Biomass ash-free combustion furnace

A biomass and combustion furnace technology, applied in combustion methods, combustion equipment, fuel supply, etc., can solve the problem of high cost of compressed particles, and achieve the effects of protecting the environment, fully burning, and increasing furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

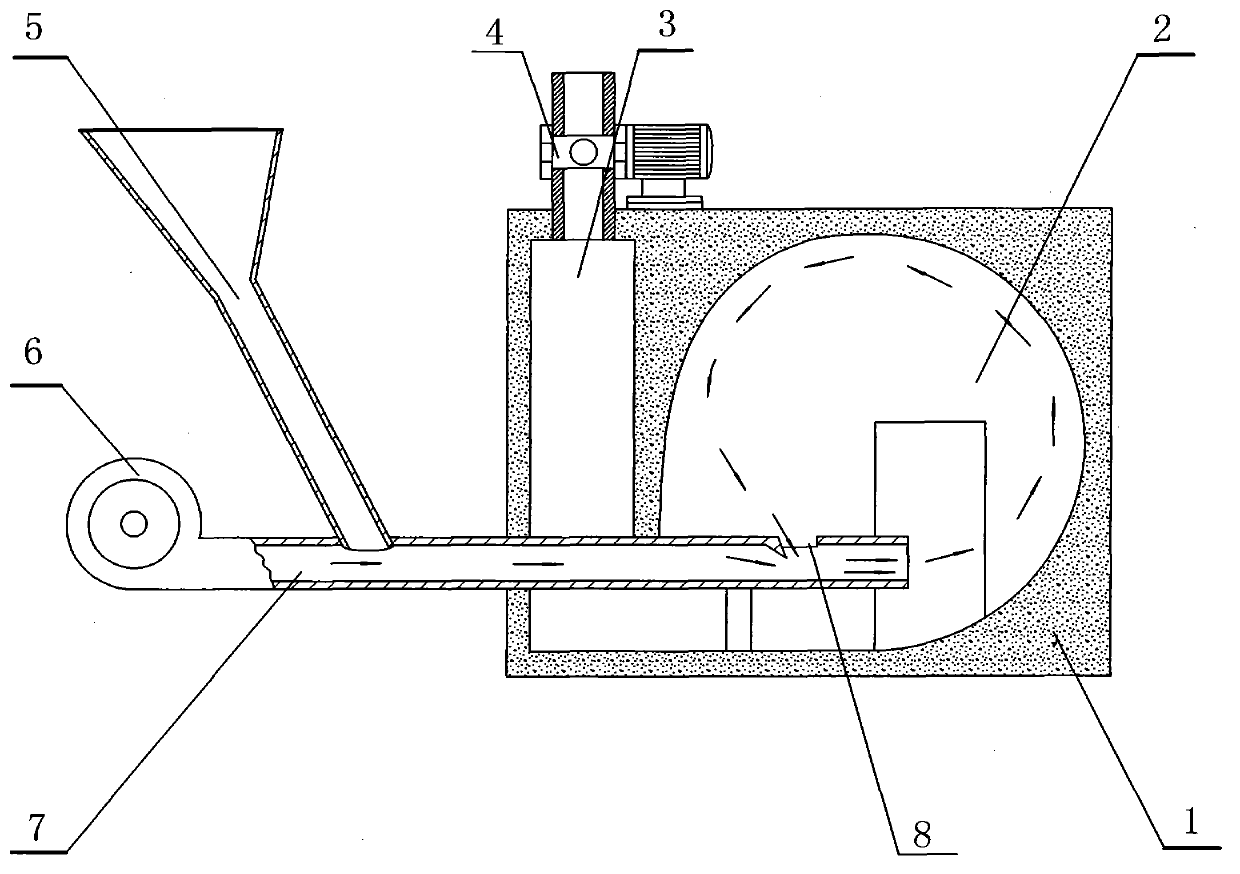

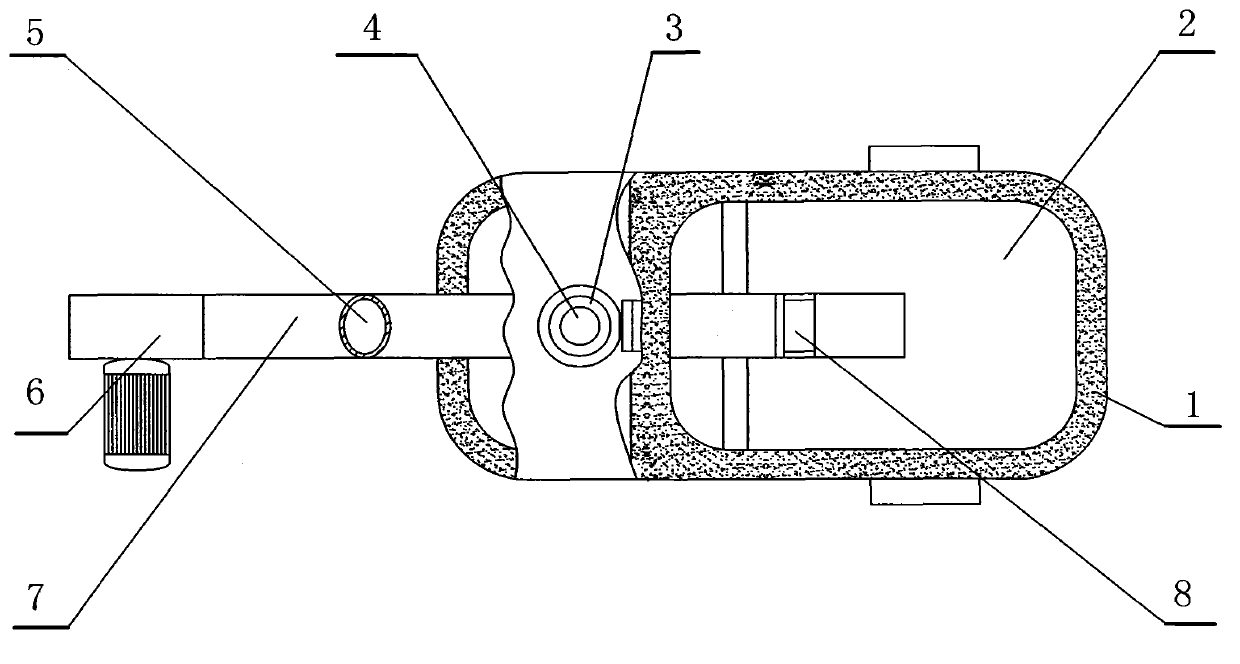

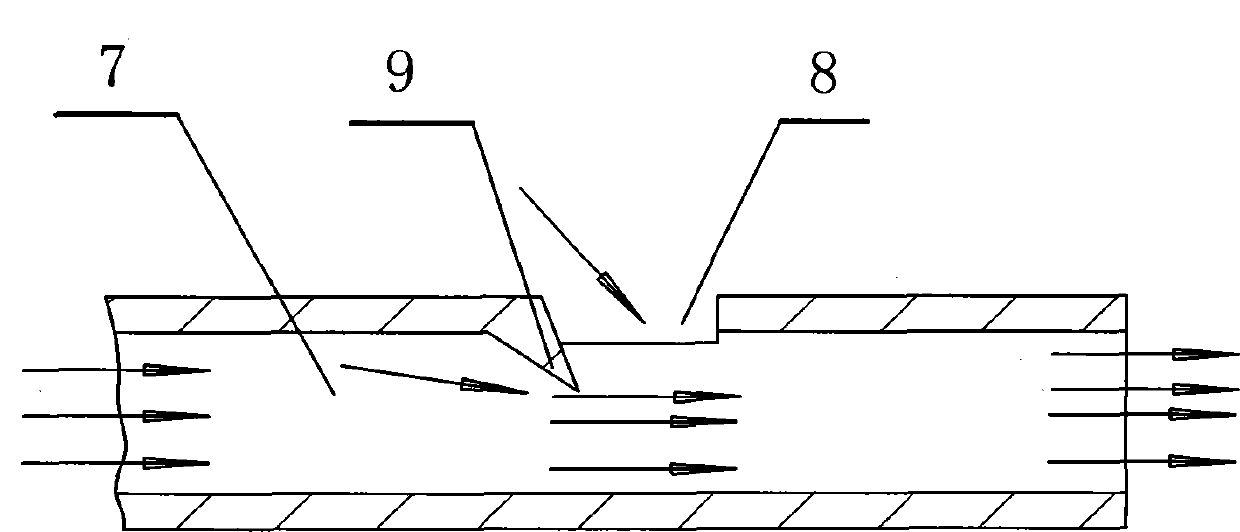

[0027] The first embodiment: as figure 1 , 2 As shown, the furnace body 1 of this biomass ashless combustion furnace has a furnace 2 inside, and a heat output pipe 3 is provided on one side of the furnace, and a flow limiting valve 4 is arranged on the heat output pipe 3 . The outside of the body of heater 1 is provided with a fuel delivery pipe 5 and a fan 6 , the lower end of the fuel delivery pipe 5 communicates with the air delivery pipe 7 of the fan 6 , and the air delivery pipe 7 enters the furnace 2 . The two sides of the inner wall of the furnace 2 are planes, and the remaining four inner walls, that is, the inner wall of the furnace 2 facing the port of the air supply pipe 7, and the inner wall of the furnace 2 above the air supply pipe 7 are smoothly connected by a plurality of arc surfaces to form A continuous, nearly closed circular arched surface. to combine image 3 It can be seen that there is a negative pressure port 8 on the upper side of the section where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com