Apparatus for sealing and removing ash for biomass gasification stoves of static bed

A biomass and gasifier technology, used in new energy and environmental protection fields, can solve the problems of low density and high temperature, reduce contact opportunities, avoid thermal deformation, and ensure the quality of gasification gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

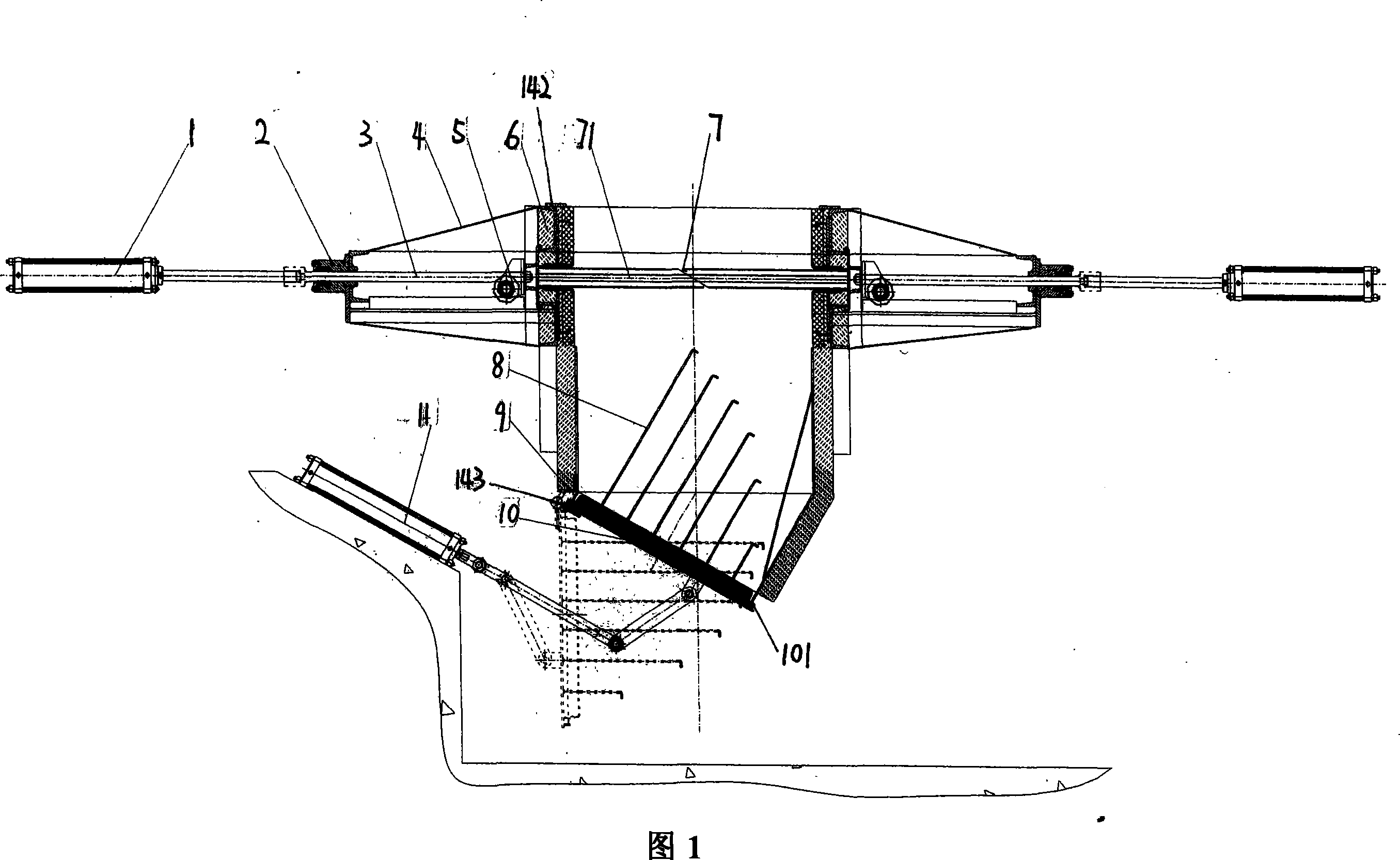

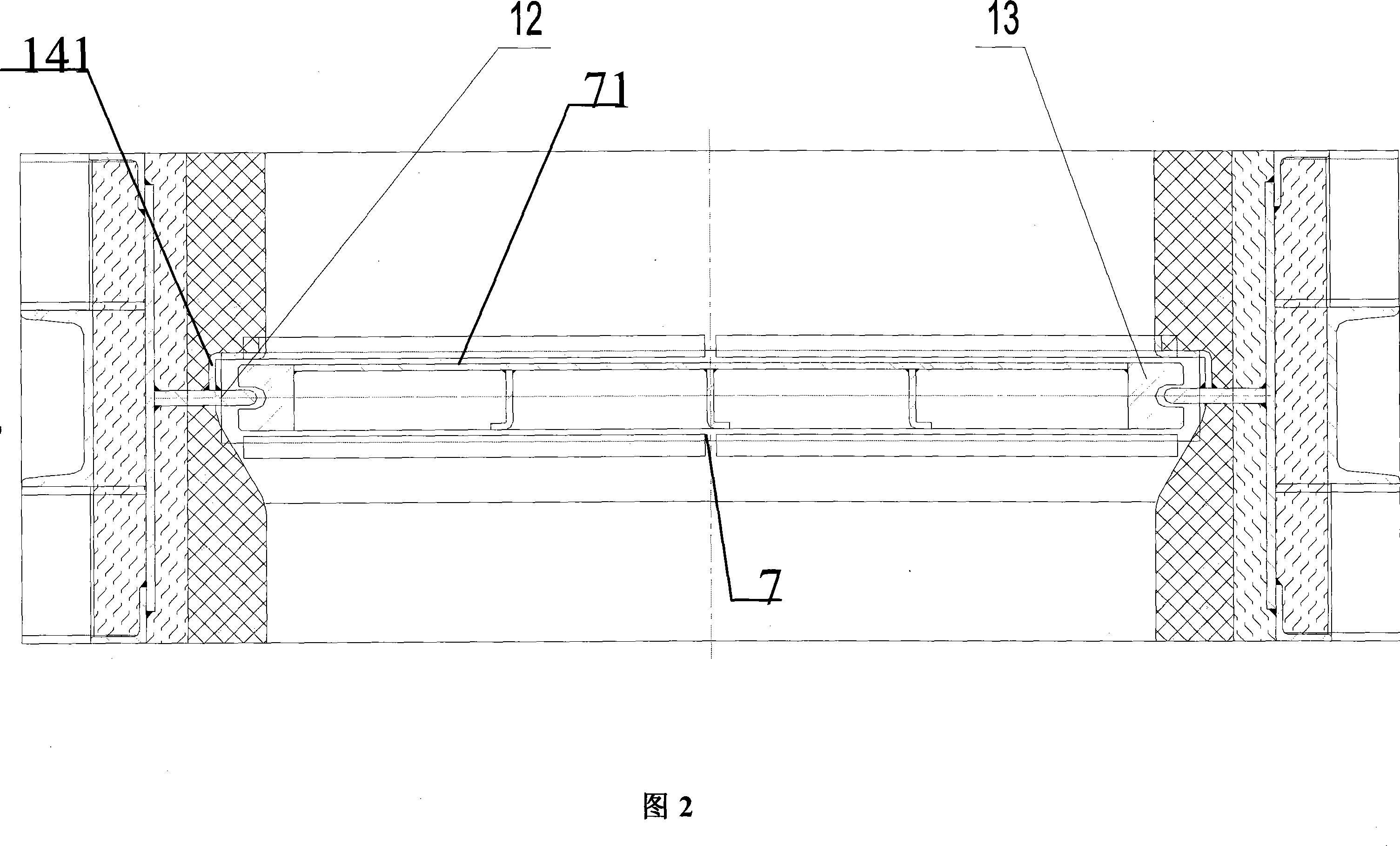

[0014] Referring to Fig. 1, combined with Fig. 2, the present invention, that is, the sealed ash removal device for a fixed-bed biomass gasifier, includes a driving device 1, an upper gate 7, and a lower gate relatively arranged below the upper gate 7. Flip door 10 and seal, wherein:

[0015] The upper gate gate 7 includes: two gate gates 71 that move towards each other, two gate seal grooves 6 that are welded to the rear of the gate gate 71 and are made of channel-shaped folded plates, and two gate seal grooves 6 respectively. The side seal frame 12 arranged at both ends of the gate door 71, two gate drive links 3 respectively connected to the gate door 71, and two gate guide wheels 5 respectively connected to the gate drive links 3 ;

[0016] The next reversing door 10 is made of cast steel material with grooves on both sides, and it includes: the reversing door frame 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com