Method for direct conversion of plant soapstock into fatty acid

A technology of fatty acid and soapstock, which is applied in the field of direct conversion of vegetable soapstock into fatty acid, can solve the problems of large energy consumption and acid consumption, a large amount of waste water and waste gas, etc., and achieves simple process operation, large device processing capacity, and low sulfuric acid consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

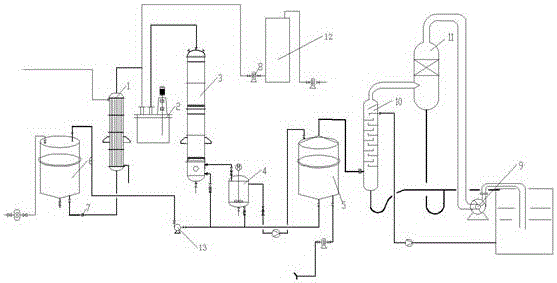

[0015] This method, such as figure 1 shown, including the following steps:

[0016] 1) The plant soapstock raw material in the raw material tank 6 is transported to the preheater 1 by the gear pump 7 at a flow rate of 9000Kg / h and heated to 70~80°C;

[0017] 2) After the plant soapstock raw material is heated by the preheater 1, it is transported to the high-speed stirring reactor 2, and under the high-speed stirring at a speed of 1200 rpm, it fully contacts and reacts with sulfuric acid, and the reaction temperature is controlled at 105-115°C. After the discharge, the fatty acid hydrolysis rate has reached more than 94%, wherein the sulfuric acid is uniformly and quantitatively input from the sulfuric acid storage tank 12 with the flow rate of 200Kg / h by the metering pump 8, and the raw material ratio of sulfuric acid and plant soapstock is 2:90;

[0018] 3) The mixed solution of plant soapstock raw material and sulfuric acid in the high-speed stirring reactor 2 after stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com