Disassembled and assembled light supporting shed rack

A support shed, dismantling technology, applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of reducing the service life of the support frame, time-consuming and laborious dismantling methods, affecting the appearance of the support frame, etc., saving manpower. Material strength, not easy to lose, the effect of extending the height at will

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

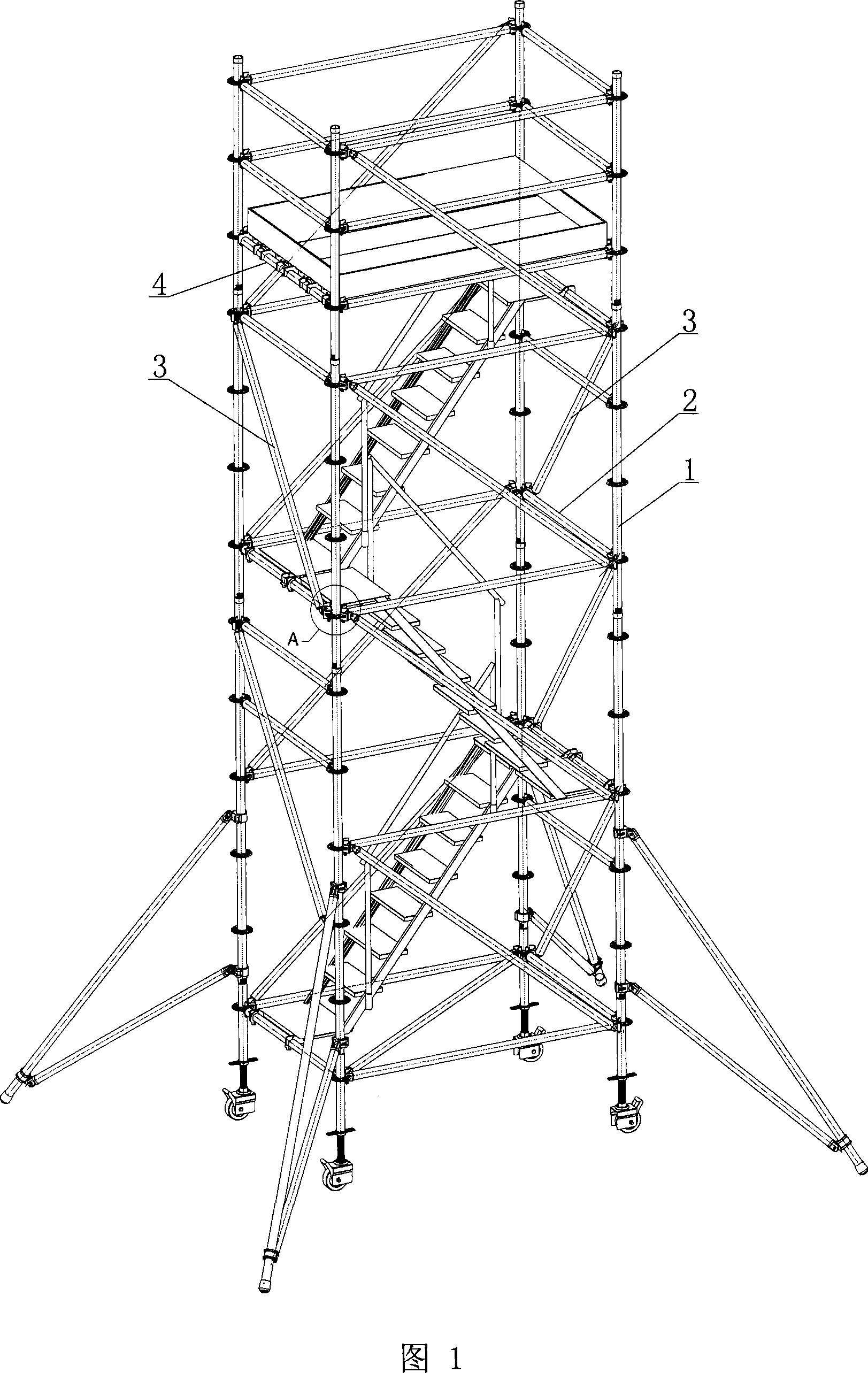

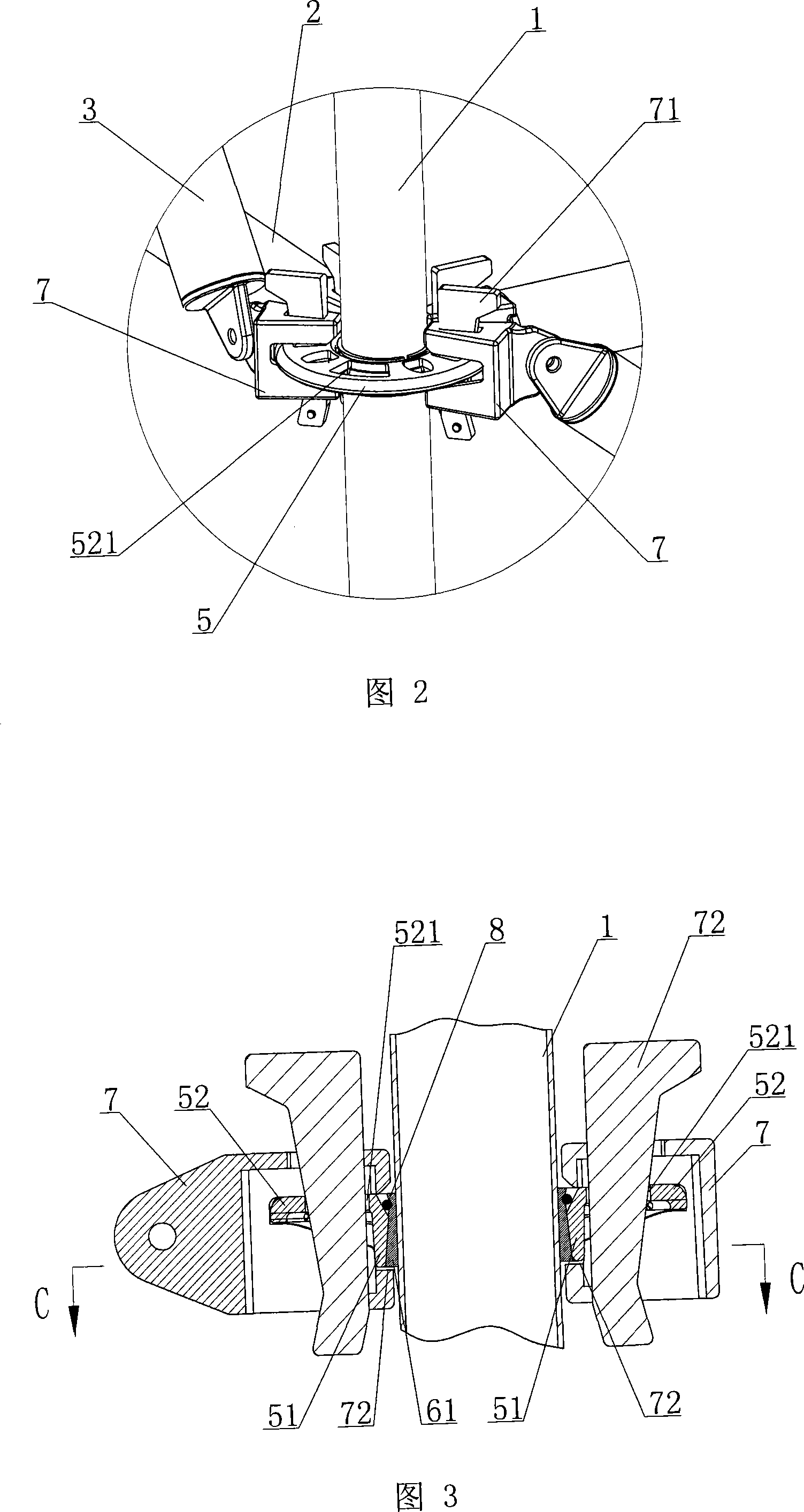

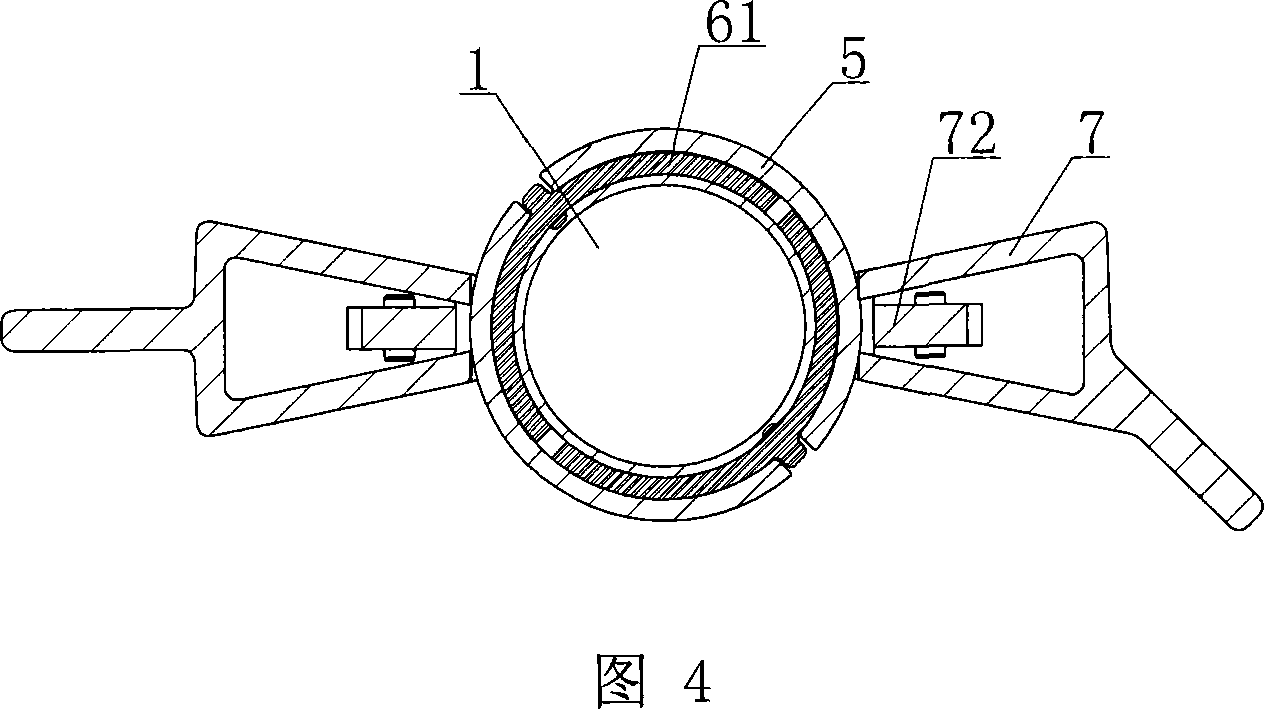

[0014]As shown in Figures 1 to 4, the detachable lightweight support scaffolding of the present invention includes two aluminum alloy or magnesium alloy or steel castings or aluminum die castings and plastic steel pipes or aluminum-plastic pipes or other composite Support rods 1 made of light materials such as pipes and several light weight rods connected between the two support rods 1 are made of aluminum alloy or magnesium alloy or steel castings or aluminum die castings and plastic steel pipes or aluminum-plastic pipes or other composite pipes. The height is adjustable and the planar space can be extended freely by the horizontal bar 2 and / or the inclined rod 3 and / or the horizontal bracket 4 made of high quality materials. The scaffolding is conveniently equipped with a ladder or a ladder for easy construction. Ladders or platforms, etc., wherein the connection positions of each cross bar 2 or diagonal stay bar 3 or cross bracket 4 and support bar 1 are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com