Stack loading mechanism

A technology of stacking and feeding, applied in the field of feeding mechanism equipment, can solve the problems of low work efficiency, large space occupation, time-consuming and labor-intensive, etc., and achieve the effect of high work efficiency and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

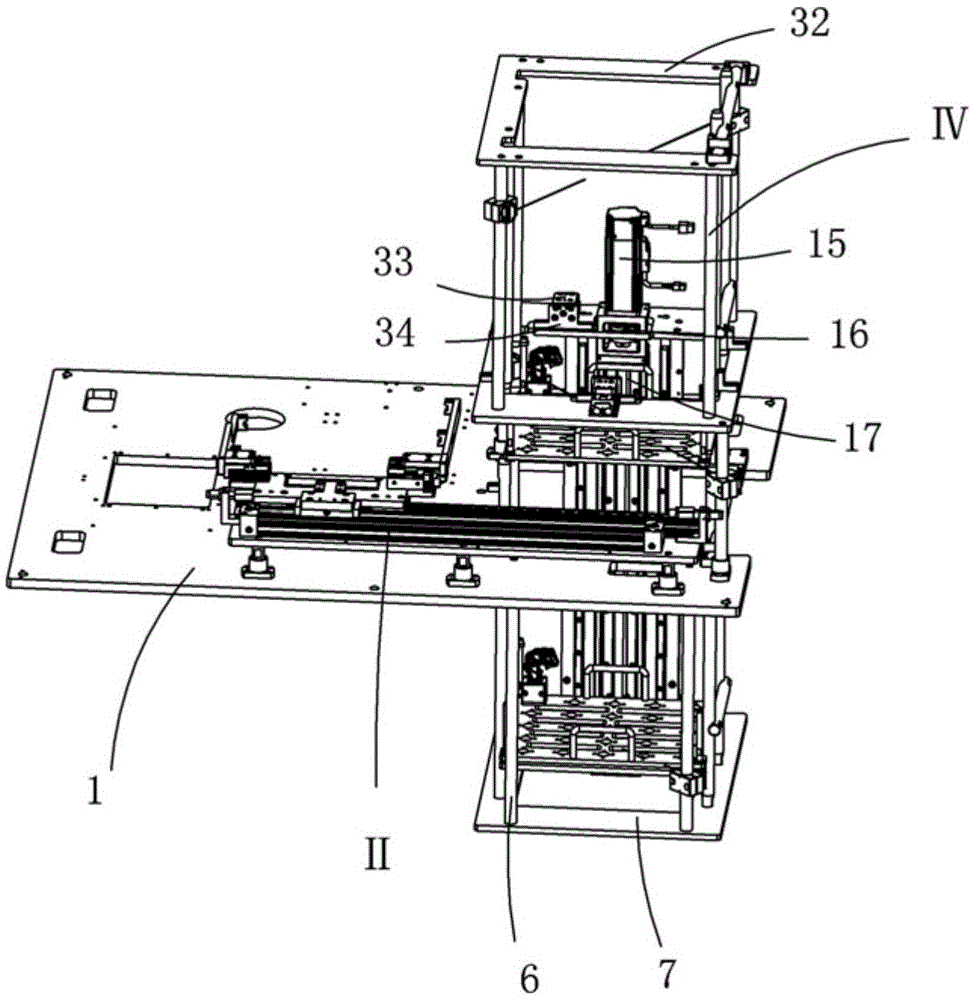

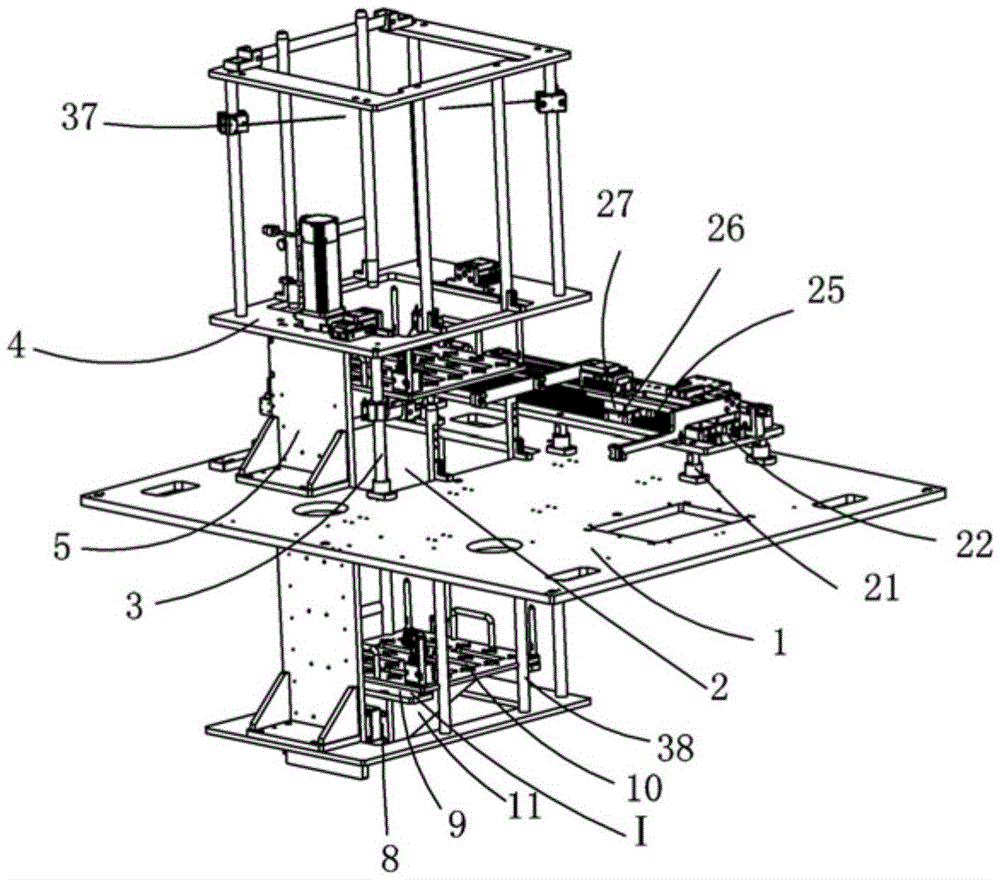

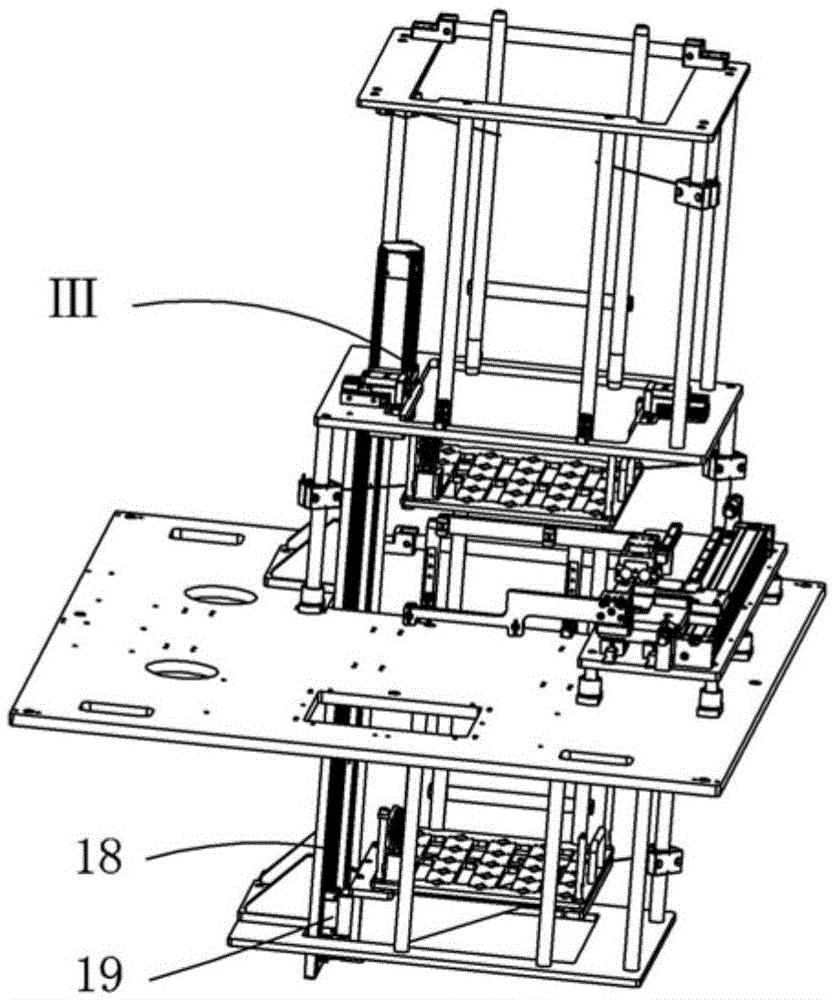

[0022] Examples, see attached Figure 1~5 , a stack feeding mechanism, including a bottom plate 1, a square slot 2 is arranged on the bottom plate, a feeding mechanism I is installed under the bottom plate, a feeding mechanism II is installed on the bottom plate, and the middle pillar 3 passes through the bottom plate The middle fixing plate 4 is installed, the module fixing plate 5 is installed on the lower part of the middle fixing plate, and the module fixing plate passes through the square slot; the lifting module III is installed on the module fixing plate; The carrier return mechanism IV is installed on the upper part of the middle fixing plate.

[0023] The feeding mechanism includes a lower pillar 6, a lower fixing plate 7, a lifting slide 8 and a carrier plate 9, on which a carrier 10 is placed, and there are four sets of the lower pillars, which are respectively installed at the bottom of the base plate, and the four sets of lower pillars The lower end is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com