Novel rotary air-cooled grate system for biomass boiler

A biomass boiler and rotating air technology, applied in the field of machinery, can solve the problems of insufficient fuel combustion, damage to the rotating shaft, uneven primary air supply, and achieve the effects of sufficient combustion, protection of the rotating shaft, and improved heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

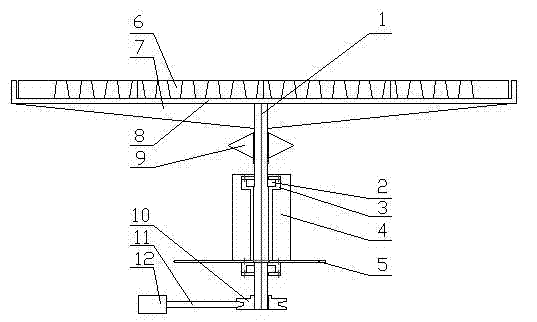

[0010] Such as figure 1 As shown, a new type of biomass hot water boiler rotary air-cooled grate system of the present invention includes 1 rotating shaft, 2 bearings, 3 bearing seats, 4 grate chassis, 5 chassis brackets, 6 fire grates, and 7 primary air ducts , air duct support 8, windshield 9, belt pulley 10, belt 11, motor 12. The upper end of the rotating shaft 1 is connected with the motor 12 through the pulley 10 and the belt, and is connected with the primary air pipe 7, and the lower end of the rotating shaft is fixed with a connected fire grate and can rotate together. There is a windshield 9 at the center, and the middle part of the rotating shaft 1 is provided with a chassis bracket 5 and a grate chassis 4 through the bearing seat 3 and the bearing 2. The rotating shaft 1 rotates to drive the grate to rotate together, and the wind enters once through the windshield 9 The air duct 7 is evenly blown out to the fire grate to burn the fuel on it.

[0011] When the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com