Circulating fluidized bed boiler capable of adjusting circulating ash flow

A technology of circulating fluidized bed and circulating ash, which is used in fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., can solve problems such as small load adjustment range, low ash content, and boiler inner wall wear Achieve the effect of improving ash adjustment capacity, convenient load adjustment and reducing boiler load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

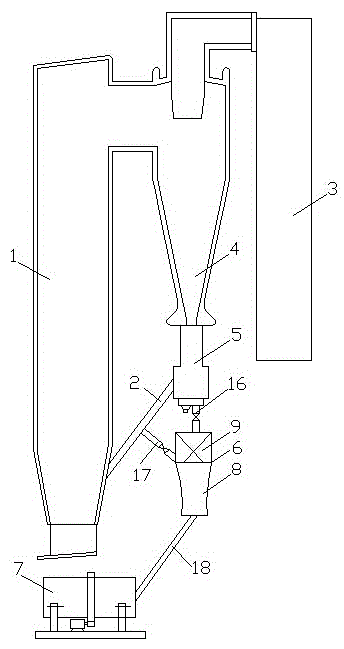

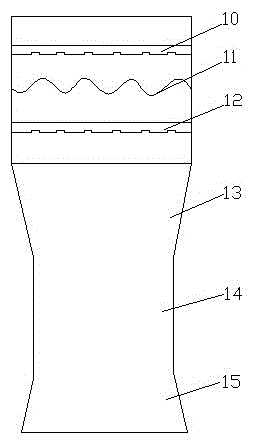

[0037] see figure 1 and figure 2 , a circulating fluidized bed boiler that can adjust the circulating ash flow, including a furnace 1, an ash return pipe 2, a tail flue 3, a cyclone separator 4 arranged between the furnace 1 and the tail flue 3, and a cyclone separator connected to the The ash return device 5 at the bottom of the furnace 4 and the cyclone separator 4 are connected to the furnace 1 and the tail flue 3 respectively, and the ash return device 5 is connected to the bottom of the furnace 1 through the ash return pipe 2, and also includes an ash adjustment device 6 and a slag cooler 7 , the ash adjuster 6 is composed of the lower Venturi fluidization air chamber 8 and the upper cylindrical cold ash chamber 9, the Venturi fluidization air chamber 8 and the cold ash chamber 9 are connected, and the cold ash chamber 9 is From top to bottom, the first flow sharing ring plate 10, the serpentine cooling coil 11 and the second flow sharing ring plate 12 are sequentially ...

Embodiment 2

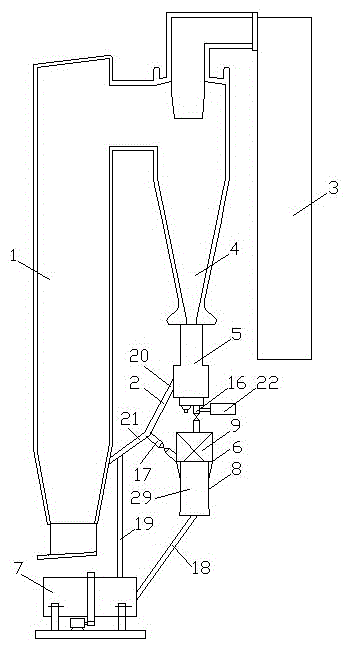

[0040] see figure 2 and image 3 , a circulating fluidized bed boiler that can adjust the circulating ash flow, including a furnace 1, an ash return pipe 2, a tail flue 3, a cyclone separator 4 arranged between the furnace 1 and the tail flue 3, and a cyclone separator connected to the The ash return device 5 at the bottom of the furnace 4 and the cyclone separator 4 are connected to the furnace 1 and the tail flue 3 respectively, and the ash return device 5 is connected to the bottom of the furnace 1 through the ash return pipe 2, and also includes an ash adjustment device 6 and a slag cooler 7 , the ash adjuster 6 is composed of the lower Venturi fluidization air chamber 8 and the upper cylindrical cold ash chamber 9, the Venturi fluidization air chamber 8 and the cold ash chamber 9 are connected, and the cold ash chamber 9 is From top to bottom, the first flow sharing ring plate 10, the serpentine cooling coil 11 and the second flow sharing ring plate 12 are sequentially ...

Embodiment 3

[0045] see figure 2 and image 3 , a circulating fluidized bed boiler that can adjust the circulating ash flow, including a furnace 1, an ash return pipe 2, a tail flue 3, a cyclone separator 4 arranged between the furnace 1 and the tail flue 3, and a cyclone separator connected to the The ash return device 5 at the bottom of the furnace 4 and the cyclone separator 4 are connected to the furnace 1 and the tail flue 3 respectively, and the ash return device 5 is connected to the bottom of the furnace 1 through the ash return pipe 2, and also includes an ash adjustment device 6 and a slag cooler 7 , the ash adjuster 6 is composed of the lower Venturi fluidization air chamber 8 and the upper cylindrical cold ash chamber 9, the Venturi fluidization air chamber 8 and the cold ash chamber 9 are connected, and the cold ash chamber 9 is From top to bottom, the first flow sharing ring plate 10, the serpentine cooling coil 11 and the second flow sharing ring plate 12 are sequentially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com