Hydride gas-phase epitaxy apparatus for preparing nitride monocrystalline substrate

A hydride gas phase, nitride technology, applied in the direction of single crystal growth, chemical reactive gas, crystal growth, etc., can solve the problems of poor temperature uniformity, poor repeatability, poor controllability of metal halides, etc., to reduce the growth cost. , the effect of high growth rate and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

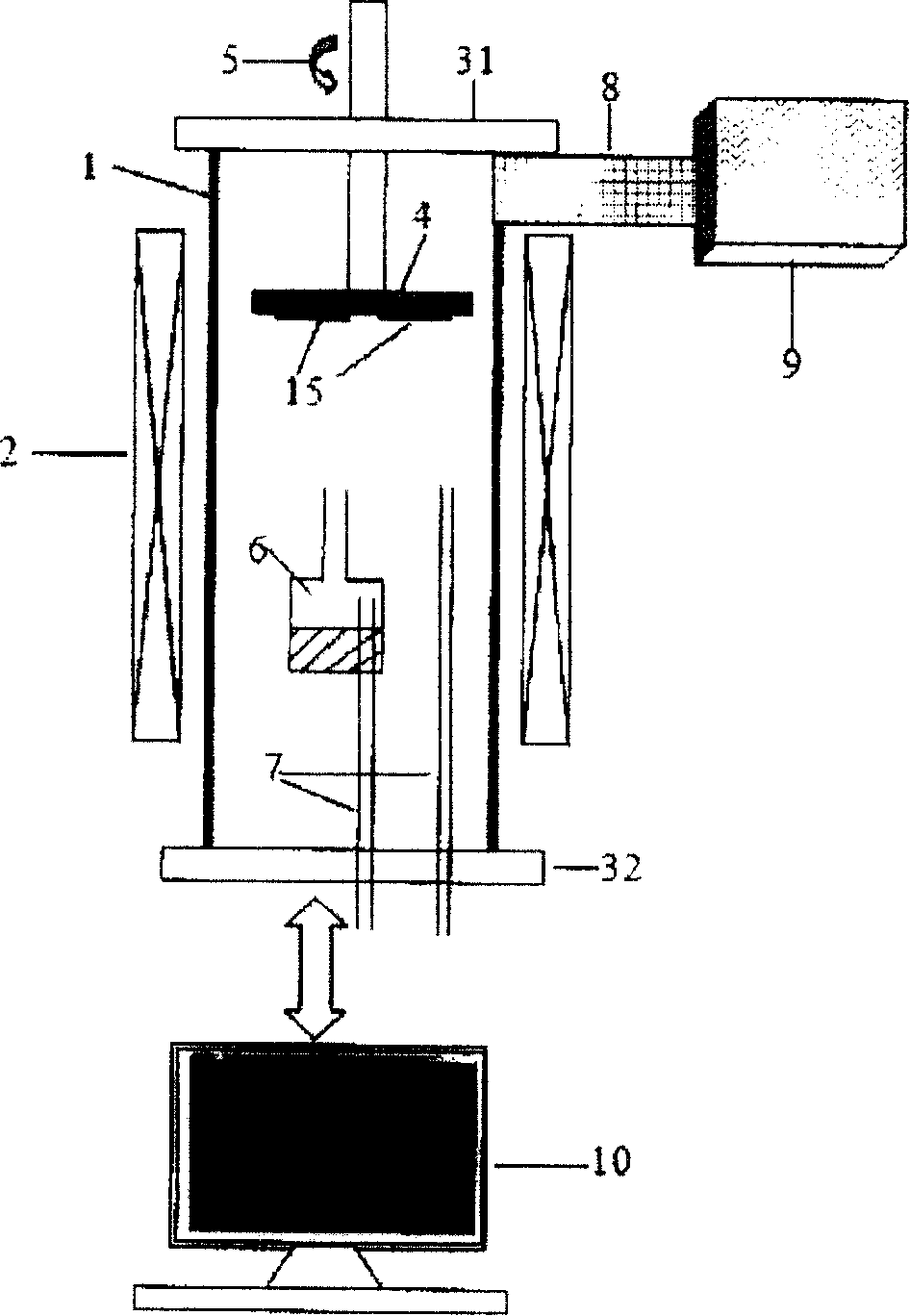

[0042] Such as figure 1 Shown is a schematic structural diagram of this embodiment. The device can add a vacuum pump to grow from low pressure to normal pressure. The device consists of epitaxial growth chamber 1, heating device 2, upper and lower chassis 31 and 32, substrate device 4, speed regulating motor 5, metal reaction source placer 6, reaction The gas pipeline 7, the by-product collection device 8, the wet waste gas treatment device 9 and the automatic control system 10 are composed. Wherein, the epitaxial growth chamber 1 is vertically arranged, and the heating device 2 is heated around the outer circumference of the epitaxial growth chamber 1, and the upper and lower ends of the epitaxial growth chamber 1 are equipped with a chassis 31 for sealing; the substrate device 4 enters from above the epitaxial growth chamber 1, and the substrate 15 is placed face down; the substrate device 4 is connected with a speed-regulating motor 5 outside the growth chamber; the metal ...

Embodiment 2

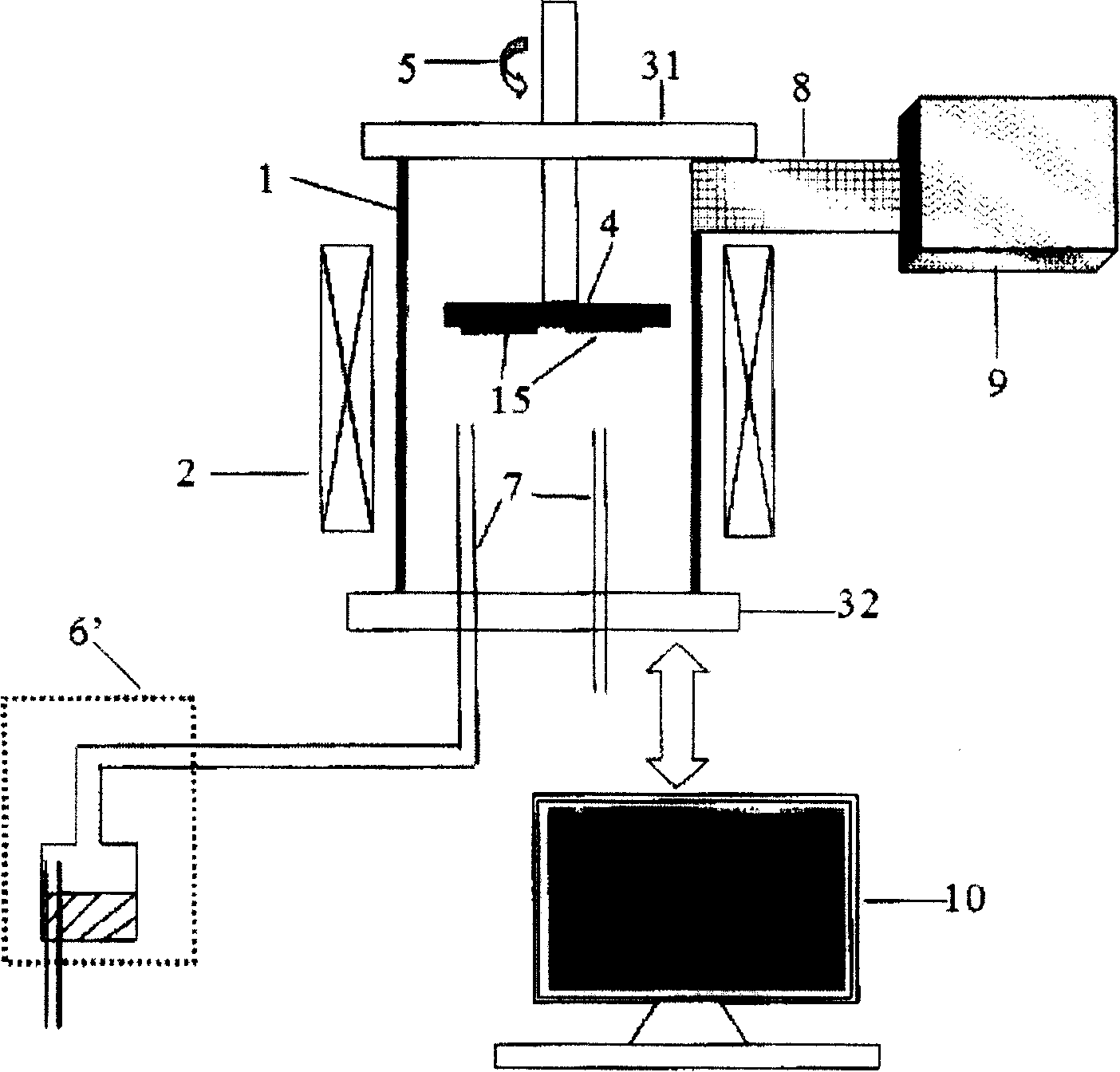

[0045] Such as figure 2 Shown is a schematic structural diagram of the second embodiment. The device can add a vacuum pump to grow from low pressure to normal pressure. The device consists of epitaxial growth chamber 1, heating device 2, upper and lower chassis 31 and 32, substrate device 4, speed regulating motor 5, metal halide reactor 6', The reaction gas pipeline 7, the by-product collection device 8, the wet waste gas treatment device 9 and the automatic control system 10 are composed. Wherein, the epitaxial growth chamber 1 is arranged vertically, the heating system 2 surrounds the outer circumference of the epitaxial growth chamber 1 to heat, and the upper and lower ends of the epitaxial growth chamber 1 are equipped with a chassis 31 for sealing; the substrate device 4 enters from above the epitaxial growth chamber 1, and the substrate 15 is placed face down; the substrate device 4 is connected with a speed-regulating motor 5 outside the growth chamber; the metal rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com