Straw fuel flying furnace

A fly-burning furnace and fuel technology, applied in the field of heating equipment, can solve the problems of restriction implementation and cost increase, and achieve the effects of not easy to pile up, save coal, and make full use of it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

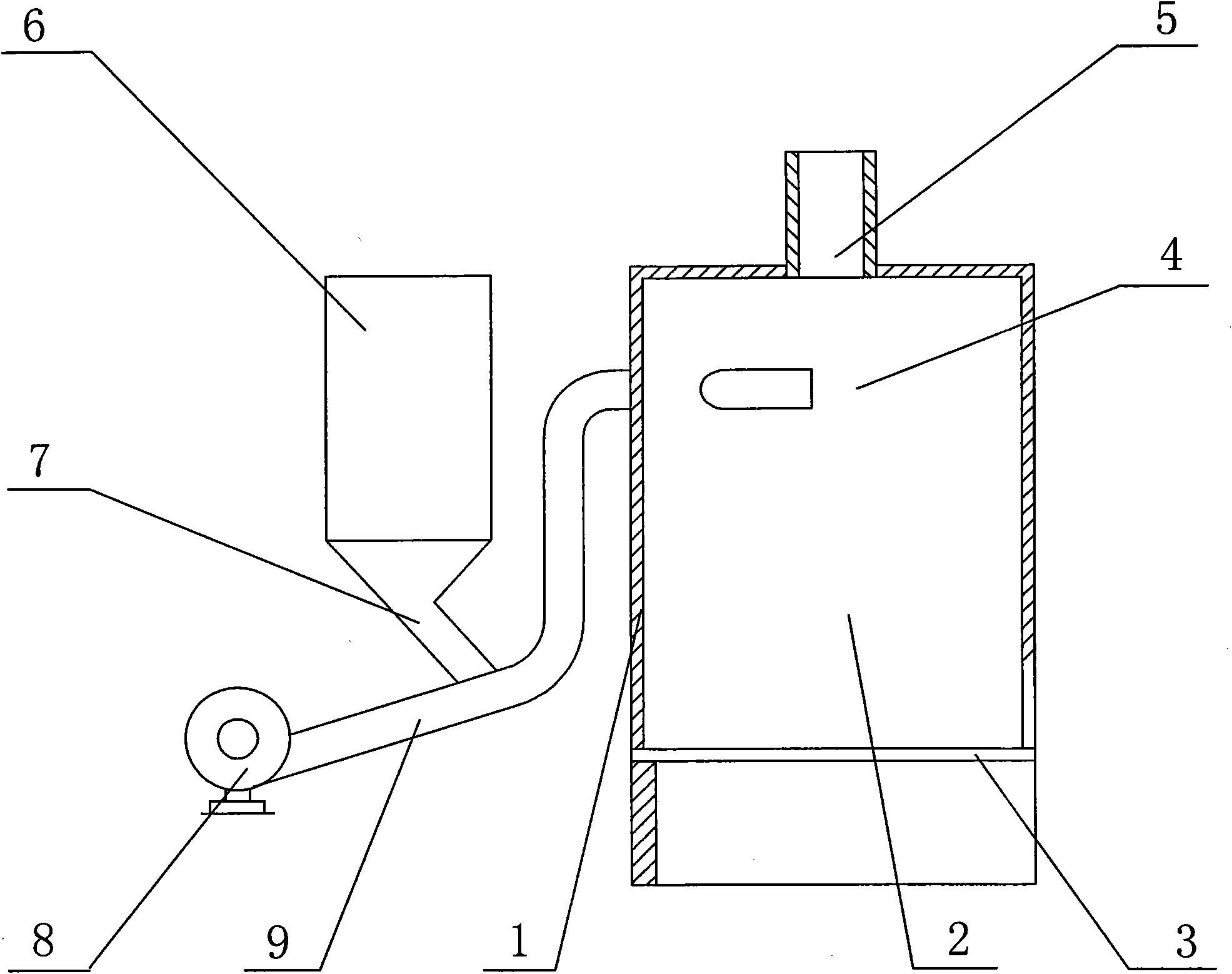

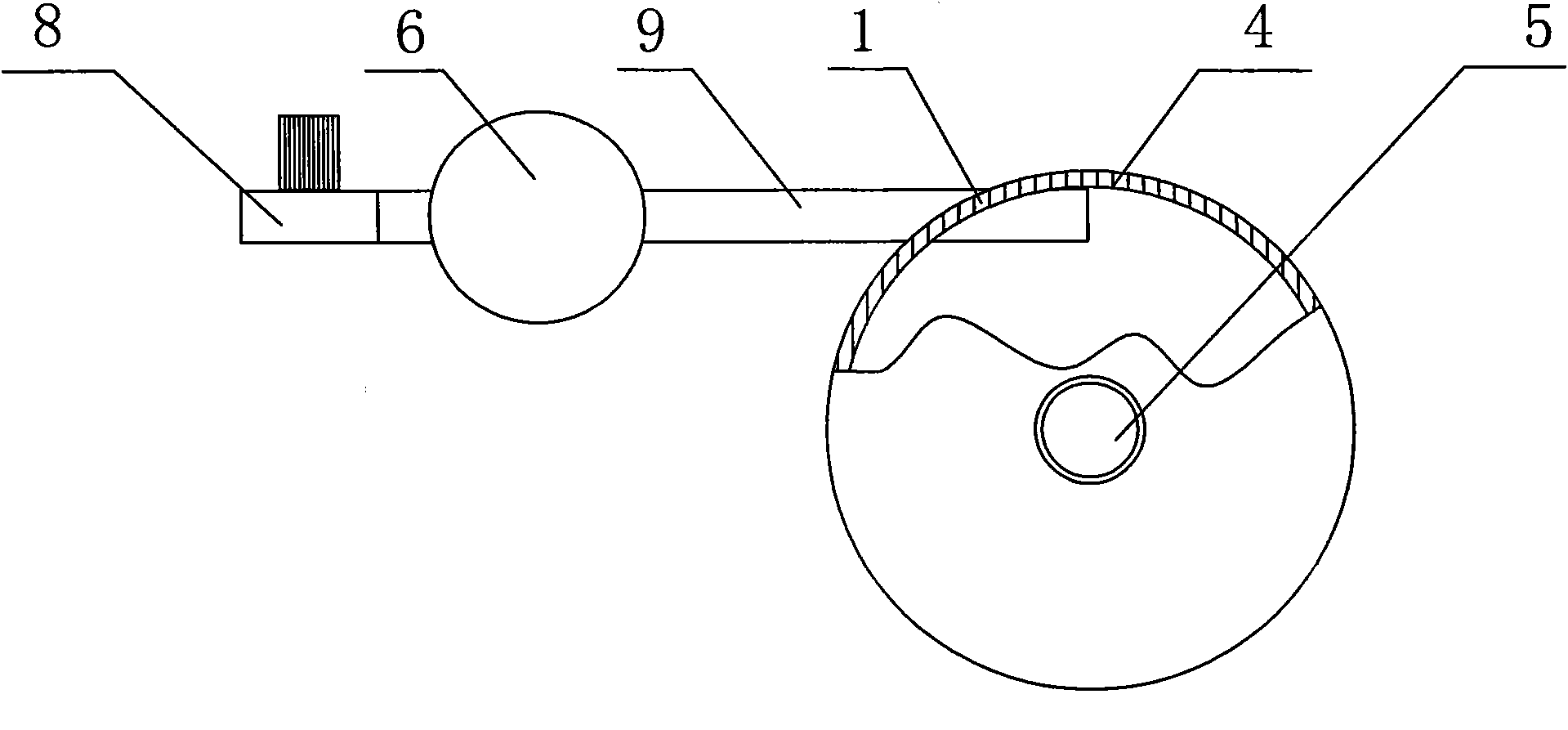

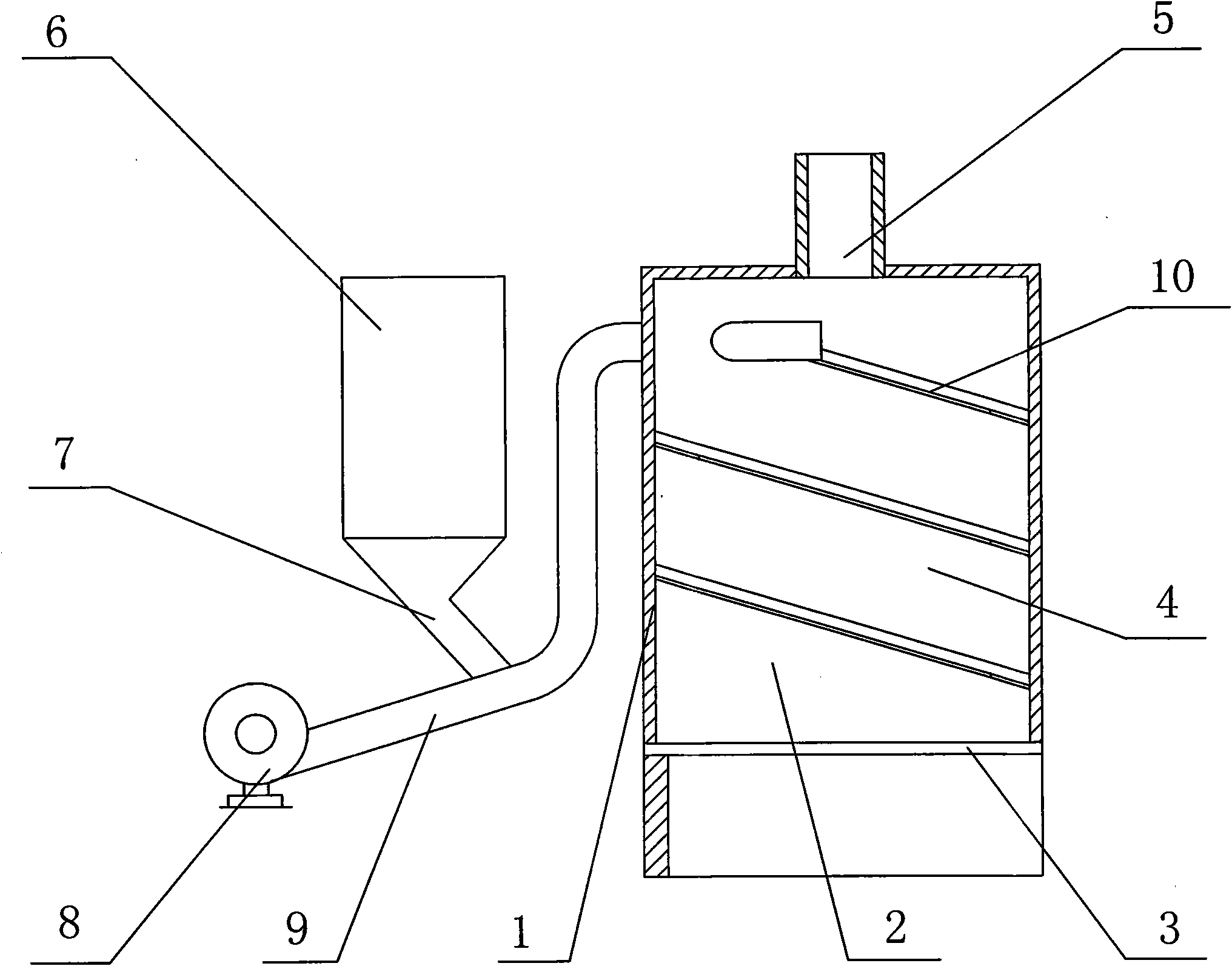

[0039] The first example: as figure 1 , 2 As shown, this straw burning furnace is composed of a furnace body 1, a furnace hearth 2, a grate 3, a smoke exhaust pipe 5, and the like. Outside the furnace body 3, there is a fuel hopper 6, and below the fuel hopper 6 there is a downwardly extending drop pipe 7. A fan 8 is provided below the fuel hopper 6 , and the end of the air supply pipe 9 of the fan 8 enters the furnace 2 . The blanking pipe 7 under the fuel hopper 6 communicates with the air supply pipe 9 . The air supply pipe 9 of the fan 8 contacts a section of the cyclone guide curved surface 4 after entering the furnace 2 . There are various forms of the cyclone guide curved surface 4. In this example, the inner wall of the circular furnace body 1 is borrowed. In order to use this inner wall, the outer end of the air supply pipe 9 is at the upper part of the furnace chamber 2, along the tangent of the arc surface of the inner wall of the furnace chamber. Directions int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com