System and method for constructing a three-dimensional multi-scale vascularized stent

A construction method and vascularization technology, applied in the field of biomanufacturing, can solve the problems that cannot be effectively solved, have no branches, and the size of the vascular network is single, and achieve the effect of easy removal, easy material, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

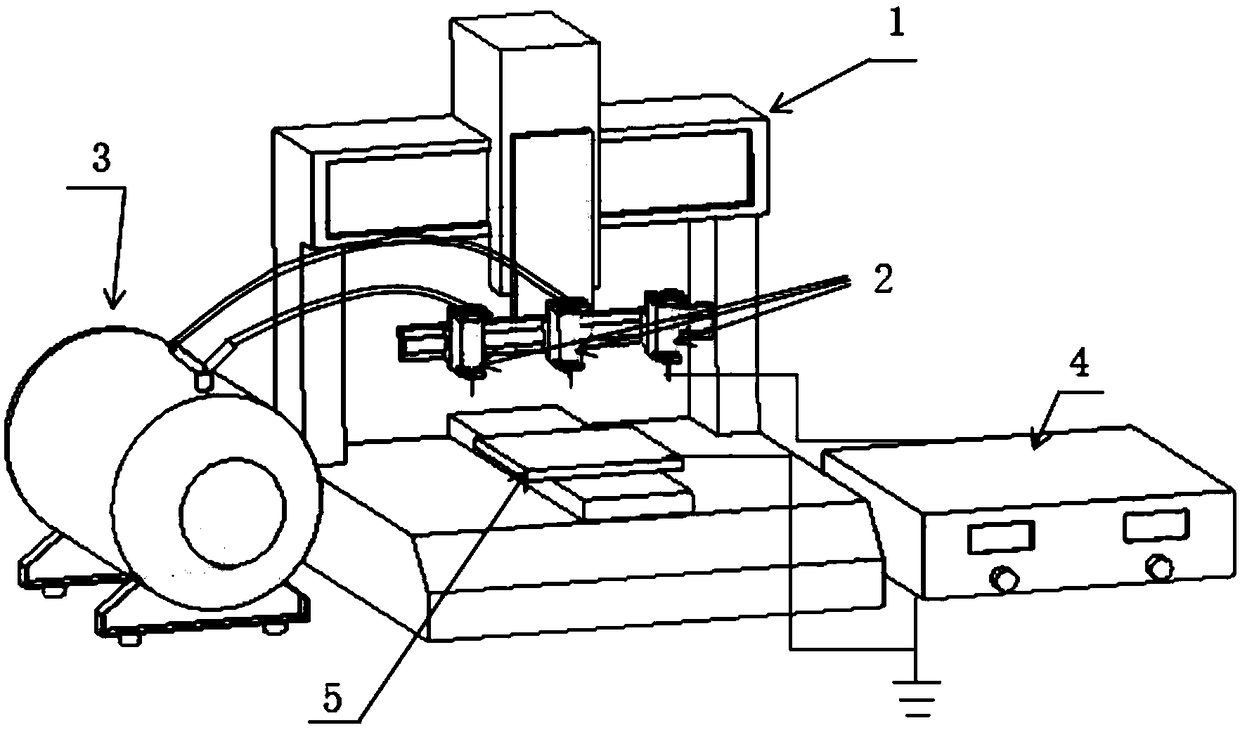

[0029] Such as figure 1 As shown, the construction system of the three-dimensional multi-scale vascularized stent includes a 3D printer, a medical syringe, an air compressor and a high-voltage power supply. The three medical syringes are installed on the 3D printer, and the first and second medical syringes are connected with air compressors The machine phase is connected as the first and second nozzles of 3D printing for printing modified gelatin with Pluronic F127. The needle of the third medical syringe is connected to the positive pole of the high-voltage power supply as the third nozzle of 3D printing, and the receiving platform of the 3D printer is connected to the ground wire of the high-voltage power supply for electrohydrodynamic direct writing. Including the following steps:

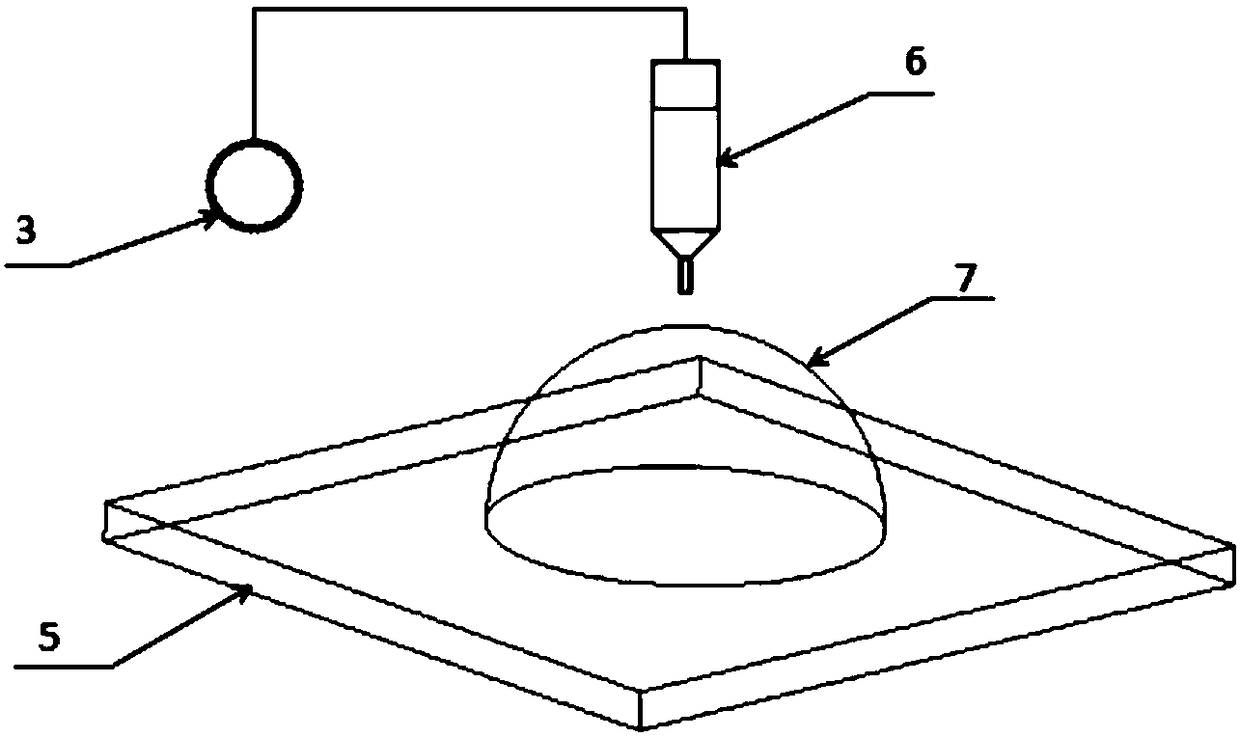

[0030] a. Print the hemispherical bracket (7) used to receive the sacrificial template on the 3D printer receiving platform (5): configure 15 ± 0.5% hydrogel with deionized water, place it in ...

Embodiment 2

[0035] see Figure 1 to Figure 5 , the construction method of the three-dimensional multi-scale vascularized stent, comprising the following steps:

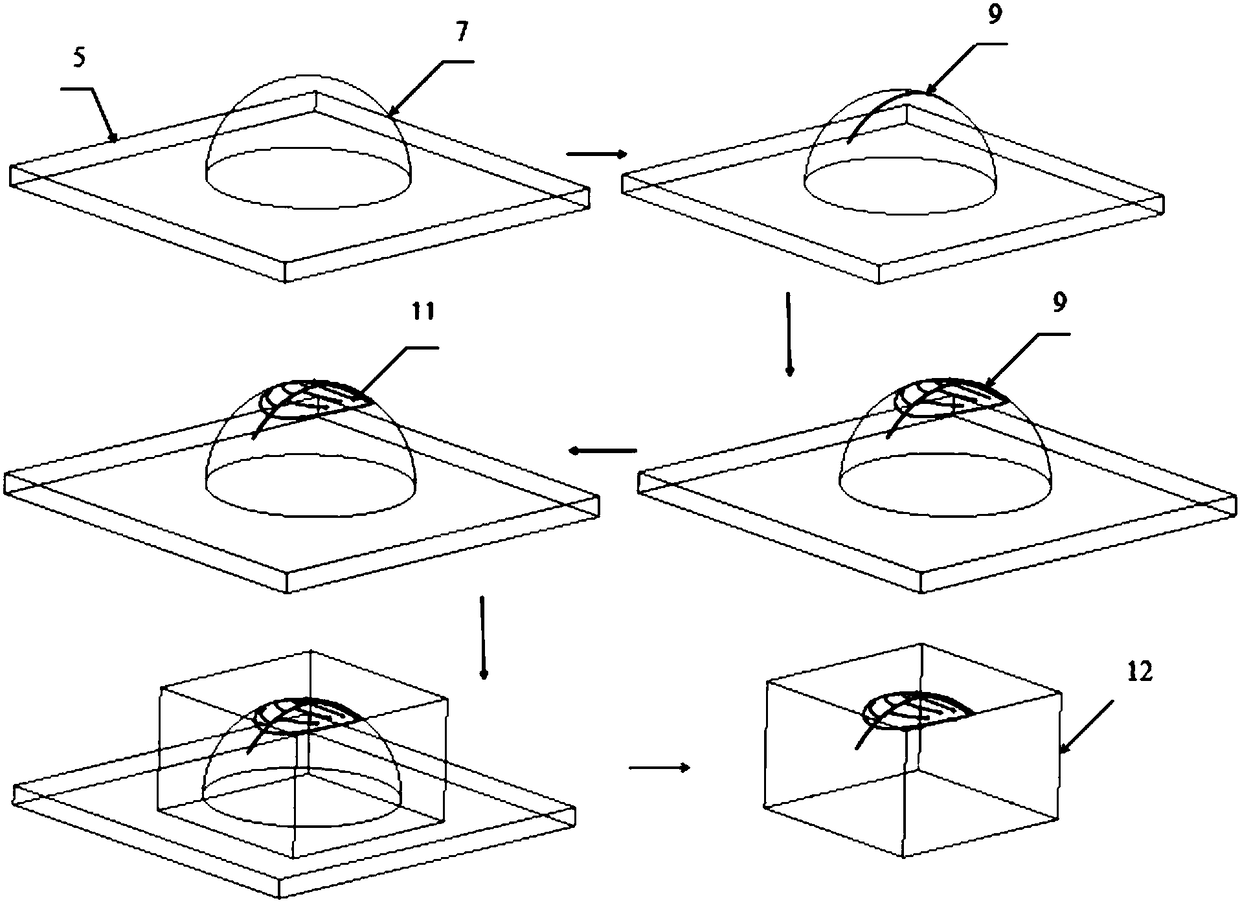

[0036] a. Print the hemispherical bracket (7) used to receive the sacrificial template on the 3D printer receiving platform (5): configure 15±0.5% gelatin with deionized water, place it in a 60±2°C water bath and stir until the gelatin particles Dissolve evenly and the temperature drops to 30±1°C. At this time, add mTG enzyme (the mass ratio of gelatin to mTG enzyme is 10:1) to cross-link the gelatin solution, heat the prepared gelatin solution to a molten state and keep it in the first In a medical syringe, use the first nozzle of the bioprinter to print out the hemispherical bracket (7) from the molten gelatin (6) on the receiving platform (5) of the 3D printer;

[0037] b. Print the main channel and secondary channel sacrificial template of the vascular network (9): use deionized water to configure 35±1% Pluronic F127, stir a...

Embodiment example 3

[0041] This implementation case is basically the same as the implementation case 2, and the special features are as follows:

[0042] see Figure 1 ~ Figure 3 , taking advantage of the printability of Pluronic F127 and the electrospinnability of PCL and both are easy to remove, the Pluronic F127 and PCL solutions were printed on the printed hydrogel hemispheres by 3D printing and electrohydrodynamic direct-writing printing, respectively. The designed sacrificial model is printed on the printed circuit board, and then the gelatin-wrapped sacrificial template with a configured concentration is printed to obtain a scaffold containing three-dimensional multi-scale vascularized channels. First, the configured hydrogel is heated to a molten state and kept loaded into the first medical syringe, and the molten gelatin is printed out of a hemispherical bracket on the receiving platform of the 3D printer using the first nozzle of the bioprinter, and then a hemispherical scaffold is prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com