Adjusting mechanism, hinge and window

An adjustment mechanism and hinge technology, which is applied in the field of doors and windows, can solve the problems of adjusted position change, unsmooth use, and sticking of the adjustment mechanism, so as to achieve the effects of reducing the slippage range, smooth use, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

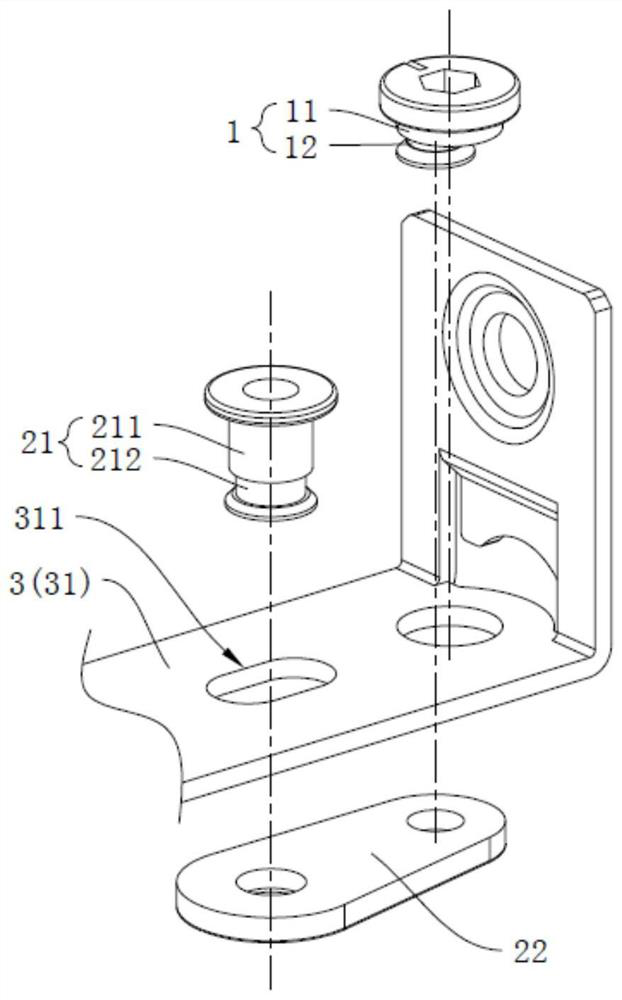

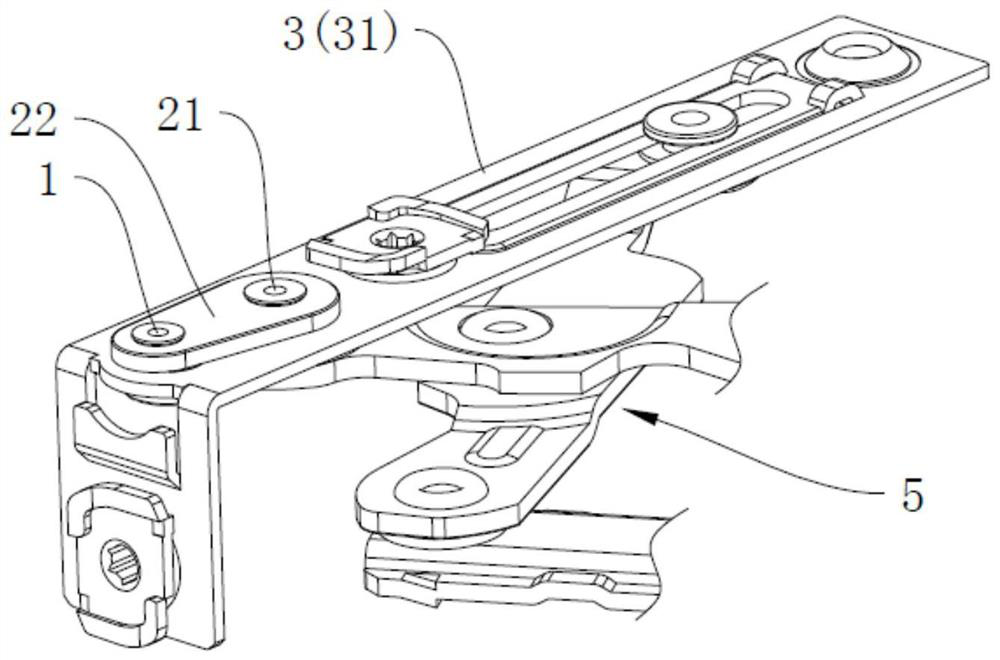

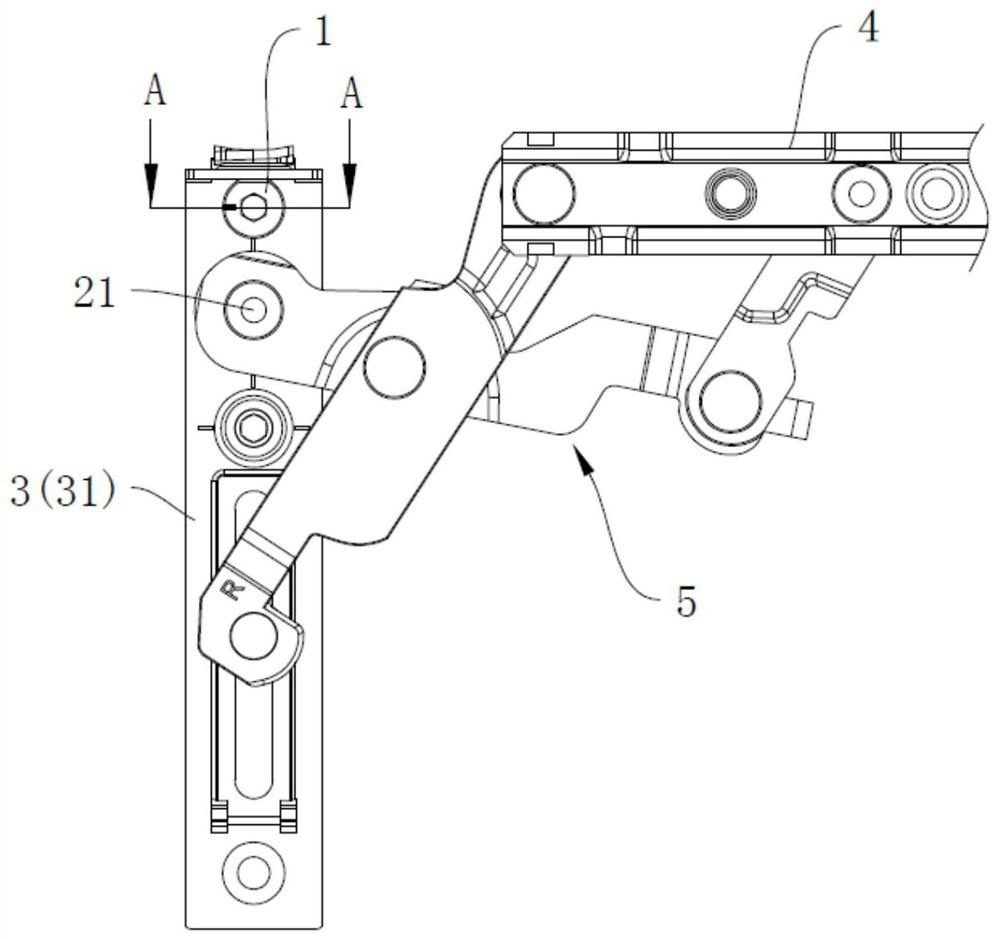

[0026] Such as Figure 1 to Figure 4 As shown, this is an embodiment of the present invention, specifically: an adjustment mechanism for adjusting the position of the end of the planar linkage 5, including an adjustment member 1, a first connecting member 21, a second connecting member 22, a set There is a mounting body 31 with a guide groove 311. The adjustment member 1 includes a first connecting shaft 11 and a second connecting shaft 12. The axis line of the first connecting shaft 11 is arranged parallel to the axis line of the second connecting shaft 12. The first connection There is an offset distance H1 between the axis line of the shaft 11 and the axis line of the second connecting shaft 12, the first connecting shaft 11 is pivotally connected to the mounting body 31; the first connecting piece 21 is slidably connected to the guide groove 311, and the second A connecting member 21 is provided with a first connecting end 211 for connecting with the planar linkage mechani...

Embodiment 2

[0028] Different from Embodiment 1, the second connecting end 212 and the second connecting shaft 12 are arranged on the same side of the installation body 31 , which can reduce the space occupied by the adjustment mechanism.

Embodiment 3

[0030] The difference from Embodiment 1 is that the second connecting piece 22 is set as a plate, and the plate thickness direction of the second connecting piece 22 is set along the axial direction of the second connecting shaft 12; the width of the second connecting piece 22 is along the The directions of the two connecting shafts 12 gradually decrease. Such as figure 1 , Figure 4 As shown, the width of the second connecting piece 22 decreases gradually along the direction close to the second connecting shaft 12, and the small end of the second connecting piece 22 can be adjusted when the adjustment mechanism is used to cooperate with the installation groove 321 of the window frame profile 32. By providing a larger matching gap H2, the eccentric distance H1 between the first connecting shaft 11 and the second connecting shaft 12 can be set larger, so that the adjustment mechanism has a larger adjustment range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com