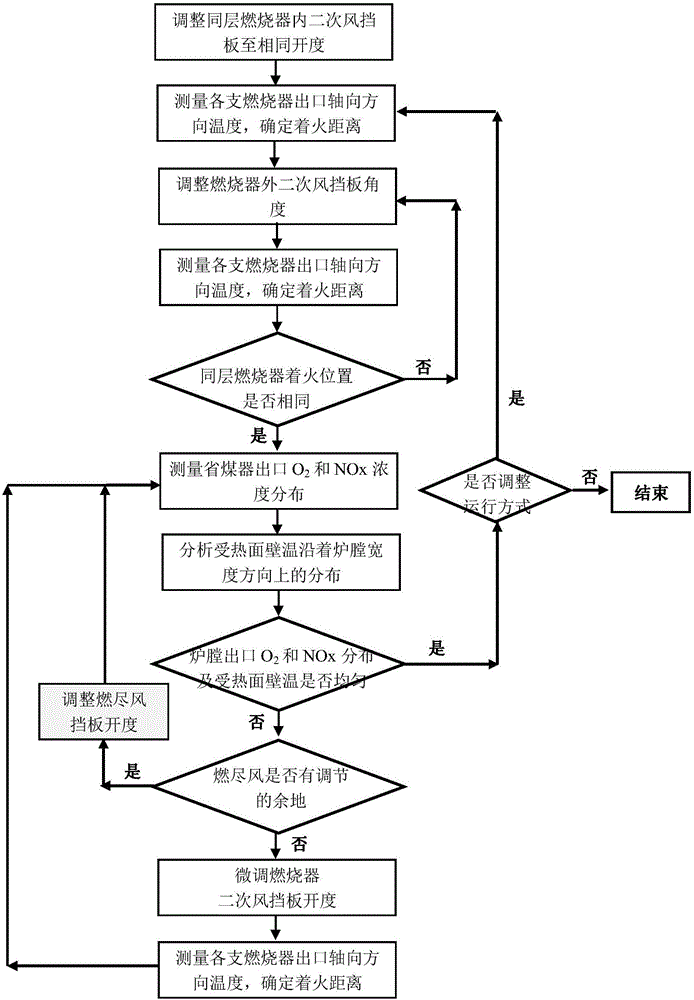

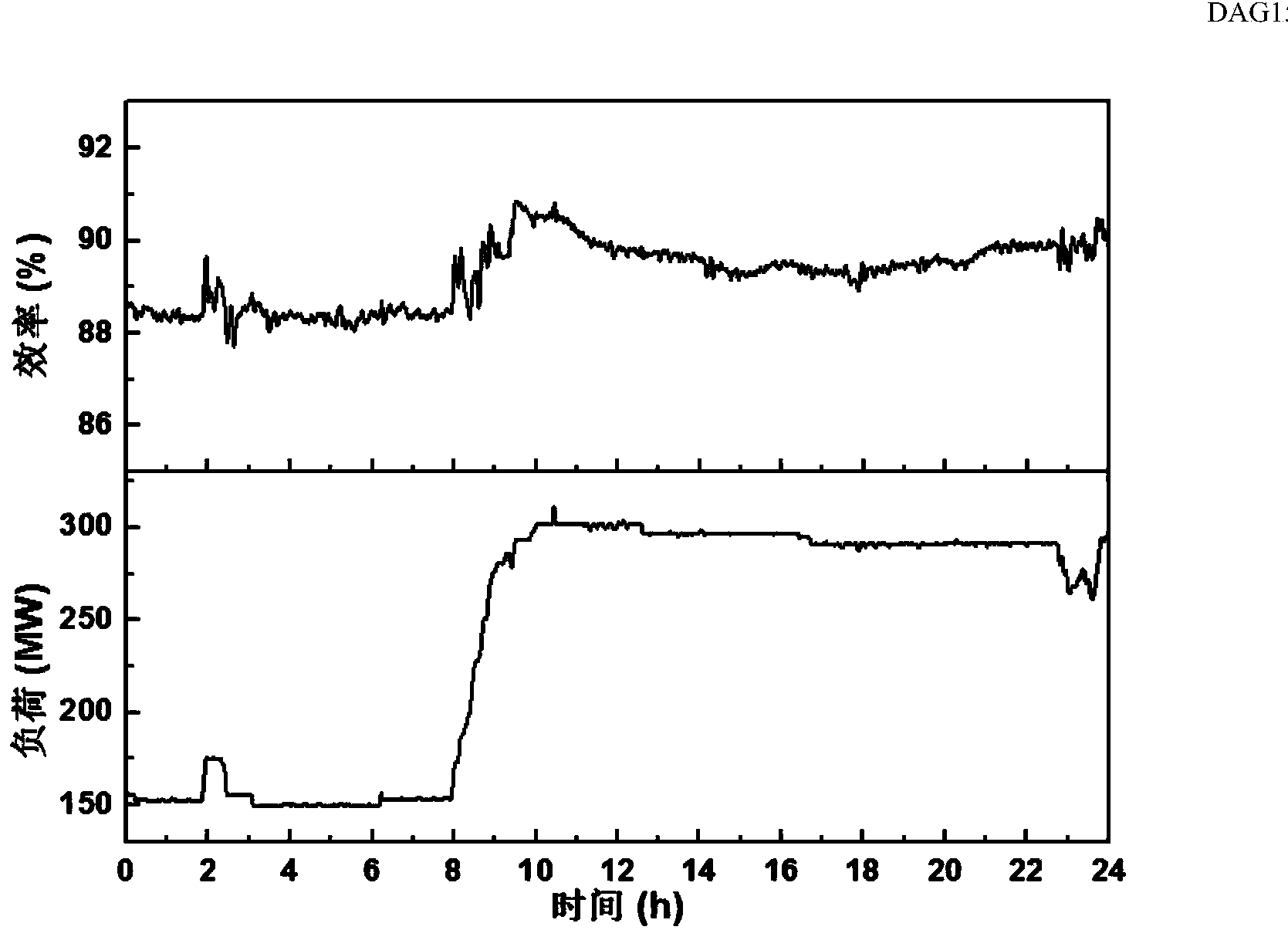

Coal-fired power plant boiler system and denitration system operation collaborative optimization method

ActiveCN105953259AEconomic operation modeGuaranteed operational safetyFuel supply regulationFuel feeding arrangementsOperation modeOxygen

The invention provides a coal-fired power plant boiler system and denitration system operation collaborative optimization method. The method comprises the following steps: the operation of a powder preparation system is optimized and adjusted; the operation of a combustion system is optimized and adjusted; the operation of a denitration system is optimized and adjusted; the coal-fired boiler NOx emission control and the SCR denitration system ammonia escape control are coupled for optimization and adjustment; an optimal operation oxygen quantity range of a coal-fired boiler under different loads and an optimal openness range of a burnt wind nozzle in the optimal oxygen quantity operation range are determined by combining the reductive atmosphere distribution characteristics in a near wall area of a hearth water cooling wall and the denitration ammonia escape conditions; and an optimal denitration efficiency range of the denitration system under different loads is determined. The three system operation collaborative optimization methods, provided by the invention, see the boiler system and the denitration system as a large system; the mutual correlation and influence among the three systems are decoupled from the angle of the large system; and the most economical and safest operation mode of the large system is obtained through optimization.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

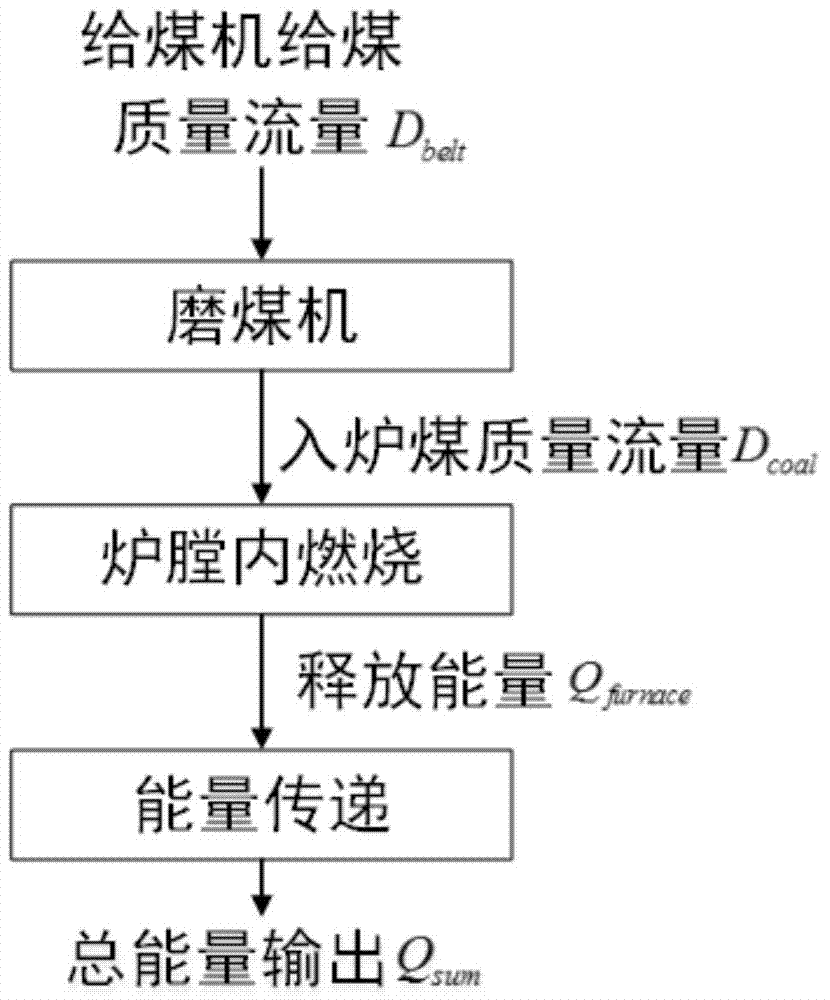

Real-time identification method for fired coal lower heating value of coal-fired power plant

ActiveCN103674333ARealize online identificationStable productionCalorimeterRelational modelMeasurement point

The invention provides a real-time identification method for a fired coal lower heating value of a coal-fired power plant. The real-time identification method includes the steps of (1) obtaining boiler structure parameters according to a boiler operation design discipline, and reading an operation condition measurement point real-time value at the given moment from a real-time database of a DSC, (2) calculating the specific enthalpy and the density of working media and the specific heat and the density of smoke based on a working medium physical property parameter base and a smoke physical property parameter base, (3) correcting main steam flow masses based on a relation model of main steam adjustment door opening degrees and the main steam flow masses, (4) respectively calculating corresponding energy output of various parts on the boiler side and total energy output at the given moment according to a boiler-side complete-flow-path mechanism model, (5) building a transfer function model between coal feeding flow masses of a coal feeder and the fired coal flow masses, and (6) building a transfer function model between the fired coal flow masses and the total energy output. The real-time identification method is used for on-line identification on the fired coal lower heating value, and has the application potential of combustion and coal blending optimization.

Owner:SHANGHAI JIAO TONG UNIV

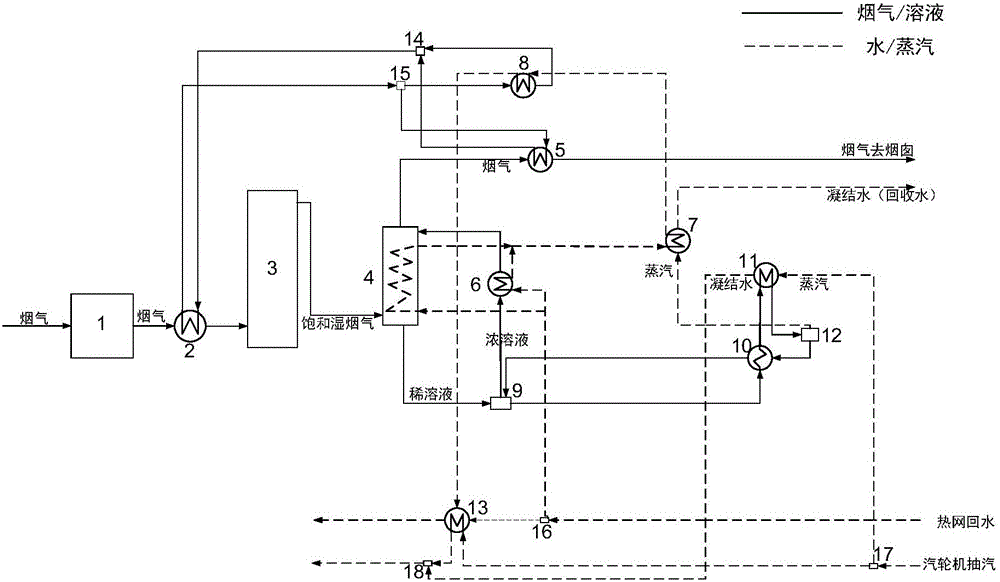

System and method for recycling flue gas waste heat and water while white fog of coal-fired power station chimney is eliminated

ActiveCN106500122AIncrease superheatReduce water vapor contentEnergy efficient heating/coolingClimate change adaptationFlue gasWater vapor

The invention provides a system and method for recycling flue gas waste heat and water while white fog of a coal-fired power station chimney is eliminated. The system comprises an absorber absorbing water vapor in flue gas through a salt solution, a solution reproducer, a corresponding heat recycling system and an integrated system for flue gas heat recycling before wet desulphurization. By means of the system and method, white fog of the wet desulphurization coal-fired power station chimney can be eliminated, especially, white fog in winter is eliminated, waste heat and water of flue gas can be recycled, the energy utilizing efficiency of a power station is improved, and consumed water of the power station is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

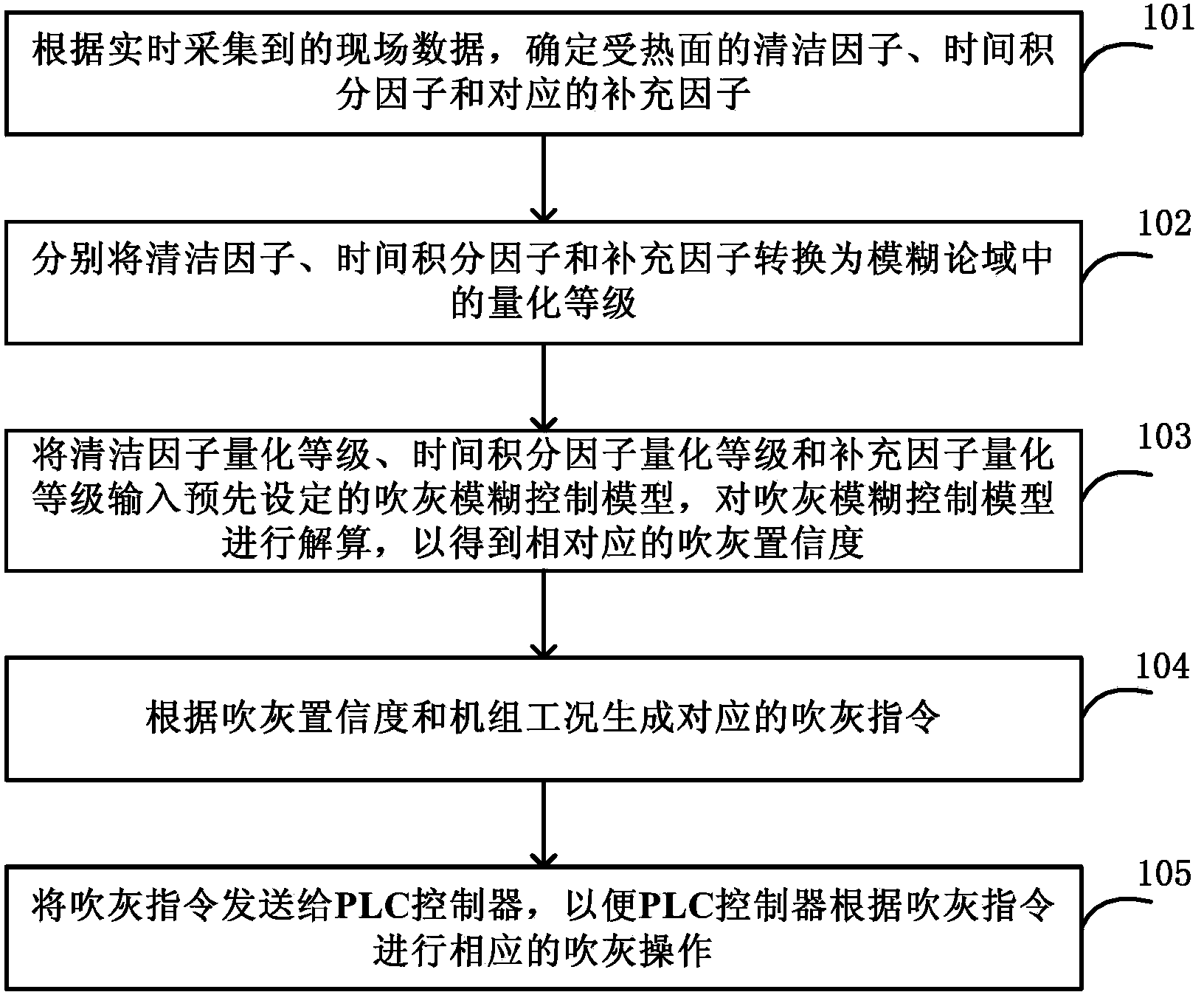

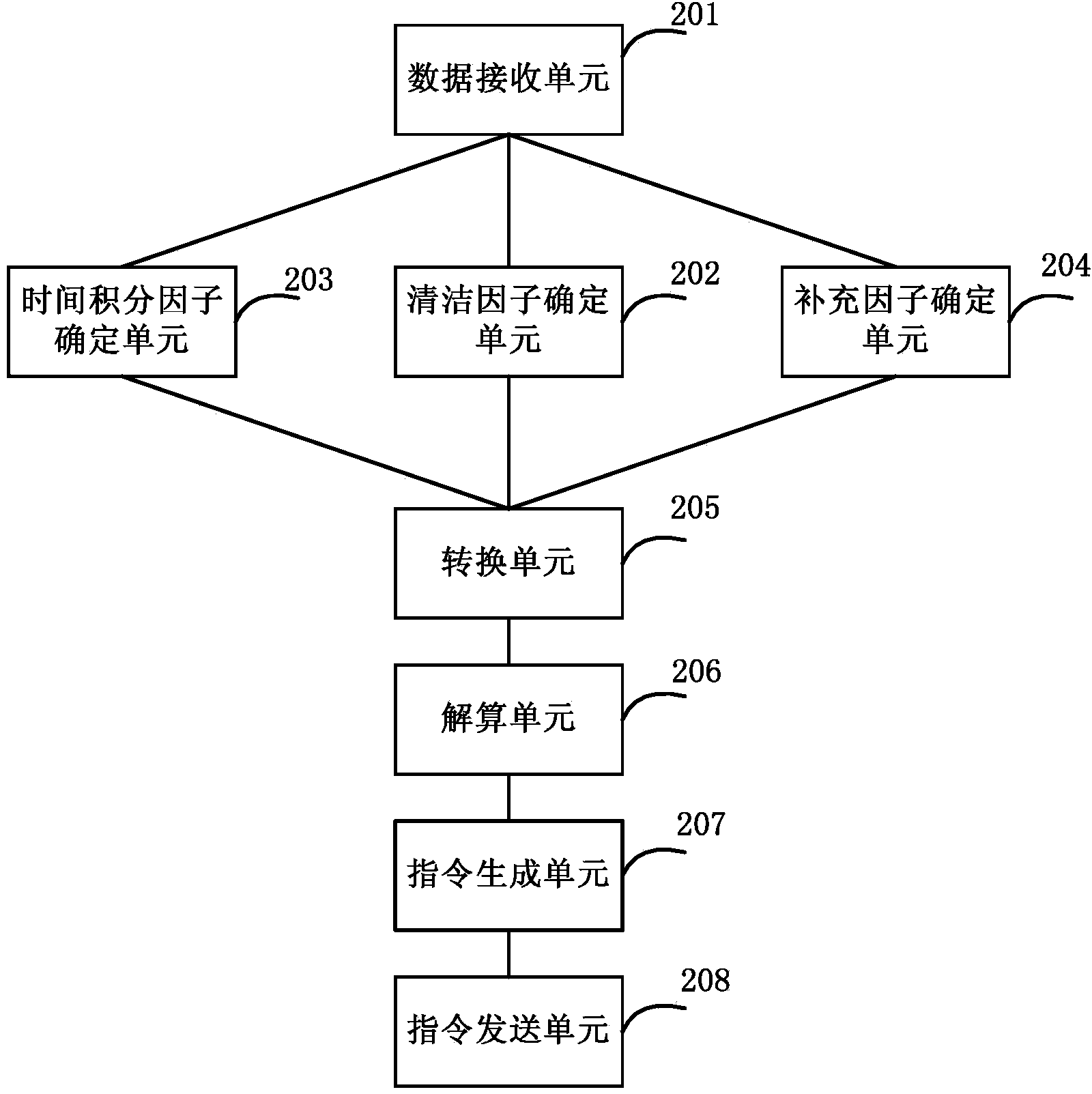

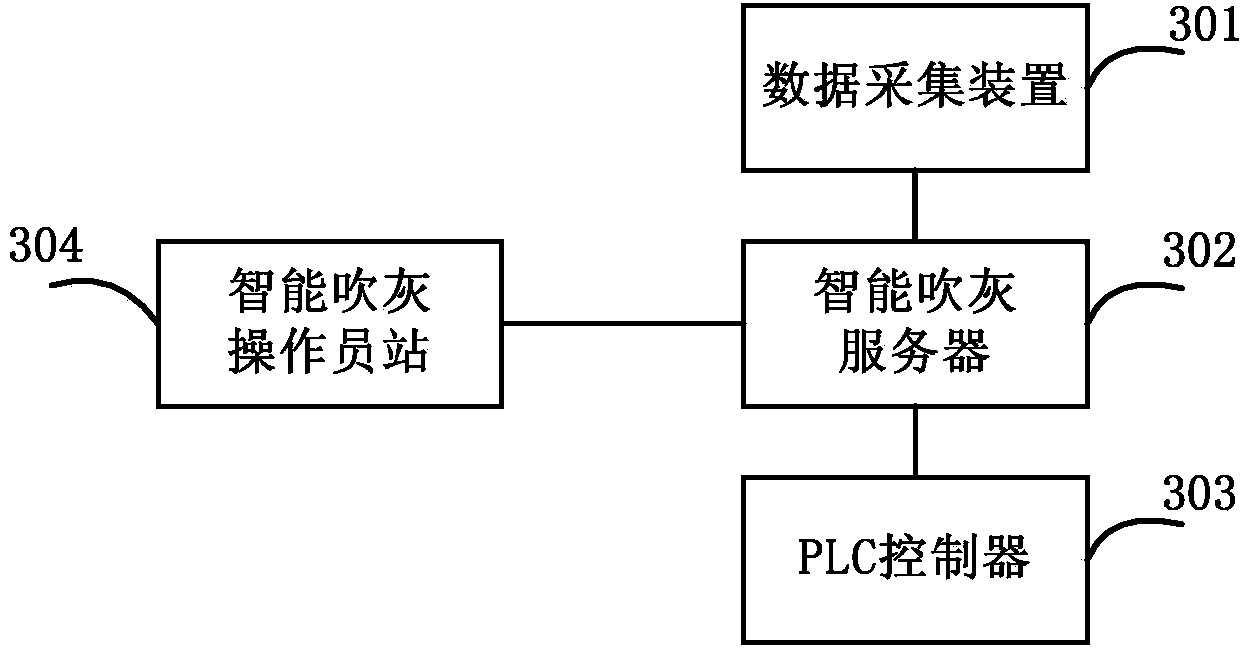

Intelligent soot blowing closed-loop control method, device and system for coal-fired power station boiler

The invention discloses an intelligent soot blowing closed-loop control method, device and system for a coal-fired power station boiler. The method includes the steps that a cleaning factor, a time integral factor and a corresponding supplement factor of a heating surface are determined according to field data collected in real time and are converted into quantization levels respectively in the fuzzy field; the cleaning factor quantization level, the time integral factor quantization level and the supplement factor quantization level are input into a preset soot blowing fuzzy control model, and the soot blowing fuzzy control model is resolved to obtain a corresponding soot blowing confidence coefficient; a corresponding soot blowing instruction is generated according to the soot blowing confidence coefficient and working conditions of a unit and is then sent to a PLC so that the PLC can carry out corresponding soot blowing operation according to the soot blowing instruction. Closed-loop control over a soot blowing system is achieved by comprehensively considering operation factors affecting soot blowing, soot blowing frequency is reduced to the minimum under the condition that heat transfer characteristics of the heating surface are guaranteed, and the purposes of saving energy, reducing consumption and improving the operation economy and safety of the unit are achieved.

Owner:YANTAI LONGYUAN POWER TECH +1

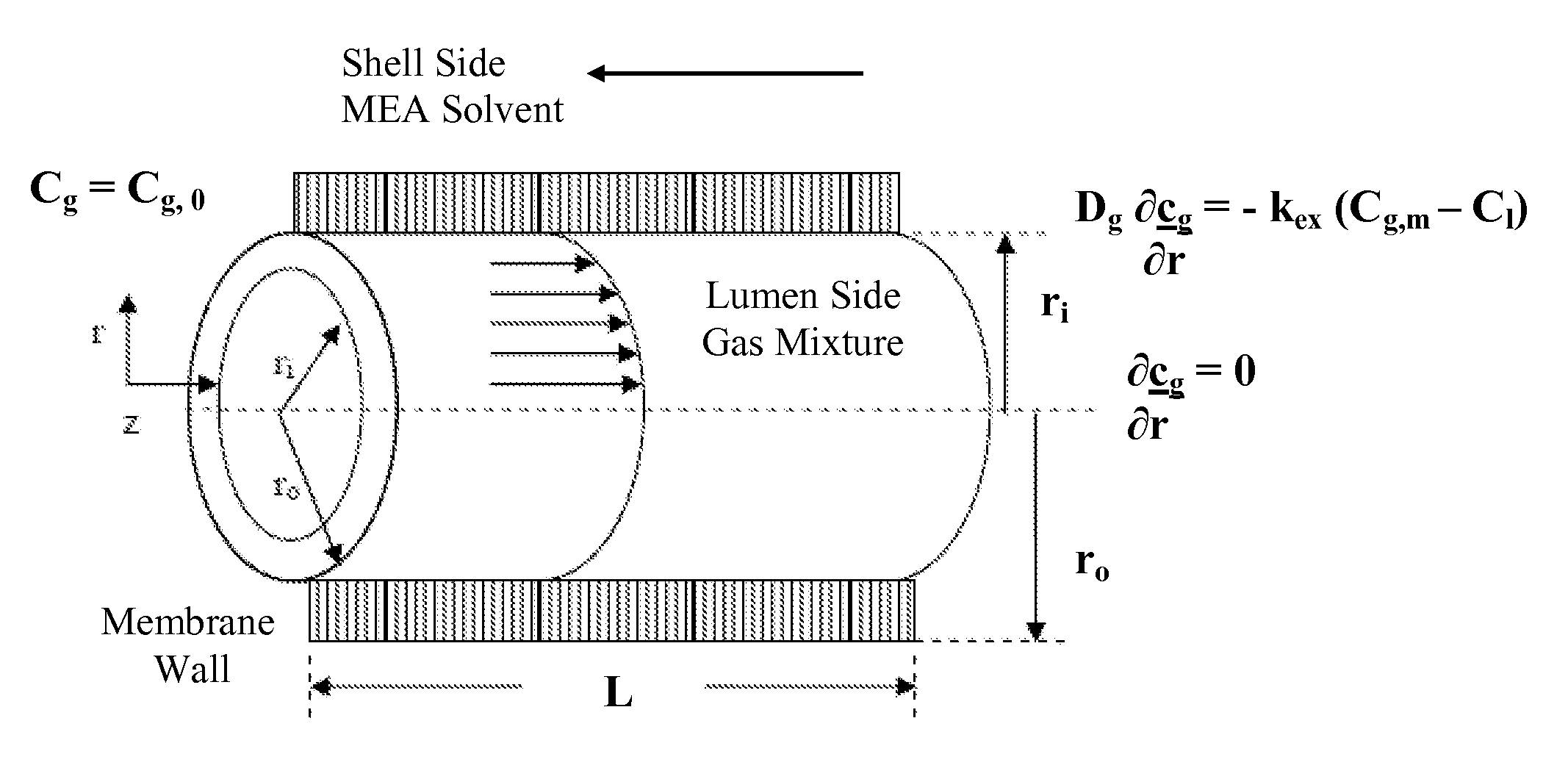

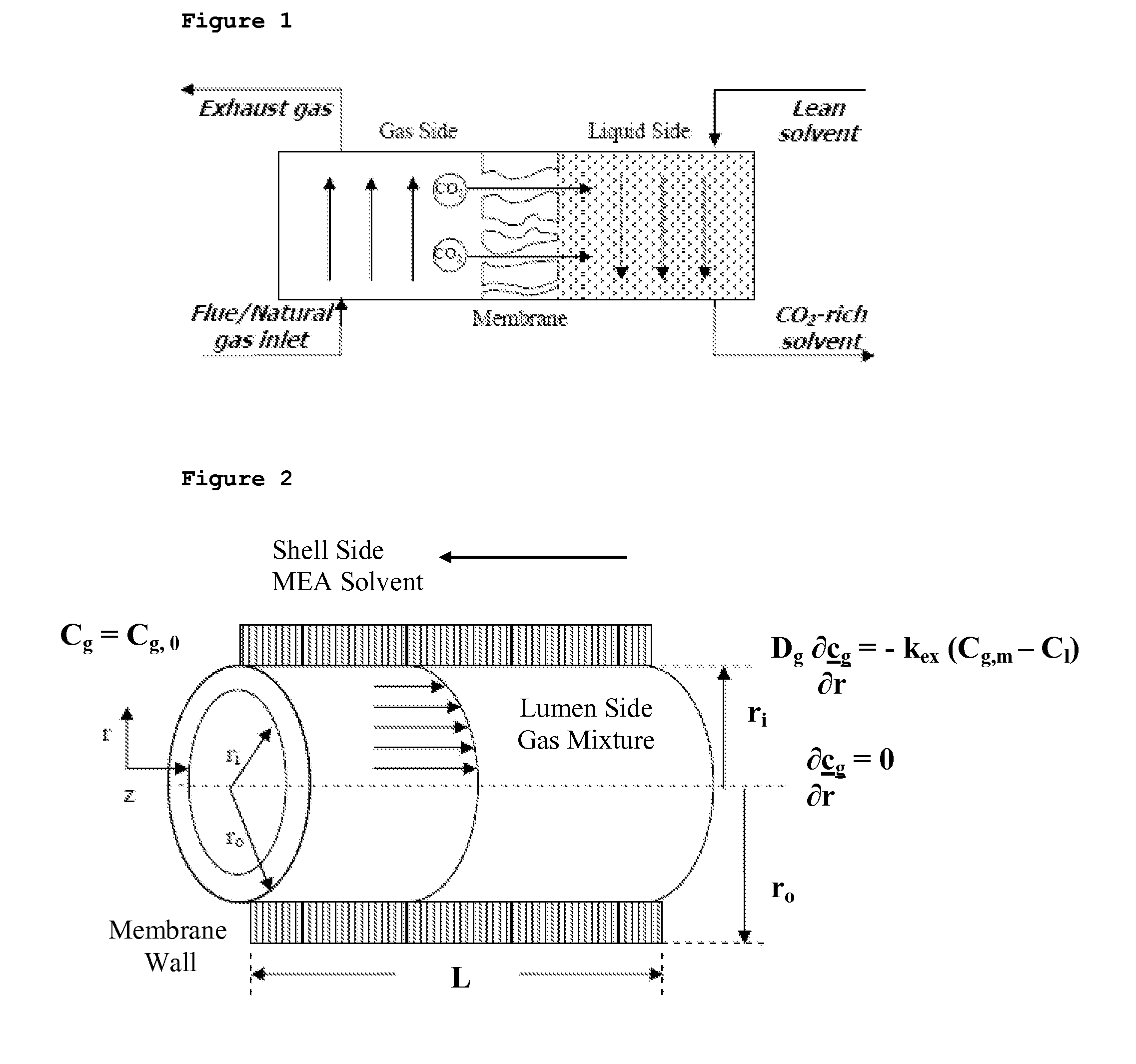

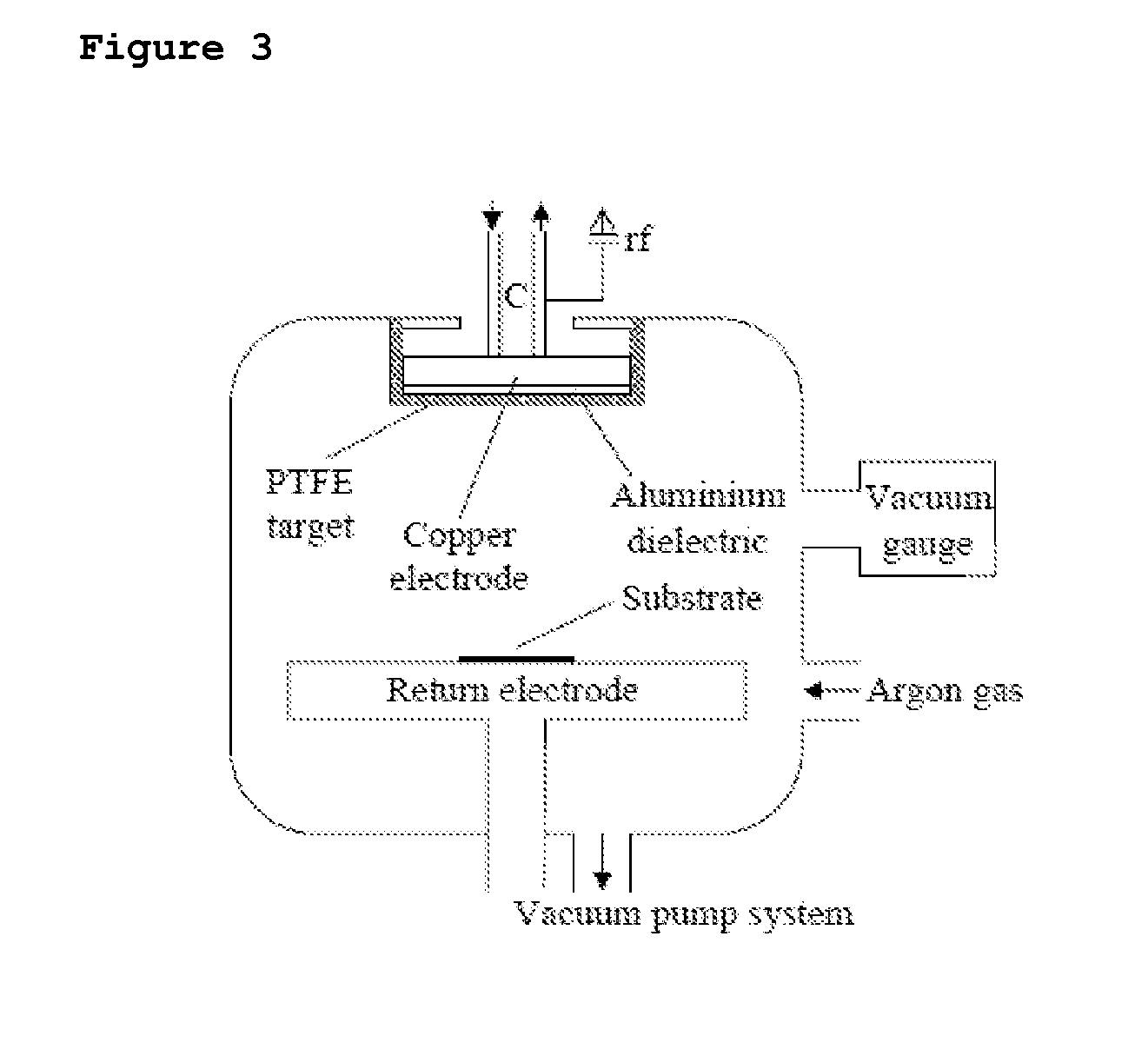

Gas absorption membranes and the manufacture thereof

A membrane is used for separating carbon dioxide from a gas phase. The membrane includes a substrate having micro-pores that extend through the substrate and a thin hydrophobic coating on one side of the substrate in which the pores of the substrate are substantially unobstructed by the coating so that the gas phase can penetrate the pores. The coating opposes or substantially resists a liquid solvent for absorbing carbon dioxide from penetrating the pores of the membrane from the side having the coating. The membrane may also be used for separating carbon dioxide in a flue gas of a coal fired power station. Further, the coating may be relatively inert to the liquid solvent compared to the substrate.

Owner:CO2CRC TECH PTY LTD

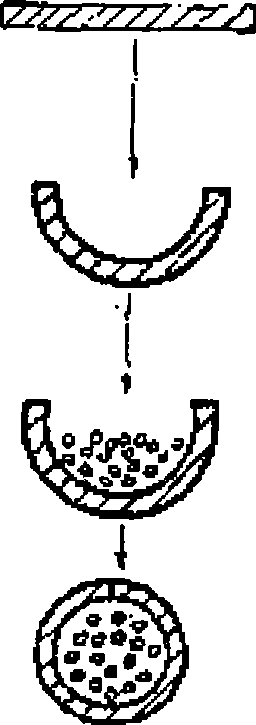

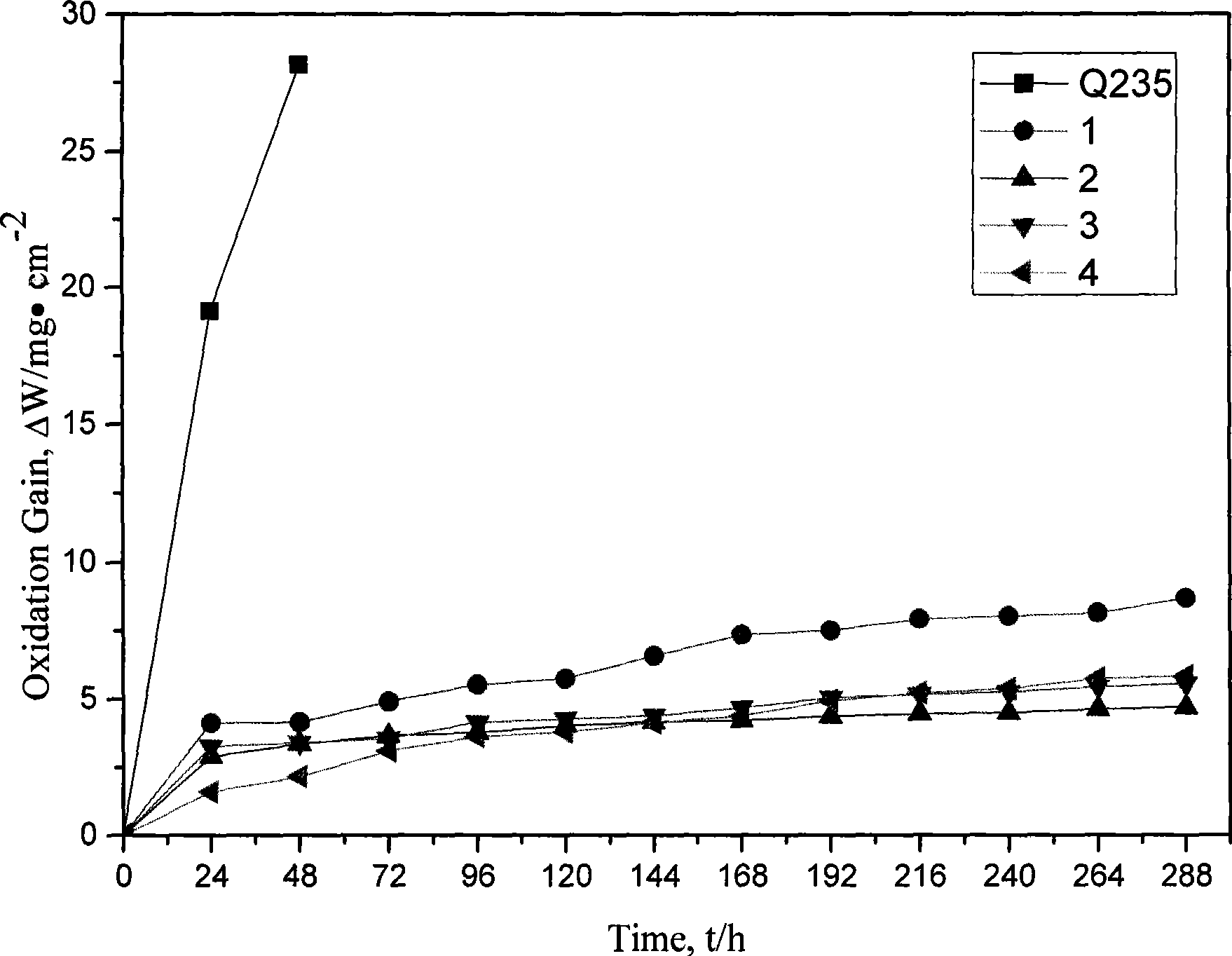

Powder core wire material for high chrome molybdenum alloy arc spraying

InactiveCN101497978AGood resistance to high temperature oxidationGood high temperature corrosion-abrasion resistanceMolten spray coatingThermal sprayingMetallic aluminum

The invention relates to a high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire which belongs to electric arc spraying powder cored wires which resist high-temperature oxidation and corrosion and used for the surface protection of metal materials. The high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire belongs to the field of hot spraying in material processing engineering and is mainly used for the high-temperature corrosion, erosion and abrasion resistance of four tubes of a general coal-powder boiler of a coal-fired power station boiler, the corrosion prevention and the abrasion resistance of a converter smoke hood and a flue in a steel works and the repair of various axles, crankshafts, plunger pistons, paper-making drying cylinders, and the like. The high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire is characterized by comprising the powder core components according to percentages by weight of 22-29 percent of crome metal, 5-9 percent of metallic molybdenum, 2.5-10 percent of metallic nickel, 4.0-6.5 percent of metallic aluminum, 0.5-1 percent of carbon, 1.0-3.0 percent of rare-earth, and metallic iron. A preparation method of the high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire adopts the prior processes of firstly rolling a low-carbon cold-rolled strip into a U shape, adding powder core powders which account for 30-40 percent of the gross weight of spraying wires into the U-shaped groove, closing the U-shaped groove and wrapping the powder cores in the U-shaped groove, drawing gradually and lightening through a wire-drawing die to lead the diameter to reach 3.0mm.

Owner:北京赛亿表面工程技术有限公司

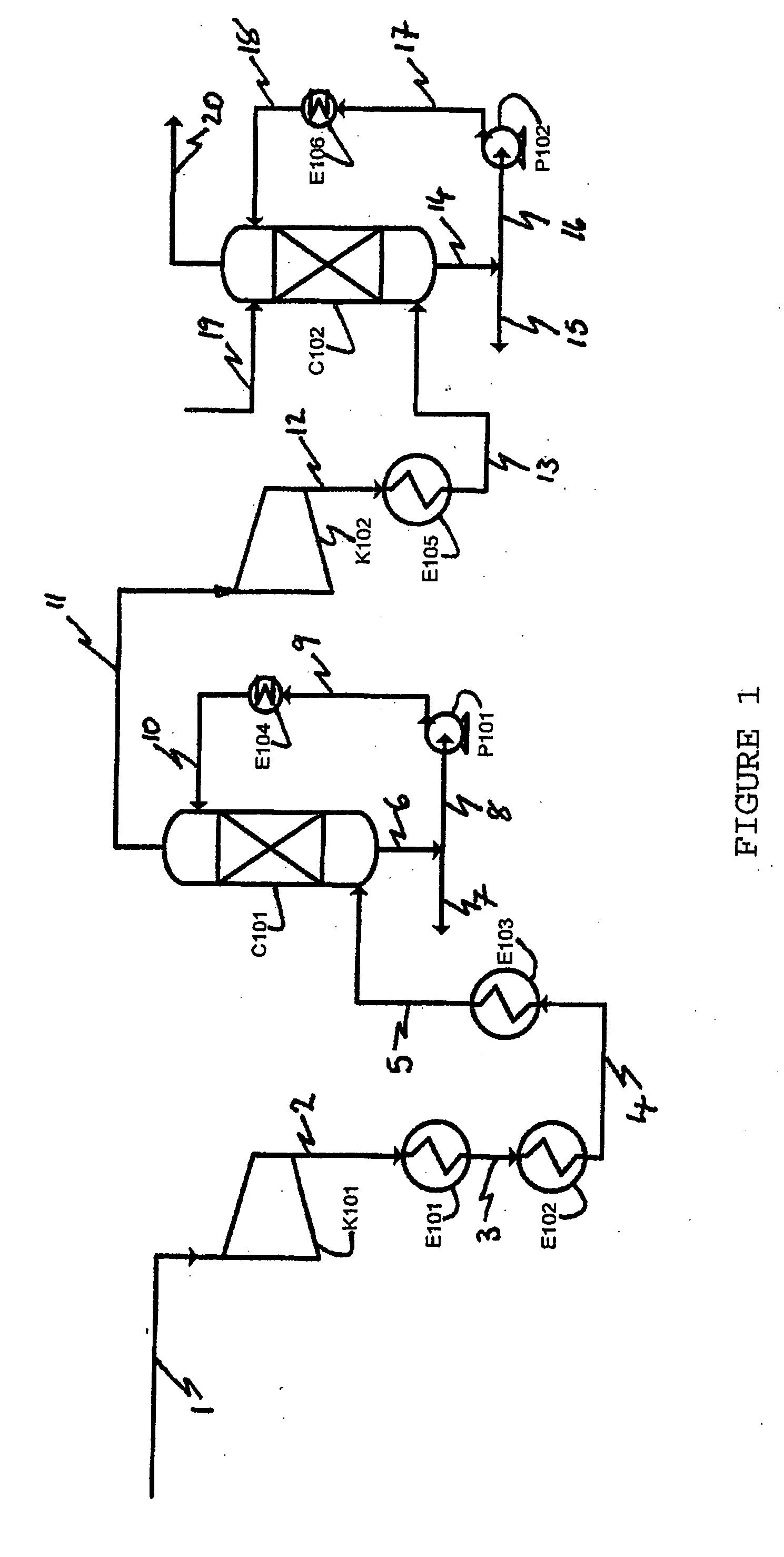

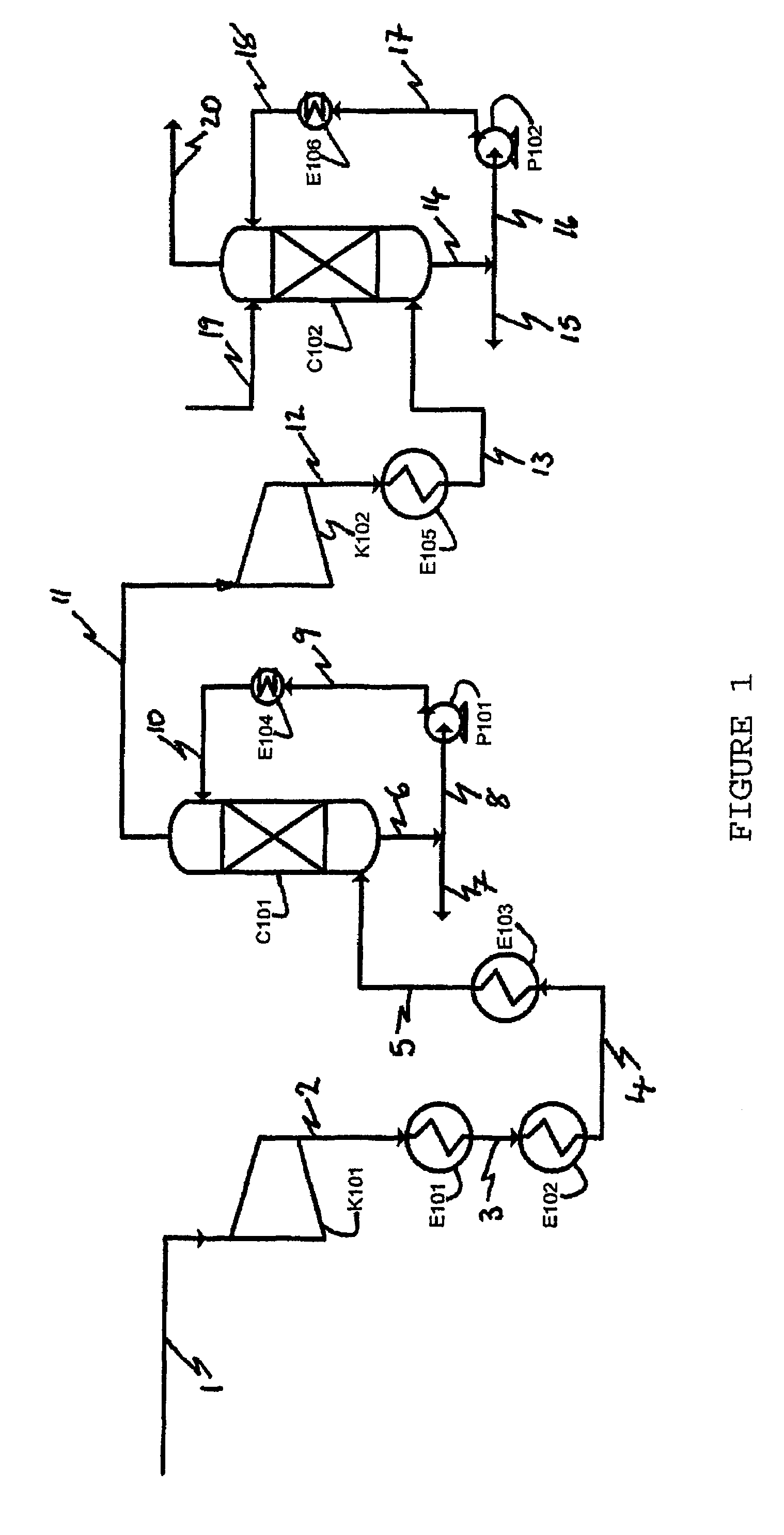

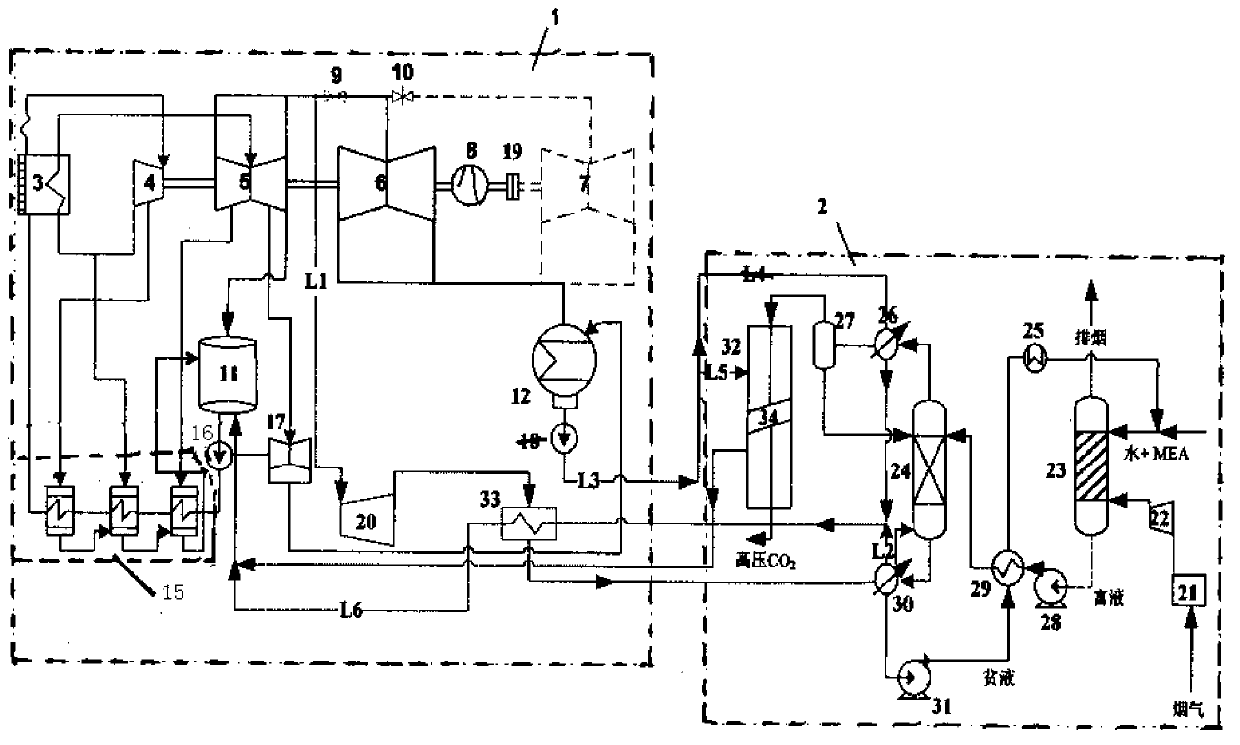

Improved heat integration coal-fired power plant decarbonization system and method

InactiveCN103272467ARealize the integration of power generation and decarbonizationReduce power generation efficiencyDispersed particle separationSteam useReboilerHigh energy

The invention discloses an improved heat integration coal-fired power plant decarbonization system and method, belonging to the technical field of energy conservation and emission reduction. The system mainly consists of two parts, namely a power plant steam turbine power generation unit and a CO2 capturing unit, wherein the two units are communicated through a cooler at the top of an analytic tower, a reboiler and a multi-stage compression cooled heat exchanger. According to the system, the low-pressure cylinder safety performance of the CO2 capture power plant is guaranteed; and meanwhile, due to the integration of the power plant steam turbine power generation unit and the CO2 capturing unit, the steam turbine power generation unit extracts steam and recovers the pressure energy through a small steam turbine, and the heat released by the CO2 capturing unit heats condensate water in the power plant through the cooler at the top of the analytic tower and the multi-stage compression cooled heat exchanger, so that the CO2 capture energy consumption is greatly reduced. According to the integration system, the safety operation of the CO2 capture power plant is guaranteed, the gradient energy utilization is realized, the CO2 emission can be effectively suppressed, the energy consumption of carbon emission reduction is reduced, and high energy utilization efficiency and technical and economic performance are obtained.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

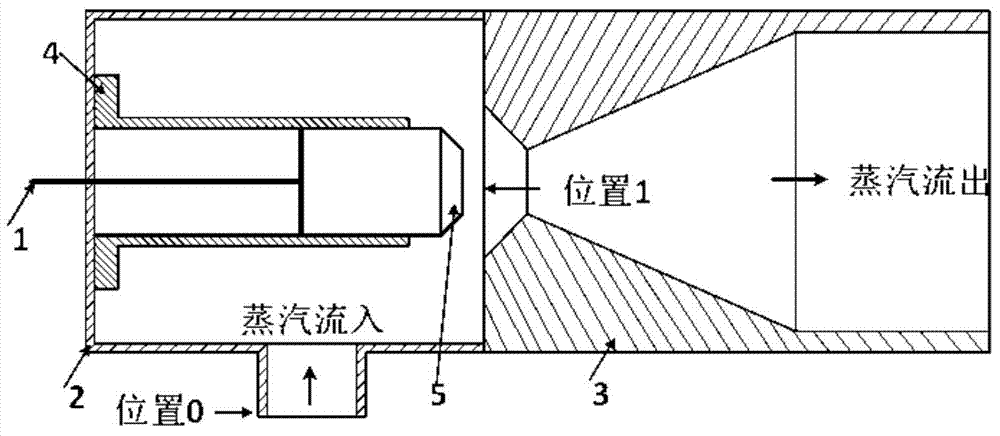

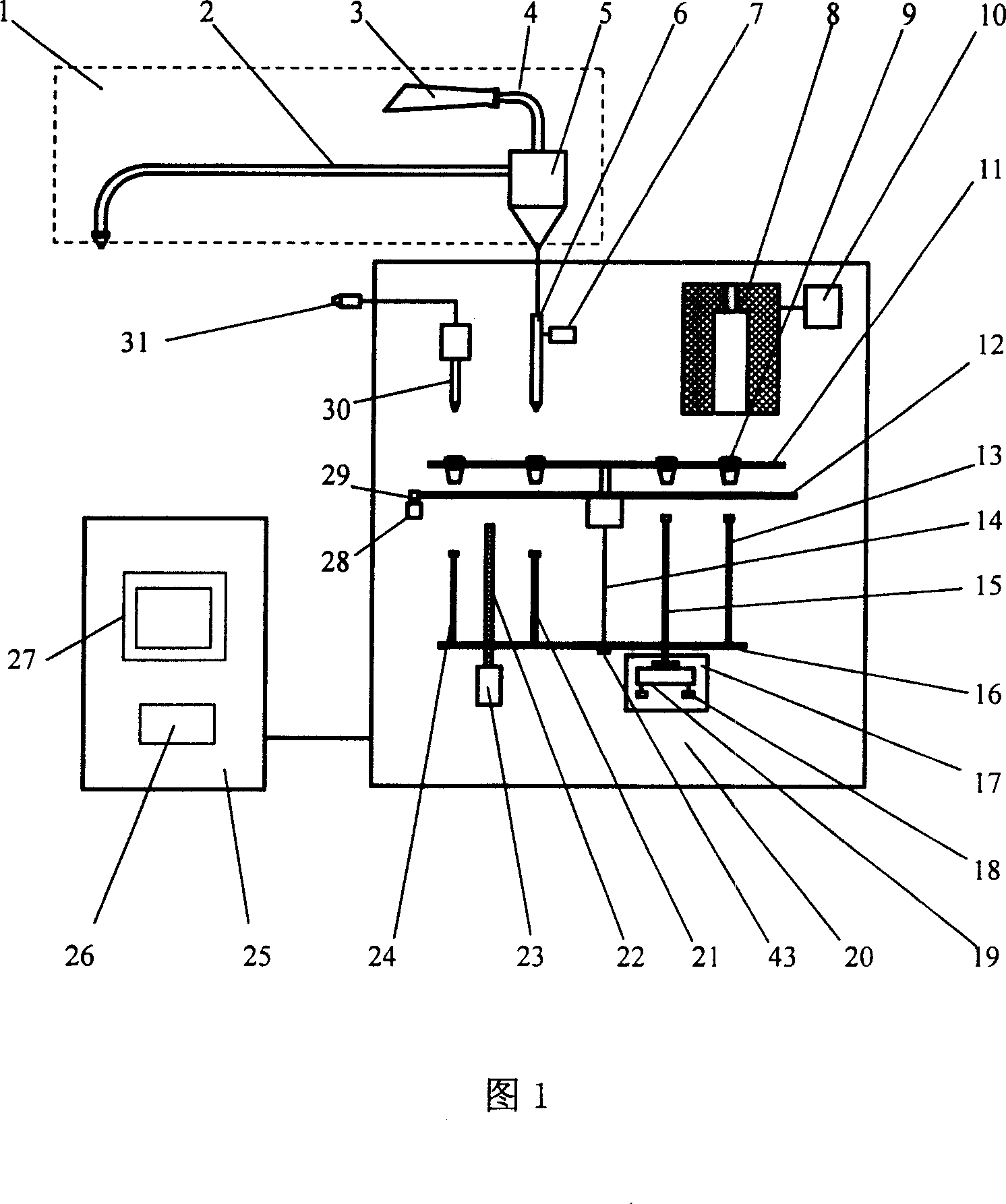

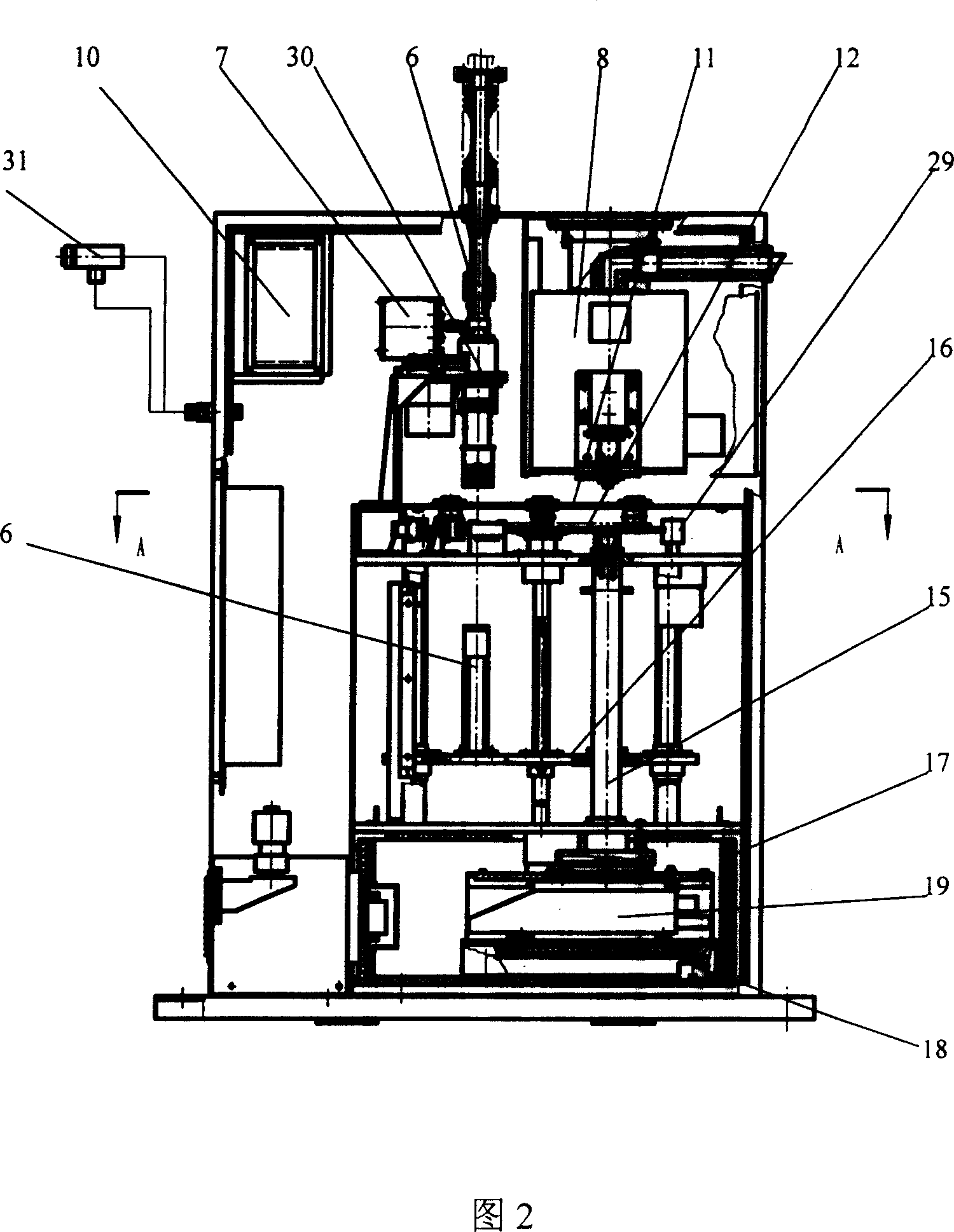

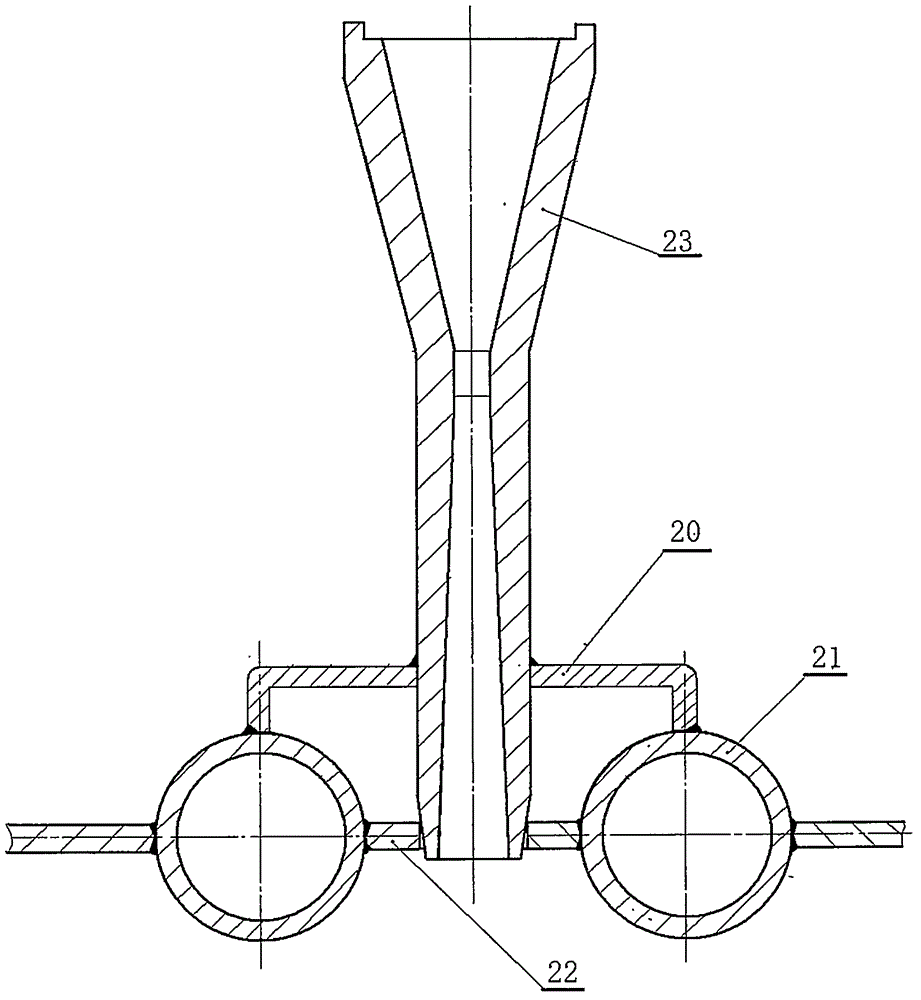

On-line testing device of carbon content in flying ashes in boiler flue for coal power station

InactiveCN1920524ASolve the technical key of online measurementHigh measurement accuracyWeighing by removing componentWithdrawing sample devicesCrucibleEngineering

The invention relates to an online carbon content detector with weight loss technique, used in the smoke channel of boiler of coal power station, wherein said device is characterized in that: it is formed by sampler (1) and testing bank (20); the sample tube (2) and ejection tube (3) of sampler (1) are inserted into the smoke channel; the ash open of cyclone dust collector (5) is connected with ash adding tube (6) inside the testing bank (20), to add ash into the pot (9) of testing bank (20); the testing bank (20) also contains a heater for heating pot (9) and a balance (19) for testing the ash weight of pot (9). The invention has high testing accuracy, without affected by coal kind, to provide real-time and correct supports to optimize burning.

Owner:南京大陆中电科技股份有限公司

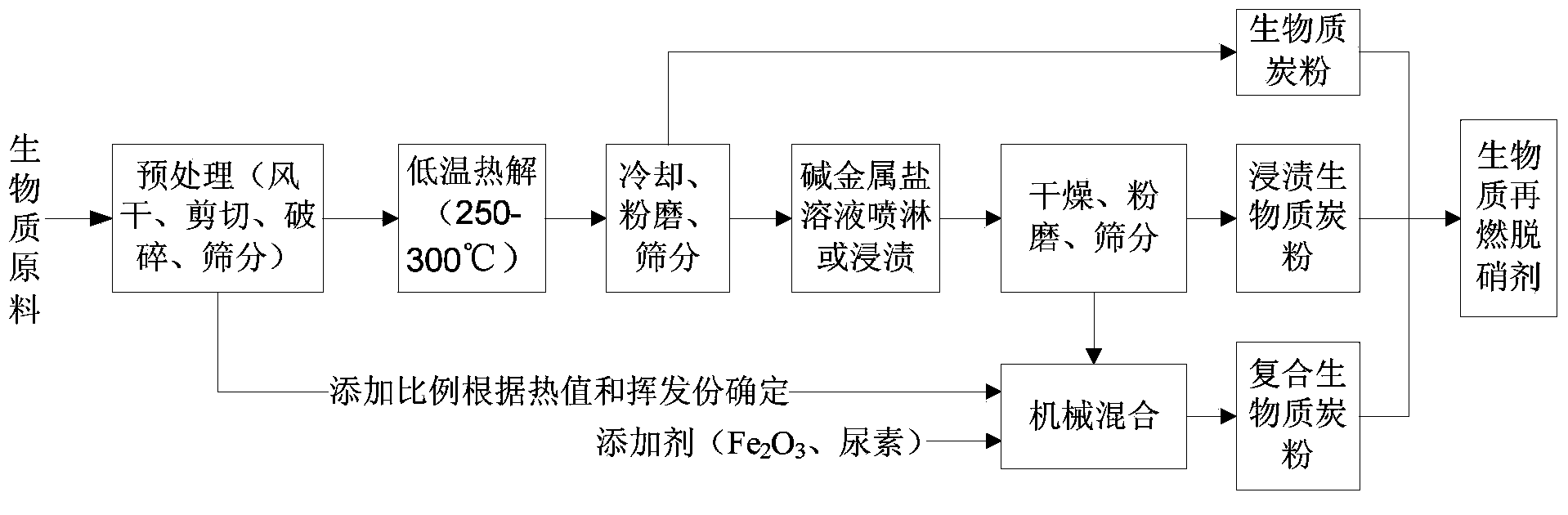

Coal-fired power plant boiler biomass reburning denitration agent and preparation method thereof

InactiveCN103525502AReduce moisture contentHigh calorific valueDispersed particle separationSolid fuelsHigh energyEngineering

The invention discloses a coal-fired power plant boiler biomass reburning denitration agent and a preparation method thereof. Based on an advanced reburning denitration technology principle and with biomass energy utilization and coal fired flue gas nitrogen oxides (NOx) control as backgrounds, the biomass reburning denitration agent prepared from biomass / biomass carbon, alkali metal salts (KCl, NaCl, Na2CO3 and the like) and additives (urea, Fe2O3 and the like) is used for controlling emissions of the coal-fired flue gas NOx. The biomass reburning denitration agent which has low water content, high energy density and easy crushing, and is suitable for storage and long distance transportation is prepared through treating processes of biomass raw material pretreatment (drying, crushing and sieving), low temperature pyrolysis (at the temperature of 200-300 DEG C for 10-30 min and under a nitrogen atmosphere), solution (Na2CO3, NaCl and KCl) spraying or dipping, and additives (urea, Fe2O3) mechanical mixing and the like. The biomass reburning denitration agent has the characteristics of wide raw material sources, simple preparation process, low cost, high denitration efficiency and the like, and is suitable for control of emissions of the nitrogen oxides of flue gas in the fields of coal-fired power plants, waste incineration and the like.

Owner:NANJING NORMAL UNIVERSITY

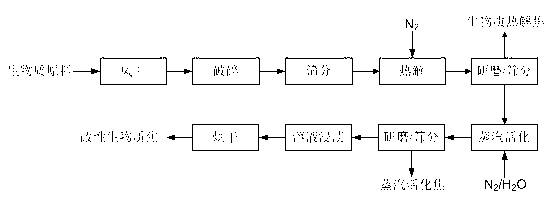

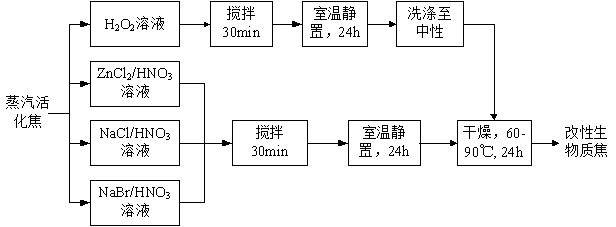

Biomass carbon-based flue gas demercuration adsorbent and preparation method thereof

InactiveCN103252212AControl pollution dischargeRealize the double effect of protectionOther chemical processesDispersed particle separationMercury pollutionNitrogen gas

The invention discloses a biomass carbon-based flue gas demercuration adsorbent and a preparation method thereof. Based on comprehensive utilization of biomass resources and control of flue gas mercury pollutants, the emission of flue gas mercury is controlled by using modified biomass tar as the adsorbent. The biomass carbon-based flue gas demercuration adsorbent with a developed pore structure and abundant surface functional groups is prepared through treating processes of pyrogenic decomposition (at 400-800 DEG C in a nitrogen atmosphere) and steam activation (at an activation temperature of 800 DEG C with an N2-to-H2O mole ratio of 1: 1) of biomass raw material, modified reagent (H2O2, ZnCl2, NaCl or NaBr) solution dipping, and the like; and the biomass carbon-based flue gas demercuration adsorbent has the characteristics of wide adsorbent raw material source, simple preparation process, low cost, high demercuration efficiency and the like, and is suitable for coal-fired power plants and management of flue gas mercury emission in the fields of waste incineration and the like. The carbon-based flue gas demercuration adsorbent is prepared by adopting biomass, so that the emission reduction of mercury pollution can be realized, and the renewable resource of biomass can be utilized efficiently in a large scale; and the biomass carbon-based flue gas demercuration adsorbent has obvious economic benefit, environmental benefit and social benefit.

Owner:NANJING NORMAL UNIVERSITY

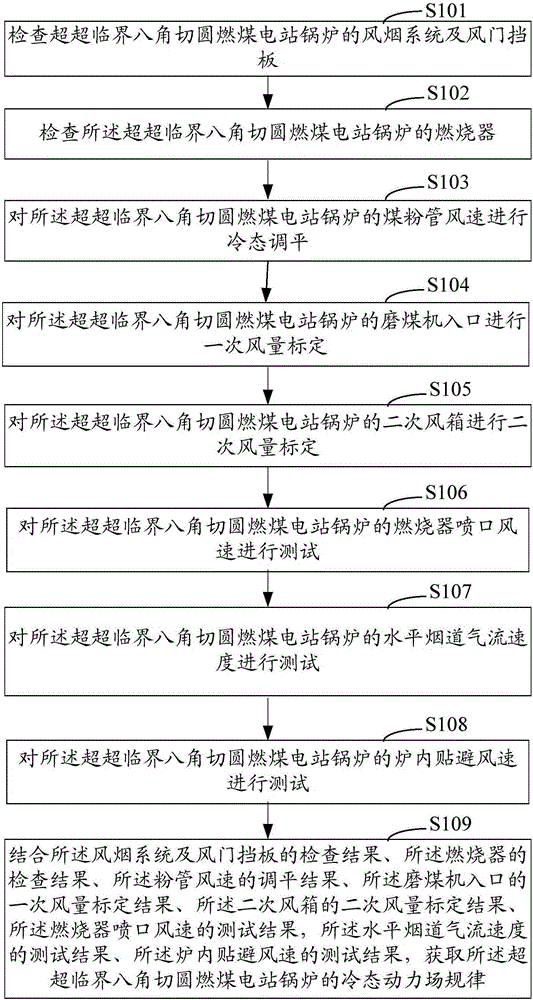

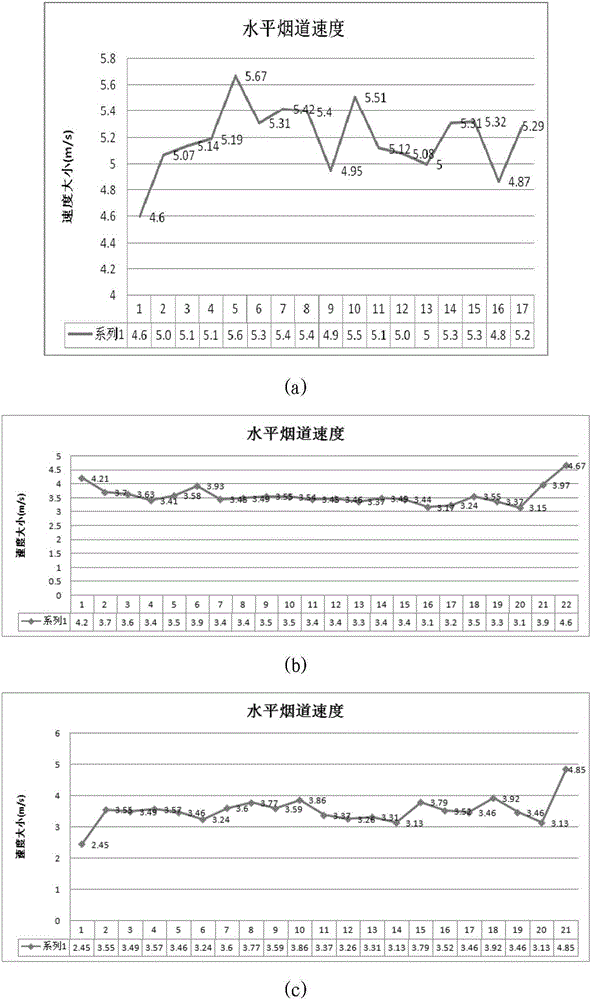

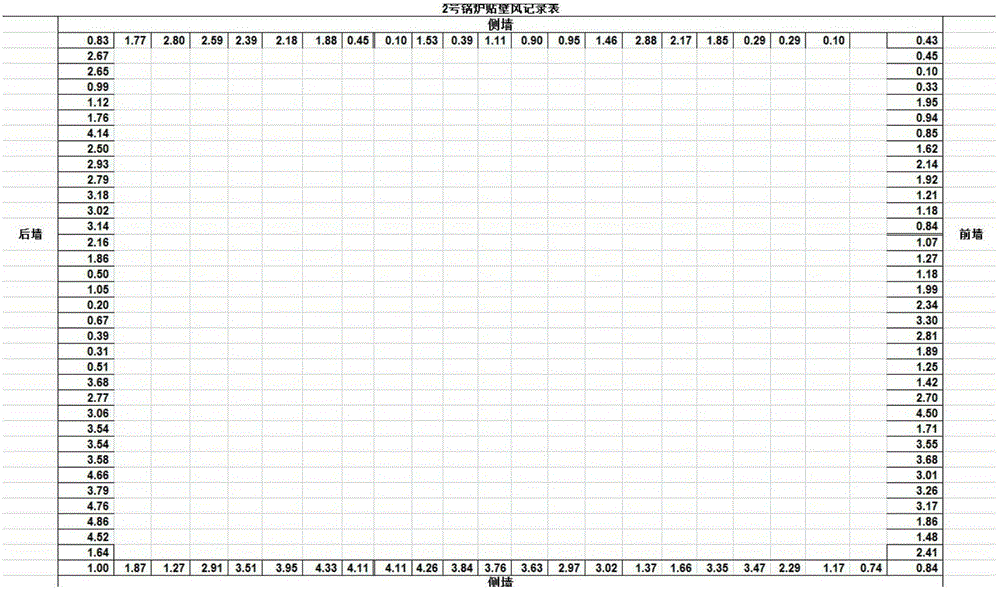

Ultra-supercritical octagonal circle cutting coal-fired power plant boiler cold-state dynamic field test method

The invention relates to an ultra-supercritical octagonal circle cutting coal-fired power plant boiler cold-state dynamic field test method. The method comprises the steps that an air and flue gas system, an air damper and a combustor of an ultra-supercritical octagonal circle cutting coal-fired power plant boiler are checked; cold-state leveling of the air speed of a pulverized coal pipe of the ultra-supercritical octagonal circle cutting coal-fired power plant boiler is performed; primary air flow calibration and secondary air flow calibration are performed on an inlet of a coal mill of the ultra-supercritical octagonal circle cutting coal-fired power plant boiler; the air speed of a nozzle of the combustor and the air flow speed of a horizontal flue of the ultra-supercritical octagonal circle cutting coal-fired power plant boiler are tested, and the attaching and avoiding air speed inside the boiler is tested. On the combination of the results of the steps, the cold-state dynamic field law of the ultra-supercritical octagonal circle cutting coal-fired power plant boiler is obtained. According to the method, references can be provided for cold-state dynamic field tests of other million thermal power generating units of the same kind, the cold-state dynamic field law can be obtained according to the tests for adjusting wrong positions of a dynamic field inside the boiler, and a foundation is laid for unit hot starting and tests.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

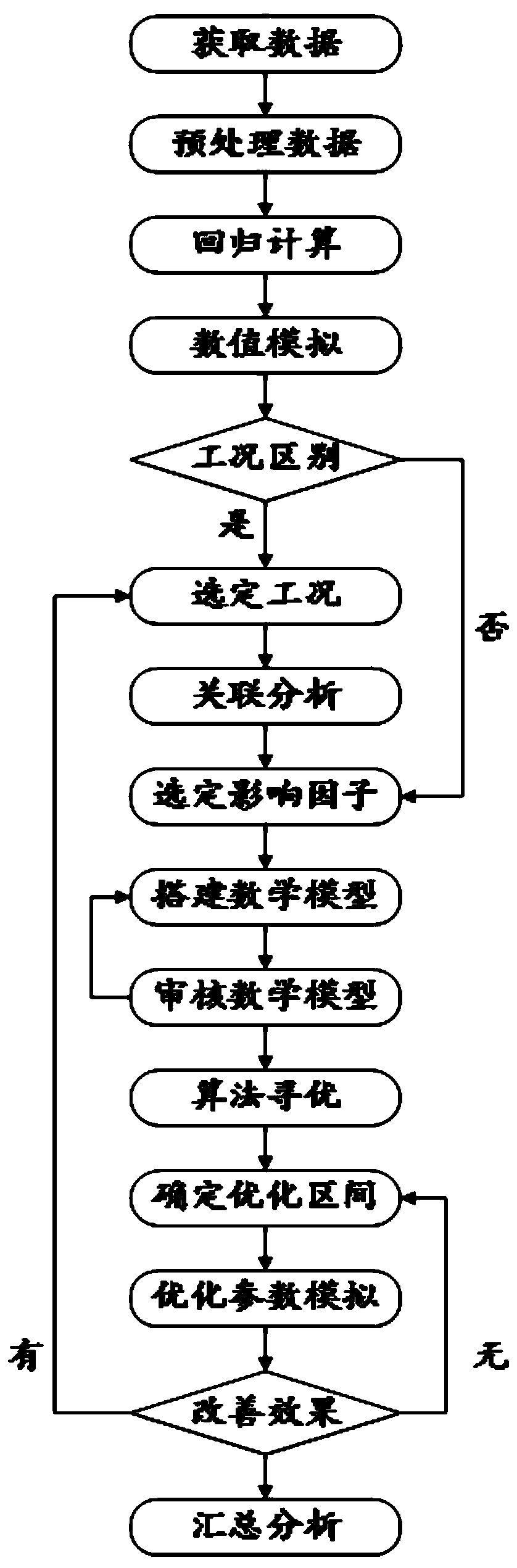

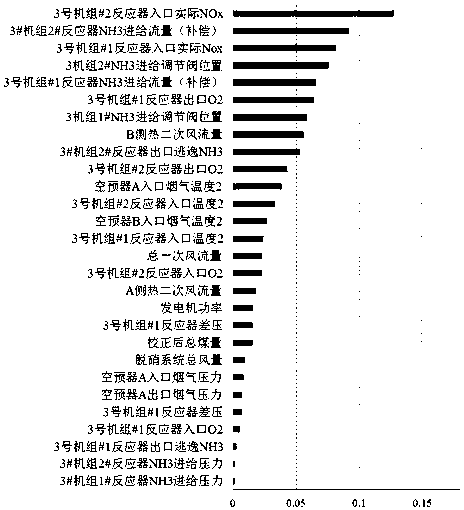

Data operation optimization method based on power plant desulfurization system

ActiveCN110263988ASmall fluctuationReduce removal costsForecastingSystems intergating technologiesRegression analysisLoad following power plant

The invention discloses a data operation optimization method based on power plant desulfurization system, and the method comprises the steps: obtaining the actual operation data of a power plant actual operation system in a certain time period, and carrying out the preprocessing and regression analysis of the actual operation data; dividing different working conditions according to the operation load, and performing numerical simulation to obtain overall flow field, temperature and SO2 component distribution conditions of the desulfurization system under different working conditions; carrying out big data analysis on the actual operation data of the desulfurization system of the coal-fired power plant to obtain an optimal interval of the operation data under the determined working condition; and practicing the big data optimization result in the simulation result to check the accuracy of the optimization result. According to the method, the working conditions are firstly distinguished before the neural network prediction model is established, so that the data size is reduced, the relationship among the energy consumption, the sulfur removal rate output parameters and the influence factors is relatively clear and simple, and the precision can be ensured.

Owner:SOUTHEAST UNIV +1

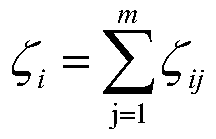

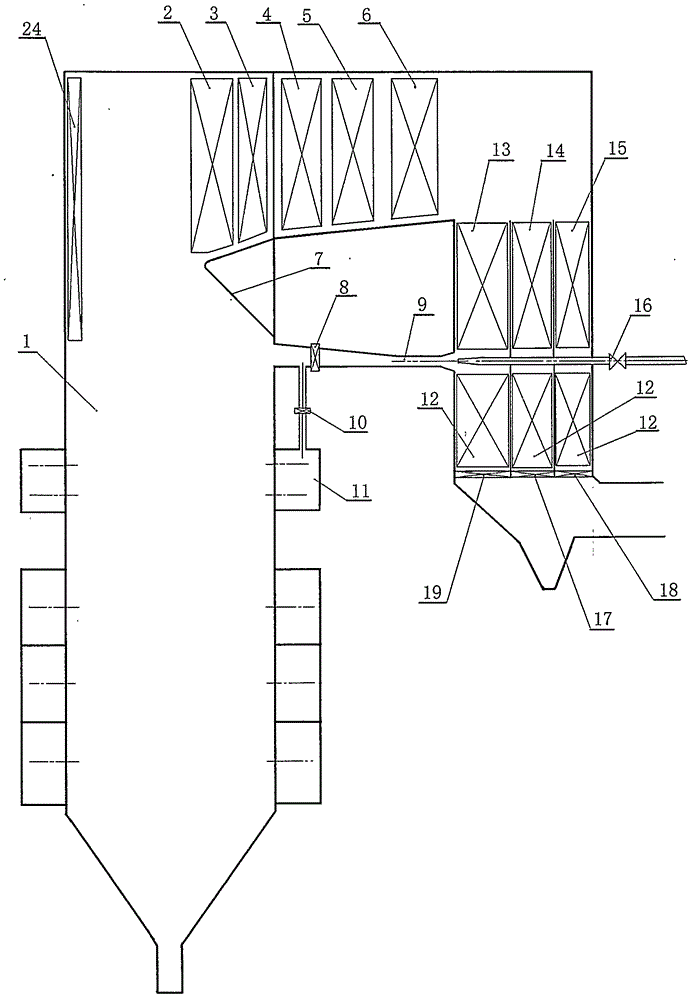

Smoke waste heat deep utilization system of power station boiler for heating supplied water at high pressure

ActiveCN102767821AIncrease output powerImprove efficiencyIncreasing energy efficiencyFeed-water heatersAir preheaterHigh energy

The invention discloses a smoke waste heat deep utilization system of a coal-fired power station boiler for heating supplied water at a high pressure, belonging to the field of energy-saving equipment using waste heat. According to the smoke waste heat deep utilization system, smoke with a temperature about 300-400 DEG C at the tail of the boiler respectively enters a high-temperature rotary type air pre-heater (2), a smoke condensed water heater (3) and a low-temperature rotary type air pre-heater (4), enters a prepositioned air pre-heater (6) after passing through a dust collector (5), and is discharged out of the system until the smoke is cooled to a temperature about 60-100 DEG C; and supplied water at the high pressure in a back-heating system is heated by using the high-temperature smoke, so that a higher energy-saving effect can be obtained. Meanwhile, the water at an inlet of the smoke condensed water heater (3) can be flexibly adjusted through a pipeline design, so as to be extracted from inlets of different high-pressure heat regenerators. Therefore, when the entire smoke waste heat utilization system at the tail of the power station boiler is in various working conditions, an air side and a water feeding side are at an optimal operation working condition.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

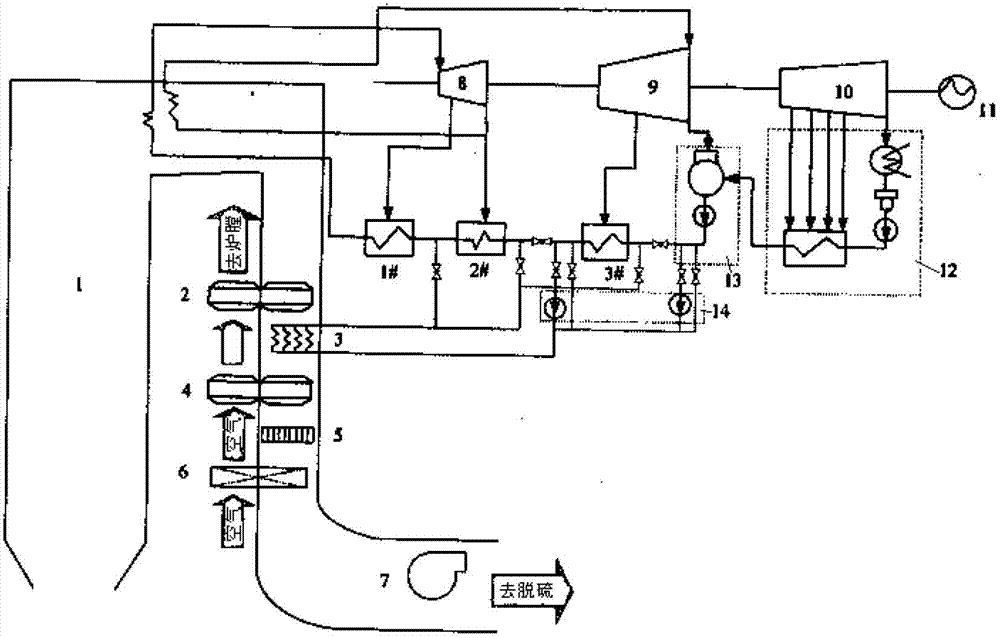

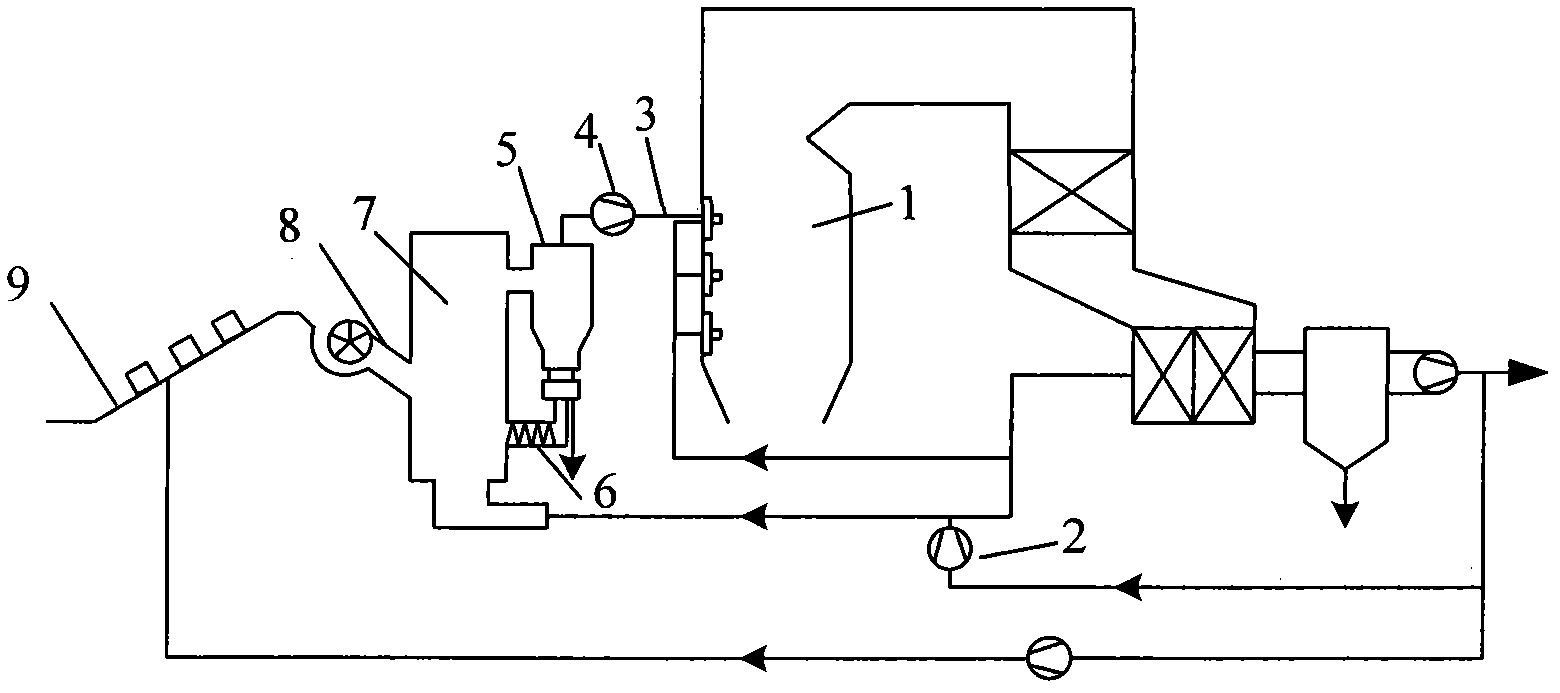

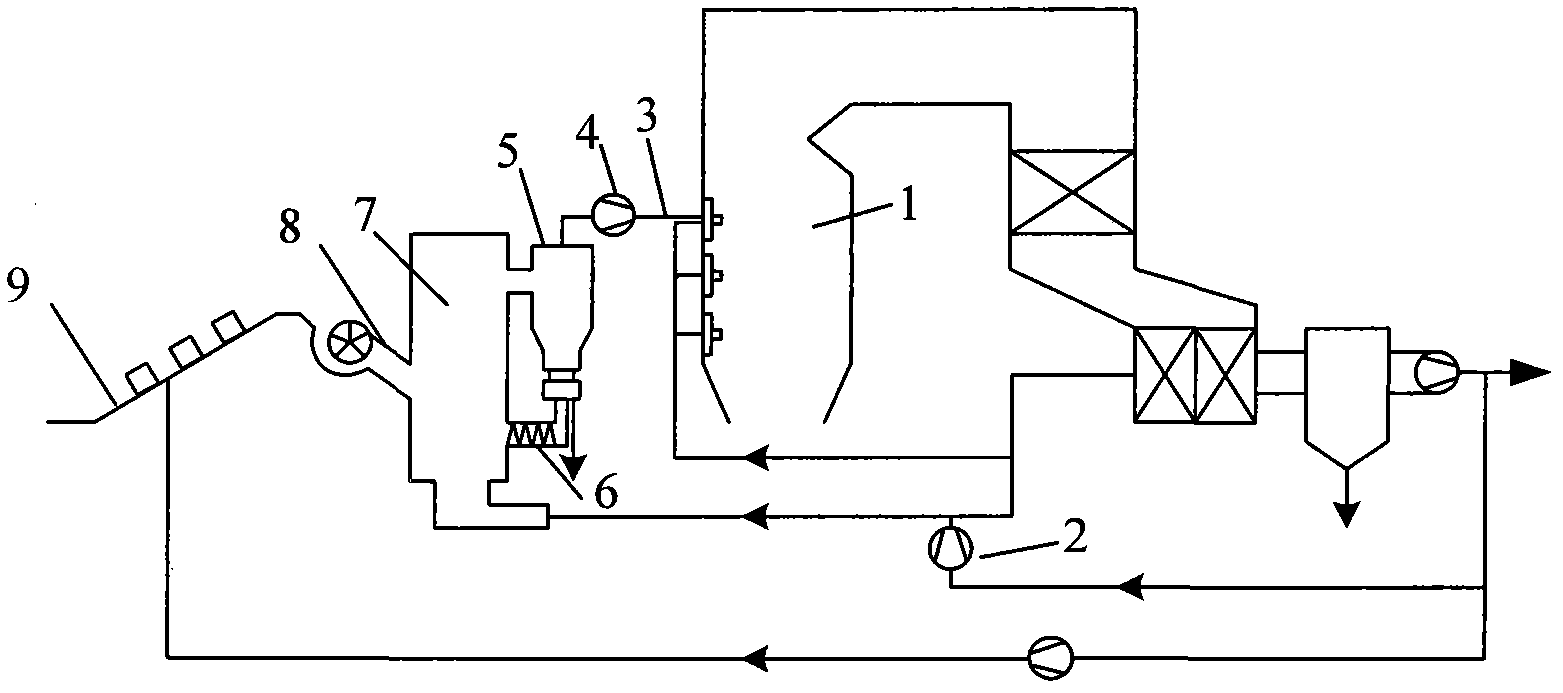

Low-cost coal-fired flue gas various pollutant ultralow emission system and low-cost coal-fired flue gas various pollutant ultralow emission method

InactiveCN104759192AReduce consumptionSmall and portableCombustion using gaseous and pulverulent fuelCombination devicesControl systemMulti pollutant

The invention relates to a low-cost coal-fired flue gas various pollutant ultralow emission system and a low-cost coal-fired flue gas various pollutant ultralow emission method. The system mainly includes a nitrogen oxide gradient control system, a semidry flue gas purifying system and a wet-type static deep purification system. In the invention, by means of the nitrogen oxide gradient control system, the emitted NOx is less than 50 mg / Nm3 in concentration; by means of the semidry flue gas purifying system, the removal efficiency of SO2 can be reach not less than 90%, the removal efficiency of SO3 can be reach not less than 90%, the removal efficiency of acidic gas can be reach not less than 95% and the dust is less than 30 mg / Nm3; and by means of the wet-type static deep purification system, the PM is less than 5 mg / Nm3 and the removal efficiency of SO2 can be reach not less than 50%. The dust-containing waste water in the wet-type static deep purification system is used for slaking limestone and moistening and activating an absorbent in the semidry flue gas purifying system, so that near-zero emission of the waste water in the system is achieved and finally it is achieved that the pollutant emission concentrations of PM is less than 5 mg / Nm3, the emission concentration of SO2 is less than 35 mg / Nm3 and the emission concentration of SO2 is less than 50 mg / Nm3 in a coal-fired power plant, thereby achieving an ultralow emission requirement of the main pollutant under a condition of the near-zero emission of the waste water.

Owner:ZHEJIANG UNIV

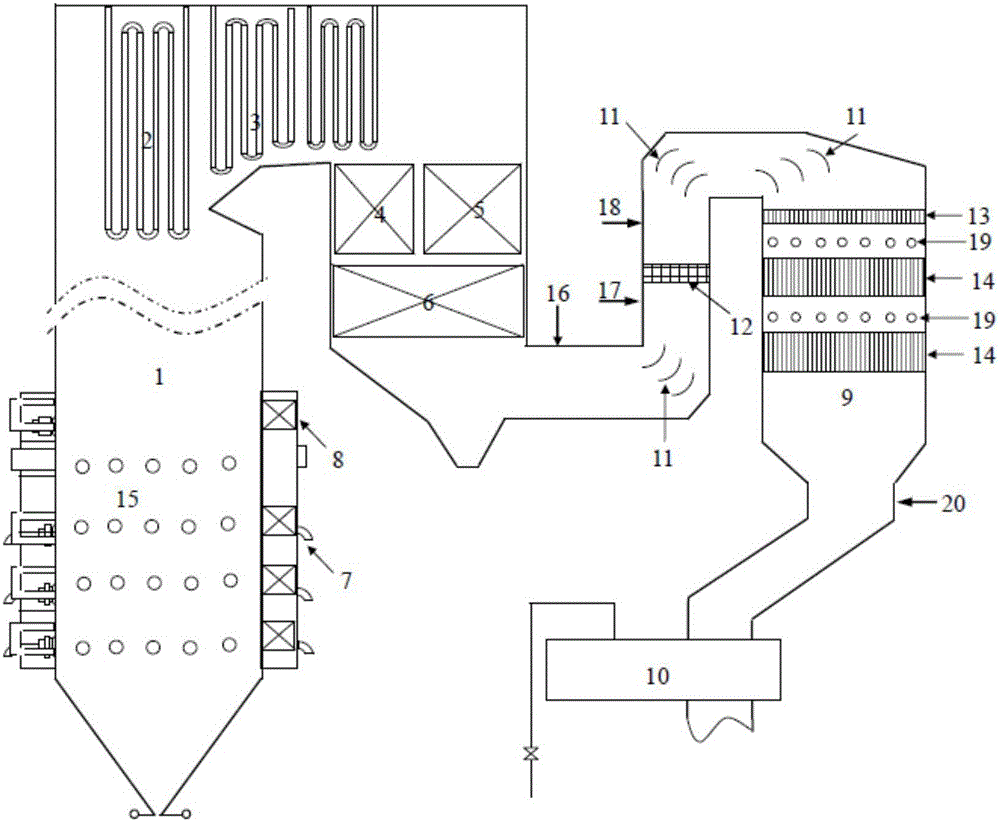

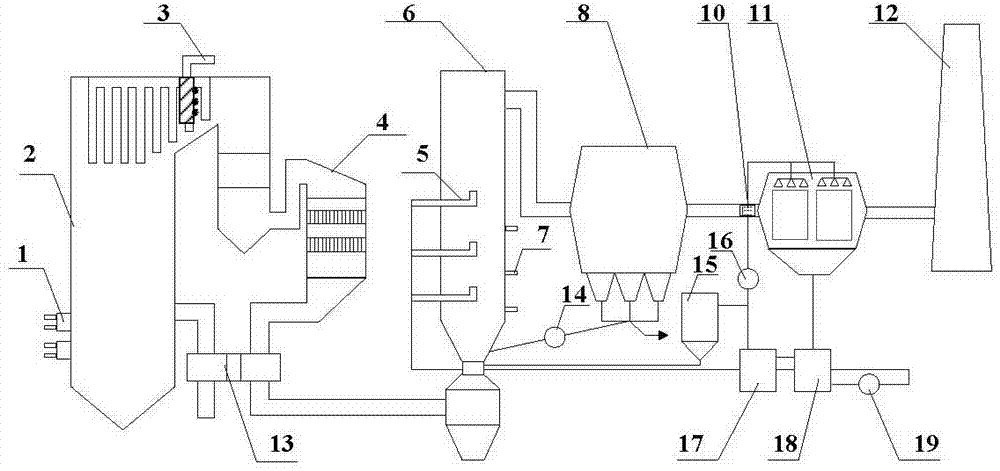

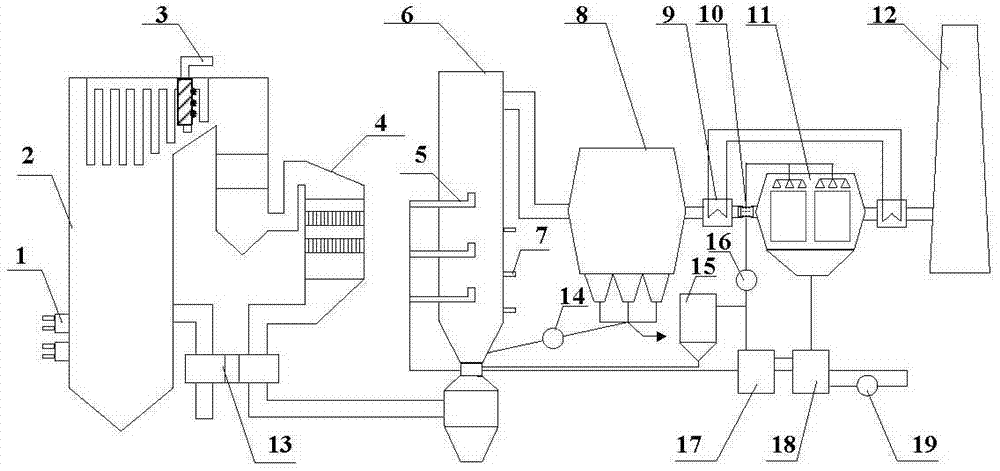

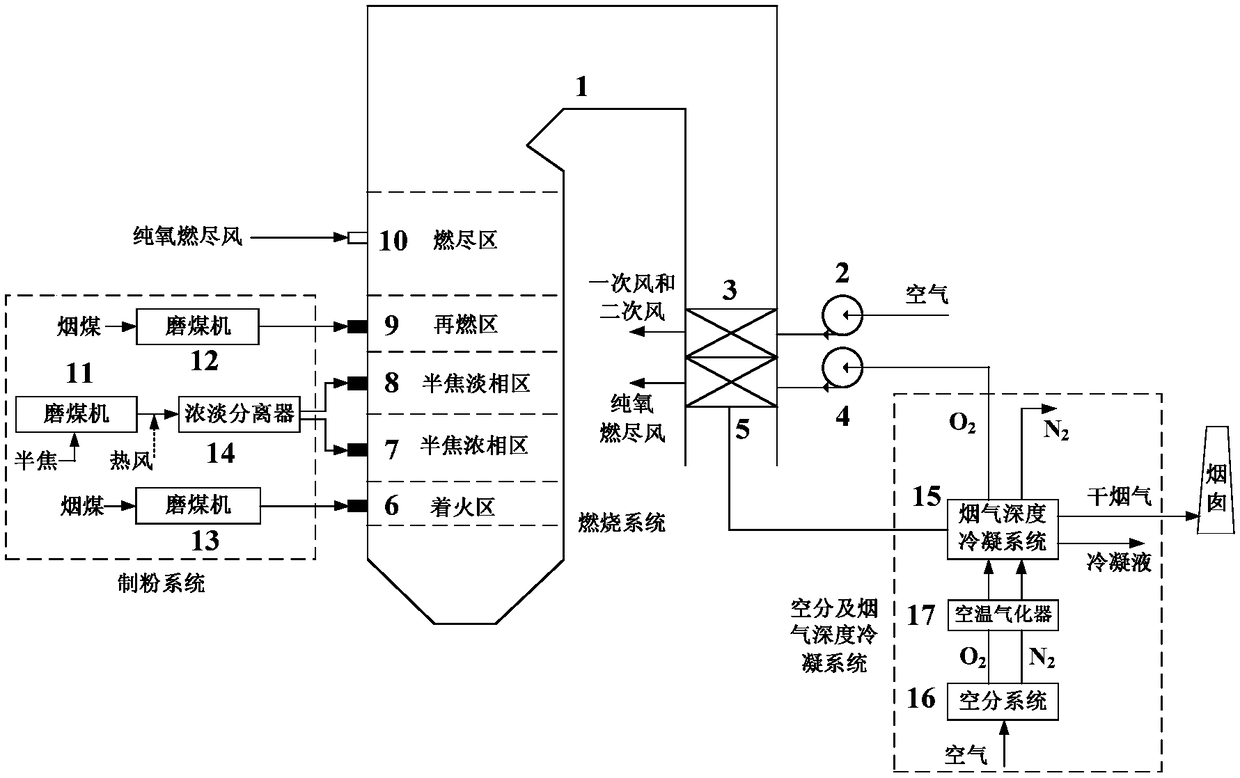

System and blending combustion method for coal-fired power station boiler for large-proportion blending combustion of semi-coke

ActiveCN108151051APromote fireImprove combustion characteristicsLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationFlue gasEngineering

The invention relates to a system and a blending combustion method for a coal-fired power station boiler for large-proportion blending combustion of semi-coke. According to the system and the blendingcombustion method, the problems that the low-volatile semi-coke fuel is difficult to fire, poor in burnout performance and high in NOx emission during combustion are solved; optimization of a pulverizing system, dense-dilute regional combustion of semi-coke fuel, in-furnace layered blending combustion of the semi-coke and bituminous coal, pure oxygen over fire air arrangement and cold energy comprehensive utilization are comprehensively considered; a four-corner tangential combustion mode is adopted, a boiler hearth five-zone combustion environment is built, and a power station boiler systemfor large-proportion blending combustion of the semi-coke is developed, so that the proportion of blending combustion of the semi-coke is larger than or equal to 45%; low NOx emission of an outlet ofa hearth is realized while high-efficiency combustion of the semi-coke is realized; and low-temperature O2 and low-temperature N2 which are close to 0 DEG C and are obtained by air separation and obtained through an air-temperature type gasifier are used for realizing deep condensation of desulfurized clean flue gas, so that water in the clean flue gas is reduced to the maximum degree, corrosion of a chimney is reduced, white smoke is also eliminated, and visual pollution around a power station is reduced.

Owner:XI AN JIAOTONG UNIV

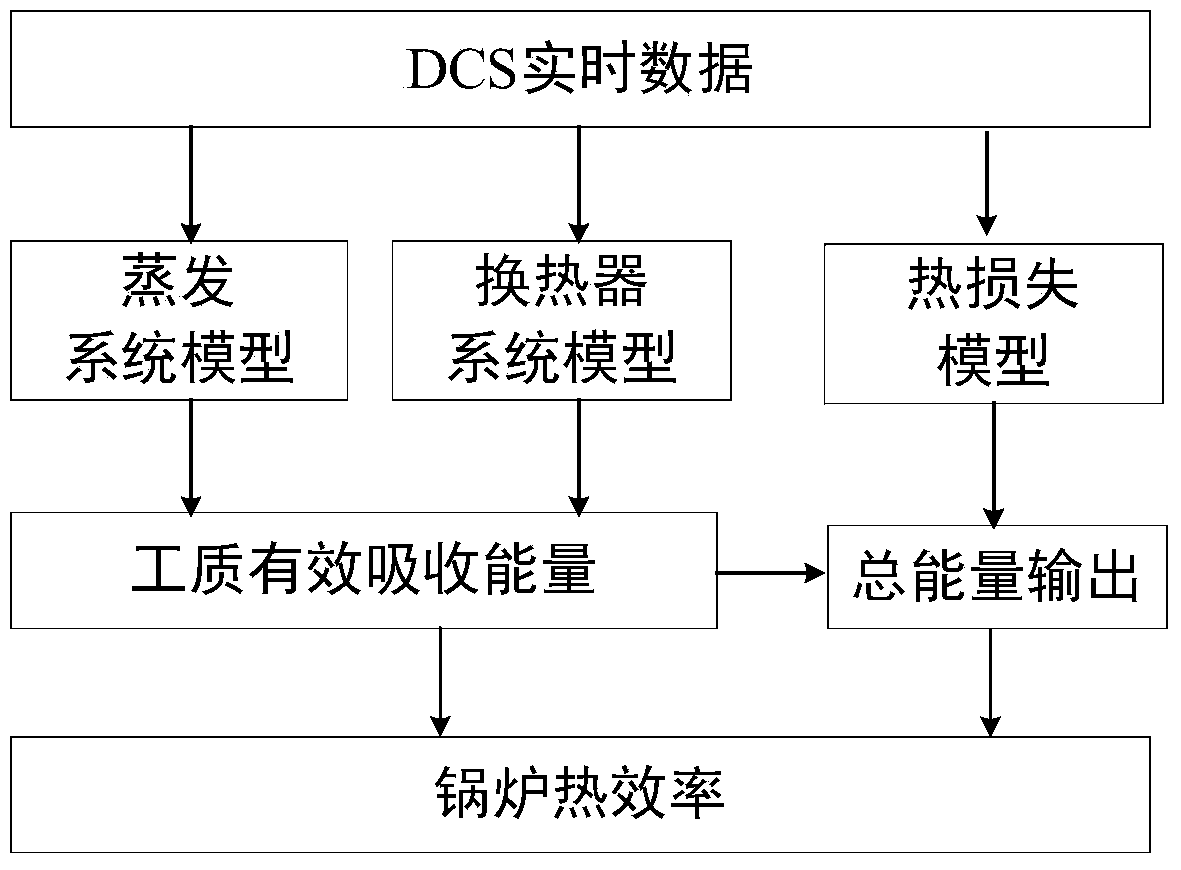

Method for measuring boiler thermal efficiency of coal fired power plant in real time

InactiveCN103778334AStable productionRealize online measurementBoiler indication operationsSpecial data processing applicationsVolumetric Mass DensityEngineering

The invention provides a method for measuring boiler thermal efficiency of a coal fired power plant in real time. The method comprises the following steps: step 1, obtaining boiler structure parameters according to the boiler operation design discipline, and reading a real-time value of an operation working condition measuring point at a set moment from the real-time database of a DCS (Distributed Control System); step 2, calculating the specific enthalpy and density of a working medium and the specific heat and density of fume according to a working medium physical property parameter library and a fume physical property parameter library; step 3, respectively determining the energy output of each part on the boiler side and the total energy output at the set moment according to an vaporization system model, a heat exchanger system (including a superheater system and a reheater system) model and a heat loss model on the boiler side; Step 4, determining the boiler thermal efficiency. The method can be used for measuring the boiler thermal efficiency in an online manner and further providing a technical support for plant-level load scheduling.

Owner:SHANGHAI JIAO TONG UNIV +1

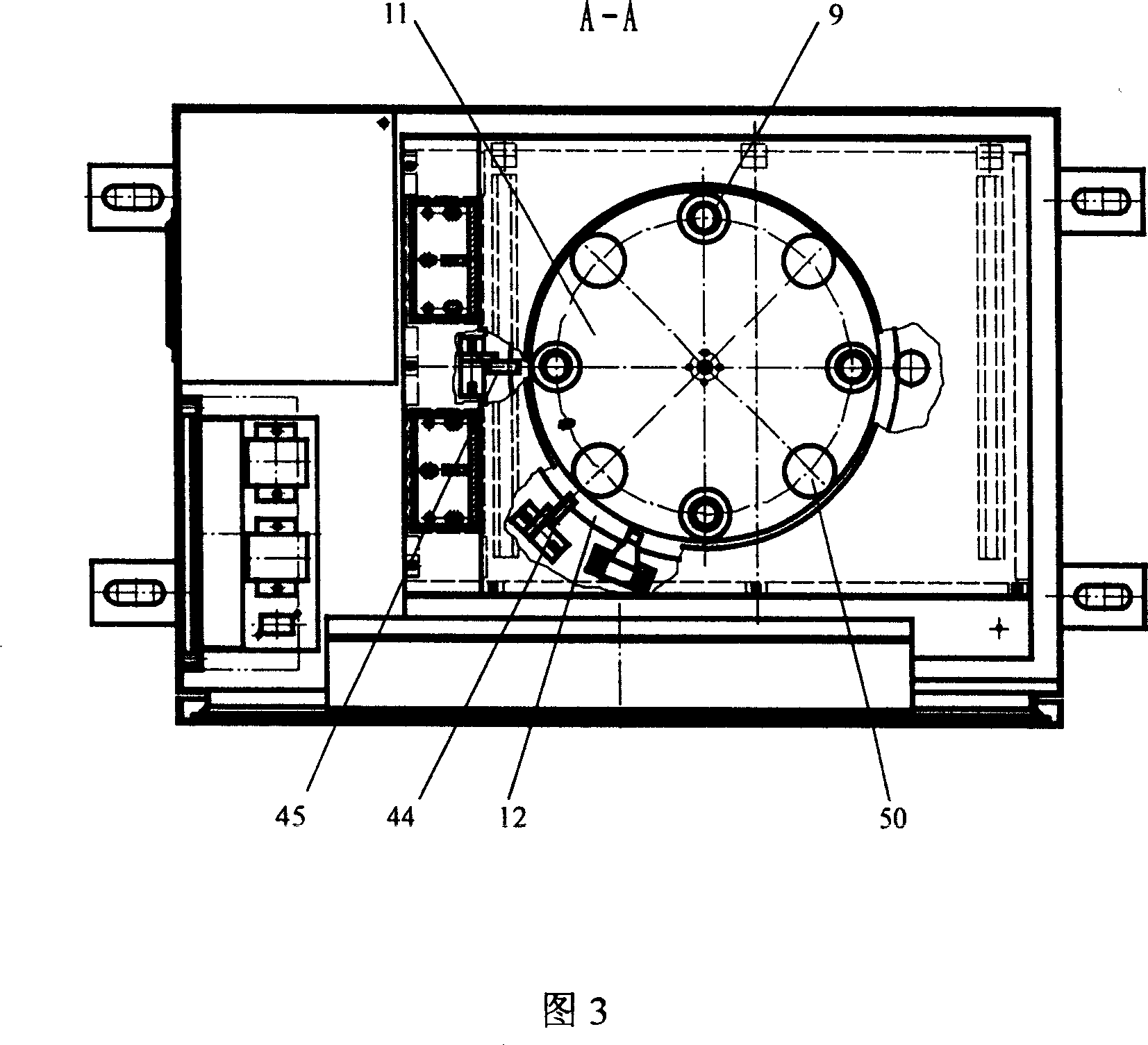

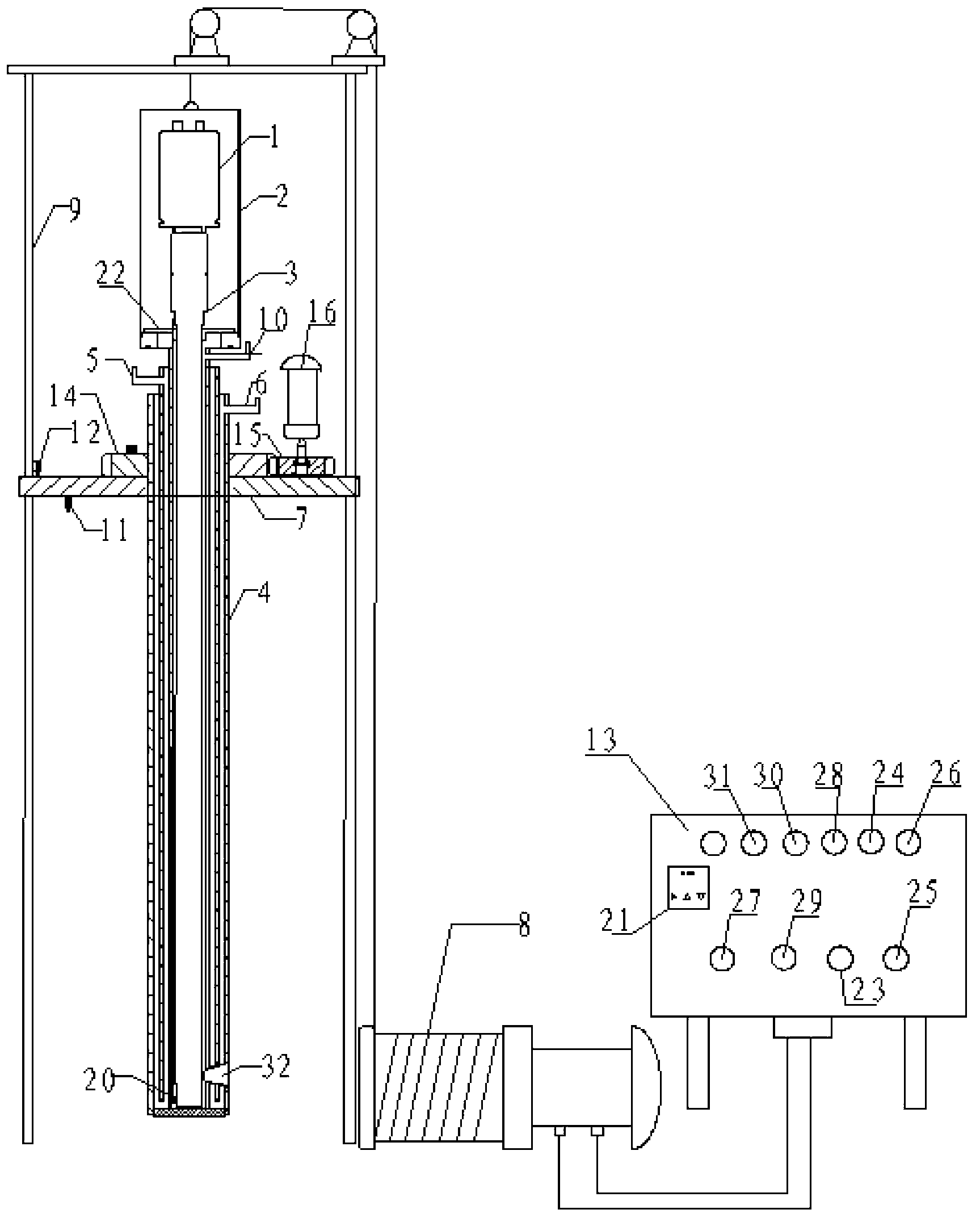

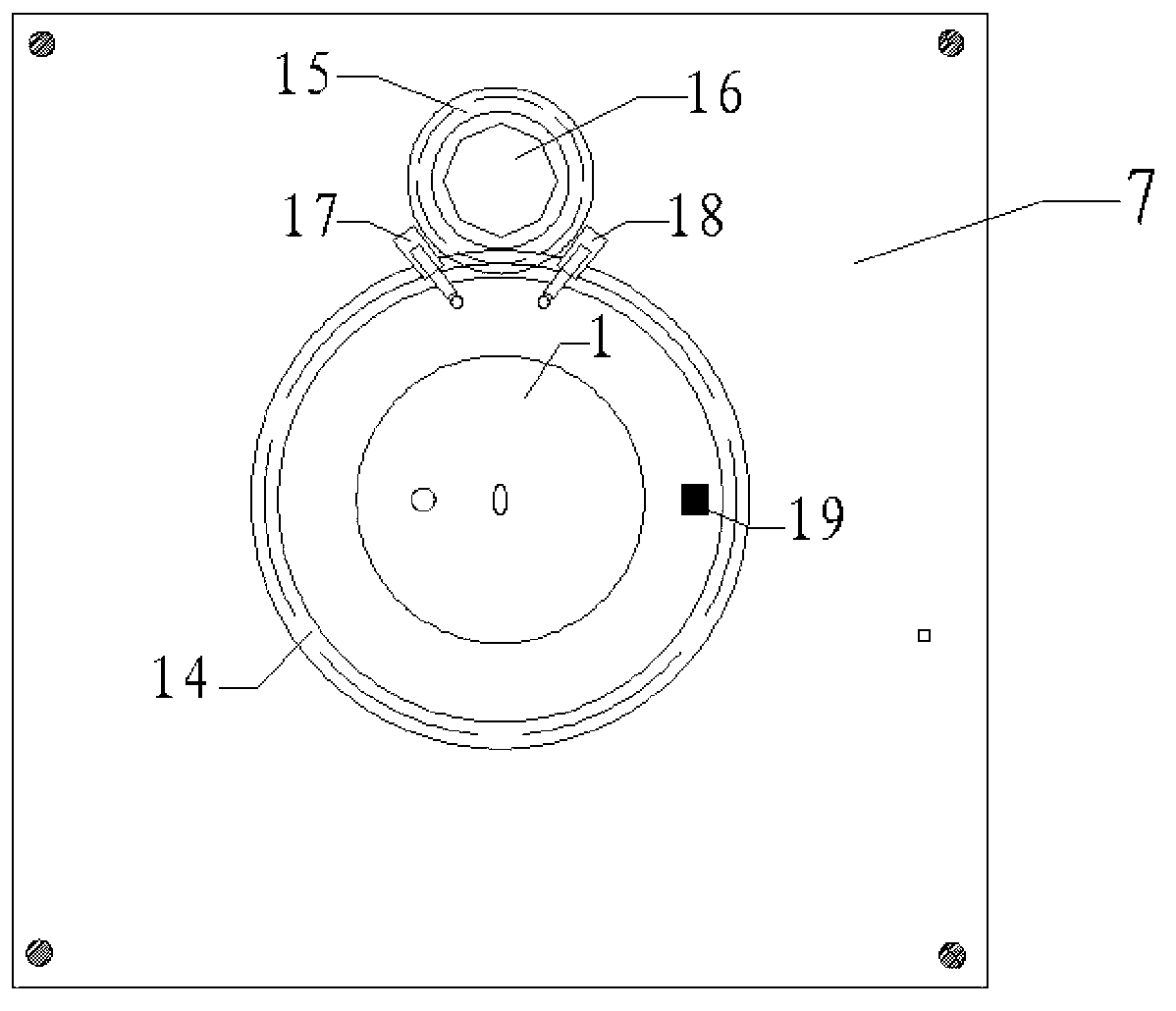

Automatic rotational lifting monitoring system for fouling and slagging of boiler furnace of coal-fired power plant

ActiveCN103024357AEasy to useFlexible liftingTelevision system detailsColor television detailsDisplay deviceEngineering

The invention discloses an automatic rotational lifting monitoring system for fouling and slagging of a boiler furnace of a coal-fired power plant. The system comprises a fixing support, a lifting platform, an imaging system, a cooling device, a driving mechanism and a displayer, wherein the lifting platform is matched with the fixing support in a sliding mode, the imaging system is installed on the lifting platform and comprises a charge coupled device (CCD) camera and an optical lens, the cooling device is fixedly sleeved outside the optical lens, an observation port which is matched with the optical lens is arranged at the bottom of the cooling device, the driving mechanism is used for driving the imaging system to rotate, and the displayer is connected with the imaging system. The system is convenient to use, flexible to lift and rotate, safe, reliable, high in economical efficiency and capable of integrating visualization, rotating and lifting functions and achieving the effect that the condition of the heating surface of the furnace can be monitored in a multi-angle and all-round mode through a single camera.

Owner:ZHEJIANG UNIV

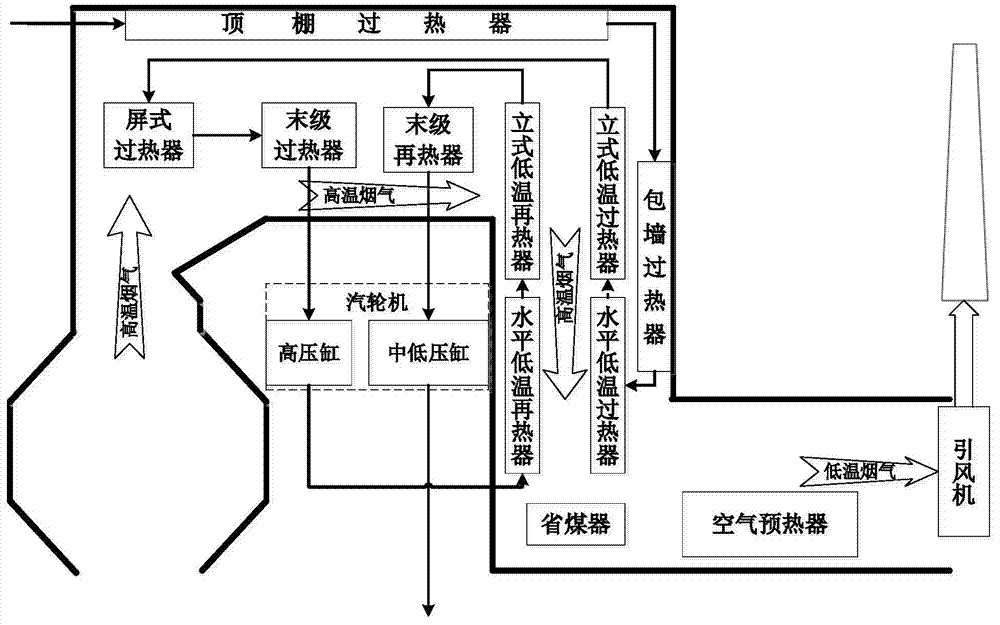

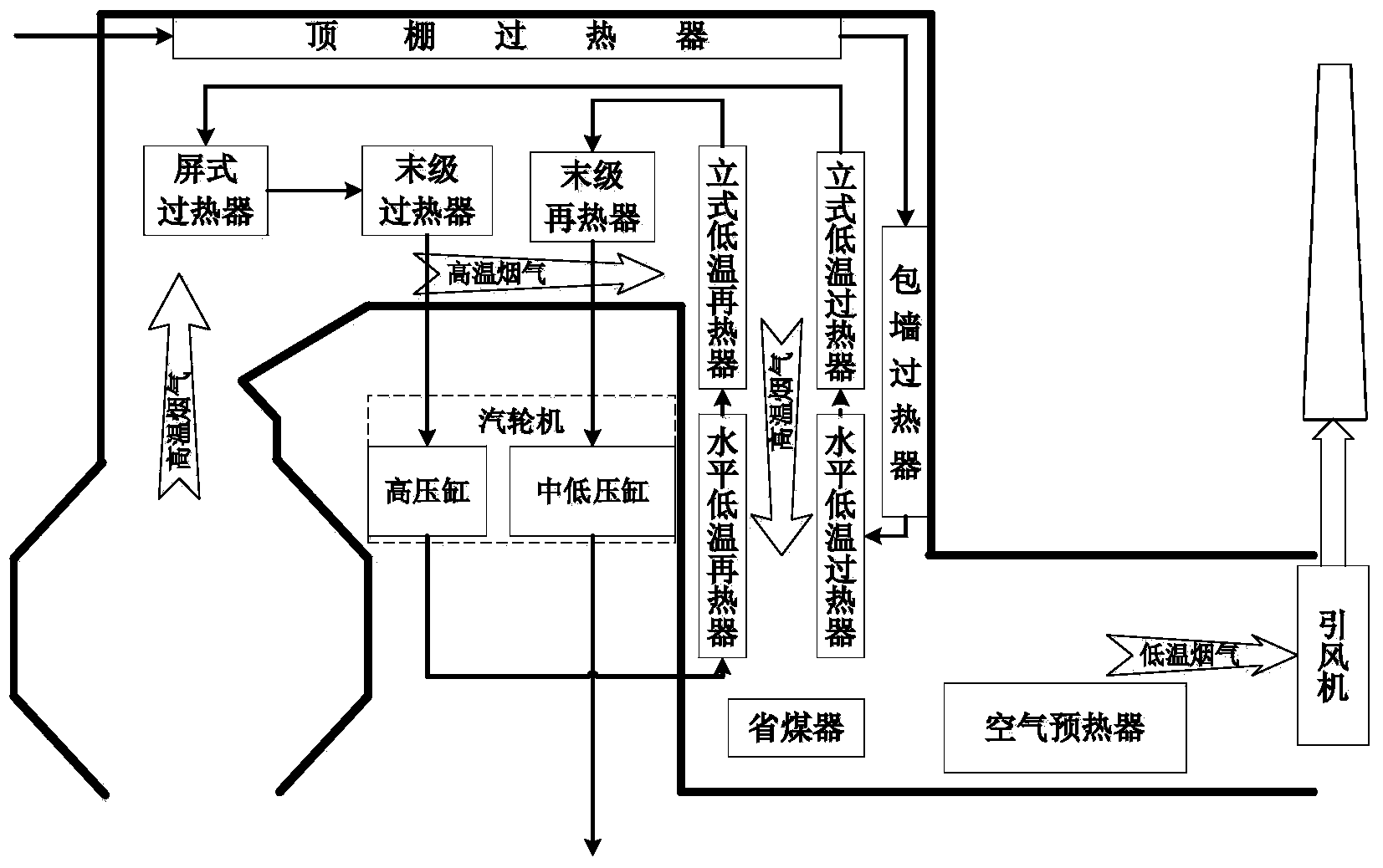

720-DEG C efficient ultra-supercritical secondary reheating power plant boiler

ActiveCN104676573ATake full advantage of high temperature creep resistanceClear main steam/primary reheat steam/secondary reheat steam temperature adjustment logicSuperheating controlSteam boilersLow loadEngineering

The invention provides a 720-DEG C efficient ultra-supercritical secondary reheating power plant boiler and relates to a high-efficiency, safe, low-emission and low-manufacturing-cost 720-DEG C efficient ultra-supercritical secondary reheating power plant boiler which is used in a coal fired power station and matched with a parameter-optimized 720-DEG C efficient ultra-supercritical secondary reheating turboset. The parameters of a main steam inlet at a boiler side are optimized as 590 DEG C and 42MPa; primary reheating steam parameters are optimized as 723 DEG C and 10.5MPa; secondary reheating steam parameters are optimized as 603 DEG C and 2.1MPa; a tail smoke channel is divided into a front smoke channel, a middle smoke channel and a rear smoke channel by separation walls; hot primary air regulation baffles of an ejector are positioned in the boiler and are opened when in low load; by virtue of controlling the opening and use quantity of the hot primary air regulation baffles of the ejector, primary reheating steam temperature is maintained at a rated value within a BMCR (Boiler Maximum Continuous Rating) interval of 40%-100%; by virtue of changing the use sequence and use quantity of tempering air-smoke ejectors along the furnace width direction, the thermal deviation of a high-temperature surface along the furnace width direction can be compensated and reduced.

Owner:章礼道

Method for generating power by gasifying integrated straws in supercritical coal-fired generator set

InactiveCN102010757AEasy to storeSmall footprintInternal combustion piston enginesEnergy inputBiomass gasifierBubbling fluidized bed

The invention discloses a method for generating power by gasifying integrated straws in a supercritical coal-fired generator set. The method comprises the following steps of: packing and forming biomass straws serving as a gasification raw material of a gasifier of a bubbling fluidized bed, wherein primary wind-heat air surplus in a power station and tail gas fume of a boiler are used as gasifying agents. A biomass gasifier is effectively integrated by simply modifying the conventional supercritical unit to make biomass gasified, combusted and generate power, so that the defect that the biomass is directly blended and combusted is effectively overcome, the influence of biomass ash on fly ash is avoided, and the problem that the conventional auger feeding equipment is easy to damage is solved; therefore, biomass energy can be efficiently utilized and pollutant emission of coal-fired power stations is further reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

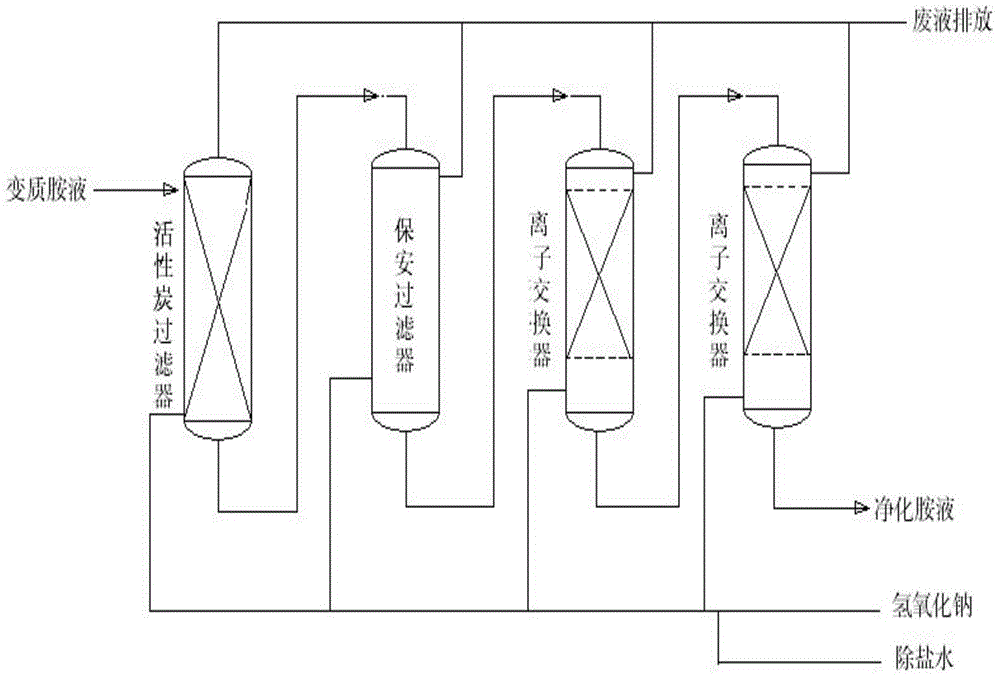

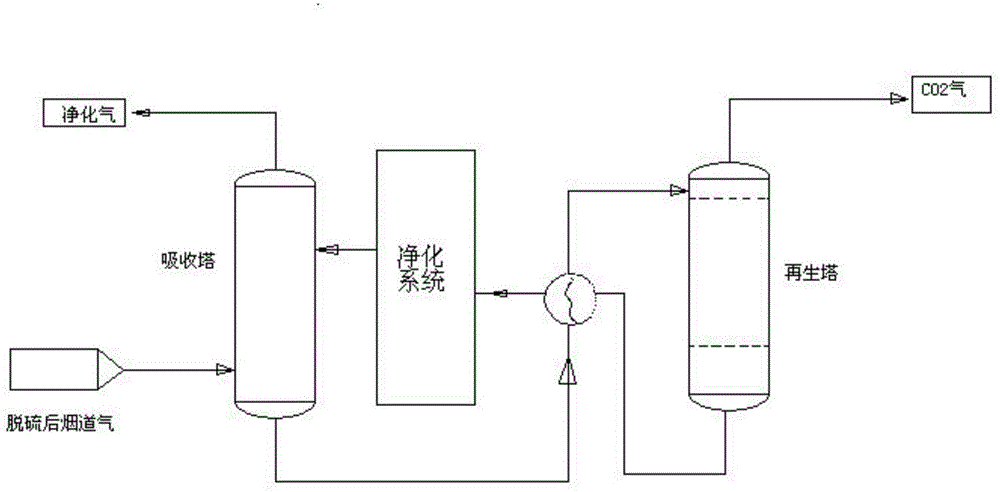

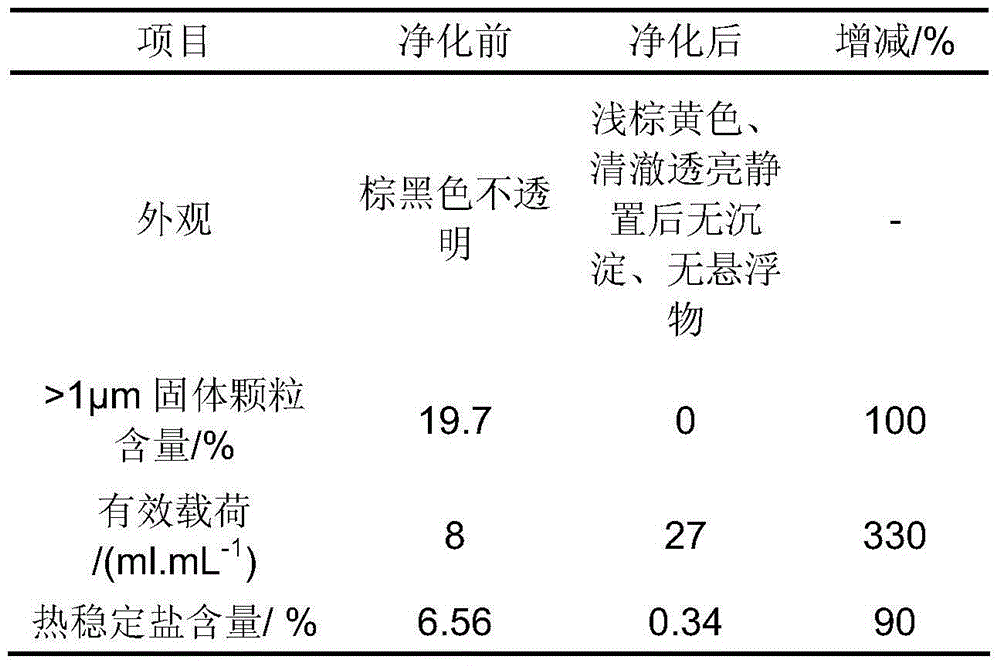

System and method for purifying and recycling amine liquid of smoke CO2 trapping system for coal-fired power plant

InactiveCN103979716AEfficient removalExtended service lifeDispersed particle separationMultistage water/sewage treatmentHybrid typeTrapping

The invention discloses a system and method for purifying and recycling amine liquid of a smoke CO2 trapping system for a coal-fired power plant. The system comprises an activated carbon filter and a security filter, which are communicated and used for removing solid particles and corrosion products, and a plurality of ion exchangers which are communicated with the security filter and used for removing thermal stable salts. The method comprises the following steps: with activated carbon and macroporous adsorption-strong base mixed anion exchange resin in combination, removing thermal stable salts by adopting strong base mixed anion exchange resin, and removing chromaticity color and a corrosion product ferric salt by adopting fine filtration of activated carbon and macroporous resin. Thus, the thermal stable salts can be efficiently removed, and meanwhile, the chromaticity color of a degenerative organic amine solution and corrosion products such as the ferric salt are removed; the efficiency of absorbing carbon dioxide by alcohol amine in the smoke trapping system for the coal-fired power plant is improved, and corrosion to equipment of the trapping system caused by the degenerative amine solution is relieved; meanwhile, energy consumption of the system is reduced, and the damage to the environment caused by emission of high-pollution solutions is avoided.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Dust-removal mercury-removal filter bag for bag-type dust remover and preparation method of filter bag

The invention discloses a dust-removal mercury-removal filter bag for a bag-type dust remover. The dust-removal mercury-removal filter bag is bag which is loaded with a mercury-removal catalyst and made of high-temperature filtration fiber; and the mercury-removal catalyst is a mixture of manganese oxide and cobalt oxide. The invention further discloses a preparation method of the dust-removal mercury-removal filter bag; the filter bag is loaded with the mercury-removal catalyst and applied to the bag-type dust collector; the catalyst can be used for oxidizing elemental mercury in coal-fired flue gas into bivalent mercury (Hg2+), so that absorption or adsorption of a flue gas pollutant purifying device is facilitated. The dust-removal mercury-removal filter bag is applied to controlling mercury emission of a coal-fired power plant, so that adsorbent is substituted by catalytic oxidation; on the basis of keeping the smoke dust removal effect, the removal efficiency of the elemental mercury is bigger than 30%, so that the flue gas mercy removal effect of the coal-fired power plant can be satisfied.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

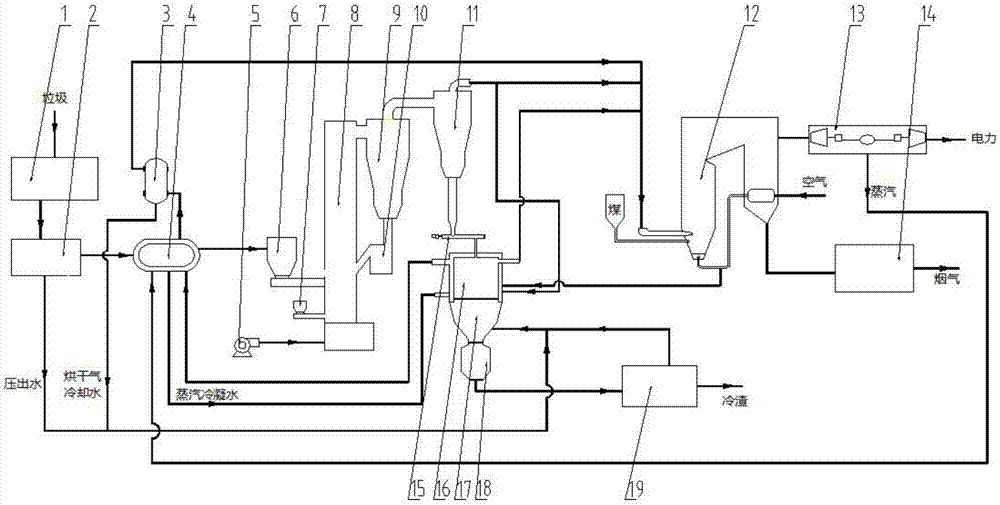

Garbage gasification coupling coal-fired power plant power generating apparatus and power generating process

PendingCN107384484AEnvironmental protectionImprove power generation efficiencyGasification processes detailsCombined combustion mitigationNuclear engineeringSmall footprint

The invention discloses a garbage gasification coupling coal-fired power plant power generating apparatus and power generating process. The power generating apparatus comprises a garbage primary treatment unit, a garbage pyrolysis gasification unit, a garbage flying ash melting unit and a coal-fired power plant power generating unit. The power generating process comprises the following steps: pyrolysing and gasifying garbage by utilizing a circulating fluidized bed gasification furnace to generate high-temperature fuel gas, sending the high-temperature fuel gas into a coal-fired boiler, burning and coupling the high-temperature fuel gas to generate power, melting the garbage flying ash in a melting chamber, chilling, and using as a construction material or directly burying. The fuel gas obtained by pyrolysing and gasifying the garbage and high-temperature smoke generated by the molten slag are coupled with the coal-fired power station to generate the power, and the power generating efficiency is high; by adding dechloridation co-solvent in a gasification furnace, the emission amount of dioxin is far less than the international standard; and the garbage flying ash of the invention is molten and then chilled to form glassy slag which can be used as the construction material or can be directly buried, so that the floor occupation area is small, no heavy metal is leached, and safety and environmental protection can be realized.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

Power generation system of solar aided coal-fired power plant

A power generation system of a solar aided coal-fired power plant comprises a coal-fired power generation thermodynamic system and a solar heat collection and steam generation system, wherein the solar heat collection and steam generation system comprises a solar receiver which is used for absorbing solar energy, the coal-fired power generation thermodynamic system comprises a boiler, a turbine, a power generator and a condenser, the turbine at least comprises two steam inlets such as a primary steam inlet and a secondary steam inlet, superheated steam produced after the solar heat collection and steam generation system absorbs solar heat can be connected with the primary steam inlet of the turbine through a steam pipeline selectively, and the turbine is driven by the superheated steam and superheated steam produced by the boiler together and power is generated. The heat produced by the solar heat collection system is directly used for driving the turbine, so that the temperature of actual utilization of the solar energy is improved, and the conversion efficiency of solar aided power generation is improved.

Owner:浙江和际投资管理有限公司

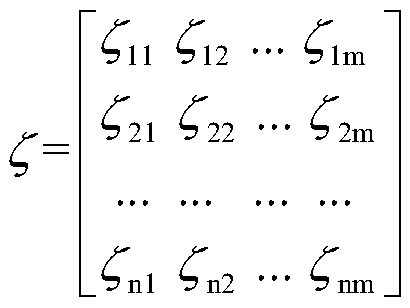

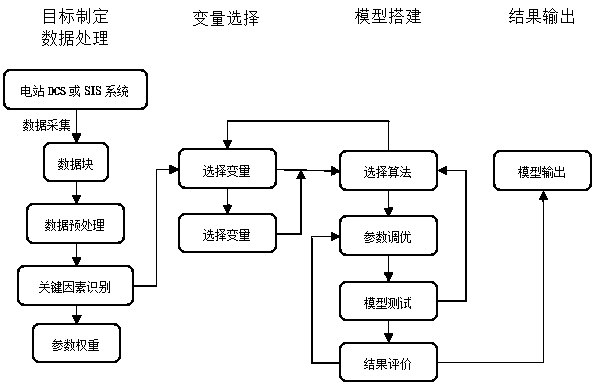

Environment-friendly equipment performance prediction method based on coal-fired power plant operating data

InactiveCN110716512AImprove accuracyEfficient data preprocessing improves accuracyProgramme total factory controlRegression analysisQuality data

The invention discloses an environment-friendly equipment performance prediction method based on coal-fired power plant operating data. According to the method, the operating data of unit environment-friendly equipment is collected, the data is preprocessed, noise interference and abnormal data are removed, and high-quality data is obtained; then, key factor recognition is performed on all collected state parameters of the environment-friendly equipment, and the state parameters which influence environment-friendly equipment performance and have large weights are selected to serve as input ofan environment-friendly equipment performance model; based on this, a data model for environment-friendly equipment performance prediction is set up depending on regression analysis and is trained; and data model evaluation indexes are selected to determine the effectiveness and accuracy of the data model. Through the method, the prediction model has high precision and high self-adaptability; andbased on the unit actual operating data and by aid of an efficient and intelligent data algorithm, the environment-friendly equipment performance of a coal-fired power plant can be predicted scientifically, efficiently and accurately, and an important technical foundation is laid for energy-saving optimization and fault diagnosis subject research and application of the environment-friendly equipment subsequently.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

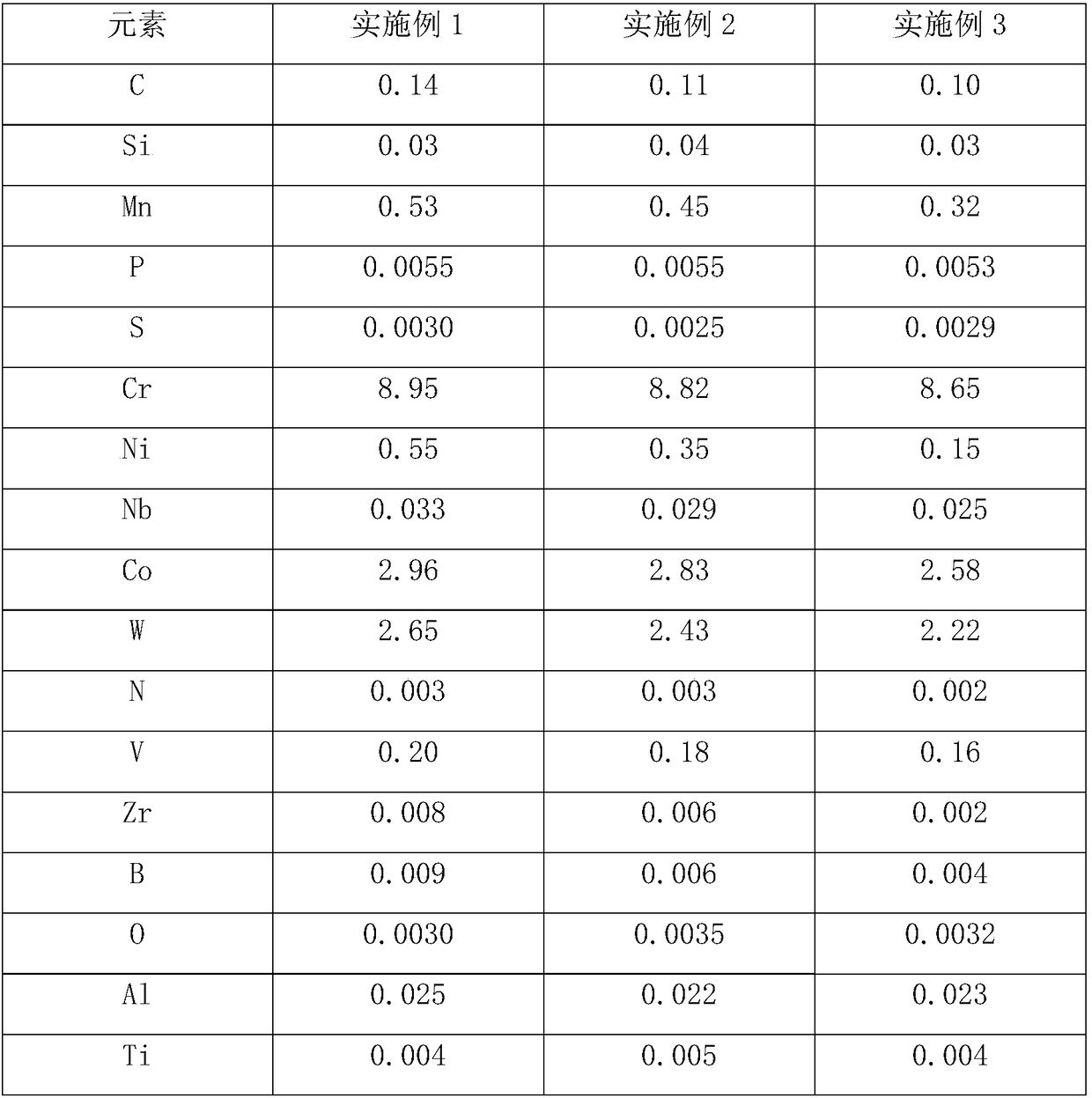

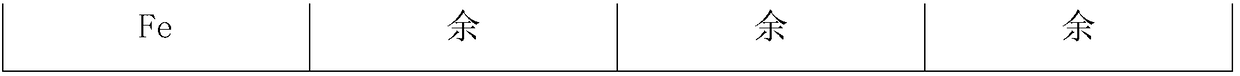

Bright welding wire for heat-resistant steel for ultra-supercritical coal-fired power station

ActiveCN108838579AImprove welding processabilityImprove surface cleanlinessWelding/cutting media/materialsSoldering mediaRoom temperatureMechanical property

The invention discloses a bright welding wire for heat-resistant steel for an ultra-supercritical coal-fired power station and belongs to the technical field of welding materials. The welding wire comprises, by weight, 0.10-0.15% of C, 8.5-9.0% of Cr, 0.1-0.6% of Ni, 0.3-0.6% of Mn, 2.5-3.0% of Co, 2.0-2.7% of W, 0.020-0.035% of Nb, 0.001-0.010% of Zr, less than or equal to 0.006% of N, 0.16-0.20%of V, 0.003-0.010% of B, less than or equal to 0.20% of Si, less than or equal to 0.006% of P, less than or equal to 0.006% of S, less than or equal to 0.010% of O, less than or equal to 0.03% of Al,less than or equal to 0.01% of Ti and the balance Fe and inevitable impurity elements. The bright welding wire has the advantages that the welding wire has good welding process performance and excellent deposited metal flowability and formability, and the deposited metal after welding has excellent mechanical properties and good room temperature impact toughness.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com