Patents

Literature

251 results about "Heat-only boiler station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heating plant, also called a physical plant, or steam plant, generates thermal energy in the form of steam for use in district heating applications. Unlike combined heat and power installations which produce thermal energy as a by-product of electricity generation, heating plants are dedicated to generating heat for use in various processes.

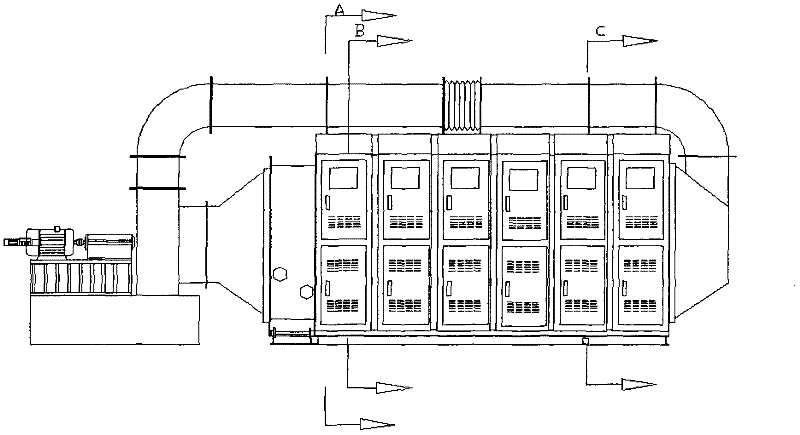

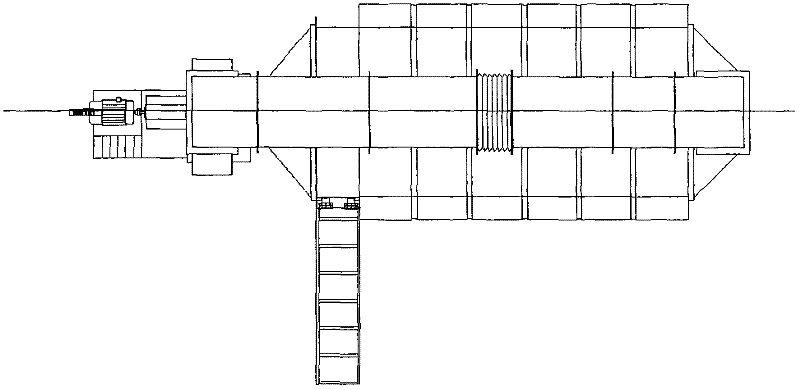

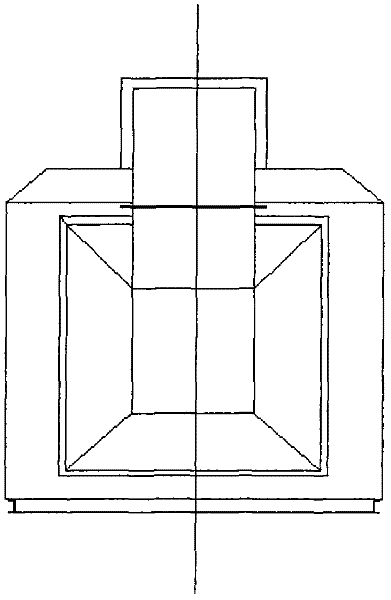

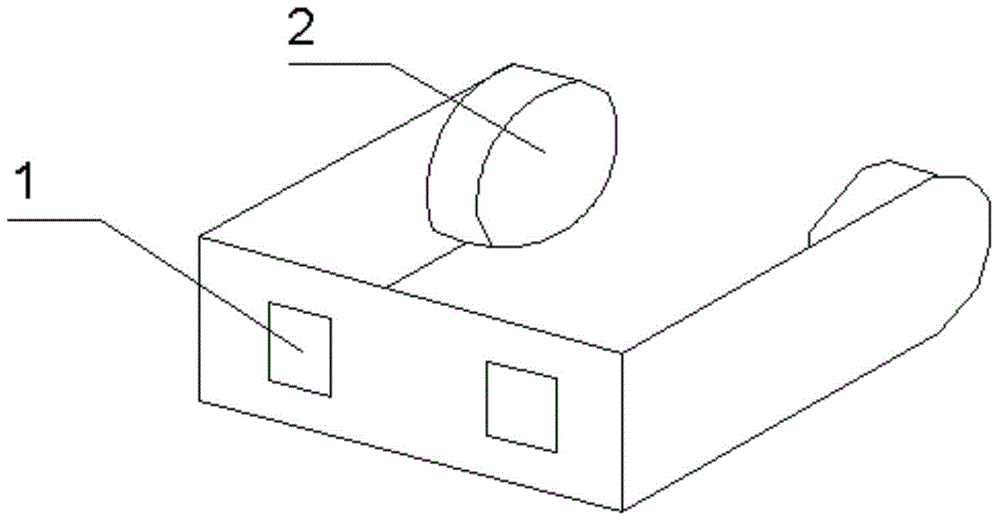

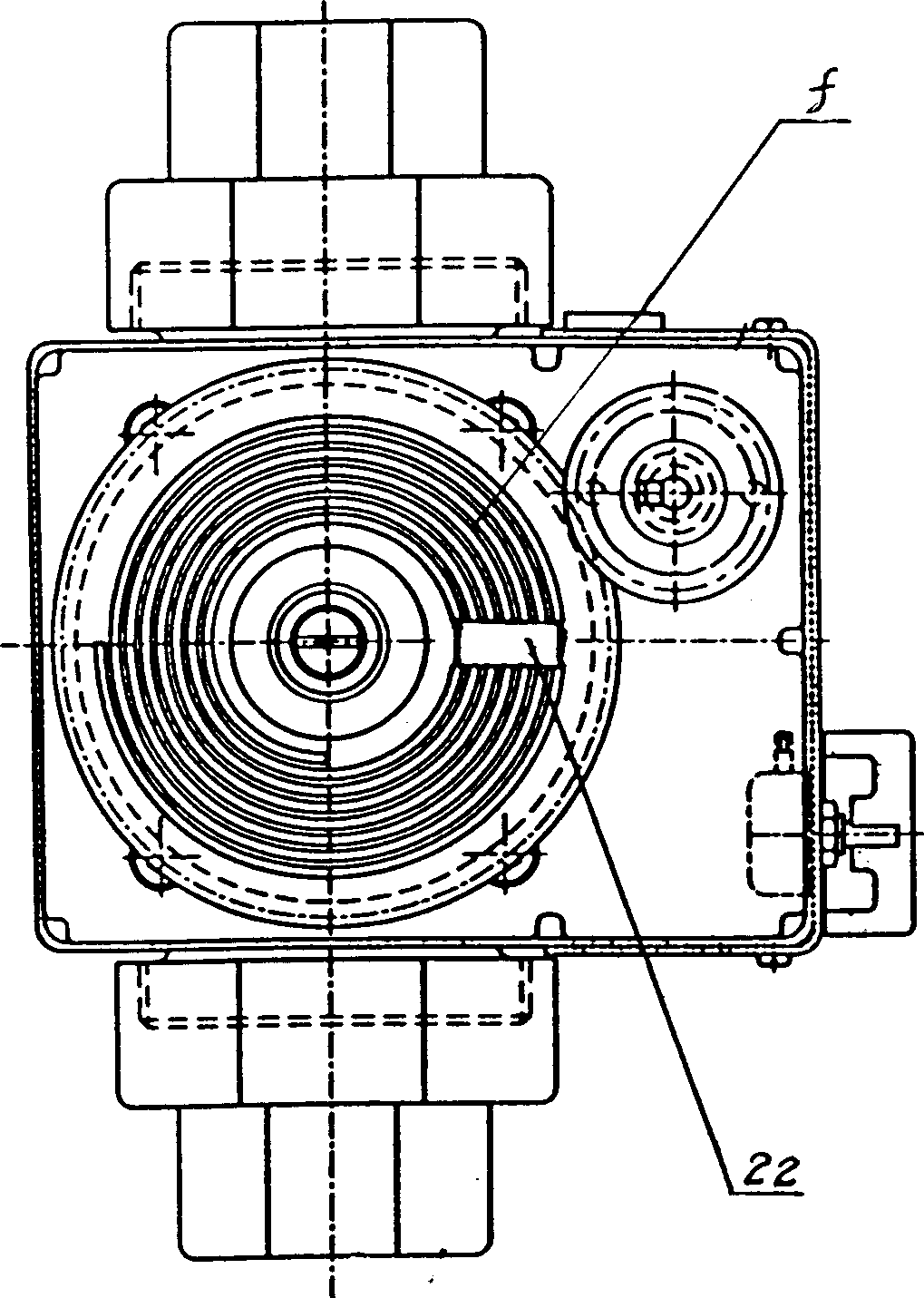

Solid energy storage electric boiler and heat exchanging structure thereof

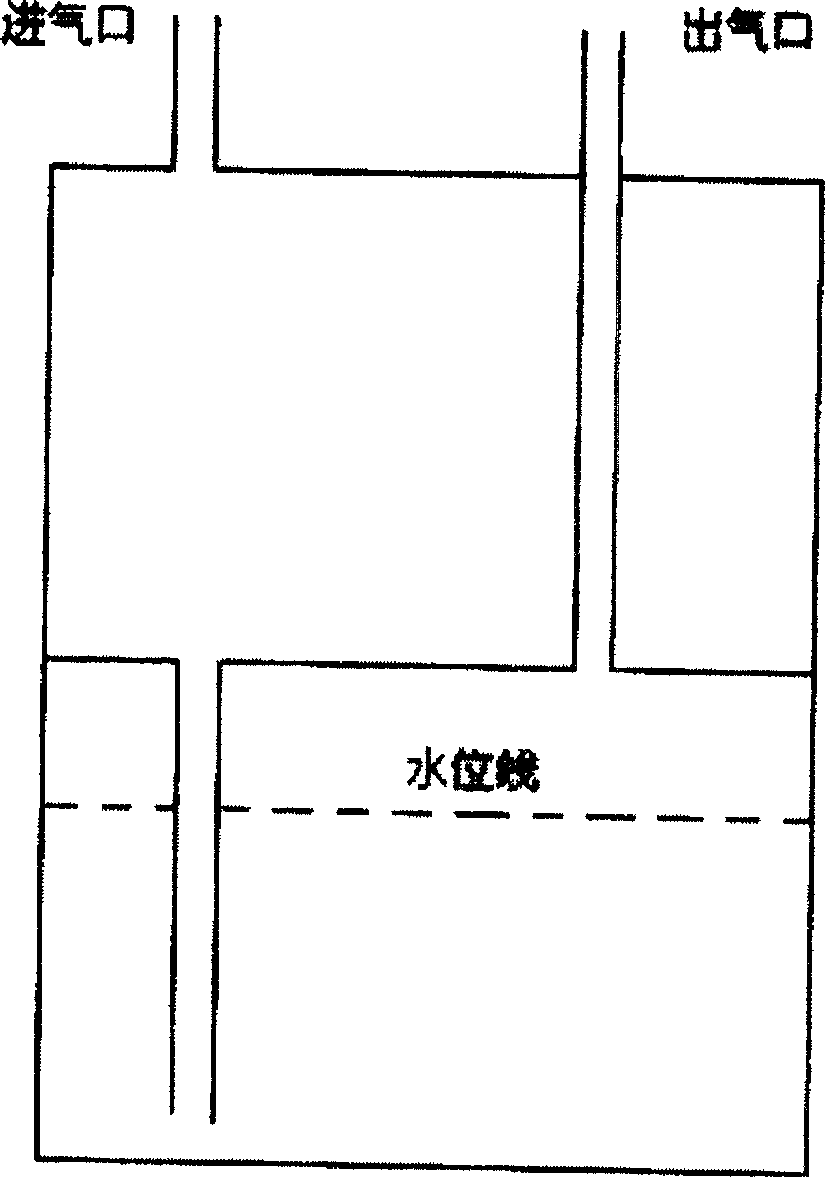

InactiveCN102175018AUniform and effective conductionRuntime controlSteam generation heating methodsHeat storage plantsBrickExothermic process

The invention aims to overcome the defects of the existing heating plants, such as a boiler, and to provide a solid energy storage electric boiler and a heat exchanging structure thereof. A heat storage brick is utilized as a heat storage medium for the solid energy storage electric boiler, and a high-capacity heat exchanging structure with a controllable exothermic process. Particularly, the heat exchanging structure comprises a heat storage structure, a heat insulation material layer, a heat insulation wall with holes, a heat exchanger and an outer shell; two ends of the outer shell are provided with air openings; the heat storage structure, the heat insulation wall with holes and the heat exchanger are arrayed in the outer shell; the heat insulation material is placed among the heat storage structure, the heat insulation wall with holes and the outer shell; and the heat exchanging structure also comprises an air door, a fan and a circulation outer air duct.

Owner:北京蓝景圣诺尔能源科技有限公司 +1

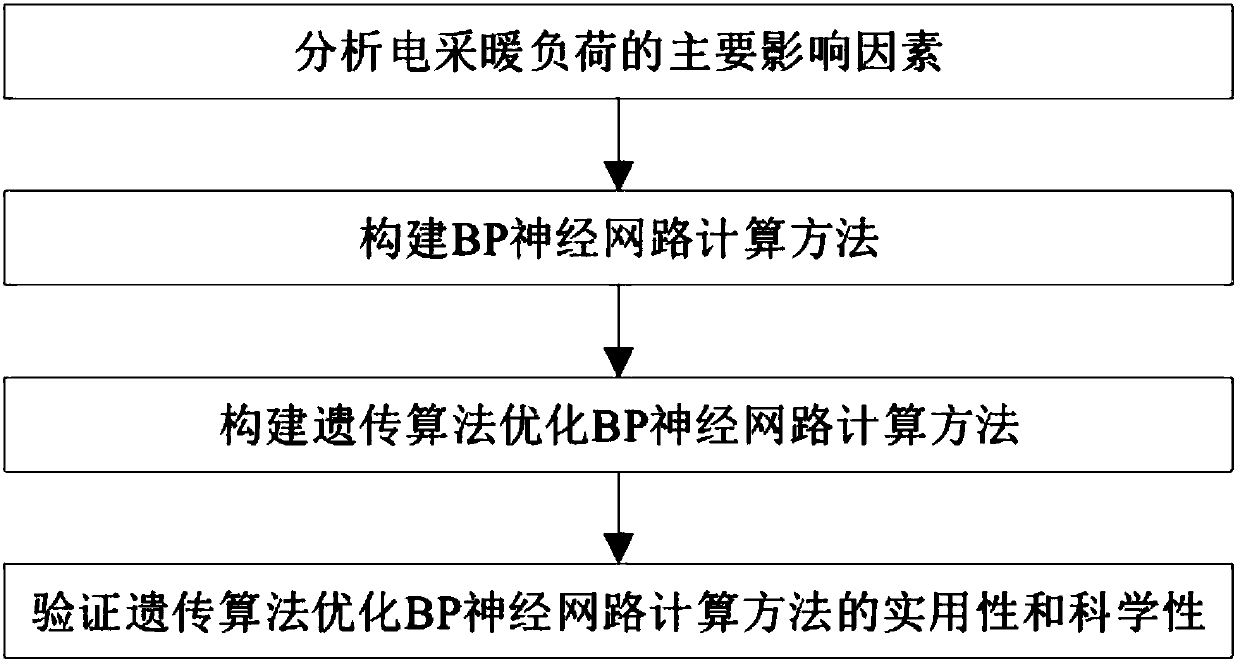

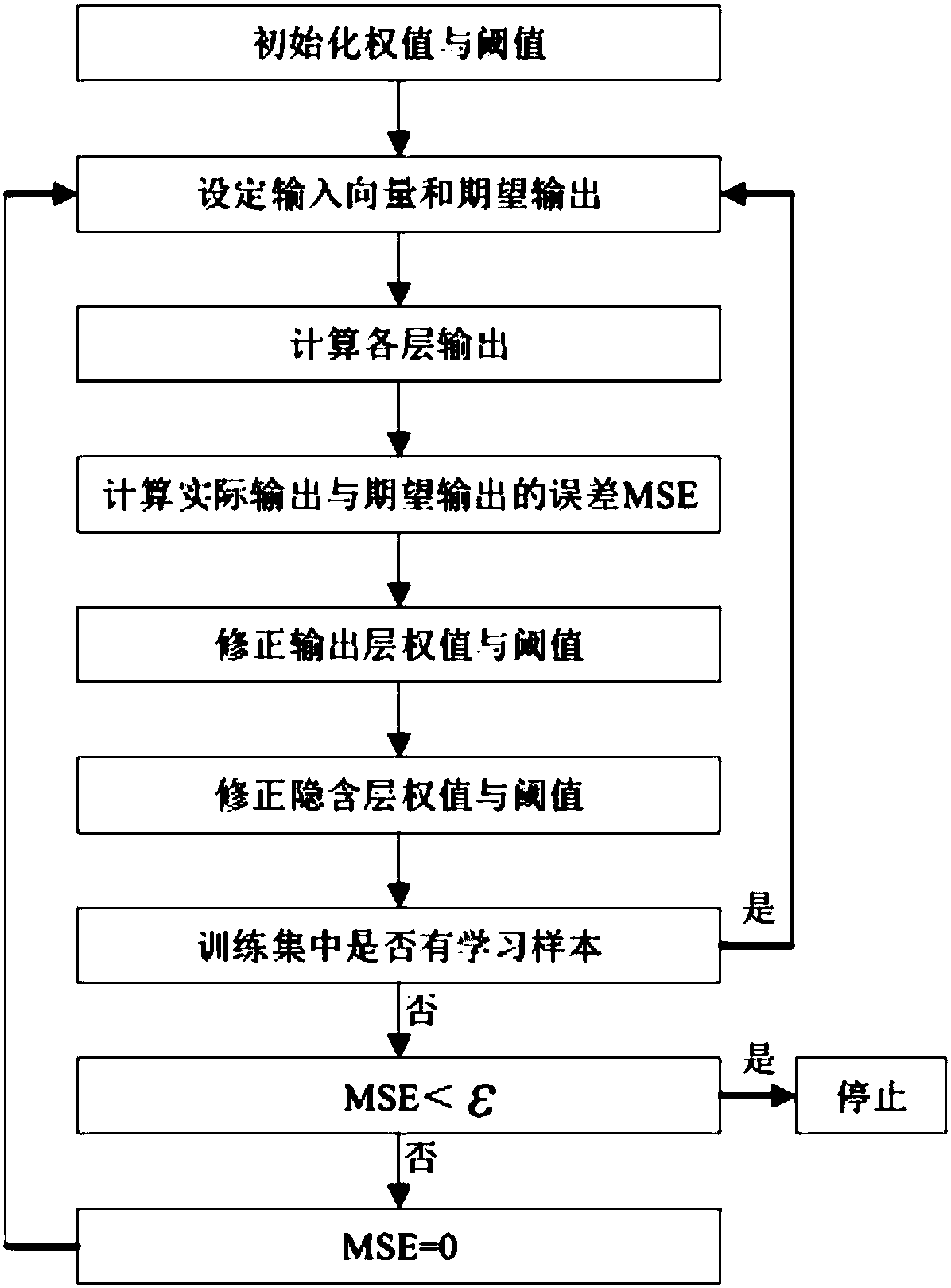

Electric heating load prediction method

InactiveCN107909220ARun accuratelyScientific and reasonable operationForecastingNeural architecturesElectricityLoad forecasting

The invention provides an electric heating load prediction method. The electric heating load prediction method comprises steps that main influence factors of an electric heating load are analyzed; theBP neural network calculation method is constructed; a genetic algorithm is constructed to optimize the BP neural network calculation method; integral data is selected as a training sample and a prediction sample, the BP neural network calculation method and the genetic algorithm are utilized to optimize the BP neural network calculation method to respectively predict an electric heating load, and effectiveness and scientificity of the genetic algorithm for optimizing the BP neural network calculation method are verified. The method is advantaged in that the electric heating load can be precisely predicted, a type of heating equipment of a heating system and a new load size can be accurately determined, heating parameters, idle capacity and a system operating status, etc., can be accurately determined, so operation, maintenance and overhaul of the heating equipment are made to be more scientific and reasonable.

Owner:TIANDAQIUSHI ELECTRIC POWER HIGH TECH CO LTD

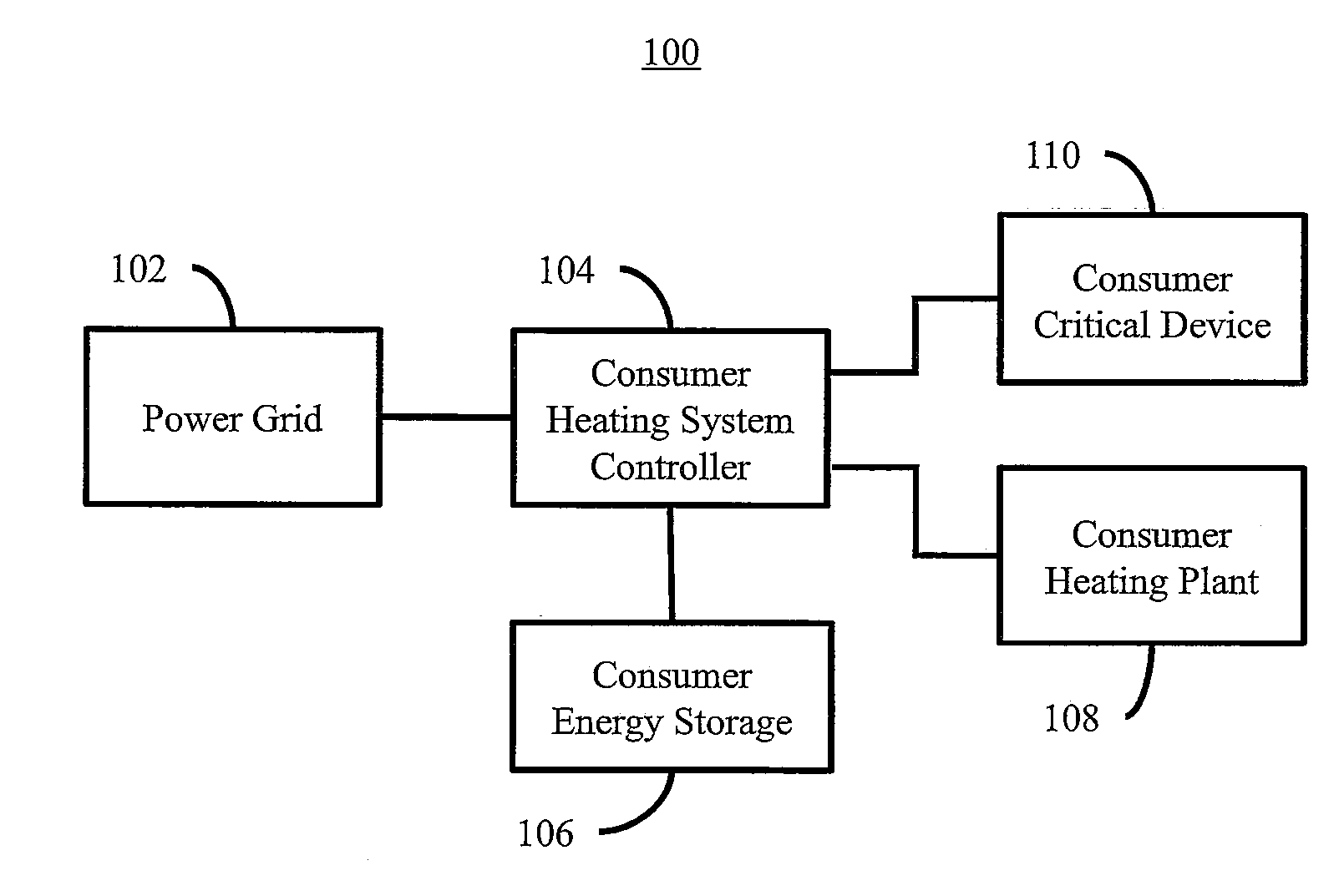

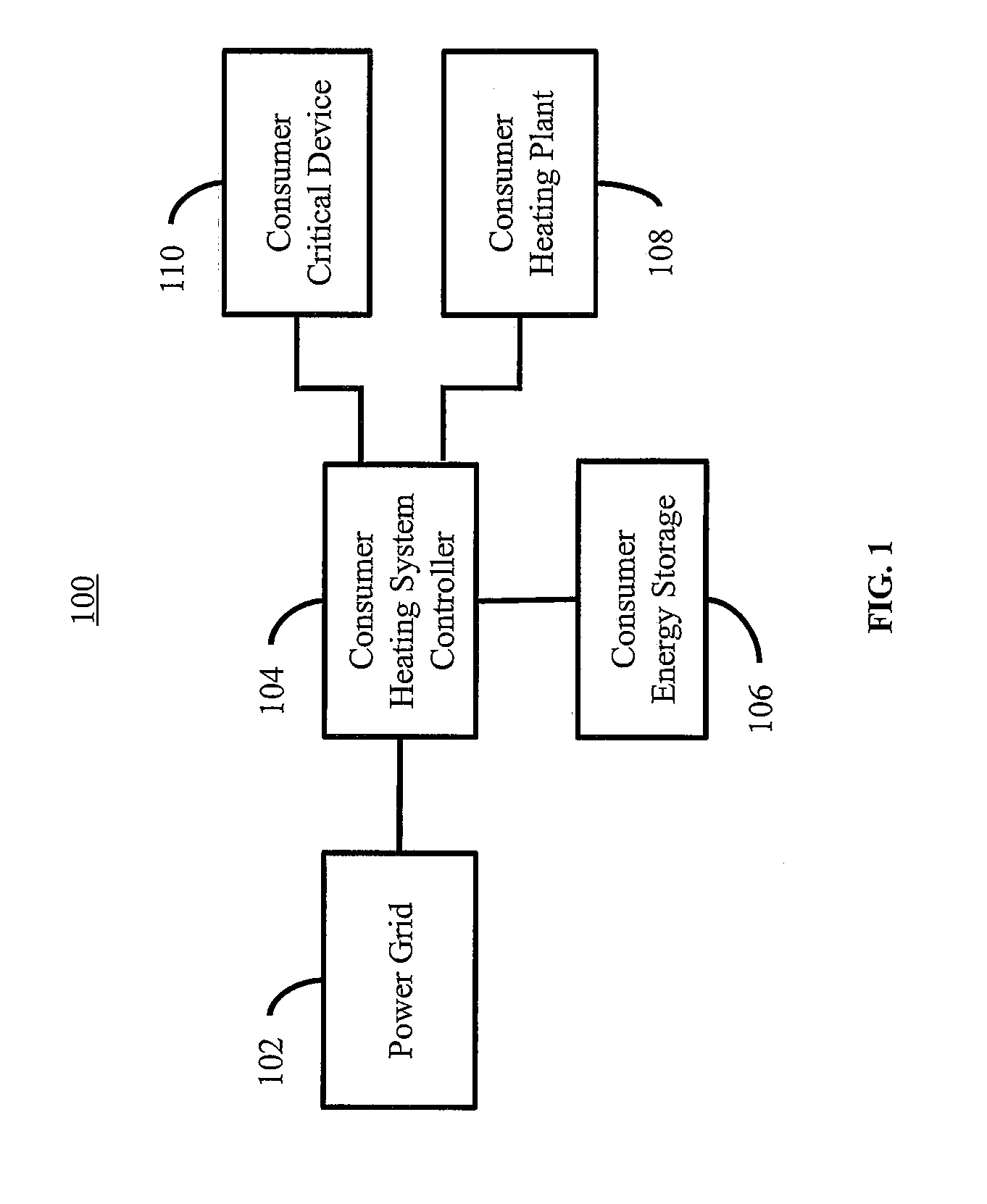

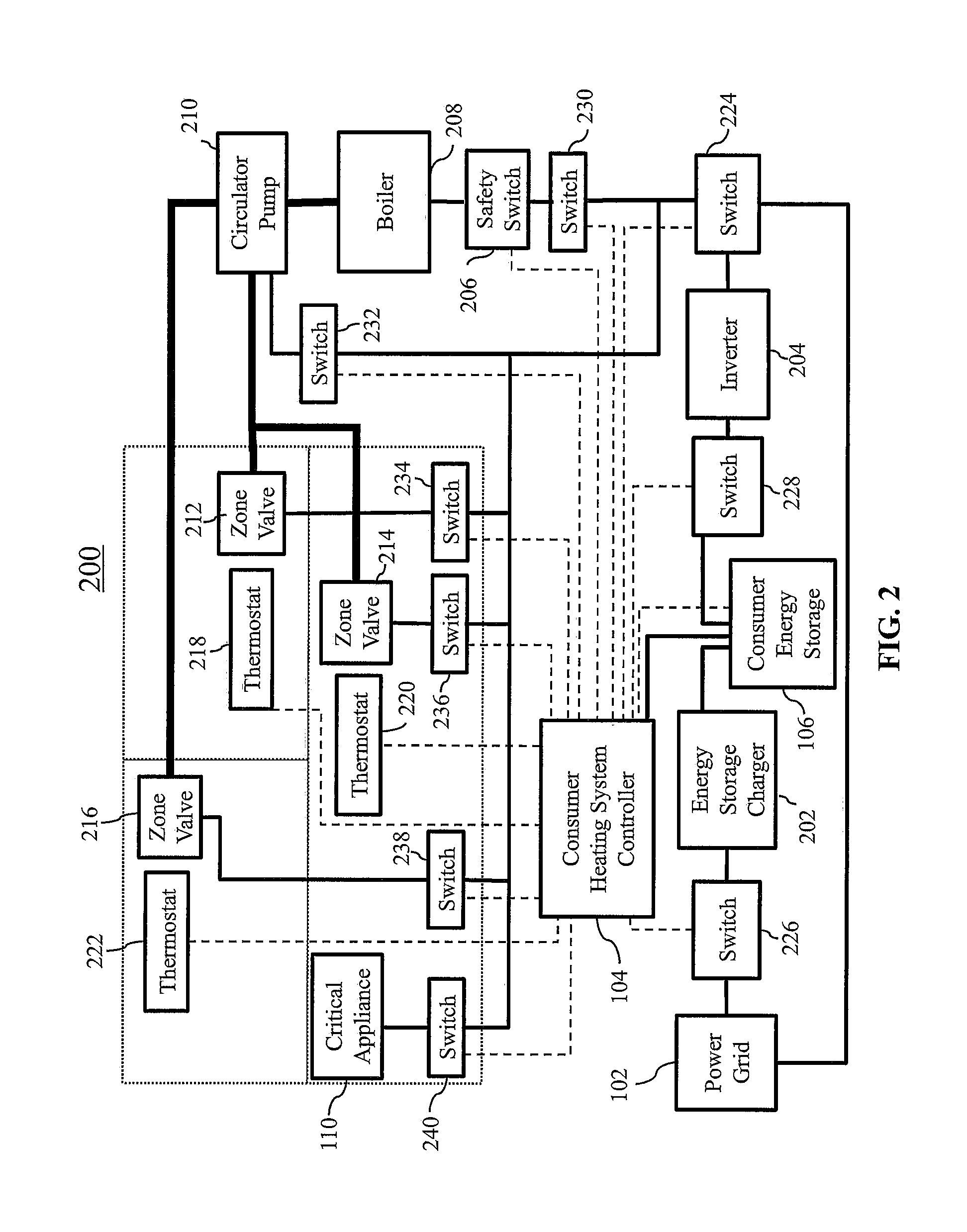

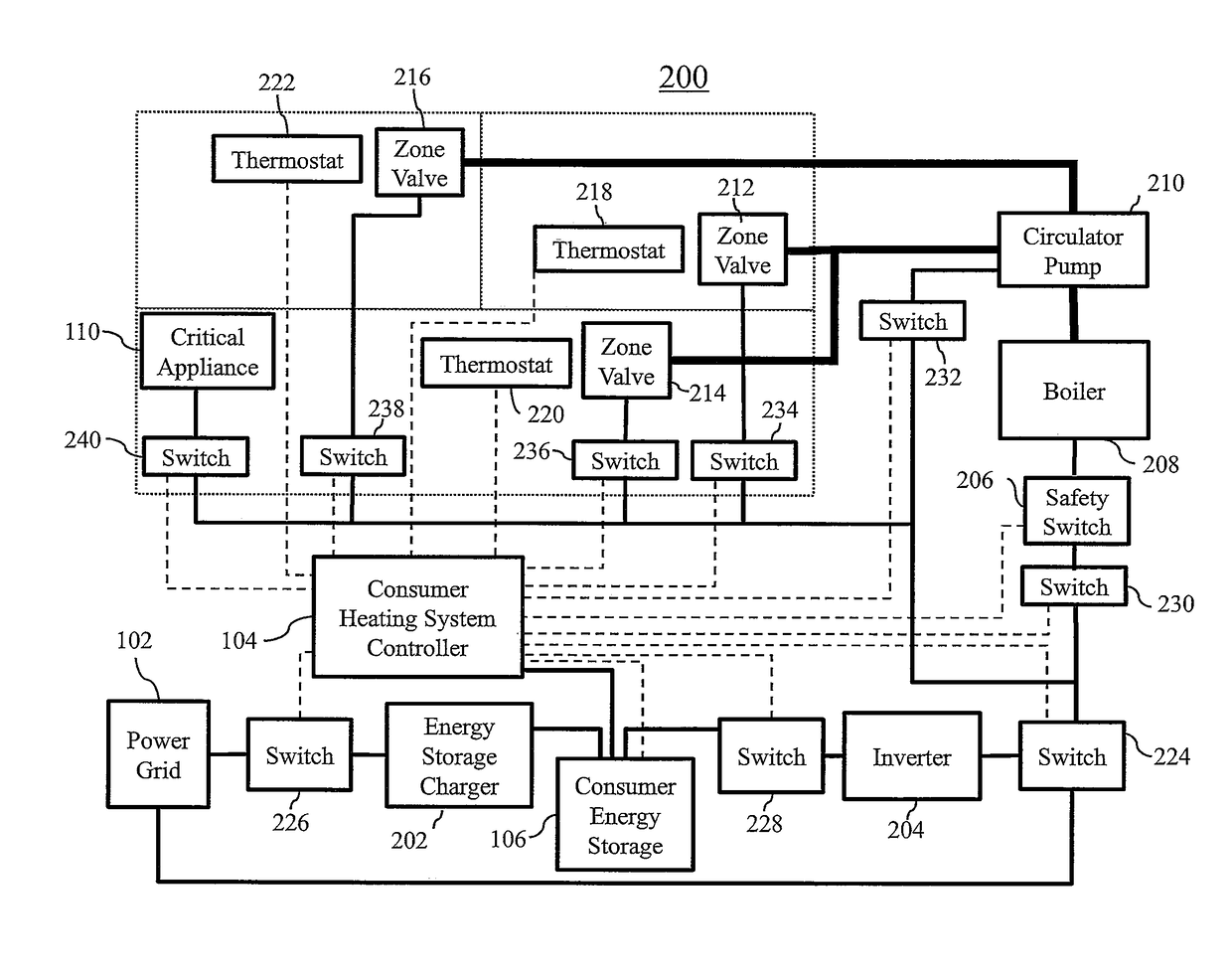

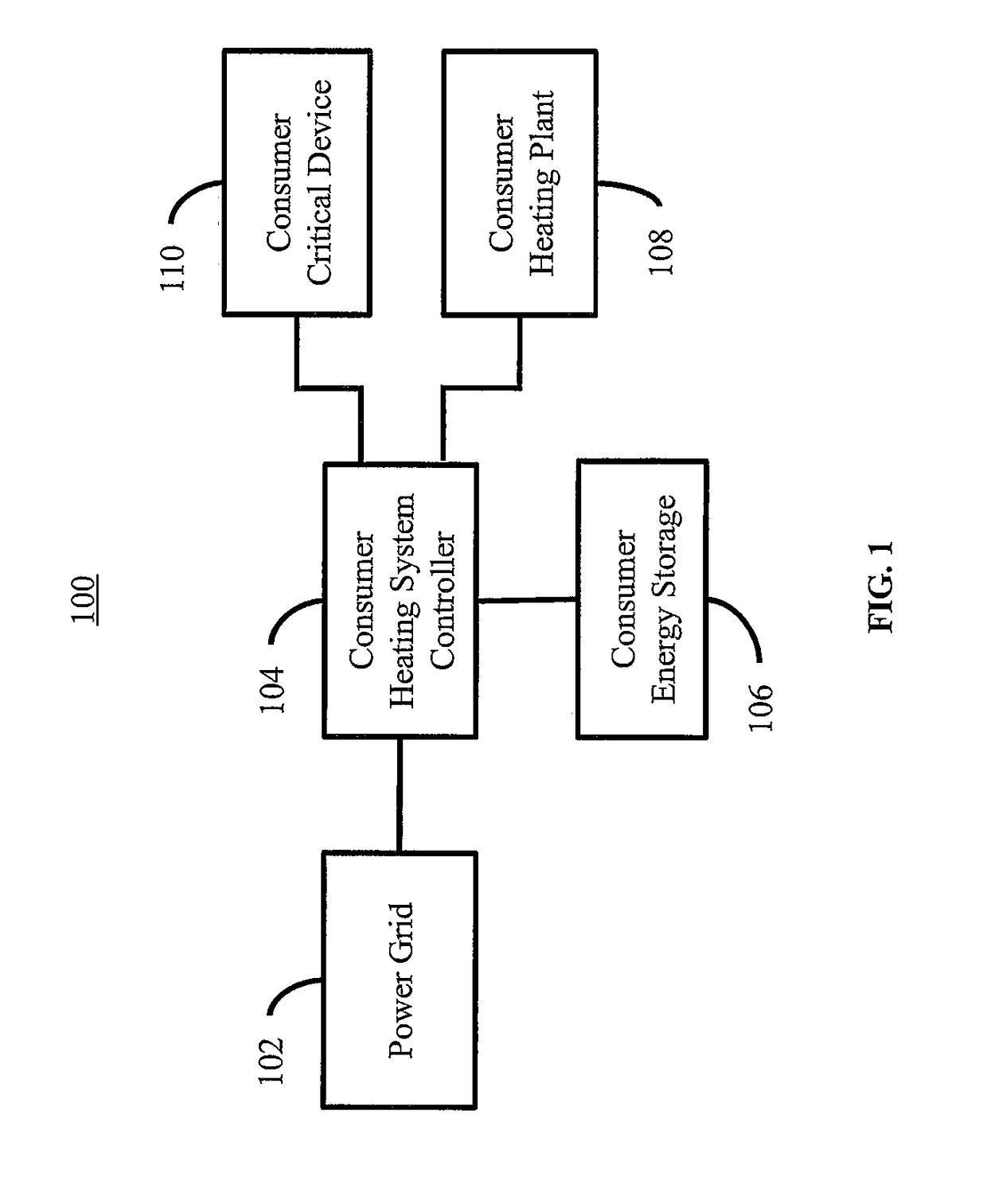

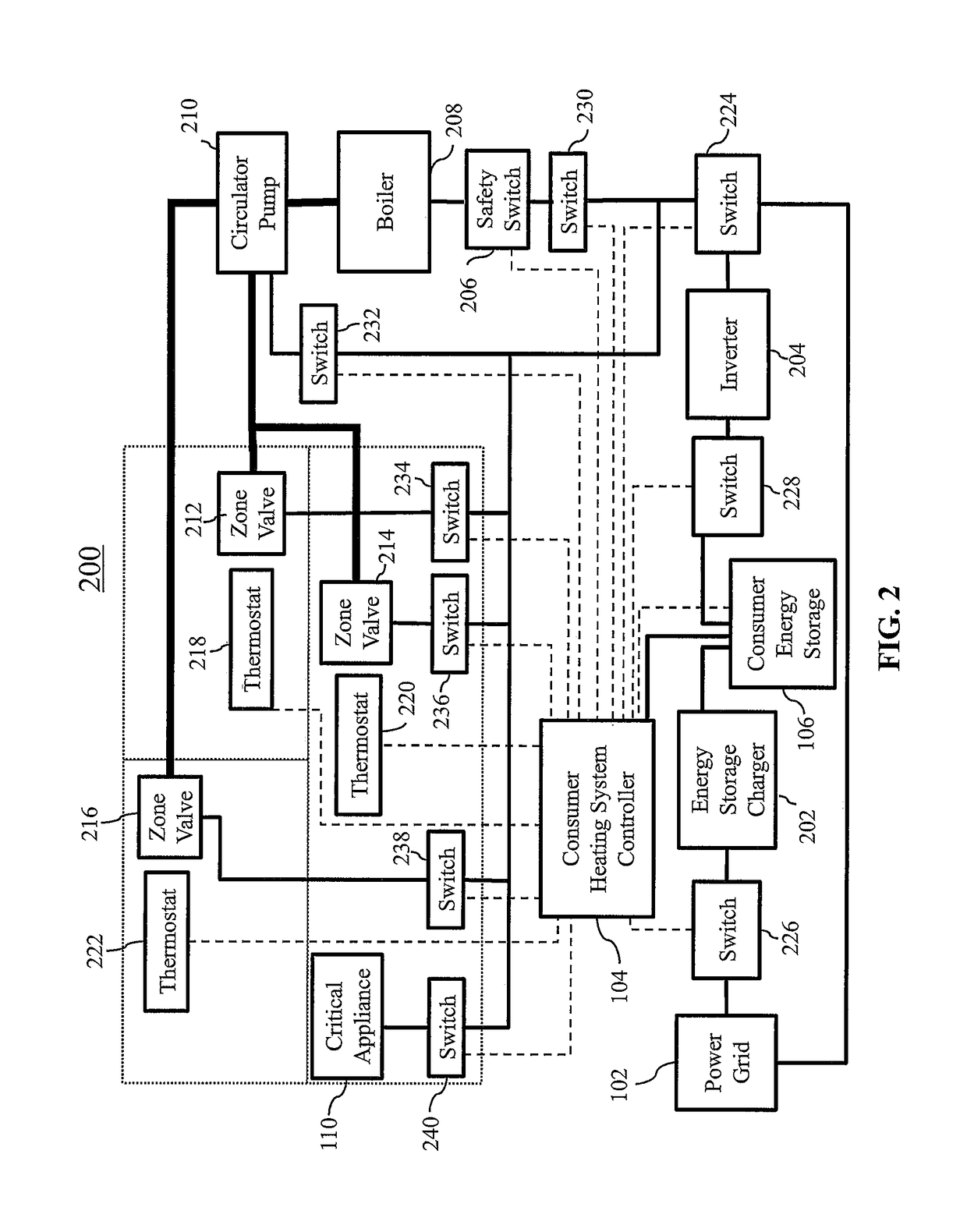

System and Methods for Controlling a Supply of Electric Energy

ActiveUS20150270743A1Health and safetyNot compromise safety and integrityBatteries circuit arrangementsTemperatue controlStored energyEngineering

A system and methods for controlling the supply and distribution of backup electrical power determine when backup power is needed and allocates available backup power among connected devices in a power outage. Batteries may be used as an energy storage subsystem, and may backup a home heating plant and other devices based on a dual set of user-established priorities that may change during power blackouts and brownouts as the amount of stored energy decreases.

Owner:REDLINE INNOVATIONS GRP +1

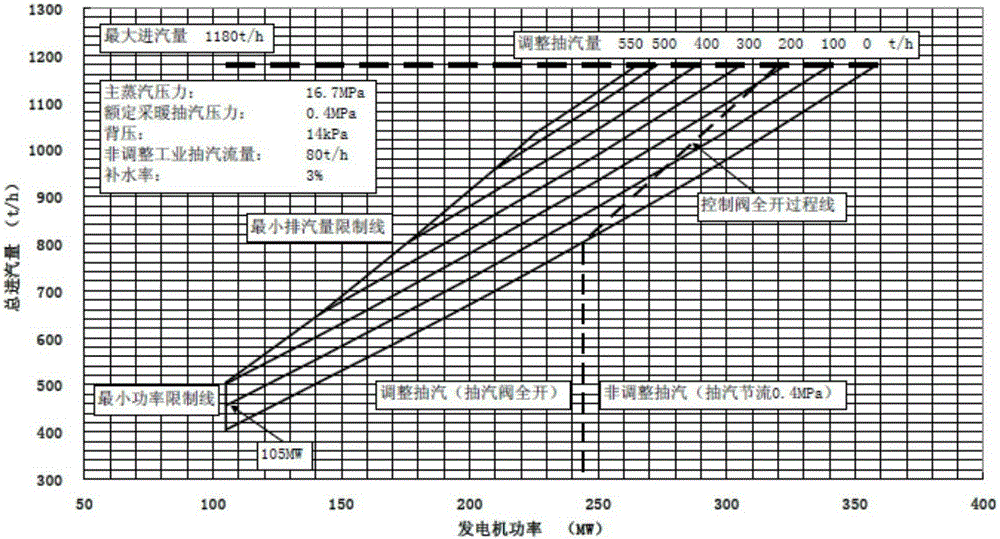

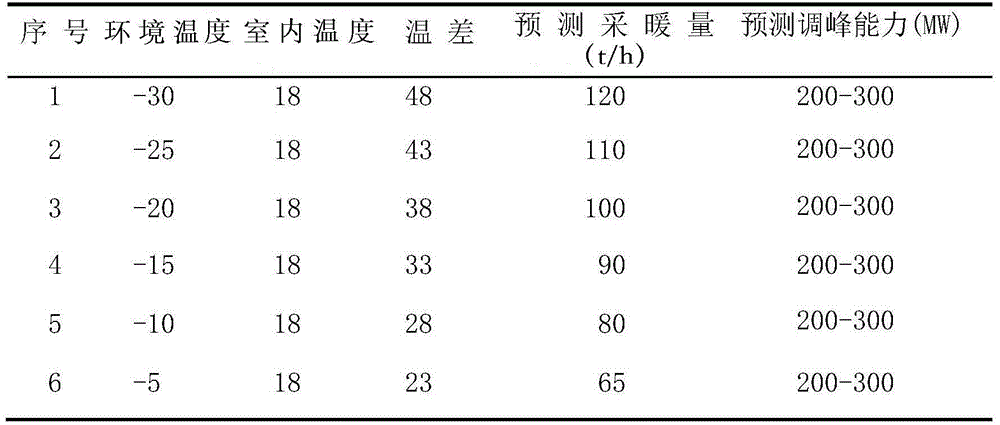

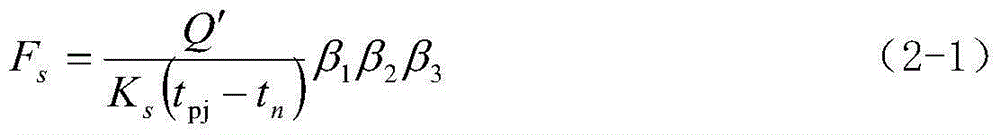

Method for predicting heating peak modulation capacity of heat supply unit

ActiveCN105202623AGuaranteed uptimeSafe and stable operationLighting and heating apparatusSpace heating and ventilation detailsData acquisitionEngineering

The invention relates to a method for predicting heating peak modulation capacity of a heat supply unit. The method is characterized by comprising the steps of selecting at least one representative power plant, and performing data collection on heat supply design data, heat supply device conditions, industrial heat load and heating thermal load mediums, parameters and modes of the heat supply unit; through data analysis and theoretical calculation, determining design thermal load and the heat dissipation area of a radiator, considering impact analysis of temperature changes on building heat dissipating capacity and heating capacity, and predicting the heating period peak modulation load of the power plant. The method has the advantages of being scientific, rational and high in practicality. By utilizing the method, the maximum power generating and heat supply potential of the heat supply unit can be brought into full play, and the problem of difficulty in heating period power grid peak modulation is effectively relieved and solved.

Owner:STATE GRID CORP OF CHINA +2

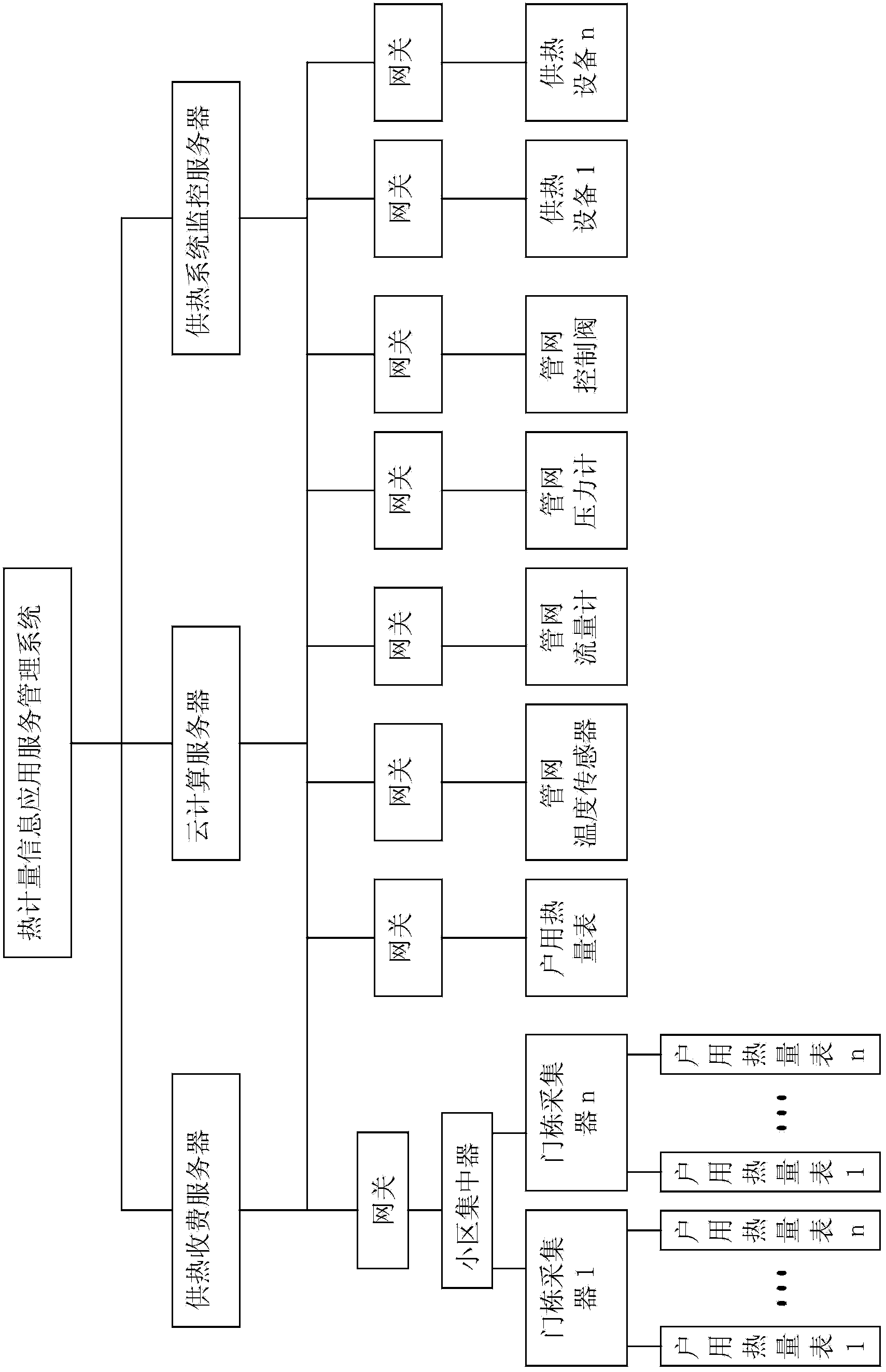

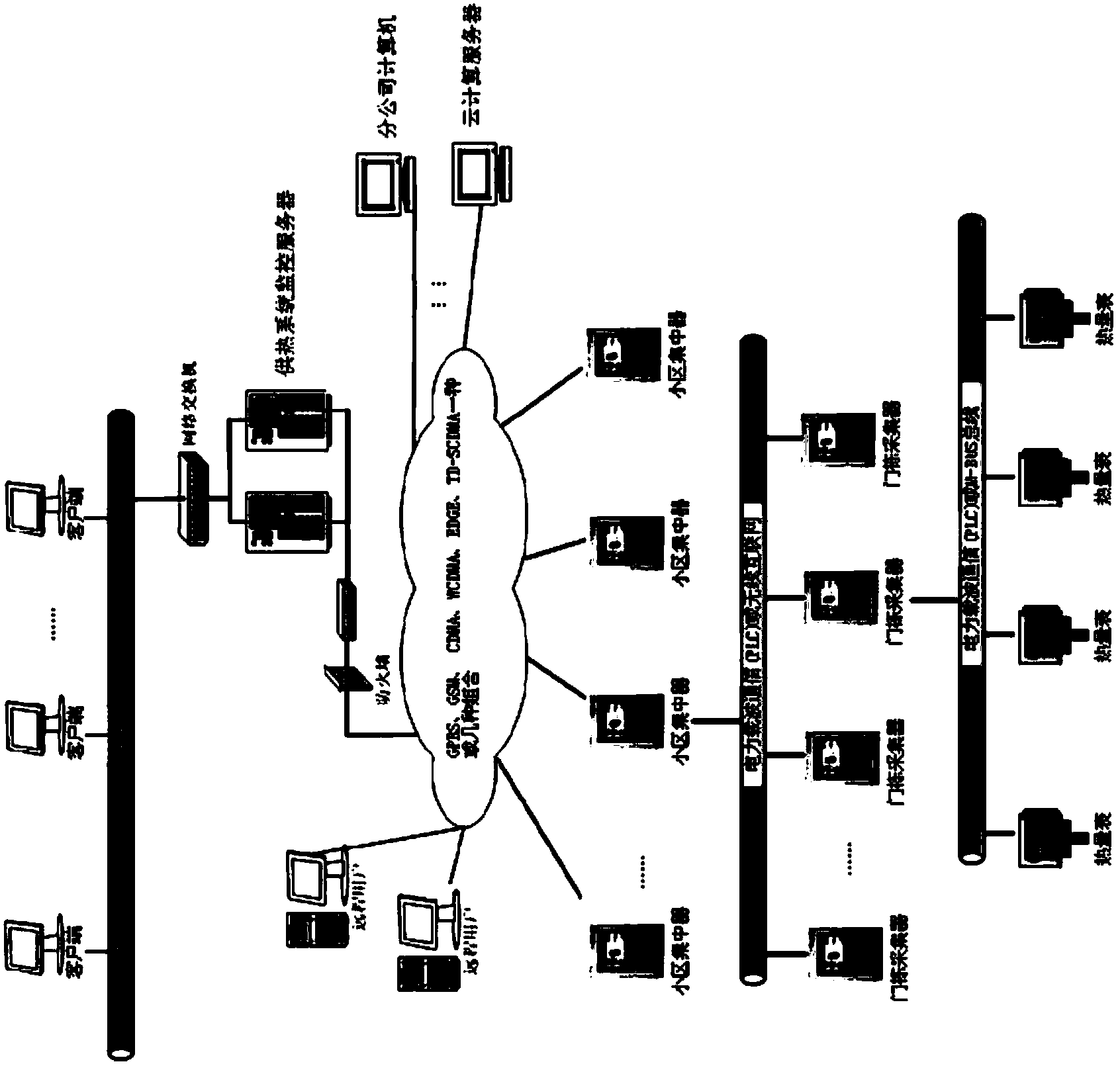

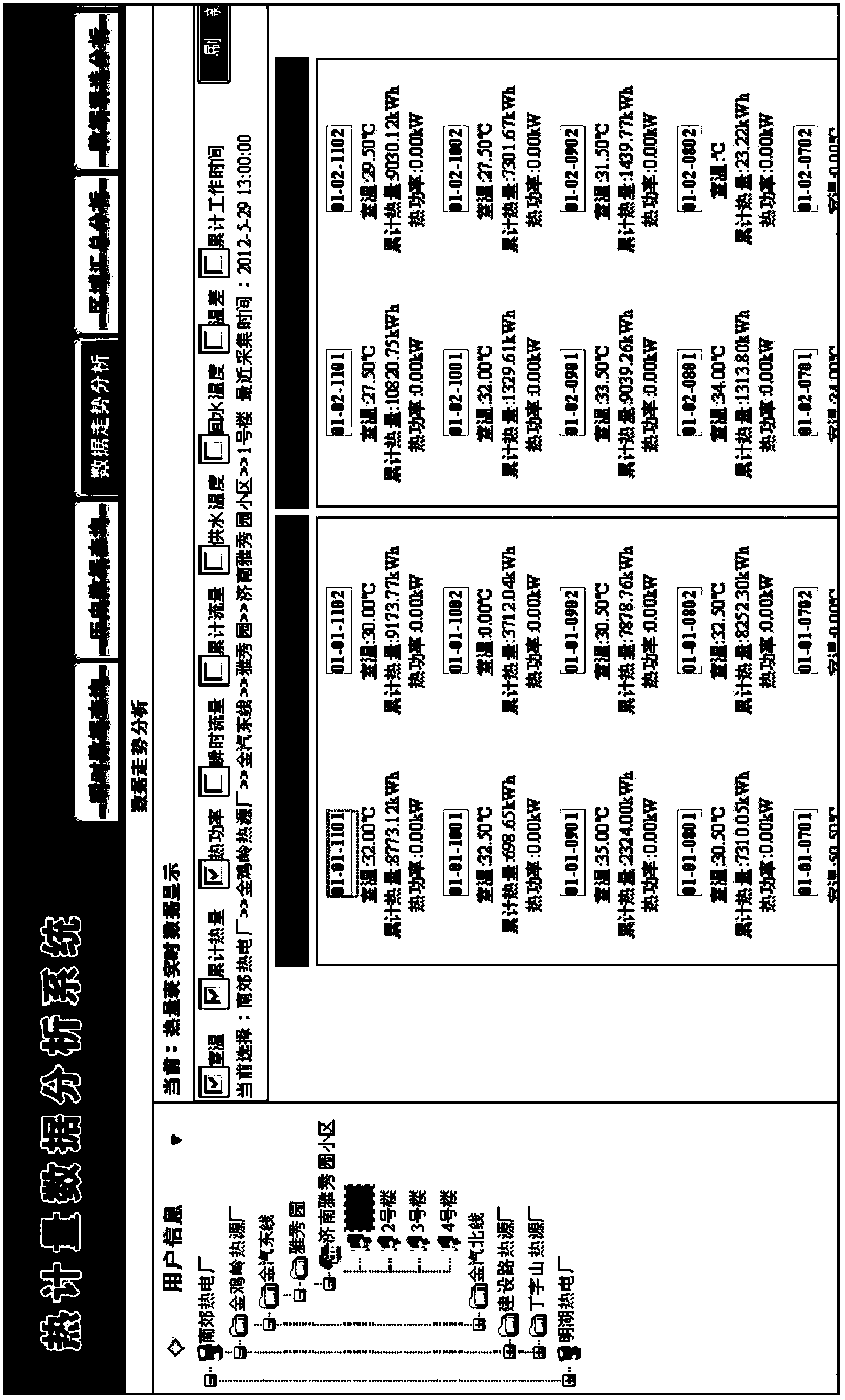

Heat metering information application service management platform on basis of internet of things for heat supply industry

ActiveCN103631240ARealize automatic allocationEasy to useProgramme total factory controlInformatizationCloud of things

The invention discloses a heat metering information application service management platform on the basis of an internet of things for the heat supply industry. The heat metering information application service management platform comprises an application layer, a service layer, a network layer and a device layer; signals are transmitted among the application layer, the service layer and the device layer via the network layer; the application layer comprises a heat metering information application service management system; the service layer comprises a heat charging server, a cloud computing server and a heat supply system monitoring server; the network layer comprises a wired internet and / or a wireless internet; the device layer comprises gateways and terminal devices, the terminal devices are connected with the wired internet and / or the wireless internet by the gateways and include household heat meters, a pipe network temperature sensor, a pipe network flow meter, a pipe network pressure meter, a pipe network control valve and heat supply devices, the household heat meters are arranged at user terminals, the pipe network temperature sensor, the pipe network flow meter, the pipe network pressure meter and the pipe network control valve are arranged in a heat transfer pipe network, and the heat supply devices are arranged at heat supply stations; each terminal device has a unique address code. The heat metering information application service management platform has the advantages that running states of the heat meters can be counted and monitored, heat supply conditions can be analyzed, and management and information services can be provided.

Owner:TIANJIN WANHUA CO LTD

Machine and method for the thermal treatment of liquid and semi-liquid food products

ActiveUS20140212559A1Quality improvementMilk preservationFrozen sweetsLiquid productProcess engineering

A machine for the homogenization and thermal treatment of liquid and semi-liquid food products comprises, in combination:a tank for containing the food products;electric first heating means, operating on the food product to heat it and so thermally treat it;a heating plant with thermodynamic cycle comprising at least a first heat exchanger;second heating means comprising said first heat exchanger, operating on the food product to heat it and so thermally treat it.

Owner:ALI - CARPIGIANI GROUP

System and methods for controlling a supply of electric energy

ActiveUS9735613B2Health and safetyNot compromise safety and integrityElectric signal transmission systemsBatteries circuit arrangementsStored energyConnected device

A system and methods for controlling the supply and distribution of backup electrical power determine when backup power is needed and allocates available backup power among connected devices in a power outage. Batteries may be used as an energy storage subsystem, and may backup a home heating plant and other devices based on a dual set of user-established priorities that may change during power blackouts and brownouts as the amount of stored energy decreases.

Owner:REDLINE INNOVATIONS GRP +1

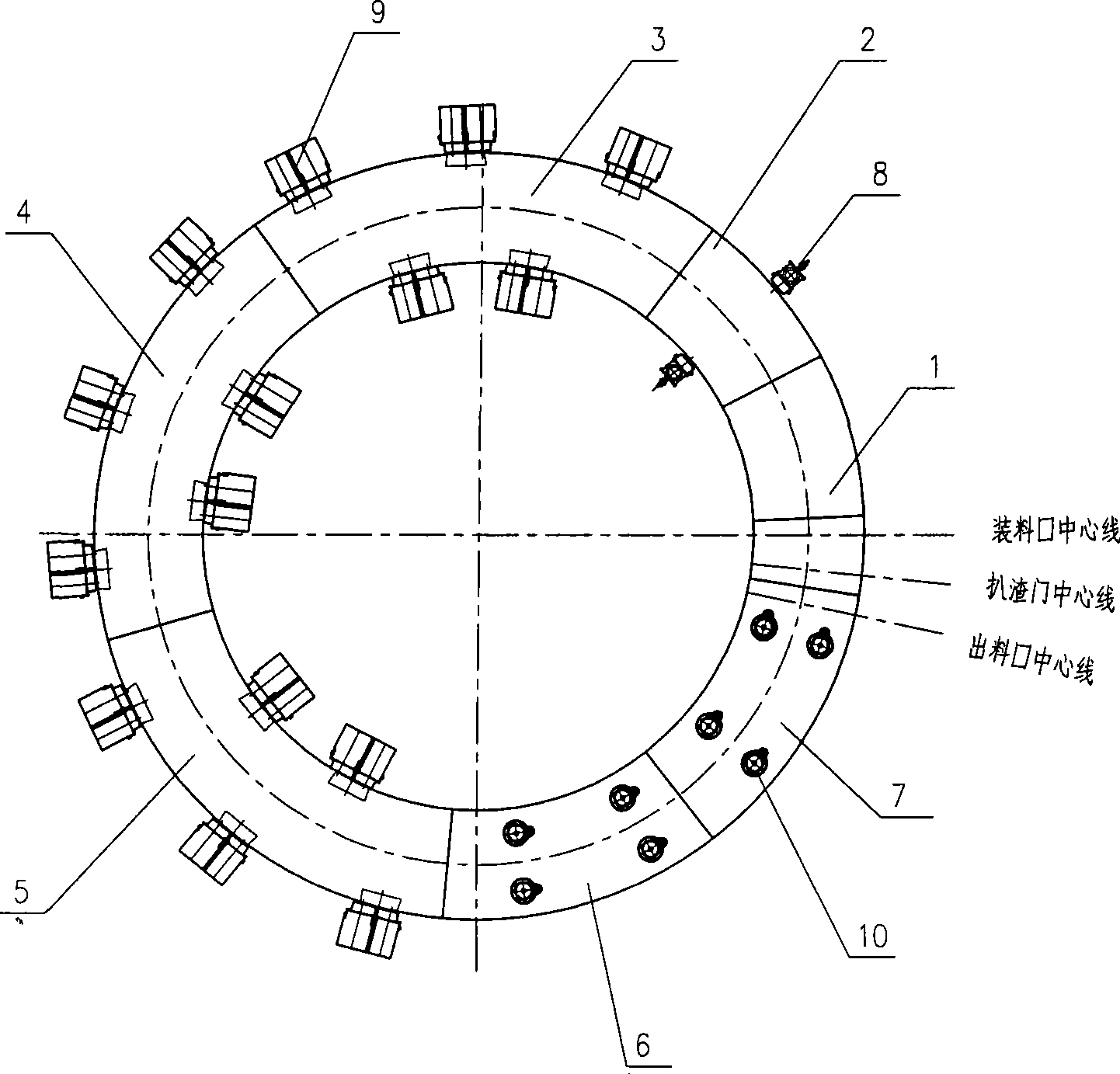

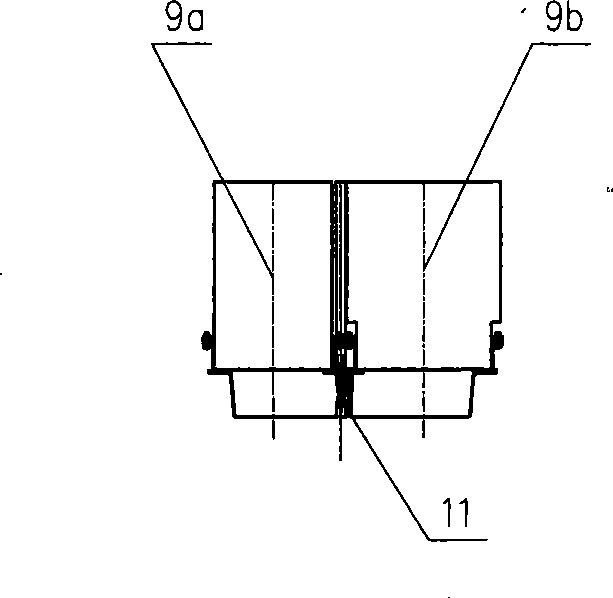

Annular furnace and annular furnace heat supply process

InactiveCN101441037ASolve the problem of applying to the ring furnaceMeet the installation requirementsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelKilnHeat-only boiler station

The invention relates to a circular furnace and heat supply technique thereof, belonging to technique field of furnace and kiln engineering. Combination heat supply of a heat accumulation burner and a normal burner is provided on the whole circular furnace. The circular furnace is divided into a heat recover segment, a warm-up segment, a heating segment and a soaking segment from the furnace tail to the furnace head. A heat supply device is not disposed on the heat recovery segment of the circular furnace, fume in the furnace flowing through the heat recovery segment transfers heat to material blank for primary warm-up of the material blank. A flame adjusting burn is disposed on the inner-outer circular furnace wall of the circular furnace warm-up segment for supplying heat to the circular furnace, and the material blank is further warmed up. The normal flame burner is disposed on the top of the circular furnace soaking segment for soaking material blank. Large temperature field required by installation and technique of double heat accumulation burners is provided, application of blast furnace gas with low heat value in the circular furnace is effectively solved, and the invention can be used in circular furnace in the steel industry.

Owner:CISDI ENG CO LTD

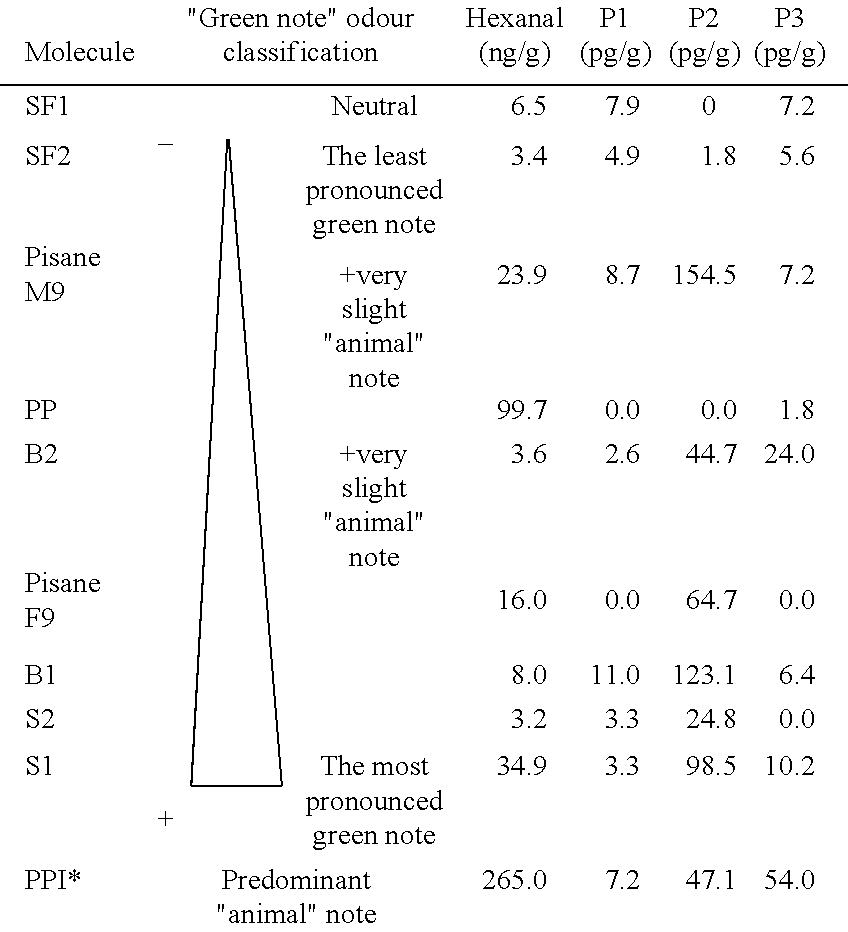

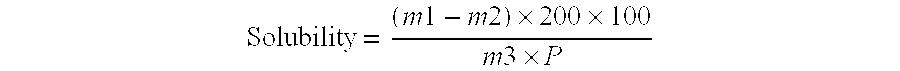

Process for Manufacturing Soluble and Functional Plant Proteins, Products Obtained and Uses

ActiveUS20130017310A1Improve functional propertiesHigh in proteinDepsipeptidesPeptide preparation methodsBiotechnologySolubility

The invention relates to a process for manufacturing soluble and functional plant proteins, characterized in that it comprises at least one functionalizing step that consists of a treatment of 0.01 s to 1 s constituted of a step of heating plant proteins at a temperature of 100° C. to 160° C. and a step of cooling the heated plant proteins. The invention also relates to a process for converting non-functional plant proteins to functional proteins. Another subject of the invention is a plant protein, characterized in that it has a solubility in water of greater than 50% (with the exception of a potato protein for which the solubility in water is 25%), an emulsifying capacity between 700,000 mPa·s and 1,200,000 mPa·s for a sample directly placed at 4° C. for 24 h (with the exception of a potato protein for which the emulsifying capacity for a sample directly placed at 4° C. for 24 h is between 400,000 mPa·s and 600,000 mPa·s) and between 500,000 mPa·s and 1,100,000 mPa·s for a sample treated at 75° C. then placed at 4° C. for 24 h and an emulsifying capacity between 70% and 95%. A further subject of the invention is the use of said plant protein in the manufacture of food.

Owner:ROQUETTE FRERES SA

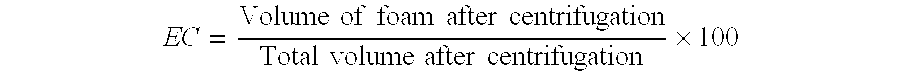

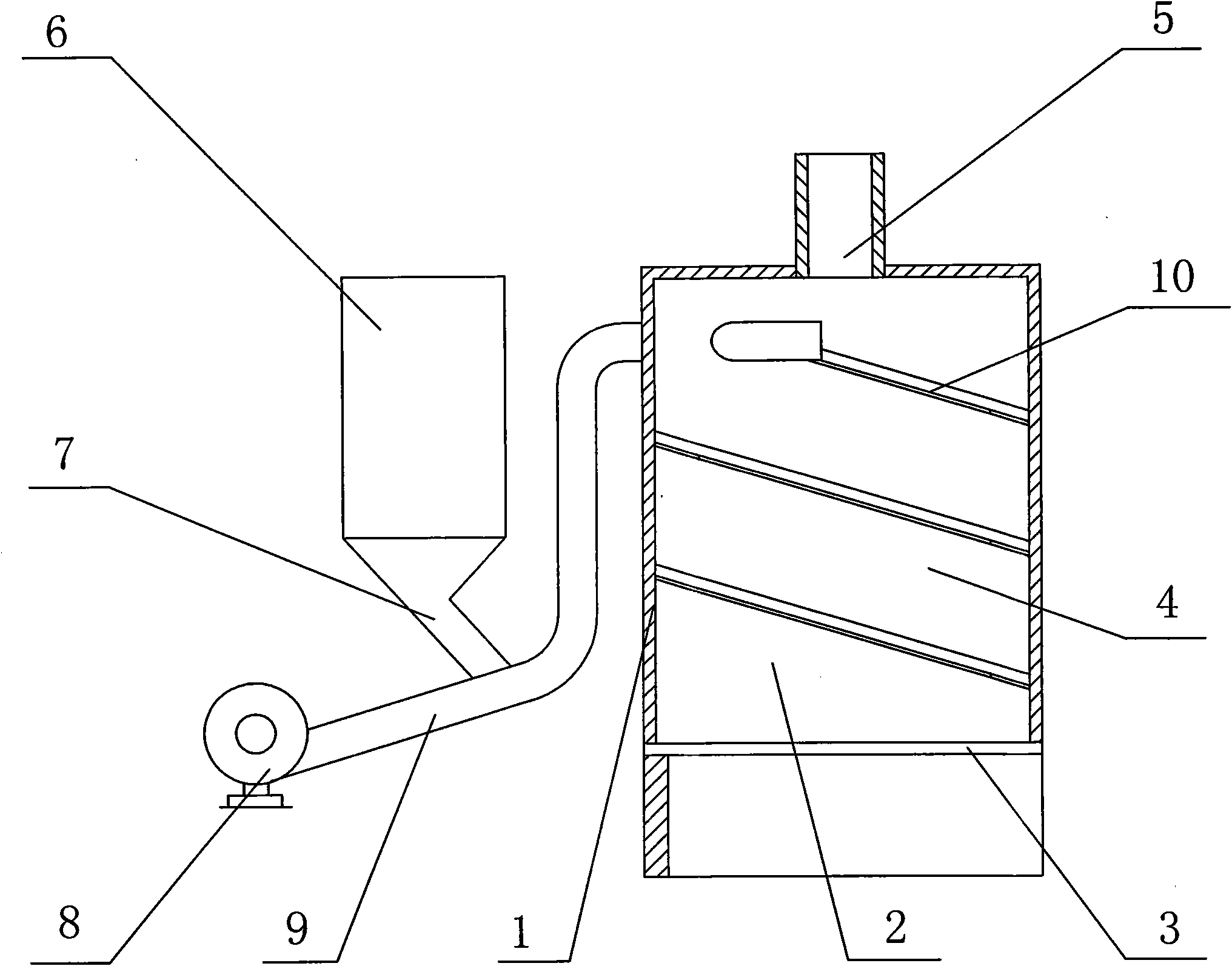

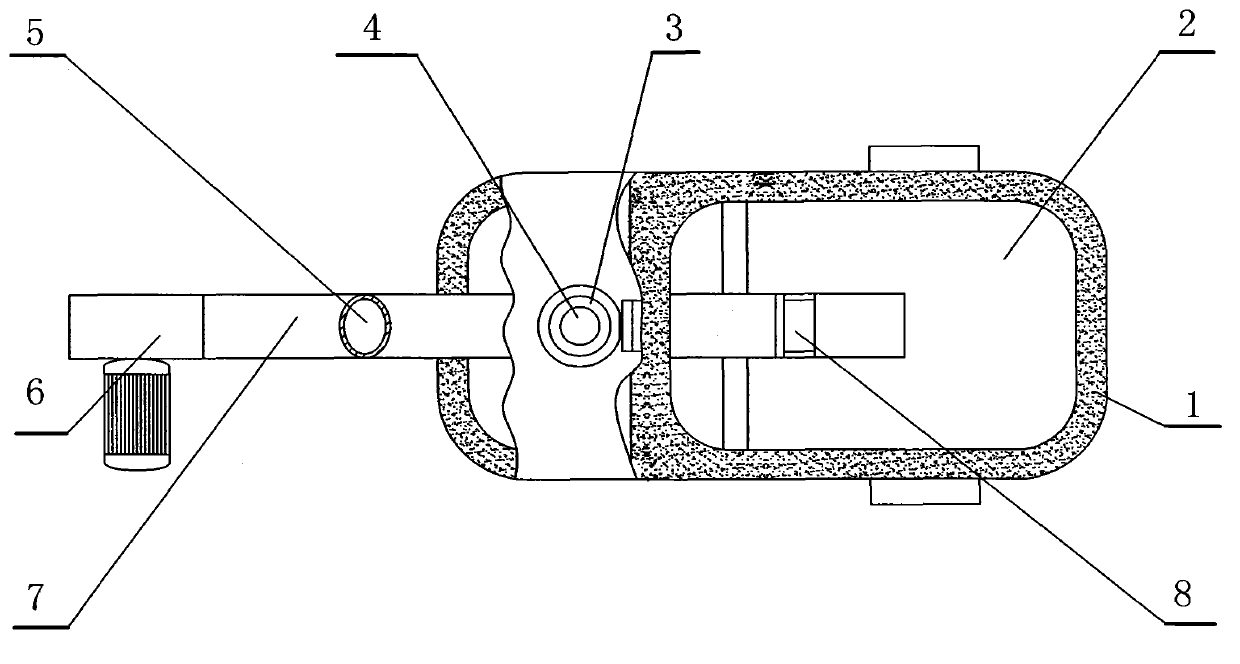

Straw fuel flying furnace

ActiveCN101818892ANot easy to pile upIncrease valueSolid fuel combustionIndirect carbon-dioxide mitigationHeat lossesHearth

The invention relates to heat supply equipment, in particular to a straw fuel flying furnace which comprises a furnace body (1), a hearth (2), a fire grate (3) and a smoke exhaust pipe (5), wherein the furnace body (1) is externally connected with a fan (8), and an air supply pipe (9) of the fan (8) enters the hearth (2) from one side of the furnace body. The straw fuel flying furnace is characterized in that a fuel hopper (6) is arranged outside the furnace body (1), a blanking pipe (7) under the fuel hopper (6) is communicated with the air supply pipe (9) of the fan (8); and one end of the air supply pipe (9) entering the hearth (2) is provided with a cyclone guide curved surface (4). Fuel is combusted in rotatably flying after entering the hearth following wind, is not easy to accumulate, and is fully combusted. The fan blows the fuel by using hot air in the hearth to ensure that straws are heated in advance to be ignited. The furnace body and a flue are both provided with residual head recovery devices, thereby closing various channels of heat loss and remarkably improving the heat efficiency. The invention is suitable for being used as various heat exchange devices of a hot air furnace, a hot water furnace, an oil furnace and the like, replaces coal furnaces to carry out various heat supply operations, and has important implications on saving coal, protecting environment, fully utilizing crop plants, improving the straw value, and increasing the income of farmers.

Owner:张建臣

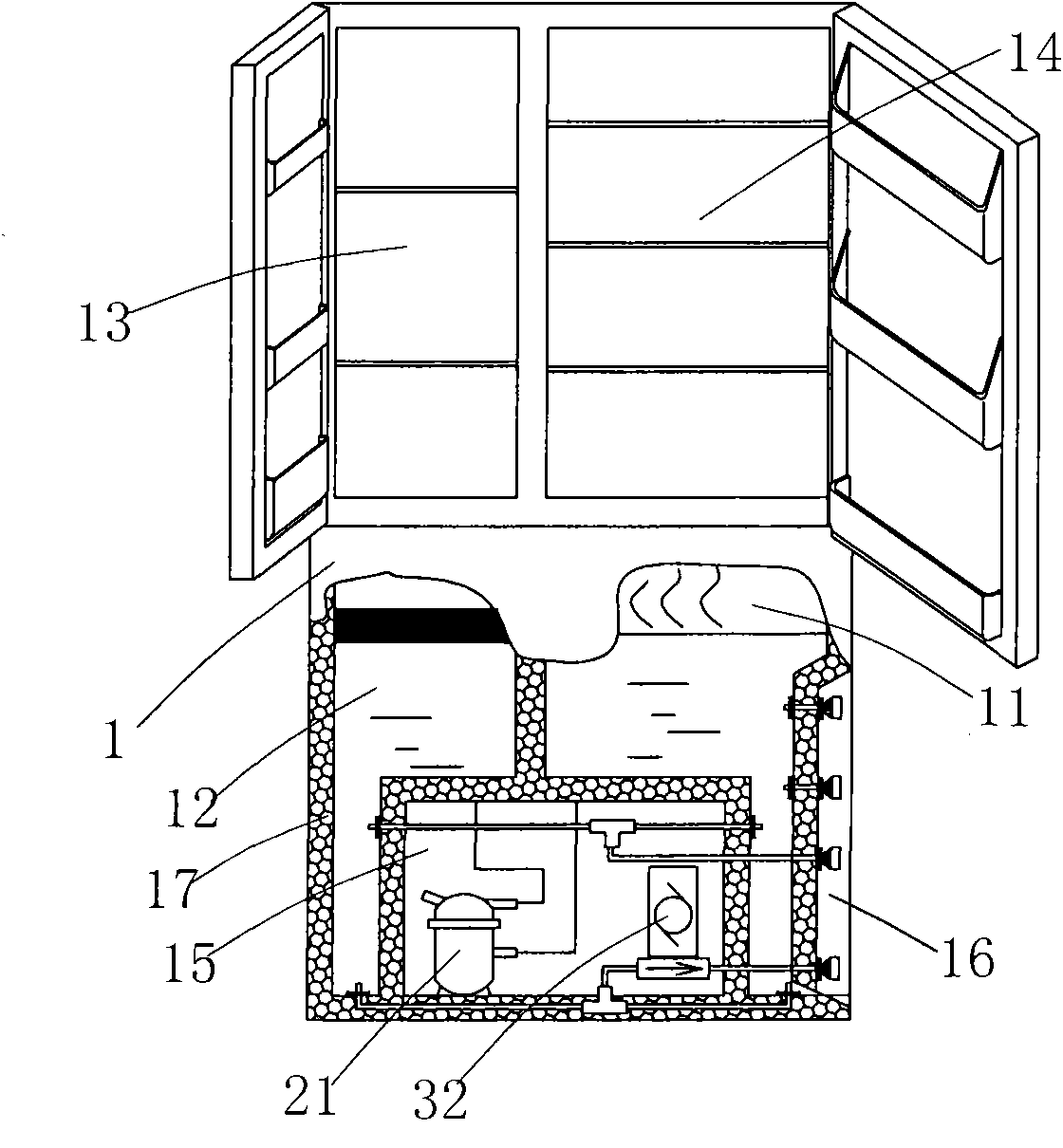

Multiple-energy box

InactiveCN101881547AReduce the temperatureTo achieve the purpose of heatingDomestic cooling apparatusLighting and heating apparatusWater flowEngineering

The invention discloses a multiple-energy box. A heat preservation box body is internally and respectively provided with a cold water box, a hot water box, a refrigerating box and a refrigerated box, wherein a condenser is arranged in the hot water box, evaporators are respectively arranged in the cold water box, the refrigerating box and the refrigerated box, a compressor is arranged and connected with the condenser and the evaporators in series to form a compressing loop, an expansion valve and a capillary tube are also connected in series on a pipeline between the condenser and the evaporators, and the hot water box and the cold water box are respectively connected with heating equipment and refrigerating equipment through the pipeline to form a water flow loop capable of exchanging heat. In the invention, the heat generated in the heating process and the low temperature formed in the refrigerating process can be stored and fully utilized, thereby achieving the purposes of saving energy and reducing consumption, and a traditional refrigerator, an air conditioner, an electric kettle, a water heater, and the like can be replaced by one multiple-energy box.

Owner:郭维存

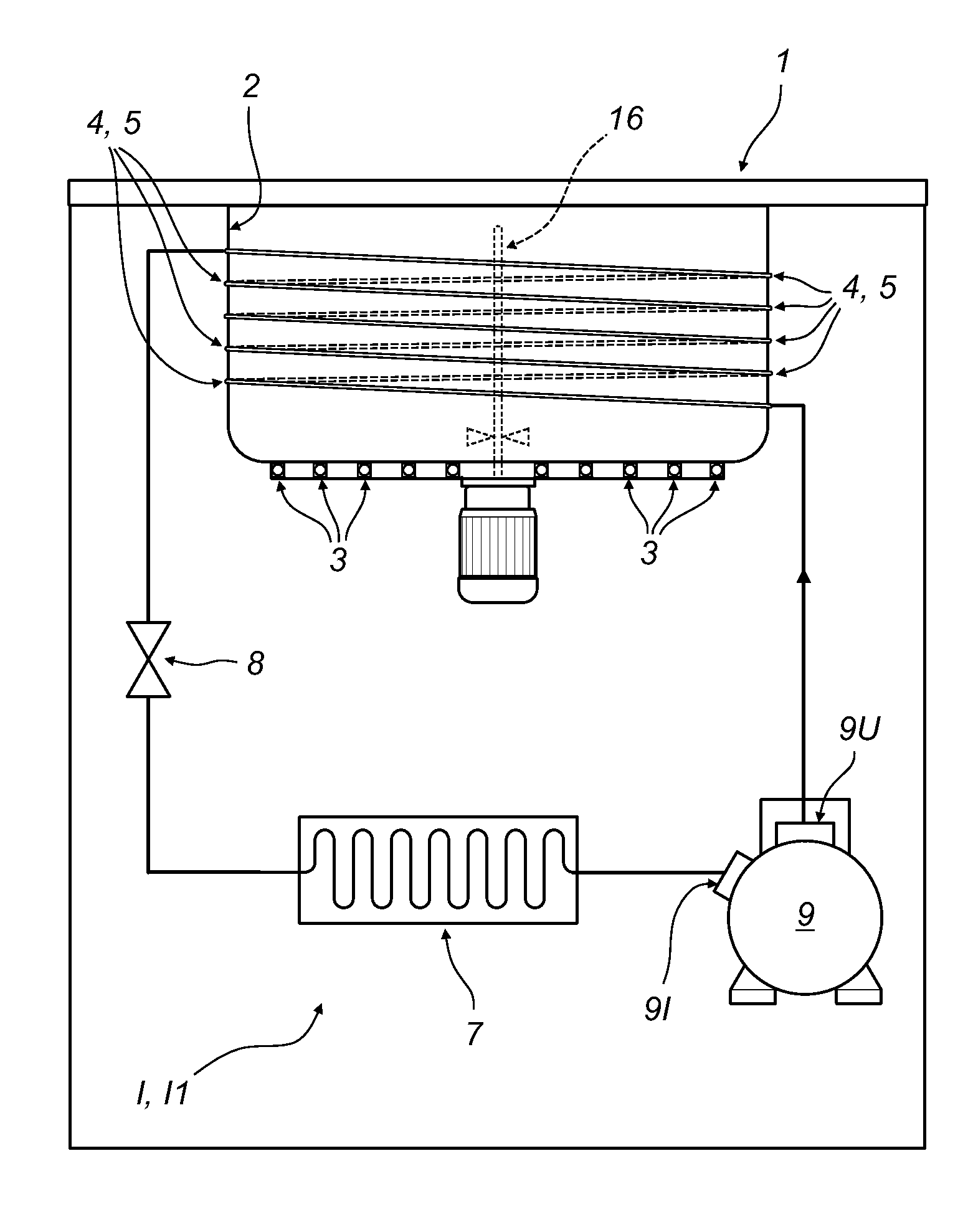

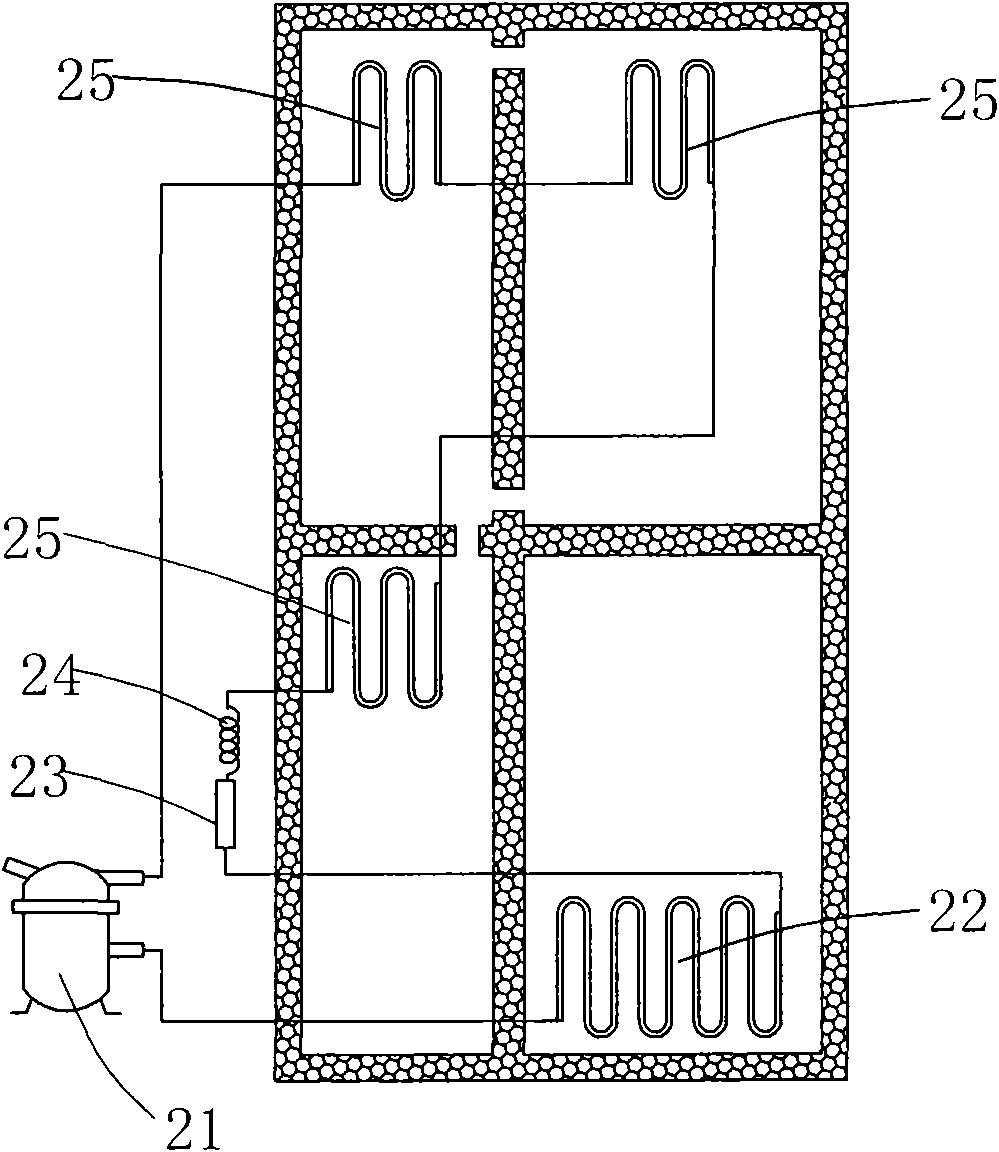

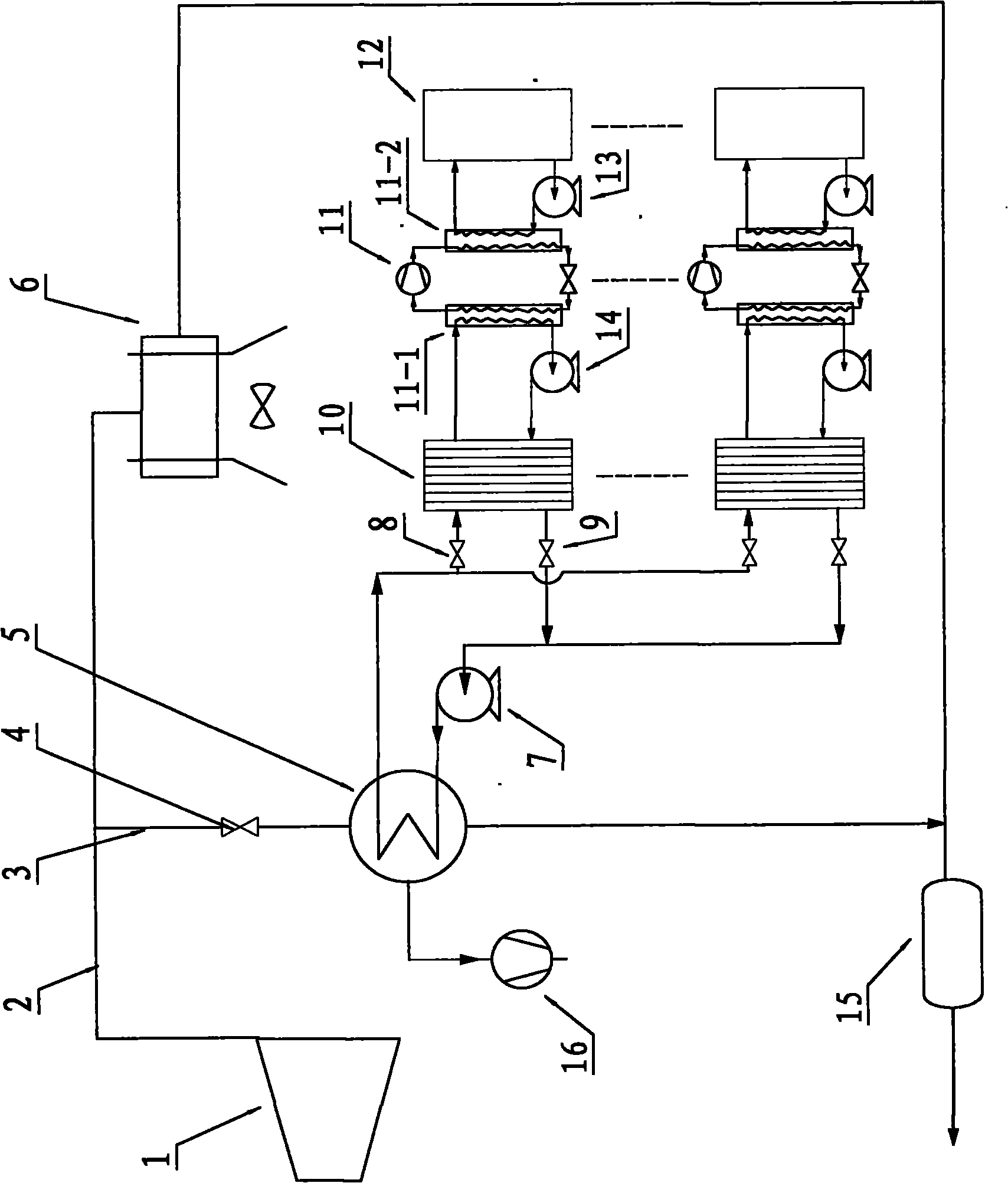

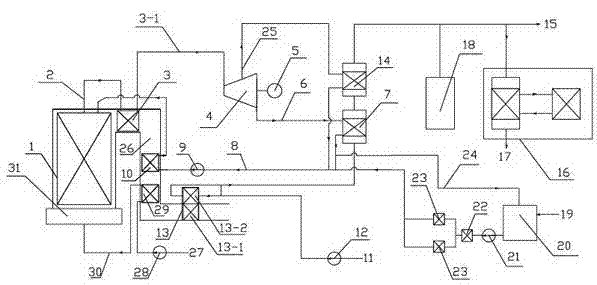

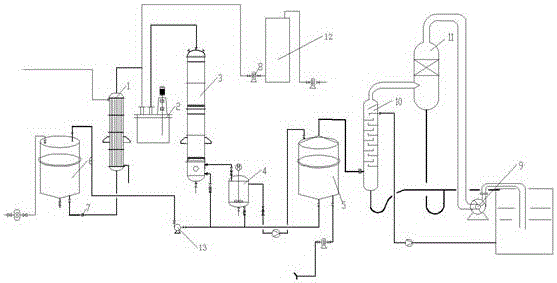

Heating plant for supplying heat for heat-engine plant by recovering exhaust steam and vaporizing latent heat

InactiveCN101832595AReduce energy consumptionReduce power consumptionLighting and heating apparatusEnergy efficient heating/coolingClosed loopEngineering

The invention relates to a heating plant for supplying heat for a heat-engine plant by recovering exhaust steam and vaporizing latent heat for solving the question of dead steam heat supply for an air cooling machine unit of the heat-engine plant. The invention has the following technical proposal: a condenser branch is led out from the middle part of a dead steam pipeline, a plurality of heat supply units are arranged on a cooling circulating water loop of the condenser, each heat supply unit comprises a heat exchanger, a heat exchanger circulating water pump, a heat pump machine unit and a heat supply user terminal; the condenser cooling circulating water passes through the exchanger, the cooling circulating water pump and the condenser to form a cooling water closed loop; the heat exchanger circulating water passes through a heat pump machine unit heat absorption side, the heat exchanger circulating water pump and the heat exchanger to form a heat exchange water closed loop; heat user circulating water passes through a heat pump machine unit heat release side, the heat supply user terminal and the heat supply circulating pump to form a hot water supply closed loop. In the invention, exhaust steam of a steam turbine is recover and latent heat is vaporized to supply heat in combination with the heat pump, so that work-doing steam is not consumed, heat supply temperature can be adjusted according to needs at the user terminal; in addition, the heating plant features flexible application, obvious energy conservation effect and improved machine unit efficiency.

Owner:安能科技股份有限公司

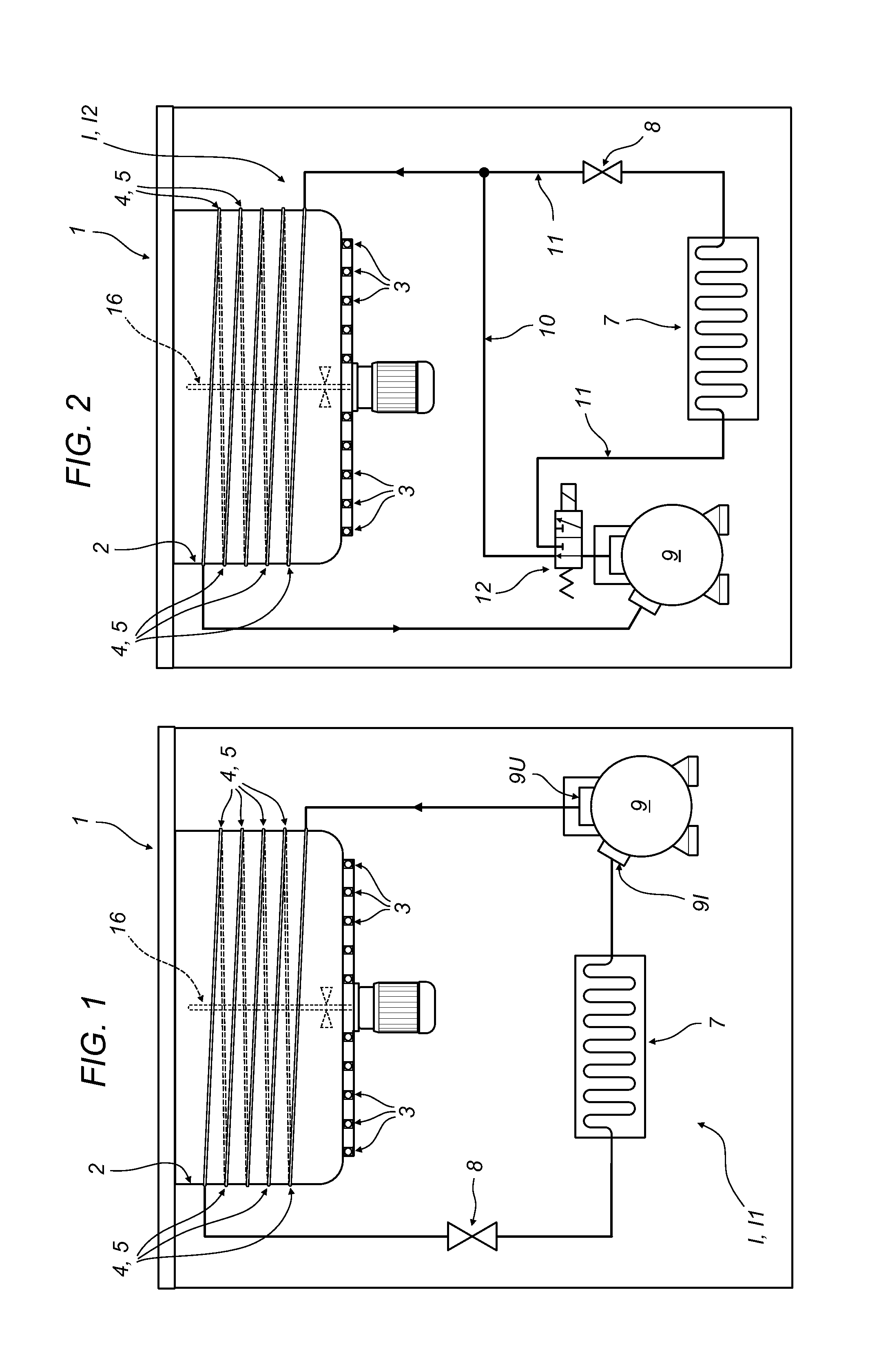

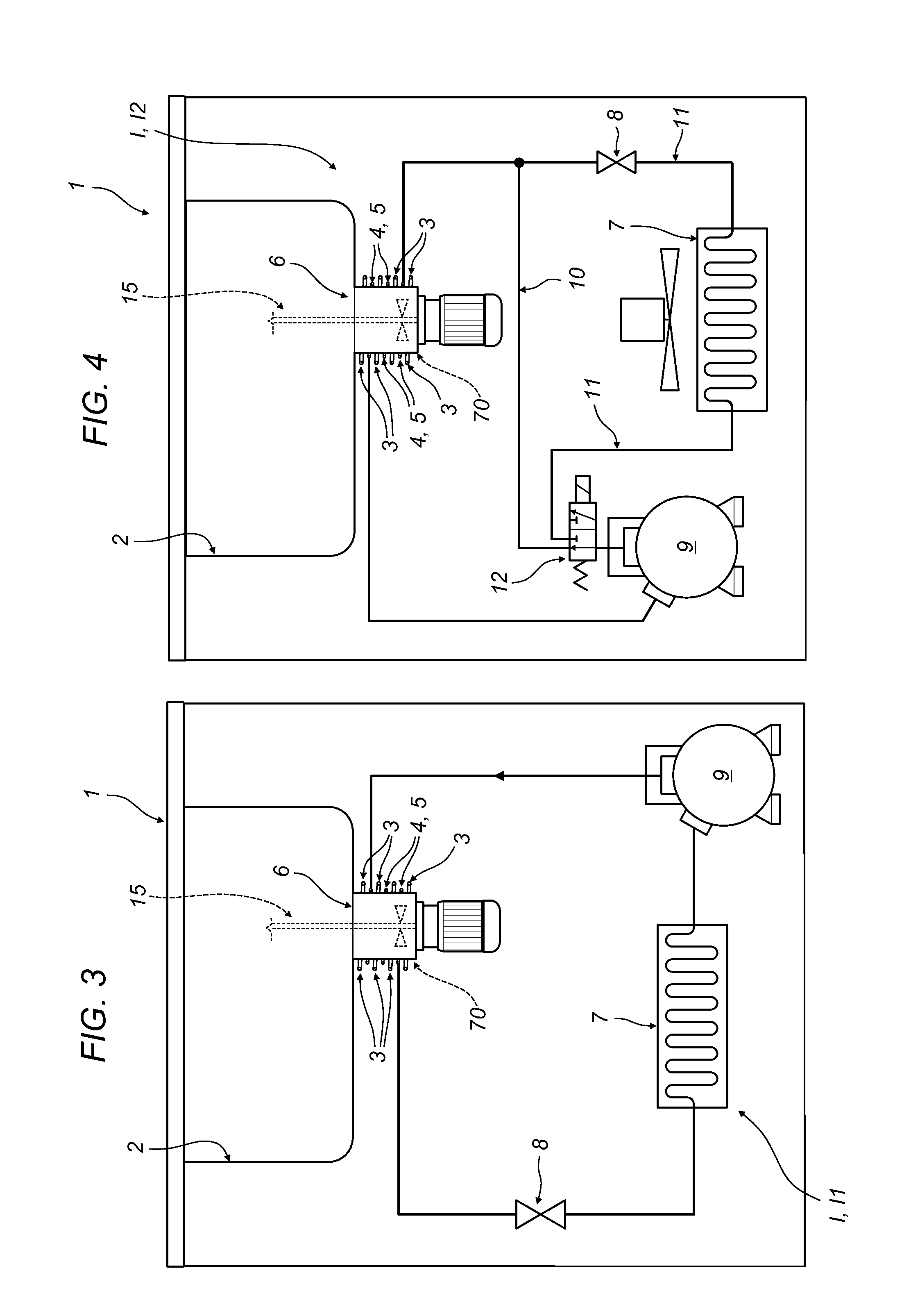

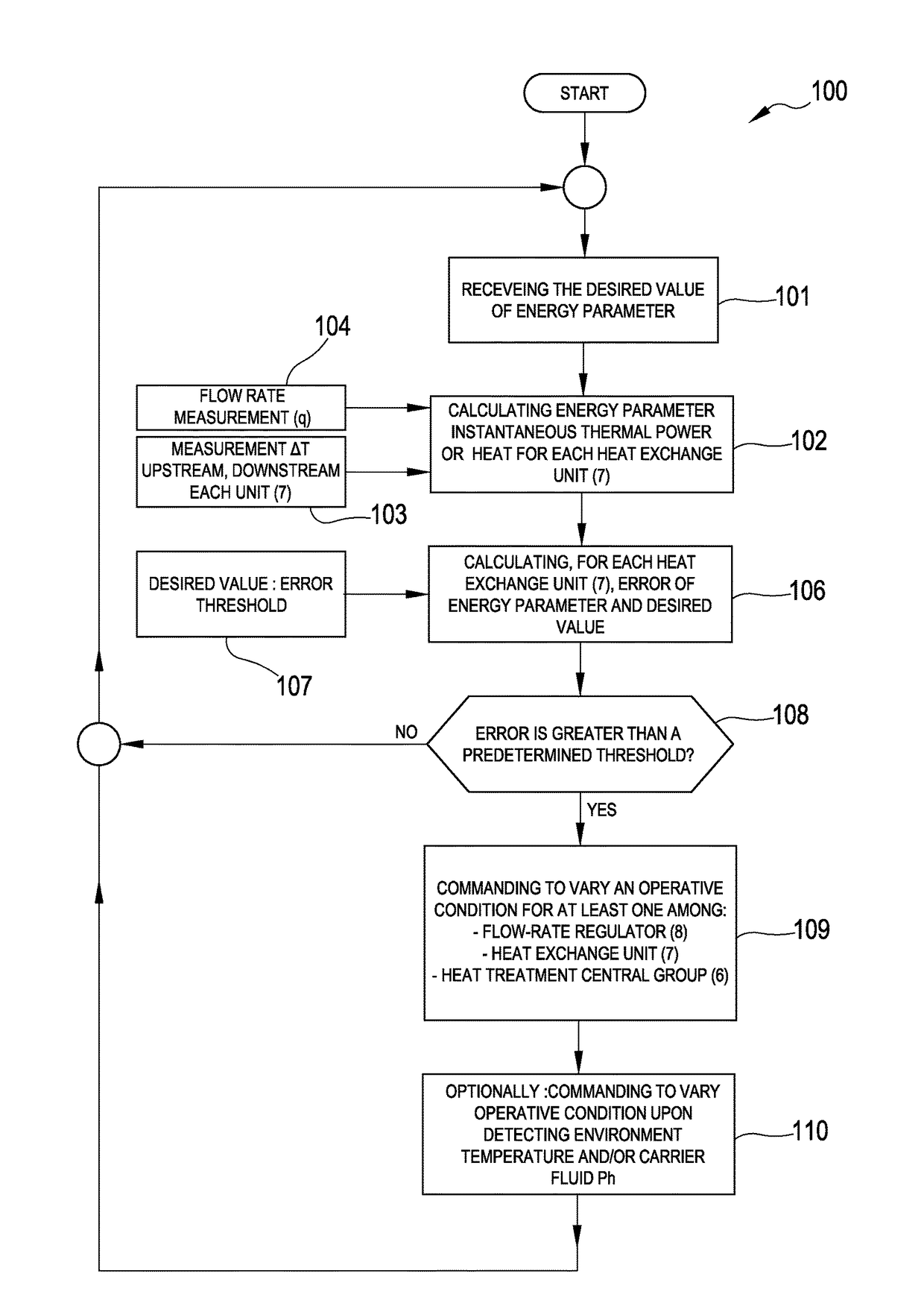

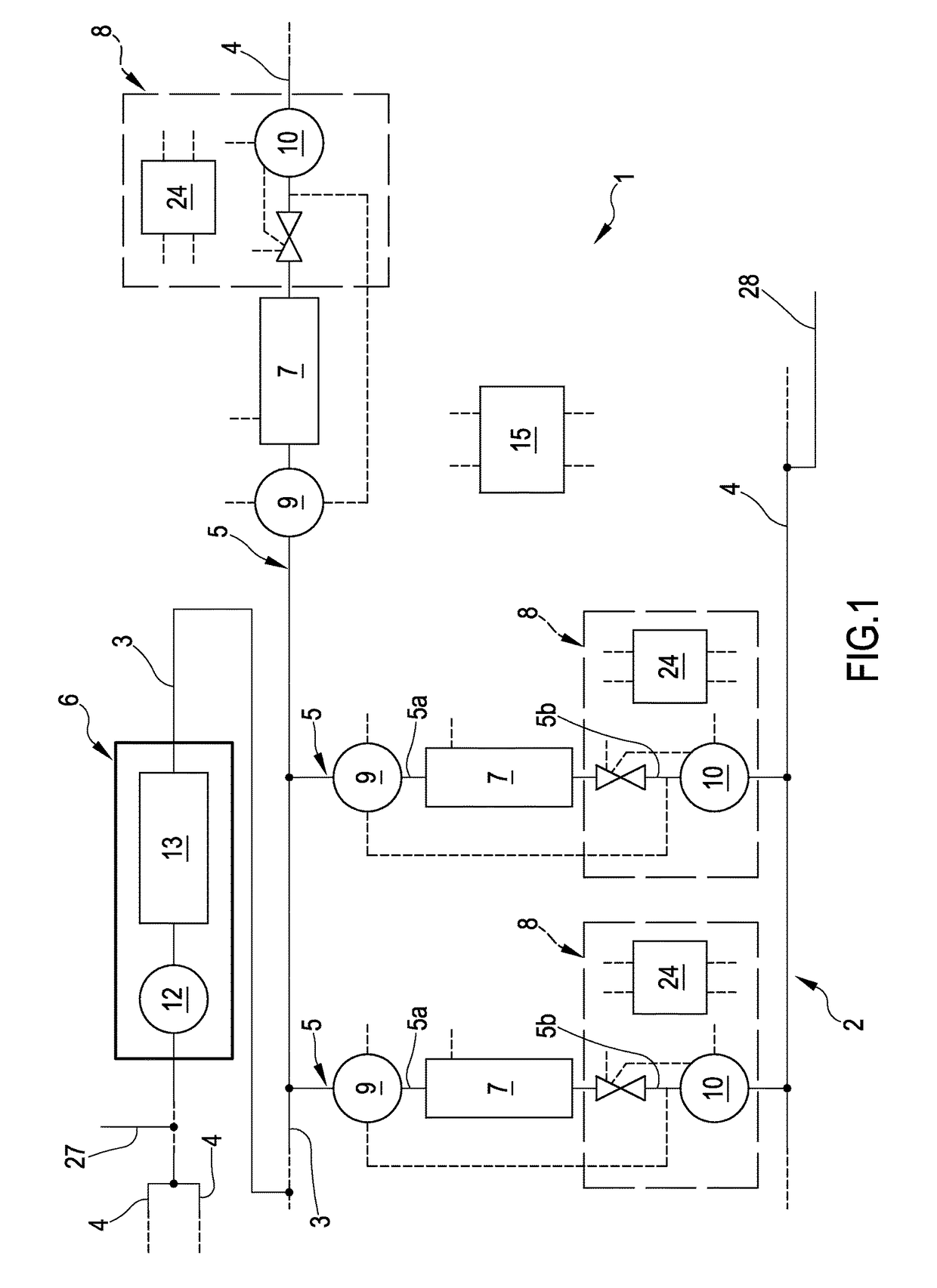

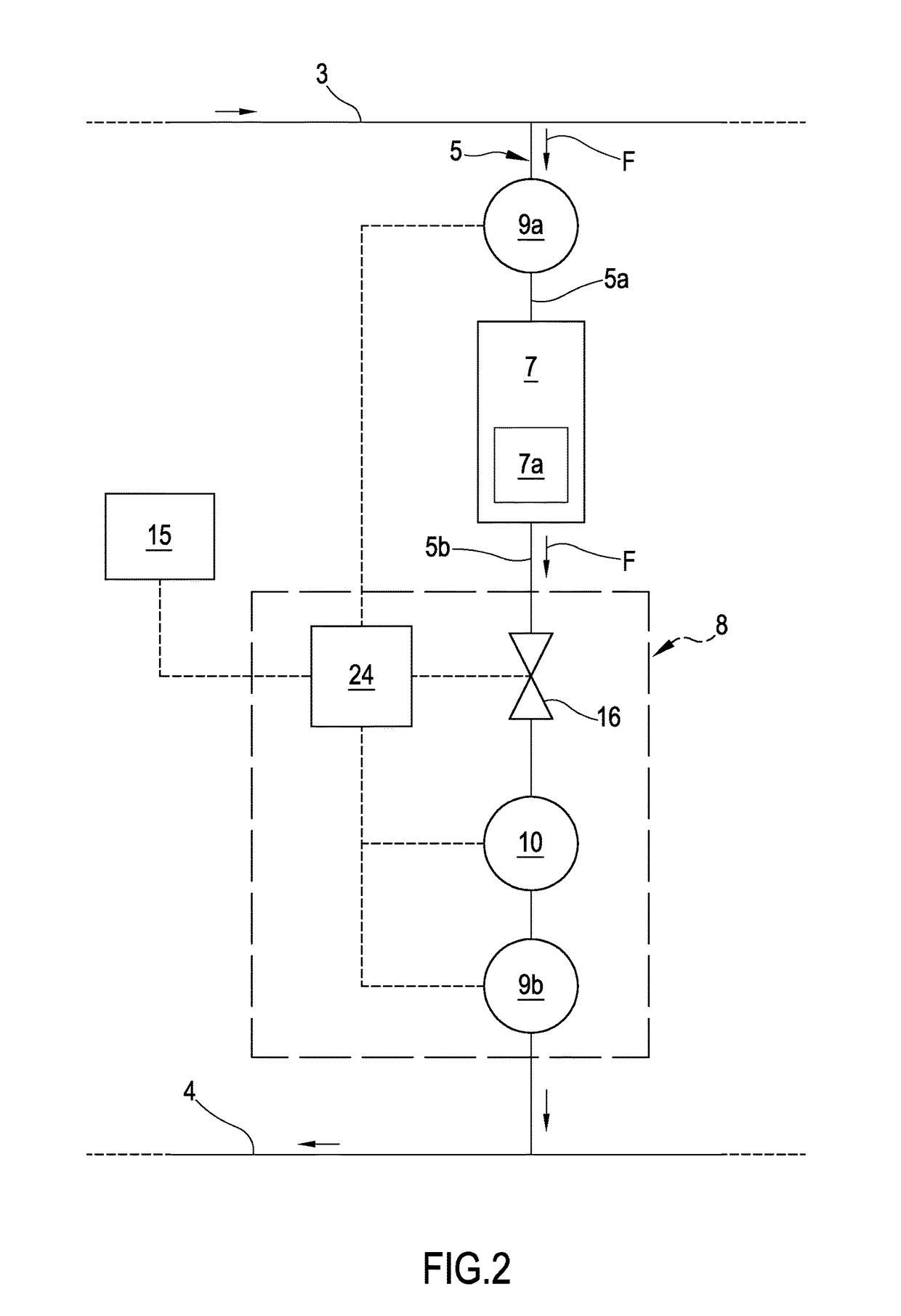

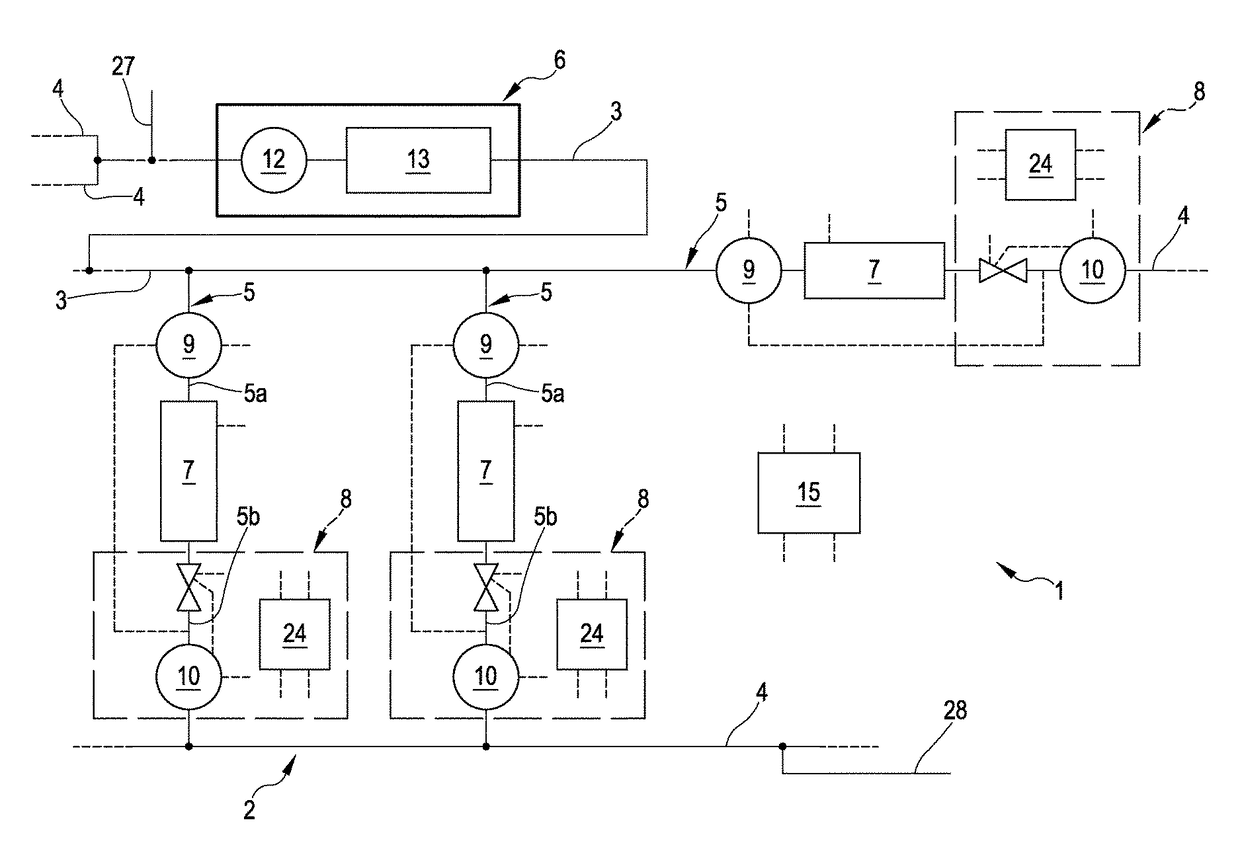

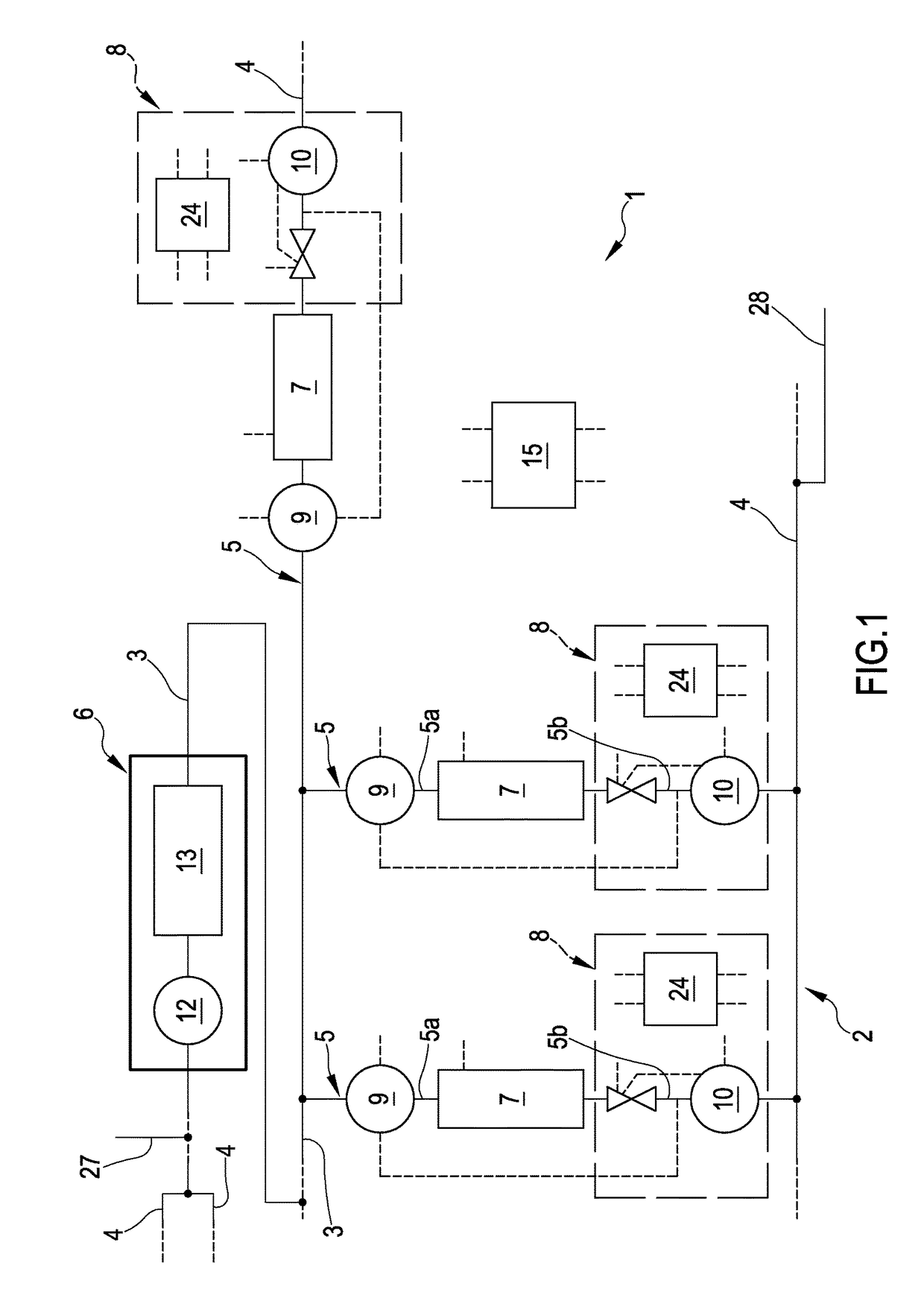

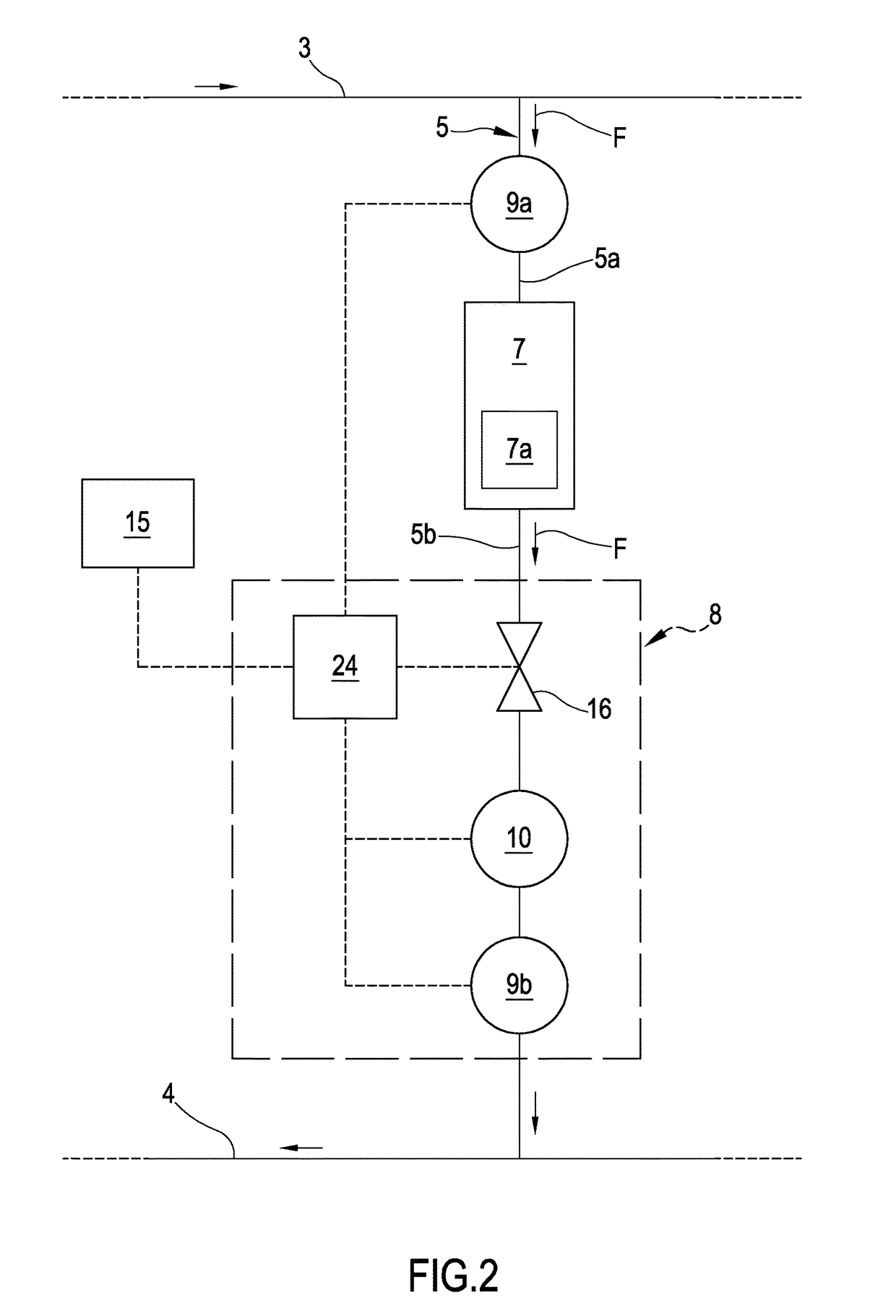

Conditioning and/or heating plant and process of controlling the same plant

ActiveUS20170067656A1Increase temperatureConvenient energy managementDistrict heating systemPlug valvesEngineeringCarrier fluid

A conditioning or heating plant and a process of controlling the plant, wherein plant comprises at least one circuit for distributing a carrier fluid, having a delivery line, a return line, and a plurality of channels directly or indirectly connected to the delivery line and return line and configured for supplying respective environments to be conditioned and / or heated, at least one heat treatment central group placed on the circuit. The plant has, for each of the channels, at least one respective heat exchange unit and at least one flow-rate regulator.

Owner:FIMCIM

Novel process for reducing and regenerating waster rubber continuously

ActiveCN102501335AReduce consumptionNo pollution in the processPlastic recyclingChemical reactionPolymer science

The invention relates to a novel process for reducing and regenerating waster rubber continuously. The process comprises the following steps of: (1) plasticizing at high speed, namely feeding waste rubber powder, a rubber reclaiming agent and softening oil into an agitation tank of a high-speed plasticization reaction unit, and mixing; (2) performing mechanochemical reaction, namely shearing the rubber powder, and rolling to form stripped particles by using a mechanochemical device; (3) reducing the rubber by using a screw reduction unit, namely cutting S-S cross bonds of vulcanized rubber and hardly damaging C-C bonds at short time to keep a high physical property of the rubber by using a high-shearing screw combination; (4) kneading by using another screw reduction unit, namely performing secondary shearing, and cooling; and (5) refining, namely extruding by using an open mill to obtain regenerated rubber. The process has the advantages that: a high-temperature and high-pressure process is eliminated, so technical basis is provided for safety of a human body and equipment; waste gas and water is avoided in the process, so environmental protection is facilitated; few heat supply equipment is needed in the process, and energy resources are saved; and the production process is short, the regenerated rubber can be continuously and the like.

Owner:HEBEI RICHWAY TECH

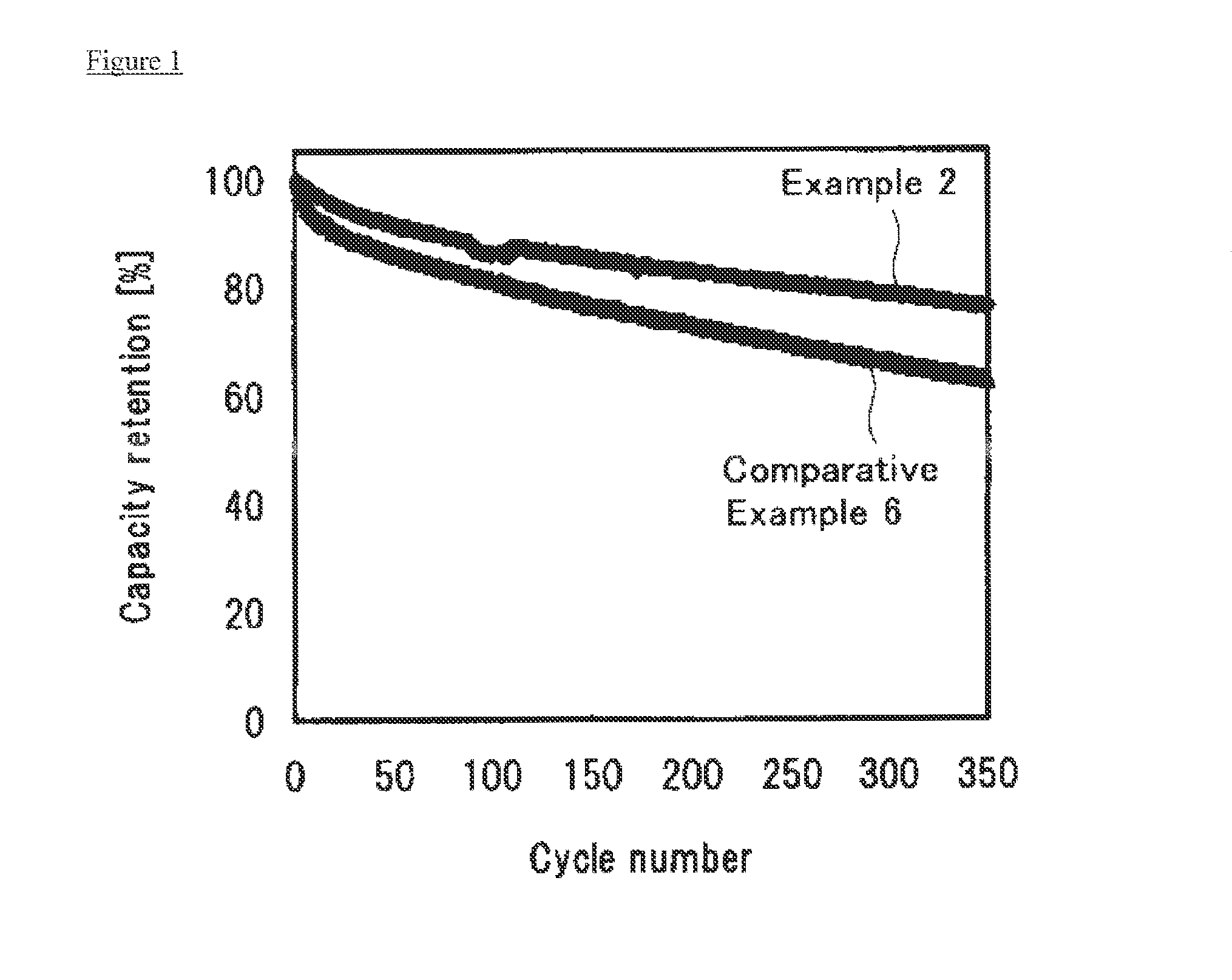

Carbonaceous material for negative electrodes of nonaqueous electrolyte secondary batteries and method for producing same

ActiveUS20160064735A1Excellent electrical propertiesEfficient removalNegative electrodesSecondary cellsHalogenGas phase

The object of the present invention is to provide a manufacturing method of carbonaceous material for a negative electrode of non-aqueous electrolyte secondary batteries, wherein the carbonaceous material is obtained from plant-derived char as a source, potassium is sufficiently removed, and an average particle diameter thereof is small; and a carbonaceous material for a negative electrode of non-aqueous electrolyte secondary batteries.The object can be solved by a method for manufacturing a carbonaceous material having an average particle diameter of 3 to 30 μm, for a negative electrode of non-aqueous electrolyte secondary batteries comprising the steps of: (1) heating plant-derived char having an average particle diameter of 100 to 10000 μm at 500° C. to 1250° C. under an inert gas atmosphere containing halogen compound to demineralize in a gas-phase, (2) pulverizing a carbon precursor obtained by demineralization in a gas-phase, (3) calcining the pulverized carbon precursor at 1000° C. to 1600° C. under an non-oxidizing gas atmosphere.

Owner:KURARAY CO LTD

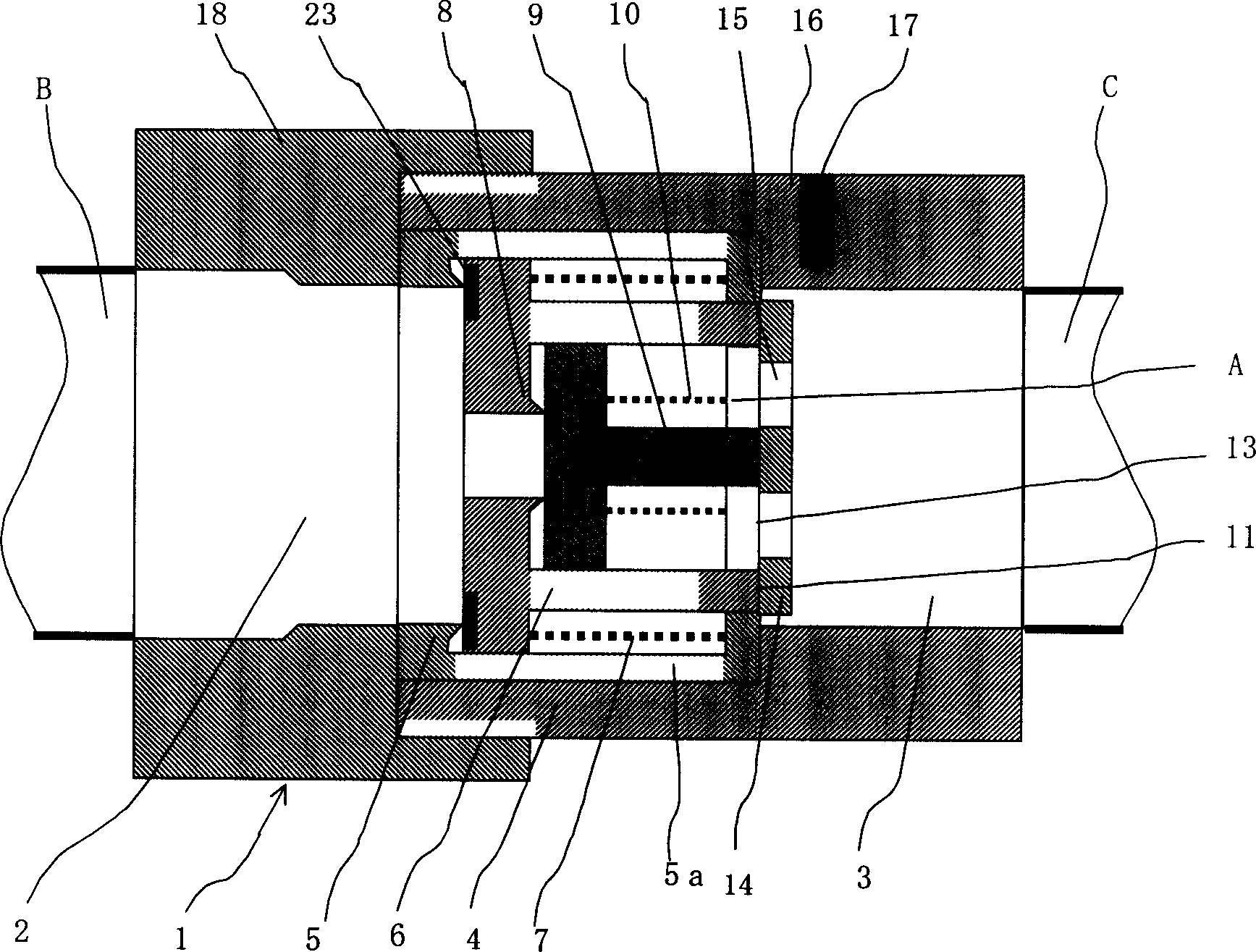

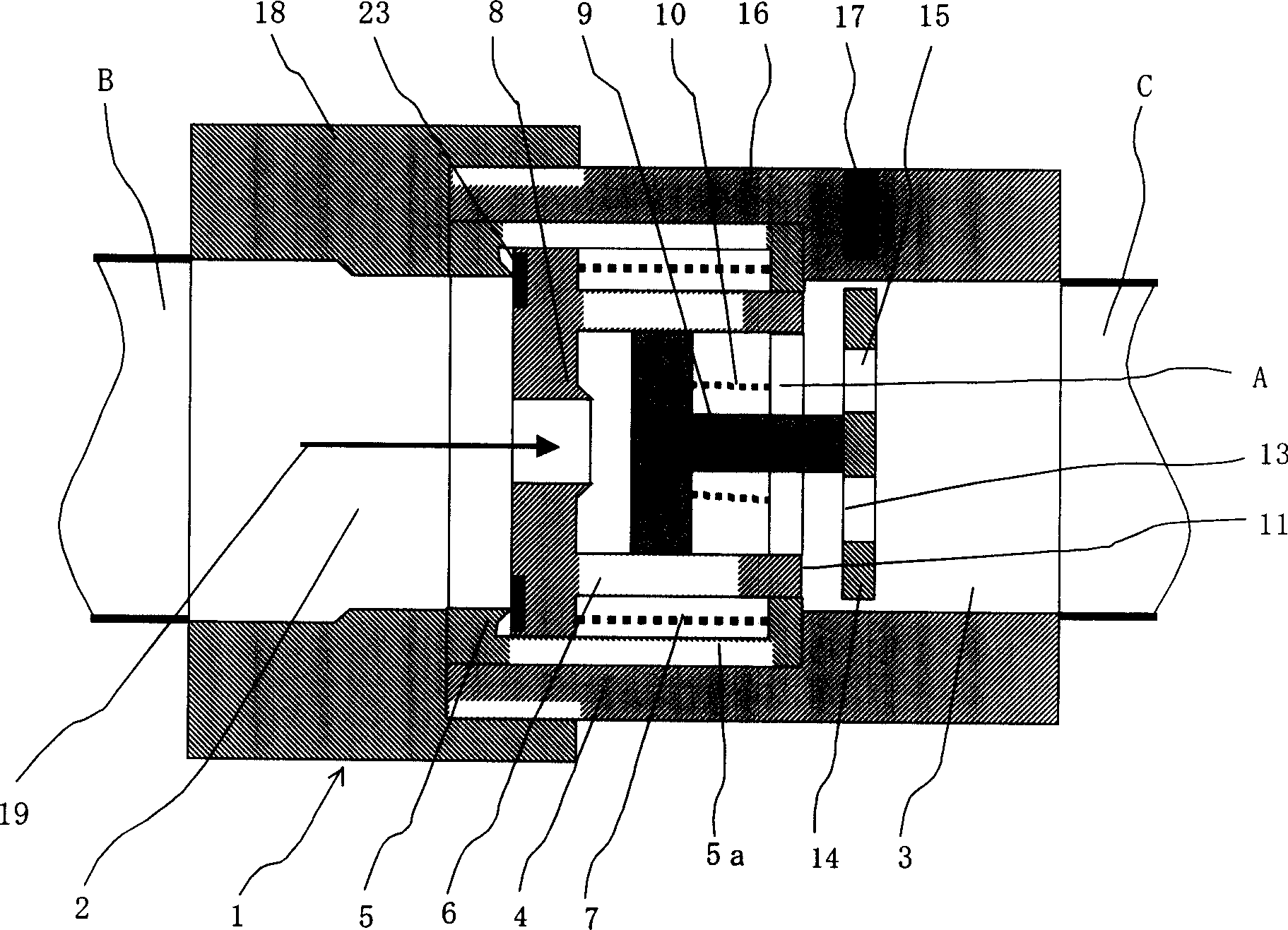

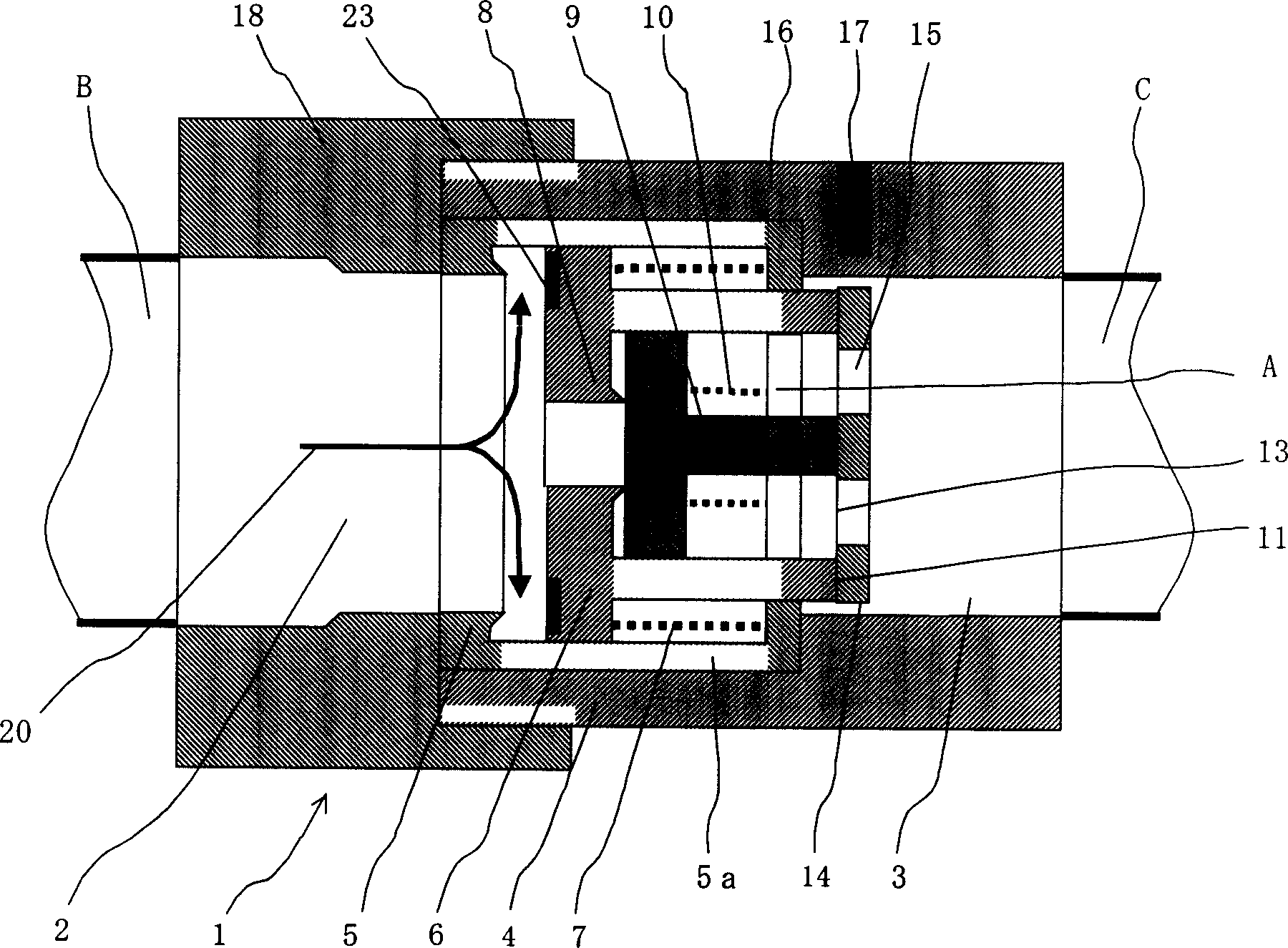

Check valve for detecting water leakage and water leakage alarm system using the same

InactiveCN1607348AAvoid destructionMeasurement of fluid loss/gain rateCheck valvesWater leakageEngineering

The object of the present invention is to provide a device which can frequently detect water leakage with simple equipment and issue a water leakage alarm. Regardless of whether it is natural water leakage caused by aging water pipes or human-made water leakage, such as forgetting to turn off the water tap, failure of heating equipment, and operational errors, it can be dealt with. The water leakage alarm system in the present invention includes two main parts: the water leakage detection check valve, which can detect the movement of the mover and transmit the detection signal of the movement of the valve body; A valve body moves in the same way; the signal processing device analyzes the detection signal from the water leakage detection check valve and activates the water leakage alarm. The water leakage detection check valve has a main valve and a sub valve. When a large water leakage is caused by human beings, the main valve operates. When a small water leakage occurs naturally, the sub valve operates.

Owner:高砂工程株式会社

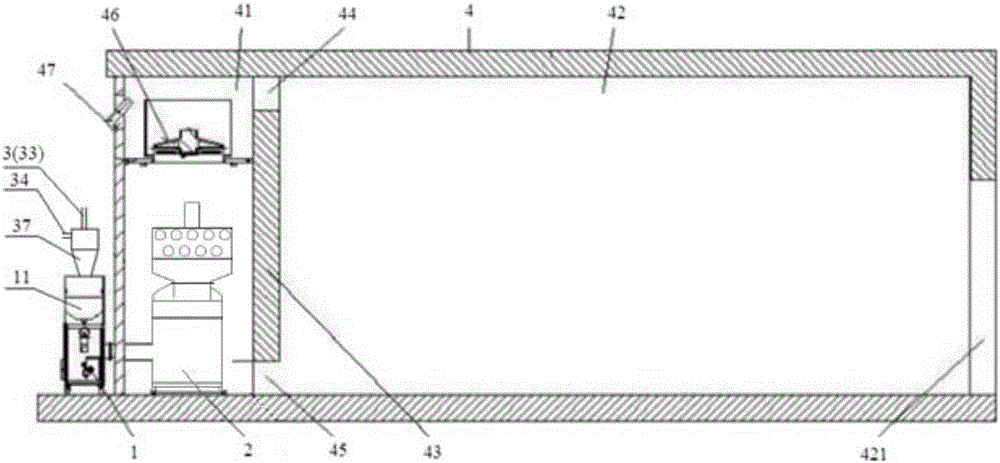

Biomass pellet fuel heating appliance

ActiveCN105942568AEnsure consistencyGuaranteed versatilityTobacco preparationDrying gas arrangementsEconomic benefitsRecuperator

The invention provides a biomass pellet fuel heating appliance, comprising a combustion furnace, a heat exchanger, a central supply system for supplying biomass pellet fuel to the combustion furnace, and a barn; the heat exchanger is used for being connected to one end of a horizontal nozzle of the combustion furnace, the barn includes a heating chamber, the heat exchanger is disposed in the heating chamber, and the combustion furnace and the central supply system are disposed outside the barn; the central supply system is used for providing biomass pellet fuel centrally for more than two combustion furnaces and comprises a suction unit with a vacuum pump, a storage barrel, more than two suction pipes, more than two feed pipes, a screw feeding mechanism, a feeding distribution connector, more than two electromagnetic valves, more than two vacuum buckets and more than two gravity valves. The heating appliance provided herein is reasonable and practical in design, safe and green, and efficient and labor-saving, reduces cost, saves resources, improves work efficiency and enterprise economic benefit, and is suitable for popularization and use.

Owner:HUNAN XINDI NEW ENERGY TECH CO LTD

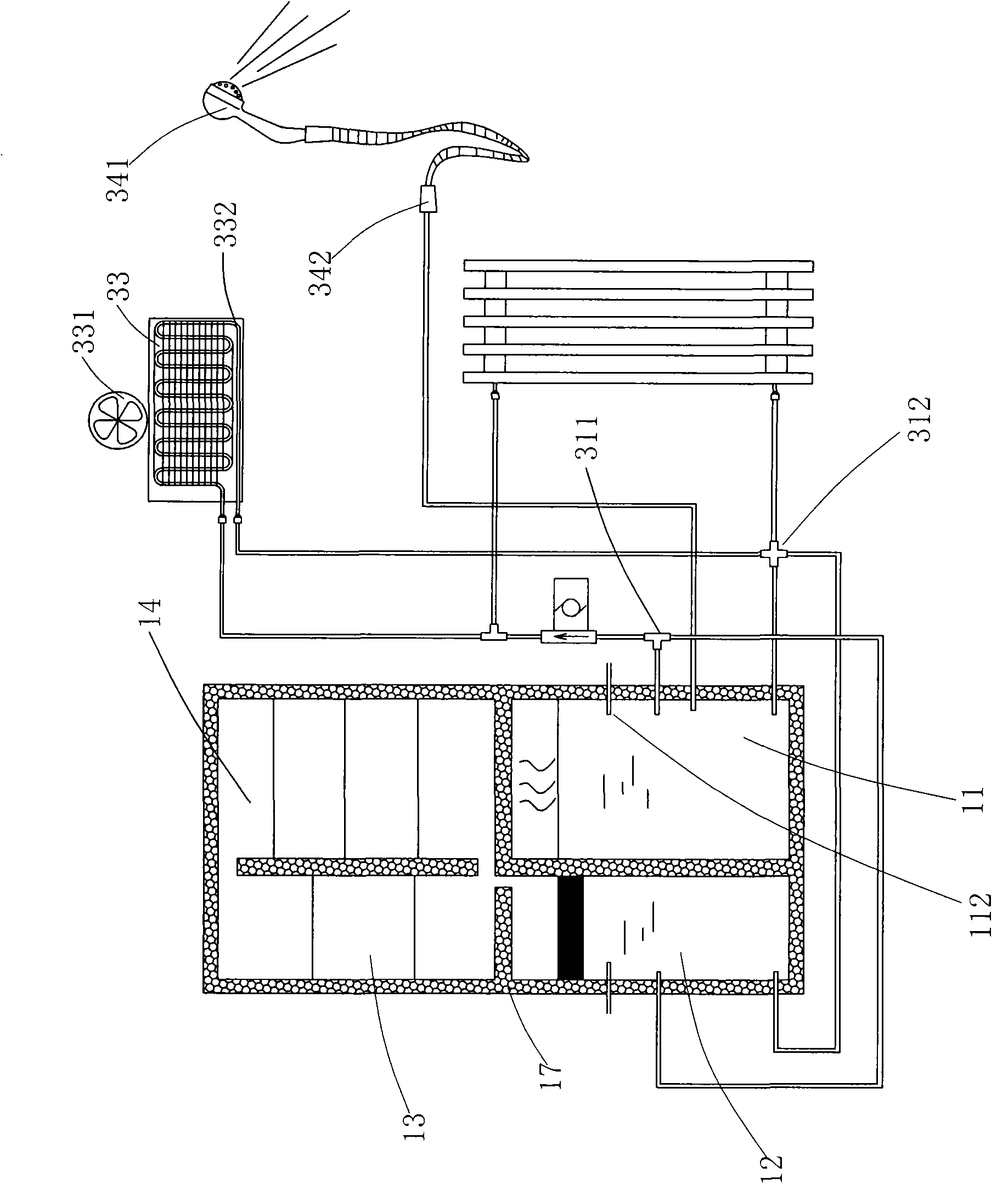

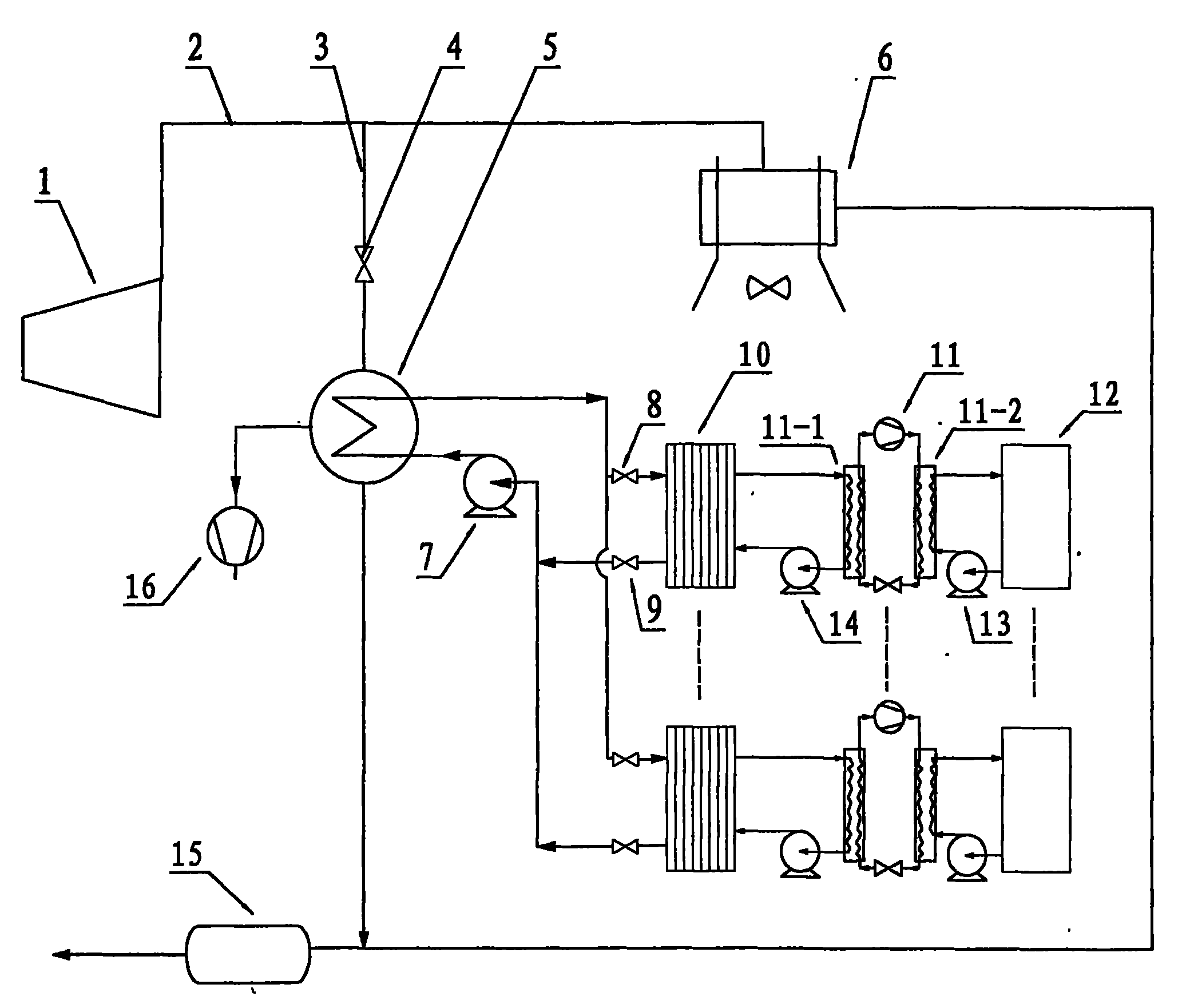

Combined cooling, heating and power device of distributed type industrial boiler

ActiveCN103089349ALow costImprove energy savingSteam engine plantsSteam boilersRefrigerationEnergy source

The invention relates to a combined cooling, heating and power device of a distributed type industrial boiler. A steam Rankine cycle system positive pressure and closed type method is adopted, a condenser of an outlet steam exhaust of a steam turbine serves as heat sources for a heating plant and an absorption refrigeration device, and therefore gradient utilization of energy sources is achieved. High quality energy of fuel is recovered for generating electricity, more than 260 KWh electric quantity can be recovered from per ton evaporation capacity (or 0.7MW heating load), at the same time, cooling and heating combination is achieved, and exhaust gas waste heat can be effectively recovered. According to a steam Rankine cycle system, waste acid and waste alkali are not produced, and the problems of oxygen corrosion and scale formation of the boiler are effectively avoided. Therefore the distributed type industrial boiler is energy-saving, environment-friendly and very remarkable in social benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

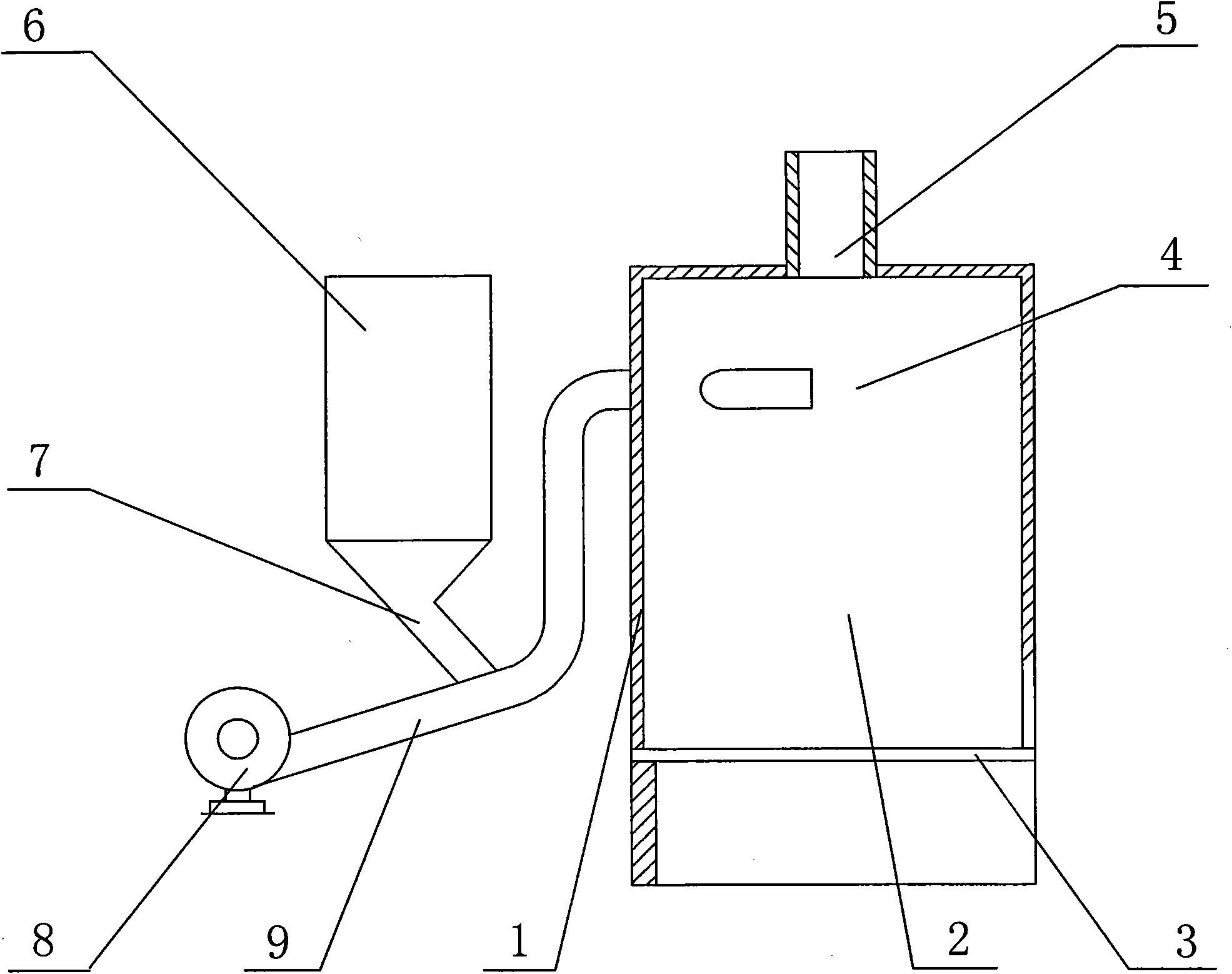

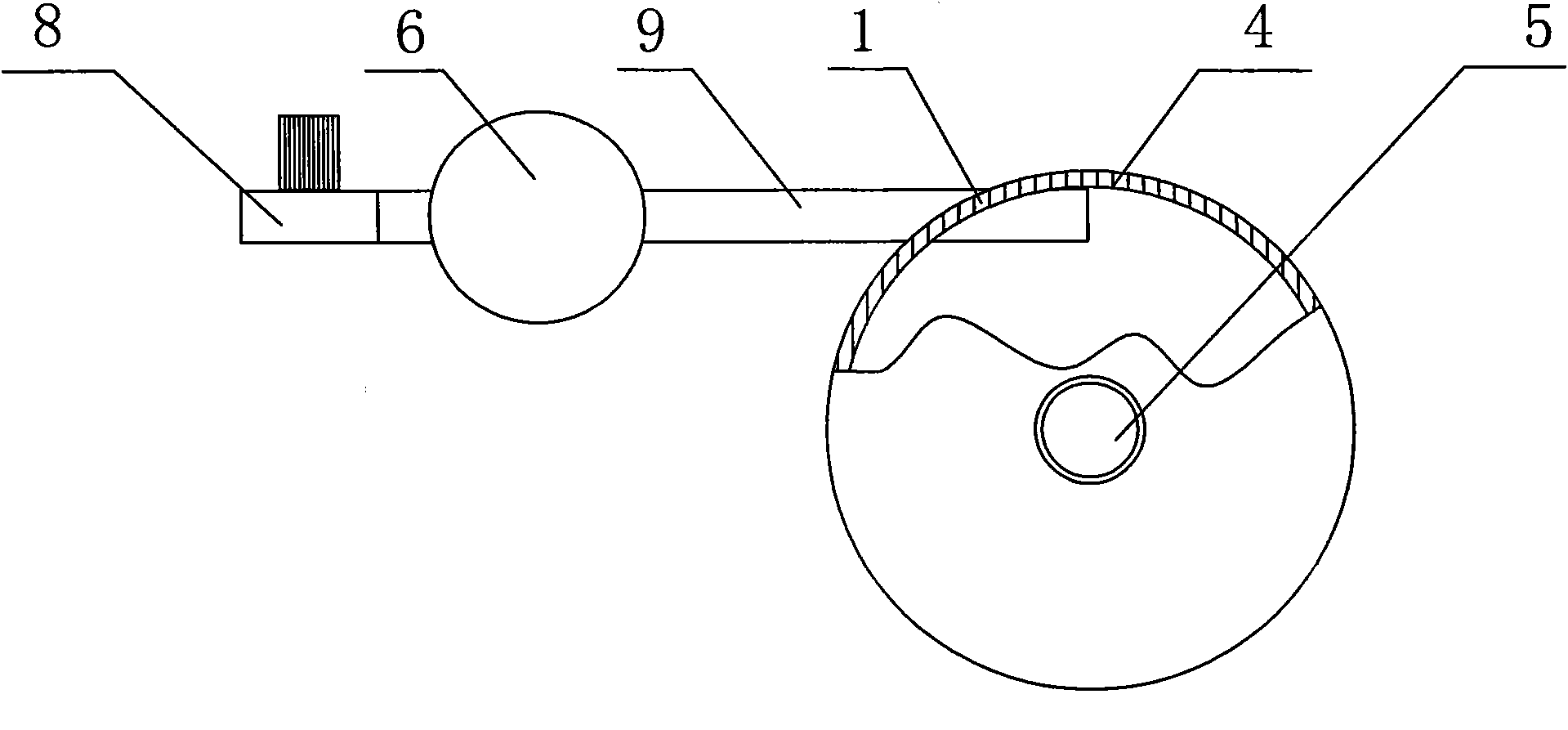

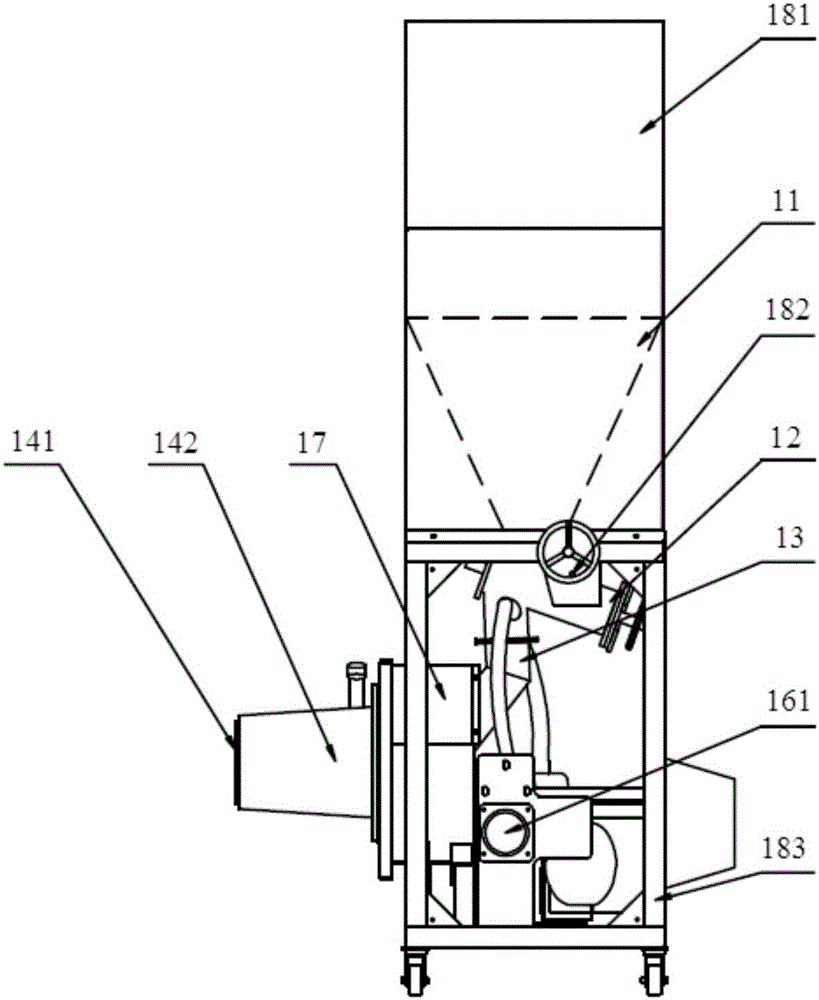

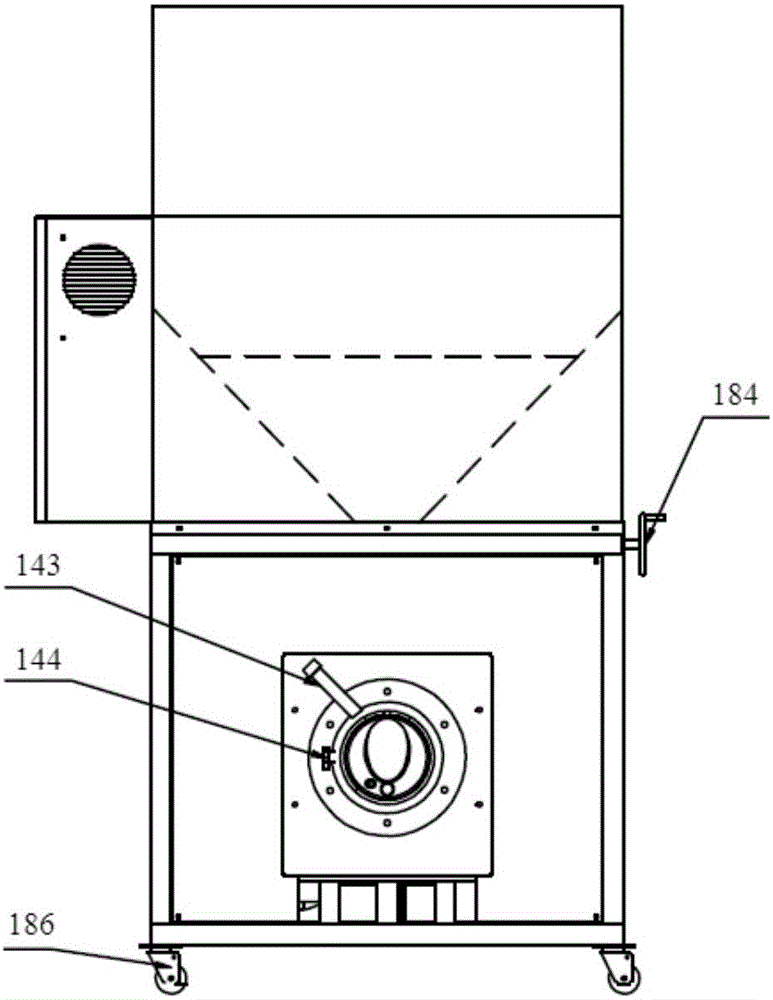

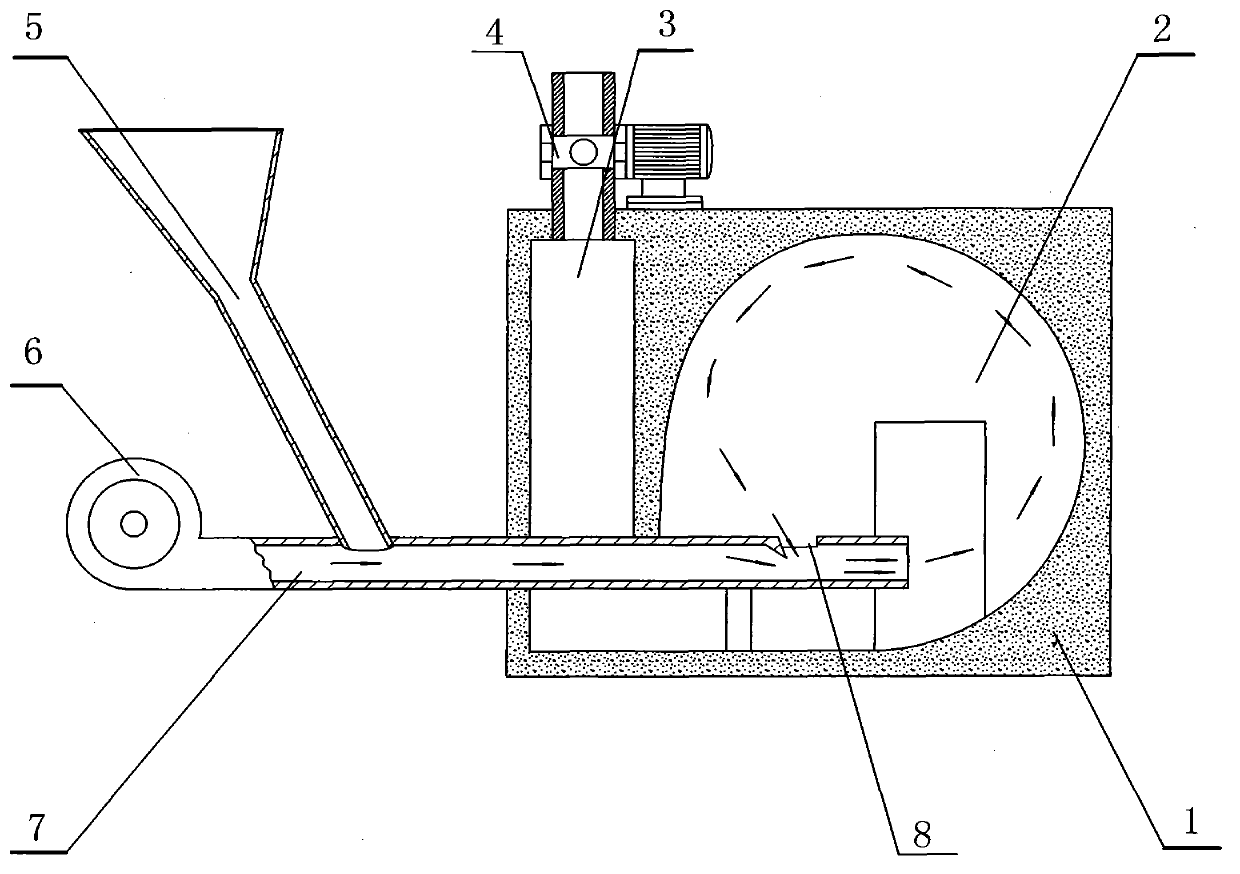

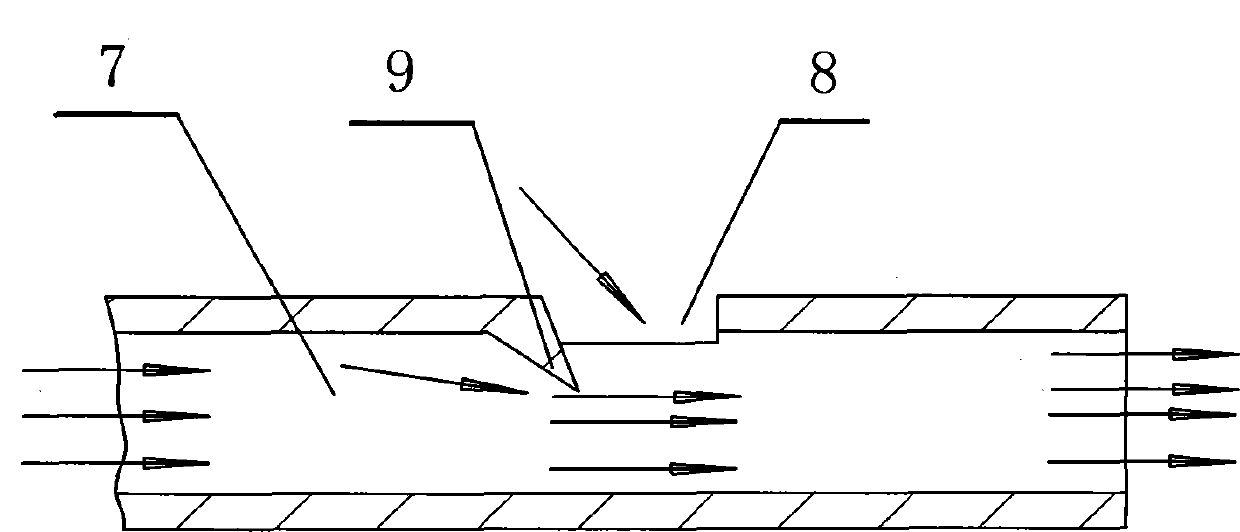

Biomass ash-free combustion furnace

ActiveCN103134177ANot easy to pile upIncrease temperatureAir heatersWater heatersThermal energyFurnace temperature

The invention relates to heat supply equipment, in particular to a biomass ash-free combustion furnace. The biomass ash-free combustion furnace is characterized in that the inner wall, faced by an end port of an air feeding pipe (7), of a hearth (2) and the inner wall, above the air feeding pipe (7), of the hearth (2) are a circular arch-shaped curved surface formed by circular arch-shaped surfaces in a smooth connection mode, a negative-pressure port (8) is formed at the upper side of the air feeding pipe (7) entering the hearth (2), combustion air at the negative-pressure port (8) firstly passes through a wind pressing piece (9), the edge of one side of the wind pressing piece (9) is bent obliquely towards the rear lower direction, and the air feeding pipe (7) outside a furnace body (1) is communicated with a fuel conveying pipe (5). The biomass ash-free combustion furnace has the advantages that fuel enters the hearth along with the wind, rotates and flies up and down, is combusted and is not accumulated easily, the unburnt fuel is sucked to the air feeding pipe and is sprayed out again for combustion, so that the combustion is more sufficient, and almost no ash is reserved. In addition, a heat storage chamber stores a large amount of heat to improve the temperature of the hearth. The air feeding pipe passes through the heat storage chamber, so that the fuel and the combustion air can be preheated, a large amount of combustion air is from the hearth, and the heat of the furnace is accumulated continuously and reaches or approaches the heat of compressed straws and coal. The biomass ash-free combustion furnace can serve as various heat exchanging equipment such as a hot blast heater, a water heater and an oil furnace, substitutes coal-fired furnaces to carry out a heat-supply operation, and has great significance of saving coal, protecting the environment, fully utilizing crop straws, improving the value of the crop straw and increasing the income for farmers.

Owner:张建臣

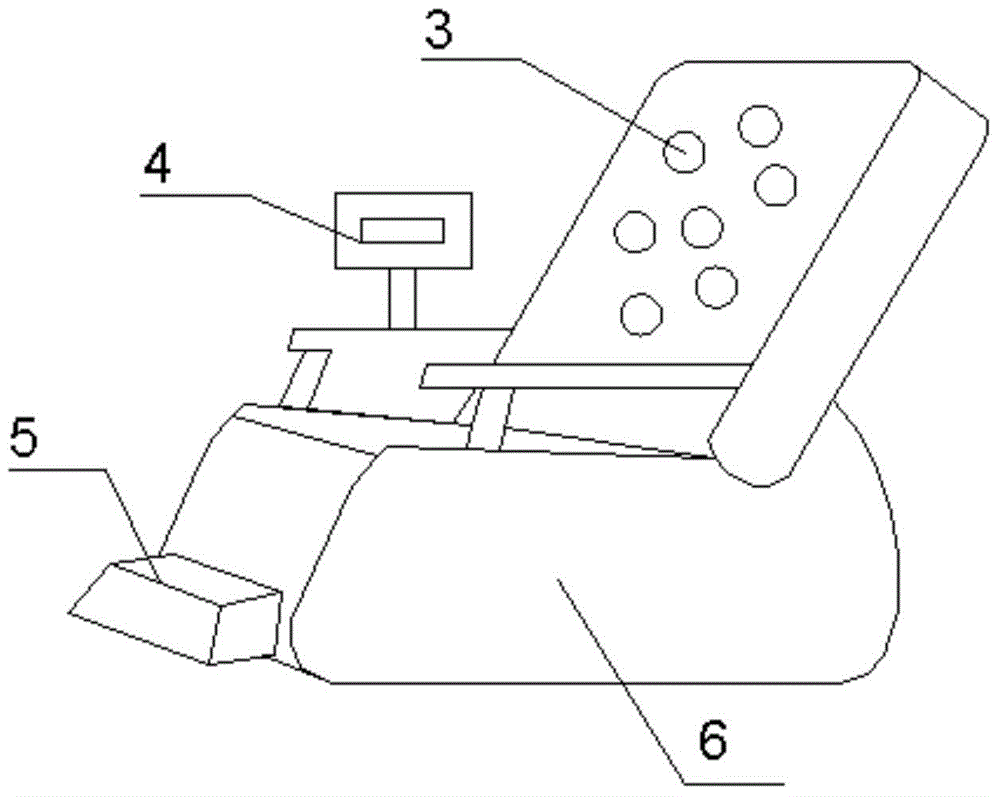

Virtual reality somatosensory interaction massage chair

The invention relates to a virtual reality somatosensory interaction massage chair which comprises an imaging device (1), an earphone (2), a massage and induction device (3), a console (4), a pedal (5) and a built-in line and a heat supply device (6). The working principle is as follows: various physical parameters and physiological conditions and the like of the human body are collected through the massage and induction device (3) on the massage chair and transmitted to the console (4), the temperature and dynamics and the like suitable for users are analyzed, instructions are transmitted to the imaging device (1), the earphone (2), the massage and induction device (3) and the built-in line and the heat supply device (6), the massage standard is regulated in real time, the virtual scene is provided, and different kinds of enjoyment is brought to users. According to the virtual reality somatosensory interaction massage chair, according to the different users' physiological element changes, the massage temperature, the degree of massage force and angle and the like are adjusted synchronously, and the injury to the human body caused by the situation that a machine executes operation instructions blindly is avoided. Through virtual images revealed in intelligent glasses and the sound effect played by the earphone, body and mind enjoyment is provided.

Owner:NANJING ZHUANCHUANG INTPROP SERVICES

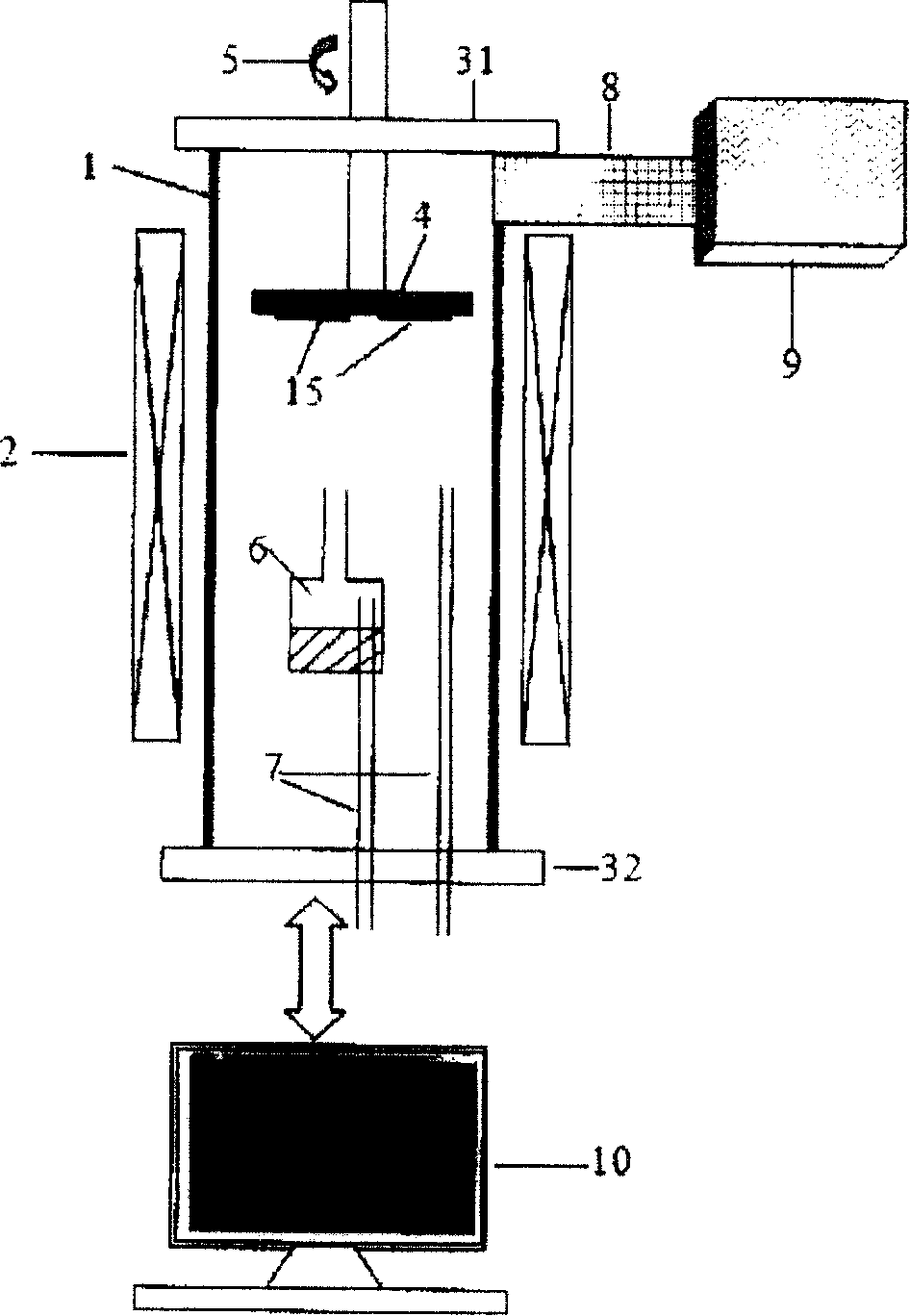

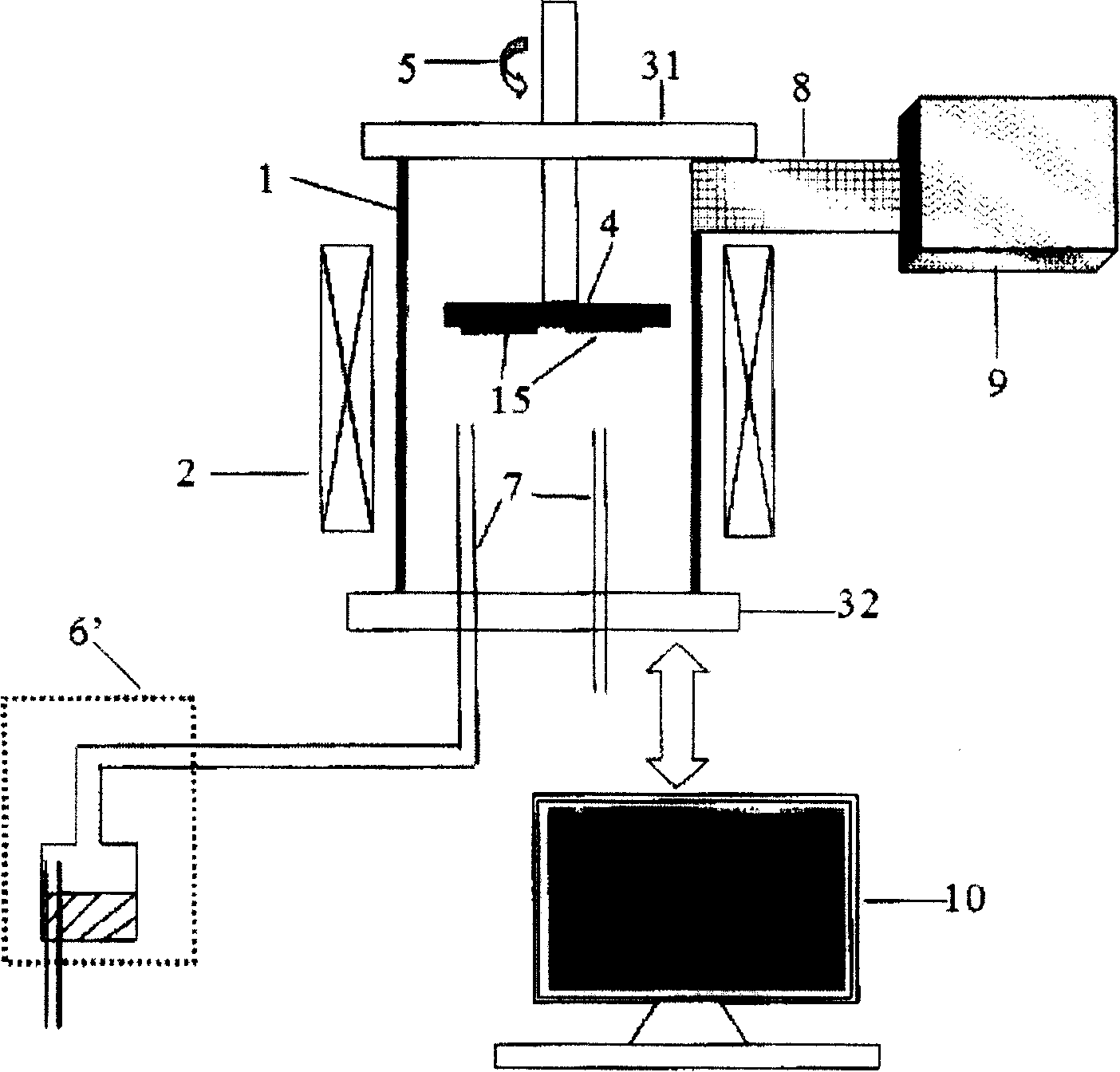

Hydride gas-phase epitaxy apparatus for preparing nitride monocrystalline substrate

InactiveCN101205627AImprove uniformityQuality improvementFrom chemically reactive gasesAutomatic controlGas phase

The invention provides a hydride gas phase epitaxial device of preparing nitride monocrystal substrate, which comprises an epitaxial growth chamber which is vertically arranged; a chassis which are arranged on the upper head face and the lower head face of the epitaxial growth chamber for sealing; a substrate device which is arranged at the upper side in the epitaxial growth chamber with the substrate arranging mode of face downwards; a governor motor which is connected with the substrate device outside the growth chamber to control the speed of the substrate device; a metal reacting source placer which is positioned under the substrate device in the epitaxial growth chamber or outside of a reaction furnace; a reaction gas pipeline which enters into the epitaxial growth chamber through the chassis of the lower head face of the growth chamber, wherein, supporting gas enters into the epitaxial growth chamber through the reaction gas pipeline, carries reaction gas, flows upwards onto the substrate, and conducts a reaction for growing the nitride monocrystal substrate; an outgrowth gathering unit which is connected with an outlet of the epitaxial growth chamber to gather outgrowth of the reaction, thereby preventing the reaction gas pipeline from being blocked; a heating plant which is surrounded with the outer annulus of the epitaxial growth chamber; and an automatic control system for controlling.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Conditioning and/or heating plant and process of controlling the same plant

ActiveUS20170067662A1Convenient energy managementReduce the temperaturePlug valvesOperating means/releasing devices for valvesProcess engineeringIndustrial engineering

A conditioning or heating plant and a process of controlling the plant, wherein plant comprises at least one circuit for distributing a carrier fluid, having a delivery line, a return line, and a plurality of channels directly or indirectly connected to the delivery line and return line and configured for supplying respective environments to be conditioned and / or heated, at least one heat treatment central group placed on the circuit. The plant has, for each of the channels, at least one respective heat exchange unit and at least one flow-rate regulator.

Owner:FIMCIM SPA

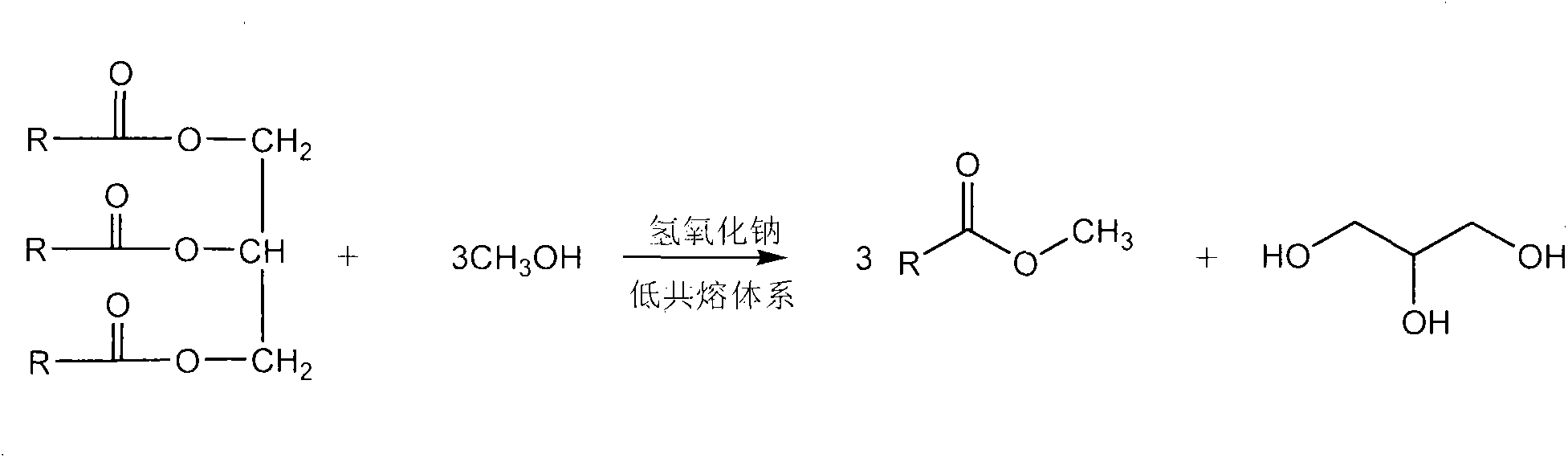

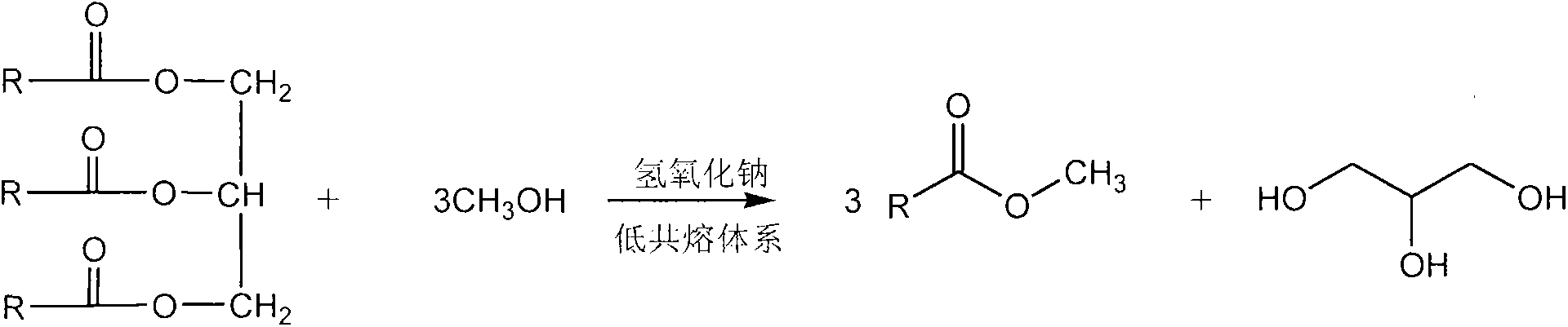

Method for preparing biodiesel in eutectic system

InactiveCN103525561ALow costHigh catalytic activityFatty acid esterificationBiofuelsBiodieselGlycerol

The invention discloses a method for preparing biodiesel in a eutectic system. The biodiesel is prepared by stirring and heating plant oil and methyl alcohol, which are used as raw materials, under normal pressure. The method has the advantages that a sodium hydroxide catalyst is adopted, so that the cost is low, the catalysis activity is high, and the using amount is small; the reaction conditions are mild, and the reaction can be executed under normal pressure and methyl alcohol backflow temperature conditions; a eutectic solvent consists of choline chloride and glycerinum, so that an emulsification phenomenon is avoided, and the technical flow is simplified; the product is high in purity and contains few impurities; the eutectic catalysis system consisting of the eutectic solvent and the sodium hydroxide is easy to recycle and use and has an environment-friendly effect.

Owner:YANCHENG TEACHERS UNIV

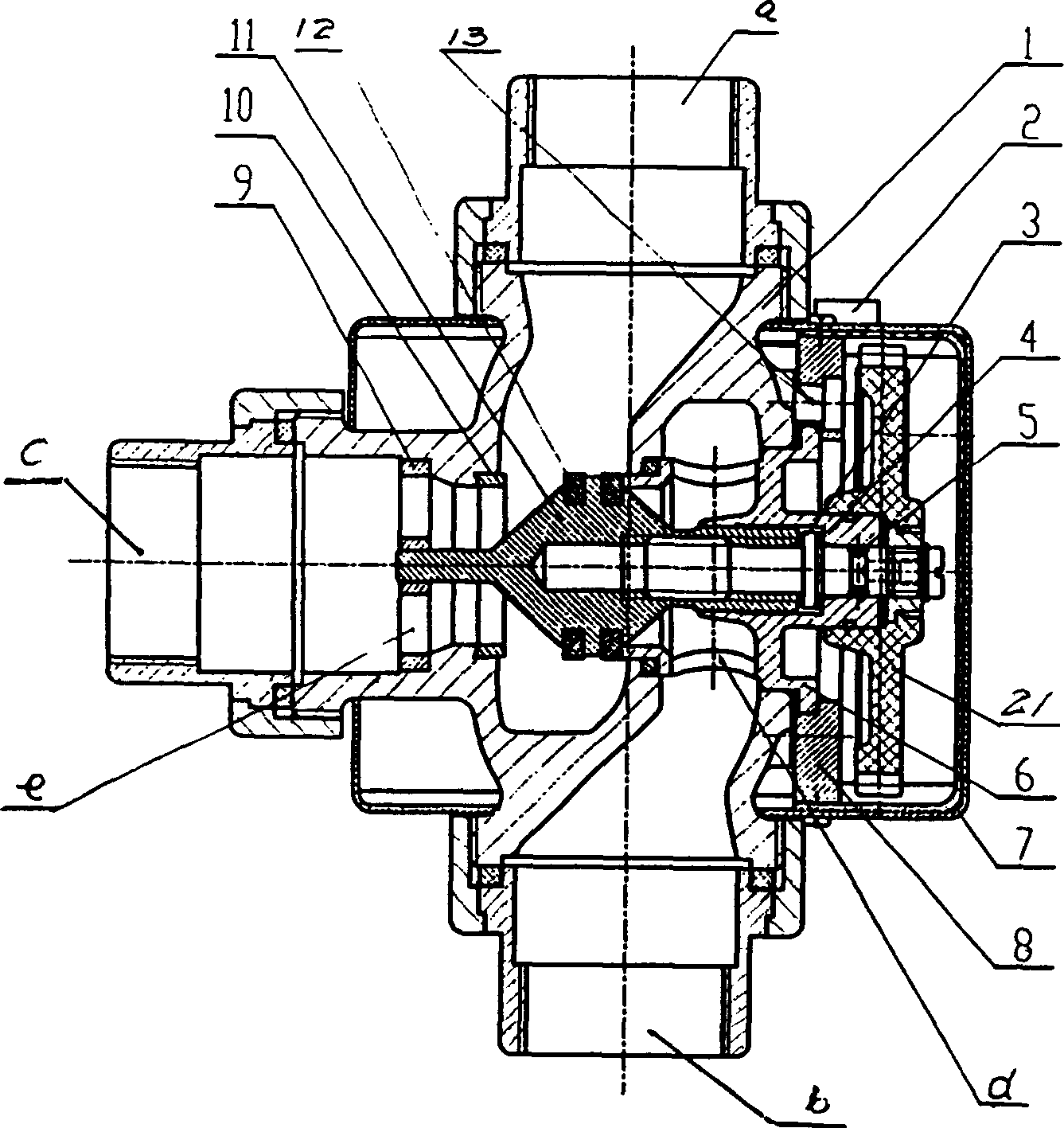

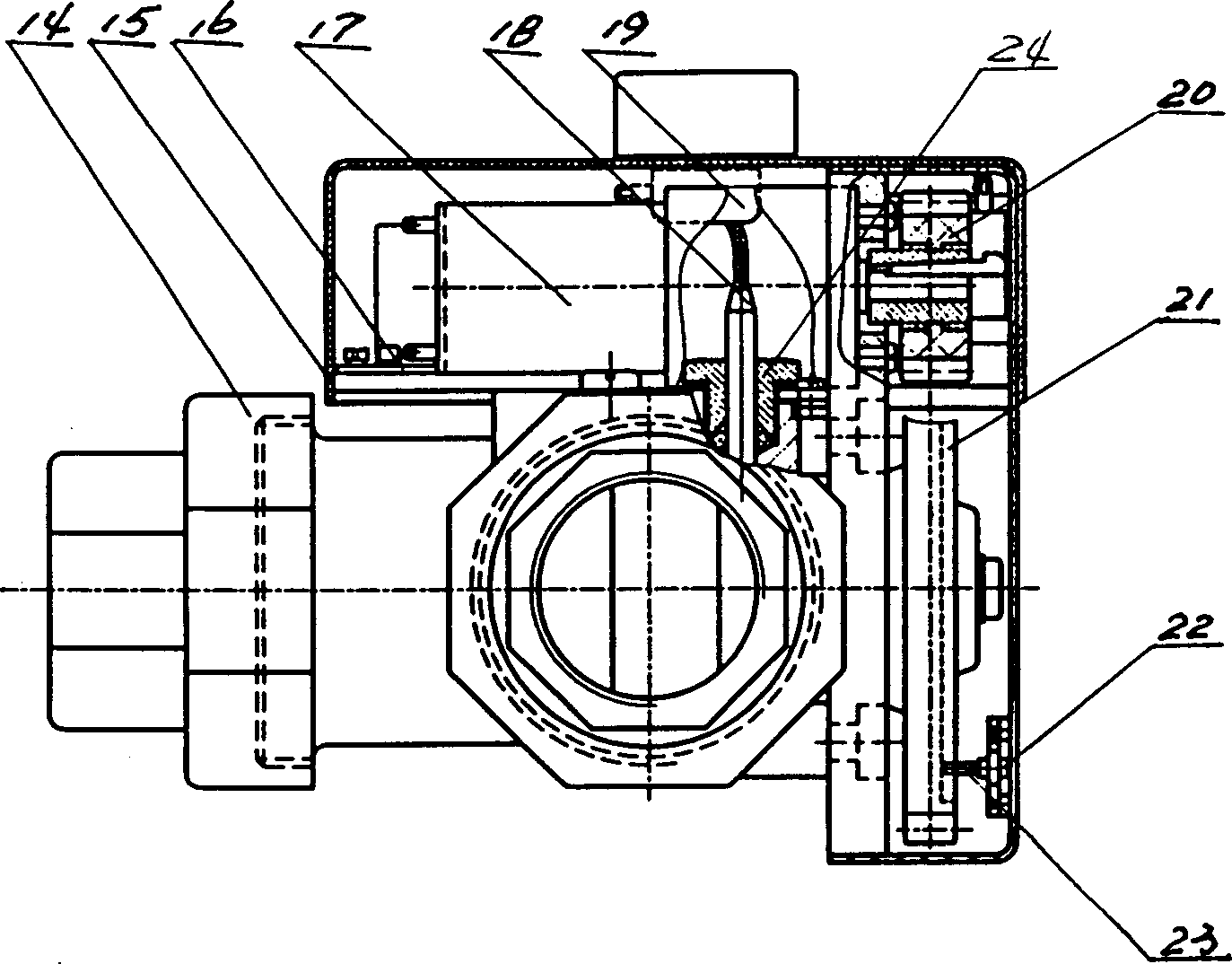

Intelligent electric stop valve for three-way flow proportional distribution

InactiveCN1779305AAccurate temperature measurementSimple structureOperating means/releasing devices for valvesMultiple way valvesControl valvesScrew thread

The invention relates to a flow control valve for use in the heating plant, which consists of a valve body connected with an liquid inlet, an outlet and a bypass liquid outlet. The generator is firm-jointed on the connection board and its shaft is firm-jointed with the gear. The gear is connected with the valve stem. The top cover interlinked on the valve stem and the spool is firm-jointed on the valve body via the connection board. The spool is disposed on the valve stem. The internal thread disposed in the inner hole of the spool is connected with the thread of the valve stem. A guide seat with the through-hole is disposed under the spool and in its centre is set the guide hole, into which is inserted the bottom end of the spool. The sealing seat ring of the valve body disposed in the inner cavity of the bypass liquid outlet is closed with the sealing washer on the spool.

Owner:甘肃德邦智能机电科技有限公司

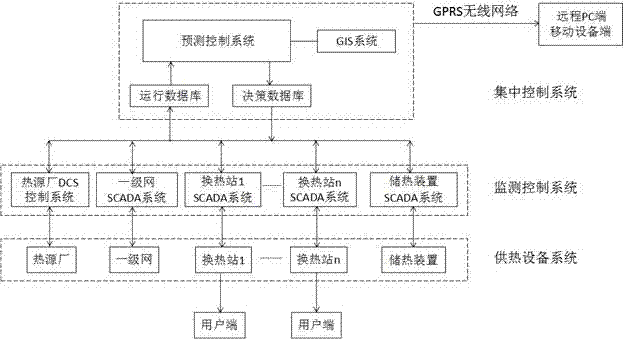

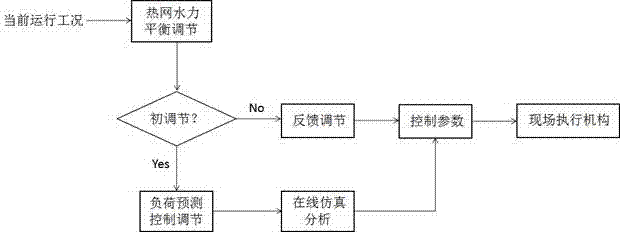

Intelligent control system for centralized heating

InactiveCN107491020AEasy to viewUsage optimizationProgramme controlComputer controlLoad forecastingEngineering

The invention discloses an intelligent control system for centralized heating. The system comprises a centralized control system, a monitoring control system and a heating equipment system. By using a communication network, a heat source factory, a primary network, a plurality of subordinate heat exchange stations and a heat storage device are connected for centralized management, according to actual heating use loads of different user ends of different stages of a heating period, through a prediction control system with a load prediction module and a virtual simulation module, the comprehensive control of the heat source factory, the primary network, the subordinate heat exchange stations and the heat storage device is carried out, the optimization of heating temperature and coal consumption is realized, and an effect of energy saving is achieved while the heating is ensured. The centralized control system established based on GIS system is remotely connected to PC end or a mobile equipment end through a GPRS wireless network, inspection personnel views equipment and parameters of pipeline temperature, repairs and records in real time, convenience is brought to a user to view real-time heating temperature and give a feedback, and the efficiency of production safety is greatly improved.

Owner:ZHONGQINGYUAN ENVIRONMENTAL PROTECTION ENERGY SAVING

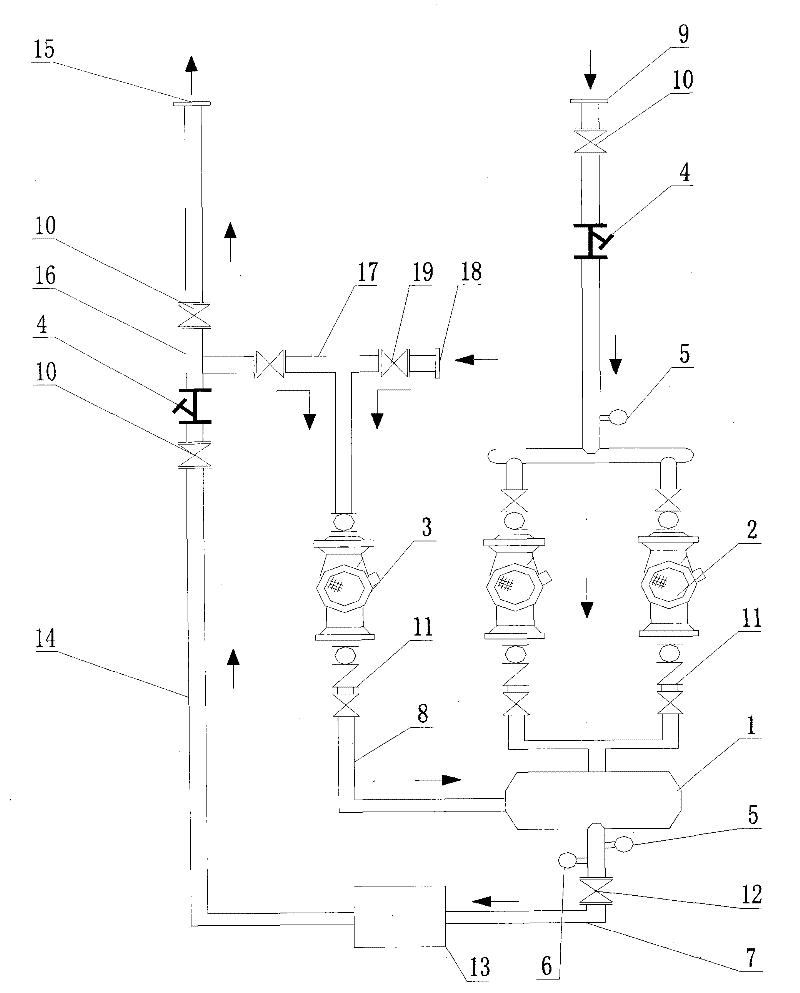

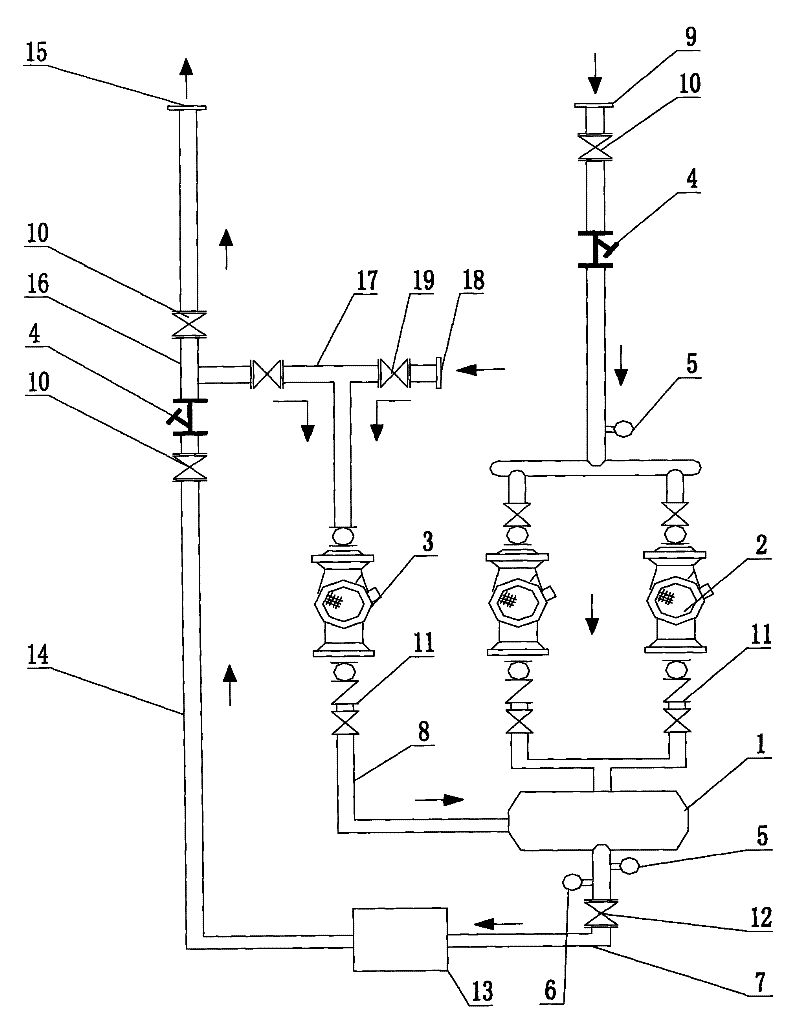

Heat supply equipment

InactiveCN102538067AReduce consumptionReduce labor intensityLighting and heating apparatusSpace heating and ventilation detailsWater useSoftened water

The invention discloses heat supply equipment which consists of a mixer, a valve, a sensor, a circular pump, a temperature regulating pump, a filter, a connecting tube and a control system, wherein a water inlet of the circular pump passes through the filter and the valve and then is directly connected with a high-temperature water source pipe mouth of a heating station; a water pump outlet passes through a valve blank and then is connected with the mixer; a mixer outlet passes through the valve and then is connected with the heat equipment; an outlet of the temperature regulating pump passes through the valve blank and then is connected with the mixer; an inlet of the temperature regulating pump is connected with a water supplementing port through one end of a tee joint; the other end of the temperature regulating pump is connected with a low-temperature water return pipe; and the low-temperature water return pipe is respectively connected with the heat equipment and a reclaimed water pipe mouth of the heating station through the tee joint. Due to the adoption of the structure, high-temperature incoming water of the heating station is pressurized into the mixer by the circular pump; meanwhile, low-temperature water in water reclaimed by a user or normal temperature softened water used for the first time is pumped into the mixer by the temperature regulating pump; and the mixer is used for mixing two kinds of water with different temperatures, and then conveying the water to the inside of the heat equipment of the user after the temperature of water is reduced to the temperature of the water required by the user, to form a heat supply system.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

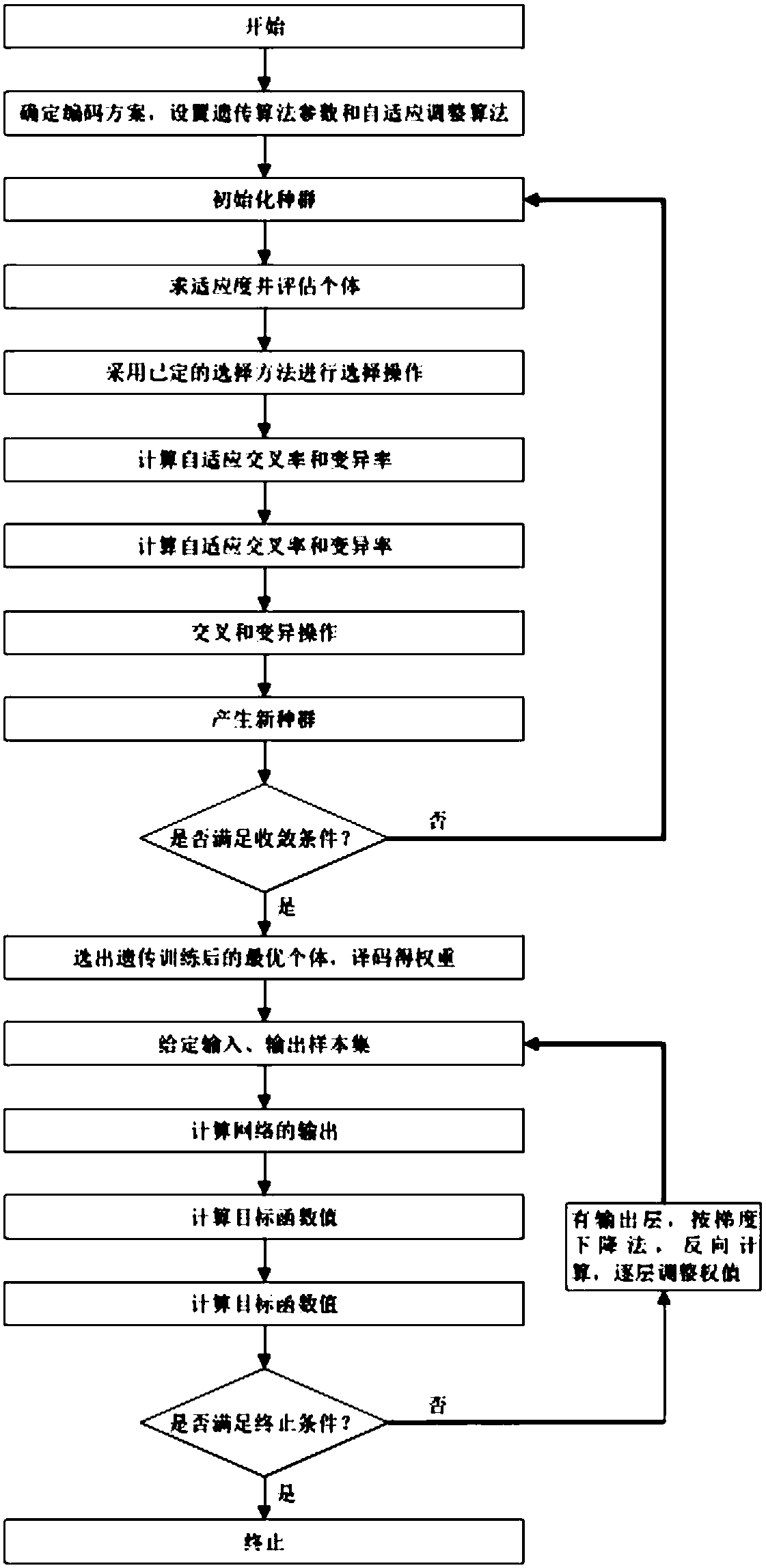

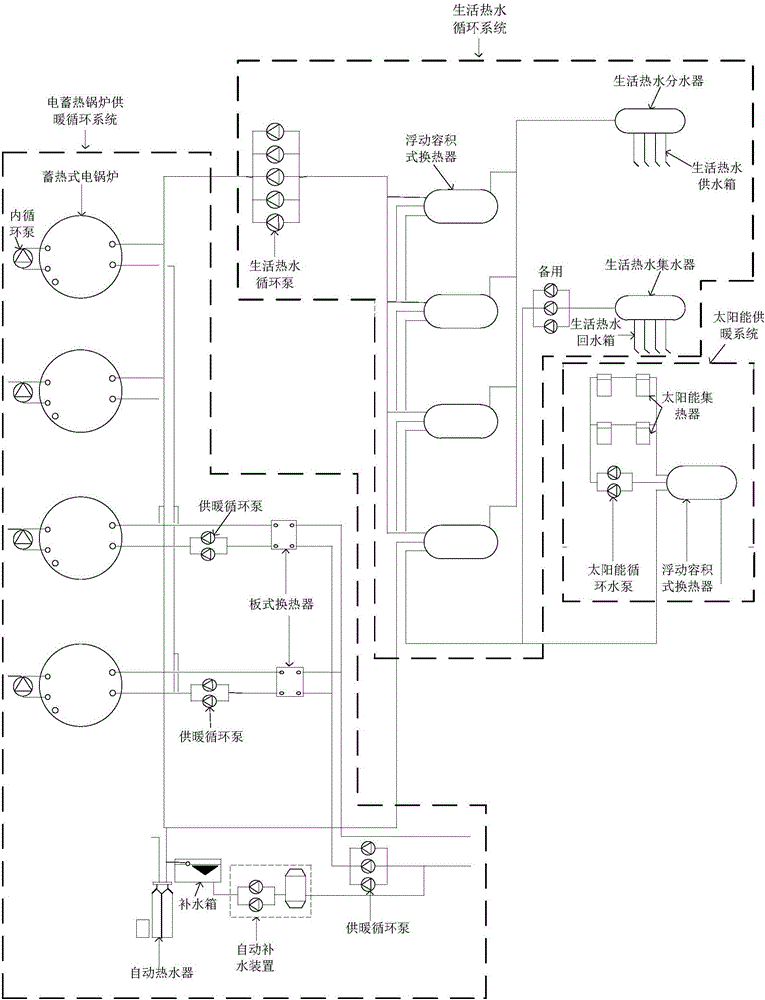

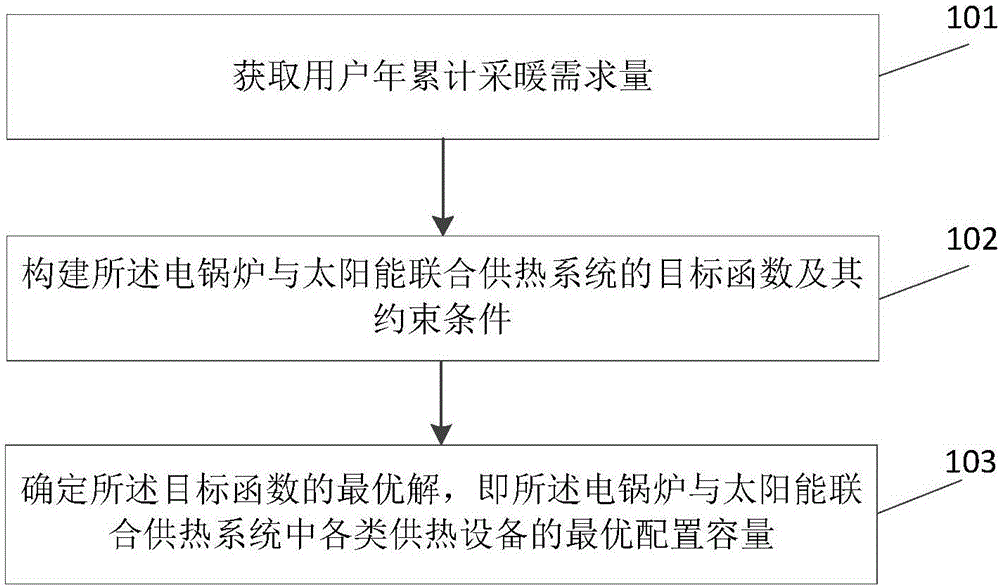

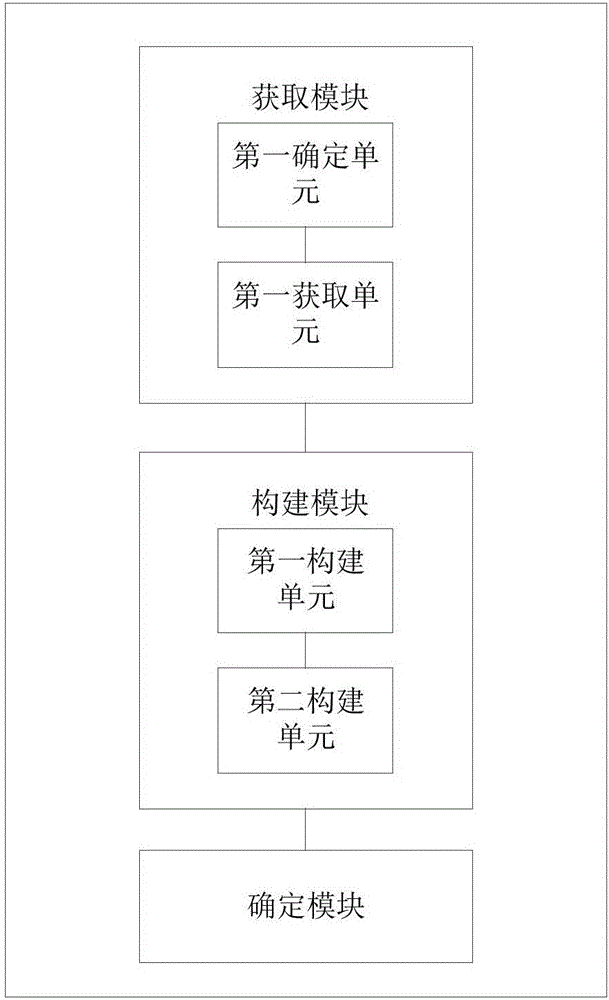

Method and device for configuring equipment capacity of electric boiler and solar heating system

ActiveCN106503466AHigh economic advantageFacilitates modeling of annual value of expensesInformaticsSpecial data processing applicationsEconomic benefitsGenetic algorithm

The invention relates to a method and a device for configuring the capacity of an electric boiler and a solar heating system. The method comprises the following steps: obtaining the accumulated heating demand of the user; setting up the objective function and the constraint conditions of the electric boiler and the solar heating system; determining the optimal solution of the objective function which means the optimal allocation capacity of the heating equipment in the electric boiler and the solar heating system; The invention provides a method which is based on a genetic algorithm of the optimization algorithm that can be used as an optimization method for the global search of complex systems. The equipment configuration is optimized by generations and finally lowest annual cost of the combined capacity can be obtained, so that the utilization rate of energy can be improved, higher economic benefits and environmental benefits can also be achieved, and it also has important significance and reference value to the engineering practice.

Owner:CHINA ELECTRIC POWER RES INST +2

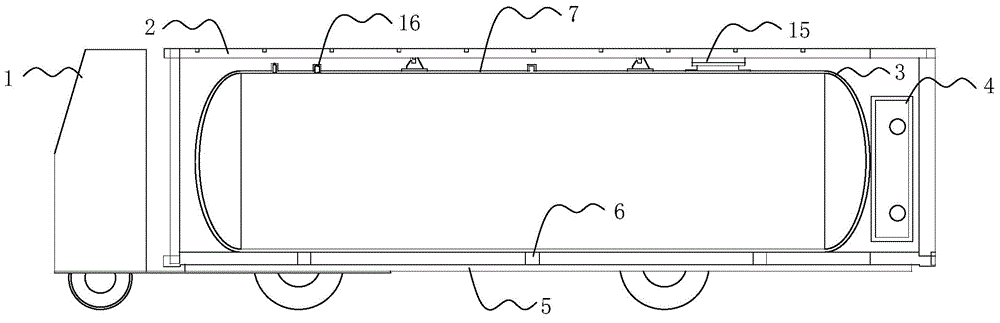

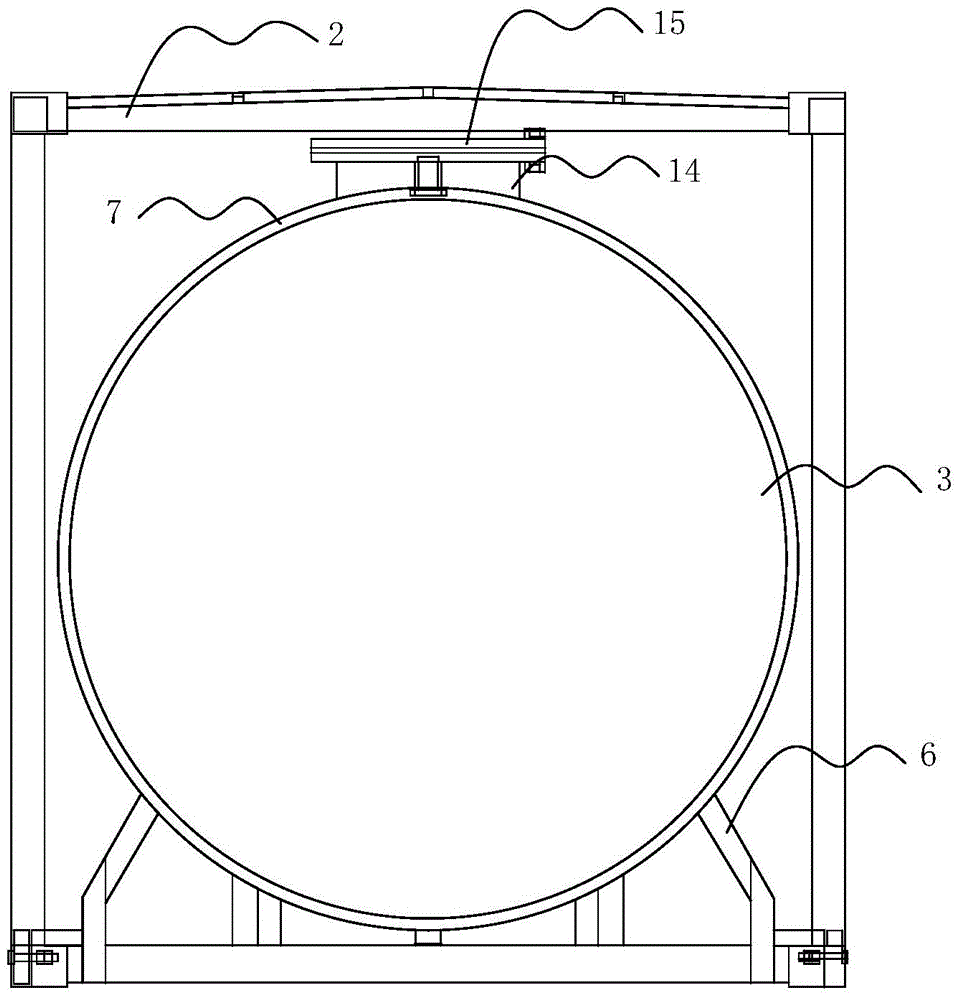

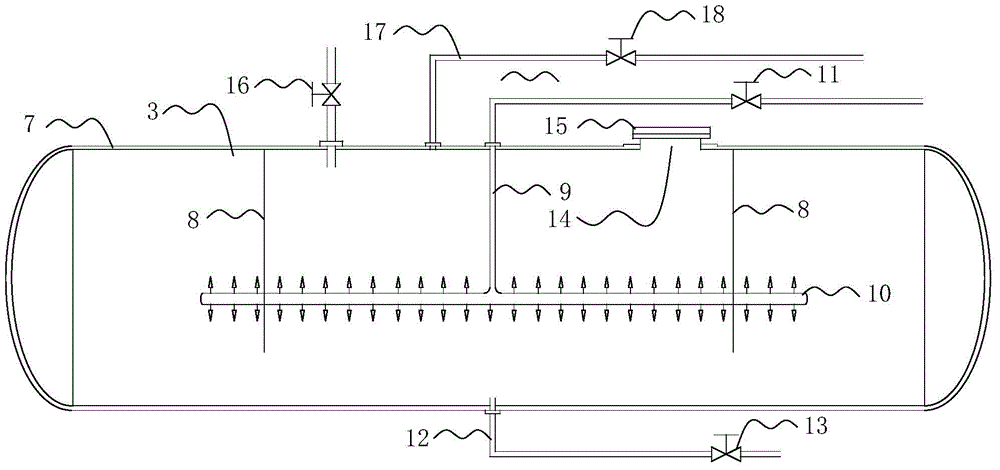

Separable tank container movable heating plant with high stored energy

ActiveCN104696936AAdaptableImprove heat storage capacityStorage heatersItem transportation vehiclesEngineeringTank container

The invention discloses a separable tank container movable heating plant with high stored energy. The separable tank container movable heating plant comprises a motor tractor, a steel framework, a heat storage tank and an operation control box, wherein a trailer is connected with the rear part of the motor tractor; the steel framework is mounted on the trailer; the heat storage tank is mounted in the steel framework through a pedestal arranged at the bottom of the steel framework; an insulating layer is arranged on the outer wall of the heat storage tank; two vertical fluid baffles are arranged inside the heat storage tank; an access hole is formed in the top of the heat storage tank; a cover is arranged on the access hole; a safety valve is arranged at the top of the access hole side of the heat storage tank; a steam output tube is further arranged at the top of the heat storage tank; a steam outlet control valve is arranged at the steam output tube; the operation control box is arranged at the rear side of the heat storage tank and positioned in the steel framework. The movable heating plant has the advantages of being high in heat storage capacity, high in waste heat recovery utilization ratio, capable of reducing the heat supplying transportation cost, high in practicability and the like.

Owner:QINGDAO AOHUAN NEW ENERGY GRP CO LTD

Carbonaceous material for negative electrodes of lithium ion capacitors and method for producing same

ActiveUS20150270072A1Excellent electrical propertiesEfficient removalGraphiteElectrolytic capacitorsHalogenGas phase

The object of the present invention is to provide a manufacturing method of carbonaceous material for a negative electrode of lithium ion capacitors, wherein the carbonaceous material is obtained from plant-derived char as a source, potassium and iron are sufficiently removed, and an average particle diameter thereof is small; and a carbonaceous material for a negative electrode of lithium ion capacitors.The object can be solved by a method for manufacturing a carbonaceous material having an average diameter of 3 to 30 μm, for a negative electrode of lithium ion capacitors comprising the steps of: (1) heating plant-derived char having an average particle diameter of 100 to 10000 μm at 500° C. to 1250° C. under an inert gas atmosphere containing a halogen compound to demineralize in a gas-phase, (2) pulverizing a carbon precursor obtained by the demineralization in a gas-phase, (3) calcining the pulverized carbon precursor at less than 1100° C. under a non-oxidizing gas atmosphere.

Owner:KURARAY CO LTD

Method for direct conversion of plant soapstock into fatty acid

InactiveCN105754724ANothing producedNo pollution in the processFatty oils/acids recovery from wasteFatty acid chemical modificationIodo fatty acidWastewater

The invention relates to a method for direct conversion of plant soapstock into fatty acid. The method includes: heating plant soapstock by a preheater and conveying it into a high-speed stirring reactor, and fully stirring the plant soapstock with quantitative sulfuric acid, then conducting secondary mixing through a static mixer, then carrying out stirring reaction in a reaction kettle, then performing deslagging and dehydration through a reaction precipitation tank to obtain high yield fatty acid. And the discharged water is returned to a raw material tank to carry out acid-base reaction with plant soapstock raw material, and part of the generated fatty acid enters the next cycle. The invention is a new approach for direct generation of fatty acid by continuous acidification of plant soapstock, and avoids the procedure of producing soapstock into acid oil and then performing hydrolysis. The method provided by the invention has the characteristics of easy technological operation, complete reaction of plant soapstock and sulfuric acid, small sulfuric acid dosage, thorough acidification and direct generation of fatty acid, large device treatment capacity, stable quality, no odor, low energy consumption, low cost, no wastewater production, and energy saving and environmental protection.

Owner:九江力山环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com