Method for recycling used lead-acid batteries in full circulation mode

A lead-acid battery, recycling technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of waste of rare metals, incomplete desulfurization, increased energy consumption, etc., to improve recovery rate and avoid equipment Loss and environmental pollution, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

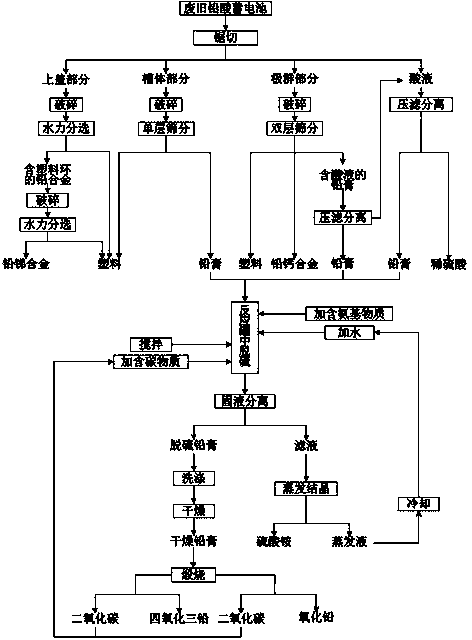

[0066] A method for full-cycle recycling and processing waste lead-acid batteries. The specific steps are as figure 1 shown:

[0067] Step 1. Sawing

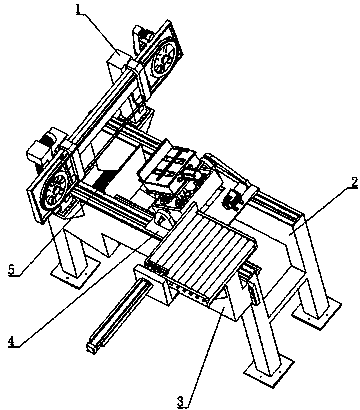

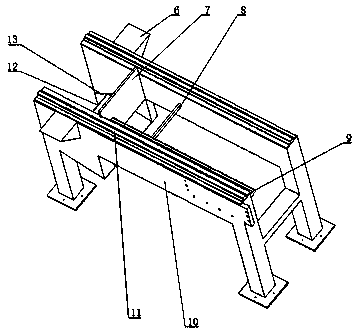

[0068] Using "a band sawing machine for cutting waste lead-acid batteries", the waste lead-acid batteries to be recycled are first cut into the upper cover part, the tank body part, the pole group part and the acid solution, and then the process is carried out.

[0069] Step 1. First, crush the sawed upper cover to a particle size of 50-100 mm, and then perform hydraulic separation to obtain lead alloy and plastic containing plastic rings; then crush the lead alloy containing plastic rings to a particle size of 15 ~30mm, and then perform hydraulic separation to obtain plastic and lead-antimony alloy.

[0070] Step 2: Crushing the sawed groove body to a particle size of 15-50 mm, and then sieving through a single-layer vibrating screen to obtain lead paste and plastic.

[0071] Step 3: Crushing the sawed pole group to a parti...

Embodiment 2

[0094] A method for full-cycle recycling and processing of waste and old lead-acid batteries, the specific steps of which are as follows: figure 1 shown:

[0095] Step 1 is the same as Step 1 of Embodiment 1.

[0096] Step 2, lead paste treatment

[0097] The lead paste obtained in step 1 is added to the reaction tank, and then the amino-containing substance is added, and the ratio of the amount of the lead sulfate in the lead paste to the amount of the amino-containing substance in the amino-containing substance is 1: (6~10); then add water to adjust the liquid Solid ratio to (5~10): 1, stir at room temperature for 2~5h, finally add carbonaceous material for desulfurization, desulfurization time is 5~10h, solid-liquid separation, obtain desulfurization lead paste and filtrate; desulfurization lead paste and filtrate are obtained; The paste is washed until neutral, and the washed desulfurized lead paste is dried at 80 to 120°C for 1 to 12 hours to obtain dry lead paste.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com