Patents

Literature

188 results about "Biomass ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass ash is produced by combustion of biomass for heat and power production. It is produced in boilers of different size and combustion technology. For the ash management requirements by the Industrial Emissions Directives as well as best practises for utilisation according to the waste hierarchy in the Waste Directive have...

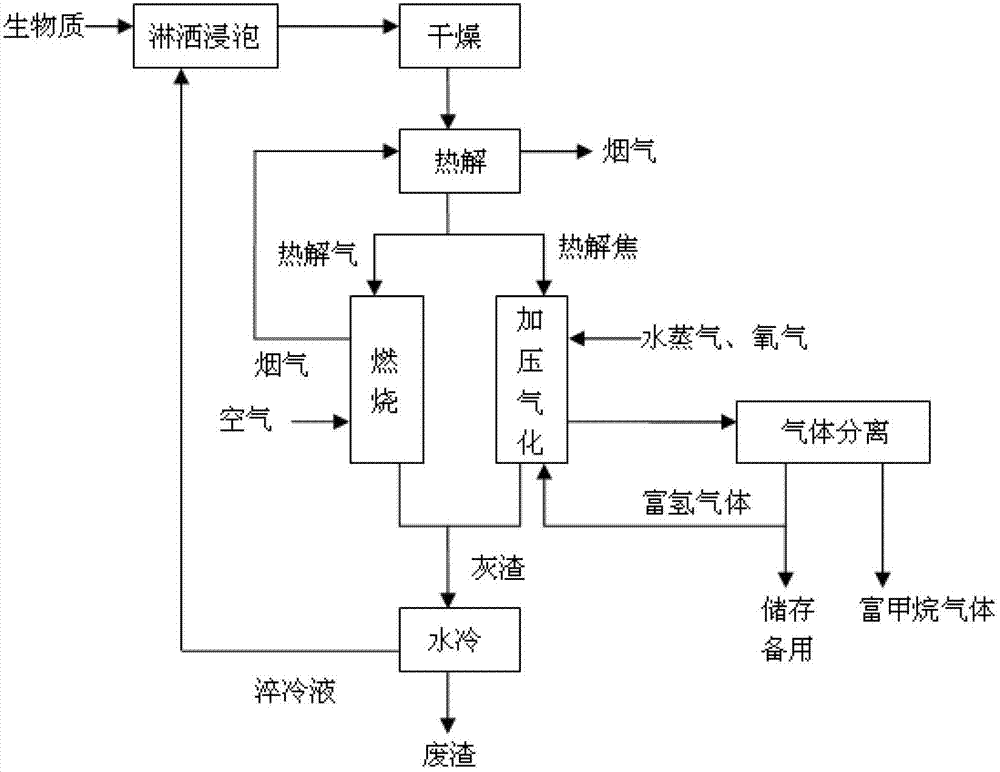

Method for preparing methane-rich gas through autocatalytic gasification of biomass

ActiveCN102786994AEasy to synthesizeImprove gasification efficiencyGaseous fuelsBiofuelsParticulatesAlkaline earth metal

The invention aims to provide a method for preparing methane-rich gas through cyclic utilization of alkali / alkaline earth metals contained in biomass for autocatalytic pyrolysis and autocatalytic pressurized gasification of the biomass. According to the method, water quenching is carried out on biomass ash so as to cyclically extract alkali / alkaline earth metals in the biomass ash, and the alkali / alkaline earth metals are sprinkled on and dipped in biomass; the biomass containing the alkali / alkaline earth metals undergoes autocatalytic pyrolysis at a low temperature of 280 to 320 DEG C at first, then a pyrolysis gas product enters into a combustion reactor and burns together with solid particles separated from a gasification reactor so as to supply heat for the process of pyrolysis, a pyrolysis solid product enters into the gasification reactor and undergoes autocatalytic pressurized gasification in a steam / oxygen atmosphere, hydrogen-rich gas is separated from crude synthetic gas produced in gasification and is returned to the pressurized gasification reactor, and the pyrolysis solid product is subjected to hydrogasification at the same time. With the method provide by the invention, biomass can be used for preparing methane-rich gas with low tar content, and high gasification efficiency is obtained. The method has the advantages of simple operation, less water consumption, strong technological adaptability and easy operation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

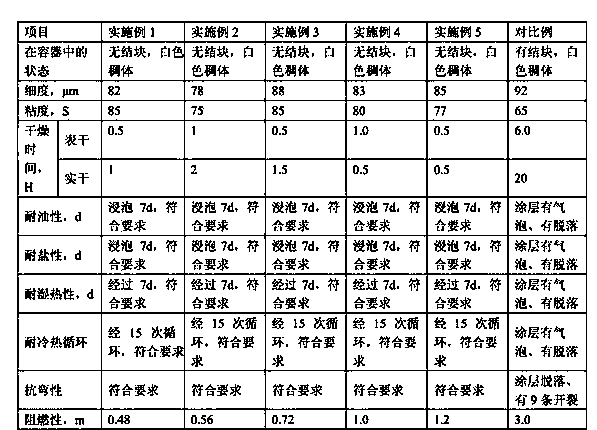

Water-based expansive type nano fireproof coating for cable and preparation method thereof

ActiveCN103740231AGood component compatibilityImprove bending resistanceFireproof paintsEpoxy resin coatingsPtru catalystFoaming agent

The invention relates to a water-based expansive type nano fireproof coating for a cable and a preparation method of the water-based expansive type nano fireproof coating. The water-based expansive type nano fireproof coating for the cable is characterized by comprising the following components in parts by weight: 20-40 parts of a coating base body, 15-45 parts of a nano flame retardant, 2-10 parts of a flame retardant synergist, 5-10 parts of a filler, 1-5 parts of an assistant and 10-30 parts of water, wherein the nano flame retardant is obtained by nano-crystallizing the flame retardant which comprises soluble aluminum salt, a charring catalyst, a charring agent and a foamer, and the flame retardant synergist is biomass ash of a power plant. As the components of the water-based expansive type nano fireproof coating are good in compatibility, the water-based expansive type nano fireproof coating is good in buckling resistance, humidity resistance, oil resistance and water resistance, excellent in flame retardance and low in charring height.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

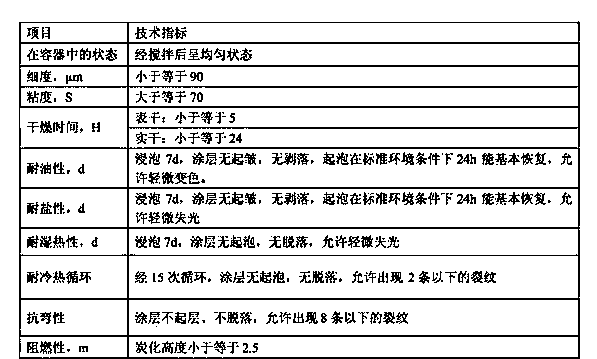

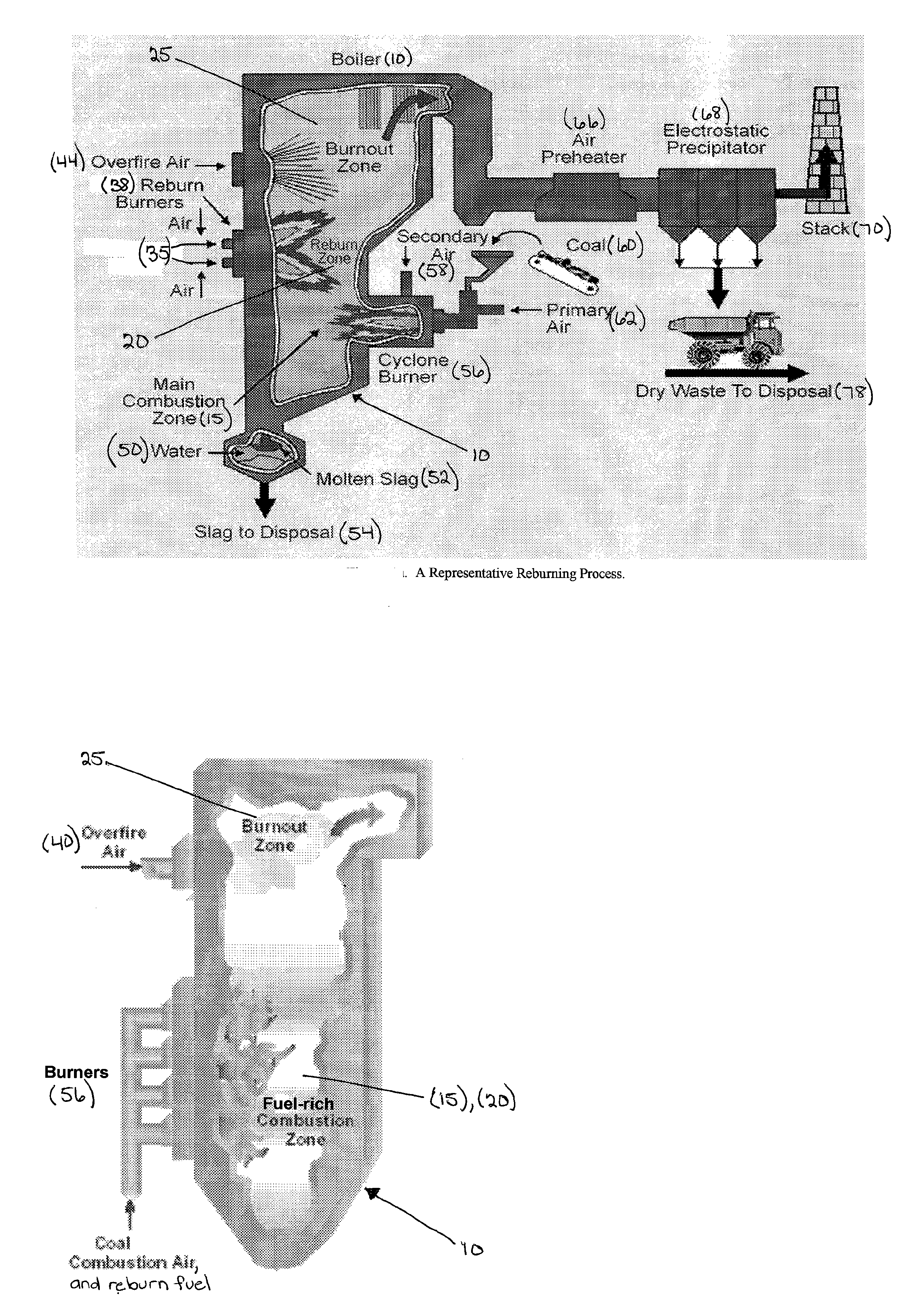

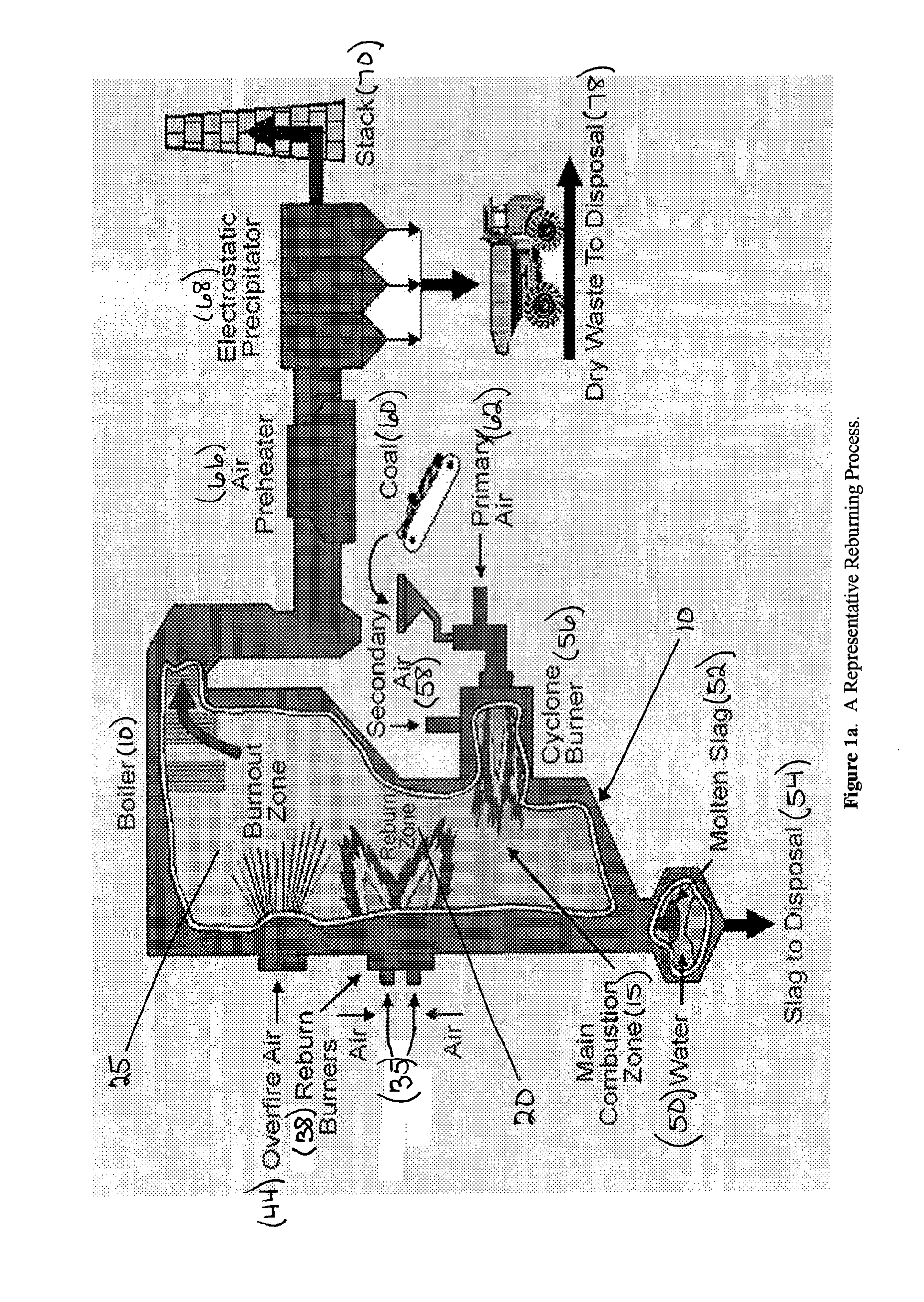

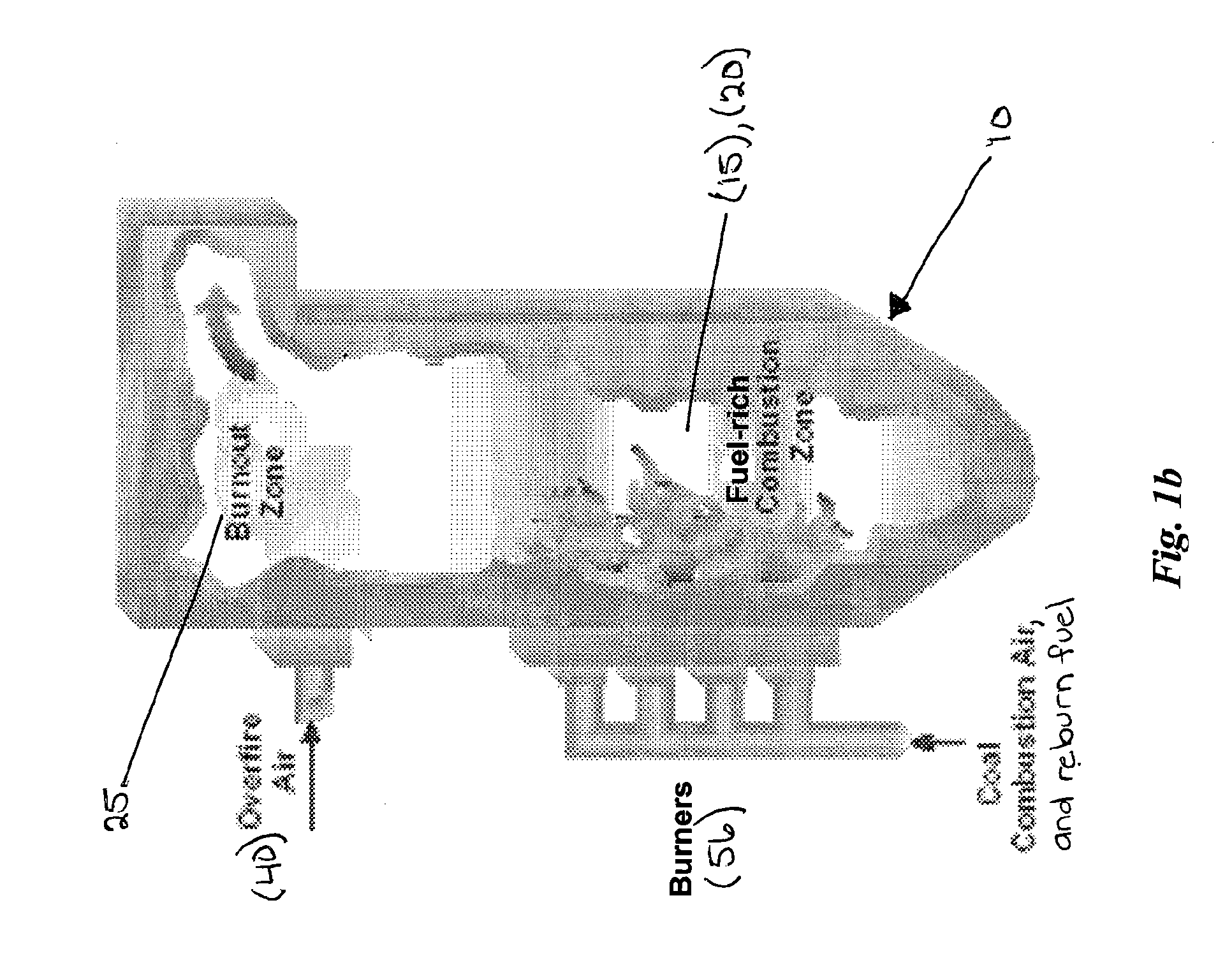

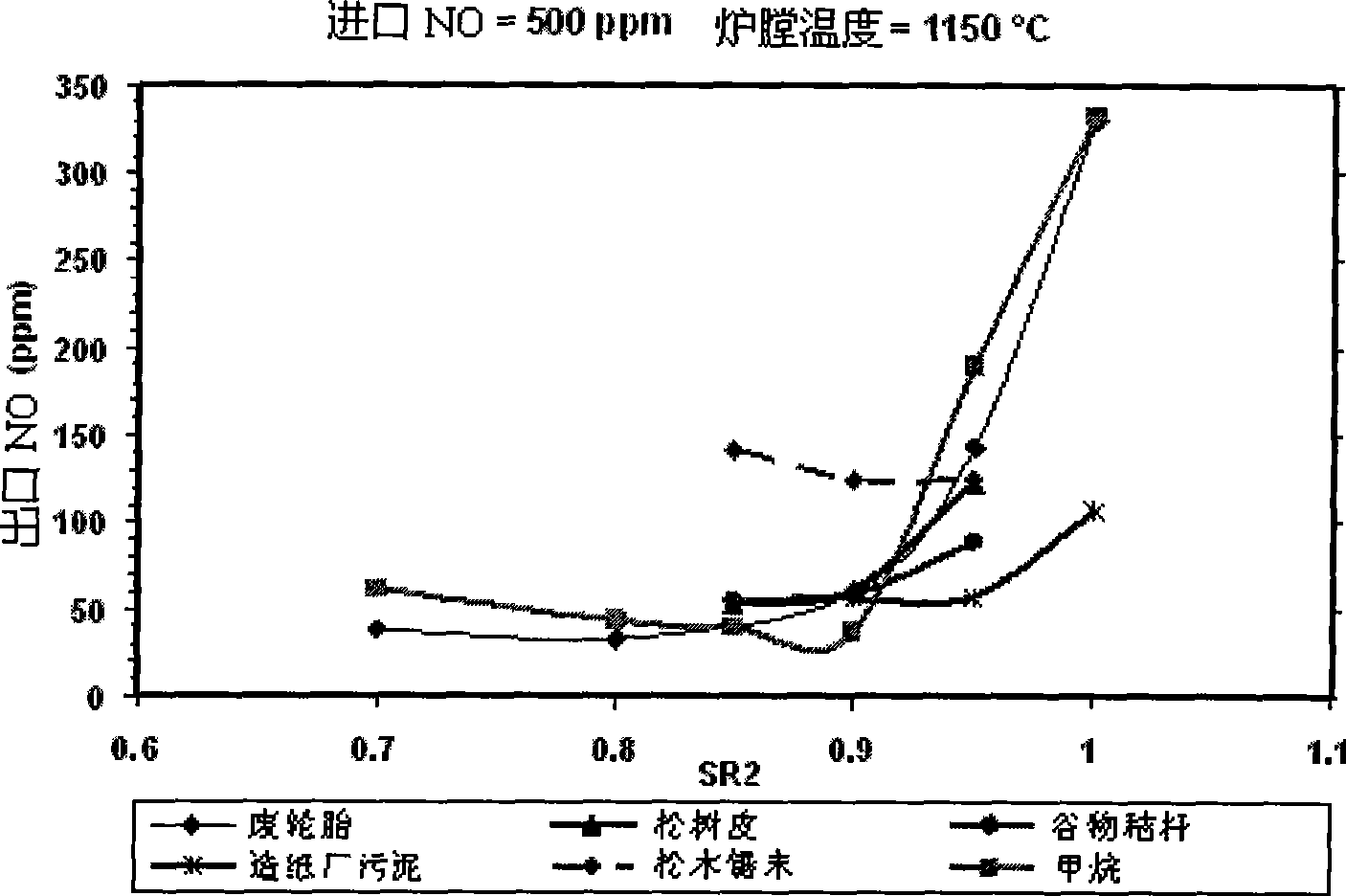

In-Furnace Reduction Of Nitrogen Oxide By Mixed Fuels Involving A Biomass Derivative

InactiveUS20070034126A1Maximize NO removal efficiency% reductionSolid fuel combustionChimneysCombustion chamberNitrogen oxide

A method of reducing nitrogen oxide emissions formed during fuel combustion by introducing biomass ash into a combustion chamber.

Owner:THE BABCOCK & WILCOX CO +1

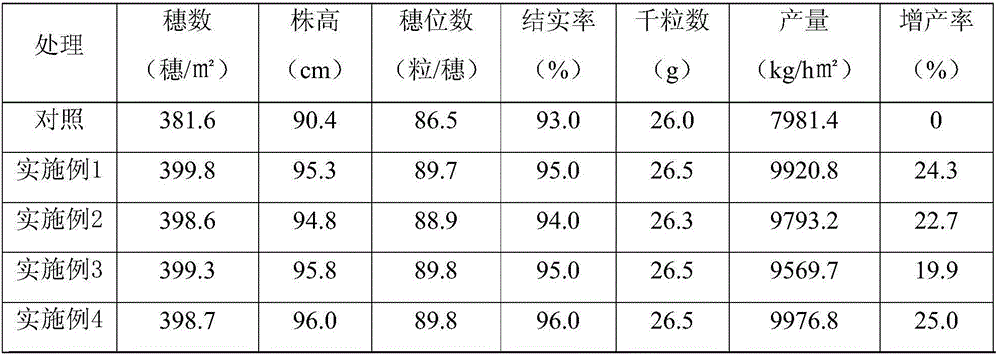

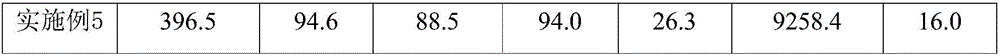

Special fertilizer for rice

InactiveCN105819972AResistant to decompositionPromote absorptionCalcareous fertilisersNitrogenous fertilisersSucroseNitrohumic acid

The invention provides a special fertilizer for rice. The special fertilizer is prepared from the following raw materials: nitrogen-phosphorus-potassium fertilizer, animal amino acid, nitrohumic acid, organic trace elements, inorganic trace elements, medium elements, biomass ash and lime powder, wherein the ratio of nitrogen fertilizer, phosphorus fertilizer to potassium fertilizer in the nitrogen-phosphorus-potassium fertilizer is (15-20):(8-12):(10-15); and the organic trace elements include sucrose complex copper, sucrose complex iron, sucrose complex zinc, sucrose complex manganese, sucrose complex magnesium, silicon humate fertilizer, sodium humate, magnesium humate, zinc humate and urea iron humate. With high nitrogen content and high-quality humic acid, the special fertilizer for rice provided by the invention improves the soil fertility, promotes quick growth of rice plants, increases the utilization rate of fertilizer, reduces fertilizer loss and obviously increases the rice yield.

Owner:STANLEY FERTILIZER GUIGANG

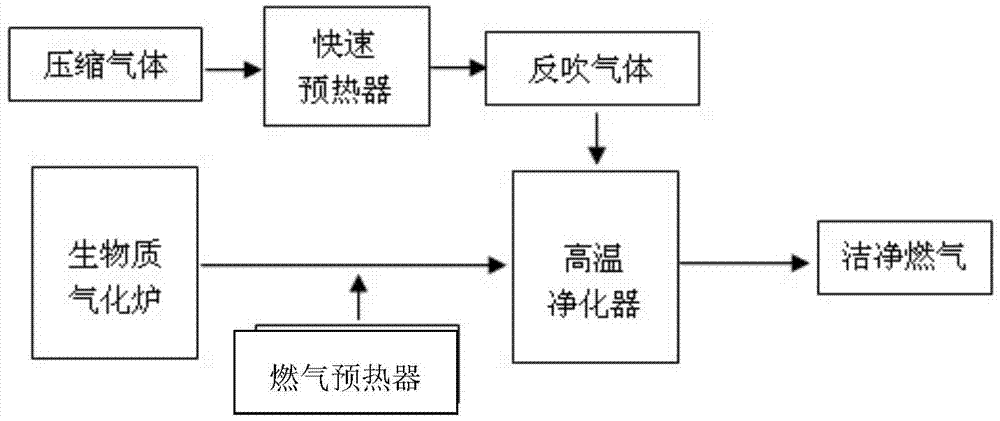

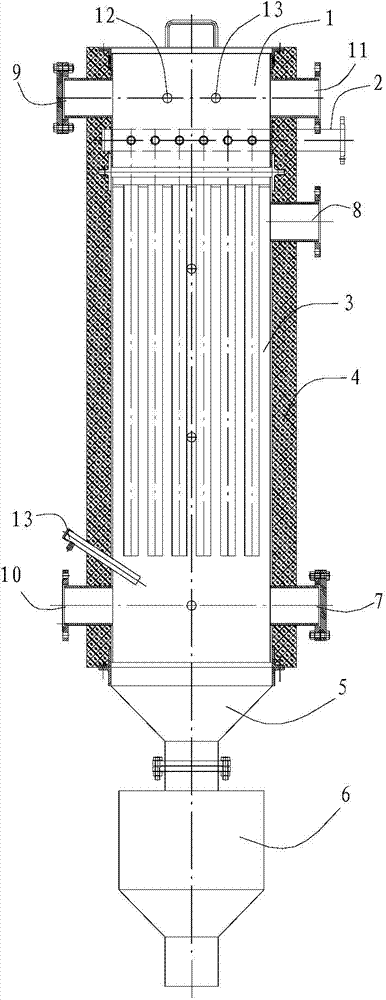

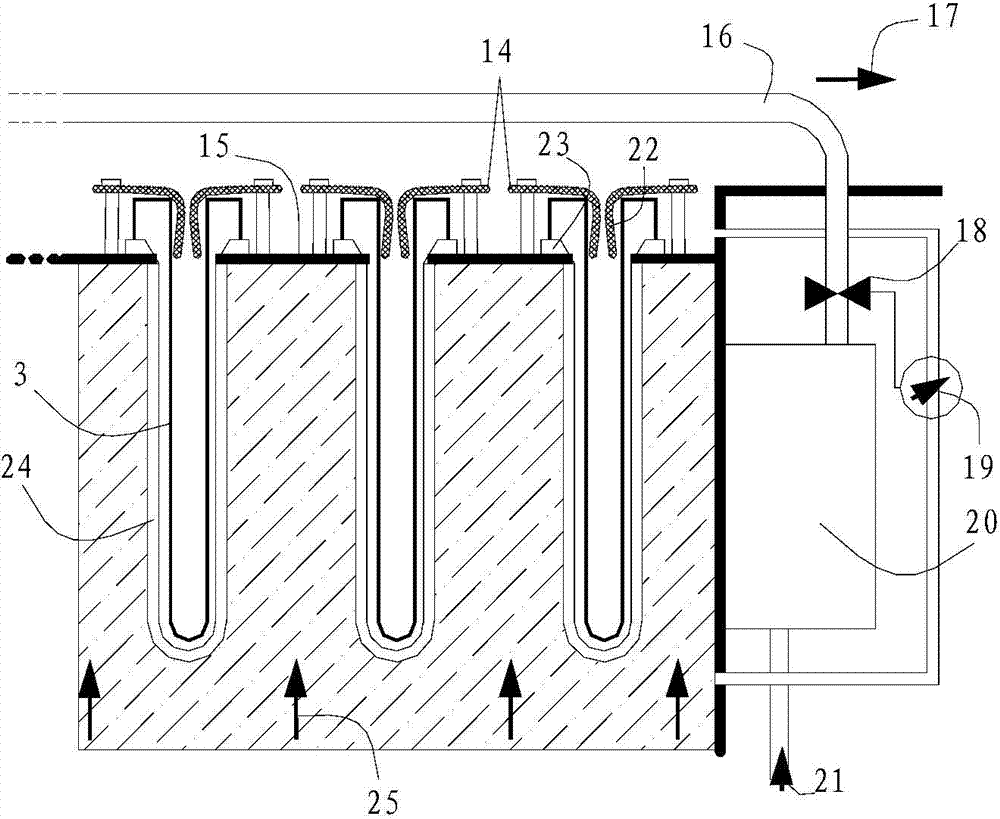

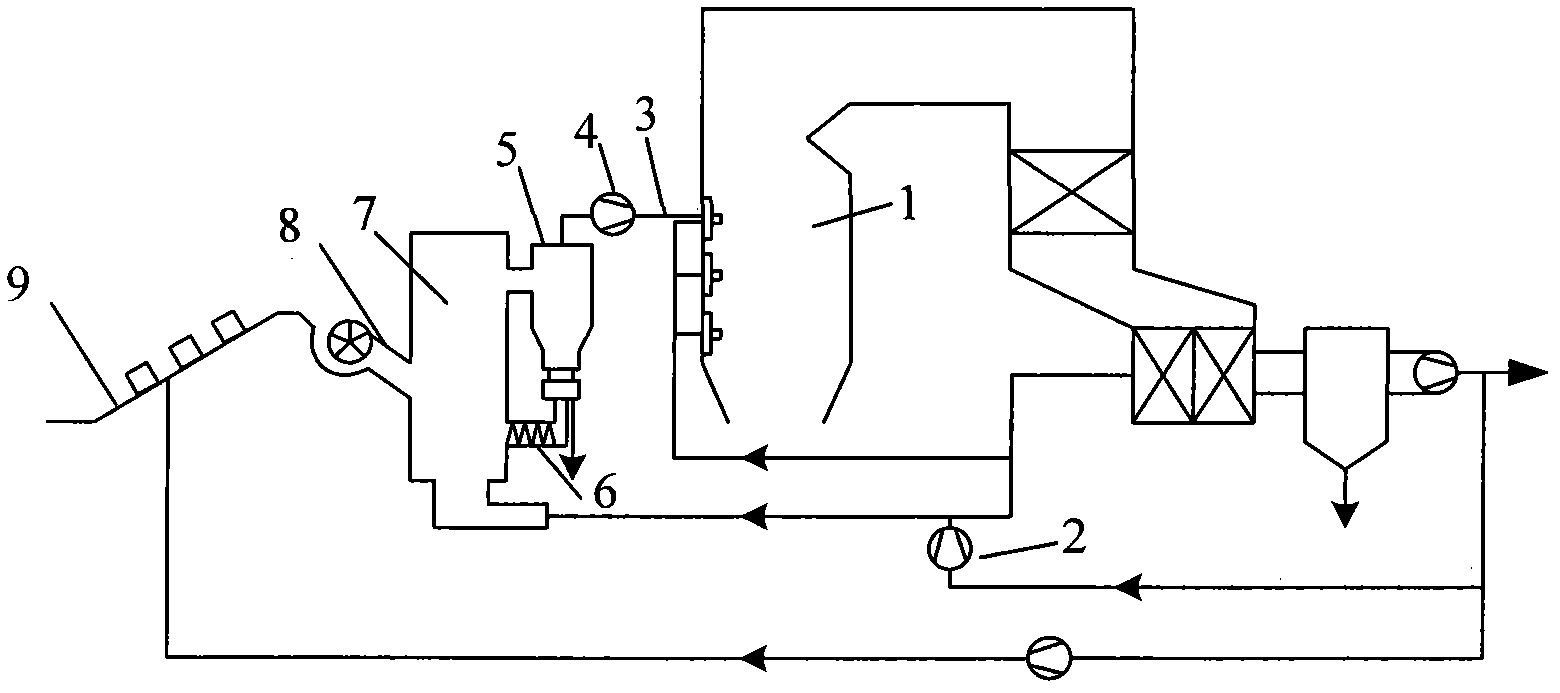

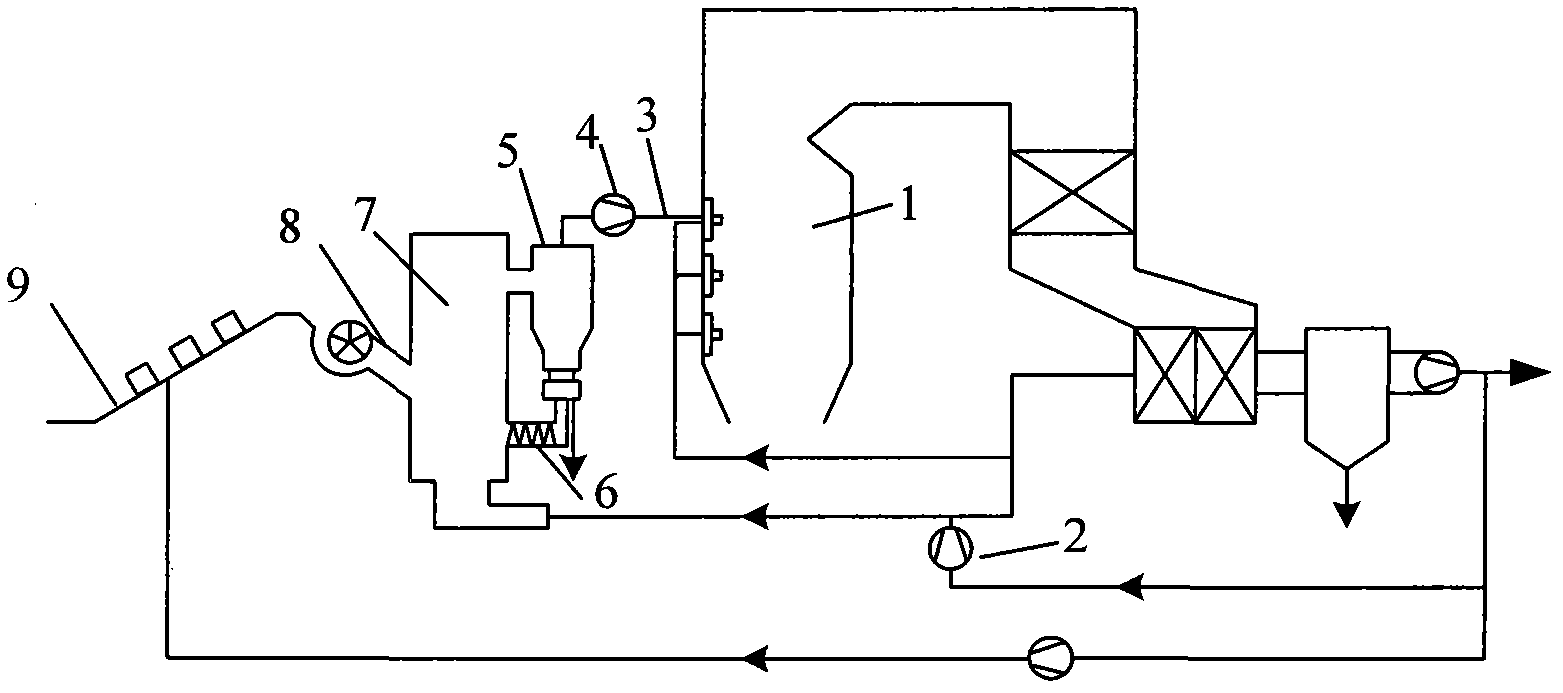

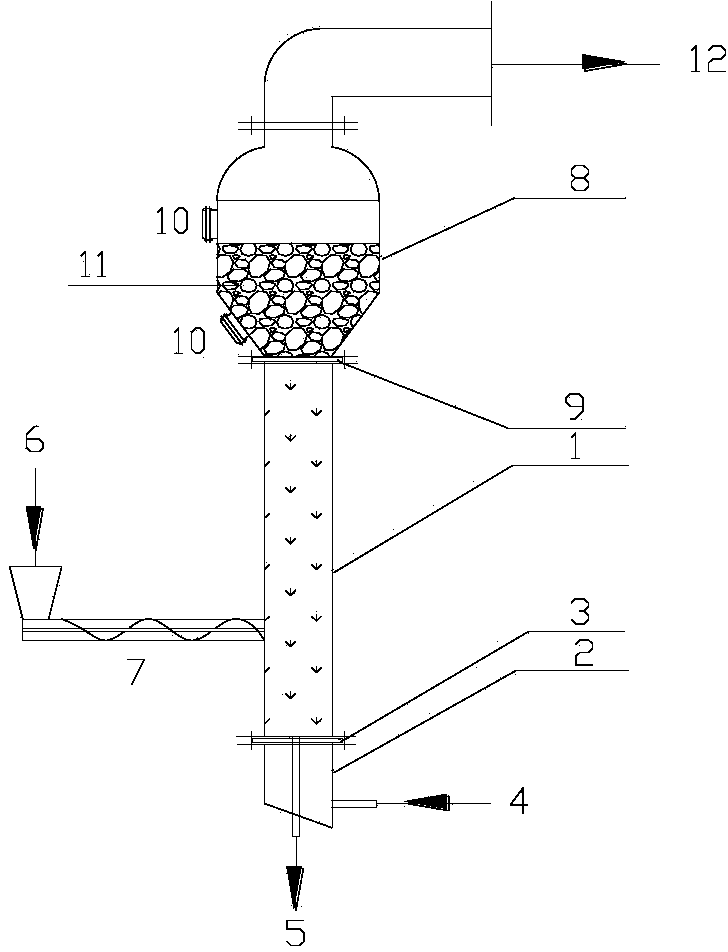

High-temperature dust-removing and coke-removing integrated purifying process of biomass crude gas

ActiveCN103614167AFully purifiedAvoid secondary pollutionGas purification by catalytic conversionGas dust removalInsulation systemIntegrated devices

The invention discloses a high-temperature dust-removing and coke-removing integrated purifying process of biomass crude gas and provides a new process for high-efficiency purification of biomass high-temperature gas at low cost. The process comprises a high-temperature gas heat exchanger (A), a high-temperature gas purifier (B), a Venturi pulse back-blowing system (C), a gas preheater (D) and an electric-heating insulation system (E), wherein the five sets of equipment operate cooperatively to form a set of complete high-temperature gas purifying integrated device; a filtering medium in the high-temperature gas purifier is a modified ceramic membrane dust-removing pipe. When filtering cakes on the outer surface of the modified dust-removing pipe are deposited to certain thickness, deposited ash can be back-blown into an ash discharging hopper box for collection by the Venturi pulse back-blowing system. The high-temperature dust-removing and coke-removing integrated purifying process disclosed by the invention has the advantages that high-efficiency separation and integrated treatment of ash and coke components in biomass gas are realized; the dust-removing temperature is low so as to be beneficial to reducing the manufacturing cost of the equipment and prolonging the service life; biomass ash side products with commercial value are produced while the high-efficiency purification of the biomass crude gas is realized; the process flow is simple and flexible, the operation is simple, the purification cost is low and the suitability for industrial production is achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

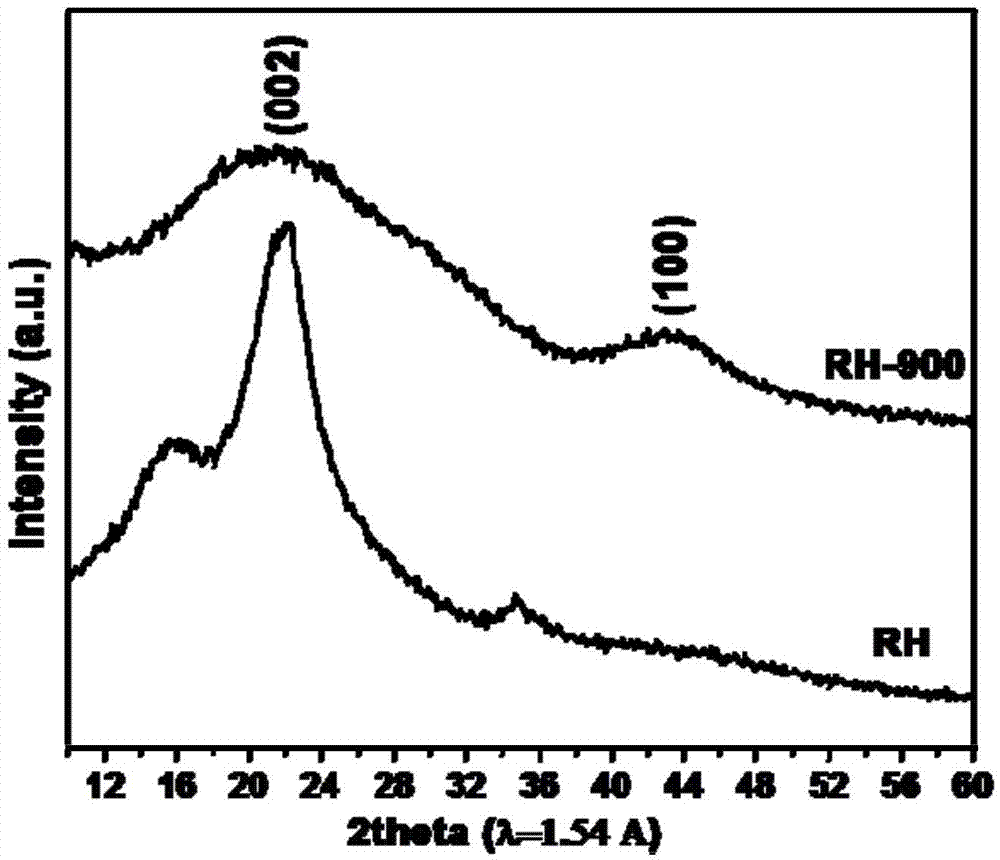

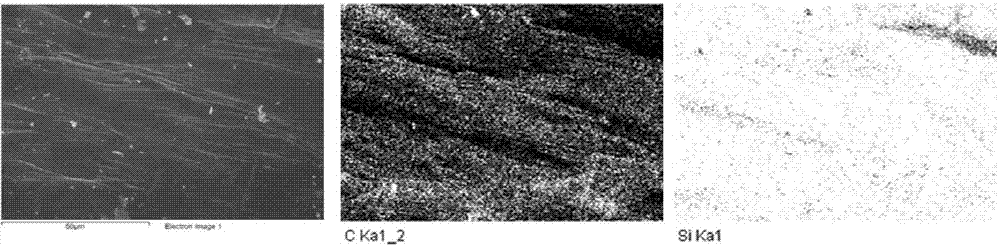

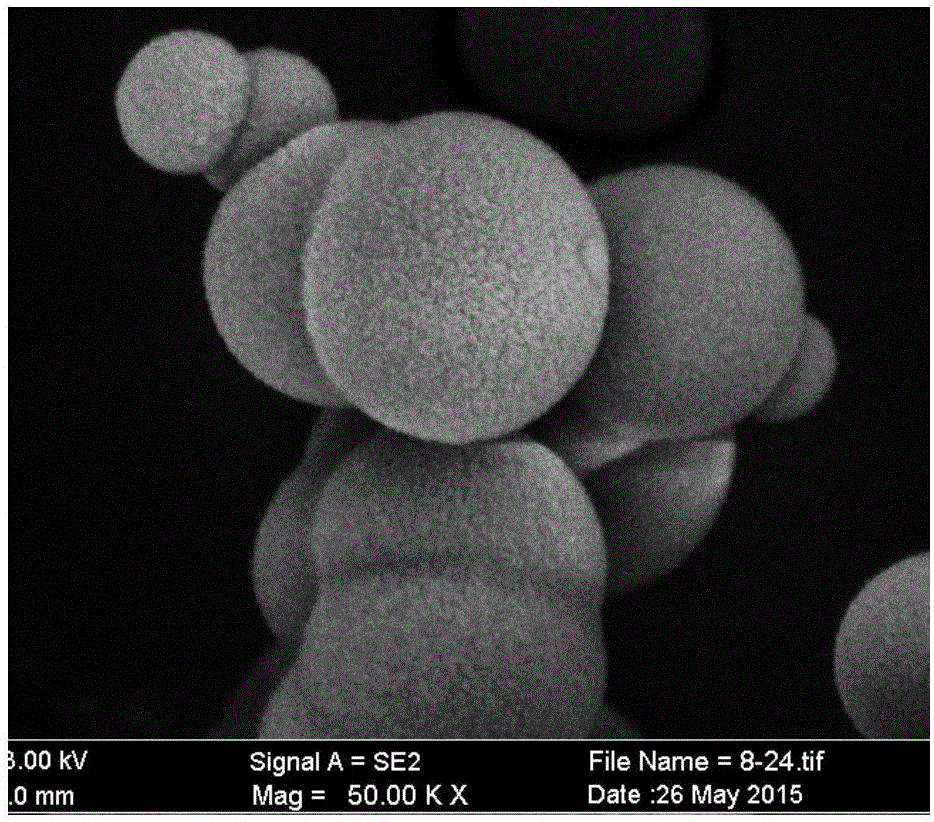

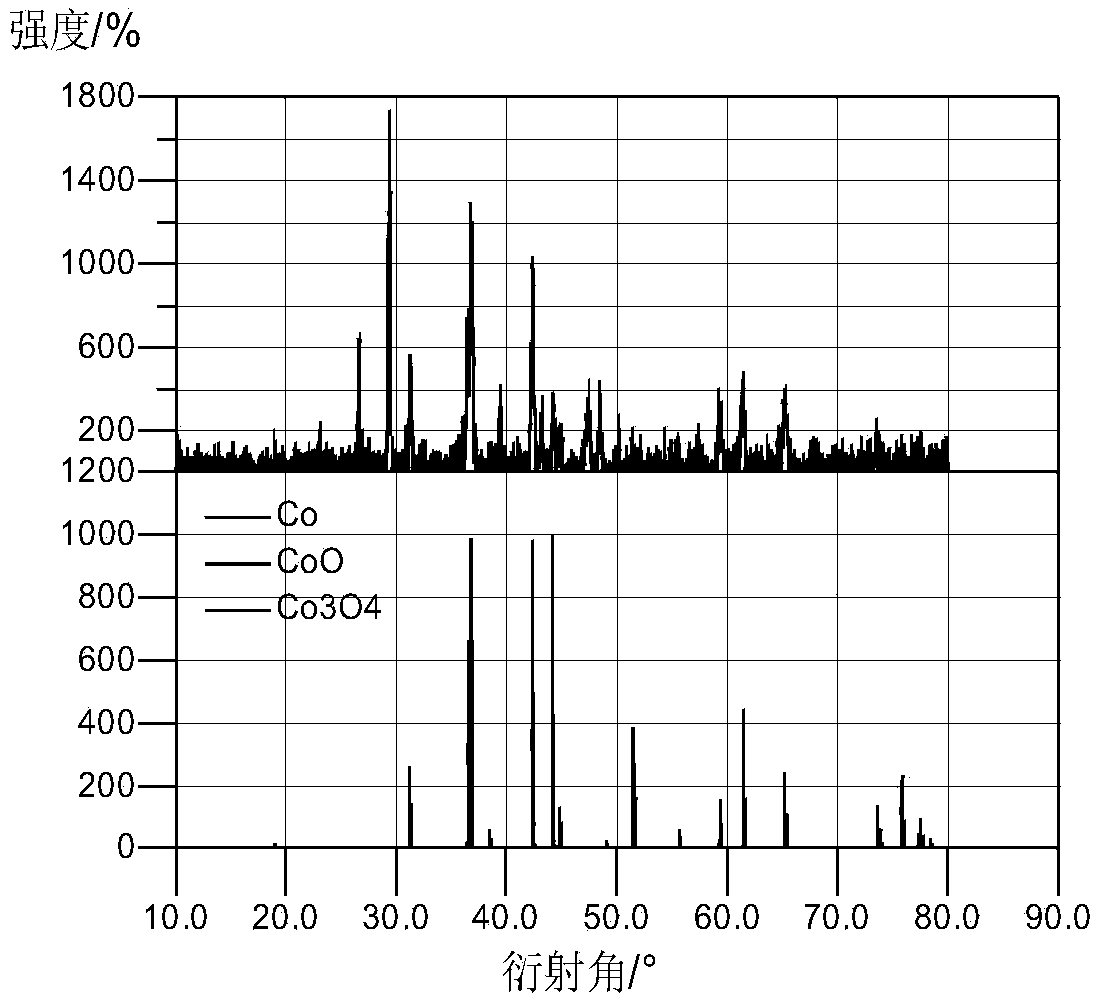

Preparation method for silicon dioxide/carbon compound and application to lithium/sodium ion batteries

ActiveCN104300124AWide variety of sourcesLow costCell electrodesSecondary cellsFurnace temperatureWater vapor

The invention provides a preparation method for a silicon dioxide / carbon compound and application to lithium / sodium ion batteries, and belongs to the technical field of composite materials. The technical scheme is shown as follows: firstly, crushing biomass ash into particles with the size less than centimeter level; then performing heat processing at 800-1500 DEG C in an argon, nitrogen, carbon monoxide, hydrogen or water vapor atmosphere for 4-20 h, and cooling to room temperature along with the furnace temperature; and finally cleaning the obtained product in water or a diluted acid, separating, and drying the solid obtained after separation in a vacuum drying box at 80 DEG C, so as to obtain the silicon dioxide / carbon compound. The silicon dioxide / carbon compound is wide in raw material resource, low in cost and free of pollution to environment, and is suitable for industrialized large-scale production, and the obtained silicon dioxide / carbon compound is a lithium / sodium ion battery anode material with excellent performances.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

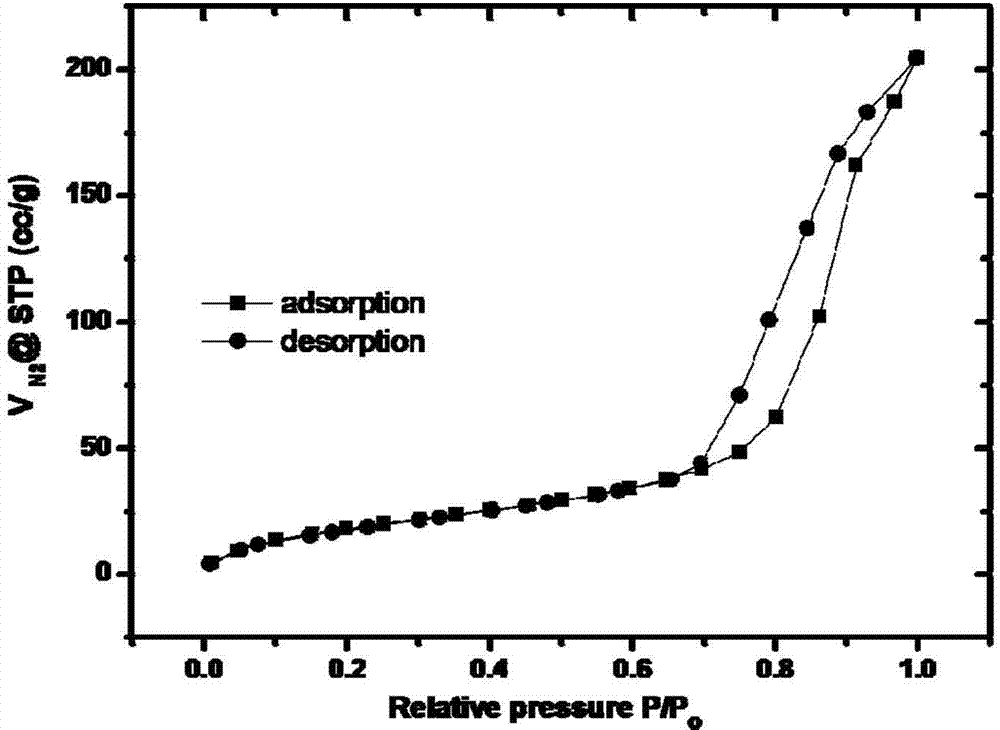

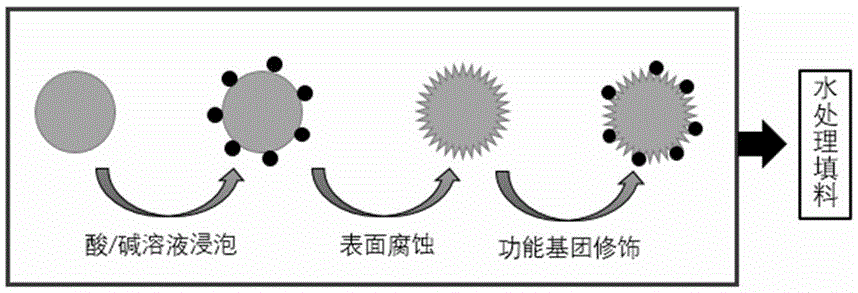

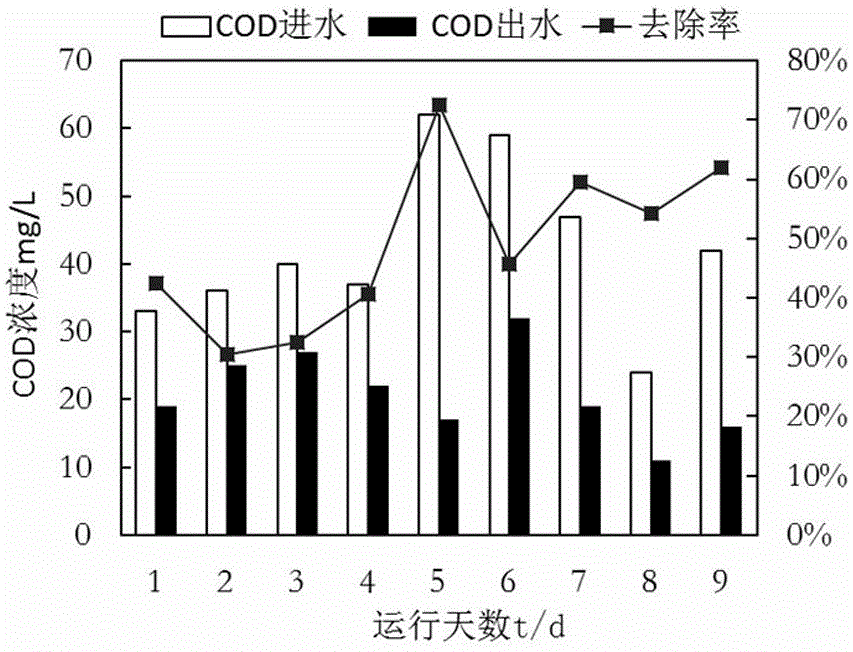

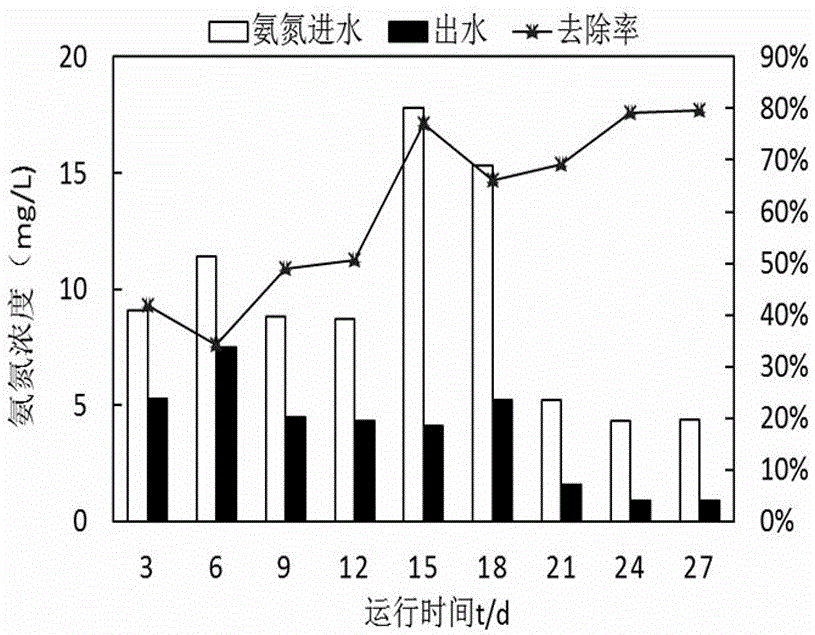

Water treatment filler based on modified biomass ash and preparing method thereof

InactiveCN106186285AGood removal effectReasonable useTreatment with microorganism supports/carriersAcetic acidChemisorption

The invention discloses water treatment filler based on modified biomass ash and a preparing method thereof. The preparing method includes the steps that biomass ash is added into a mixed solution according to the ratio of 0.6-1 kg of biomass ash to 1 L of mixed solution, mixed and stirred uniformly, soaked and rinsed to obtain granular water treatment filler based on modified biomass ash; the biomass ash is obtained by combusting biomass fuel, and the mixed solution contains acetic acid and organic matter. Acetic acid and organic matter are adopted to compounding and modifying the biomass ash, the specific area of the biomass ash is increased, and the number of surface functional groups is increased, which is beneficial for provides more attachment points for microorganisms and beneficial to chemisorption of nutrient substances in water; recycling of waste is achieved by adopting biomass power plant waste namely biomass ash as the raw material, the biomass ash is reasonably and effectively used, and water treatment cost is reduced.

Owner:SUZHOU SAIHUA INSTR CONTROL CO LTD

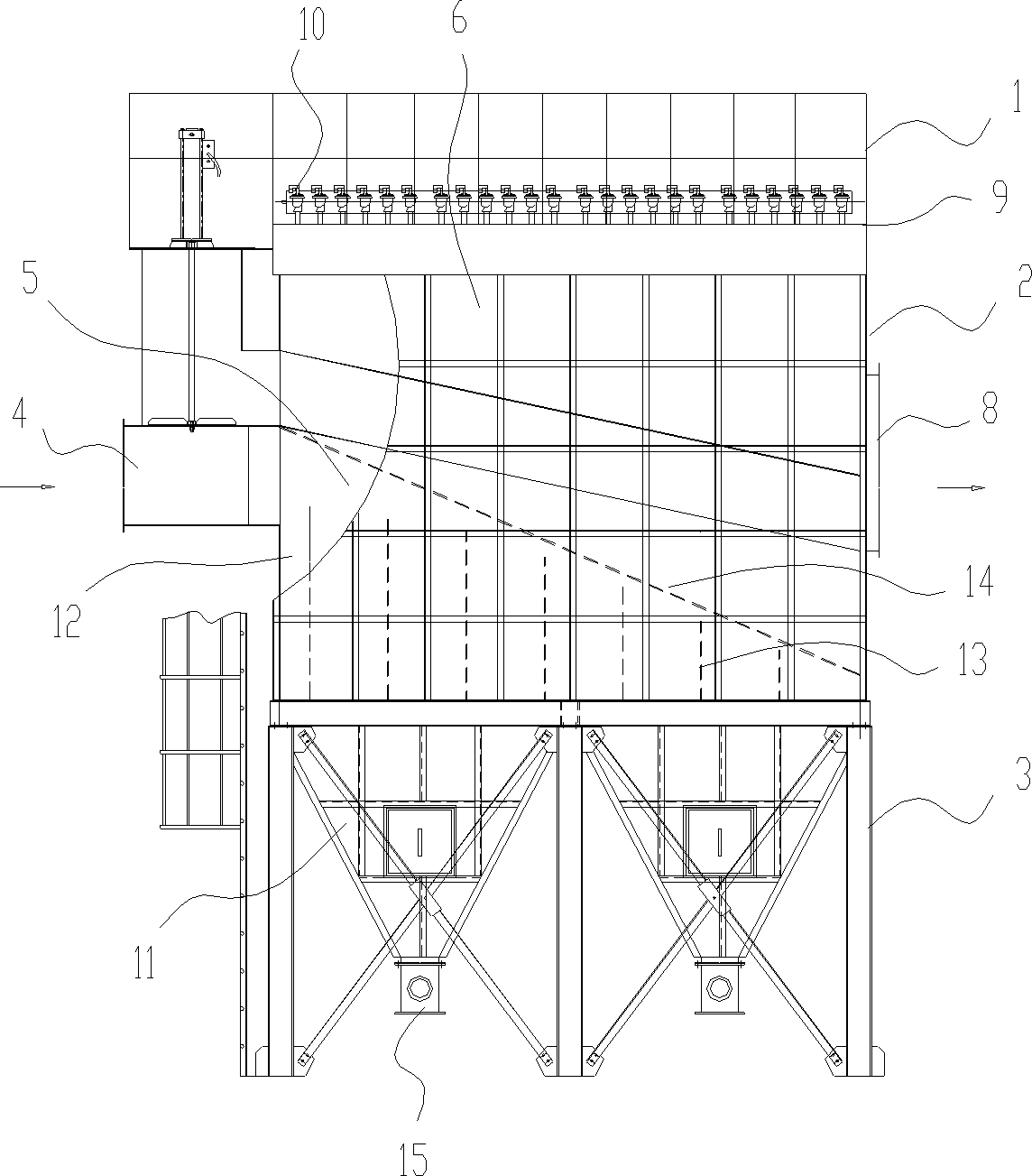

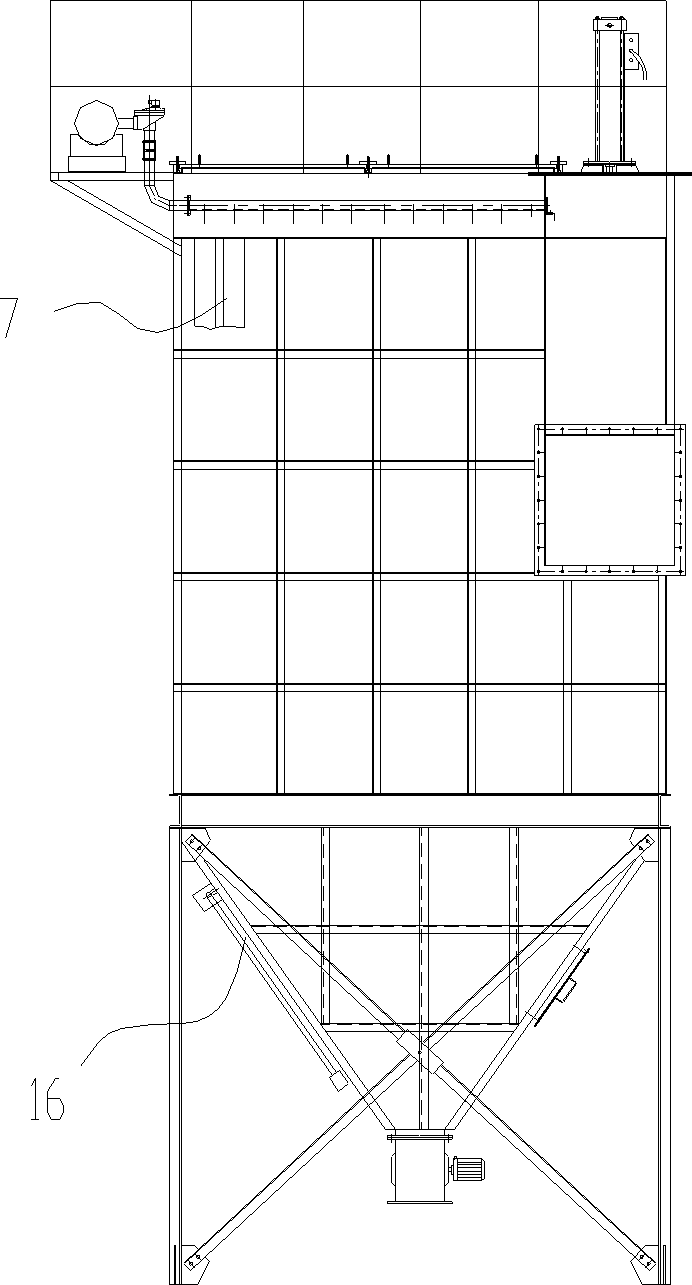

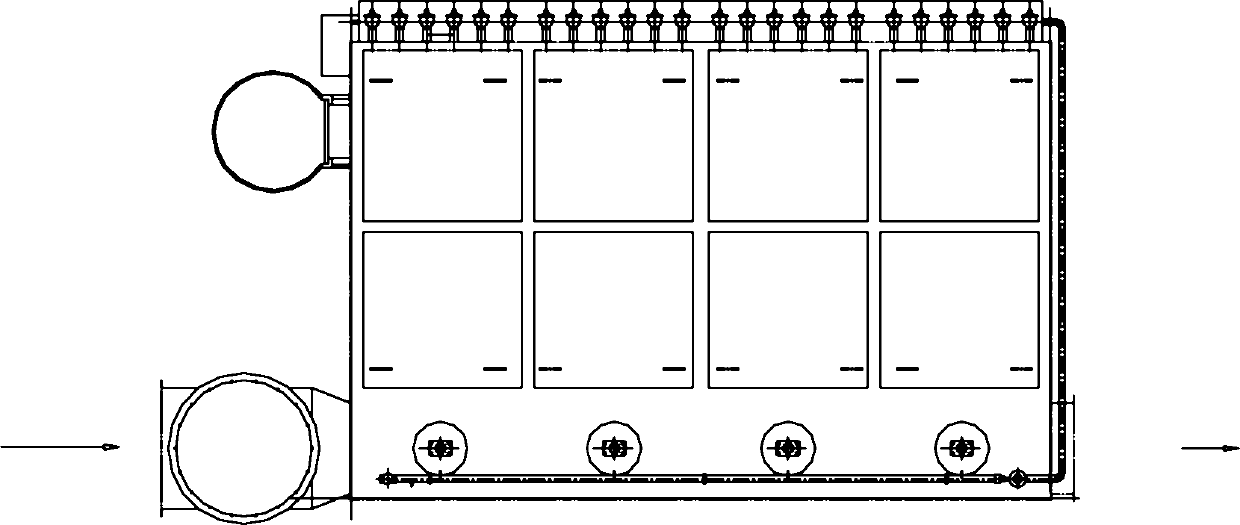

Biomass ash bag deduster

ActiveCN102553360ASolve the problem of difficult cleaningDispersed particle filtrationInlet channelEngineering

The invention discloses a biomass ash bag deduster, which contains an upper box, a central box and a lower box. An air inlet channel, which communicates with a dust-laden gas inlet, is arranged inside the central box. A plurality of bag cages which communicate with the air inlet channel are disposed in a spaced manner over the air inlet channel inside the central box. A filter bag is disposed inside each bag cage, which respectively communicates with a purified gas outlet through an outlet valve and communicates with a pulse valve disposed inside the upper box through a jet pipe. A dust hopper for ash discharge is arranged inside the lower box. Pulse-jet dust-cleaning is alternately carried out on an off-line compartment. The whole deduster is divided into a plurality of chambers (bag cages), which are connected with duct outlets through valves. When cleaning dust, the valve of one chamber is closed such that the chamber is off-line. Compress air is injected into the filter bag through a jet pipe by the pulse valve so as to finish dust removal by blowing. After the dust removal, the valve of the chamber is opened. Similarly, the chambers of the whole deduster undergo dust removal one by one. Therefore, the problem that it is difficult to remove dust during the biomass boiler operation is solved.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Method for generating power by gasifying integrated straws in supercritical coal-fired generator set

InactiveCN102010757AEasy to storeSmall footprintInternal combustion piston enginesEnergy inputBiomass gasifierBubbling fluidized bed

The invention discloses a method for generating power by gasifying integrated straws in a supercritical coal-fired generator set. The method comprises the following steps of: packing and forming biomass straws serving as a gasification raw material of a gasifier of a bubbling fluidized bed, wherein primary wind-heat air surplus in a power station and tail gas fume of a boiler are used as gasifying agents. A biomass gasifier is effectively integrated by simply modifying the conventional supercritical unit to make biomass gasified, combusted and generate power, so that the defect that the biomass is directly blended and combusted is effectively overcome, the influence of biomass ash on fly ash is avoided, and the problem that the conventional auger feeding equipment is easy to damage is solved; therefore, biomass energy can be efficiently utilized and pollutant emission of coal-fired power stations is further reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

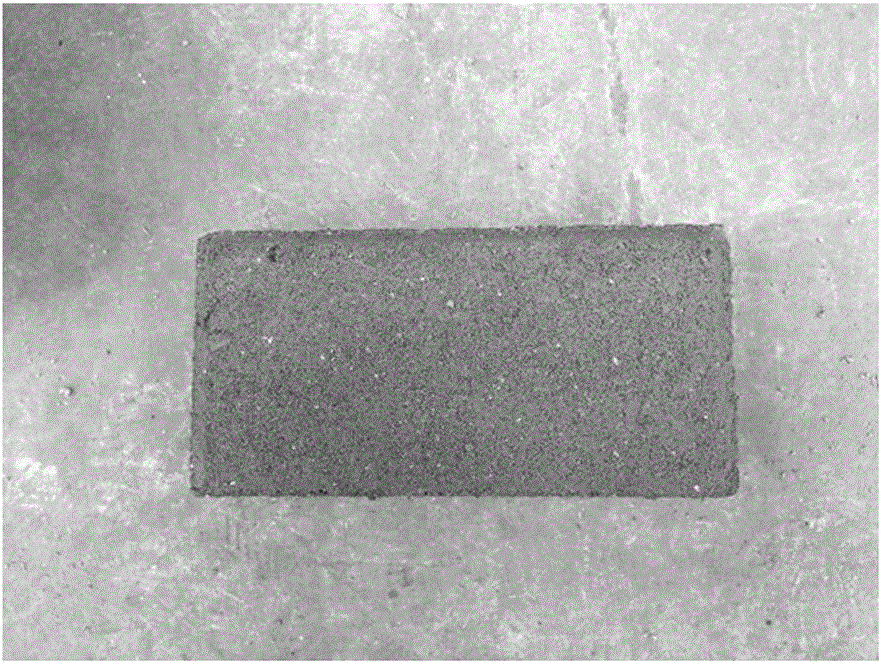

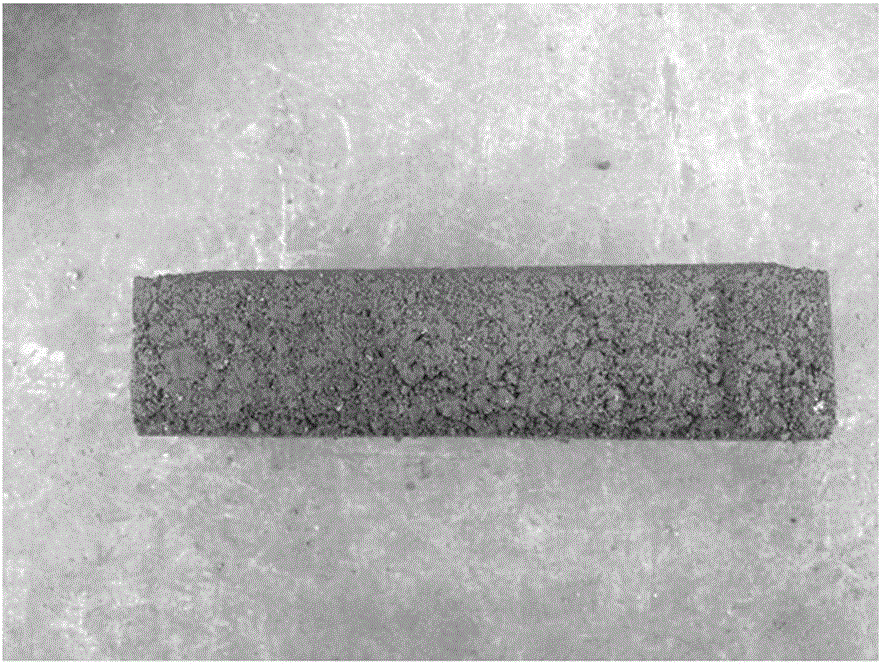

Biomass-ash-residue brick as well as preparation method and application thereof

The invention discloses a biomass-ash-residue brick as well as a preparation method and application thereof. Biomass ash residues are used as raw materials; the biomass-ash-residue brick is obtained after the biomass ash residues with different particle sizes and cement are mixed and agitated by adopting a certain matching ratio, an obtained mixture is molded, and the molded mixture is maintained. The problems that the utilization rate of the ash residues from a biomass power plant is currently low and the resource waste and the environmental pollution are caused are solved; a feasible resource utilization path is provided for the biomass ash residues of the power plant; meanwhile, the biomass-ash-residue brick is prepared by adopting a sintering-free technique, and has the advantages of being free from sintering, free from high temperature and high pressure, short in treatment period, good in treatment effect, and the like. The compression strength of the biomass-ash-residue brick provided by the invention can meet requirements in the GBT17431.1-2010; meanwhile, the biomass-ash-residue brick also conforms to the GB5085.3-2007 standard; the leachability of heavy metal is extremely low; the biomass-ash-residue brick has no harmful elements, has no ecological risks, and belongs to an environment-friendly product.

Owner:苏州赛华仪控股份有限公司

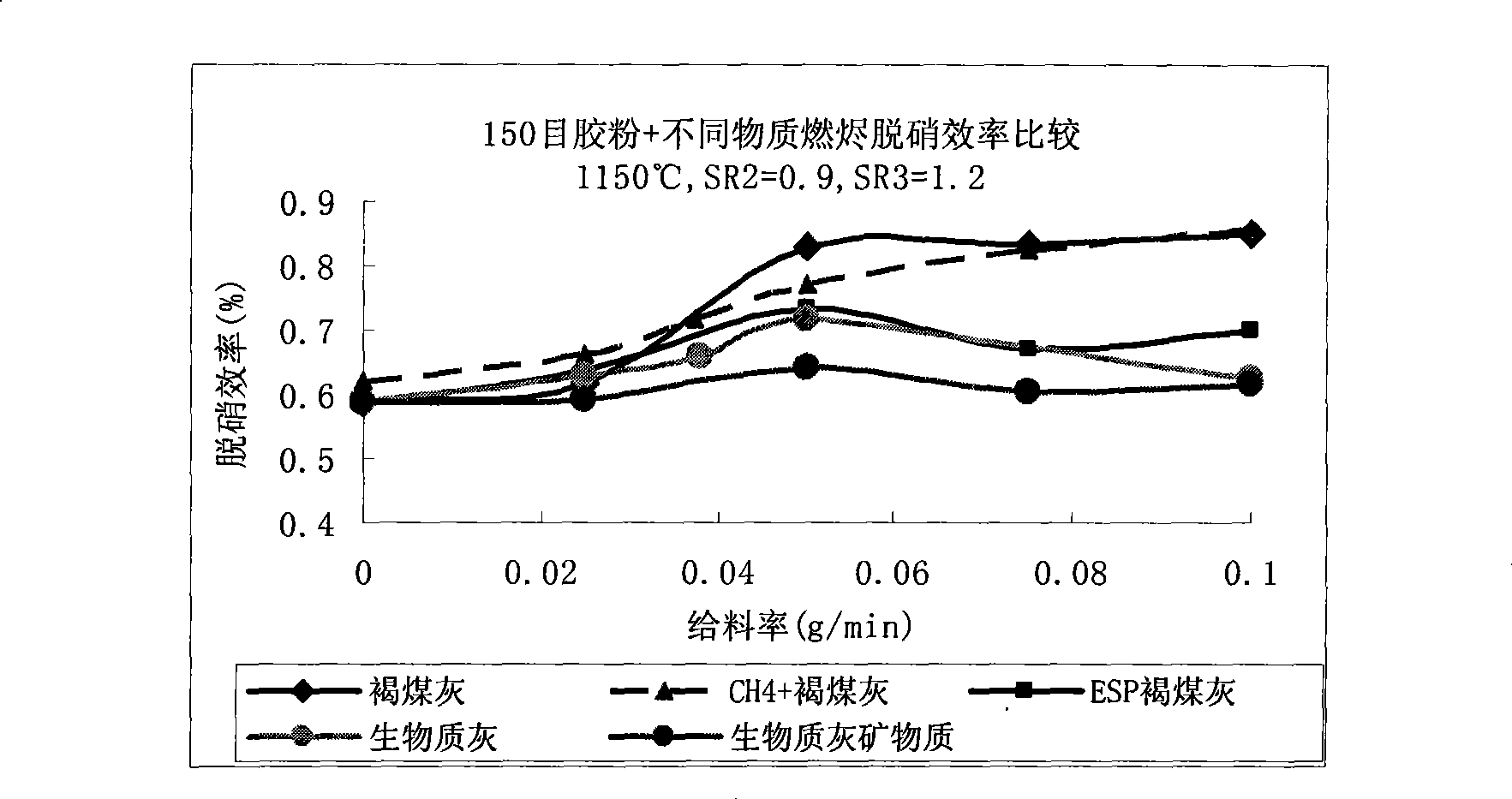

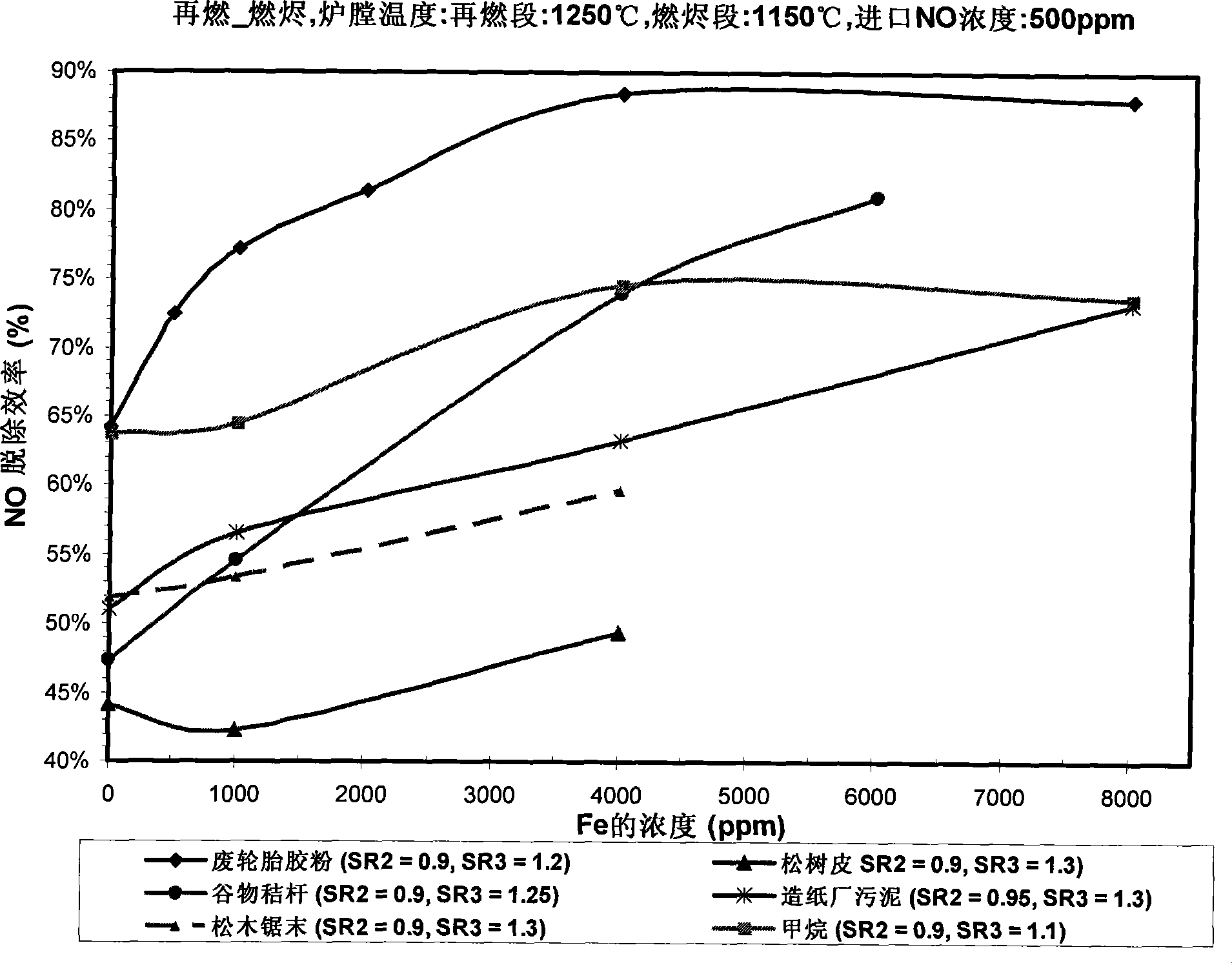

Efficient reburning denitration mixed fuel made from solid wastes and preparation thereof

InactiveCN101440322AEasy to handleReduce pollutionSolid fuelsWaste based fuelNitrogen gasWaste material

The invention relates to a solid waste high-efficiency reburning denitration blended fuel and a method for preparing the same. The blended fuel comprises main fuel of used tire rubber powder, various biomass waste materials, power plant brown coal ash, biomass ash, biomass minerals, and iron oxide (Fe2O3) which are matched at appropriate parameters to be used as reburning fuels. The blended fuel can eliminate as high as more than 80 percent of nitrogen oxides (NOX) generated in the process of coal burning to convert the nitrogen oxides into nitrogen so as to achieve the aim of reducing the emission of nitrogen oxide pollutants, and the solid waste energy sources are recycled effectively and simultaneously.

Owner:DONGHUA UNIV

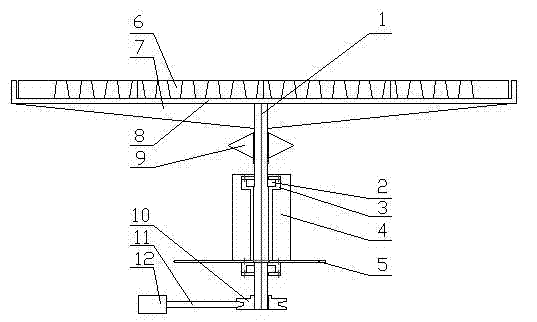

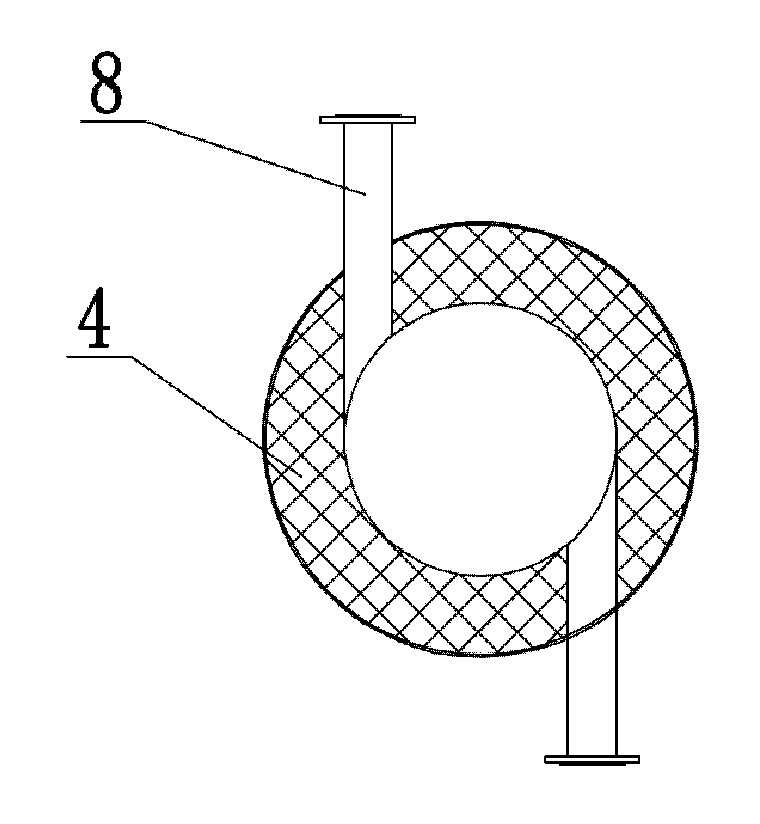

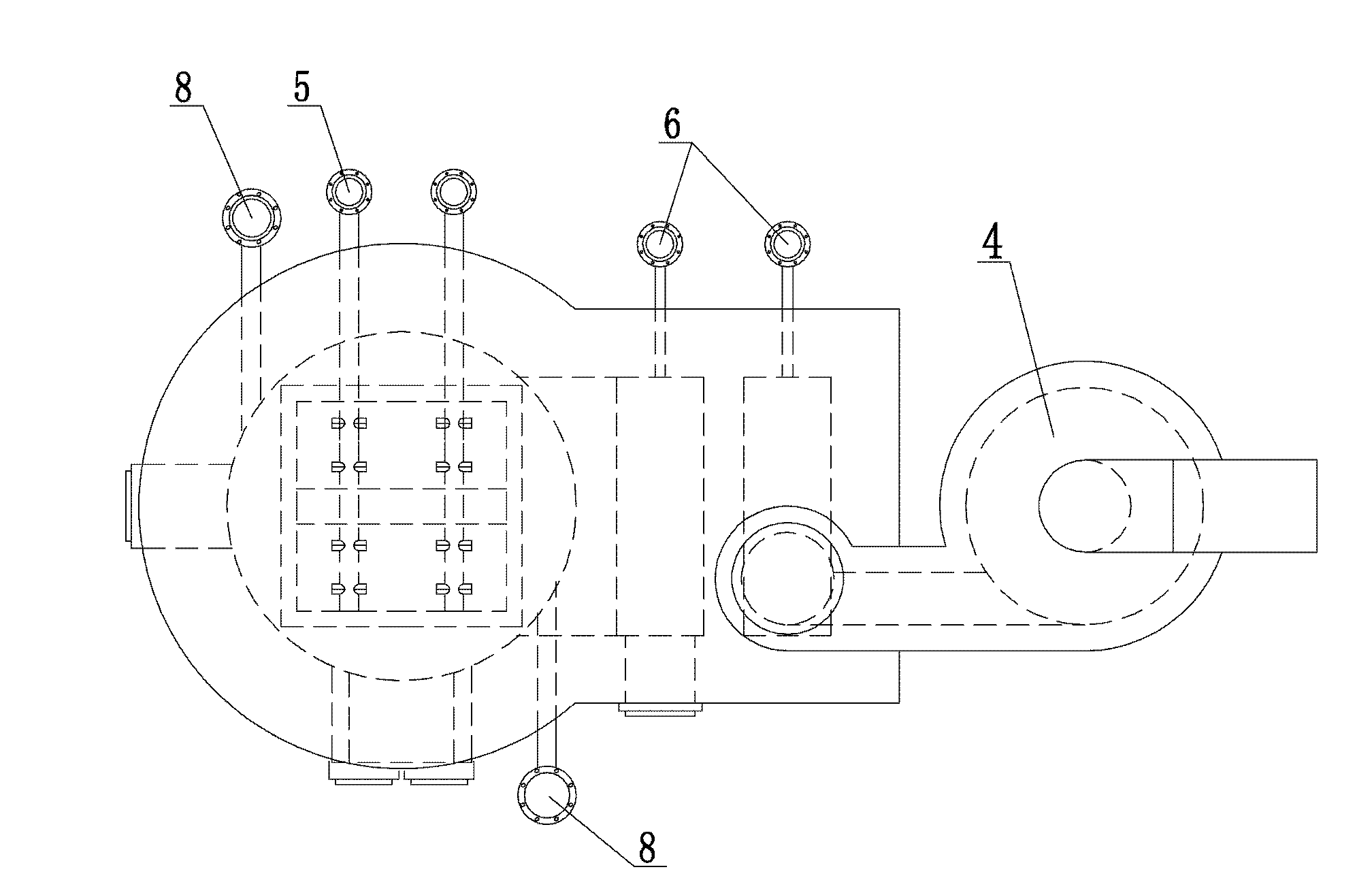

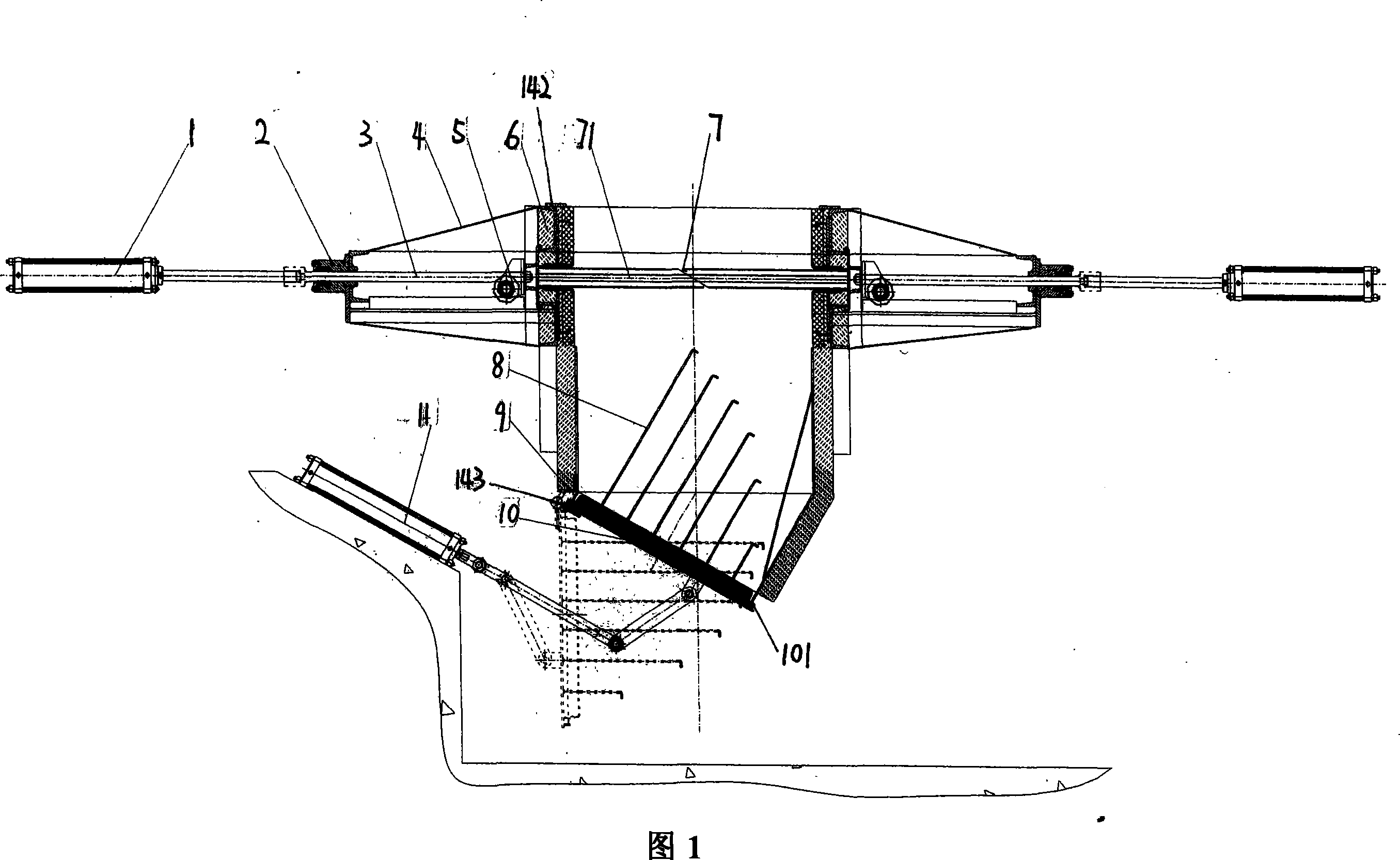

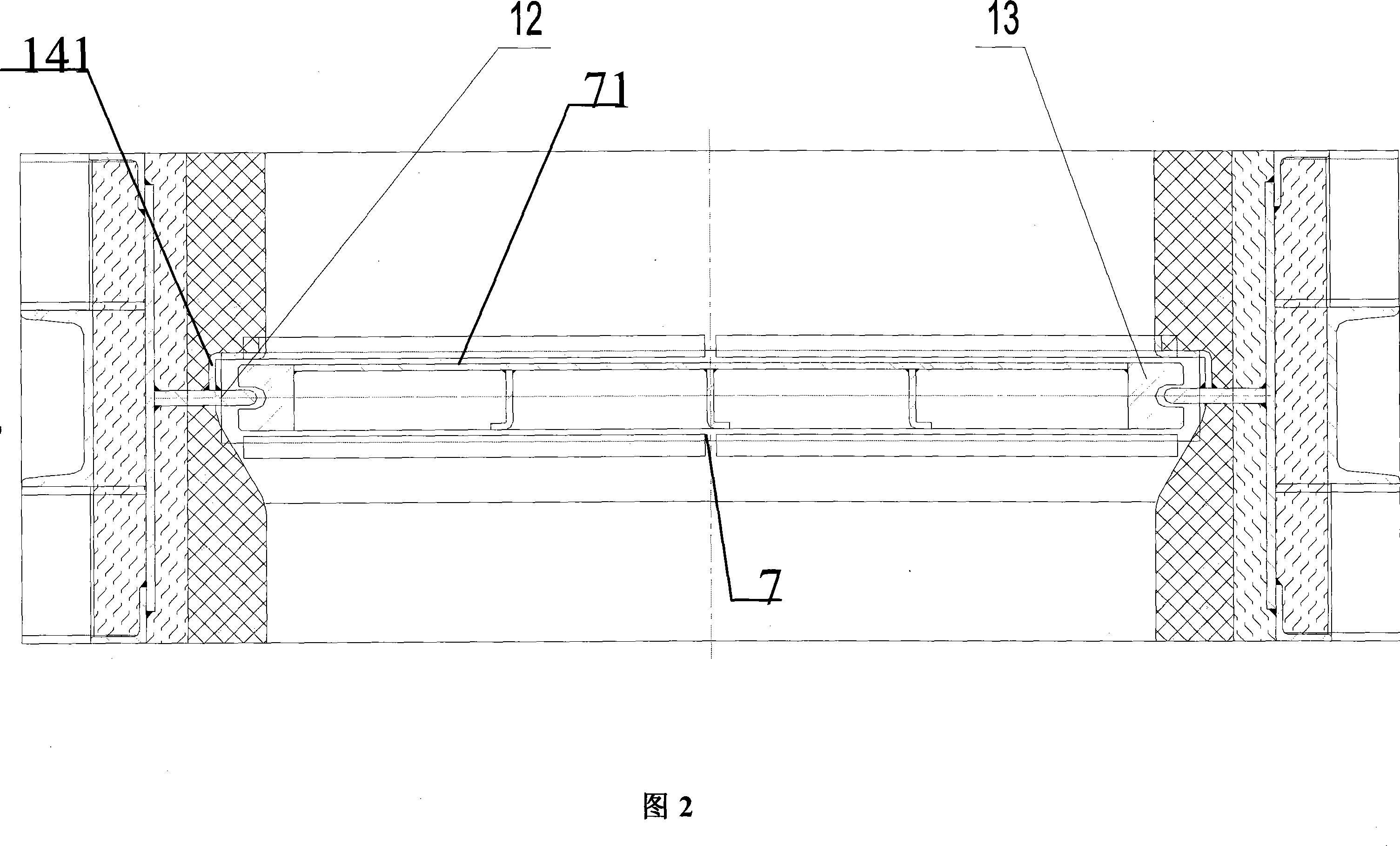

Novel rotary air-cooled grate system for biomass boiler

The invention discloses a novel rotary air-cooled grate system for a biomass boiler, which comprises a rotating shaft (1), a grate chassis (4), a chassis bracket (5), a grate (6), a primary air duct (7), an air duct bracket (8), a wind deflector (9), a belt pulley (10), a belt (11) and a motor (12). The novel rotary air-cooled grate system for the biomass boiler is characterized in that the rotating shaft (1) rotates to drive the grate (6) to rotate; and air enters the primary air duct (7) through the wind deflector (9) and is uniformly blown towards the grate (6), so that the fuel on the grate is combusted. The novel rotary air-cooled grate system for the biomass boiler has the advantages that firslty, a variable-speed gear can be manually adjusted, so that the grate is low and uniform in rotating speed, and the fuel is uniformly arranged on the grate and is fully combusted; secondly, the shaft and the bearing are cooled by the air, and the self-temperature is effectively reduced, so that the primary air temperature is raised, and the fuel is conveniently combusted; and thirdly, the air supply temperature is changed through the wind deflector, so that the primary air is uniformly blown to the grate; and therefore, the grate is cooled, and the phenomenon that the biomass ash drops on the bearing so as to damage the shaft and accessories is avoided.

Owner:JIANGSU YUANTONG AGRI MACHINERY TECH

Biomass pyrolysis and gasification method

InactiveCN103980947AReduce usageImprove the economy of useBiofuelsSpecial form destructive distillationGas phaseProduct gas

The invention discloses a biomass pyrolysis and gasification method comprising the following steps of (1) carrying out pyrolysis transformation on a biomass raw material; (2) separating a solid-phase product from a gas-phase product; (3) cracking the gas-phase product generated after pyrolysis at the temperature of 800-950 DEG C; (4) lighting the gas and using the gas. In such a way, the biomass pyrolysis and gasification method has the advantages of wide raw material application range, little biomass ash generated in the transformation process, no primary energy with high cost, economical efficiency increment of energy utilization and the like so as to have wide market prospects on the aspect of popularization.

Owner:苏州煦融环保科技有限公司

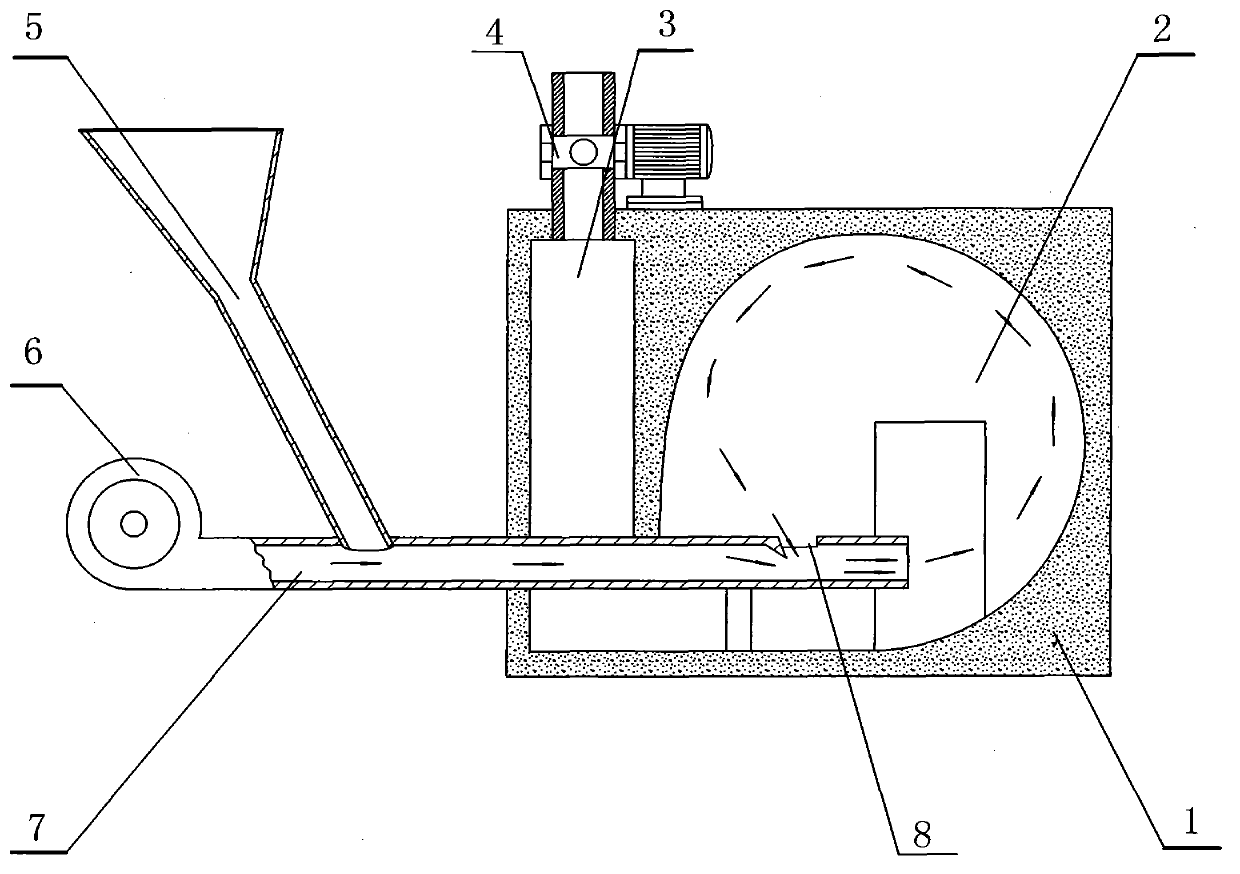

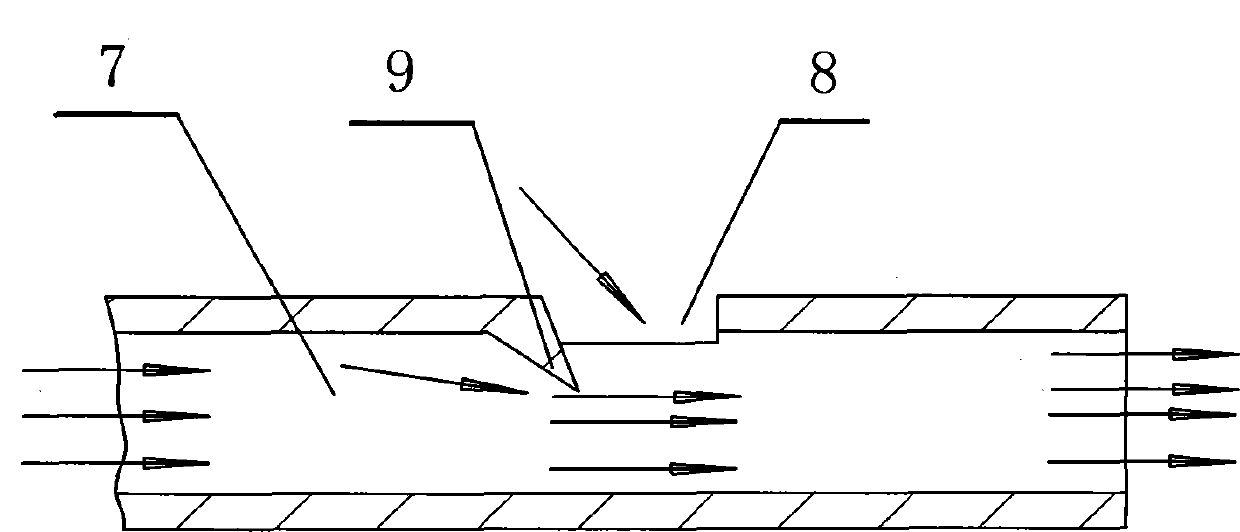

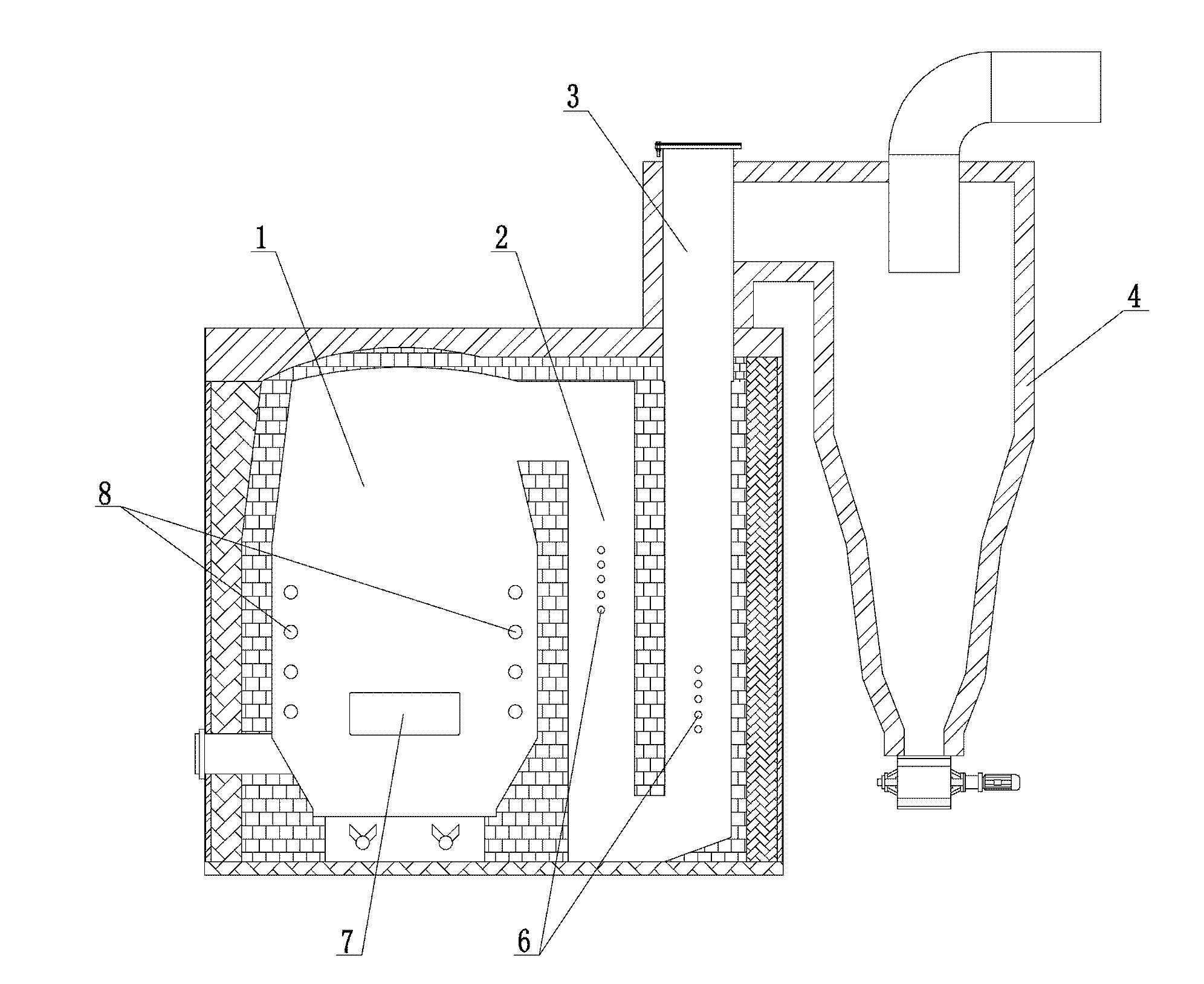

Biomass ash-free combustion furnace

ActiveCN103134177ANot easy to pile upIncrease temperatureAir heatersWater heatersThermal energyFurnace temperature

The invention relates to heat supply equipment, in particular to a biomass ash-free combustion furnace. The biomass ash-free combustion furnace is characterized in that the inner wall, faced by an end port of an air feeding pipe (7), of a hearth (2) and the inner wall, above the air feeding pipe (7), of the hearth (2) are a circular arch-shaped curved surface formed by circular arch-shaped surfaces in a smooth connection mode, a negative-pressure port (8) is formed at the upper side of the air feeding pipe (7) entering the hearth (2), combustion air at the negative-pressure port (8) firstly passes through a wind pressing piece (9), the edge of one side of the wind pressing piece (9) is bent obliquely towards the rear lower direction, and the air feeding pipe (7) outside a furnace body (1) is communicated with a fuel conveying pipe (5). The biomass ash-free combustion furnace has the advantages that fuel enters the hearth along with the wind, rotates and flies up and down, is combusted and is not accumulated easily, the unburnt fuel is sucked to the air feeding pipe and is sprayed out again for combustion, so that the combustion is more sufficient, and almost no ash is reserved. In addition, a heat storage chamber stores a large amount of heat to improve the temperature of the hearth. The air feeding pipe passes through the heat storage chamber, so that the fuel and the combustion air can be preheated, a large amount of combustion air is from the hearth, and the heat of the furnace is accumulated continuously and reaches or approaches the heat of compressed straws and coal. The biomass ash-free combustion furnace can serve as various heat exchanging equipment such as a hot blast heater, a water heater and an oil furnace, substitutes coal-fired furnaces to carry out a heat-supply operation, and has great significance of saving coal, protecting the environment, fully utilizing crop straws, improving the value of the crop straw and increasing the income for farmers.

Owner:张建臣

Method for improving biomass ash fusion point

InactiveCN102041130ARaise the ash melting pointSimple processSolid fuelsFuel additivesSodium BentoniteProcess engineering

The invention discloses a method for improving biomass fuel ash fusion point, which is characterized in that the aim of improving the ash fusion point of biomass fuel is realized by mixing the compounding additives with the biomass fuel. By taking the mass of ash in the biomass fuel as 100 parts, the compounding additives contain the following components in parts by weight: 5-20 parts of kaolin, 0-15 parts of acid clay, 0-15 parts of diatomite, 0-10 parts of bentonite, 0-20 parts of coal, and 0-25 parts of coal gangue. The biomass fuel and the compounding additives are crashed, and are mixed uniformly by adopting a direct mixing method, The ash fusing point Ts (softening temperature) of the biomass fuel can be improved greatly, the range improved can reach 200-300 DEG C. The method has the characteristics of simple operation and low cost, and can be widely used for improving the ash fusing point of various biomass fuels.

Owner:EAST CHINA UNIV OF SCI & TECH

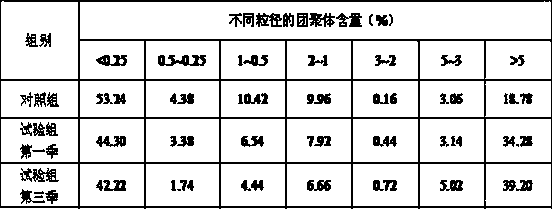

Method for quickly improving soil aggregate content through biomass ash

InactiveCN103918375ARealize resource utilizationHigh porositySoil-working methodsSoil aggregateSoil porosity

The invention discloses a method for quickly improving the soil aggregate content through biomass ash. A vegetable field with the slope smaller than 10 degrees is selected, and organic fertilizer is applied 800 kg / mu before crop sowing to serve as base fertilizer; the biomass ash is evenly applied 1200 kg / mu two days later, and then soil is ploughed with the ploughing depth of 20 cm; it is guaranteed that the soil moisture content is not smaller than 45% seven or more days, and then crops can be planted. In the method, engineering development on land is not needed; the method is easy to implement, operation is easy, raw materials are easy to get, cost is low, and the aggregate amount can be improved within a short period of time which is mainly embodied in the aspects of improving the water-stable aggregate amount, soil porosity and soil water retention capacity. By quickly improving the soil aggregate content through the biomass ash, ecological and economical benefits can be achieved.

Owner:SOUTHWEST UNIVERSITY

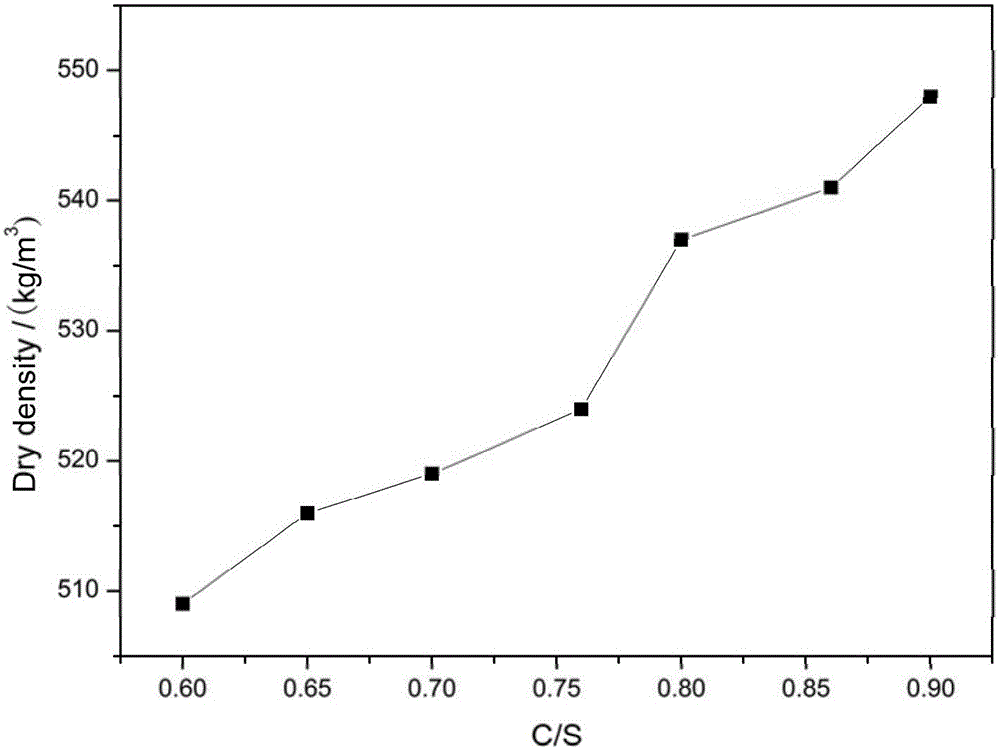

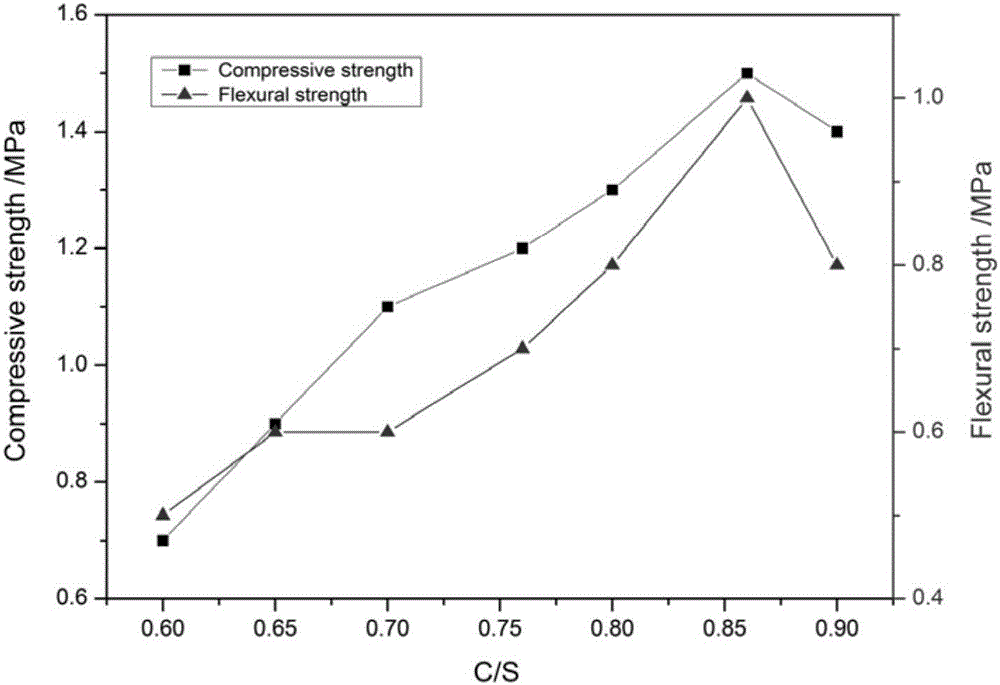

Biomass ash concrete block and preparation method thereof

InactiveCN107522433AAchieve reuseHigh hardnessSolid waste managementCeramicwareSuperplasticizerSlurry

The invention discloses a biomass ash concrete block and a preparation method thereof and relates to the field of concrete blocks. The biomass ash concrete block is mainly prepared from raw materials in parts by weight as follows: biomass ash, fly ash, cement, quick lime, gypsum, aluminum powder, an alkali-activator, a foam stabilizer, a polycarboxylate superplasticizer and water. The biomass ash is used as a raw material of the biomass ash concrete block, reutilization of the biomass ash is realized, and the product has high hardness, good strength and good use effect. The preparation method of the biomass ash concrete block comprises steps as follows: firstly, the biomass ash and the fly ash are mixed uniformly, secondly, cement, quick lime and gypsum are added, the mixture is continuously stirred for 2-3 min, later, water, aluminum powder, the alkali-activator, the foam stabilizer and the polycarboxylate superplasticizer are added, the mixture is sufficiently stirred, and slurry is obtained; the slurry is poured, left to stand for gas formation for 3-4 h, demolded, cut and cured. By means of the preparation method, the biomass ash is effectively utilized, the method is simple, low in cost and good in economic benefits.

Owner:YANCHENG INST OF TECH

Fertilizer special for bananas

InactiveCN105777444AImprove immunityPrevention of Common DiseasesMagnesium fertilisersNitrogenous fertilisersSucroseNitrohumic acid

The invention discloses a fertilizer special for bananas. The fertilizer is prepared from nitrogenous fertilizer, phosphatic fertilizer, potash fertilizer, silicon-calcium-magnesium organic fertilizer, nitrohumic acid, amino acid, organic microelements, inorganic microelements, biomass ash residue and lime powder. The organic microelements comprise tartaric acid complex copper, sucrose complex iron, sucrose complex zinc, sucrose complex manganese, sucrose complex magnesium, humic acid complex potassium, humic acid complex magnesium, humic acid complex molybdenum, humic acid urea iron and EDTA chelation boron. According to the fertilizer special for bananas, the organic fertilizer and the inorganic fertilizer are reasonably combined, so that the fertility lasting time is longer, plant body resistance can be effectively adjusted, diseases are reduced, and the yield is improved; the crop quality is greatly improved, and the taste is good. The fertilizer special for bananas can resist diseases and disasters, improve the immunity of bananas, and well prevent commonly-occurring diseases of bananas.

Owner:STANLEY FERTILIZER GUIGANG

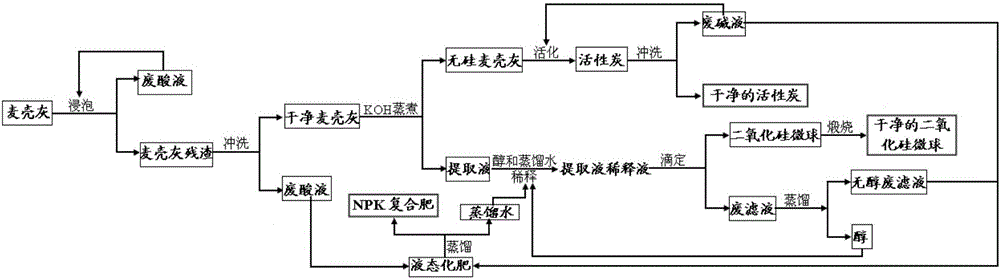

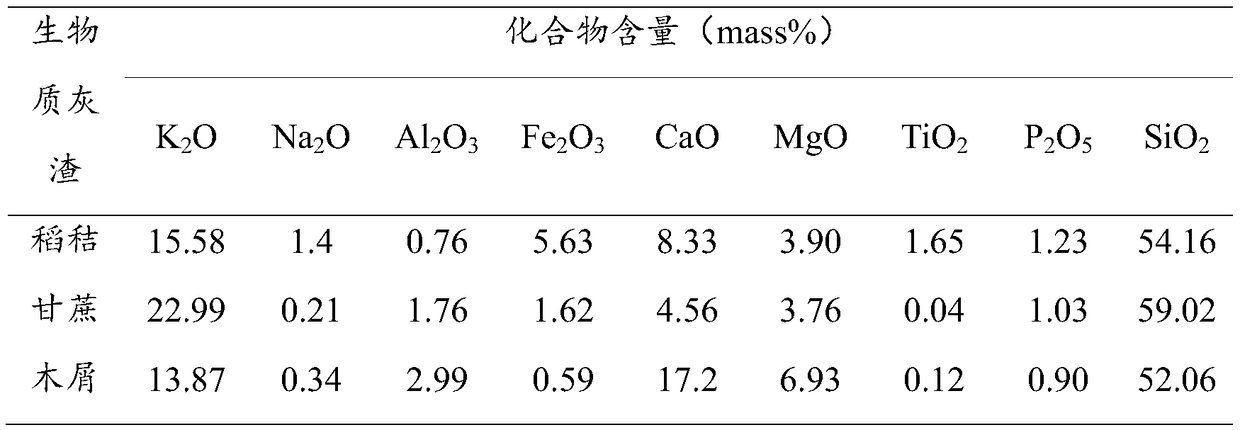

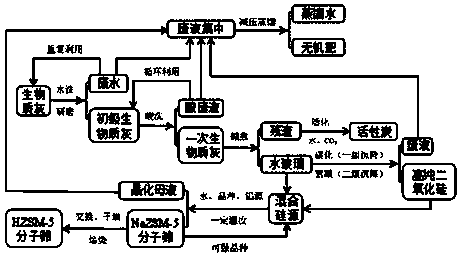

Green method for comprehensively utilizing biomass ash

ActiveCN105016346AZero pollutionRaw materials are easy to getBio-organic fraction processingSilicaActivated carbonSilicon dioxide

The invention discloses a green production technology for preparing silicon dioxide pellets with low specific surface areas, activated carbon and nitrogen-phosphorus-potassium compound fertilizers by utilizing biomass ash. The green production technology comprises the steps of: soaking raw materials of the biomass ash with acid so as to remove impurities introduced in the process of agricultural production, extracting silicon dioxide from clean biomass ash with a KOH solution, and then precipitating the silicon dioxide pellets with low specific surface areas from a diluted extracting solution with acid liquor. The biomass ash residues after silica removal are directly dried and activated for preparing the activated carbon, and waste liquor produced in the whole preparation process is uniformly blended for preparing the nitrogen-phosphorus-potassium compound fertilizers. All the components in the biomass ash and various chemical reagents put in the biomass ash are fully utilized.

Owner:DALIAN MARITIME UNIVERSITY

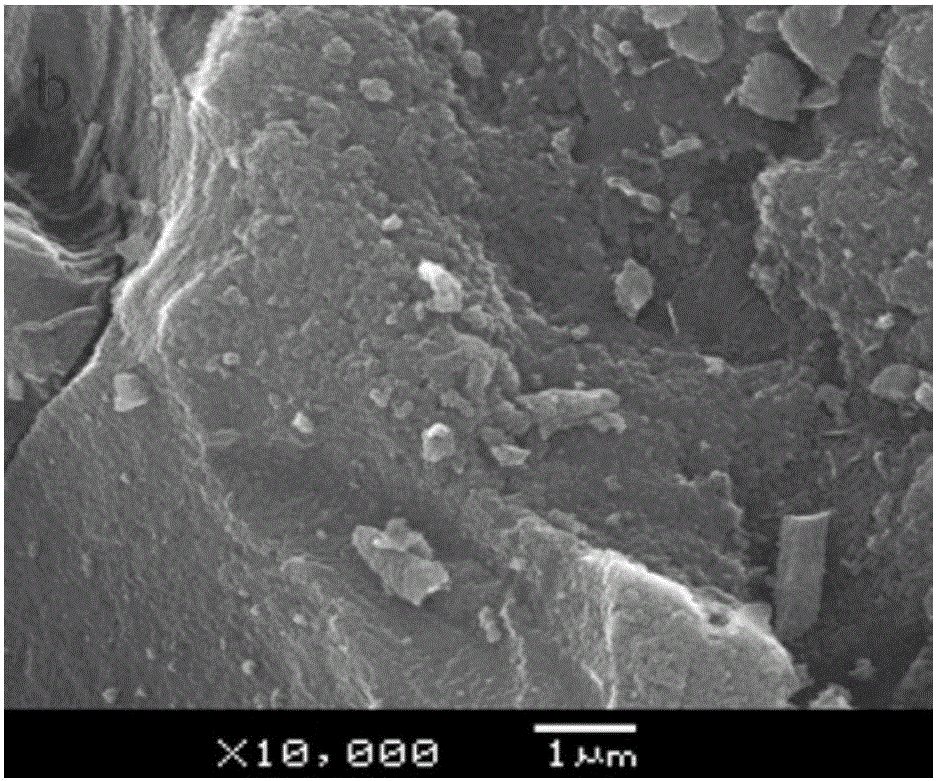

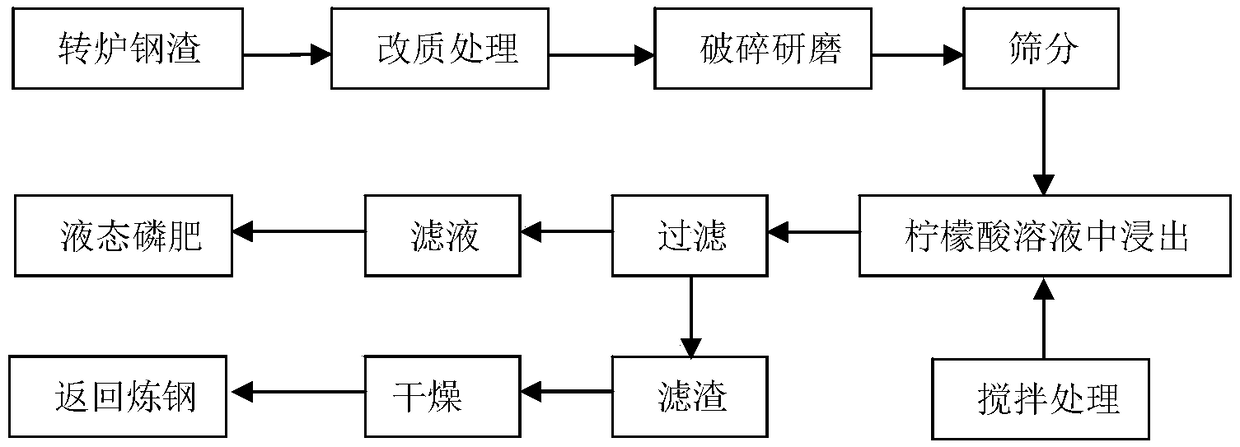

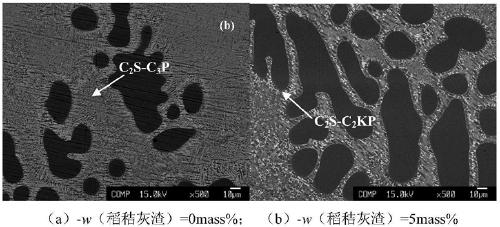

Circulating utilizing method of using biomass ash and slag to modify converter steelmaking slag to remove phosphorous

ActiveCN109207658AImprove solubilityPromote dissolutionFertilisers by pryogenic processesRecycling and recovery technologiesSteelmakingOrganic acid

The invention discloses a circulating utilizing method of using biomass ash and slag to modify converter steelmaking slag to remove phosphorous, and belongs to the technical field of resource reuse inmetallurgy. According to the method, biomass ash and slag is used to modify molten converter steelmaking slag; then modified converter steelmaking slag is finely grinded; finely grinded converter steelmaking slag is added into a critic acid solution; under the stirring of an electric stirrer, phosphorus in converter steelmaking slag is dissolved out, phosphorus containing filtrate and phosphorusfree steel slag are obtained; the phosphorus containing organic acid solution can be used to produce a liquid phosphorus fertilizer; and the phosphorus free steel slag is dried and then applied to metallurgy. The dissolution rate of phosphorus in steel slag can reach 90%; the dissolution rate of iron is lower than 10%, the iron loss is effectively avoided; the critic acid has weak acidity, the equipment requirements of leaching treatment are low, compared with a strong acid treatment, the processing cost is reduced, and environmental pollution is avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

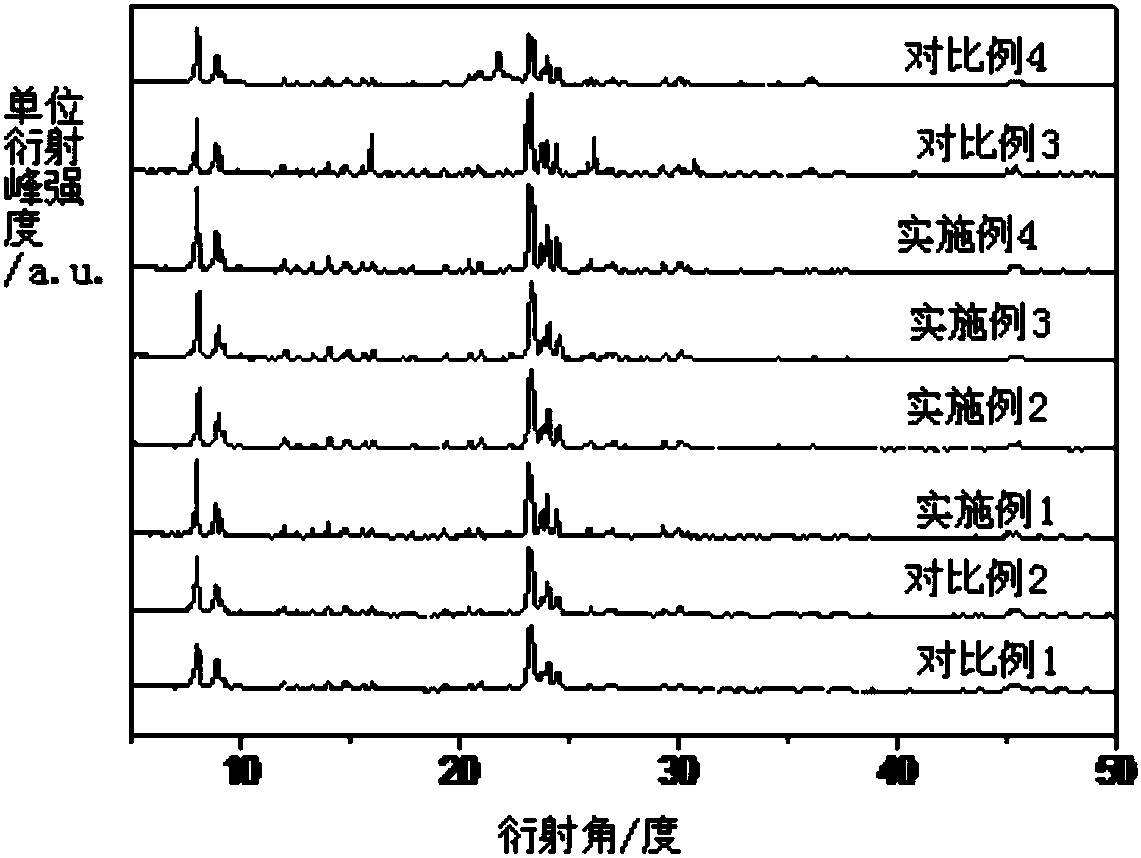

Biomass ash resource utilization method

ActiveCN107934986AReduce manufacturing costEasy to shapeCarbon compoundsAlkali orthophosphate fertiliserResource utilizationSilicon dioxide

The invention discloses a biomass ash resource utilization method which comprises the following steps: 1) pretreating biomass ash so as to obtain primary biomass ash; 2) soaking the primary biomass ash with an acid liquid so as to obtain first biomass ash; 3) melting and boiling the first biomass ash with an alkali liquid so as to obtain sodium silicate; 4) introducing a carbon dioxide gas into apart of the sodium silicate, neutralizing till the pH value of the solution is 9-11, further adding a flocculant according to a mass ratio of the flocculant to the solution of 1:(40-100), performing flocculation precipitation, filtering, and drying so as to obtain a solid sample; 5) roasting the solid sample so as to obtain nano silicon dioxide; 6) taking the rest sodium silicate and the nano silicon dioxide as a silicon source, and performing synthesis with an aluminum source, deionized water and crystal seeds, thereby obtaining a porous ZSM-5 molecular sieve. By adopting the method, the porous ZSM-5 molecular sieve of high quality is prepared, the waste residue treatment efficiency is improved, zero emission and zero pollution are achieved, and efficient utilization of biomass raw materials is achieved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Integrated reaction device for preparing aromatic hydrocarbon through biomass pyrolysis-catalytic cracking and application method

ActiveCN106753482AImprove pyrolysis efficiencyIncrease profitBiofuelsIndirect and direct heating destructive distillationHeat carrierFluidized bed

The invention discloses an integrated reaction device for preparing aromatic hydrocarbon through biomass pyrolysis-catalytic cracking and a method thereof. The integrated reaction device is formed by a biomass pyrolysis furnace, a catalytic cracking reactor, a two-stage spiral feeder, a heat carrier feeder, a catalytic filler feeder, a charcoal collector and the like. A biomass raw material and a heat carrier respectively enter the biomass pyrolysis furnace through the two-stage spiral feeder and the heat carrier feeder; biomass steam enters the catalytic cracking reactor through an outlet in the top end of the pyrolysis furnace so as to be subjected to catalytic cracking reaction to obtain an aromatic hydrocarbon product; biomass ash and the heat carrier enter the charcoal collector through an outlet in the bottom end of the pyrolysis furnace, and is separated through a screen so as to be stored; a catalytic filler is collected through a fan blade type feeder in an outlet in the lower end of the catalytic cracking reactor, and is regenerated and recycled; the heat carrier is recycled through a fluidized bed. According to the integrated reaction device provided by the invention, biomass pyrolysis and product catalytic cracking reaction are coupled, so that the biomass pyrolysis efficiency and the aromatic hydrocarbon product yield are remarkably improved.

Owner:WUHAN UNIV

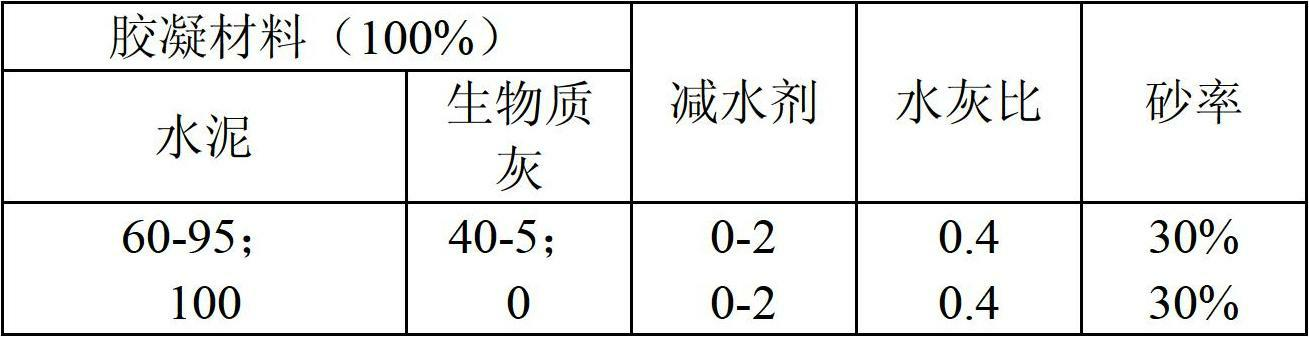

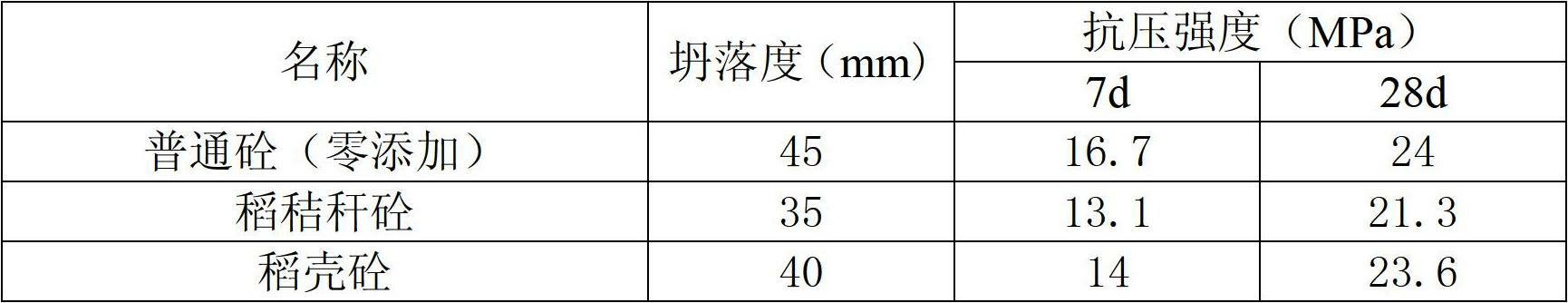

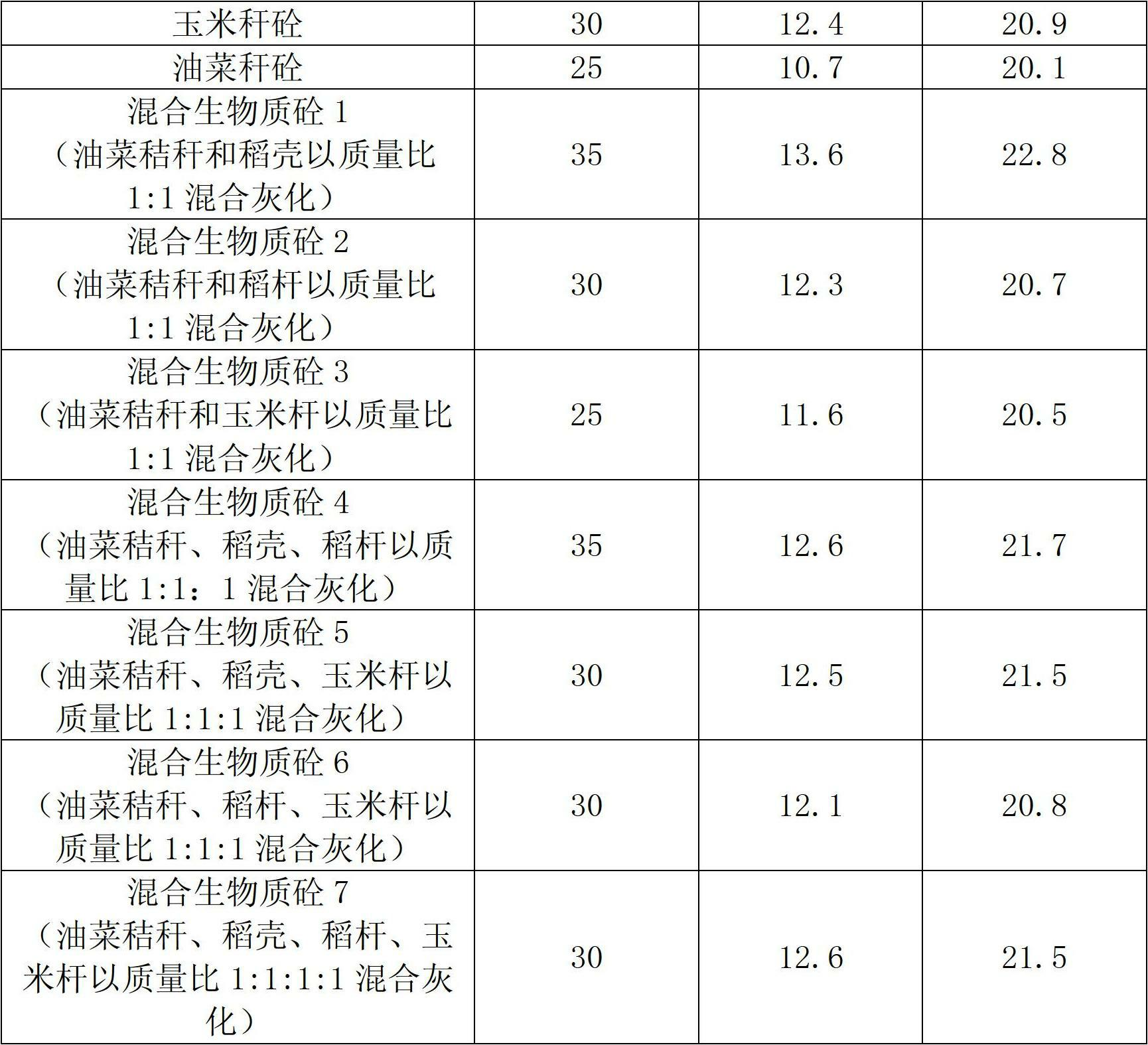

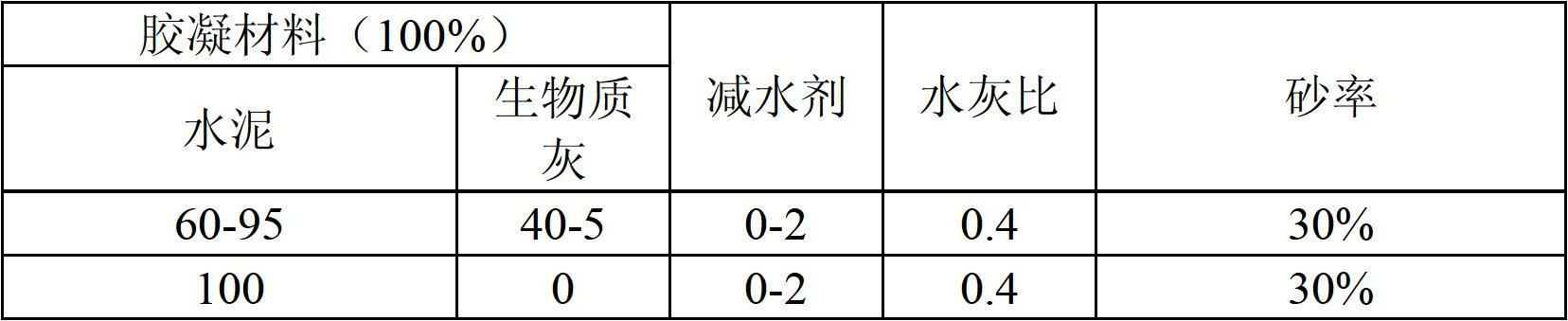

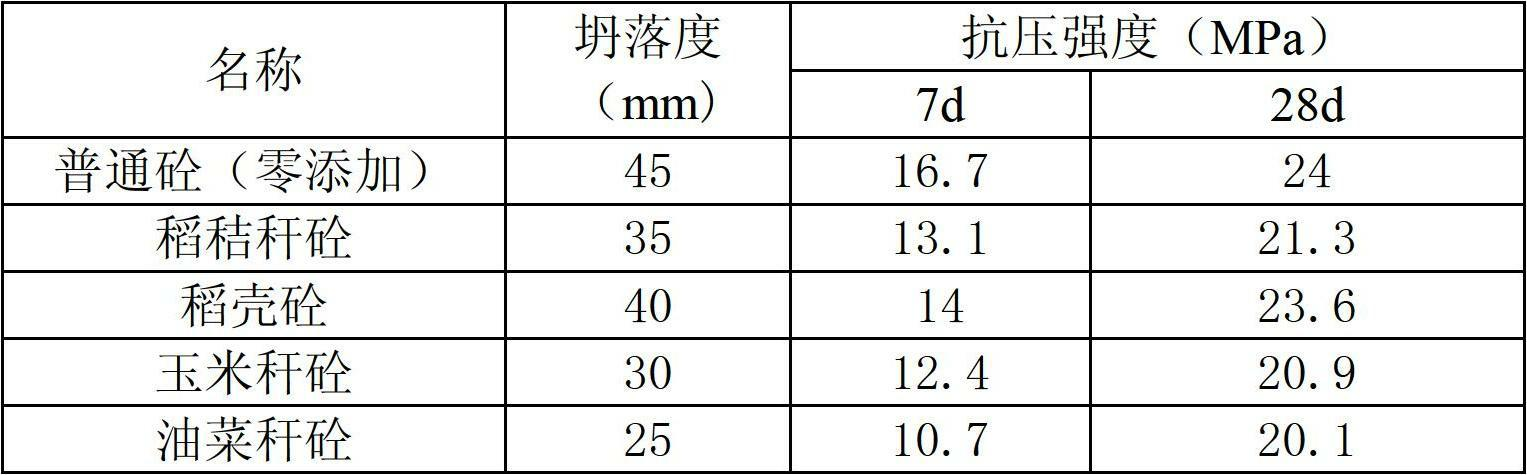

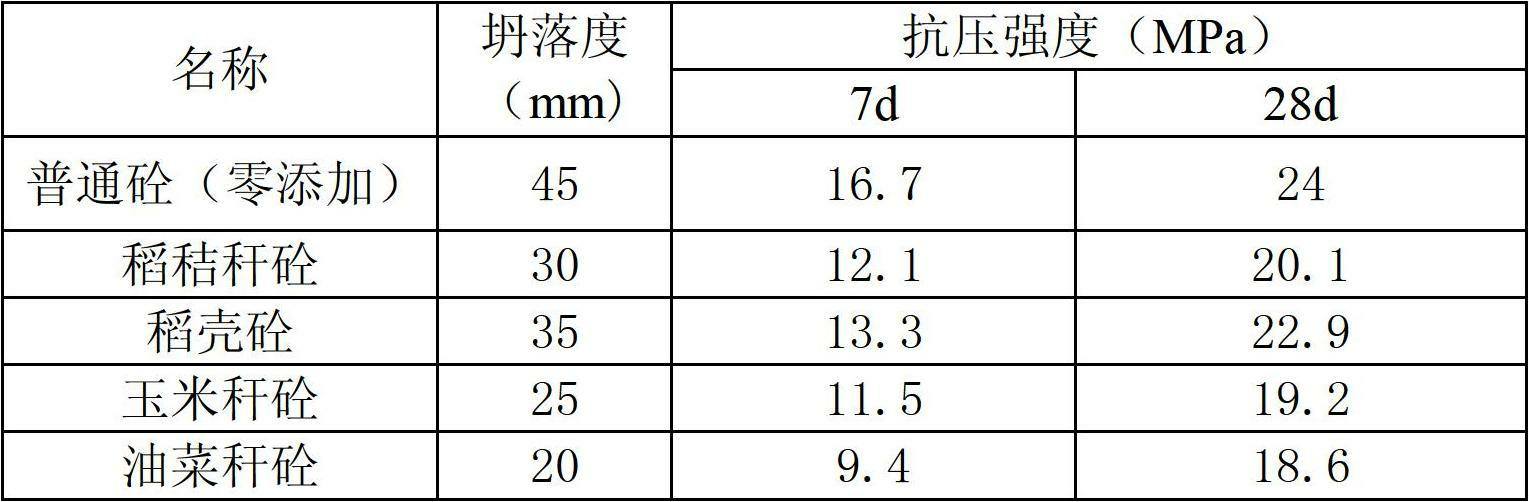

Method for preparing concrete admixture by utilizing mixture of multiple biomasses

InactiveCN102674732AGood mechanical propertiesGood physical propertiesSolid waste managementCooking & bakingNational standard

The invention provides a method for preparing a concrete admixture by utilizing a mixture of multiple biomasses. The method comprises the following steps: drying any two, three or four biomass materials of rice straws, rice hulls, corn stalks and rape stalks; soaking at a temperature of 15-35 DEG C; washing with water, and baking; and ashing the treated biomass materials to obtain the admixture. The concrete prepared by the admixture has excellent mechanical performance and excellent physical performance, and is in accordance with various indexes of the concrete national standard. The preparation method has the advantage of recycling biomass ash to make waste profitable, and achieving remarkable social and beneficial benefits.

Owner:HUNAN AGRICULTURAL UNIV

Method for preparing concrete admixture by using biomass

InactiveCN102674721AEasy to useMeet the indicator requirementsCement productionEconomic benefitsNational standard

The invention relates to a method for preparing concrete admixture by using biomass. The method is characterized in that the method comprises the steps of: drying the biomass, soaking at 15-35 DEG C, washing with water and drying; and ashing the treated biomass to obtain the admixture, wherein the mass content of SiO2 in the treated and ashed biomass is not less than the mass content of SiO2 of agricultural and forestry waste with concentration being 30 percent. After the admixture is added into concrete, the concrete still has good mechanical performance and excellent physical performance and satisfies the requirements on all indexes in the national standard. By recycling biomass ash, the wastes are turned into valuable things and the social and economic benefits are remarkable.

Owner:HUNAN AGRICULTURAL UNIV

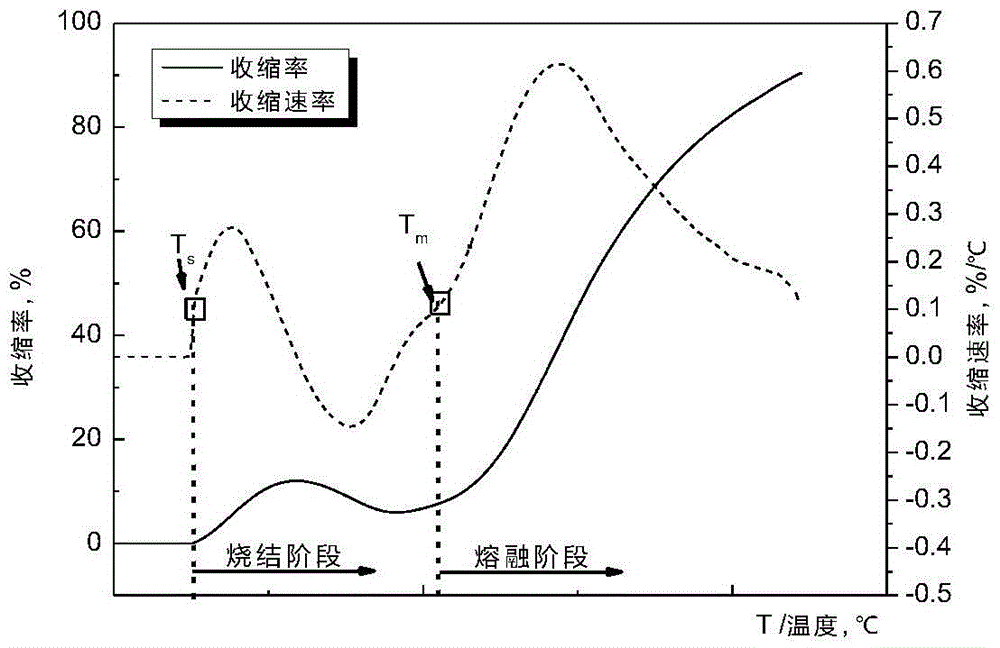

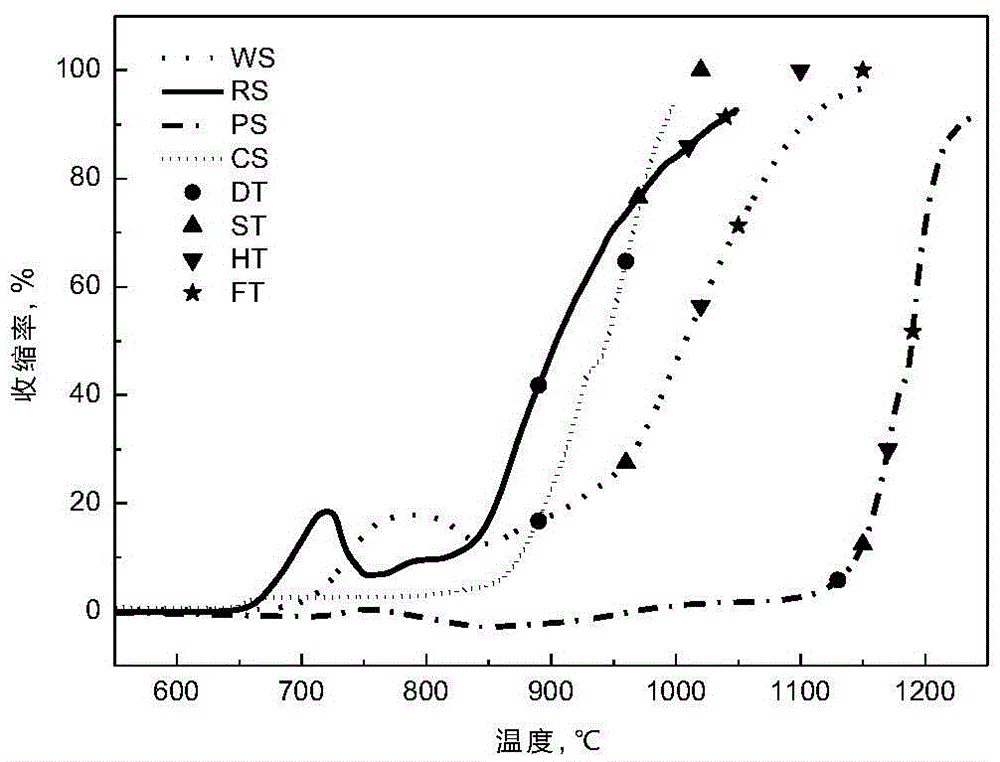

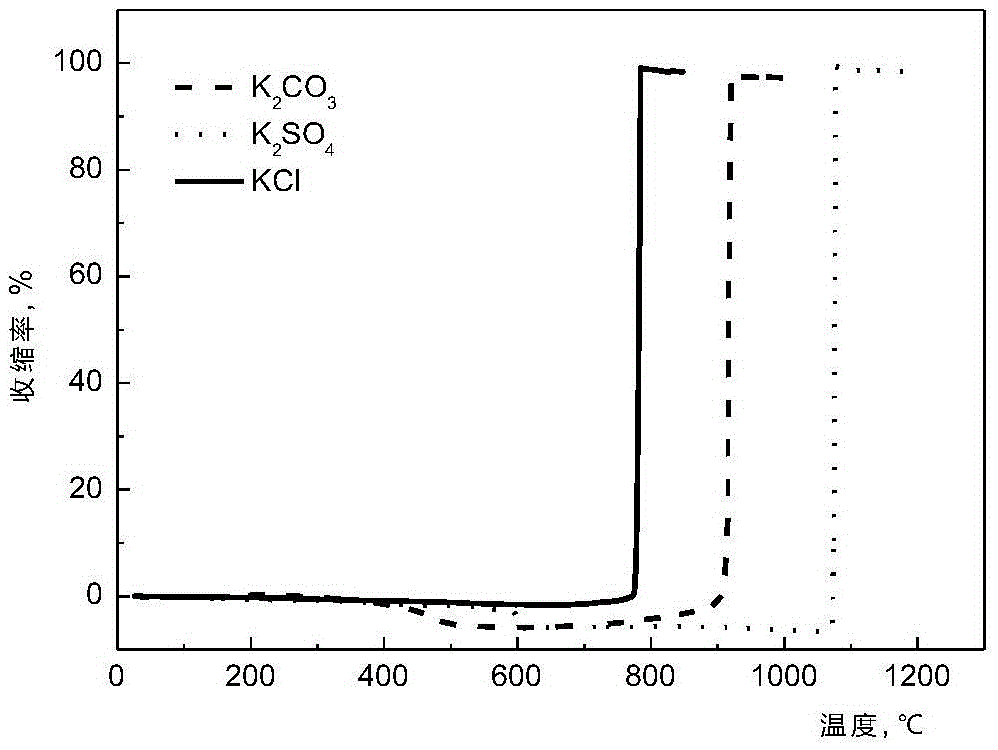

Method for analyzing melting characteristics of biomass ash

ActiveCN105527312AMelting properties reflectGood repeatabilityInvestigating phase/state changeThermomechanical analysisRepeatability

The invention relates to the field of gasifying of biomass energy sources, in particular to a method for analyzing melting characteristics of biomass ash. The method uses a thermal mechanical analyzer to test, and specifically comprises the following steps of preparing a biomass ash sample, testing the melting characteristics of the biomass ash, and analyzing a curve of the melting characteristics of the biomass ash; respectively defining the feature temperature Ts of a biomass ash sintering phase and the feature temperature Tm of a biomass ash melting phase, and utilizing the feature temperatures to analyze and evaluate the melting characteristics of the biomass ash; utilizing the feature temperature Tm to predict the agglomeration flow loss temperature caused by the melting of the biomass ash in the combusting and gasifying processes of a fluidized bed. The method has the advantages that the melting characteristics of the biomass ash in the whole heating process can be continuously observed, and the change caused by the viscosity and temperature characteristics of the biomass ash under high-temperature condition can be presented in the test process, so that when a thermal mechanical analyzing method is used for testing the melting characteristics of the biomass ash, the melting characteristics of the biomass ash can be more objectively and comprehensively reflected; the repeatability is good, and the accuracy is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Vertical biomass hot blast heater

InactiveCN102192591AReduce consumptionImprove combustion efficiencyAir heatersCombustion chamberFlue gas

The invention discloses a vertical biomass hot blast heater. A furnace cavity consists of a separated main combustion chamber for primary combustion, a secondary combustion chamber for secondary combustion, and a settling chamber for settling biomass ash; the upper part of the main combustion chamber is communicated with the upper part of the secondary combustion chamber; the lower part of the secondary combustion chamber is communicated with the lower part of the settling chamber; and high-temperature flue gas generated through the combustion of the main combustion chamber circuitously flows in the furnace cavity. The vertical biomass hot blast heater is designed to be a layer combustion structure with a three-layer combustion chamber structure, a combustion area is divided into the primary combustion chamber and the secondary combustion chamber, the gasification stage and the oxidation stage are separated, and primary air is prevented from being mixed too early. The combustion efficiency of the hot blast heater is improved obviously, the consumption level of fuel can be saved by about 10 percent compared with that of the conventional hot blast heater, and the vertical biomass hot blast heater is suitable for biomass with high moisture content, large dimensional change and high ash content.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Device and method for preparing hydrogen-enriched gas through in-situ catalytic gasification of biomasses

InactiveCN104178225AGuaranteed gasification reaction timeAvoid the problem of sticking together and clogging pipesChemical recyclingGranular/pulverulent flues gasificationHydrogenTar

The invention discloses a device and method for preparing hydrogen-enriched gas through in-situ catalytic gasification of biomasses. The method comprises the steps of uniformly adding a catalyst with catalytic cracking activity and a biomass raw material into a biomass gasification reactor according to a certain ratio; carrying out in-situ catalytic cracking on tar supervened in the biomass gasification process under the action of the catalyst to generate the hydrogen-enriched gas; discharging the catalyst playing a catalyzing role and biomass ash from the bottom of the reactor; separating the catalyst and the biomass ash; and then, recycling the catalyst. The catalytic cracking temperature of the tar is consistent with the biomass gasification temperature, and carbon deposits generated in the catalytic cracking process of the tar are removed through carrying out redox reaction in a gasification furnace, so that the catalytic activity is kept, the problem that the catalyst is rapidly deactivated by carbon deposition in the current biomass and tar catalytic cracking process is solved, the biomass gasification efficiency is increased, and the broad application prospect is provided for the development and utilization of biomass energy.

Owner:HUAZHONG NORMAL UNIV

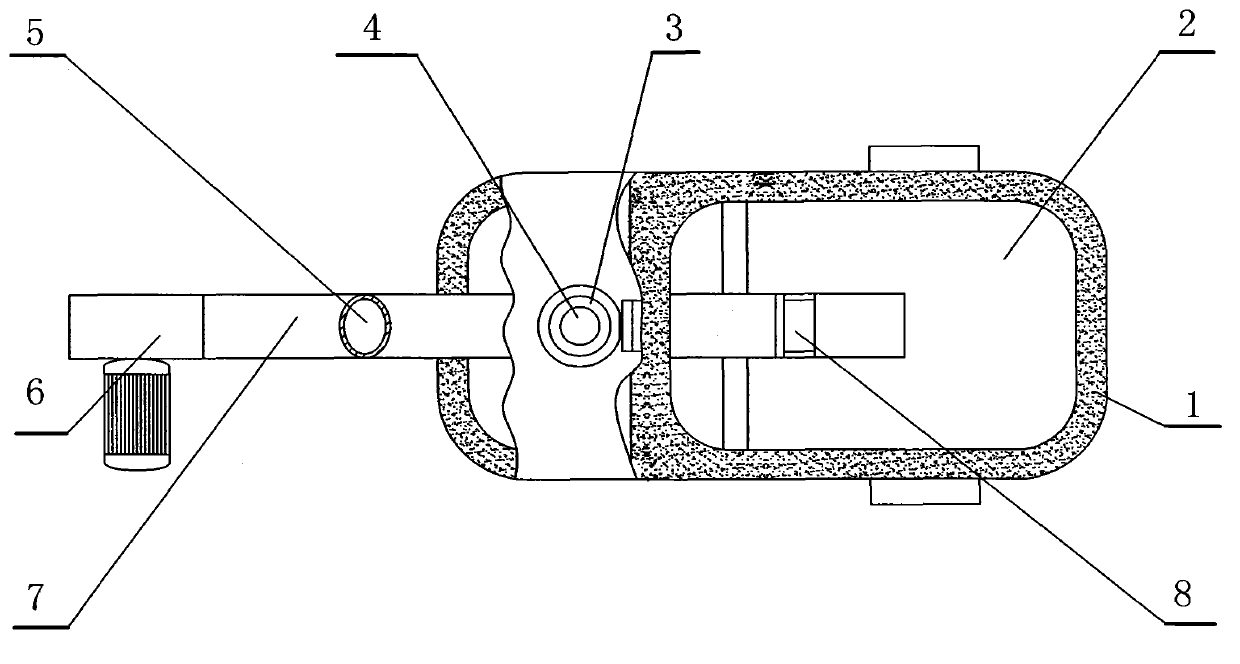

Apparatus for sealing and removing ash for biomass gasification stoves of static bed

InactiveCN101201170AEasy dischargeEnsure normal dischargeLighting and heating apparatusSpecial form destructive distillationFixed bedEngineering

The invention relates to a fixed bed biomass gasification furnace sealing ash removing device which comprises a drive device (1). The invention is characterized in that the invention also comprises an upper channel lock gate hatch(7) and a lower channel turning door (10) and a sealing element correspondingly arranged below the upper channel lock gate hatch(7); wherein, the upper channel lock gate hatch(7) comprises two lock gate hatches moving oppositely, two lock gate hatch sealing slots formed by a folded plate with a channel steel shape (6) respectively welded at the back part of the lock gate hatches, two lateral sealing frames (12) respectively at two sides of the lock gate hatches, two lock gate hatch drive connecting rods (3) respectively connected with the lock gate hatches as well as two lock gate hatch guiding wheels (5) respectively connected with the lock gate hatch drive connecting rods (3). The invention combines the characteristics of the biomass ash and the gasification furnace to lead the biomass ash to be discharged through intermission and sealing, thus ensuring the quality of the gasified gas.

Owner:上海四方锅炉厂

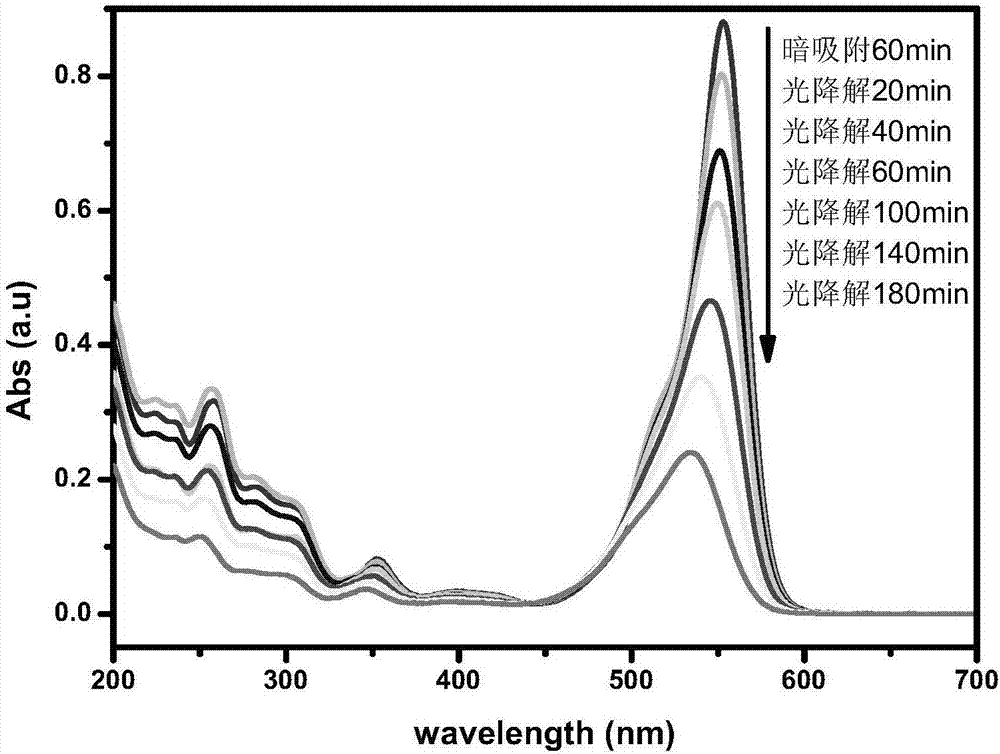

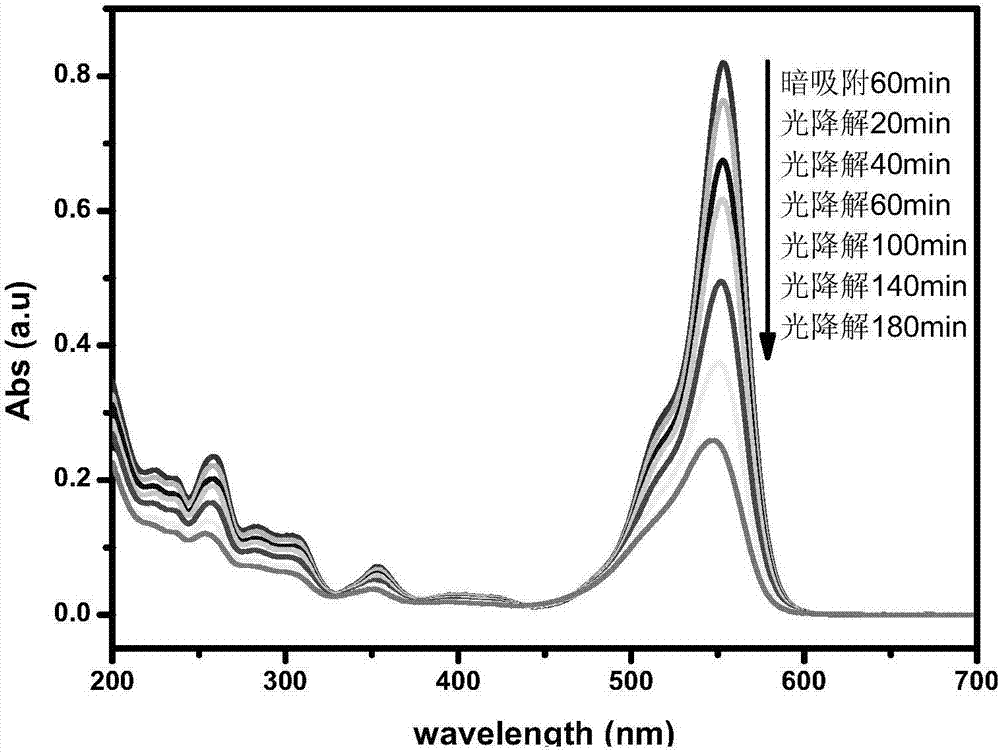

Visible light photocatalyst doped with modified titanium dioxide and preparation method thereof

InactiveCN106984293ABroaden the response rangeIncrease profitPhysical/chemical process catalystsTitaniumSorghum

The invention discloses a visible light photocatalyst doped with modified titanium dioxide and a preparation method thereof. The preparation method comprises the following steps: hydrolyzing bran-doped titanium alkoxide to obtain sol and adding biomass ash to stir; drying the sol into gel; finally calcining the gel to obtain the visible light photocatalyst doped with the modified titanium dioxide. Bran is one of or more of rice bran, wheat bran, sorghum bran and bran coat, and has a particle size of 50-300 meshes. The biomass ash is a mixture of plant ash and seaweed ash of which the mass ratio is 1:(0.5-10). The preparation method disclosed by the invention has the benefits that raw materials are easy to obtain, the process is simple, and the industrial production can be realized; the prepared light photocatalyst has a good visible light photocatalytic degradation effect on organic pollutants.

Owner:SHANXI LANHUA HUAMING NANO MATERIALS +1

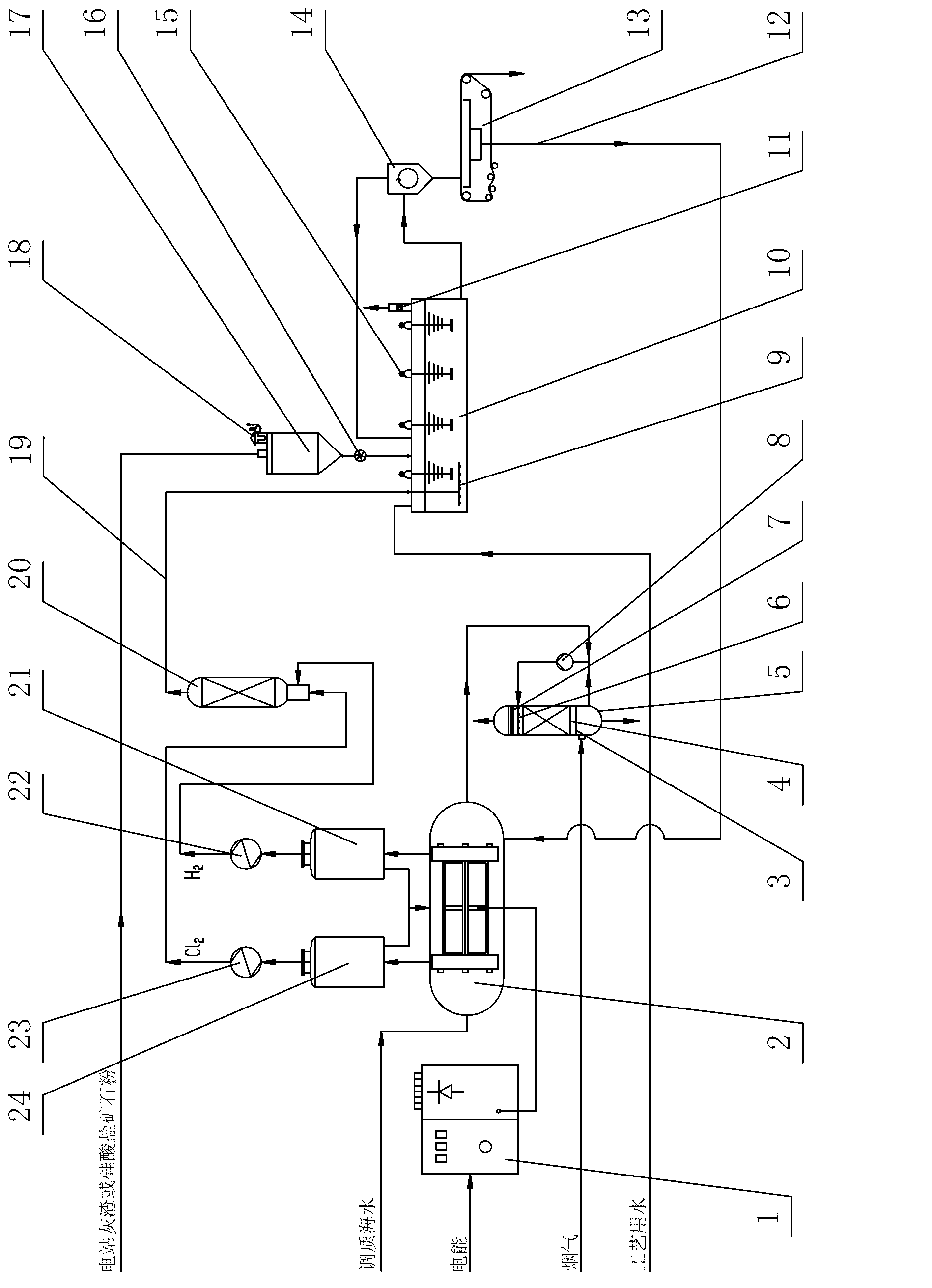

Waste comprehensive treatment process and equipment for solid fuel generating station

ActiveCN103055682AAvoid serious impactLong-term stable storageChlorine/hydrogen-chlorideProductsElectrolysisCo2 absorption

The invention discloses a waste comprehensive treatment process and equipment for a solid fuel generating station. In the process, thermal refined seawater containing metal ions like Na<+>, K<+>, Ca<2+> and Mg<2+> is electrolyzed and generates alkaline matters and acid gas, the alkaline matters are used to absorb carbon dioxide in emitted fuel gas of the generating station, and the carbon dioxide is treated in a harmless manner and then emitted to the sea to be stored, the acid gas is used to synthesize hydrochloric acid and conducts a dissolution replacement reaction with coal ash, biomass ash or cheap silicate salt mine emitted by the generating station, the separated dissolved solution containing the ions of Na<+>, K<+>, Ca<2+>, Mg<2+> and Cl <->is recycled and returned to the thermal refined seawater to continue to be electrolyzed, and the separated SiO2 is used as an industrial raw material, so that virtuous circle of comprehensive treatment of the waste of the generating station is formed. The equipment mainly comprises an electrolysis device, a carbon dioxide absorption tower, a hydrogen chloride synthesis tower, a silicate reactor, a cyclone separator and a vacuum belt conveyer, so that the waste of the generating station can be comprehensively utilized to the greatest extent.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com