Heating plant for supplying heat for heat-engine plant by recovering exhaust steam and vaporizing latent heat

A technology of air-cooling unit and latent heat of vaporization, which is applied in the field of heating and heating, and can solve problems such as the influence of normal power generation in thermal power plants and changing the operating conditions of cooling units, achieving remarkable energy-saving effects, improving unit efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

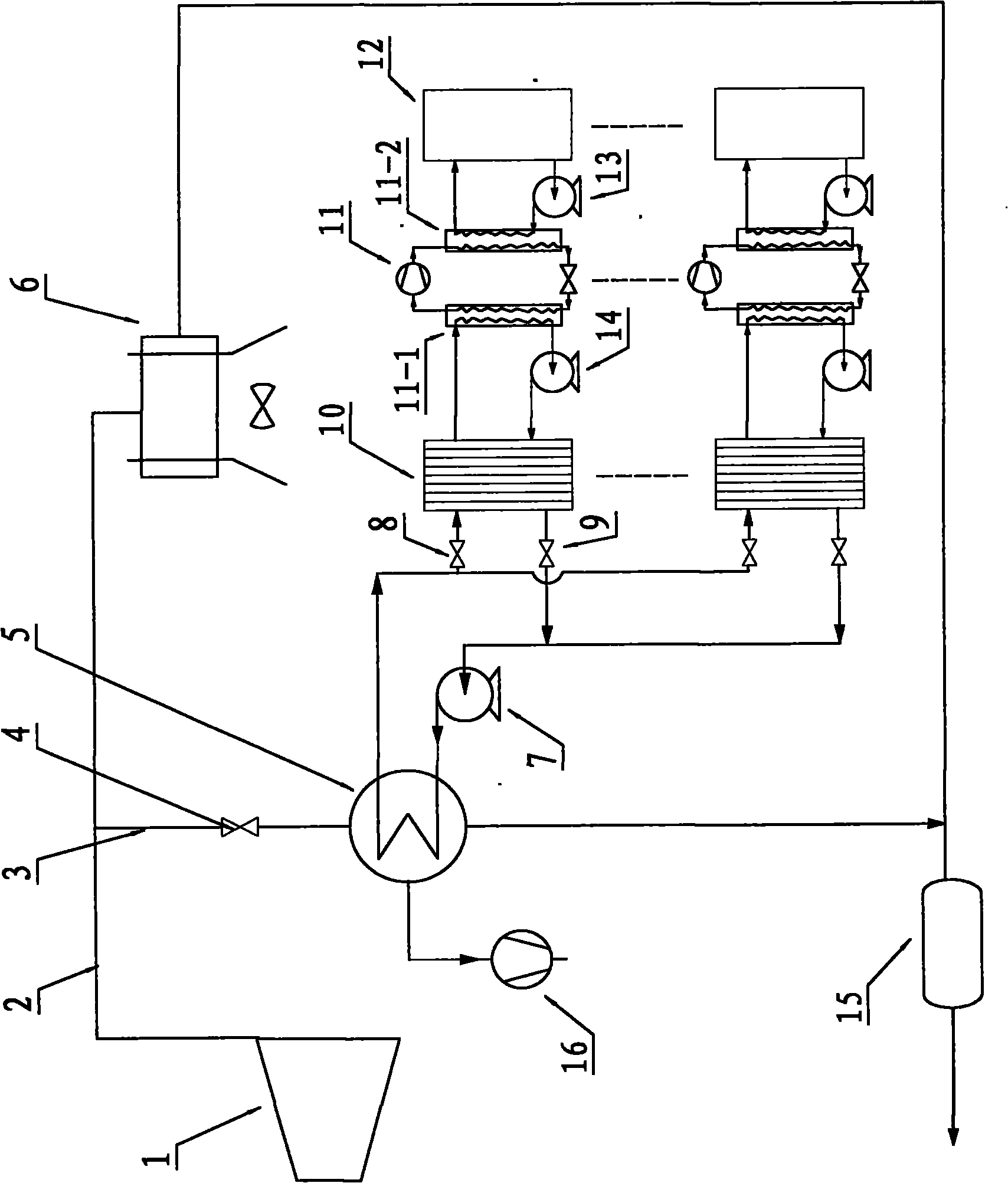

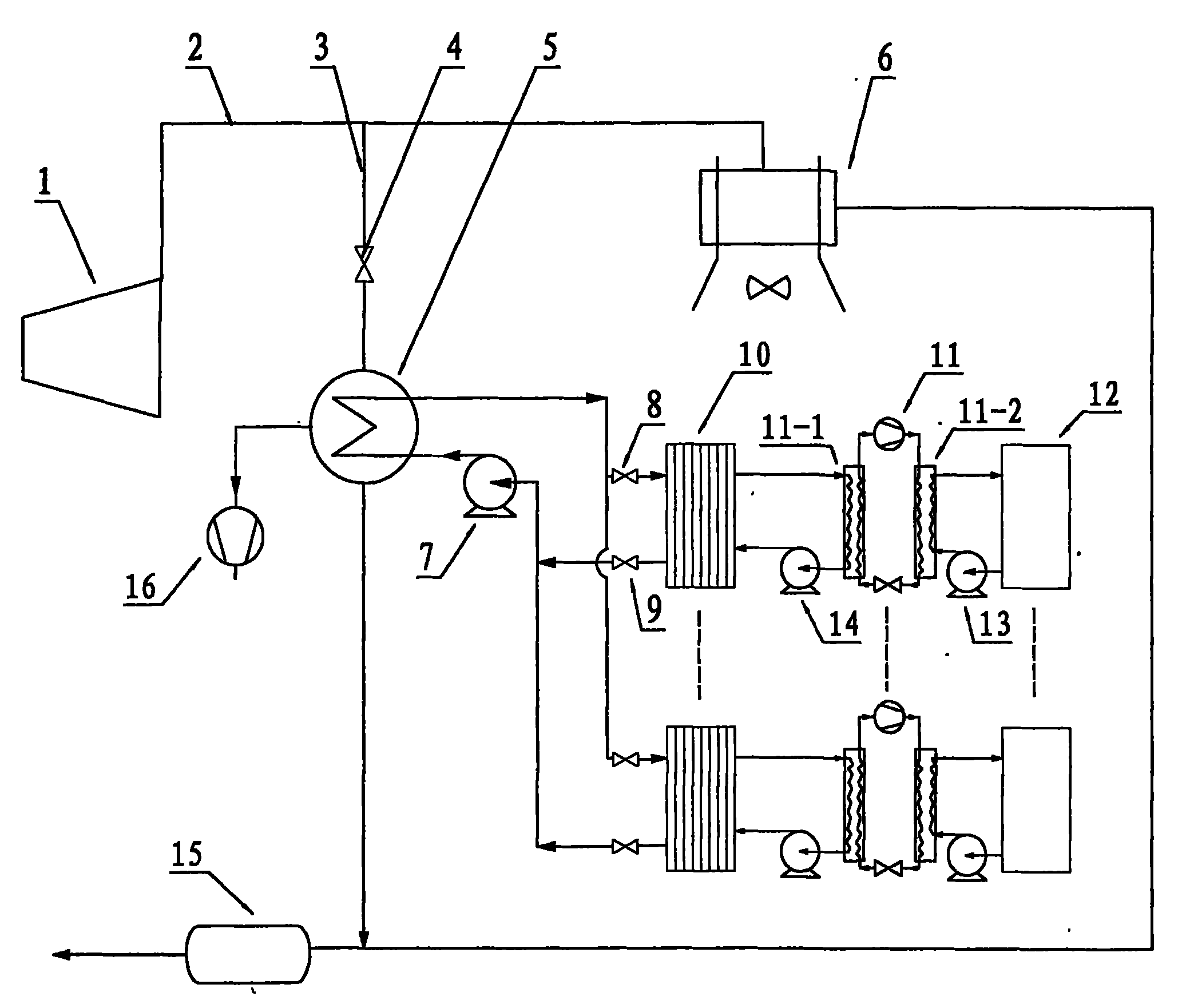

[0012] The key point of the improvement of the present invention is to lead out the exhaust steam of the steam turbine, convert the latent heat of vaporization of the recovered low-quality exhaust steam into higher-quality heat through the heat pump unit, and provide it to the heat supply user end, so as to achieve no consumption of working steam and no influence on air cooling Based on the operating conditions of the unit, the purpose of using the exhaust steam of the air-cooled unit to save energy and provide heat.

[0013] see figure 1 The device of the present invention includes a steam turbine 1 of an air-cooled unit of a thermal power plant, an air-cooled island 6, a exhaust steam pipeline 2 and a drain tank 15, and an additional condenser 5, a cooling circulating water pump 7, and a vacuum pump 16. The condenser 5 is arranged on the condenser branch 3 drawn from the exhaust steam pipeline 2 . On the cooling circulating water circuit of the condenser, there are multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com